Abstract

We explore the value of information sharing for smoothing the dynamics of supply chains when some echelons do not collaborate. To this end, we study seven information sharing structures in a four-echelon supply chain using a system dynamics approach. We find that the overall propagation of the bullwhip effect in supply chains decreases as the number of echelons sharing information grows, but it is not dependent on their position. Nonetheless, the performance of the echelons strongly relies on the degree of downstream collaboration; therefore, information sharing in the lower nodes has a higher impact on the overall supply chain costs. We also investigate the benefits of adding new members to the collaborative strategy in different lead-time scenarios. Finally, we provide managerial recommendations for decentralised supply chains.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

1.1 Background

Decentralised Supply Chains (SCs) are large and complex systems formed by a set of competitive organisations that are managed independently, which are characterised by dynamic structures and asymmetric information (Hearnshaw and Wilson 2013; Long and Zhang 2014; Mokhtar et al. 2019). The lack of coordination of such systems fosters the generation of harmful inefficiencies in the SC, causing significant financial losses that lead to suboptimal performance (El Ouardighi and Erickson 2014; Klug 2017). This occurs due to two major phenomena: double marginalisation and the bullwhip effect (Zhang and Chen 2013; Rached et al. 2016). This research is mainly concerned with the latter, which refers to the tendency of orders to become more variable as they move up the SC (Lee et al. 1997; Rong et al. 2008; Chen et al. 2000; Trapero et al. 2012; Wang and Disney 2016; Oiha et al. 2019). This variability is well-known to create SC waste in various fronts, which often results in high holding requirements, long lead times, poor customer service and lost sales, increased capacity-related and transportation costs, and added uncertainties (Metters 1997; Disney and Lambrecht 2008).

Coordination strategies have proved to be effective for enhancing the dynamics and improving the performance of SCs (see e.g. Cannella et al. 2016; Klug 2016; Ponte et al. 2016). Such strategies are generally built on Information Sharing (IS) (Cannella et al. 2015; Li et al. 2017; Wang et al. 2019). IS can be defined as the practice of making strategic (e.g. long-term forecasts and marketing strategies), tactical (e.g. plans and trends), and/or operational (e.g. orders and demand information) information available to SC partners (Dominguez et al. 2014; Kembro and Selviaridis 2015). This may happen in one dimension of the SC, i.e. vertically or horizontally, or in both (Huang et al. 2017).

In line with the previous discussion, it is well known that IS enables a mitigation of the bullwhip effect (e.g. Chatfield et al. 2004; Lee 2010; Wang et al. 2016; Jeong and Hong 2019). This occurs as IS helps SC managers better match supply with demand by bridging downstream retailing and upstream production (Lee and Whang 2000; Qian et al. 2012). This results in a wide range of operational improvements. For example, IS allows for a huge reduction of the inventory levels in the SC (Lee and Whang 2000). Cachon and Fisher (1997) quantified that, by implementing information technologies, Campbell Soup’s SC reduced the retailer’s mean inventory by 66%. IS also makes forecasts more accurate (Kembro and Selviaridis 2015), reducing the occurrence of stock-outs (Li and Zhang 2015) and increasing the efficiency of production planning mechanisms (Kembro and Näslund 2014). In addition, IS promotes the creation of long-term, stable relationships between SC partners (Ciancimino et al. 2012).

1.2 Problem statement

Despite the aforementioned benefits, meaningful barriers hinder the implementation of IS strategies in practice (Fawcett 2011; Kembro and Näslund 2014; Viet et al. 2018). These barriers include the risk of information leakage, the lack of trust between SC partners, the necessary investments in information technologies, the wide variety of existing technologies, the existence of different types of information that can be shared, the distortion of information, and the unbalanced distribution of gains between SC partners (see e.g. Ali et al. 2017; Gunasekaran et al. 2017; Huang et al. 2016; Jeong and Leon 2012; Kembro et al. 2014; Kong et al. 2013; Rached et al. 2015; Shnaiderman and Ouardighi 2014; Soosay and Hyland 2015, among others).

These barriers, together with the decentralisation and globalisation of modern SCs, make it difficult to achieve a full IS among all SC members (Qian et al. 2012; Fawcett et al. 2015; Dominguez et al. 2018a). Thus, this assumption is often not realistic (Huang and Wang 2017). As a consequence, partial IS is a prevalent scenario in real-world SCs (Shnaiderman and Ouardighi 2014; Xu et al. 2015; Zhou et al. 2009). For instance, some retailers do not find incentives to share data with suppliers (GMA 2009; Shang et al. 2016). However, the literature that investigates scenarios with partial IS is scarce, with most papers that study the benefits of IS for bullwhip reduction assuming that all SC members collaborate (Holmstrőm et al. 2016), the. In the light of these considerations, studying the dynamics of SCs in this context, where the full IS among all SC members cannot be achieved, represents a challenge for researchers and may bring potential benefits for industry. This would allow us to get insights on how much bullwhip can be reduced using IS when the classic full collaboration structure cannot be arranged.

In this work, we investigate partial IS when the information is accurately, timely, and vertically shared, but only among some echelons of the SC. That is, we assume that some SC members are willing to participate in the IS-based collaborative strategy but others refuse their involvement. SC performance under this typology of partial IS has been briefly analysed in the literature. Lau et al. (2004) explore the effects of different levels of IS in a three-echelon SC by measuring operating costs, inventory holding, and backlog level at the different echelons. Costantino et al. (2014) model a set of four-echelon SC with different combination of IS under deterministic lead times, reasserting the importance of collaboration for mitigating the bullwhip effect. Ganesh et al. (2014a) investigate the impact of full IS and two partial IS modes (namely, upstream IS and downstream IS) on inventory holding and shortage costs of a multi-echelon serial SC. Under the same SC setup, Ganesh et al. (2014b) consider the impact of product substitution. Dominguez et al. (2018a) study different partial IS configurations among four retailers and one wholesaler, by looking at their impact on the dynamic performance of the SC. Dominguez et al. (2018b) extend the previous work by suggesting an innovative strategy to implement partial IS in multi-retailer SCs, named as Order VAriance Prioritization (OVAP). This is shown to outperform the benchmark method by 27.2% and 7.8% in terms of bullwhip effect and average inventory respectively.

These prior works arguably shed some light on the dynamics generated by partial IS in multi-echelon SCs. Our focus in this work is different and aims to complement previous findings. Specifically, we mainly differ from those studies by Lau et al. (2004) and Ganesh et al. (2014a, b) in the fact that we explore the bullwhip effect in the SC, i.e. the dynamics of orders, while they focus on inventory performance. In addition, we consider common features of real-world SCs that have not been considered by previous studies in this field, such as Costantino et al. (2014), including variable lead times and a dynamic safety stock factor (i.e. depending on the stock-out risk of each period). On the other hand, Dominguez et al. (2018a, b) considers different IS strategies between a group of retailers and a wholesaler. In this work, we extend the scope of the IS strategies to the wider SC, by investigating the potential involvement of four echelons. In this sense, we make an effort to capture the multi-echelon effects of partial IS. This emerges as an important avenue for research from the perspective of Chatfield’s (2013) study, who highlights that decomposing SC problems by looking at the relationship between two consecutive echelons often underestimates the bullwhip effect.

1.3 Objective and contributions

As per the previous discussion, we highlight the need for a more comprehensive understanding of the efficiency of partial IS strategies in multi-echelon SCs in terms of dealing with the bullwhip effect. This will be investigated in this work. To this end, we explore the dynamic behaviour and compare the performance of a four-echelon serial SCs under seven partial IS structures. Each one is defined by a different combination of echelons involved in the collaboration, ranging from no IS to full IS.

Due to the nature of the investigated problem, we adopt computer simulation as the methodological approach, since it has the advantage of being able to handle complex problem settings with situational behaviour changes in the system over time (see e.g. Chatfield et al. 2004; Kleijnen 2005; Ponte et al. 2017; Dominguez et al. 2019; Oliveira et al. 2019). Specifically, the SC structures have been modelled via systems dynamics (see e.g. Sterman 2000; Kleijnen 2005; Ciancimino et al. 2012; Hussain et al. 2016). This approach allows us to easily introduce stochasticity in demands and lead times in an effort to model relevant features of real-world SCs. To provide comprehensive findings, we use a full factorial experimental design (see e.g. Evers and Wan 2012). The, the bullwhip behaviour of the IS structures is studied via statistical techniques through two common indicators: the Order Rate Variance Ratio (ORVrR) (Chen et al. 2000) and the Bullwhip Slope (BwSl) (Cannella et al. 2013). Together, they provide a rich picture of the operational performance of both the overall SC and its members.

All in all, this work contributes to the research stream exploring partial IS in SCs by:

-

1.

Addressing the impact of different partial IS structures across echelons in a decentralised multi-echelon SC on the bullwhip effect both at the system (SC) level and at the echelon (organisation) level, thus offering a different perspective than prior research.

-

2.

Assessing the interactions between stochastic lead times, both in mean and in variance, and the different partial IS structures, thus evaluating how lead times affect the efficiency of partial IS strategies in multi-echelon SCs.

The main results of this work can be summarised as follows:

-

1.

At the system (SC) level,

-

a.

The overall propagation of the bullwhip effect in SCs is very sensitive to the number of echelons participating in the IS-based collaborative strategy, but, interestingly, it does not depend on the position of this echelons in the SC.

-

b.

Downstream IS collaborative solutions have a positive effect on more SC echelons than upstream IS collaborative solutions; therefore, the total SC costs will tend to be lower in the former case than in the latter case.

-

a.

-

2.

At the echelon (organisation) level, the bullwhip reduction heavily relies on the number of downstream collaborative echelons that share information. However, again, it does not depend on which of them are involved in the collaborative strategy.

-

3.

Lead times show a strong interaction with the performance of the different partial IS structures in terms of bullwhip effect reduction, especially at upstream echelons of the SC. The impact of the average lead times proves to be more significant than the one of lead-time variability.

The rest of the paper has been organised as follows. Section 2 presents the seven partial IS structures under evaluation. The modelling assumptions and mathematical formulations are described in Sect. 3. Section 4 discusses the design of experiments and the performance metrics. Section 5 reports the simulation results, the statistical analysis, and the relevant findings. Section 6 provides the managerial implications of the study. Finally, Sect. 7 conclusions and suggests avenues for future research.

2 Partial information sharing structures

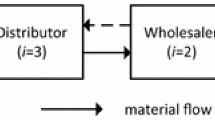

To study the impact of different partial IS structures, we model a set of serially-linked SCs, each one characterised by the echelons involved in the collaborative strategy. The modelled SCs are identical and composed of four echelons, i.e. Manufacturer (i = 1), Distributor (i = 2), Wholesaler (i = 3), and Retailer (i = 4), who meets the consumer (i = 5) demand. This SC is probably the most common multi-echelon structure for investigating the dynamics of SCs in the literature (see e.g. Sterman 1989; Van Ackere 1993; Mason-Jones et al. 1997; Sterman 2000; Chatfield et al. 2004; Dejonckheere et al. 2004; Paik and Bagchi 2007; Croson and Donohue 2005; Wright and Yuan 2008). Note that we employ a monolithic model of a four-echelon SC to avoid any significant under-estimation of the bullwhip effect due to the commonly adopted decomposability assumption (Chatfield 2013). Also, this SC structure is well known to be able to capture the dynamics of real-life SCs, as demonstrated by the well-known Beer Game (Jarmain 1963; Macdonald et al. 2013; Croson and Donohue 2005).

The notation used is reported in Table 1. Importantly, \(\tau\) denotes the degree of SC collaboration, which is defined as the number of echelons that share information (Ganesh et al. 2014a, b). This parameter allows us to classify the different SCs under analysis. As in Lau et al. (2004), we assume that each echelon is willing to share its local information only to its immediate upstream echelon. In fact, according to the empirical study by Kembro and Selviaridis (2015), there are important obstacles to IS beyond dyadic SC relationships, such as the disaggregation of demand information, the risk of misinterpretation by SC partners, and the risk of making decisions based on incomplete information. Under this assumption, we model all possible combinations of collaborative echelons, from the lowest (i.e. τ = 0) to the highest degree (i.e. τ = 3). This results in a set of seven partial IS structures, which are displayed in Table 2. This table provide a graphic representation and a short description of the transmission of information in each partial IS structure, together with their degree of collaboration.

It is important to notice that, for SCs with τ > 1, the information is transmitted across several echelons, thus making the relevant information available to echelons that are not directly linked to the source. For instance, on the R-W-D IS structure, the Retailer shares its order forecast with the Wholesaler, who at the same time shares the Retailer’s forecast with the Distributor.

3 Modelling assumptions and mathematical formalization

To compare the different IS structures, we model the four-echelon SCs by using various assumptions that have been largely used in the SC dynamics literature (see Sterman et al. 1989; Towill 1982; Van Ackere et al. 1993; Sterman 2000; Beamon and Chen 2001; Dejonckheere et al. 2004; Machuca and Barajas 2004; Disney and Lambrecht 2008; Hussain and Drake 2011; Chatfield and Pritchard 2013; Cannella et al. 2015; among many others). Specifically, these assumptions are the following:

-

Backlogging is allowed (e.g. Sterman 1989; Hussain et al. 2016) When stock-out occurs in an echelon (i.e. on-hand inventory decreases to 0), new orders cannot be fulfilled in time and are backlogged. The backlog will be satisfied as soon as on-hand inventory becomes available.

-

Returns are forbidden Products cannot move upstream in the SC. Forbidding returns to suppliers is a reasonable assumption in many practical settings that, when ignored, can result in a bullwhip effect overestimation (Chatfield and Pritchard 2013).

-

Unconstrained capacities No quantity limitations in production, transportation, storage, or sourcing processes are considered in this work (Beamon and Chen 2001).

-

First-order delay representation of lead times Variable lead times are modelled in the form of a first-order delay; see Sterman’s (2000) framework for continuous-time modelling of lead times. This is likely the most common dynamic lead-time modelling approach (Wikner 2003).

-

Exponential smoothing forecasting Each echelon forecasts according to an exponential smoothing method, as it is popular with practitioners and provides reasonably good results with some real-world time series (Makridakis et al. 1982; Disney and Lambrecht 2008).

-

Proportional order-up-to replenishment rule The periodic-review, order-up-to family of replenishment rules is very common in practice, since retailers generally replenish inventories frequently and manufacturers tend to produce to satisfy demand (Boute et al. 2009). Specifically, we use the proportional order-up-to model (see e.g. Gaalman 2006), which incorporates a controller that regulates the gap between the target and the actual inventory to be recovered. We select this model as it is able to achieve a good trade-off between production smoothness and inventory performance (Disney and Lambrecht 2008; Ponte et al. 2017).

-

Normally distributed demand and lead times We consider two sources of stochasticity in our model: consumer demand, and lead times. Both are assumed to be independent and identically distributed (i.i.d.) random variables following normal distributions. The assumption of normal demand is common in the literature, as this distribution models reasonably well the purchasing behaviour of many independent customers (e.g. Chatfield et al. 2013). The assumption of normal lead times has also been adopted by several authors (e.g. Park and Kyung 2014).

We adopt the System Dynamics modelling approach (see e.g. Guertler and Spinler 2015, Spiegler et al. 2016, Li et al. 2017, among others), using Vensim software (Sterman 2000) to implement the SC model. In the following paragraphs, we formalise the mathematical model in a discrete form. First, we look at the balance equations of the state variables, i.e. inventory, work-in-progress, and backlog. Equation (1) focuses on the on-hand inventory. The inventory of echelon i at time t, \({I}_{i}\left(t\right)\), increases due to the receipts of echelon i at time t, which are expressed as the ratio of the work-in-progress \({W}_{i} \left(t-1\right)\) to the lead time \({\lambda }_{i} (t)\) (see Wikner 2003), and decreased by quantity sent to the echelon i + 1 at time t, \({C}_{i}\left(t\right)\).

Analogously, Eq. (2) provides the work-in-progress balance. The work-in-progress of echelon i at time t, \({W}_{i}\left(t\right)\), is increased by the quantity sent by its supplier, echelon i-1, at time t, \({C}_{i-1}\left(t\right)\), and decreased by echelon i’s receipts at time t, i.e. the product that has just been received.

Equation (3) expresses the backlog of echelon i at time t, \({B}_{i}\left(t\right)\), as the backlog of this echelon at the end of the period t-1, \({B}_{i}\left(t-1\right)\), plus the new orders received from the subsequent echelon, i + 1, at time t, \({O}_{i+1}\left(t\right)\), minus the items delivered to this echelon at period t, \({C}_{i}\left(t\right)\).

The quantities sent between the different echelons are expressed through Eq. (4). The products sent from echelon i at time t, \({C}_{i}\left(t\right)\), to the next echelon, i + 1, are the minimum value between: (i) the sum of echelon i + 1′s order at time t, \({O}_{i+1}\left(t\right)\), and echelon i’s backlog at time t-1, \({B}_{i}\left(t-1\right)\), representing the demand that needs to be satisfied by echelon i at period t; and (ii) the position of the inventory at the end of the period t-1, \({I}_{i}\left(t-1\right)\), and the receipts at time t, representing the maximum demand that can be satisfied.

Importantly, Eq. (5) models the assumption of infinite raw material availability. Therefore, orders issued by the factory, i.e. echelon i = 1 are always entirely fulfilled.

Equations (6) and (7) formalise the proportional order-up-to ordering rule. Equation (6) is adopted by those echelons that only receive the order placed by their adjacent downstream partner as external information, i.e. \(i\notin \varphi\), where \(\varphi\) is the subset of echelons receiving information on downstream order forecasts. The order issued by echelon i at time t, \({O}_{i}\left(t\right)\), is the sum of three components: (i) the forecast of the order from echelon i + 1 at time t, \({\widehat{O}}_{i+1}\left(t\right)\), (ii) the difference between the target and the actual on-hand inventory of echelon i at time t, adjusted by echelon i’s proportional controller, i.e. \({\beta }_{i}\left[{TI}_{i}\left(t\right)-{I}_{i}\left(t\right)\right]\), and (iii) the difference between the target and the actual work-in-progress of echelon i at time t, adjusted by echelon i’s proportional controller, i.e. \({\beta }_{i}\left[{TW}_{i}\left(t\right)-{W}_{i}\left(t\right)\right]\). The logical operator “max” models the non-negative condition of orders that forbids returns in the SC.

Equation (7) provides the proportional order-up-to rule for those echelons that benefit from up-to-date information not only on the order placed by their customer, but also on the orders received by this echelon, i.e. \(i\in \varphi\). For instance, in the R-W IS structure, \(\varphi =\{3\}\), while in the W-D-M IS structure, \(\varphi =\{\mathrm{1,2}\}\); see Table 2. The difference between Eqs. (6) and (7) is in the first term, as now the forecast \({\widehat{O}}_{\theta }\left(t\right)\) is used, where \(\theta\) denotes the lowest collaborative echelon in the SC. Following with the previous example, in the R-W IS structure, \(\theta =4\), while in the W-D-M IS structure, \(\theta =3\). In this fashion, \({\widehat{O}}_{\theta }\left(t\right)\) refers to the forecast made by the lowest collaborative echelon; therefore, in the R-W IS structure, \({\widehat{O}}_{\theta +1}\left(t\right)={\widehat{O}}_{5}\left(t\right)\), and in the W-D-M IS structure, \({\widehat{O}}_{\theta +1}\left(t\right)={\widehat{O}}_{4}\left(t\right)\). In this sense, the forecast is transmitted along the collaborative echelons.

Equation (8) models the simple exponential smoothing, where the constant \({\alpha }_{i}\) defines the weight of the most recent observation. The former presents the forecasts of the orders made by echelon i at time t, \({\widehat{O}}_{i}\left(t\right)\), as the weighted average of the last order issued by this echelon, \({O}_{i}\left(t-1\right)\), and the previous forecast, \({\widehat{O}}_{i}\left(t-1\right)\).

We now focus on the target inventory and the target work-in-progress. The target inventory at echelon i at time t, \({TI}_{i}\left(t\right)\), is expressed as the product of the forecast of the order from echelon i + 1 at time t, \({\widehat{O}}_{i+1}\left(t\right)\), and the local safety stock factor \({\varepsilon }_{i}\), as per Eq. (9).

The target work-in-progress at echelon i at time t, \({TW}_{i}\left(t\right)\), is computed as the product of the forecast of the order from the echelon i + 1 at time t, \({\widehat{O}}_{i+1}\left(t\right)\), and the lead time of echelon i at time t, \({\lambda }_{i}\left(t\right)\), according to Eq. (10).

Finally, we denote by \({\mu }_{d}\) and \({\sigma }_{d}\) the mean and standard deviation of the normally distributed consumer demand, i.e. \({O}_{5}\left(t\right)\to N({\mu }_{d},{{\sigma }_{d}}^{2})\). Similarly, we denote by \({\mu }_{\lambda }\) and \({\sigma }_{\lambda }\) the mean and standard deviations of the normally distributed lead times, i.e. \({\lambda }_{i}\left(t\right)\to N({\mu }_{\lambda },{{\sigma }_{\lambda }}^{2})\), \(\forall i,t\). Both variables have been constrained to non-negative values.

4 Design of experiments and performance metrics

Herein we describe the experimental design. The main experimental factor is the IS structure of the SC. We consider seven levels for this factor, corresponding to the IS structures defined in Table 2. Moreover, we include the mean and variability of lead times in the design of experiments. We aim to analyse how they affect the dynamics of IS, as it is well known that lead times enormously contribute to the bullwhip effect, and hence strongly impact on SC performance (e.g. Chatfield et al. 2004; Kim et al. 2006; Cannella et al. 2017; Ponte et al. 2018).

We select two levels for each factor. For the mean, we use \({\mu }_{\lambda }=\left\{2, 5\right\}.\) Note that \({\mu }_{\lambda }=2\) is a standard value that has been widely used in SC dynamics studies, including the Beer Game (e.g. Sterman et al. 1989), and \({\mu }_{\lambda }=5\) represents a significantly longer lead time, illustrating a more geographically dispersed SC (e.g. Holweg et al. 2005). Meanwhile, the variability is considered in relative terms to the mean via the coefficient of variation. In this case, we use \({cv}_{\lambda }={\sigma }_{\lambda }/{\mu }_{\lambda }=\{0.2, 0.4\}.\) Here, \({cv}_{\lambda }=0.2\) represents a scenario with a relatively low lead-time variability, and \({cv}_{\lambda }=0.4\) considers the case where lead-time uncertainty is significantly larger (e.g. Chatfield and Pritchard 2013). All in all, we explore different scenarios related both to the geographical dispersion of the SC members (mean of lead times) and the uncertainty in the transportation system (variability of lead times).

We use a full-factorial design, which leads us to explore 28 (7 × 2 × 2) scenarios, each one defined by a different combination of the three factors. We perform 50 replications in each scenario, obtaining a total of 1,400 simulation runs. Each run has a time length of 1,000 periods, where the results of the first 200 periods, a warm-up area, are removed to minimise the impact of the initial state of the SC.

To set the numerical values for the rest of SC parameters, we build on the problem-specific literature. These values are described below.

-

The mean customer demand is \({\mu }_{d}=100\), and the standard deviation is \({\sigma }_{d}=20\). This results in a coefficient of variation of \({cv}_{d}={\sigma }_{d}/{\mu }_{d}=0.20\), which as per Dejonckheere et al. (2004) is within the typical range of variation of retail time series.

-

The safety stock factor is \({\varepsilon }_{i}=3, \forall i\), and the exponential smoothing constant is \({\alpha }_{i}=0.3, \forall i\). We have taken this setting from the influential work by Sterman (1989), which has been used in many relevant SC analyses (e.g. Machuca and Barajas 2004; Wright and Yuan 2008).

-

The proportional controller \({\beta }_{i}\) needs be regulated within the interval [0,1]. Low values generally help managers reduce the bullwhip effect; however, excessively low regulations are often problematic from the perspective of inventory performance; e.g. see Fig. 1 in Ponte et al. (2017). Taking this into consideration, we establish \({\beta }_{i}=0.3, \forall i\).

We note that the initial values of the state variables have been defined as follows. For the inventory, we employ \({I}_{i}(\mathrm{t})={\varepsilon }_{i}{\mu }_{d}=300, \forall i\). For the work-in-progress, \({W}_{i}(\mathrm{t})={\mu }_{\lambda }{\mu }_{d}=300, \forall i\). For the backlog, \({B}_{i}(\mathrm{t})=0\). This configuration has emerged from assuming that the SC starts in a steady state.

Adopting the above-described setting for all SCs facilitates the development of a ‘ceteris paribus’ comparison of the different IS structures, and allows us to analyse this comparison under different operational conditions. Also, this allows to contrast our results against two largely studied, well-known SC structures, i.e. the traditional SC and the collaborative SC with full information.

In order to assess the impact of the different IS strategies on SC performance at the system level, we use the Bullwhip Slope metric, BwSl (see Cannella et al. 2013). This concisely provides a global understanding of the fluctuation of orders in the whole SC. To compute BwSl, we first obtain the Order Rate Variance Ratio (ORVrR), which allows us to assess the performance at the echelon level. The ORVrR (Chen et al. 2000) is by far the most widely used indicator to measure the bullwhip effect, and can be calculated for each echelon. It is defined as the ratio of the variance of orders at echelon i, \({{\sigma }_{{O}_{i}}}^{2}\), to that of consumer demand, \({{\sigma }_{d}}^{2},\) as per Eq. (11) (Miragliotta, 2006). This metric provides information of potential unnecessary costs for the SC nodes, such as lost capacity or opportunity costs and overtime working and subcontracting costs (Disney and Lambrecht 2008).

To calculate BwSl, we plot the individual values of ORVrR in a Cartesian diagram using the echelon’s position pi as the independent variable. This interpolated curve is referred in the literature to as the Dejonckheere et al.’s (2004) curve. Essentially, BwSl is the tangent of the inclination angle of the linear regression of this curve, as per Eq. (12). At the system level, BwSl measures the magnitude of the bullwhip propagation across the SC, i.e., how significant the amplification of the variance of orders across the SC echelons is, and allows for a concise and holistic comparison between different SCs (Cannella and Ciancimino 2010). High values of BwSl indicate a fast propagation of the bullwhip effect in the SC, whereas low values indicate a smooth propagation. Therefore, a BwSl reduction leads to an improved cost effectiveness of members’ operations. Both metrics, ORVrR and BwSl, are suitable to compare the dynamics of the different IS structures (Cannella et al. 2013).

5 Results

The results of the simulation runs have been statistically analysed by means of an ANOVA for each dependent variable (i.e. ORVrRi and BwSl), through which we tested the significance of the experimental factors and their interactions. Since the impact of the lead times and their variability on the bullwhip phenomenon has been widely analysed in literature, we focus on the effects of the different IS structures (i.e. the IS_structure factor) and on how the mean and variability of lead times influence the performance of such IS structures (i.e. the interactions of IS_structure with \({\mu }_{\lambda }\) and \({cv}_{\lambda }\)). First, we discuss the results by looking at the overall propagation of the bullwhip effect in SCs, illustrated by BwSl. Second, we continue by analysing the individual performance of each echelon, characterised by ORVrRi.

5.1 Impact of the partial IS structure on the overall propagation of the bullwhip effect (BwSl)

We use the SPSS software to perform the ANOVA on BwSl and to analyse the main effects of the factors and their interactions. Table 3 shows the ANOVA results. Importantly, the main effects of the experimental factors and their interactions are significant with a 95% confidence level (p < 0.05) and, thus, they have relevant effects on BwSl. Table 3 also shows the average BwSl estimations for each IS structure. Given that some of these values are very similar, we ranked the partial IS structures with a higher precision and create clusters with similar performance by carrying out an additional test based on Tukey’s grouping method with 95% significance.

Tukey’s method ranks the IS structures in four different clusters. IS structures that belong to cluster #1 show the best performance (lowest BwSl) while those that belong to cluster #4 present the worst performance (highest BwSl). Interestingly, the Full IS structure (with τ = 3) falls into cluster #1, those IS structures with τ = 2 belong to cluster #2, those with τ = 1 belong to cluster #3, and the Traditional scenario (τ = 0) is in cluster #4. This test indicates that there are no significant differences in terms of BwSl between the partial IS structures with equal number of collaborative echelons.

To assess the benefits provided by the incorporation of new echelons into the IS strategy, we can use Eq. (13). This measures the bullwhip reduction for each degree of collaboration in relative terms to the traditional scenario, \({\gamma }_{BwSl}\). Figure 1 plots \({\gamma }_{BwSl}\) for τ = {0,1,2,3}, suggesting a linear relationship between \({\gamma }_{BwSl}\) and \(\tau\) (coefficient of determination, R2 = 0.997). Interestingly, under the conditions of our experiments, we obtained a bullwhip reduction of 20% (approx.) for each new echelon involved in the IS strategy. Figure 1 represents the average of \({\gamma }_{BwSl}\) for those scenarios with the same τ.

These results offer a new perspective on SC performance under partial IS, extending those obtained previously in literature. Lau et al. (2004) found that sharing information between downstream echelons is more beneficial for the SC than that between upstream echelons, since the former generally hold larger inventories than the latter (due to the higher ratio of unit backlog cost to unit holding cost). Ganesh et al. (2014a) derived the value of IS for any single firm as an increasing concave function of the degree of collaboration, considering inventory holding and backlog costs. The results obtained in this paper complement those previous findings by showing that, when the value of IS is measured through the lens of the bullwhip effect of the entire SC,

-

1.

The benefits of IS in terms of bullwhip reduction increase linearly with the number of echelons involved. Each new echelon sharing information reduces the propagation of the bullwhip effect by approximately 20% over the traditional scenario.

-

2.

These benefits are independent of the position of the echelons that collaborate in the supply chain. Therefore, IS at upstream and downstream levels of the SC have the same value for smoothing the overall bullwhip propagation in SCs.

Now we analyse the impact of the lead times on the BwSl of the different partial IS structures. Table 3 shows significant interactions between the two lead-time factors and the IS structures. The interaction with the mean, \({\mu }_{\lambda }\), has been found to have a higher explanatory power (F = 140.632) than that of the coefficient of variation, \({cv}_{\lambda }\) (F = 14.843). To analyse the interactions, Fig. 2 displays the interaction plots, showing both average values and 95% confidence intervals (CI).

On the left side of Fig. 2, an important interaction between IS_structure and \({\mu }_{\lambda }\) can be observed (notice that the curves are clearly not parallel). This suggests that high lead times make the SC more sensitive to the partial IS structure adopted, which is in line with the results obtained by Lau et al. (2004) for inventory costs. In other words, the effect of increasing the number of collaborative echelons is higher, in absolute terms, for SCs with higher lead times. As an example, BwSl in the traditional SC with longer lead times mean (5 periods) decreases from 12.5 to an average of 10.46 when \(\tau\)=1, and to an average of 7.5 when \(\tau\)=2. The BwSl in the traditional SC with shorter lead times (2 periods) is significantly lower than in the previous case and, even though the relative improvement obtained by the partial IS may be even stronger than in the previous case, the absolute reduction of the BwSl is lower. For example, the BwSl in the traditional SC with short lead times mean decreases from 2 to an average of 1.4 when \(\tau\)=1, and to an average of 0.8 when \(\tau\)=2.

On the right side of Fig. 2, we show the interaction between IS_structure and \({cv}_{\lambda }\). As anticipated by the F ratio, this interaction is less important, as it can be seen by certain level of parallelism in the lines. In other words, the reduction of the BwSl obtained by a partial IS structure depends to a lesser extent on the variability of lead times. As an example, BwSl in the traditional SC with high lead times variability (c.v. = 0.4) decreases from 9 to an average of 7.3 when one echelon shares information, while in the case of low variability (c.v. = 0.2), BwSl decreases from 5.2 to an average of 4.2.

The impact of lead times on the performance of partial IS for reducing the propagation of the bullwhip effect in SCs can be summarised as follows:

-

3.

The effects of partial IS on the propagation of the bullwhip effect in SCs significantly depends on the mean of the relevant lead times: SCs with higher lead times are more sensitive, in absolute terms of BwSl, to the degree of collaboration among echelons.

-

4.

The effects of partial IS on the propagation of the bullwhip effect in SCs depends to a lesser extent on the variability of the lead times: SCs with more variable lead times are more sensitive, in absolute terms of BwSl, to the degree of collaboration among echelons.

5.2 Impact of the partial IS structure on the performance of the echelons (ORVrRi)

We now analyse the impact of the IS structures on the bullwhip effect suffered by each SC echelon using ORVrRi. The ANOVA results are shown in Table 4 and ORVrRi estimations are provided in Table 5. ANOVA shows that the IS structure has a significant impact on ORVrRi at all SC nodes, with the expected exception of the lowest echelon (Retailer). Table 5 shows that moving from one IS structure to another significantly impacts ORVrRi. Considering the F ratios in Table 4, we see that this impact monotonously decreases as we move downstream in the SC, which is confirmed by the estimations of Table 5 (F ratios show a quasi-linear decrease, coefficient of determination R2 = 0.989).

To explain the results and analyse in detail each IS structure, we also use Tukey’s grouping with 95% significance; see Table 5. Interestingly, the Manufacturer shows exactly the same number of clusters for ORVrRi as before, while other echelons have a lower number of clusters. The Distributor has three clusters. The same performance is obtained for full IS (τ = 3) and for R-W-D IS (τ = 2), while W-D-M IS (τ = 2) belongs to the same cluster as R-W IS and W-D IS (τ = 1). Furthermore, D-M IS (τ = 1) performs like the traditional scenario (τ = 0). The Wholesaler includes two clusters. It achieves the best performance for full IS, R-W-D IS and R-W IS, while the other structures belong to the low-performing cluster. Finally, as discussed before, there is only one cluster for the Retailer.

Since the degree of collaborationτcannot explain precisely the echelon’s performance, we now define the degree of downstream collaboration τ, i.e. the number of downstream echelons that share information. Looking at the Distributor in Table 5, it can be noticed that the IS strategies in the top-performing clusters (full IS, R-W-D IS) have τ = 2, while the strategies in the second cluster (W-D-M IS, R-W IS, W-D IS) have = 1, and those strategies in the third cluster (D-M IS, Traditional) have τ = 0. Therefore, the benefits obtained from IS at the Distributor echelon are related to the degree of downstream collaboration. The same rationale applies for the Manufacturer (note that here τ = τ), the Wholesaler, and the Retailer (where τ = 0). This result suggests that a given echelon in the SC obtains identical benefits from IS structures with the same τregardless of which echelons share information.

For example, we consider the Manufacturer and IS structures with τ = 2, i.e. R-W-D IS and W-D-M IS. This node is equally benefitted from both structures despite the fact that they involve different SC echelons. Therefore, this node benefits from the same bullwhip reduction if the information is shared from the Retailer to the Distributor via the Wholesaler than if it is shared from the Wholesaler to the Manufacturer itself via the Distributor. Note that both IS structures are conceptually different. The former involves up-to-date information on market demand and keeps the Manufacturer out of the IS, while the latter is based on information on the orders issued by the Retailer (hence market demand is not known) that is used by the Manufacturer (who here participates in the IS strategy).

From this perspective, it is relevant to note that the benefits of IS are transmitted upstream in SCs. Therefore, despite we observed before that the overall propagation of the bullwhip effect does not depend on the position of the nodes that collaborate in the SC, if we consider the joint cost performance of all the SC echelons, it is better to adopt a downstream IS structure. This occurs because more echelons will benefit from IS, and thus the intermediate echelons will benefit from a significant reduction in the operational costs; for instance, comparing R-W-D IS to W-D-M IS, the ORVrRi at the Wholesaler and at the Distributor is lower in the former structure than in the latter. This observation is aligned with the previously discussed conclusions by Lau et al. (2004).

Using the same rationale as before, we now estimate the improvement of partial IS structures in terms of ORVrR reduction, \({\gamma }_{ORVrR}\), using the traditional scenario as a reference, as per Eq. (14). Figure 3 plots \({\gamma }_{ORVrR}\) for the set of all partial IS structures with the same degree of downstream collaboration (τ’) and for each echelon of the SC. Again, \({\gamma }_{ORVrR}\) is averaged for the scenarios with the same τ’.

Like Fig. 1 for τ, Fig. 3 suggests a quasi-linear increase of \({\gamma }_{ORVrR}\) as τ’ grows, which is in line with the F ratios in Table 4. Nonetheless, the curve for each echelon is constrained by the number of downstream echelons it has (i.e. the maximum τ’). Interestingly, while the benefits in terms of inventory cost reduction have been found to follow an increasing concave function of the degree of collaboration (Ganesh et al. 2014a) (that is, the ‘marginal’ benefits decrease as collaboration increases), from a bullwhip reduction perspective we have observed a linear relationship (that is, the benefits in relative terms are identical as \(\tau ^{\prime}\) increases).

Furthermore, it is interesting to note that, in relative terms (i.e. Eq. 14), all echelons upstream of a certain τ’partial IS structure obtain identical benefit, e.g. both the manufacturer and the distributor reduce the bullwhip effect around 36% for τ’ = 2. However, since the bullwhip effect is higher in the echelons upstream, the most upstream SC echelons always experience a higher absolute performance improvement, e.g. the bullwhip effect at the manufacturer, ORVrR1 = 25.74, decreases to an average of ORVrR1 = 16.79 for τ’ = 2, while in the case of the distributor, the bullwhip effect ORVrR2 = 13.16, decreases to an average of ORVrR2 = 8.47.

The previous discussion leads us to the following findings:

-

5.

The benefits in terms of bullwhip reduction obtained by a given echelon of the SC from a partial IS structure

-

Monotonously increase as the degree of downstream collaboration grows.

-

Do not depend on which downstream echelons share information.

-

Are higher for the upstream echelons of the SC.

-

-

6.

Downstream partial IS structures are more advantageous for the SC than upstream partial IS structures from the perspective that the former have a positive impact on a higher number of echelons, which will benefit from a significant cost reduction in their operations.

To illustrate and clarify the key findings of our work, we now analyse one of the simulated scenarios in more detail. Figure 4 shows \({ORVrR}_{i}\) for the traditional (no IS), R-W IS (downstream collaboration), and D-M (upstream collaboration) IS structures, when \({\mu }_{\lambda }\)=5 and \({cv}_{\lambda }\)=0.4. In line with prior discussions, \(ORVrR\) decreases at the Wholesaler with R-W IS, since this node uses the forecast shared by the Retailer. This also benefits the upstream echelons (i.e. Distributor and Manufacturer), which all show \(ORVrR\) s below the Traditional structure. However, D-M IS only benefits the Manufacturer, which shows the same \(ORVrR\) as in the case of R-W IS. Note that, from the perspective of the Manufacturer, both structures have the same degree of downstream collaboration (i.e. τ’ = 1); however, from the perspective of the other Wholesaler and the Distributor, the R-W IS structure entails τ’ = 1 while the D-M structure entails τ’ = 0. This confirms what we discussed before: the benefits obtained by an echelon depend on τ’, but not on which nodes are sharing information. Nevertheless, downstream IS is more beneficial for the SC since more echelons benefit from lower bullwhip effect.

At this point, it is reasonable to wonder why both IS structures show a similar propagation of the bullwhip effect (BwSl = 13.75 for R-W and BwSl = 13.97 for D-M), despite the fact that more echelons operate with a lower variability when collaboration takes place downstream in the SC. The reason behind this finding is that the stage variance amplification that occurs between two consecutive echelons reduces in a similar proportion due to IS regardless of the echelons involved.

Let \({SVAmp}_{i}={\sigma }_{i}^{2}/{\sigma }_{i+1}^{2}\) denote the stage variance amplification between echelons i and i + 1, where \({SVAmp}_{i}^{*}\) refers to the value of \({SVAmp}_{i}\) when in the traditional scenario. We find that: (a) if echelon i + 1 is not sharing information with echelon i, \({SVAmp}_{i}\approx {SVAmp}_{i}^{*}\) regardless of whether or not the other SC nodes share information; and (b) \({SVAmp}_{i}\approx \delta {SVAmp}_{i}^{*}\), with \(\delta <1\), if echelons i + 1 shares information with echelon i, also regardless of whether or not the other SC nodes are collaborating. And more importantly, in the context of our study, \(\delta\) is independent of the echelons who are sharing information; that is, the proportional reduction of \({SVAmp}_{i}\) caused by IS is similar for all SC echelons. To illustrate this observation, Fig. 5 shows \({SVAmp}_{i}\) for the different nodes in the scenario considered in Fig. 4 (note, \({SVAmp}_{4}\) has been exclude since the Retailer does not benefit from IS). For the R-W IS structure, \({SVAmp}_{3}<{SVAmp}_{3}^{*}\), and \({SVAmp}_{i}\approx {SVAmp}_{i}^{*}\) for i = {1,2}; and for the D-M IS structure, \({SVAmp}_{1}<{SVAmp}_{1}^{*}\), and \({SVAmp}_{i}\approx {SVAmp}_{i}^{*}\) for i = {2,3}. Moreover, \({SVAmp}_{i}/{SVAmp}_{i}^{*}\approx \delta\) is approximately equal for i = 3 in the R-W structure and i = 1 in the D-M structure.

Finally, we analyse how lead times affect the impact of the IS structures on the bullwhip effect from a single-echelon perspective. Figure 6 plots the average values and 95% CIs of the relevant interactions (these are excluded for the Retailer and Wholesaler due to their lower significance). The interaction between IS_structure and \({\mu }_{\lambda }\) has a significant impact for the upstream echelons, showing a decreasing trend as we move downstream (see F ratios in Table 4). Note that the effect of increasing the degree of collaboration on echelon’s performance is highly influenced by \({\mu }_{\lambda }\) at upstream echelons (Manufacturer and Distributor), e.g. the bullwhip effect at the manufacturer, ORVrR1 = 45, decreases to an average of ORVrR1 = 37.8 for τ’ = 1 and \({\mu }_{\lambda }\)=5, while in the case of shorter lead times (\({\mu }_{\lambda }\)=2), the bullwhip effect at the manufacturer decreases from ORVrR1 = 5.2 to an average of ORVrR1 = 4.2. Similarly, the interaction between IS_structure and \({cv}_{\lambda }\) is significant for the upstream echelons of the SC but, nevertheless, this interaction is of lower intensity than the previous one, i.e. the bullwhip effect reduces in similar magnitudes under partial IS for different values of \({cv}_{\lambda }\).

We summarise these findings as follows:

-

7.

The echelon’s bullwhip reduction obtained by a partial IS structure is more significant for higher lead times. This effect diminishes as we move downstream in the SC.

-

8.

The echelon’s bullwhip reduction obtained by a partial IS structure slightly depends on lead times variability. This effect diminishes as we move downstream in the SC.

6 Managerial implications

Over the last two decades, a considerable amount of evidence has suggested that bullwhip costs play a pivotal role in many organisations (Wang and Disney 2016). It is thus essential for managers of decentralised SCs to understand how they can benefit from different types of IS schemes, especially since it has been generally recognised the high difficulty to reach full collaboration among all SC members. In the light of our results, herein we provide SC managers with some recommendations on how to implement and benefit from partial IS strategies.

The implementation of a full IS structure naturally leads to the highest bullwhip reduction while, as expected, the worst SC dynamics are obtained without IS mechanisms. Between both extremes, the bullwhip effect significantly reduces as the number of collaborative echelons grows. As it might be hard to involve all echelons of real-world SCs at first due to different barriers, a potential solution to start implementing IS practices may be focused on a dyadic relationship. In addition, since the overall propagation of the bullwhip effect is independent of “who” the echelons involved are, it would be reasonable to start with members with higher willingness to share information and/or where the collection and sharing of data is easier and less costly. This should strongly depend on the industry under consideration (Chae et al. 2018). In any case, this first stage will have a positive impact on the dynamics of the SC, allowing to reduce the propagation of the bullwhip effect in the SC by \(\sim\) 20%. This should provide SC decision makers with confidence to enlarge the coalition by extending IS to other echelons, since the benefits obtained are proportional to the number of collaborative echelons.

While the overall bullwhip reduction does not depend on the echelons that share information, the benefits perceived by each node are significantly affected by the position of these echelons in the SC. Specifically, an organisation at a given echelon will experience higher bullwhip reduction as more downstream echelons participate in IS. However, again, this is independent of which downstream echelons share information. In the light of this, managers of a specific organisation may be tempted to start by focusing on those echelons that are more prone to collaborate. Nonetheless, it should be highlighted that the benefits obtained by the addition of new downstream echelons to the IS strategy are equally distributed among the relevant upstream echelons. From this perspective, it may be worth to start the design and implementation of IS-based collaborative strategies for SCs by looking at the downstream echelons. Managers at upstream echelons of the SC have powerful reasons to motivate lower echelons to share information, creating the need for aligning incentives in the wider SC.

That is, with the aim of obtaining benefits over all echelons of the SC, a suitable strategy may be to start by implementing IS from the retailers, which would report significant benefits to the rest of echelons. This can be seen in Fig. 7, where the echelons’ bullwhip reduction (\({\gamma }_{ORVrR}\)) is plotted for IS structures with τ = 1 and τ = 2. Note that the benefit of a full IS structure is also plotted in both figures for benchmarking purposes. It can be seen how involving the Retailers in IS (R-W IS for τ = 1 and R-W-D for τ = 2) reports benefits for a higher number of SC members than any other partial IS structure.

However, as the Retailer does not directly benefit from sharing information with other SC members from the perspective of order variability—nonetheless, smoothing the upstream flow of materials should eventually result in benefits for the Retailer, e.g. through less stock-outs in the SC—, upstream members in the SC need to share the economic gains derived from the IS strategies (see e.g. Lau et al. 2004; Ganesh et al. 2014a; Audy 2012). Essentially, this means that upstream SC members must compensate the downstream ones for the operational advantage the former obtain thanks to the information provided by the latter. One potential solution for aligning incentives could be based on the implementation of a structured reward scheme (e.g. reduction of product prices, improvement of contract agreements and/or fixed revenues, etc.). To successfully implement a win–win strategy and encourage companies to become more collaborative, the benefits, costs and risks of IS must be shared among the maximum number of members. By targeting the retailer as the first member for IS, all upstream members will benefit from collaboration and thus the distribution of benefits, costs and risks can be more effectively done.

The analysis of production and distribution lead times and their impact on the efficiency of partial IS structures also led to meaningful managerial insights. From a systemic point of view, SCs characterised by long and variable lead times experience a more intensive bullwhip reduction by adding new collaborative members than those with short and stable lead times. Consequently, the above-mentioned recommendations may be particularly useful for managers of SCs operating under prominent geographical dispersion and/or uncertain lead times.

7 Conclusions and future research

It is well known that IS promotes the reduction of the bullwhip effect along SCs. However, within a decentralised SC it is difficult to implement full IS strategies among all SC members due to a number of barriers. It then becomes crucial to understand the effectiveness of sharing demand data where the full collaboration in SCs cannot be achieved. This is the focus of the present study, where we model a set of partial IS structures under stochastic lead times and demand using system dynamics, and analyse SC performance in terms of bullwhip effect both at the system and the echelon levels.

Our main findings are:

-

The reduction of the propagation of the bullwhip effect in SCs is proportional to the degree of collaboration (i.e. the number of echelons sharing information), but it is independent of the position of the nodes involved in IS. Each echelon sharing information may reduce the bullwhip effect by up to 20% with respect to the traditional SC.

-

The reduction of the bullwhip effect for each echelon is proportional to the degree of downstream collaboration (i.e. the number of downstream echelons sharing information), and it is also independent of the downstream echelons involved. Each downstream echelon sharing information may reduce the bullwhip effect faced by upstream echelons by up to 15–20%. Therefore, upstream echelons (which generally suffer more severely from the consequences of the bullwhip effect) are the most benefited from IS.

-

Downstream partial IS structures benefit a higher number of echelons than upstream partial IS structures. Hence, the former structures provoke a larger reduction of the overall SC costs.

-

The impact of the partial IS on the bullwhip effect, both at the SC and the echelon levels, strongly depends on the mean lead times. In this sense, IS becomes more beneficial under long lead times. This is particularly important at the upstream members of the SC.

-

The impact of the partial IS structure on the bullwhip effect depends to a lesser extent on the variability of lead times. Nonetheless, IS is more favourable under highly uncertain lead times.

From these findings, we have derived relevant managerial implications on how to implement IS in a decentralised SC. A good strategy may be to start by involving just one echelon, and then continue with involving the rest of echelons at a later step, given that the SC performance improvement increases as the degree of collaboration grows. Specifically, involving retailers first might be the best alternative, as in this situation a higher number of echelons in the SC experience a decrease in their order variability. In this fashion, the costs associated with the required compensation to the retailers can be shared among a higher number of members who benefit from bullwhip reduction.

Finally, several limitations to our study can be found, which are mainly related to the assumptions made and define interesting avenues for future research. An important consideration is the i.i.d. nature of the demand. Exploring partial IS in SCs that face different demand characteristics, including seasonality and trend, may lead to different findings. In these cases, sharing consumer demand information may be more valuable, thus downstream echelons may play a more important role in IS. Another important assumption is the unlimited capacity. A capacity constraint would increase the nonlinear behaviour of the SC, which may generate different dynamic behaviours and findings. Also, the present research has focused on serial SCs. Thus, the results of this work can be extended by analysing the performance of the partial IS structures in more complex SCs, including divergent and convergent effects as well as the emerging closed-loop structures for circular economic models.

Furthermore, we have considered the exchange of only one source of information (demand forecasts). Future work could analyse partial IS scenarios where different types of information are exchanged among the participant members. Finally, we have assumed that the information is transmitted without errors. However, this is not always true in practice (Kwak and Gavirneni 2015), as errors may occur when the information is transmitted from one echelon to another. Depending on the frequency and magnitude of errors, partial IS structures with a lower degree of collaboration may provide better SC performance than others with a higher involvement. Therefore, further research needs to address the performance of different partial IS structures under the presence of errors in information transmission.

References

Ali MM, Babai MZ, Boylan JE, Syntetos AA (2017) Supply chain forecasting when information is not shared. Eur J Oper Res 260(3):984–994

Audy JF, Lehoux N, D’Amours S, Rönnqvist M (2012) A Framework for an Efficient Implementation of Logistics Collaborations. Int Trans Oper Res 19(5):633–657

Beamon BM, Chen VC (2001) Performance analysis of conjoined supply chains. Int J Prod Res 39(14):3195–3218

Boute RN, Disney SM, Lambrecht MR, Van Houdt B (2009) Designing replenishment rules in a two-echelon supply chain with a flexible or an inflexible capacity strategy. Int J Prod Econ 119(1):187–198

Cachon GP, Fisher M (1997) Campbell Soup’s continuous product replenishment program: evaluation and enhanced decision rules. Prod Oper Manag 6(3):266–276

Cannella S, Barbosa-Povoa AP, Framinan JM, Relvas S (2013) Metrics for bullwhip effect analysis. J Oper Res Soc 64(1):1–16

Cannella S, Ciancimino E (2010) On the bullwhip avoidance phase: supply chain collaboration and order smoothing. Int J Prod Res 48(22):6739–6776

Cannella S, Dominguez R, Framinan JM (2016) Turbulence in market demand on supply chain networks. Int J Simul Modell 15(3):450–459

Cannella S, Dominguez R, Framinan JM (2017) Inventory record inaccuracy – The impact of structural complexity and lead time variability. Omega 68:123–138

Cannella S, López-Campos M, Dominguez R, Ashayeri J, Miranda PA (2015) A simulation model of a coordinated decentralized supply chain. Int Trans Oper Res 22(4):735–756

Chae HC, Koh CE, Park KO (2018) Information technology capability and firm performance: role of industry. Inf Manage 55(5):525–546

Chatfield DC (2013) Underestimating the bullwhip effect: a simulation study of the decomposability assumption. Int J Prod Res 51(1):230–244

Chatfield DC, Kim JG, Harrison TP, Hayya JC (2004) The bullwhip effect – Impact of stochastic lead time, information quality, and information sharing: A simulation study. Prod Oper Manage 13(4):340–353

Chatfield DC, Pritchard AM (2013) Returns and the bullwhip effect. Transp Res Part E Log Transp Rev 49(1):159–175

Chen F, Drezner Z, Ryan JK, Simchi-Levi D (2000) Quantifying the bullwhip effect in a simple supply chain: The impact of forecasting, lead times, and information. Manage Sci 46(3):436–443

Ciancimino E, Cannella S, Bruccoleri M, Framinan JM (2012) On the bullwhip avoidance phase: the Synchronised Supply. Eur J Oper Res 221(1):49–63

Costantino F, Di Gravio G, Shaban A, Tronci M (2014) The impact of information sharing and inventory control coordination on supply chain performances. Comput Ind Eng 76:292–306

Croson R, Donohue K (2005) Upstream versus downstream information and its impact on the bullwhip effect. Syst Dyn Rev J Syst Dyn Soc 21(3):249–260

Dejonckheere J, Disney SM, Lambrecht MR, Towill DR (2004) The impact of information enrichment on the Bullwhip effect in supply chains: A control engineering perspective. Eur J Oper Res 153(3):727–750

Disney SM, Lambrecht MR (2008) On replenishment rules, forecasting, and the bullwhip effect in supply chains. Found Trends Technol Inf Oper Manage 2(1):1–80

Dominguez R, Cannella S, Framinan JM (2014) On bullwhip-limiting strategies in divergent supply chain networks. Comput Ind Eng 73(1):85–95

Dominguez R, Cannella S, Póvoa AP, Framinan JM (2018a) Information sharing in supply chains with heterogeneous retailers. Omega 79:116–132

Dominguez R, Cannella S, Póvoa AP, Framinan JM (2018b) OVAP: a strategy to implement partial information sharing among supply chain retailers. Transp Res Part E Log Transp Rev 110:122–136

Dominguez, R., Cannella, S., Ponte, B., Framinan, J. M. 2019. On the dynamics of closed-loop supply chains under remanufacturing lead time variability. Omega, p 102106

Evers PT, Wan X (2012) Systems analysis using simulation. J Bus Log 33(2):80–89

Fawcett SE, McCarter MW, Fawcett AM, Webb GS, Magnan GM (2015) Why supply chain collaboration fails: the socio-structural view of resistance to relational strategies. Supply Chain Manage An Int J 20(6):648–663

Fawcett SE, Wallin C, Allred C, Fawcett AM, Magnan GM (2011) Information technology as an enabler of supply chain collaboration: a dynamic-capabilities perspective. J Supply Chain Manage 47(1):38–59

GMA - Grocery Manufacturers Association (2009) Retail-direct data report. Report, GMA, Washington, DC, http://www.gmaonline .org/downloads/research-and-reports/WP-Retailer-DDR09–6.pdf.

Gaalman G (2006) Bullwhip reduction for ARMA demand: The proportional order-up-to policy versus the full-state-feedback policy. Automatica 42(8):1283–1290

Ganesh M, Raghunathan S, Rajendran C (2014a) Distribution and equitable sharing of value from information sharing within serial supply chains. IEEE Trans Eng Manage 61(2):225–236

Ganesh M, Raghunathan S, Rajendran C (2014b) The value of information sharing in a multi-product, multi-level supply chain: Impact of product substitution, demand correlation, and partial information sharing. Decis Support Syst 58(1):79–94

Guertler B, Spinler S (2015) When does operational risk cause supply chain enterprises to tip? A simulation of intra-organizational dynamics. Omega 57:54–69

Gunasekaran A, Subramanian N, Papadopoulos T (2017) Information technology for competitive advantage within logistics and supply chains: a review. Transp Res Part E Log Transp Rev 99:14–33

Hearnshaw EJS, Wilson MMJ (2013) A complex network approach to supply chain network theory. Int J Oper Prod Manage 33(4):442–469

Holmstrőm, J., Småros, J., Disney, S. M., & Towill, D. R. (2016). Collaborative supply chain configurations: the implications for supplier performance in production and inventory control. In Developments in Logistics and Supply Chain Management, pp 27–37. Palgrave Macmillan UK.

Holweg M, Disney S, Holmström J, Småros J (2005) Supply chain collaboration: making sense of the strategy continuum. Eur Manage J 23(2):170–181

Huang Y-S, Hung J-S, Ho J-W (2017) A study on information sharing for supply chains with multiple suppliers. Comput Ind Eng 104:114–123

Huang Y-S, Li M-C, Ho J-W (2016) Determination of the optimal degree of information sharing in a two-echelon supply chain. Int J Prod Res 54(5):1518–1534

Huang Y, Wang Z (2017) Values of information sharing: a comparison of supplier-remanufacturing and manufacturer-remanufacturing scenarios. Transp Res Part E Log Transp Rev 106:20–44

Hussain M, Drake PR (2011) Analysis of the bullwhip effect with order batching in multi-echelon supply chains. Int J Phys Distrib Log Manage 41(8):797–814

Hussain M, Khan M, Sabir H (2016) Analysis of capacity constraints on the backlog bullwhip effect in the two-tier supply chain: a Taguchi approach. Int J Log Res Appl 19(1):41–61

Jarmain WE (1963) Problems in industrial dynamics. Mit Press, Cambridge

Jeong K, Hong JD (2019) The impact of information sharing on bullwhip effect reduction in a supply chain. J Intell Manuf 30(4):1739–1751

Jeong I-J, Jorge Leon V (2012) A serial supply chain of newsvendor problem with safety stocks under complete and partial information sharing. Int J Prod Econ 135(1):412–419

Kembro J, Näslund D (2014) Information sharing in supply chains, myth or reality? A critical analysis of empirical literature. Int J Phys Distrib Log Manage 44(3):179–200

Kembro J, Selviaridis K (2015) Exploring information sharing in the extended supply chain: an interdependence perspective. Supply Chain Manage Int J 20(4):455–470

Kembro J, Selviaridis K, Näslund D (2014) Theoretical perspectives on information sharing in supply chains: a systematic literature review and conceptual framework. Supply Chain Manage Int J 19:609–625

Kleijnen JP (2005) Supply chain simulation tools and techniques: a survey. Int J Simul Process Model 1(1–2):82–89

Klug F (2016) Analysing bullwhip and backlash effects in supply chains with phase space trajectories. Int J Prod Res 54(13):3906–3926

Klug F (2017) Analysing the interaction of supply chain synchronisation and material flow stability. Int J Log Res Appl 20(2):181–199

Kong G, Rajagopalan S, Zhang H (2013) Revenue sharing and information leakage in a supply chain. Manage Sci 59(3):556–572

Kwak JK, Gavirneni S (2015) Impact of information errors on supply chain performance. J Oper Res Soc 66(2):288–298

Lau JSK, Huang GQ, Mak KL (2004) Impact of information sharing on inventory replenishment in divergent supply chains. Int J Prod Res 42(5):919–941

Lee HL (2010) Taming the bullwhip. J Supply Chain Manage 46(1):7–7

Lee HL, Padmanabhan V, Whang S (1997) Information distortion in a supply chain: the bullwhip effect. Manage Sci 43(4):546–558

Lee HL, Whang S (2000) Information sharing in a supply chain. Int J Technol Manage 20(3):373–387

Li Q, Disney SM, Gaalman G (2014) Avoiding the bullwhip effect using Damped Trend forecasting and the Order-Up-To replenishment policy. Int J Prod Econ 149:3–16

Li H, Pedrielli G, Lee LH, Chew EP (2017) Enhancement of supply chain resilience through inter-echelon information sharing. Flex Serv Manuf J 29(2):260–285

Li T, Zhang H (2015) Information sharing in a supply chain with a make-to-stock manufacturer. Omega 50:115–125

Long Q, Zhang W (2014) An integrated framework for agent based inventory–production–transportation modeling and distributed simulation of supply chains. Inf Sci 277:567–581

Macdonald JR, Frommer ID, Karaesmen IZ (2013) Decision making in the beer game and supply chain performance. Oper Manage Res 6(3–4):119–126

Machuca JAD, Barajas RP (2004) The impact of electronic data interchange on reducing bullwhip effect and supply chain inventory costs. Transp Res Part E Log Transp Rev 40(3):209–228

Makridakis S, Andersen A, Carbone R, Fildes R, Hibon M, Lewandowski R, Winkler R (1982) The accuracy of extrapolation (time series) methods: Results of a forecasting competition. J Forecast 1(2):111–153

Mason-Jones R, Naim MM, Towill DR (1997) The impact of pipeline control on supply chain dynamics. Int J Log Manage 8(2):47–62

Metters R (1997) Quantifying the bullwhip effect in supply chains. J Oper Manage 15(2):89–100

Miragliotta G (2006) Layers and mechanisms: a new taxonomy for the bullwhip effect. Int J Prod Econ 104(2):365–381

Mokhtar S, Bahri PA, Moayer S, James A (2019) Supplier portfolio selection based on the monitoring of supply risk indicators. Simul Model Pract Theory 97:101955

Ojha D, Sahin F, Shockley J, Sridharan SV (2019) Is there a performance tradeoff in managing order fulfillment and the bullwhip effect in supply chains? The role of information sharing and information type. Int J Prod Econ 208:529–543

Oliveira JB, Jin M, Lima RS, Kobza JE, Montevechi JAB (2019) The role of simulation and optimization methods in supply chain risk management: Performance and review standpoints. Simul Model Pract Theory 92:17–44

El Ouardighi F, Erickson G (2014) Production capacity buildup and double marginalization mitigation in a dynamic supply chain. J Oper Res Soc 66(8):1281–1296

Paik SK, Bagchi PK (2007) Understanding the causes of the bullwhip effect in a supply chain. Int J Retail Distrib Manage 35(4):308–324

Park K, Kyung G (2014) Optimization of total inventory cost and order fill rate in a supply chain using PSO. Int J Adv Manuf Technol 70(9–12):1533–1541

Ponte B, Costas J, Puche J, de la Fuente D, Pino R (2016) Holism versus reductionism in supply chain management: An economic analysis. Decis Support Syst 86:83–94

Ponte B, Costas J, Puche J, Pino R, de la Fuente D (2018) The value of lead time reduction and stabilization: a comparison between traditional and collaborative supply chains. Transp Res Part E Log Transp Rev 111:165–185

Ponte B, Sierra E, de la Fuente D, Lozano J (2017) Exploring the interaction of inventory policies across the supply chain: An agent-based approach. Comput Oper Res 78:335–348

Qian Y, Chen J, Miao L, Zhang J (2012) Information sharing in a competitive supply chain with capacity constraint. Flex Serv Manuf J 24(4):549–574

Rached M, Bahroun Z, Campagne J-P (2015) Assessing the value of information sharing and its impact on the performance of the various partners in supply chains. Comput Ind Eng 88:237–253

Rached M, Bahroun Z, Campagne J-P (2016) Decentralised decision-making with information sharing versus centralised decision-making in supply chains. Int J Prod Res 54(24):7274–7295

Rong Y, Shen ZJM, Snyder LV (2008) The impact of ordering behavior on order-quantity variability: a study of forward and reverse bullwhip effects. Flex Serv Manuf J 20(1–2):95

Shang W, Ha AY, Tong S (2016) Information sharing in a supply chain with a common retailer. Manage Sci 62(1):245–263

Shnaiderman M, Ouardighi FE (2014) The impact of partial information sharing in a two-echelon supply chain. Oper Res Lett 42(3):234–237

Soosay CA, Hyland P (2015) A decade of supply chain collaboration and directions for future research. Supply Chain Manage Int J 20(6):613–630

Spiegler VLM, Naim MM, Towill DR, Wikner J (2016) A technique to develop simplified and linearised models of complex dynamic supply chain systems. Eur J Oper Res 251(3):888–903

Sterman JD (1989) Modelling managerial behavior: Misperceptions of feedback in a dynamic decision-making experiment. Manage Sci 35(3):321–339

Sterman JD (2000) Business dynamics: systems thinking and modeling for a complex world. Irwin/McGraw-Hill, New York

Towill DR (1982) Dynamic analysis of an inventory and order based production control system. Int J Prod Res 20:369–383

Trapero JR, Kourentzes N, Fildes R (2012) Impact of information exchange on supplier forecasting performance. Omega 40(6):738–747

Van Ackere A, Larsen ER, Morecroft JD (1993) Systems thinking and business process redesign: an application to the beer game. Eur Manage J 11(4):412–423

Viet NQ, Behdani B, Bloemhof J (2018) The value of information in supply chain decisions: a review of the literature and research agenda. Comput Ind Eng 120:68–82

Wang X, Disney SM (2016) The bullwhip effect: Progress, trends and directions. Eur J Oper Res 250(3):691–701

Wang N, Lu J, Feng G, Ma Y, Liang H (2016) The bullwhip effect on inventory under different information sharing settings based on price-sensitive demand. Int J Prod Res 54(13):4043–4064

Wang JC, Wang YY, Che T (2019) Information sharing and the impact of shutdown policy in a supply chain with market disruption risk in the social media era. Inf Manage 56(2):280–293

Wikner J (2003) Continuous-time dynamic modelling of variable lead times. Int J Prod Res 41(12):2787–2798

Wright D, Yuan X (2008) Mitigating the bullwhip effect by ordering policies and forecasting methods. Int J Prod Econ 113(2):587–597

Xu K, Dong Y, Xia Y (2015) “Too little” or “Too late”: The timing of supply chain demand collaboration. Eur J Oper Res 241(2):370–380

Zhang J, Chen J (2013) Coordination of information sharing in a supply chain. Int J Prod Econ 143(1):178–187

Zhou, X., Ma, F., Wang, X. 2009. An incentive model of partial information sharing in supply chain. In 2009 IEEE/INFORMS International Conference on Service Operations, Logistics and Informatics, SOLI, 5203904, pp 58–61

Acknowledgements

Funding was provided by Universidad de Sevilla (Grant No. V/VI PPIT-US), Università di Catania (Grant No. Piano della Ricerca programme, under the project GOSPEL), Junta de Andalucía (Grant Nos. US-1264511, P18-FR-1149), Ministerio de Ciencia, Innovación y Universidades (Grant No. PID2019-108756RB-I00).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dominguez, R., Cannella, S., Ponte, B. et al. Information sharing in decentralised supply chains with partial collaboration. Flex Serv Manuf J 34, 263–292 (2022). https://doi.org/10.1007/s10696-021-09405-y

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10696-021-09405-y