Abstract

The present study was conducted with the aim of evaluating the effects, over 6 days, of different intensities of continuous light (20, 40, and 60 µmol photons m-2 s-1) on the growth of Arthrospira platensis and its impact on the production of phycocyanin, carotenoids, and intracellular/extracellular auxins, using a medium supplemented with 0.5 g L-1 of L-tryptophan. Additionally, the study aimed to assess the effect of treatments on the biostimulant activity of the supernatant (T0: untreated, T1: treated) compared to that of biomass extracts (T2). T0, T1, and T2 were adjusted to a concentration of 0.1 mg L-1 of indole-3-acetic acid (IAA) and a pH of 7.4. The results revealed that light intensities of 40 and 60 µmol photons m-2 s-1 produced the highest levels of extracellular IAA on day 2 (20.1 and 33.01 mg L-1, respectively), while an intensity of 20 µmol photons m-2 s-1 reached peak IAA production on day 3 (25.74 mg L-1), followed by a subsequent decrease. Phycocyanin concentrations markedly decreased after maximal IAA production under all light conditions. Tukey's analysis indicated that treatments T1 and T2 significantly increased the number and length of secondary roots in mung beans by 157% and 350%, respectively, with no significant differences between them, while the untreated supernatant (T0) exhibited a minor effect. The study concludes that under all assessed light conditions, concentrations of phycocyanin and carotenoids drastically decreased after peak IAA production, gradually recovering in the following days. Additionally, the treated supernatant and biomass extract significantly enhanced root growth in mung beans, highlighting the importance of the treatment method for biostimulation and suggesting potential for improved storage and transportation. Future research should focus on refining supernatant treatments to optimize biostimulant activity and facilitate commercialization.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

One of the most significant challenges facing humanity involves finding a delicate balance between technological advancement and environmental preservation. The increasing demand for food has placed agriculture at the forefront of this issue. Central to these concerns is the need to enhance crop quality and yield in response to global population growth while simultaneously mitigating losses caused by biotic and abiotic stress, which currently amount to around 30–40% and 60–70%, respectively. Additionally, there is a pressing need to minimize the environmental and human health impacts that result from the widespread use of mineral fertilizers and chemicals aimed at improving crop quality and yield, as outlined by Kapoore et al (2021) and Villaró et al (2023). Consequently, this necessitates the prioritization of alternative technologies, such as the adoption of natural products with biostimulant properties for crops, as a strategy to boost productivity within sustainable agricultural systems, as demonstrated by Mógor et al. (2018).

Biostimulant compounds play a crucial role in enhancing the inherent processes of plants within agricultural systems. They achieve this by increasing nutrient absorption and efficiency, bolstering tolerance to abiotic stressors, and enhancing the physiological characteristics of fruits, as highlighted by the European Union in 2019 (EU 2019). Numerous studies have illustrated the diverse array of substances, molecules, microorganisms, and algae that exhibit biostimulant properties. Notable examples include chitosan (Pichyangkura & Chadchawan 2015), silicon (Savvas & Ntatsi 2015), humic substances (Conselvan et al. 2017), seaweed extracts (Di Filippo-Herrera et al. 2019), aqueous extracts of mugwort (Artemisia vulgaris L.)(Pannacci et al. 2022), brown seaweed extracts (Sharma et al. 2012), collagen-derived protein hydrolysate (Ambrosini et al. 2022), and microalgal or cyanobacteria extracts (Varia et al. 2022), among others. Notably, Arthrospira stands out among the latter group as a dominant species due to its well-documented bio-stimulating capabilities.

Arthrospira is a photosynthetic filamentous cyanobacterium as described by Dos Santos et al. (2019). It exhibits a remarkable adaptability, thriving in alkaline conditions with a pH range of 9 to 10 and flourishing in temperatures ranging from 30 to 40 ºC. Notably, it can thrive in both freshwater and saltwater environments, with researchers employing the synthetic Zarrouk medium for cultivation, as detailed by Tanaka et al (2020). The commercial production of both A. platensis and A. maxima annually amounts to approximately 10,000 t. This market is characterized by continuous growth and is projected to yield a production value of 968.6 million US$ by the year 2028. While its biomass is primarily marketed as a dietary supplement, as indicated by Fernandes et al (2023), its exceptional composition, rich in macronutrients, micronutrients, and phytohormones, has led to its utilization as a biostimulant and/or biofertilizer. Furthermore, recent research has delved into its biostimulating potential.

Research, exemplified by the work of Zapata et al (2021), reaffirms the extensive array of phytohormones present in Arthrospira sp. biomass, encompassing auxin compounds like indole-3-acetic acid (IAA) and indole butyric acid, among others. Similarly, investigations such as the one conducted by Ahmed (2010), demonstrate that Arthrospira synthesizes IAA through the tryptophan dependent pathway. This study demonstrated that the addition of L-tryptophan at concentrations ranging from 0.25 to 1.5 g L-1 resulted in the production of endogenous and exogenous IAA at levels of 194.34 - 211.67 mg L-1, respectively. However, this investigation did not explore how this supplementation might affect the growth and metabolism of Arthrospira sp. Nonetheless, the presence of IAA in the culture medium can potentially impact the production of pigments in biomass (Mohammed & Mohd 2011).

Moreover, although studies like those by Gifuni et al (2019) have demonstrated that the relative content of phycocyanin, chlorophyll, and carotenoids undergoes significant changes in response to various cultivation conditions, and it is well-established that cells produce antioxidant molecules as a defense mechanism during environmental stress (such as exposure to high light levels, extreme pH fluctuations, high salt concentrations, and temperature variations), to date, no studies have investigated the combined impact of light intensity and medium supplementation with L-tryptophan, along with the extracellular production of IAA, on pigment production in A. platensis biomass.

While the literature includes studies on the biostimulating effects of A. platensis biomass extracts and supernatants on various plant species such as mung bean (Vigna radiata) (Ahmed 2010; Mógor et al. 2018), onion (Allium cepa) (Geries & Elsadany 2020), radish (Raphanus sativus 'Caro') (Godlewska et al. 2019), wheat and barley seeds (Akgül 2019), cucumber (Cucumis sativus) (Mógor et al. 2018), lettuce, and tomato (Solanum lycopersicum) (Mógor et al. 2018), there remains a gap in these studies. This gap is primarily due to the lack of control over the concentration of bioactive molecules, including pigments like phycocyanin, polysaccharides, and phytohormones like IAA, which are attributed to the observed bioactivity. Among the few studies found on the biostimulant effects of phycocyanin extracts with specific concentrations is the one conducted by Varia et al (2022), which mentions that its usage increased the yield of hydroponic lettuce cultivation by 12.5%.

On the other hand, these investigations predominantly focus on assessing the bioactivity of either biomass extracts or supernatants, without conducting a comparative analysis between the two. It is worth noting that biomass extracts provide a more comprehensive perspective due to the synergy among the various compounds present. Additionally, many studies involving biomass extracts start with biomass for which cultivation conditions, harvest timing, and, in some cases, extraction procedures and criteria for selecting concentrations for plant applications, remain unspecified.

Consequently, this study was conducted to evaluate the impact of L-tryptophan supplementation and varying light intensities on the growth of A. platensis, as well as on the production of phycocyanin, total carotenoids, and indole-3-acetic acid. Additionally, the research aimed to assess the biostimulant properties of treated and untreated biomass extracts and supernatants on mung beans, while maintaining controlled concentrations of the active compounds.

Materials and methods

Chemicals and biomaterials

Pure IAA phytohormone standards, ferric chloride (FeCl3), 70% perchloric acid (HClO), and L-tryptophan were obtained from Sigma-Aldrich (Merck, Germany). Analytical grade ethyl acetate and ethanol were obtained from PanReac AppliChem. Arthrospira platensis strain (UTEX LB 2340) was obtained from UTEX, the Culture Collection of Algae at the University of Texas. Certified mung bean seeds were obtained from a local producer in Bogotá, D.C.

Culture condition

Arthrospira platensis was cultured using a modified synthetic medium (Zarrouk 1966). A stock culture was prepared using the unmodified synthetic medium with the following concentrations (g L-1): NaNO3: 2.50, K2HPO4: 0.50, NaHCO3: 10.00, NaCl: 1.00, MgSO4⋅7H2O: 0.2, CaCl2⋅2H2O: 0.02, FeSO4⋅7H2O: 0.01. A 300 mL inoculum was prepared in a 1000 mL Erlenmeyer flask and agitated on a shaker (Tecnal, TE-4200, Brazil) at 85 rpm and a constant temperature of 30 ± 0.5 °C under continuous light intensity of 40 μmol photons m-2 s-1 (measured on the walls of the flask) (De Oliveira et al. 1999) for 7 days until reaching an optical density (OD) at 680 nm of 0.85 ± 0.05 approximately.

The investigations were carried out using seven 1-L Erlenmeyer flasks (each flask corresponded to one day of cultivation: 0 – 6 days), each of which contained 300 mL of culture initially characterized by an optical density (OD) at 680 nm of 0.40 ± 0.02. These flasks were placed in an incubation chamber and agitated using a shaker operating at a continuous temperature and light intensity while an LED light lamp (Atreum lighting, Hydra-1000, China) served as the light source. The Zarrouk culture medium was supplemented with L-tryptophan at a concentration of 0.5 g L-1 except for the control. This concentration was selected in accordance with what was reported by Ahmed (2010). Additionally, three different light intensities were evaluated (20, 40, and 60 μmol photons m-2s-1), while maintaining a constant temperature of 30 ± 0.5 °C. For the control culture, a light intensity of 60 μmol photons m-2s-1 was used. It's worth noting that each experiment was conducted in duplicate and every day, one cultivation from one flask was harvested.

Culture health was assessed through daily observations using an optical microscope at 40x magnification. This allowed us to verify that the culture was not contaminated and to observe the morphology, color, and characteristic growth.

Monitoring growth and production of intracellular and extracellular compounds

The growth of A. platensis was monitored daily, measuring pH, optical density at 680 nm, and IAA concentration. On harvest day, the optical density was determined prior to vacuum-filtering the culture through a 0.45 µm glass membrane. Afterwards, the biomass was dried at 40 °C and its moisture content was assessed after 24 h at 105 °C. The dry weight was then recorded. Additionally, the phycocyanin and carotenoid concentrations (intracellular) in the biomass were quantified using the best conditions found in the following section. The specific growth rate (µ) was calculated during the exponential growth phase on the 4th day of cultivation using the following equation:

where N and N0 stand for the concentrations of biomass at times t and t0, respectively.

Phycocyanin content (C-PC) and selection of extraction conditions

To evaluate the parameters for the ultrasonic extraction of phycocyanin (C-PC), three variables were considered: power levels (0%, 60%, and 100% or 120 W), ultrasonication duration (0, 5, 10, and 15 min), and resting intervals (0, 30, and 60 min), with 0% power and 0 min of ultrasonication serving as the reference point. Each set of conditions was assessed in triplicate.

The quantification of C-PC was conducted following an adapted protocol based on Bennett and Bogorad (1973). To disrupt the cells in the biomass, 8 mg of dried material and 0.8 mL of a pH 7.4 1M buffer solution (comprising NaCl, KCl, Na2HPO4, KH2PO4, CaCl2.2H2O, MgCl2.2H2O) were used. Subsequently, the mixture was agitated for 10 s and subjected to an ultrasonic bath operating at a frequency of 40 kHz, with varying power settings. Throughout this process, the bath temperature was closely monitored to ensure it did not exceed 30 °C. Following ultrasonication, the samples were left to incubate for 1 h in a refrigerated and light-free environment, with vortexing occurring every 30 min during this period. After the incubation, the samples were centrifuged at 5,500 rcf for 5 min. The biomass was separated from the supernatant, and a 100 µL aliquot was extracted and subsequently diluted with 900 µL of buffer (Dilution Factor – DF: 10). Following this, the absorbance was measured using a UV-VIS spectrophotometer (Merck Spectroquant Prove 300) at 720 nm (A720), 652 nm (A652), and 615 nm (A615). Phycocyanin content was quantified in g L-1 using equation 2 and as a percentage using equation 3 (Zavřel et al. 2018). These measurements were performed in triplicate.

Intracellular carotenoids

To quantify the levels of chlorophyll (Cla) and total intracellular carotenoids (TCintra), a revised version of the protocol, derived from Lichtenthaler (1987) original work and updated by dos Santos et al (2019), was utilized with several modifications. The biomass remaining after biomass extraction was used, and 98 % ethanol was added to the biomass in the same proportion as used for C-PC extraction. The mixture was vortexed for 10 s and then stored at 4 °C in the dark for 80 min, with vortexing every 30 min. Afterward, the extract was centrifuged at 6,800 RCF for 5 min, and the absorbance of the resulting supernatant was measured spectrophotometrically at 661.6 nm against 98% ethanol. The content of chlorophyll a (mg L-1) was calculated by multiplying the absorbance at 661.6 nm (Abs 661.6 nm) by 10.82 (Eq. 4), and the total carotenoid content was estimated using Eqs. 5 and 6 (dos Santos et al. 2019). This measurement was performed in triplicate

where TCintra denotes the concentration of carotenoids in each extract, while A470, and A661.6 refer to the absorbance values at 470 nm, and 661.6 nm, respectively. Cla represents the concentration of chlorophyll a in each extract. TCintra signifies the total intracellular carotenoid content, v represents the total volume of solvent (mL), and bs represents the mass of dry biomass utilized (mg).

Extracellular IAA

The study employed the colorimetric method with the established Salkowski reagent (Salkowski 1885) to estimate IAA in cyanobacterial culture supernatants. This widely-used method involved preparing the Salkowski reagent by combining 0.5 M ferric chloride (FeCl3) and 35% perchloric acid (HClO4). The reagent was added to the extract in a 1:2 (v/v) ratio. A calibration curve was constructed using analytical-grade indole-3-acetic acid (IAA) in Zarrouk medium, ranging from 6 to 50 mg L-1 (Eq. 7) with a high correlation coefficient (R2 = 0.99). The absorbance of each sample was measured at 530 nm. A blank was prepared by mixing 333 µL of Zarrouk medium with 666 µL of the Salkowski reagent. This method is widely recognized in the scientific literature for its accuracy in measuring auxins, with IAA as a standard in cyanobacterial culture supernatants (Ahmed 2010; Duong et al. 2021).

Intracellular IAA

For the intracellular auxins-IAA, the extract obtained in Section "Phycocyanin content (C-PC) and selection of extraction conditions" was processed using the same protocol mentioned in Section "Extracellular IAA". However, after incubation, the solution was centrifuged at 9,700 RCF for 10 min to remove the precipitated C-phycocyanin, and then it was measured using the same method as for extracellular IAA. Initial trials showed that phycocyanin interferes with measurements at 530 nm.

Mung bean bioassay

Supernatant and Biomass extracts treatment before bioassay

Untreated supernatant (T0), treated supernatant (T1), and biomass extracts (T2) were assessed for their biostimulating capacity on mung beans plants using the imbibition method. The following outlines the characteristics of the evaluated treatments:

-

Control: Sterile distilled water at pH 7.4.

-

T0: Supernatant without any treatment diluted with sterile distilled water to achieve a concentration of 0.1 mg L-1 of IAA and adjusted to a pH of 7.4.

-

T1: A 50 mL portion of the supernatant was adjusted to pH 2.8 with 50% (w/w) citric acid and mixed with 100 mL of analytical-grade ethyl acetate in a separation funnel. After agitation, the solution separated into two phases; the upper phase containing ethyl acetate was separated and concentrated via rotary evaporation at 37 °C to form a paste, which was then resuspended in 1 mL of 98% ethanol. The resulting sample was stored in Eppendorf tubes at 4 °C, shielded with aluminum foil, until ready for the bioassay. The concentrated solution was subsequently diluted with sterile distilled water to achieve a concentration of 0.1 mg L-1 of indole-3-acetic acid (IAA) and adjusted to a pH of 7.4.

-

T2: The biomass extracts were obtained using the optimal extraction conditions identified in Section "Phycocyanin content (C-PC) and selection of extraction conditions", utilizing dry biomass from the cultivation on day 3 at 60 µmol photons m-2s-1. After obtaining the extracts, they were adjusted to a concentration of 9 mg L-1 of C-PC and 0.1 mg L-1 of IAA using sterile distilled water.

Bioassay

To investigate the biostimulating properties of treatments T0, T1, and T2 compared to the control, certified mung bean seeds (Vigna radiata L.) were used. These seeds were carefully selected based on their size, density, and uniform bright green color. The seeds were washed three times with distilled water and then disinfected with a 4% sodium hypochlorite (NaClO) solution for 10 min. Afterward, they were rinsed three times with sterile distilled water and allowed to air dry at room temperature (26 ± 1°C) for 1 h. All materials used for the bioassay were sterilized using a Phoenix autoclave (AV-30Plus, Brazil).

All treatments were sterilized by filtering them through a 0.45 µm nylon filter. Once the solutions were prepared, 30 seeds were allocated for each treatment evaluation (T0, T1, T2, and control), with groups of 5 seeds added to sterilized glass vials containing 5 mL of the corresponding treatment solution. The seeds were kept in the dark at a temperature of 26 ± 1°C for 24 h for germination. Subsequently, the seeds were carefully washed with sterile distilled water and transferred to vials containing 5 mL of sterile distilled water. These vials were then placed in a growth chamber at a temperature of 26 ± 1°C, with a light intensity of 10 µmol photons m-2s-1 and a photoperiod of 12 h of light followed for 12 h of darkness. Evaporated water was replenished daily. After 5 days, the bioassay concluded, and the number and length of secondary roots were measured.

Experimental design and statistical analysis

An ANOVA one-way statistical analysis with a Tukey test was carried out to identify significant differences with a p˂0.05, using Minitab v.18 software. For the ANOVA analysis, it was verified that the data met the assumptions of normality and homogeneity.

Results

Phycocyanin content (C-PC) and selection of extraction conditions

Table 1 shows the results of phycocyanin concentration in the extracts obtained under different ultrasound conditions (ultrasound time, power, and resting time). It demonstrates that all factors had a significant effect on C-PC (p<0.05), indicating an increase in this pigment as the ultrasound time and resting time increased, and the power decreased.

Monitoring growth and production of intracellular and extracellular compounds

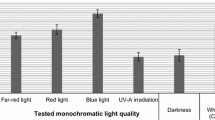

Figure 1 illustrates the growth kinetics, cultivation pH monitoring, IAA production kinetics, and the dynamics of intracellular pigments, including phycocyanin and carotenoids, under the different light conditions evaluated.

Growth and production of intracellular and extracellular compounds under different culture light conditions, supplementing the medium with 0.5 g L-1 of L-tryptophan. ●20 µmol photons m-2s-1 ▲ 40 µmol photons m-2s-1 ♦ 60 µmol photons m-2s-1 ■ Control. The values correspond to the average of n = 2 ± standard deviation

Mung bean bioassay

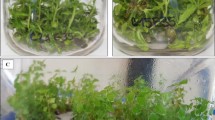

The results obtained regarding the effect of the evaluated treatments: untreated supernatant (T0), treated supernatant (T1), and biomass extract (T2) compared to the control, are depicted in Figs. 2 and 3. Overall, significant differences (p<0.05) were observed among treatments for the three evaluated response variables (number and length of secondary roots and main root length).

Effect of the evaluated treatments. Control: water; T0: untreated supernatant; T1: treated supernatant; T2: biomass extract on the number of secondary roots (SR), length of secondary roots (LSR) and main root length (MRL). Different letters a,b… correspond to significant differences due to the treatment effect (Tukey, p˂0.05). Values correspond to the average of n = 30 ± standard deviation

Discussion

Phycocyanin content (C-PC) and selection of extraction conditions

In Table 1, it is evident that the evaluated factors, including ultrasonication time (Utime), power, and standing time (Stime), significantly influenced the phycocyanin concentration in the extract (dry basis) with a significance level of p<0.05. Increasing the ultrasonication time from 5 to 15 min notably raised the C-PC concentration from the initial resting period, showcasing how ultrasonication reduces extraction time and enhances yield. Additionally, escalating the power from 60% to 100% amplified the phycocyanin concentration compared to the control; however, at 100%, it decreased due to microheating, causing C-PC degradation from 47 °C onwards (Chaiklahan et al. 2012).

Crucially, dried biomass released phycocyanin into the solvent without additional disruptive methods due to enhanced porosity from the drying process (Stramarkou et al. 2021). Extraction times significantly extended without ultrasonication, with unprocessed samples showing only 6.83 ± 0.39% C-PC after 60 min. Ultrasonication, operating through acoustic cavitation, ruptures the cell wall, increasing porosity (Pagels et al. 2021), facilitating extraction from the beginning and optimizing the process efficiently and swiftly.

Therefore, a 15 min ultrasonication time, 60% power, and 60 min standing period were selected as the optimal conditions for biomass extraction, intended for subsequent application in mung bean cultivation.

Monitoring growth and production of intracellular and extracellular compounds

Supplementation of the culture medium with L-tryptophan at a concentration of 0.5 g L-1 proved to be effective in extracellular auxin-IAA production, reaching concentrations exceeding 5 mg L-1, easily detectable through the Salkowsky reagent. In the analysis of varying light intensities, an expected growth increment was observed (Fig. 1a). However, under low-light conditions (20 µmol photons m-2s-1), the growth rate was minimal (approximately 0.013 h-1), insufficient to counterbalance the medium acidification resulting from the expulsion of compounds like IAA. This led to a decline in the medium's pH and a reduction in biomass concentration starting from day 4. Although the pH gradually recovered in the following days, indicating an upward trend, when utilizing light intensities surpassing 60 µmol photons m-2s-1, the growth rate significantly increased (0.018 h-1), closely approaching that of the control culture (0.020 h-1), compensating for the acid production in the medium. This translated into pH stability and consistent biomass production. It is imperative to note that light intensities of 40 and 60 µmol photons m-2s-1 exhibited the highest extracellular IAA production on day 2, with concentrations of 20.1 mg L-1 (40 µmol photons m-2s-1) and 33.01 mg L-1 (60 µmol photons m-2s-1), respectively. For the light intensity of 20 µmol photons m-2s-1, the highest IAA production was obtained on day 3, with 25.74 mg L-1. In all cases, there was a strong decrease in the concentration of IAA in the supernatant from day 3, reaching values between 2.8 and 8.16 mg L-1 on day 6 of culture. This pattern contrasts with the findings of Ahmed (2010), who reported a continuous increase in IAA concentration in the medium. In this study, however, a peak in production was evident within a few days of cultivation, followed by a subsequent decrease. The reasons for these differences remain unclear, as the study does not provide specific details about the cultivation conditions employed.

The influence of L-tryptophan addition and IAA production on intracellular pigments is illustrated in Fig. 1d and e. These figures reveal that under all evaluated light conditions, the phycocyanin concentration decreased dramatically one day after the peak production of IAA was observed. Specifically, for the 20 µmol photons m-2 s-1 and 40 µmol photons m-2 s-1 conditions, the decrease was observed on day 4, and for 60 µmol photons m-2 s-1, it was observed on day 3. Subsequently, under all conditions, phycocyanin tends to gradually recover in the following days. The same behavior was observed for the carotenoid content. This pattern differed from the control culture, where intracellular carotenoid levels remained stable. Consequently, an inhibitory effect associated with the IAA production peak was evident. The inhibitory impact of IAA in the medium on A. platensis growth and pigment production has previously been reported by Mohammed & Mohd (2011). They noted that adding IAA at concentrations between 1 – 7 µg mL-1 increased carotenoid content in biomass, peaking at 6 µg mL-1. Concentrations exceeding 7 µg mL-1 resulted in inhibition of both growth and pigment synthesis.

Based on this analysis, the cultivation condition of 60 µmol photons m-2s-1 and day 3 of harvest was selected for conducting bioassays on mung beans, evaluating the biostimulant activity of both treated and untreated supernatant and biomass extracts. To conduct the biomass extraction tests using ultrasound, biomass harvested on day 3 from the culture under 40 µmol photons m-2 s-1 conditions was employed.

Mung bean bioassay

Tukey's analysis revealed that the effects of T1 and T2 were significantly greater, increasing the number of secondary roots by 157%, with no significant differences between them. In contrast, the untreated supernatant (T0) was significantly lower, closely resembling the control in this variable. Similarly, T1 and T2 showed significantly greater lengths of secondary roots. Although T0 was significantly shorter than them, it exhibited a significant increase compared to the control in this variable (Fig. 3).

These results highlight several key points. One of them is the significant influence of IAA present in both the biomass extract and the supernatant on these response variables. Additionally, the presence of salts or other compounds in the supernatant inhibits plant growth, leading the untreated supernatant to induce plant oxidation and adversely affect its development. This effect may have been mitigated by the presence of IAA. Furthermore, regardless of treatment, the supernatant tends to reduce the main root length while increasing the number and length of secondary roots (Fig. 3). In some instances, this even triggers the formation of adventitious roots, a phenomenon influenced by IAA and a primary reason for their widespread use in rooting cuttings. Authors such as Ahmed (2010) observed a gradual decrease in root length but a positive effect on the number of lateral roots when evaluating different supernatant concentrations (1, 2.5, and 5 mL per 10 mL solution). This effect was particularly pronounced when the extract was applied at a concentration of 5 mL per 10 mL. However, the treatment applied to the supernatant before its application and the concentration of IAA present in these cases were not clearly defined.

Moreover, Godlewska et al (2019) demonstrated that radish plants (Raphanus sativus) given A. platensis extract improved their growth by 60%. Jafarlou et al (2022) subjected milkweed seeds (Calotropis procera) to high salt concentrations and applied the biostimulant at a concentration of 10 mL L−1. They found a significant increase in root and shoot length, as well as in the root-shoot ratio, using 10 mL L−1 of A. platensis extract. On the other hand, Varia et al (2022) reported the effective use of phycocyanin at a concentration of 0.25 g L-1 on lettuce to increase yield and improve its composition. Thus, the biomass extracts from this study, which also contain IAA due to the cultivation conditions used, not only have a positive rooting effect but also provide nutrients that influence other important plant parameters such as the nutrient profile (Villaró et al. 2023). This is because they serve as sources of amino acids and other compounds that function as bio-fertilizers. This presents an advantage over supernatant use. However, the supernatant can be considered for biomolecule production. The main challenge lies in extracting it from the aqueous phase and purifying it, as it involves the use of expensive technologies.

In contrast, it is important to consider that indole-3-acetic acid in the aqueous phase degrades easily due to the action of oxidase enzymes or light stimulation (Hu et al. 2011). Therefore, such aqueous extracts must be cryopreserved. This underscores the potential utility of rotary-evaporated supernatants as a compelling alternative, given their capacity to reduce water activity, potentially mitigating degradation processes.

Conclusions

This study revealed that under light conditions of 40 and 60 µmol photons m-2 s-1, a higher extracellular IAA production was observed on day 2, reaching concentrations of 20.1 mg L-1 and 33.01 mg L-1, respectively. Meanwhile, at 20 µmol photons m-2 s-1, peak IAA production was achieved on day 3. Regarding the impact of the evaluated cultivation conditions on pigment production in biomass, it was evident that under all assessed light conditions, concentrations of phycocyanin and carotenoids drastically decreased after the peak IAA production, gradually recovering in subsequent days. Consequently, an inhibitory effect associated with the IAA concentration in the medium was evident.

Among all treatments evaluated on mung bean, both the treated supernatant and biomass extract significantly outperformed others, increasing the number of secondary roots by 157% and their length by 350%. In contrast, untreated supernatant (T0) had a lesser effect. The IAA present in the biomass extract, as well as in the supernatant, and the method of supernatant treatment, significantly influenced the bio-stimulating activity. Therefore, this article presents an advantageous method of treating supernatant, making it more stable for storage and facilitating its use and transportation. Hence, it is important for future research to explore alternative supernatant treatment methods that enhance its activity and enable easy storage and commercialization.

Data availability

The data supporting the findings of this study are available from the corresponding author upon reasonable request.

References

Ahmed M (2010) Production of indole-3-acetic acid by the cyanobacterium Arthrospira platensis strain MMG-9. J Microbiol Biotechnol 20:1259–65

Akgül F (2019) Effect of Spirulina platensis (Gomont) Geitler extract on seed germination of wheat and barley. Alienteri J Agr Sci 34:148–153

Ambrosini S, Prinsi B, Zamboni A, Espen L, Zanzoni S, Santi C, Varanini Z, Pandolfini T (2022) Chemical characterization of a collagen-derived protein hydrolysate and biostimulant activity assessment of its peptidic componentsm. J Agric Food Chem 70:11201–11211

Bennett A, Bogorad L (1973) Complementary chromatic adaptation in a filamentous blue-green alga. J Cell Biol 58:419–35

Chaiklahan R, Chirasuwan N, Bunnag B (2012) Stability of biomass extracted from Spirulina sp.: Influence of temperature, pH and preservatives. Process Biochem 47:659–664

Conselvan GB, Pizzeghello D, Francioso O, Di Foggia M, Nardi S, Carletti P (2017) Biostimulant activity of humic substances extracted from leonardites. Plant Soil 4:119–134

De Oliveira MA, Monteiro MP, Leite DG (1999) Growth and chemical composition of Spirulina maxima and Spirulina platensis biomass at different temperatures. Aquacult Int 7:261–275

Di Filippo-Herrera DA, Muñoz-Ochoa M, Hernández-Herrera RM, Hernández-Carmona G (2019) Biostimulant activity of individual and blended seaweed extracts on the germination and growth of the mung bean. J Appl Phycol 31:2025–203

Dos Santos RR, Corrêa PS, Dantas FML, Teixeira CMLL (2019) Evaluation of the co-production of total carotenoids, C-phycocyanin and polyhydroxyalkanoates by Arthrospira platensis. Bioresour Technol Rep 7:100226

Duong TT, Nguyen TTL, Van Dinh TH, Hoang TQ, Vu TN, Doan TO et al (2021) Auxin production of the filamentous cyanobacterial Planktothricoides strain isolated from a polluted river in Vietnam. Chemosphere 284:131242

European Union (2019) Regulation of the European parliament and of the council laying down rules on the making. Available on the market of EU fertilising products and amending regulations (EC) No 1069/2009 and (EC) No 1107/2009 and repealing regulation (EC) No 2003/2003. European Commission, Brussels, p 4. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=OJ:L:2019:170:TOC. Accessed 17 Aug 2023

Fernandes R, Campos J, Serra M, Fidalgo J, Almeida H, Casas A, Toubarro D, Barros AIR (2023) Exploring the benefits of phycocyanin: From Spirulina cultivation to its widespread applications. Pharmaceuticals 16:592

Geries LSM, Elsadany AY (2020) Maximizing growth and productivity of onion (Allium cepa L.) by Spirulina platensis extract and nitrogen-fixing endophyte Pseudomonas stutzeri. Arch Microbiol 203:169–181

Gifuni I, Pollio A, Safi C, Marzocchella A, Olivieri G (2019) Current bottlenecks and challenges of the microalgal biorefinery. Trends Biotechnol 37:242–252

Godlewska K, Michalak I, Pacyga P, Baśladyńska S, Chojnacka K (2019) Potential applications of cyanobacteria: Spirulina platensis filtrates and homogenates in agriculture. World J Microbiol Biotechnol 35:80

Hu Y, Li Y, Zhang Y, Li G, Chen Y (2011) Development of sample preparation method for auxin analysis in plants by vacuum microwave-assisted extraction combined with molecularly imprinted clean-up procedure. Anal Bioanal Chem 399:3367–74

Jafarlou MB, Pilehvar B, Modaresi M, Mohammadi M (2022) Interactive effects of seaweed and microalga extract priming as a biostimulant agent on the seed germination indices and primary growth of milkweed (Calotropis procera Ait.). Biologia 77:1283–1293

Kapoore RV, Wood EE, Llewellyn CA (2021) Algae biostimulants: A critical look at microalgal biostimulants for sustainable agricultural practices. Biotechnol Adv 49:107754

Lichtenthaler HK (1987) [34] Chlorophylls and carotenoids: Pigments of photosynthetic biomembranes. Meth Enzymol 148:350–382

Mógor ÁF, Ördög V, Lima GPP, Molnár Z, Mógor G (2018) Biostimulant properties of cyanobacterial hydrolysate related to polyamines. J Appl Phycol 30:453–460

Mohammed MK, Mohd MK (2011) Enhancement in production of phenolic compounds (AntiOxidants) in Spirulina plantensis under different IAA regimes. Int J Eng Sci Technol 3:3004–3009

Pagels F, Pereira RN, Vicente AA, Guedes AC (2021) Extraction of pigments from microalgae and cyanobacteria—A review on current methodologies. Appl Sci 11:5187

Pannacci E, Baratta S, Falcinelli B, Farneselli M, Tei F (2022) Mugwort (Artemisia vulgaris L) aqueous extract: hormesis and biostimulant activity for seed germination and seedling growth in vegetable crops. Agriculture 12:1329

Pichyangkura R, Chadchawan S (2015) Biostimulant activity of chitosan in horticulture. Sci Hortic 196:49–65

Salkowski E (1885) Ueber das Verhalten der Skatolcarbonsäure im Organismus. Z Physiol Chem 9:23–33

Savvas D, Ntatsi G (2015) Biostimulant activity of silicon in horticulture. Sci Hortic 196:66–81

Sharma SHS, Lyons G, McRoberts C, McCall D, Carmichael E, Andrews F, Swan R, McCormack R, Mellon R (2012) Biostimulant activity of brown seaweed species from Strangford Lough: Compositional analyses of polysaccharides and bioassay of extracts using mung bean (Vigno mungo L.) and pak choi (Brassica rapa chinensis L.). J Appl Phycol 24:1081–1091

Stramarkou M, Papadaki S, Kyriakopoulou K, Tzovenis I, Chronis M, Krokida M (2021) Comparative analysis of different drying techniques based on the qualitative characteristics of Spirulina platensis biomass. Aquat Food Prod Technol 30:498–516

Tanaka K, Kishi M, Assaye H, Toda T (2020) Low temperatures in dark period affect biomass productivity of a cyanobacterium Arthrospira platensis. Algal Res 52:102132

Varia J, Kamaleson C, Lerer L (2022) Biostimulation with phycocyanin-rich Spirulina extract in hydroponic vertical farming. Sci Hortic 299:111042

Villaró S, Acién G, Alarcón J, Ruiz Á, Rodríguez-Chikri L, Viviano E, Lafarga T (2023) A zero-waste approach for the production and use of Arthrospira platensis as a protein source in foods and as a plant biostimulant in agriculture. J Appl Phycol 35:2619–2630

Zapata D, Arroyave C, Cardona L, Aristizábal A, Poschenrieder C, Llugany M (2021) Phytohormone production and morphology of Spirulina platensis grown in dairy wastewaters. Algal Res 59:102469

Zarrouk C (1966) Contribution a l’étude d’une cyanophycée. Influence de divers facteurs physique et chimique sur la croissance et la photosynthèse de Spirulina maxima (Sech. et Gardner) Geitler. PhD Thesis, University of Paris, France

Zavřel T, Chmelík D, Sinetova MA, Červený J (2018) Spectrophotometric determination of phycobiliprotein content in cyanobacterium Synechocystis. J Vis Exp 11:58076

Funding

Financial support was provided by Colombian Ministry of Science and Technology (Grant 445-2021).

Author information

Authors and Affiliations

Contributions

Experimentation, analysis, writing, original draft development: NL. Review and supervision: HA. Methodology, conceptualization, review, and funding acquisition: HF.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

López Mejía, N., Martínez Correa, H.A. & Lobatón García, H.F. Biostimulating activity of biomass extracts and supernatants from a culture of Arthrospira platensis enriched with L-tryptophan. J Appl Phycol 36, 1875–1884 (2024). https://doi.org/10.1007/s10811-024-03237-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-024-03237-7