Abstract

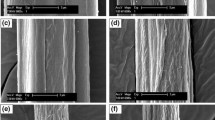

Natural fibers such as bamboo, kenaf, flax, ramie and hemp were chemically treated to improve their adherence with hydrophobic matrices. One common chemical process for altering the surface of these natural fibers is alkali treatment (AT). The experiment involves soaking bamboo fibers (BF) in solutions of 1, 10, and 30 wt % sodium hydroxide (NaOH) for one day, half an hour, and twenty minutes at room temperature. These alkali-treated and untreated bamboo fibers was compared with their physical and mechanical qualities. Using scanning electron microscopy (SEM) and the circular fiber assumption, the CSA of bamboo fibers both before and after AT were compared. Improving the AT procedures for BF at room temperature using varying NaOH concentrations is the focus of this effort. Additionally, the tensile characteristics of both untreated and variously treated AT Bamboo fibres are examined using a two-parameter Weibull distribution. Instead of just showing the average tensile strength, probabilistic tensile strength has shown to be a more effective method. This study proves without a reasonable doubt that adding 1 wt % NaOH to bamboo fiber makes natural fiber reinforced composites mechanically better. According to the SEM, the CSA of bamboo fibers decreases by about 13.62–20.24% and about 18.42–22.63%, respectively, after alkali treatment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Data availability

No datasets were generated or analysed during the current study.

References

Li, X.-G., Wu, Y.-Q.: Effect of alkali treated bamboo fibres on mechanical properties of fibre-reinforced green composites, in International Conference on Mechanic Automation and Control Engineering, MACE2010, 2010, pp. 5399–5401. (2010)

Lin, J., Yang, Z., Hu, X., Hong, G., Zhang, S., Song, W.: The effect of alkali treatment on properties of dopamine modification of bamboo fiber/polylactic acid composites. Polym. (Basel), 10, 4, (2018)

Wang, Y., Zhang, H., Zheng, C., Xu, L., Tang, J.: Study of metakaolin geopolymer composites reinforced by clean broom-like bristle bamboo fibers. J. Mater. Res. Technol. 25, 3507–3521 (2023)

Satishkumar, P., Gokila Krishnan, G., Seenivasan, S., Rajarathnam, P.: A study on tribological evaluation of hybrid aluminium metal matrix for thermal application, in Materials Today: Proceedings, Elsevier Ltd, pp. 1097–1104. (2021)

Veeranjaneyulu, I., et al.: Friction and wear optimization of SiC/graphite reinforced AZ31 hybrid composite using Taguchi method. Int. J. Interact. Des. Manuf. 18(3), 1373–1386 (2024)

Wang, F., Lu, M., Zhou, S., Lu, Z., Ran, S.: Effect of fiber surface modification on the interfacial adhesion and thermo-mechanical performance of unidirectional epoxy-based composites reinforced with bamboo fibers. Molecules. 24, 15 (2019)

Srividya, K., et al.: Design and analysis of wear parameters for epoxy based composite using RSM-box behnken optimization tool. Int. J. Interact. Des. Manuf., (2023)

Ma, L., He, H., Jiang, C., Zhou, L., Luo, Y., Jia, D.: Effect of alkali treatment on structure and mechanical properties of acrylonitrile-butadiene-styrene/bamboo fiber composites. J. Macromolecular Sci. Part. B: Phys. 51(11), 2232–2244 (2012)

Karthik, A., Daniel James, J., Sampath, D.P.S., Thirumurugan, V.: Effect of alkali treatment on cotton/bamboo fibres for application as a reinforcement material, Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, (2023)

Wang, C., Liu, S.: Effects of alkali treatment on properties of bamboo fiber and bamboo fiber reinforced polypropylene composites. Fuhe Cailiao Xuebao/Acta Materiae Compositae Sinica. 32(3), 683–690 (2015)

Prasanna Venkatesh, R., Ramanathan, K., Srinivasa Raman, V.: Tensile, flexual, impact and water absorption properties of natural fibre reinforced polyester hybrid composites, Fibres and Textiles in Eastern Europe, vol. 24, no. 3, pp. 90–94, (2016)

Girimurugan, R., Shilaja, C., Mayakannan, S., Rajesh, S., Aravinth, B.: Experimental investigations on flexural and compressive properties of epoxy resin matrix sugarcane fiber and tamarind seed powder reinforced bio-composites. Mater. Today Proc. 66, 822–828 (2022)

Li, Y., Jiang, L., Xiong, C., Peng, W.: Effect of different surface treatment for Bamboo Fiber on the crystallization behavior and Mechanical Property of Bamboo Fiber/Nanohydroxyapatite/Poly(lactic-co-glycolic) composite. Ind. Eng. Chem. Res. 54(48), 12017–12024 (2015)

Murugan, G., Loganathan, G.B., Sivaraman, G., Shilaja, C., Mayakannan, S.: Compressive behavior of tamarind shell powder and fine granite particles reinforced epoxy matrix based hybrid bio-composites. ECS Trans. 107(1), 7111 (2022)

Satishkumar, P., Infant Jegan Rakesh, A.J., Meenakshi, R., Saravana Murthi, C.: Characterization, mechanical and wear properties of Al6061/Sicp/fly ashp composites by stir casting technique, in Materials Today: Proceedings, Elsevier Ltd, pp. 2687–2694. (2020)

Lakshmipathi, A.R., et al.: Shear strength, wear, thermal conductivity, and hydrophobicity behavior of fox millet husk biosilica and Amaranthus dubius stem fiber–reinforced epoxy composite: A concept of biomass conversion. Biomass Convers. Biorefin, (2023)

Wang, F., Zhou, S., Yang, M., Chen, Z., Ran, S.: Thermo-mechanical performance of polylactide composites reinforced with Alkali-treated bamboo fibers. Polym. (Basel), 10, 4, (2018)

Uawongsuwan, P., et al.: Mechanical properties of poly (Lactic acid) based biocomposites: Comparison of different reinforcements, in Annual Technical Conference - ANTEC, Conference Proceedings, pp. 1437–1443. (2013)

Sukumar, N., Bayeleyegn, M., Aruna, S.: Development and characterization of epoxy resin composite reinforced with bamboo fiber and bagasse as filler. Res. J. Text. Appar. 26(1), 73–89 (2022)

Jayaraman, R., Girimurugan, R., Suresh, V., Shilaja, C., Mayakannan, S.: Improvement on tensile properties of epoxy resin matrix sugarcane fiber and tamarind seed powder reinforced hybrid bio-composites. ECS Trans. 107(1), 7265 (2022)

Wang, C., Ren, Z., Zhang, Q.: Effect of surface modification of unidirectional bamboo fiber on the properties of its reinforced unsaturated polyester resin composites. Fuhe Cailiao Xuebao/Acta Materiae Compositae Sinica. 34(2), 314–321 (2017)

Thangaraj, S., Pradeep, G.M., Dani, M.S.H., Mayakannan, S., Benham, A.: Experimental investigations on tensile and compressive properties of nano alumina and arecanut shell powder reinforced polypropylene hybrid composites. Mater. Today Proc. 68, 2243–2248 (2022)

Sivasubramanian, P., et al.: Effect of alkali treatment on the properties of Acacia caesia bark fibres. Fibers 9.8: 49. (2021)

Bothiraj, T., Boopathi, K., Kalaiselvan, K., Benham, A., Mayakannan, S.: Experimental investigations on mechanical and wear behavior of waste marble dust and coconut fiber reinforced hybrid bio composites. Mater. Today Proc. 68, 2239–2242 (2022)

Guo, C., Li, M., Wang, S., Zhang, S., Li, Y., Li, C.: Alkali treatment of bamboo fibers improves the mechanical properties of metakaolin geopolymer. J. Dispers Sci. Technol. 45(5), 980–989 (2024)

Enyew, S.Y., Ali, A.N.: Investigate the Effects of Fiber Surface Chemical Treatment on the Mechanical Properties of Bamboo Fiber Reinforced Polyester Resin Composites, in Lecture Notes of the Institute for Computer Sciences, Social-Informatics and Telecommunications Engineering, LNICST, pp. 350–364. (2022)

Palanisamy, S., et al.: Tensile properties and fracture morphology of Acacia caesia bark fibers treated with different alkali concentrations. J. Nat. Fibers. 19(15), 11258–11269 (2022)

Wang, Q., Zhang, Y., Liang, W., Wang, J., Chen, Y.: Improved mechanical properties of the graphene oxide modified bamboo-fiber-reinforced polypropylene composites. Polym. Compos. 41(9), 3615–3626 (2020)

da Costa, L.L., Loiola, R.L., Monteiro, S.N.: Diameter dependence of tensile strength by weibull analysis: Part I bamboo fiber. Revista Materia. 15(2), 97–102 (2010)

Palaniappan, M., et al.: Novel Ficus retusa L. aerial root fiber: A sustainable alternative for synthetic fibres in polymer composites reinforcement. Biomass Convers. Biorefinery: 1–17. (2024)

Gao, J., Ge, W., Cheng, H.-T., Shi, S.Q.: Physical and mechanical properties of inorganic particles filled individual bamboo fibers. Adv. Mater. Res., pp. 1930–1933. (2012)

Mayakannan, S., Raj, J.B., Raja, V.L., Nagaraj, M.: Effectiveness of silicon nanoparticles on the mechanical, wear, and physical characteristics of PALF/sisal fiber–based polymer hybrid nanocomposites. Biomass Convers. Biorefin. 13(14), 13291–13305 (2023)

Kar, A., et al.: Effect of alkali treatment under ambient and heated conditions on the physicochemical, structural, morphological, and thermal properties of Calamus tenuis cane fibers. Fibers 11.11: 92. (2023)

Satishkumar, P., Mahesh, G., Meenakshi, R., Vijayan, S.N.: Tribological characteristics of powder metallurgy processed Cu-WC/SiC metal matrix composites, in Materials Today: Proceedings, Elsevier Ltd, pp. 459–465. (2020)

Sujaritjun, W., Uawongsuwan, P., Pivsa-Art, W., Hamada, H.: Mechanical property of surface modified natural fiber reinforced PLA biocomposites. Energy Procedia. 34, 664–672 (2013)

Mylsamy, B., et al.: A Review on Natural fiber Composites: Polymer Matrices, fiber Surface Treatments, Fabrication Methods, Properties, and Applications. Polymer Engineering & Science (2024)

Chunhong, W., Shengkai, L., Zhanglong, Y.: Mechanical, hygrothermal ageing and moisture absorption properties of bamboo fibers reinforced with polypropylene composites. J. Reinf. Plast. Compos. 35(13), 1062–1074 (2016)

Zhang, X., Wang, F., Keer, L.M.: Influence of surface modification on the microstructure and thermo-mechanical properties of bamboo fibers. Materials. 8(10), 6597–6608 (2015)

Sánchez, M.L., Patiño, W., Cárdenas, J.: Physical-mechanical properties of bamboo fibers-reinforced biocomposites: Influence of surface treatment of fibers. J. Building Eng., 28, (2020)

Palaniappan, M., et al.: Synthesis and suitability characterization of microcrystalline cellulose from Citrus x sinensis sweet orange peel fruit waste-based biomass for polymer composite applications. J. Polym. Res. 31(4), 105 (2024)

Da Costa, L.L., Loiola, R.L., Monteiro, S.N.: Tensile strength of bamboo fibers: Weibull analysis to characterize the diameter dependence, in 65th ABM International Congress, 18th IFHTSE Congress and 1st TMS/ABM International Materials Congress 2010, pp. 4952–4961. (2010)

Acknowledgements

Each author has reviewed the final version of the manuscript and agrees to be accountable for all aspects of the work, ensuring that questions related to the accuracy or integrity of any part of the work are appropriately investigated and resolved.

Author information

Authors and Affiliations

Contributions

All authors contributed significantly to the conception, design, and execution of the research study. Madhuri S Bhagat and Varsha D. Jadhav conducted the experimental work, including the alkali treatment of bamboo fibers and the characterization of their physical and mechanical properties. Sumant Khanderao Kulkarni performed the statistical analysis and interpretation of the tensile test data using the Weibull distribution. Satishkumar P provided expertise in composite materials and contributed to the conceptualization of the research methodology. Rajasekaran Saminathan oversaw the project, provided guidance throughout the research process, and contributed to the interpretation of the results.Specifically, Madhuri S Bhagat and Varsha D. Jadhav were responsible for the practical implementation of the alkali treatment process, including the preparation of solutions and the treatment of bamboo fibers. They also conducted the scanning electron microscopy (SEM) analysis to assess the morphological changes in the fibers.Sumant Khanderao Kulkarni conducted the statistical analysis of the tensile test data and contributed to the interpretation of the results, particularly regarding the probabilistic tensile strength analysis using the two-parameter Weibull distribution.Satishkumar P provided expertise in composite materials and contributed to the selection of appropriate methodologies for the mechanical characterization of the bamboo fiber reinforced composites.Rajasekaran Saminathan played a supervisory role throughout the project, providing guidance on experimental design, data analysis, and interpretation of results. Additionally, [Author 5] facilitated collaboration among the co-authors and ensured that the research objectives were met within the specified timeline.All authors participated in the drafting and revision of the manuscript, providing critical feedback and intellectual input to ensure its accuracy and integrity. Rajasekaran Saminathan supervised the writing process and provided final approval of the version to be submitted.Each author has reviewed the final version of the manuscript and agrees to be accountable for all aspects of the work, ensuring that questions related to the accuracy or integrity of any part of the work are appropriately investigated and resolved.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bhagat, M.S., Jadhav, V.D., Kulkarni, S.K. et al. Comparative analysis of alkali-treated natural fibres for improved interfacial adhesion in composite materials. Interactions 245, 206 (2024). https://doi.org/10.1007/s10751-024-02041-6

Accepted:

Published:

DOI: https://doi.org/10.1007/s10751-024-02041-6