Abstract

Rock abrasivity index (RAI) and uniaxial compressive strength (UCS) are two key parameters for assessing abrasivity and durability of building stones, respectively. Direct determination of these parameters is a time-consuming, tedious and costly task. Hence, indirect and nondestructive tests such as P-wave velocity (Vp) and Schmidt hammer rebound (SHR) are good alternative for prediction of RAI and UCS. This study mainly focuses on developing fast and reliable correlations for predicting RAI and UCS of Iranian granite building stones using Vp and SHR. For this purpose, 15 types of commercial granite building stones were collected from different regions of Iran. After preparing the required samples, petrographic studies and physico-mechanical tests were performed. Then, using simple and multiple regression analysis, various empirical correlations for RAI and UCS prediction based on Vp and SHR were developed. The coefficient of determination (R2), the variance account for (VAF), the normalized root mean square error (NRMSE) and the performance index (PI) were calculated to check the prediction performance of the correlations. The results showed that the proposed correlations derived from nonlinear multiple regression have more prediction capability than the others. These correlations can be applied for fast prediction of RAI and UCS with acceptable error for practical applications in building stone industry.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Granites are one of the most widely used natural stones to decorate the interior and exterior of buildings because of their durability, strength and beauty. Since quartz is one of the main minerals forming granites, these stones are considered as abrasive stones. The stone abrasivity plays a significant role in consumption of cutting and polishing tools during quarrying and processing of granite building stones. Hence, tool wear and short tool life span constitute the main cost factors in quarrying and processing of abrasive building stones (Gupta 2018; Farhadian et al. 2021).

During recent years, various methods have been proposed for determining stone abarsivity that can be classified into two broad categories, namely, petrological methods and mechanical methods (Majeed and Abu Bakar 2016). In mechanical methods, the stone abrasivity is generally determined using laboratory test rigs under standard controlled test conditions. CERCHAR, LCPC, and NTNU tests are the main mechanical methods which have gained popularity over the past several years. The details about these tests can be found in the literature (West 1989; Fowell and Abu Bakar 2007; Käsling and Thuro 2010; Gharahbagh et al. 2011; Labaš et al. 2012; Majeed and Abu Bakar 2016 and 2018; Janc et al. 2020). In petrological methods such as Schimazek’s F value and rock abrasivity index (RAI), the stone abrasivity is generally determined using indirect methods using a combination of petrological and mechanical stone properties based on mechanical properties tests and petrographic thin sections analysis.

RAI is a reliable method for evaluating stone abrasivity that has experienced increasing international use, since its introduction in 2002 (Plinninger 2010). RAI is calculated by multiplying the stone’s uniaxial compressive strength (UCS) and equivalent quartz content (EQC) according to Eq. 1:

Based on this equation, the RAI is calculated using a combination of petrological and mechanical stone properties. Petrographic thin sections analysis is a common method for EQC determination and UCS can be determined using various laboratory testing methods such as international society for rock mechanics suggested method (ISRM 1978) and the American society for testing and material standard (ASTM 1995). Thus, direct measurement of UCS and EQC for calculating RAI is only possible by destructive and tedious laboratory and petrographic studies (Yurdakul and Akdas 2013; Bharti et al. 2017; Azimian 2017; Kong and Shang 2018; Rezaei et al. 2021). In other words, direct determination of RAI is costly and time-consuming. Therefore, development of indirect and nondestructive methods for rapid and low-cost estimation of RAI seems necessary. P-wave velocity (Vp) and Schmidt hammer rebound (SHR) tests are two common nondestructive tests in the field of rock mechanic engineering (Rajabi et al. 2017; Teymen and Mengüç 2020; Wang et al. 2020; Kong et al. 2021). These tests are simple, fast, flexible and economical, so during recent years their applications for developing nondestructive and indirect models have increased remarkably. The primary purpose of this study is to develop of empirical correlations for estimating RAI of Iranian granite building stones based on two common nondestructive tests namely P-wave velocity (Vp) and Schmidt hammer rebound (SHR) using statistical techniques. The literature surveys show that there is no study about the estimation of RAI based on nondestructive methods. Hence, for the first time, an effort has been made in this study to use Vp and SHR tests for indirect prediction of RAI.

On the other hand, UCS is a critical parameter for determining engineering properties of building stones such as durability and abrasivity (Yurdakul and Akdas 2013; Hazrathosseini and Mahdevari 2018; Kong et al. 2021). UCS has remarkable role in selection of building stones for different purposes. As mentioned before, direct measurement of UCS based on standard tests is costly and time-consuming. Thus, during recent years, researchers have developed many indirect models for estimating UCS based on Vp and SHR using statistical and artificial intelligence methods (Momeni et al. 2015; Wang et al. 2020; Rahman and Sarkar 2021). Table 1 presents some of these models which have been developed based on simple regression analysis (SR).

As can be seen in Table 1, the proposed models are of significantly different. In other words, there is no comprehensive relationship for the prediction of UCS. This can be attributed to the differences in the conditions of the performed studies, along with the various geological characteristics of the referenced samples (Hebib et al. 2017). Therefore, the secondary purpose of this study is to develop indirect models for estimating UCS of Iranian granite building stones using statistical techniques.

2 Materials and Methods

As mentioned before, in this study various empirical correlations are developed for predicting RAI and UCS of Iranian granite building stones based on Vp and SHR. It should be noted that the term “granite” has two different definitions of scientific and commercial. Granite is scientifically defined as a crystalline and hard igneous rock essentially composed of quartz, feldspars, and accessory minerals such as mica, whereas commercial granite covers all hard and crystalline igneous rocks with different mineralogical and petrographic properties that can be polished well (Yilmaz 2011).

To do this study, 15 different types of commercial granite stones of Iran with various mineralogical compositions were collected from various building stone processing plants of Mahmood Abad industrial town, Isfahan province (Fig. 1). For all stone types, the block samples with large enough dimensions were provided from the stone processing plants and were brought to the laboratory for sampling and testing. All of these samples were unweathered and free from any defects such as visible cracks or fractures to avoid the impact of anisotropy on the measurement. Laboratory investigations in this study include petrographic analyses and physico–mechanical properties tests.

2.1 Petrographic analyses

The main purpose of petrographic analyses is to define the scientific names and EQC of studied stones. For this purpose, thin sections were prepared from each sample and the sections were then examined under a polarized microscope. Once the mineral compositions of each stone sample were identified, they were classified based on Streckeisen classification system (Streckeisen 1976). In Fig. 2, the thin section photomicrographs for 4 samples of studied stones have been shown. After determining the composition of mineral content of stone samples, the obtained results were used to calculate the EQC for each stone sample using Eq. 2 (Thuro 1997):

where Pi is the percentage content of minerals present in the rock, Ri is the Rosiwal hardness of minerals, and n is the number of minerals.

The commercial name, scientific name and EQC value for each stone sample have been presented in Table 2.

2.2 Physico-mechanical properties tests

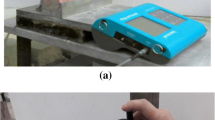

The main purpose of this stage is to determine the physico-mechanical properties of all stone types by standard methods. The physico-mechanical properties include apparent density (d), effective porosity (P), P-wave velocity (Vp), Schmidt hammer rebound (SHR) and uniaxial compressive strength (UCS). According to Fig. 3a, d and P were determined using the saturation and buoyancy method following the ISRM suggested method (ISRM 1981). To determine these properties, at least three samples of each stone type were tested and the average values were considered. The Vp was determined for each stone type using a Portable Ultrasonic Nondestructive Digital Indicating Tester (PUNDIT Lab +) instrument and two transducers (a transmitter and a receiver) having a frequency of 54 kHz according to ISRM (1981) (Fig. 3b). The direct transmission method was used to measure the P-wave travel times. Also, a coupling gel was applied on the surfaces of the specimens to avoid any air gap between the sample and transducers to maximize the accuracy of transit time measurement. The Vp values were calculated by dividing the length of sample and the transit pulse time. The Vp test was performed on three cubical shaped samples with the dimensions of 7 × 7 × 7 cm from each stone type and the average of measurements was considered as Vp in this study. The SHR was determined for each stone type using the L-type Schmidt hammer with an impact energy of 0.735 N.m according to ISRM suggested method (Aydin 2008). The hammer was held vertically downwards at rock faces to avoid the necessity for a correction factor (Fig. 3c). The UCS of samples was measured according to the ASTM C170 (2017). Three cubical shaped samples with the dimensions of 7 × 7 × 7 cm from each stone type were used to determine the UCS values (Fig. 3d). The stress rate was applied uniformly within the limits of 0.5–1 MPa/s until failure occurred. The average of three measurements were used as UCS in this study.

The value of d, P, Vp, SHR and UCS, of the different studied stones are listed in Table 2. As mentioned before, the values of these parameters for each stone were obtained based on three tests and due to the fact that the results were very close to each other, no more tests were carried out. Standard deviation value for each parameter is presented in Table 2 in parenthesis.

2.3 Rock abrasivity index (RAI)

After determining EQC and UCS using petrographic analyses and physico–mechanical properties tests, the RAI value for each stone sample was calculated using Eq. 1. The values of RAI for each stone type can be found in Table 2.

In next section, the correlation of RAI and UCS of studied stones with two nondestructive parameters, i.e. Vp and SHR, are investigated to develop predictive models using regression statistical technique. The histograms of RAI, UCS, Vp and SHR values of the studied samples are shown in Fig. 4.

3 Development of Correlations

One of the most common methods for developing empirical correlations is regression analysis. In this study, various correlations will be developed to predict RAI and UCS based on Vp and SHR using simple and multiple regression analysis. SPSS software (SPSS16.02007) was used to develop these correlations.

3.1 Simple regression analysis

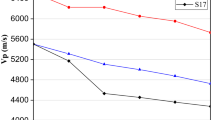

The simple regression analysis (SR) provides a means of summarizing the correlation between two variables (Draper and Smith 1981). To perform simple regression analysis, four common functions, namely linear (y = ax + b), logarithmic (y = a + ln x), exponential (y = aex) and power (y = axb), were used. The RAI and UCS were assumed to be dependent variables and Vp and SHR were considered as independent variables. After developing various correlations, the correlations with higher determination coefficient (R2) were selected as best correlations. Accordingly, the best correlations are given in Table 3. All the obtained correlations were found to be statistically significant according to the student's t-test at a 95% level of confidence. The best correlations with their corresponding R2 are presented in Fig. 5. As can be seen, Vp and SHR have significant and meaningful relationship with RAI and UCS. The results reveal that for RAI the exponential function presents the best correlations. While, for UCS the logarithmic function presents the best correlations. The best correlation was obtained between UCS and Vp with R2 of 0.820. Furthermore, the results indicate that there is direct relationship between dependent and independent variables. In other words, RAI and UCS increase by increasing Vp and SHR.

3.2 Multiple Regression Analysis

The general purpose of multiple regression is to learn more about the relationship between several independent variables and a dependent variable (Draper and Smith 1981). In other words, this technique identifies the simultaneous effect of two or more independent variables on a dependent variable. This method can be useful in cases where complex relations are involved (Azimian 2017).

Multiple regression analysis is generally divided into two categories of linear and nonlinear. In linear multiple regression (LMR), the relationship between independent variables (Xi) and dependent variable (Y) is as follows:

where B1, B2, …, Bn are the regression coefficients and A0 is a constant.

Using linear multiple regression analysis in SPSS software, two correlations were developed to predict RAI and UCS based on Vp and SHR independent variables. The obtained correlations are as follows:

The nonlinear multiple regression analysis (NLMR) was also used. To obtain the best nonlinear correlations for predicting the RAI and UCS, all the combinations of nonlinear relationships based on Vp and SHR were examined and the following relationships were considered according to their resultant R2:

In these correlations, α0 is a constant value and A, B, α1, α2, β0, β1 are regression coefficients. The nonlinear correlations are developed based on the data available in the SPSS software and Eqs. 12 and 13 are formulated as:

Based on linear and nonlinear correlations, Vp and SHR have a direct effect on RAI and UCS. On the other words, RAI and UCS increase by increasing Vp and SHR. This result is in accordance with intuition based on engineering judgment and the literature findings.

3.3 Performances of the Developed Correlations

In the previous section, various correlations were developed for predicting RAI and UCS of granite building stones based on Vp and SHR nondestructive tests using SR, LMR, and NLMR techniques. Then, the quality of the developed correlations was analyzed by R2 performance index. In addition to R2, there are various indices for this purpose. Two of which, namely normalized root mean square error (NRMSE) and variance account for (VAF), are employed to evaluate the accuracy of the developed models in this section. The NRMSE and VAF are calculated using Eqs. 14 and 15, respectively (Azimian 2017; Kong et al. 2021; Yagiz et al. 2012; Yurdakul and Akdas 2013; Yesiloglu et al. 2013; Amirkiyaei et al. 2021). A predictive correlation is accepted as excellent when NRMSE is 0 and VAF is 100%.

The values of R2, NRMSE and VAF for all correlations are given in Table 4. These indices illustrate that all correlations can predict RAI and UCS with acceptable accuracy for engineering purposes.

To select the most accurate correlations, performance index (PI) suggested by Yagiz et al. (2012) was used. PI can be calculated based on combination of R2, VAF, and NRMSE indices using the following equation:

Theoretically, the PI value of excellent predictive correlations is equal to 2 as expected. the correlations with the highest average of PI value should be the most reliable and accurate ones. Computed PI values for each correlation are given in Table 4.

According to the obtained results, it is concluded that the NLMR correlations are more accurate than the SR and LMR correlations, which shows that the problem involved has high nonlinearity. Therefore, Eqs. 12 and 13 can be selected as more reliable and accurate correlations for the RAI and UCS, respectively. This result reveals that Vp and SHR are reliable tests for predicting RAI and UCS, and can be used to avoid the cumbersome and time-consuming test methods carried out in the preliminary studies. The predicted values of RAI and UCS values were plotted versus the measured values using a 1:1 diagonal line, as shown in Figs. 6 and 7. The error of predicted value is represented by the distance of each data point from the 1:1 diagonal line. Consequently, a point lying on the line indicates an exact estimation. It can be seen that the points have scattered uniformly around the diagonal lines, implying the accuracy of the proposed empirical correlations.

Measured RAI versus predicted RAI from Eq. 12

Measured UCS versus predicted UCS from Eq. 13

4 Comparison of Developed Correlations with Previous Studies

To pursue the primary purpose of this study, the relationship between RAI with Vp and SHR was investigated for the first time and the Eq. 12 was proposed as the best correlation. As mentioned before, the literature surveys show that there is no study about the estimation of RAI based on nondestructive tests. consequently, there is no previous study for comparison. To achieve the secondary purpose of this study, Eq. 13 was proposed as the best correlation for prediction of UCS using Vp and SHR. In this field, many studies have been conducted during recent years but there are limited studies that have addressed the relationship between Vp and SHR with UCS using statistical techniques, simultaneously. These correlations have been summarized in Table 5. As can be seen, the proposed correlation (Eq. 13) has acceptable accuracy for engineering practices and can be used as a fast and reliable tool for predicting UCS of granite building stones. It should be noted that the lower determination coefficient of the proposed correlation in this study than the previous ones is probably due to the limited number of studied stones. It is obvious that the suggested correlation is open to further development, and that the accumulation of more samples will lead to more comprehensive and accurate correlations.

5 Conclusions

In this study, correlations between RAI and UCS with Vp and SHR (as common nondestructive tests) were established for the Iranian granite building stones. Various statistical techniques such as SR, LMR and NLMR were employed to develop different correlations between RAI/UCS with Vp and SHR. the correlations developed by SR and with Vp as input variable gave more precise results in comparison with the models having SHR as input. On the other hand, the correlations developed by LMR and NLMR indicated that simultaneous employment of Vp and SHR as inputs leads to stronger relationships in comparison to SR. The evaluation of correlations performances reveals that the NLMR correlations are more accurate than the SR and LMR correlations. The results of the proposed NLMR correlations were quite satisfactory in terms of R2, VAF, NRMSE and PI performance indices. Hence, it is concluded that the proposed NLMR correlations are suitable and practical tools that can be effectively used in the prediction of RAI and UCS of granite building stones with acceptable error. The outcome of this study can be used to assess the abrasivity and durability of granite building stones in their different stages of quarrying, processing and final application.

Finally, it is worth mentioning that the derived correlations are valid only for the studied granites and stones with similar characteristics.

References

ASTM D 2938 (1995) Standard test method for unconfined compressive strength of intact rock core specimens. https://doi.org/10.1520/D2938-95R02

Altindag R (2012) Correlation between P-wave velocity and some mechanical properties for sedimentary rocks. J South Afr Inst Min Metall 112:229–237

Amirkiyaei V, Ghasemi E, Lohrasb F (2021) Estimating uniaxial compressive strength of carbonate building stones based on some intact stone properties after deterioration by freeze–thaw. Environ Earth Sci 80:352. https://doi.org/10.1007/s12665-021-09658-8

ASTM C170 (2017) Standard Test Method for Compressive Strength of Dimension Stone. https://doi.org/10.1520/C0170_C0170M-17

Aydin A, Basu A (2005) The Schmidt hammer in rock material characterization. Eng Geol 81:1–14. https://doi.org/10.1016/j.enggeo.2005.06.006

Aydin A (2008) ISRM Suggested method for determination of the Schmidt hammer rebound hardness: revised version, In: ISRM suggest. methods rock charact. Test. Monit. 2007–2014, Springer International Publishing, pp 25–33. https://doi.org/10.1007/978-3-319-07713-0_2

Azimian A (2017) Application of statistical methods for predicting uniaxial compressive strength of limestone rocks using nondestructive tests. Acta Geotech 12:321–333. https://doi.org/10.1007/s11440-016-0467-3

Azimian A, Ajalloeian R (2015) Empirical correlation of physical and mechanical properties of marly rocks with P wave velocity. Arab J Geosci 8:2069–2079. https://doi.org/10.1007/s12517-013-1235-4

Bharti S, Deb D, Das P (2017) Abrasivity investigation by physico-mechanical parameters and microscopic analysis of rock samples. In: Int Conference on Deep Excavation, Energy Resources and Production. 24–26 January IIT Kharagpur, India DEEP16

Çobanoǧlu I, Çelik SB (2008) Estimation of uniaxial compressive strength from point load strength, Schmidt hardness and P-wave velocity. Bull Eng Geol Environ 67:491–498. https://doi.org/10.1007/s10064-008-0158-x

Diamantis K, Gartzos E, Migiros G (2009) Study on uniaxial compressive strength, point load strength index, dynamic and physical properties of serpentinites from Central Greece: Test results and empirical relations. Eng Geol 108:199–207. https://doi.org/10.1016/j.enggeo.2009.07.002

Diamantis K, Bellas S, Migiros G, Gartzos E (2011) Correlating wave velocities with physical, mechanical properties and petrographic characteristics of peridotites from the central Greece. Geotech Geol Eng 29:1049–1062. https://doi.org/10.1007/s10706-011-9436-7

Draper NR, Smith H (1981) Applied regression analysis. Wiley, New York

Entwisle DC, Hobbs PRN, Jones LD, Gunn D, Raines MG (2005) The Relationships between effective porosity, uniaxial compressive strength and sonic velocity of intact borrowdale volcanic group core samples from Sellafield. Geotech Geol Eng 23:793–809. https://doi.org/10.1007/s10706-004-2143-x

Farhadian A, Ghasemi E, Hoseinie SH, Bagherpour R (2021) Development of a new test method for evaluating the abrasivity of granite building stones during polishing process based on weight loss of abrasive tool. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2021.124497

Fener M, Kahraman S, Bilgil A, Gunaydin O (2005) A comparative evaluation of indirect methods to estimate the compressive strength of rocks. Rock Mech Rock Eng 38:329–343. https://doi.org/10.1007/s00603-005-0061-8

Fowell RJ, Abu Bakar MZ (2007) A review of the Cerchar and LCPC rock abrasivity measurement methods. In: 11th Congr Int Soc Rock Mech. Second Half-Century Rock Mech, pp155–160

Gharahbagh AE, Rostami J, Ghasemi AR, Tonon F (2011) Review of rock abrasion testing, 45th US Rock Mech Geomech Symp San Francisco, California

Gupta RK, Gupta RK (2018) Cutting tool for marble & granite: A Review. Int Conf Mech Mater Renew Energy. https://doi.org/10.1088/1757-899X/377/1/012126

Haramy KY, Demarco MJ (1985) Use of Schmidt hammer for rock and coal testing. 26th US Symp. on Rock Mechanics, 26–28 June, pp. 549–555

Hazrathosseini A, Mahdevari S (2018) Applicability quality assessment of dimension stones for service in the buildings (A new approach using a mathematical model and fuzzy logic). J Build Eng 20:585–594. https://doi.org/10.1016/j.jobe.2018.09.002

Hebib R, Belhai D, Alloul B (2017) Estimation of uniaxial compressive strength of North Algeria sedimentary rocks using density, porosity, and Schmidt hardness. Arab J Geosci 10:383. https://doi.org/10.1007/s12517-017-3144-4

ISRM (1978) Determining the uniaxial compressive strength and deformability of rock materials. ISRM suggested methods

ISRM (1981) Rock characterization, testing & monitoring: ISRM suggested methods / editor E. T. Brown. https://lib.ugent.be/catalog/rug01:000309036

Jamshidi A, Nikudel MR, Khamehchiyan M, Zarei Sahamieh R, Abdi A (2016) A correlation between P-wave velocity and Schmidt hardness with mechanical properties of travertine building stones. Arab J Geosci 9:568. https://doi.org/10.1007/s12517-016-2542-3

Janc B, Jovičić V, Vukelić Z (2020) Laboratory test methods for assessing the abrasivity of rocks and soils in geotechnology and mining applications. Mater Geoenviron. https://doi.org/10.2478/rmzmag-2020-0012

Kahraman S (2001) Evaluation of simple methods for assessing the uniaxial compressive strength of rock. Int J Rock Mech Min Sci 38:981–994. https://doi.org/10.1016/S1365-1609(01)00039-9

Karaman K, Kesimal A (2015) A comparative study of Schmidt hammer test methods for estimating the uniaxial compressive strength of rocks. Bull Eng Geol Environ 74:507–520. https://doi.org/10.1007/s10064-014-0617-5

Käsling H, Thuro K (2010) Determining rock abrasivity in the laboratory. Civ Environ Eng Proc Eur Rock Mech Symp EUROCK 2010:425–428. https://doi.org/10.1201/b10550-100

Khandelwal M, Singh TN (2009) Correlating static properties of coal measures rocks with P-wave velocity. Int J Coal Geol 79:55–60. https://doi.org/10.1016/j.coal.2009.01.004

Kılıç A, Teymen A (2008) Determination of mechanical properties of rocks using simple methods. Bull Eng Geol Environ 67:237–244. https://doi.org/10.1007/s10064-008-0128-3

Kong F, Shang J (2018) A validation study for the estimation of Uniaxial Compressive Strength based on index tests. Rock Mech Rock Eng 51:2289–2297. https://doi.org/10.1007/s00603-018-1462-9

Kong F, Xue Y, Qiu D, Gong H, Ning Z (2021) Effect of grain size or anisotropy on the correlation between uniaxial compressive strength and Schmidt hammer test for building stones. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2021.123941

Labaš M, Krepelka F, Ivaničová L (2012) Assessment of abrasiveness for research of rock cutting. Acta Montan Slovaca 17:65–73

Majeed Y, Abu Bakar MZ (2016) Statistical evaluation of CERCHAR abrasivity index (CAI) measurement methods and dependence on petrographic and mechanical properties of selected rocks of Pakistan. Bull Eng Geol Environ 75:1341–1360. https://doi.org/10.1007/s10064-015-0799-5

Majeed Y, Abu Bakar MZ (2018) A study to correlate LCPC rock abrasivity test results with petrographic and geomechanical rock properties. Q J Eng Geol Hydrogeol 51:365–378. https://doi.org/10.1144/qjegh2017-112

Minaeian B, Ahangari K (2013) Estimation of uniaxial compressive strength based on P-wave and Schmidt hammer rebound using statistical method. Arab J Geosci 6:1925–1931. https://doi.org/10.1007/s12517-011-0460-y

Momeni E, Nazir R, Armaghani DJ, Amin MFM, Mohamad ET (2015) Prediction of Unconfined compressive strength of rocks: a review paper. Jurnal Teknologi. https://doi.org/10.11113/jt.v77.6393

Plinninger RJ (2010) Hardrock abrasivity investigation using the Rock Abrasivity Index (RAI). In: Conference 11th IAEG Congr Auckland/New Zeal, pp 3445–3452

Rahman T, Sarkar K (2021) Lithological control on the estimation of uniaxial compressive strength by the P-wave velocity using supervised and unsupervised learning. Rock Mech Rock Eng 54:3175–3191. https://doi.org/10.1007/s00603-021-02445-8

Rajabi A, Hosseini A, Heidari A (2017) The new empirical formula to estimate the uniaxial compressive strength of limestone, north of saveh a case study. J Eng Geol 11:159–180

Rezaei M, Koureh Davoodi P (2021) Determining the relationship between shear wave velocity and physicomechanical properties of rocks. Int J Min Geo Eng 55:65–72

Sachpazis CI (1990) Correlating Schmidt hardness with compressive strength and young’s modulus of carbonate rocks. Bull Int A Soc Eng Geol 42:75–83. https://doi.org/10.1007/BF02592622

Selçuk L, Nar A (2016) Prediction of uniaxial compressive strength of intact rocks using ultrasonic pulse velocity and rebound-hammer number. Q J Eng Geol Hydrogeol 49(1):67–75

Shalabi FI, Cording EJ, Al H (2007) Estimation of rock engineering properties using hardness tests. Eng Geol 90:138–147. https://doi.org/10.1016/j.enggeo.2006.12.006

Sharma PK, Singh TN (2008) A correlation between P-wave velocity, impact strength index, slake durability index and uniaxial compressive strength. Bull Eng Geol Environ 67:17–22. https://doi.org/10.1007/s10064-007-0109-y

Sousa LMO, Suárez del Río LM, Calleja L, Ruiz de Argandoña VG, Rey AR (2004) Influence of microfractures and porosity on the physico-mechanical properties and weathering of ornamental granites. Eng Geol 77:153–168. https://doi.org/10.1016/j.enggeo.2004.10.001

SPSS16.0 (2007) Statistical analysis software (Standard Version), SPSS Inc

Streckeisen A (1976) To each plutonic rock its proper name. Earth-Science Rev 12:1–33. https://doi.org/10.1016/0012-8252(76)90052-0

Tandon RS, Gupta V (2015) Estimation of strength characteristics of different Himalayan rocks from Schmidt hammer rebound, point load index, and compressional wave velocity. Bull Eng Geol Environ 74:521–533. https://doi.org/10.1007/s10064-014-0629-1

Teymen A, Mengüç EC (2020) Comparative evaluation of different statistical tools for the prediction of uniaxial compressive strength of rocks. Int J Min Sci Technol 30:785–797. https://doi.org/10.1016/j.ijmst.2020.06.008

Thuro K (1997) Drillability prediction: Geological influences in hard rock drill and blast tunneling. Int J Earth Sci 86:426–438

Tuğrul A, Zarif IH (1999) Correlation of mineralogical and textural characteristics with engineering properties of selected granitic rocks from Turkey. Eng Geol 51:303–317. https://doi.org/10.1016/S0013-7952(98)00071-4

Vasconcelos G, Lourenco PB, Alves CSA, Pamplona J (2007) Prediction of the mechanical properties of granites by ultrasonic pulse velocity and Schmidt hammer hardness. North American Masonry Conference, Missouri, 3–5 June. The Masonry Society, CO, pp 980–991

Vasconcelos G, Lourenço PB, Alves CAS, Pamplona J (2008) Ultrasonic evaluation of the physical and mechanical properties of granites. Ultrasonics 48:453–466. https://doi.org/10.1016/j.ultras.2008.03.008

Wang M, Wan W, Zhao Y (2020) Prediction of the uniaxial compressive strength of rocks from simple index tests using a random forest predictive model. Comptes Rendus Mécanique 348:3–32. https://doi.org/10.5802/crmeca.3

West G (1989) Rock abrasiveness testing for tunneling. Int J Rock Mech Min Sci 26:151–160. https://doi.org/10.1016/0148-9062(89)90003-x

Yagiz S (2009) Predicting uniaxial compressive strength, modulus of elasticity and index properties of rocks using the Schmidt hammer. Bull Eng Geol Environ 68:55–63. https://doi.org/10.1007/s10064-008-0172-z

Yagiz S (2011) Correlation between slake durability and rock properties for some carbonate rocks. Bull Eng Geol Environ 70:377–383. https://doi.org/10.1007/s10064-010-0317-8

Yagiz S, Sezer EA, Gokceoglu C (2012) Artificial neural networks and nonlinear regression techniques to assess the influence of slake durability cycles on the prediction of uniaxial compressive strength and modulus of elasticity for carbonate rocks. Int J Numer Anal Methods Geomech 36:1636–1650. https://doi.org/10.1002/nag.1066

Yasar E, Erdogan Y (2004) Correlating sound velocity with the density, compressive strength and Young’s modulus of carbonate rocks. Int J Rock Mech Min Sci 41:871–875. https://doi.org/10.1016/j.ijrmms.2004.01.012

Yesiloglu-Gultekin N, Gokceoglu C, Sezer EA (2013) Prediction of uniaxial compressive strength of granitic rocks by various nonlinear tools and comparison of their performances. Int J Rock Mech Min Sci 62:113–122. https://doi.org/10.1016/j.ijrmms.2013.05.005

Yilmaz NG (2011) Abrasivity assessment of granitic building stones in relation to diamond tool wear rate using mineralogy-based rock hardness indexes. Rock Mech Rock Eng 44:725–733. https://doi.org/10.1007/s00603-011-0166-1

Yilmaz I, Sendır H (2002) Correlation of Schmidt hardness with unconfined compressive strength and Young’s modulus in gypsum from Sivas (Turkey). Eng Geol 66:211–219. https://doi.org/10.1016/S0013-7952(02)00041-8

Yurdakul M, Akdas H (2013) Modeling uniaxial compressive strength of building stones using non-destructive test results as neural networks input parameters. Constr Build Mater 47:1010–1019. https://doi.org/10.1016/j.conbuildmat.2013.05.109

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing fnancial interests or personal relationships that could have appeared to infuence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Farhadian, A., Ghasemi, E., Hoseinie, S.H. et al. Prediction of Rock Abrasivity Index (RAI) and Uniaxial Compressive Strength (UCS) of Granite Building Stones Using Nondestructive Tests. Geotech Geol Eng 40, 3343–3356 (2022). https://doi.org/10.1007/s10706-022-02095-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-022-02095-9