Abstract

Preparing high-quality samples, which can fulfill testing standards, from weak and block-in-matrix conglomerate for laboratory tests, is a big challenge in engineering projects. Hence, using indirect methods seems to be indispensable for determination uniaxial compressive strength (UCS). The main objective of this study is to estimate the relation between sonic velocity (Vp), Schmidt hammer rebound number (SCH) and UCS. For this reason, some samples of weak conglomeratic rock were collected from two different sites of dam in Iran (Bakhtiari and Hezardareh Formations). In order to evaluate the correlation, the measured and predicted values utilizing simple and multivariate regression techniques were examined. To control the performance of the proposed equation, root mean square error (RMSE) and value accounts for (VAF%) were determined. The VAF% and RMSE indices were computed as 94.34 and 1.56 for the relation between Vp and UCS from simple regression model. These were 94.39 and 1.6 between SCH and UCS, while these were 97.24 and 1.34 for uniaxial compressive strengths obtained from multivariate regression model.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Estimation of rock mechanical properties is considered to be the most important components in any engineering project. One of the most commonly used and fundamental mechanical parameter is uniaxial compressive strength (UCS). The method for measuring UCS has been standardized by both ASTM and ISRM. This method is destructive in nature, time-consuming, expensive, and also it requires a large number of well-prepared rock specimens. For this reason, many studies have considered the possibility of a quick and easy way to estimate the UCS of rock based on Schmidt hammer rebound (SHR), point load (Is(50)), P-wave velocity (Vp), slake durability index, and shore hardness. Of these parameters, SHR, Is50, and Vp tests are the comparatively cheap and easy to apply.

The index-to-strength conversion factors have been proposed by a number of researchers and have been found to be rock-dependent (Akram and Bakar 2007). However, there is no reported equation in this regard for Plio–Pliocen conglomerate. Considering the vast distribution of conglomeratic formation around the world and especially in Iran, there is less knowledge concerning the behavior of this type of material. The rationale of the study presented herein is to evaluate the indirect methods such as Schmidt hammer rebound and P-wave velocity to estimate the uniaxial compressive strength by using statistical method.

Major engineering projects such as dams, roads, and tunnels are now under construction in Bakhtiari and Hezardareh Formations in Iran. In this study, a total of 140 specimens which were collected from two different sites of dam from mentioned formations were tested to evaluate the correlations between the UCS with the corresponding test results of Schmidt hammer rebound and P-wave velocity. The data was analyzed statistically to determine the degree of correlation and the variability of results.

Rock properties and testing procedure

The conglomeratic rocks are parts of thick synorogenic molasse sequence of upper Pliocene to Pleistocene age. These conglomerates are composed of the argillaceous–calcareous matrix with different degree of cementation and all three different types of rocks grains (tuff, limestone, and marl) ranging from few millimeters to about a meter. On the basis of thin-section studies carried out in the present study, conglomerates contained sub-angular quartz, chlorite and, to a lesser extent, plagioclase, muscovite, and biotite as well as varying amounts of opaque minerals, some of which showed evidence of oxidation.

In the present study, a total of 140 NX-sized core specimens for uniaxial compressive strength tests, sonic velocity tests, and Schmidt hammer tests were prepared. The ends of the specimens were made flattened perpendicular to the axis of specimens. Their sides were smoothed and polished, and specimens were inspected to be free of cracks, fissures, veins, and other flaws, which would act as selective planes of weakness causing an undesirable change of the real properties of the rock. The UCS, SHR, and Vp tests were then performed in accordance with the suggestions outlined by ISRM (1981). In addition to this, for UCS, ISRM (1981) also suggests that the diameter of the core specimen should be related to the size of the largest grain in rock specimen by a ratio of at least 10:1. Although for UCS tests, it was not possible to satisfy this condition due to the block-in-matrix nature of the conglomerates studied.

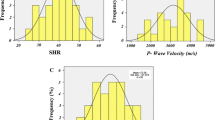

Based on the obtained result, the UCS values of the samples ranged between 3.66 and 33 MPa, with an average value of 29.34, while the average value of Vp was 5,531 m/s and values varied from 904 to 6,435 m/s. SHR values changed between 5.32 and 60.27 with an average value of 54 as are given in Table 1.

Sonic velocity tests

The relationship between uniaxial compressive strength and P-wave velocity (Vp) was investigated by many researchers such as Mccann et al. (1990), Kahraman (2001), Yasar and Erdogan (2004a, b), Entwisle et al. (2005), Sharma and Singh (2008), Cobanglu and Celik (2008), Moradian and Behnia (2009), Khandelwal and Singh (2009), Diamantis et al. (2009), Dehghan et al. (2010), Kurtulus et al. (2010), and Yagiz (2011). Table 2 lists some of the equations correlating the UCS to Vp. The velocity of ultrasonic pulses traveling in a solid material depends on the density and elastic properties of the material. The quality of some materials may be related to their elastic stiffness. To determine a comparable P-wave velocity of conglomeratic rocks and also to estimate UCS, 70 NX-sized samples were used. For sonic velocity tests, linear function shows the highest correlation coefficients.

Schmidt hammer test

A total of 70 NX-sized core samples were tested using the L-type Schmidt hammer and a rock cradle following ISRM (1981) suggested methods. The hammer was held vertically downwards and at right angles to the horizontal rock faces to avoid the necessity for a correction factor to obtain a UCS value. At least 20 readings were taken and the mean of the ten highest values was used to calculate the average UCS. Mechanical properties of cemented rocks are more depended on its cement (Bernabé et al. 1992; Yin and Dvorkin 1994). In this study, all the Schmidt hammer tests had been done on cement of samples. Various empirical equations have been proposed for calculating uniaxial compressive strength from Schmidt hammer rebound number (Singh et al. 1983; Haramy and DeMarco 1985; Katz et al. 2000; Yilmaz and Sendir 2002; Yasar and Erdogan 2004a, b; Aydin and Basu 2005; Shalabi et al. 2007; Yagiz 2009; Gupta 2009; Abdollatif 2010). Linear, power, and exponential functions have been used by different researchers to correlate these parameters. Some of the equations correlating the UCS to the Schmidt hammer rebound number are illustrated in Table 3. Again, linear function gave the highest correlation coefficients.

Regression analyses and assessment of the prediction performance

Simple regression model

Simple regression analyses were conducted to define the type of relationship between dependent and independent parameters by considering linear, logarithmic, power, and exponential functions. The results of the regression analyses undertaken using the statistical package SPSS version 17.0 are given in Table 4 with their correlation coefficients (R 2). Relationships are statistically significant according to the Student’s t test with 95% safety.

The relationship between P-wave velocity and UCS is depicted in Fig. 1. Figure 2 shows the plot of the UCS versus the Schmidt rebound number value for conglomerate samples. The predicted values of P-wave velocity, Schmidt hammer rebound number, and UCS values were then plotted versus the measured values by using a 1:1 slope line as shown in Figs. 3 and 4. These figures indicate that P-wave velocity and Schmidt hammer rebound number are reliable values for estimating UCS, question the necessity of cumbersome, and time-consuming test methods for the preliminary studies.

The coefficient of correlation between the measured and predicted values is a good indicator to check the performance of the proposed relationship. It is worthy to note that values for VAF and root mean square error (RMSE) indices were also calculated to control the performance of the prediction models developed in the study, as employed by Cobanglu and Celik (2008) and Yilmaz and Yuksek (2007)

Where y and y ′ are the measured and predicted values, N is the number of samples, and var is the variance. The calculated indices are given in Table 5. The higher values of VAF show an improvement on the prediction capability and the lower the RMSE indicate the better performs of the model. If the VAF is 100 and RMSE is 0, then, the model performs is excellent. The obtained values of VAF and RMSE, given in Table 5, indicate high prediction performances.

Multiple regression models

Multiple regression (MR) is a time-honored technique that was used in 1908 by Pearson. It is employed to account for the variance in an interval-dependent, based on linear combinations of interval, dichotomous, or dummy-independent variables. The purpose of MR is to learn more about the relationship between a number of independents or variables and a dependent or criterion variable. The MR equation is in the form of y \( y = {b_1}{x_1} + {b_2}{x_2} + \ldots + {b_{\text{n}}}{x_{\text{n}}} + c \), that b 1, b 2, …, b n are the regression coefficients. The parameter c is a constant representing the value of y when all the independent variables are zero. The standardized versions of b coefficients are beta weights. The ratio of the beta coefficients is the ratio of the relative predictive power of the independent variables. The major conceptual limitation of all regression techniques is that one can only ascertain relationships, but never be sure about underlying causal mechanism. MR analyses was carried out to correlate the measured UCS to Schmidt hammer rebound number and sonic velocity. Cross-correlation of predicted and observed values of UCS for multivariate regression mode is shown in Fig. 5. The obtained UCS from this method is summarized in Table 6 and VAF, RMSE, and R 2 multiple regression are given in Table 7. The results obtained from multiple regressions indicate the reliability of this method.

Results and conclusions

In order to describe, the relationships between UCS with Schmidt hammer rebound number and P-wave velocity of the conglomeratic rocks, regression analysis was accomplished and empirical equations have been developed.

The appropriate equation and the coefficient of correlation (R 2) were determined for each test results. The plot of the UCS as a function of P-wave velocity is demonstrated. There is a linear relation between P-wave velocity and UCS. The following equation is obtained with a coefficient of correlation of 0.82.

Similarly, linear relationship has also been observed between Schmidt hammer rebound number and UCS. Coefficient of correlation (R 2 = 0.88) was found between them for all tested rocks. The equation of this relation is as follows:

The multivariate regression model for the prediction of the UCS was then developed. The coefficient of correlation (R 2 = 0.92) was found. The equation of this relation is as follows:

The present study suggests that, as indirect tests are easy to use, the proposed equations to estimate rock strength from P-wave velocity and the Schmidt hammer rebound number are valuable at the preliminary stage of design. It is necessary to maintain that the proposed experimental equations can only be applied to conglomeratic formation of a similar geological character.

References

Abdollatif O (2010) Geomechanical properties and rock mass quality at the carbonate Rus formation, dammam dame, Saudi Arabia. The Arabian J Sci Eng 35

Akram M, Bakar ZA (2007) Correlation between uniaxial compressive strength and point load index for salt-range rocks. Pak J Eng & Appl Sci 1

Aydin A, Basu A (2005) The Schmidt hammer in rock material characterization. Eng Geol 81:1–14

Bernabé Y, Fryer TD, Hayes JA (1992) The effect of cement on the strength of granular rocks. Geophys Res Lett 19(14):1511–1514

Cobanglu I, Celik S (2008) Estimation of uniaxial compressive strength from point load strength, Schmidt hardness and P-wave velocity. Bull Eng Geol Environ 67:491–498

Dehghan S, Sattari GH, Chehre Chelgani S, Aliabadi MA (2010) Prediction of uniaxial compressive and modulus of elasticity for travertine sample using regression and artificial neural networks. Mining Sci Technol 20:41–46

Diamantis K, Gartzos E, Migiros G (2009) Study on uniaxial compressive strength, point load strength index, dynamic and physical properties of serpentinites from Central Greece: test results and empirical relations. Eng Geol 108:199–207

Entwisle DC, Hobbs PRN, Jones LD, Gunn D, Raines MG (2005) The relationship between effective porosity, uniaxial compressive strength and sonic velocity of intact Borrowdale Volcanic Group core samples from Sellafield. Geotech Geol Eng 23:793–809

Gupta V (2009) Non-destructive testing of some Higher Himalayan rocks in the Satluj Valley. Bull Eng Geol Environ 68:409–416

Haramy KY, DeMarco MJ (1985) Use of Schmidt hammer for rock and coal testing. 26th US Symp on Rock Mech, Rapid City, 549–555

ISRM (1981) Rock characterization, testing and monitoring, ISRM suggested methods. Pergamon, Oxford, 211

Kahraman S (2001) Evaluation of simple methods for assessing the uniaxial compressive strength of rock. Int J Rock Mech Mining Sci 38:981–994

Katz O, Reches Z, Roegiers JC (2000) Evaluation of mechanical rock properties using a Schmidt hammer. Int J Rock Mech Mining Sci 37(4):723–728

Khandelwal M, Singh TN (2009) Correlating static properties of coal measures rocks with p-wave velocity. Int J Coal Geol 79:55–60

Kurtulus G, Irmak T, Sertcelik I (2010) Physical and mechanical properties of Gokcseda: Imbros (NE Aegean Sea) Island andesites. Bull Eng Geol Environ 69:321–324

Mccann DM, Culshaw MG, Northmore KJ (1990) Rock mass assessment from seismic measurements. Culshaw B, Coffey C (eds) Fields testing in engineering geology. Geol Soc Eng Pub No 6:257–266

Moradian ZA, Behnia M (2009) Predicting the uniaxial compressive strength and static Young’s modulus of intact sedimentary rocks using the ultrasonic test. Int J Geomech 9:1–14

Shalabi F, Cording EJ, Al-Hattamleh OH (2007) Estimation of rock engineering properties using hardness tests. Eng Geol 90:138–147

Sharma PK, Singh TN (2008) A correlation between P-wave velocity, impact strength index, slake durability index and uniaxial compressive strength. Bull Eng Geol Environ 67:17–22

Singh RN, Hassani, FP, Elkington PAS (1983) The application of strength and deformation index testing to the stability assessment of coal measures excavations. Proc 24th US Symp on Rock Mechs, Texas A&M Univ AEG, 599–609

Yagiz S (2009) Predicting uniaxial compressive strength, modulus of elasticity and index properties of rocks using the Schmidt hammer. Bull Eng Geol Environ 68:55–63

Yagiz S (2011) Geomechanical properties of construction stones quarried in South-western Turkey. Bull Mater Sci 34:947–953

Yasar E, Erdogan Y (2004a) Correlating sound velocity with the density, compressive strength and Young’s modulus of carbonate rocks. Int J Rock Mech Mining Sci 41:871–875

Yasar E, Erdogan Y (2004b) Estimation of rock physicomechanical properties using hardness methods. Eng Geol 71:281–288

Yilmaz I, Sendir H (2002) Correlation of Schmidt hardness with unconfined compressive. Eng Geol 66:211–219

Yilmaz I, Yuksek AG (2007) An example of artificial neural network application for indirect estimation of rock parameters. Int J Rock Mech Mining Sci 5(41):781–795

Yin H, Dvorkin J (1994) Strength of cemented grains. Geophys Res Lett 21(10):903–906

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Minaeian, B., Ahangari, K. Estimation of uniaxial compressive strength based on P-wave and Schmidt hammer rebound using statistical method. Arab J Geosci 6, 1925–1931 (2013). https://doi.org/10.1007/s12517-011-0460-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12517-011-0460-y