Abstract

A novel sample preparation method for auxin analysis in plant samples was developed by vacuum microwave-assisted extraction (VMAE) followed by molecularly imprinted clean-up procedure. The method was based on two steps. In the first one, conventional solvent extraction was replaced by VMAE for extraction of auxins from plant tissues. This step provided efficient extraction of 3-indole acetic acid (IAA) from plant with dramatically decreased extraction time, furthermore prevented auxins from degradation by creating a reduced oxygen environment under vacuum condition. In the second step, the raw extract of VMAE was further subjected to a clean-up procedure by magnetic molecularly imprinted polymer (MIP) beads. Owing to the high molecular recognition ability of the magnetic MIP beads for IAA and 3-indole-butyric acid (IBA), the two target auxins in plants can be selectively enriched and the interfering substance can be eliminated by dealing with a magnetic separation procedure. Both the VMAE and the molecularly imprinted clean-up conditions were investigated. The proposed sample preparation method was coupled with high-performance liquid chromatogram and fluorescence detection for determination of IAA and IBA in peas and rice. The detection limits obtained for IAA and IBA were 0.47 and 1.6 ng/mL and the relative standard deviation were 2.3% and 2.1%, respectively. The IAA contents in pea seeds, pea embryo, pea roots and rice seeds were determined. The recoveries were ranged from 70.0% to 85.6%. The proposed method was also applied to investigate the developmental profiles of IAA concentration in pea seeds and rice seeds during seed germination.

Analytical procedure of auxins in plants

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

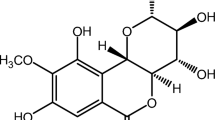

Auxin is probably the most widely investigated plant hormone and is known to be involved in virtually every aspect of plant growth and development [1]. The 3-indole acetic acid (IAA) was the first plant hormone that was used to stimulate rooting of cuttings. It was discovered that IAA stimulates growing processes such as cell elongation and division. The concentration of IAA in the tissues is regulated by the rate of synthesis, tissue concentrations, and deactivation mechanisms. There are also several synthetic compounds with structure similar to that of IAA that elicits auxin-like physiological responses, such as 3-indole-butyric acid (IBA). IBA was also found to occur naturally in a number of plant species, promoted rooting, and was even more effective than IAA [2, 3]. The chemical structure of IAA and IBA is illustrated in Fig. 1. The typical level of IAA in plants is in the range of 1–100 ng g−1, the concentration of IBA is close or lower than IAA.

Plant auxins are difficult to analyze because they occur in very low amounts in plant which are very rich in interfering substances. A number of analytical techniques have been developed for auxin analysis [4–7]. Among them, gas chromatography and high-performance liquid chromatography (HPLC) are the commonly used methods [8–12]. However, it should be noted that several sample pretreatment steps before chromatographic analysis is often required for extracting as well as cleaning up the target analytes from sample [13].

Firstly, a solvent extraction step is usually essential to transfer auxins from the solid plant tissues into the liquid fraction. Auxins are apt to degrade under oxidase or light stimulus. In order to protect auxins from oxidation, soft extraction conditions should be adopted. The routine method is to immerse the plant sample in an appropriate solvent in the dark at low temperature [14]. This procedure usually needs several hours or overnight, and is rather time-consuming. Among the modern extraction techniques, microwave-assisted extraction (MAE) has attracted particular attention as it allows rapid extraction of solutes from solid matrices with high extraction efficiency, less solvent consumption and shorter extraction times [15]. In conventional MAE, the extraction was usually performed at the temperature near the boiling point of the solvent. However, some thermo- or oxygen-sensitive compounds in plant will undergo degradation or oxidization in this condition [16, 17]. Recently, vacuum microwave-assisted extraction (VMAE) has been developed for extraction of some antioxidants in plants [18, 19]. Performing extraction in vacuum condition prevents oxygen-induced degradation. In addition, the extraction can be performed at lower temperature but under refluxing condition since the boiling point of the extraction solvent in vacuum is lower than that at normal air pressure. These advantages make VMAE a potentially alternative protocol to conventional methods for extracting auxins in plants.

After extraction, the plant extract requires a further sample enrichment and clean-up step to eliminate the interfering substances and enrich auxins. Many enrichment and clean-up protocols include liquid–liquid extraction [20], liquid–liquid–liquid microextraction [21], solid-phase extraction (SPE) [22], as well as anion-exchange column purification have been developed. However, most of the methods suffered from poor selectivity. In recent years, attempts have been made to apply molecularly imprinted polymers (MIPs) with special recognition ability to replace conventional sample pretreatment materials. MIPs are tailor-made materials with high selectivity for a target molecule [23], and are capable of enriching the target molecules with high concentration factors, whilst leaving other interfering substances in the sample matrix. Their potential as sample pretreatment material for complex biological samples has been adequately investigated [24–27]. However, there are few literatures concerning about the application of MIP to purification of plant hormones. Kugimiya et al. [28] have prepared IAA-imprinted polymer as SPE material, which exhibited a significant selectivity for the template molecule. The further investigations have been made to synthesize MIPs using 9-vinyladenine as new functional monomers and IAA as template [29]. Recently, magnetic MIP beads have been prepared in our group. The resultant particles incorporating molecular recognition and magnetic separation can provide a highly selective material for enrichment of target molecules in complicated samples [30, 31]. Because the magnetic MIP beads can be well dispersed and exposed completely in sample matrix, and they are easy to interact directly with analytes, targeted analytes can be extracted rapidly from large-volume system. What’s more, magnetic particles can be separated from liquid phase simply under magnetic field after extraction. This technology used in extraction provides a more rapid and convenient way for withdrawal of polymers from sample matrices as compared with the conventional centrifugation or filtration step.

In this study, vacuum microwave-assisted extraction and magnetic MIP beads were combined and applied to the extraction, enrichment and clean-up of auxins in plant. The extraction and clean-up conditions for the target analytes, IAA and IBA, were investigated. The analytical method for determination of IAA and IBA in pea and rice plant was developed using HPLC and fluorescence detection (FL).

Experimental

Chemicals materials

IAA, IBA, and butylated hydroxytoluene (BHT) were obtained from Guanghuang Reagent Plant (Guangzhou, China). IAA was dissolved in methanol to obtain the stock standard solutions (100 mg/L) and stored at −20 °C in the dark. FeCl3 and FeSO4 were obtained from Shenyang Chemical Reagent Plant (Shenyang, China). β-Cyclodextrin (β-CD) and azo(bis)-isobutyronitrile (AIBN) were purchased from Damao Reagent Plant (Tianjin, China); 4-vinylpyridine (4-VP) was from Sigma-Aldrich (St. Louis, MO, USA). Styrene (St), trimethylolpropane trimethacrylate (TRIM), divinylbenzene, and glycidoxypropyltrimethoxysilane (GPTMS) were all obtained from Corel Chemical Plant (Shanghai, China). Dimethyl formamide (DMF) were purchased from Guangzhou Chemical Reagent Plant (Guangzhou, China). HPLC-grade methanol and acetonitrile were obtained from Merck (Darmstadt, Germany). Water was doubly distilled. All other reagents were of analytical grade. All solutions used for HPLC were filtered through a nylon 0.45 μm filter before use.

Plant materials

The plant materials were obtained as follows: seeds of pea and rice were soaked in water for 24 h and then kept for germination in dark in trays with vermiculite in a growth chamber. The temperature of the chamber was maintained at 25 °C. After sowing for 1–5 days, the fraction of seeds, immature embryo and young root were harvested, immediately frozen, grounded and stored at −4 °C in dark until analysis.

Synthesis of the IAA-imprinted magnetic beads

Magnetic MIP beads were prepared under microwave irradiation following the procedure of our recent study [30]. Firstly, magnetite particles were synthesized by co-precipitation method. A mixture solution of 1.0 mol/L FeCl3 and 0.5 mol/L FeSO4 was mixed quickly with NH3·H2O (28%, w/v) at stirring speed of 800 rpm. Then the Fe3O4 obtained was aged in a microwave synthesizer at 80 °C for 1 h. After clean-up, the magnetite particles (2.0 g) were surface modified with ethylene glycol (PEG 6000; 10.0 g) in 30 mL of water.

Then the magnetic MIP beads were synthesized by encapsulate the magnetite particles in polymer matrix. 4-VP and derived β-CD which was obtained by chemical reaction of β-CD with GPTMS in dry DMF [32] were adopted as the binary functional monomer for imprinting system. Prior to polymerization, IAA (1.0 mmol), 4-VP (4.0 mmol), and silanized β-CD (2.0 g) were dissolved in DMSO (10 mL) and stored in dark for 12 h for self-assembly. Then, the above mixture, PEG-Fe3O4 suspension, TRIM (23.7 mmol), St (79.6 mmol), AIBN (0.6 mmol) were dispersed in 80 mL of water with vigorous agitation. The polymerization was performed at 70 °C for 60 min under nitrogen atmosphere in the microwave synthesizer. Finally, the template was removed by extensively washed with 10% (v/v) acetic acid in methanol with ultrasonic agitation until no leakage of IAA from the resulting beads was observed.

Extraction of auxins from the plant tissue

For VMAE, the experiment was performed with a reassembled MAS-I microwave oven (2,450 MHz, Sineo Microwave Chemistry Technology Company, Shanghai, China), which has been described in our previous work [18]. The degree of vacuum was controlled by connecting the extraction vessel to a vacuum pump. Room temperature is controlled by a refrigeration system and monitored by an external infrared sensor installed on the innerwall. Five grams of sample was weighed accurately and put into a round-bottom flask. The sample was homogenized with 50 mL of methanol/water mixture (80/20, v/v) containing 0.01% BHT. Then, the flask was placed in the microwave oven and connected with a condenser. The air in the vessel was pumped out by vacuum pump till the degree of vacuum was 50 kPa. The extraction was then performed in dark at 25 °C for 10 min with the stirring speed of 900 rpm.

For conventional solvent extraction, accurately weighed 5.0 g fresh plant tissues were ground and homogenized in 50 mL of methanol/water mixture (80/20, v/v) containing 0.01% BHT using a high-speed blender, and then maintained at −20 °C in a refrigerator for 24 h. The mixture was then centrifuged and the supernatant was collected.

Clean-up procedure of the plant extracts by magnetic MIP beads and C18 SPE cartridge

The methanolic extract was filtered through a 0.45-μm filter. Then the pH value of the solution was adjusted to 3.0 with 0.1 mol/L HCl. The solution was extracted by ethylacetate for three times, each time with 30 mL. The resulting organic phase, thus containing the analyte specie, was collected and dried with a rotary evaporator.

For clean-up procedure by the magnetic MIP beads, the sample was re-dissolved with 3 mL of n-hexane in a 10-mL vial with a PTFE-silicone septum. Then 0.035 g magnetic MIP beads were added. The mixture was vibrated with a reciprocating shaking-table at room temperature to make the particles contact entirely with sample solution. After extraction for 30 min, a bar of magnet was placed beside the vial to hold the magnetic MIP beads. Then, the organic solvent was removed from the vial with the sorbent remaining. The analytes were eluted by 1.0 mL methanol under ultrasonic wave. The elution was dealt with a nitrogen drying step, and re-dissolved in 100 μL of methanol. A portion of 20 μL was subjected to HPLC analysis.

For clean-up procedure by the C18 SPE cartridge, the dried extracts were re-dissolved in 20 mL 80% methanol. The C18 SPE cartridge was pre-conditioned with 10 mL ethanol, 20 mL pure water and 10 mL 80% (v/v) methanol. The sample solution was passed through the pre-conditioned C18 column. The column was then rinsed with 6 mL 80% (v/v) methanol. The elution of the sample solution and rinsed solution was collected together, dried with nitrogen, and re-dissolved in 100 μL of methanol.

HPLC conditions

The extracts and its clean-up solution of pea and rice plant were analyzed on a Shimadzu SCL-10Avp HPLC system equipped with fluorescence detector. Separation was performed on a C18 column (250 mm × 4.6 mm I.D., 5 μm) from Dikma (Beijing, China). A 7.5-mm C18 security guard column from Phenomenex (Torrance, USA) was attached to the analytical column. A solvent system consisting of methanol and 0.45% (v/v) acetic acid–water was used. The gradient profile of the mobile phase was from 38% to 80% (v/v) of methanol over 20 min. The flow rate was 1 mL/min.

Results and discussions

Vacuum microwave-assisted extraction of auxins from plant samples

Prior to clean-up and analysis of the sample, extraction of auxins from plant tissue is essential. Prinsen [10] has proposed a method by immersing the plant sample in an appropriate solvent at −20 °C overnight. This protocol was commonly accepted and applied as the extraction method for IAA in different plants. Although the method is effective to prevent degradation of the auxins, it is rather time-consuming.

This study proposed a VMAE method as an alternative extraction method for auxins. In this technique, the vacuum pump is used to keep a certain degree of vacuum in the whole system in process of extraction as illustrated in our previous study [18]. A cooling device was installed in the extraction vessel to provide a relatively low temperature and the temperature was accurately monitored by a temperature detector.

The extraction solvent, extraction time, and temperature were investigated to evaluate their influence on the extraction amounts of IAA and IBA. Results show that IBA was not detected in both pea and rice samples. Therefore, comparison of the extraction efficiencies under different extraction conditions is based on the determination of IAA levels. In comparison to different extraction solvents, methanol, water, and their mixture with different ratio, the highest extraction amount of IAA was obtained for 80% methanol (v/v) and the lowest for pure water. Thus, 80% methanol (v/v) was applied as the extraction solvent for further VMAE study. The following investigation included the effect of extraction temperature and time on the VMAE process, as illustrated in Fig. 2. For the chemically stable compounds, it has been generally supposed that increasing the extraction temperature and time facilitate the increase of the yields of analytes. However, the results in Fig. 2 indicate that extraction at 25 °C for 10 min provide the best extraction yields, and further increase of extraction temperature and time leads to lower extraction amounts of IAA, which could be caused by a thermal degradation because of the temperatures that reached inside the vessels. Since the boiling point of extraction solvent in vacuum is lower than that at normal atmosphere, higher extraction yields were obtained at relatively lower temperature.

Influence of the extraction temperature (a) and extraction time (b) on the extraction amounts of IAA from pea seeds and rice seeds by VMAE. The extraction conditions are: a extraction with 50 mL of methanol/water mixture (80/20, v/v) for 15 min; b extraction with 50 mL of methanol/water mixture (80/20, v/v) at 25 °C

To confirm that the VMAE method is suitable for its intended use, a comparison study was carried out by applying the VMAE and the conventional solvent extraction method for extraction of IAA in rice and pea seeds. The comparison of extraction conditions and extraction amounts of IAA were shown in Table 1. As can be seen from Table 1, the extraction amounts of IAA by VMAE were nearly equal or slightly higher than that by conventional solvent extraction. However, it should be mentioned that the VMAE method was much rapid as compared with the prolonged extraction time of 24 h required for conventional solvent extraction at low temperature. Only 10 min was necessary for extracting auxins in plant by VMAE, resulting in significant increase of analytical speed. This may be ascribed to the fact that the microwave accelerates the rupture of the plant cell walls, allowing the target analytes to rapidly partition into the solvent. On the other hand, the IAA that was susceptible to oxygen was protected by the vacuum condition. In conclusion, VMAE shows predominance to conventional solvent extraction regarding the short extraction time and the higher extraction efficiency.

Application of magnetic MIP beads for clean-up of auxins in the plant extracts

Auxins exist in plants at very low levels. In addition, the raw extracts by VMAE containing auxins were not clean enough for quantification by direct injection to reversed phase HPLC system. Co-extracts of other compounds in plant would seriously disturb the chromatographic detection. To address this problem, we developed an additional enrichment and clean-up step utilizing the magnetic MIP beads synthesized in our laboratory. The MIP material imprinted by IAA can selectively enrich the template molecule and its analogues while leaving interfering substances in matrix solution, and magnetic property of the sorbent can also simplify the extraction and isolation procedure.

Firstly, the conditions that influence the enrichment effect of the magnetic MIP beads were investigated using the standard solution of IAA and IBA. For the solvent optimization, a series of solvents with different polarity were selected for extraction of 30.0 ng/mL IAA and IBA mixed standard solution, and the results are shown in Fig. 3. Generally, the extraction amounts of IAA and IBA increased with the decrease of the solvent polarity. The highest extraction amounts were obtained when n-hexane was used as the extraction solvent, and in contrast, poor results were obtained with polar solvents such as water, methanol, and acetone. According to a previous work [31], polar solvent would disturb the specific interaction between target analytes and the recognition sites of MIP due to their interferences to the hydrogen-bonding based recognition. Consequently, n-hexane was selected as the re-dissolved solvent for the dried VMAE extracts of plant and it would be helpful for improving the selectivity of the magnetic MIP beads. After adsorption, the magnetic MIP beads were separated from the extraction solution with a magnetic bar, and then desorbed with a small amount of solvent to release the analytes. Experimental results revealed that desorbing with methanol provided the highest signal response in chromatography. This is due to not only the high solubility of methanol to IAA and IBA, but also the hydrogen-bonding interaction of methanol with recognition sites of MIP. The adsorption and desorption kinetic investigation was performed with 30.0 ng/mL IAA and IBA mixed standard solution. The adsorption time curve was illustrated in Fig. 4. Results show that the adsorption and desorption of IAA and IBA on the magnetic MIP beads reached equilibrium after 20 and 10 min, respectively.

Effect of extraction solvents on the extraction amount of IAA and IBA with the magnetic MIP beads at 30.0 ng/mL level (column) and corresponding Snyder polarity index of solvents (solid square) A hexane, B toluene, C benzene, D chloroform, E tetrahydrofuran, F ethyl acetate, G acetonitrile, H dimethyl sulfoxide, I acetone, J water, K methanol

Based on the optimized conditions investigated above, the IAA and IBA can be well enriched by the magnetic MIP beads, and the sensitivity improved 9.1-fold for IAA and 10.8-fold for IBA, as compared with direct injection of the standard solution without enrichment by the magnetic MIP beads. The magnetic MIP beads were then applied to pretreatment of the rice and pea samples to investigate their clean-up effect in real plant samples. Fig. 5 shows the chromatogram of the pea and rice seeds extracted by VMAE before and after clean-up procedure by the magnetic MIP beads and the C18 SPE column, respectively. It can be observed from curve d in Fig. 5 that the chromatogram was very complex for direct injection of VMAE extracts without the clean-up step. The peaks of auxins were hardly detected owing to the pigments, lipids, polyphenols and other polar or non-polar compounds coexisted in plant tissues. After the clean-up protocol by the magnetic MIP beads, as can be seen from curve b in Fig. 5, the chromatogram was significantly cleaner. The conventional SPE method with C18 column also has certain clean-up effect for eliminating sample matrix, as can be seen from curve c in Fig. 5. However, the baseline is not clean enough, while the peak of IAA cannot be well separated from the interfering substance and precisely determined, especially for the pea seeds. Therefore, it could be concluded that the magnetic MIP beads played important role for enrichment of the auxins and elimination of interfering compounds in complex plant samples.

The chromatogram of the pea (a) and rice seeds (b) extracted by VMAE before and after clean-up procedure by the magnetic MIP beads and the C18 SPE column. Curve a standard solution of 10.0 ng/mL IAA and IBA; curve b the VMAE extracts followed by clean-up procedure with the magnetic MIP beads; curve c: the VMAE extracts followed by clean-up procedure with the C18 SPE column; Curve d raw extracts of plant by VMAE. Peaks: 1 IAA, 2 IBA

Method validation

The VMAE combined with magnetic MIP beads clean-up method using HPLC-FL detection for the determination of auxins was validated by evaluating their performance regarding linearity, limit of detection (LOD) and repeatability. Relevant data are given in Table 2. Calibration curves were established from different concentration levels of mixed standard of IAA and IBA. Linear ranges of 1.0–100.0 ng/mL for IAA and 2.0–100.0 ng/mL for IBA was obtained. For calculation of the detection limits (LOD), we used three times standard deviations of calibration curves divided by their slopes. The LODs obtained for IAA and IBA are 0.47 and 1.6 ng/mL, respectively. From the above result, it indicates that the proposed method has lower detection limit than those of the methods using SPE as sample preparation method and analyzed by HPLC with photodiode array or MS detector [33, 34]. The repeatability of the method for six replicate analyses of model solutions is also presented in Table 2 for a solution containing 10 ng/mL of each compound. The relative standard deviations (RSDs) was less than 2.3% indicating that the method is reliable for analyzing auxins in plant.

The recoveries were determined by comparing the calculated amounts of IAA and IBA in the samples with the total spiking amounts, and were 81.3% and 83.7% for the pea seeds and rice seeds, respectively, for 20 ng/g standard spiked samples. The reliability of the proposed method was also evaluated by comparison with that of the conventional method which was performed by extraction of auxins in plant with 80% methanol at −20 °C overnight followed by C18 SPE clean-up procedure. Results show that the IAA contents determined by the proposed method were 11.7 ± 0.9 in pea seeds and 28.5 ± 3.0 ng/g in rice seeds, which were similar with that determined by the conventional method, 10.3 ± 0.8 and 29.2 ± 2.6 ng/g.

Sample analysis

The proposed method was evaluated for its quantification potential on various plant materials differing in species origin, including the pea seeds, pea embryo, pea roots, and the rice seeds. The different parts of pea were collected at the fifth day from sowing, as well as for the rice seeds. The results are shown in Table 3. It is apparent from Table 3 that the IAA contents in embryo and roots of pea were higher than that in the seeds. This is in accordance with the rapid growth rate of embryo and root during germination. Additionally, the IAA contents are higher in rice seeds than pea seeds during the early stage of plant development. A recovery experiment was carried out by adding 10.0 and 40.0 ng/g of auxin into the plant samples, and analyzed by using the described method. The recoveries ranged from 70.0% to 85.6% and the RSDs were from 6.9% to 13.1%.

Then, the proposed method was applied to investigate the developmental profiles of IAA concentration in pea seeds and rice seeds during seed germination and early seeding growth. The variation tendency of the IAA contents is shown in Fig. 6. It can be seen that IAA content is usually low at the initial stages of pea development, followed by a gradual increase and reached the maximum at 3 days. According to Ref. [35], the initial supply of free IAA originates from stored pools of IAA–ester conjugates. IAA–ester conjugates were initially hydrolyzed in the seed to yield maximum content of free IAA prior to initiation of root elongation. When the stored pool of conjugated IAA is used up, the total amount of free IAA is constant, however, increase of sample weight owning to water swelling resulted in decrease of mass percent of IAA. On the other hand, the IAA contents in rice seeds decreased at the early seeding stage and became stable in the following germination. Owing to the high sensitivity and selectivity of the proposed method, auxin contents in plant can be accurately determined.

Conclusions

Sample preparation method based on vacuum microwave-assisted extraction combined with molecularly imprinted clean-up method was developed for auxin analysis. The extraction and clean-up protocol described here solves several drawbacks of the commonly used procedures. The extraction time was significantly decreased by VMAE with higher extraction efficiency as compared with the conventional solvent extraction method. The clean-up procedure by the magnetic MIP beads provided highly selective enrichment of auxins while leaving other interfering substance in the plant extract through magnetic separation. Application of the method to analysis of auxins in pea and rice samples proved the established method to be selective, sensitive, and reproductive for determination of auxins in complex plant samples.

References

Woodward AW, Bartel B (2005) Ann Bot 95:707–735

Epstein E, Ludwig-Müller J (1993) Physiol Plant 88:382–389

Riov J, Yang SF (1989) Plant Growth Regul 8:131–141

Galian RE, Guillermo Bracamonte A, Veglia AV (2005) Anal Chim Acta 540:393–401

Yin XB, Liu DY (2008) J Chromatogr A 1212:130–136

Kloosterman B, Visser RGF, Bachem CWB (2006) Plant Physiol Biochem 44:766–775

Barkawi LS, Tam YY, Tillman JA, Pederson B, Calio J, Al-Amier H, Emerick M, Normanly J, Cohen JD (2008) Anal Biochem 372:177–188

Olsson J, Claeson K, Karlberg B, Nordström AC (1998) J Chromatogr A 824:231–239

Birkemeyer C, Kolasa A, Kopka J (2003) J Chromatogr A 993:89–102

Perrine FM, Rolfe BG, Hynes MF, Hocart CH (2004) Plant Physiol Biochem 42:723–729

Navas DÍaz A, GarcÍa Pareja A, GarcÍa Sánchez F (1996) Anal Chem 68:3029–3032

Pan XQ, Welti R, Wang XM (2008) Phytochemistry 69:1773–1781

Hoyerová K, Gaudinová A, Malbeck J, Dobrev PI, Kocábek T, Šolcová B, TrávnÍčková A, KamÍnek M (2006) Phytochemistry 67:1151–1159

Prinsen E, Van Laer S, Oden S, Van Onckelen H (2000) In: Tucker GA, Roberts JA (eds) Methods in molecular biology, 141: plant hormone protocols. Humana, Totowa, pp 49–65

Chen LG, Song DQ, Tian Y, Ding L, Yu AM, Zhang HQ (2008) Trends Anal Chem 27:151–159

Liazid A, Palma M, Brigui J, Barroso CG (2007) J Chromatogr A 1140:29–34

Liazid A, Palma M, Brigui J, Barroso CG (2007) Talanta 71:976–980

Wang JX, Xiao XH, Li GK (2008) J Chromatogr A 1198/1199:45–53

Xiao XH, Wang JX, Wang G, Wang JY, Li GK (2009) J Chromatogr A 1216:8867–8873

Absalan G, Akhond M, Sheikhian L (2008) Talanta 77:407–411

Wu YL, Hu B (2009) J Chromatogr A 1216:7657–7663

Dobrev PI, Havlíček L, Vágner M, Malbeck J, Kamínek M (2005) J Chromatogr A 1075:159–166

Vlatakis G, Andersson LI, Mueller R, Mosbach K (1993) Nature 361:645–647

Yan HY, Qiao FX, Row KH (2007) Anal Chem 79:8242–8248

Li YQ, Li X, Li Y, Dong CK, Jin PF, Qi JY (2009) Biomaterials 30:3205–3211

Koster EHM, Crescenzi C, den-Hoedt W, Ensing K, de-Jong GJ (2001) Anal Chem 73:3140–3145

Turiel E, Tadeo JL, Martin-Esteban A (2007) Anal Chem 79:3099–3104

Kugimiya A, Takeuchi T (1999) Anal Chim Acta 39:5251–5255

Chen CB, Chen YJ, Zhou J, Wu CH (2006) Anal Chim Acta 569:58–65

Zhang Y, Liu RJ, Hu YL, Li GK (2009) Anal Chem 81:967–976

Hu YL, Liu RJ, Zhang Y, Li GK (2009) Talanta 70:576–582

Qin L, He XW, Li WY, Zhang YK (2008) J Chromatogr A 1187:94–102

Hou SJ, Zhu J, Ding MY, Lv GH (2008) Talanta 76:798–802

Ma Z, Ge L, Lee ASY, Yong JWH, Tan SN, Ong ES (2008) Anal Chim Acta 610:274–281

Ljung K, Östin A, Lioussanne L, Sandberg G (2001) Plant Physiol 125:464–475

Acknowledgments

The authors would like to thank the National Natural Science Foundation of China for financially supporting this research under grant number 90817012, 20775095, 20705042 20905080 and 21075140, the Key Program of Guangdong Provincial Natural Science Foundation of China under grant number 9251027501000004, the Science and Technology Planning Project of Guangdong Province of China (No. 2009B010900021), and the Fundamental Research Funds for the Central Universities, respectively.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in the special issue Analytical and Bioanalytical Science in China with Guest Editors Lihua Zhang, Qiankun Zhuang, and Yukui Zhang.

Rights and permissions

About this article

Cite this article

Hu, Y., Li, Y., Zhang, Y. et al. Development of sample preparation method for auxin analysis in plants by vacuum microwave-assisted extraction combined with molecularly imprinted clean-up procedure. Anal Bioanal Chem 399, 3367–3374 (2011). https://doi.org/10.1007/s00216-010-4257-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-010-4257-8