Abstract

A single municipal solid waste treatment technique may not be adequate to effectively treat the municipal solid waste (MSW) produced across the globe. This is due to the different composition and physical characteristics of the MSW. This has changed China's waste management strategy to integrated waste management systems since the 13th Five-Year-Plan in 2016. Therefore, the present study evaluates the electricity generation potential, economic feasibility, and the environmental impact of integrated waste-to-energy technologies in China, taking the Beijing-Tianjin-Hebei region as a case study. The study considers the integration of anaerobic digestion and landfill gas to energy (AD/LFGTE), anaerobic digestion and incineration (AD/INC), and incineration and landfill gas to energy (INC/LFGTE). The prominent findings show that AD/LFGTE has the highest electricity generation potential during the project period. It was found that AD/LFGTE contributed 24.52% to the region’s electricity needs, while AD/INC and INC/LFGTE contributed 22.68% and 1.88%, respectively. According to the economic analysis, all the projects are viable in the area and have a positive net present value. The AD/LFGTE project was found to be more economical with a lower levelized cost of energy (US$0.0915/kWh), shorter investment payback period (9.1 years), and higher profit (US$1,331.19 million) on investment. It was observed that the integrated systems could avoid a considerable amount of coal consumption and greenhouse gas emissions, with AD/LFGTE having the highest saving ability.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

There has been a high energy usage and utilization of fossil resources worldwide due to population growth, urbanization, and economic development. Consequently, significant environmental issues have arisen, including increasing waste production, water contamination, and greenhouse gas emissions (Hameed et al., 2021). Applying a single municipal solid waste treatment technology might not be enough to properly manage the recently high municipal solid waste, with different compositions and physical characteristics. As a result, hybrid solid waste management (HSWM) has been proposed as an advanced approach for the long-term management of municipal solid waste (Iqbal et al., 2019). There is a noticeable and growing interest in integrated renewable energy-based systems incorporating energy storage technologies (Murphy et al., 2021). Hybrid waste management systems provide a variety of recycling, energy recovery, and disposal options based on the waste's biological, chemical, energetic, and physical properties (Mohammadi & Harjunkoski, 2020). Integrating energy networks could minimize emissions of significant air pollutants such as carbon dioxide, sulfur dioxide, and nitrous oxide from structured energy management (Hwangbo et al., 2020).

China is facing a tremendous rise in municipal solid waste generation because of economic growth, living standard development, and population growth (Wang & Nakakubo, 2020). Municipal solid waste production is now around 215 Mt (Cudjoe et al., 2020). In 2030, this is expected to rise to about 480 Mt (China’s National Bureau of Statistics, 2018). Food waste, wood, plastics, paper waste, rubber, and textiles are the major components of municipal solid waste produced in China (Gu et al., 2018). This is characterized by 46.1% to 64.1% moisture content and 5.67 to 8.03 MJ/kg lower heating value (Zhou et al., 2015). China's main municipal solid waste treatment techniques are sanitary landfills and incineration (Cheng et al., 2020). Since the 13th Five-Year-Plan in 2016, the waste treatment technique has evolved from final disposal techniques and equipment to integrated waste management systems due to the varied content and physical features of wastes generated in China (Duan et al., 2020).

Researchers from all around the globe are interested in generating electricity from municipal solid waste utilizing integrated waste-to-energy systems. For example, in Nigeria, Ayodele et al. (2017) looked at the possibilities for power production and the environmental effect of hybrid waste-to-energy systems. The authors discovered that compared to the hybrid of incineration and landfill gas to energy technology (INC/LFGTE), the integration of anaerobic digestion and incineration technology (AD/INC) had the most potential for producing power. In terms of global warming and Acidification Potential, the AD/INC technology hybrid was viable in 12 locations in Nigeria. A life cycle impact evaluation of different integrated solid waste management methods using a mix of material recovery and waste-to-energy systems was performed by Abdallah and Elfeky (2021). The research found that the scenario using a combination of anaerobic digestion and incineration technologies yielded the greatest energy recovery. Montorsi et al. (2018) examined the economic feasibility of a hybrid anaerobic digestion and gasification system to use wastes from an urban sewage treatment facility. The authors indicated that the proposed integrated system had a payback period of less than 3 years and could produce the 25% of the electricity needed for the plant operation. However, a study that assesses the economic feasibility of the integration of anaerobic digestion and incineration (AD/INC), anaerobic digestion and landfill gas to energy (AD/LFGTE), and landfill gas to energy and incinerations (LFGTE/INC) systems is scarcely available from the international literature.

In China, integrated waste treatment systems have received some attention from local researchers. The environmental effect of integrated municipal solid waste management initiatives in Hong Kong was studied by Hwangbo et al. (2020). They discovered that combining landfilling with anaerobic digestion and composting decreased net greenhouse gas emissions by 56%, while combining incineration with anaerobic digestion and composting reduced greenhouse gas emissions by up to 87%. Wang et al. (2020) examined the environmental and economic possibilities of an integrated municipal solid waste management facility in Horqin Left Banner, Inner Mongolia Province. The authors concluded that the integrated municipal solid waste management facility is environmentally and economically viable. Chen et al. (2020) suggested combining waste-to-energy systems with a coal-fired power station to generate electricity from municipal solid waste. The authors found that the proposed integration's waste-to-electricity efficiency is increased by 9.16%, resulting in an additional 3.71 MW of net power generation. The economic analysis further revealed that the dynamic payback period of the proposed integration was only 3.55 years. A life cycle evaluation of a biological and mechanical treatment (BMT)-based integrated municipal solid waste management system was performed by Hong et al. (2006). The authors concluded that developing an integrated municipal solid waste management system in Pudong using BMT-based municipal solid waste management would be ecologically justifiable and beneficial. A study that conducts a robust financial analysis of integrated biological and thermochemical waste-to-energy technologies in China is limited. The main novelty of the present study is the utilization of the formulation of model equations technique and economic metrics methods to evaluate the economic feasibility of hybrid waste-to-energy projects in China. Besides, an amortization schedule through the credit line was conducted for the integrated waste-to-energy projects to enable robust financial analysis.

2 Waste-to-energy technologies

Municipal solid waste (MSW) is converted into energy using waste-to-energy (WtE) systems. This provides long-term, ecologically acceptable answers to the current MSW disposal problems (Ahmad et al., 2020). Also, waste-to-energy conversion contributes to the high energy demand. For example, energy generation from wastes provides about 5% of the advanced countries' energy demand (Brunner & Rechberger, 2015). Waste-to-energy is regarded as a renewable energy generation means that can reduce the emission of harmful pollutants. Electricity generation from municipal solid waste can reduce greenhouse gas emissions (such as carbon dioxide, methane, and nitrous oxide) and acid gases (such as sulfur dioxide, nitrogen oxide, and hydrogen chloride). There are several WtE technology options for converting MSW into energy. The popular ones among them are anaerobic digestion (AD), landfill gas to energy (LFGTE), incineration (INC), gasification (GAS), and pyrolysis (PYR). These technologies' efficiency depends on several factors such as technical, economic, environmental, and social factors (Alao et al., 2020). It is argued that to balance energy trilemma problems in waste-to-energy production and ecologically friendly waste management strategies development in the waste chain, energy justice must also be considered one of the factors for an efficient waste-to-energy technology (Fetanat et al., 2019). The following sections briefly discuss some of the most popular waste-to-energy technologies. Table 1 summarizes the advantages and disadvantages of waste-to-energy technologies.

2.1 Anaerobic digestion (AD)

The anaerobic digestion method is one of the most ecologically friendly and effective waste-to-energy systems. Anaerobic digestion is a formidable renewable energy source since it is one of the most appropriate methods for processing an organic portion of MSW (Kumar & Samadder, 2020). The anaerobic digestion process, which produces biogas, occurs in an oxygen-free environment and is initiated by natural microorganisms in a four-stage complex process (Wainaina et al., 2020). The AD facility process situation determines the chemical composition of the virgin biogas derived from the organic fraction of the MSW. The raw biogas primarily consists of 50–75% of methane (CH4), 30–50% of carbon dioxide (CO2), 0–3% of nitrogen (N2), about 6% of water (H2O), 0–1% of oxygen (O2), 72–7200 ppm of hydrogen sulfide (H2S), 72 to 144 ppm of ammonia (NH3), and a small number of impurities (Kapoor et al., 2019). Biogas production is facilitated by the availability and quantity of feedstock such as agricultural waste, animal waste, municipal solid waste, organic landfill waste, food waste, and keratin waste (Atelge et al., 2020). The bio-methane generation can be affected by organic waste composition such as fats and protein. Anaerobic digestion technique could theoretically generate about 1014 nominal liter methane/kg volatile solids from fats, 740 nominal liter methane/kg volatile solids from proteins, and 370 nominal liter methane/kg volatile solids of carbohydrates (Harris & McCabe, 2015). If not properly operated, the anaerobic digestion technique could face high retention time requirements, partially digestible substrates, and low bio-methane production (Passos et al., 2017).

2.2 Landfill gas to energy (LFGTE)

Landfilling is one of the most cost-effective municipal solid waste management methods globally, particularly in developing nations (Cudjoe & Han, 2021). Landfills for MSW disposal lead to greenhouse gas emissions due to landfill gas production (CH4 and CO2) from decomposed organic materials (Friesenhan et al., 2017). However, if properly upgraded, landfill gas produced from MSW landfills could be a suitable energy carrier for electricity production (Ayodele et al., 2020). The main determinant factors for optimal waste-to-energy technology selection for electricity generation are landfill gas quality and its generation rate (Manasaki et al., 2021). Over the years, landfill gas as a bioenergy resource has gained global attention. When creating its guidelines for nations' bioenergy roadmap development and implementation, the International Energy Agency (IEA) identified landfill gas as bioenergy (Fei et al., 2019). During the late twentieth century, landfill gas utilization as a renewable energy resource has massively increased in the USA and European nations. Similarly, landfill gas exploitation has continued to progress steadily in China since the first LFGTE plant's construction in 1998 (Chen et al., 2010).

2.3 Incineration (INC)

Incineration has gained popularity worldwide for treating a combustible fraction of municipal solid waste. This is due to its ability to reduce the volume of waste and generate electricity (Cudjoe & Acquah, 2021). The municipal solid waste is combusted to produce ash, flue gas, and heat for electricity generation during incineration. To completely break down toxic organic substances, the flue gas temperature is set to about 850 \(^\circ{\rm C}\) in the incineration chamber (Escamilla-García et al., 2020). Municipal solid waste incineration could lessen the volume of waste by up to 90%, efficiently produce energy, save the emission of methane gas, and avoid soil and water pollution (Gu et al., 2019). Despite its contributions toward non-recyclable waste management, factors such as high investment, long-term nature of waste-to-energy incineration projects, inadequate management capacity, and public budget constraints make it difficult for local governments to solely invest, construct, and operate, especially in developing countries (Cui et al., 2020). Besides, the pollutants in its flue gases, which are composed of dust and gases such as carbon dioxide (CO2), carbon monoxide (CO), sulfur dioxide (SO2), nitrogen oxide (NOX), hydrogen chloride (HCl), nitrous oxide (N2O), hydrogen fluoride (HF), and dioxins could be harmful to the environment (Mutz et al., 2017).

2.4 Gasification (GAS)

The gasification technique is a substitute for recovering fuel from waste and conserving fossil fuels. Gasification enables sustainable waste management by minimizing carbon dioxide emissions (Liu et al., 2020). The gasification process can be summarized into four significant steps: oxidation, drying, pyrolysis, and reduction. Among these steps, only the oxidation is exothermal, and the energy utilized by the other three is produced by it. The gasification process occurs in the presence of a gasifying agent (air, steam, and oxygen) or a combination of them (Giglio et al., 2021). The process occurs at a temperature above \(>\) 650 \(^\circ{\rm C}\) (Zhang et al., 2019), with a calorific value ranging from 4 to 14 MJ/Nm3 (Hameed et al., 2021). The gasification process could transform high-sulfur petroleum coke into syngas (a mixture of CO and H2) to produce hydrogen and chemical products through synthesis. Compared to incineration or combustion, gasification has tremendous environmental performance. This is because the sulfur intrinsic in the petroleum coke can be transformed into hydrogen sulfide (H2S), which can be retrieved as sulfur (S) by the Claus process (Ba et al., 2020).

2.5 Pyrolysis (PYR)

Pyrolysis is a popular thermochemical technique that serves as an alternative strategy for managing wastes (Zhang et al., 2020a, 2020b) while recovering prudent products (Zeaiter et al., 2018). Chemical recycling through pyrolysis is one option for plastic waste management. This process can convert plastic waste into chemical feedstock, producing raw polymers of good quality (Jeswani et al., 2020). Pyrolysis produces char and volatiles that may be separated downstream into condensable products (oil or wax) and permanent gases at temperatures ranging from 400 to 700 °C without oxygen. The process uses hazardous waste and biomass waste as feedstock to produce gas, char, and pyrolysis oil for energy production (Chew et al., 2021). Relative to incineration, pyrolysis is economical and minimizes the generation of harmful chemicals (Parku et al., 2020).

3 Case study

The study assesses the power production potential, economic viability, and ecological impact of integrated waste-to-energy technologies in the Beijing-Tianjin-Hebei region. This region is considered due to the Chinese government's recent interest in establishing waste-to-energy projects to contribute to the sustainable management of the high amount of waste produced in the region. The Beijing-Tianjin-Hebei region can be found in the central part of the Bohai Sea economic area in the Northern part of China (Yang et al., 2020a, 2020b). The region has a population of 112.7 million people. About 65.8% and 34.2% of the population live in urban and rural areas, respectively (Cudjoe et al., 2021a). The Beijing-Tianjin-Hebei, referred to as the “capital circle,” has 13 cities and 200 counties (Gong et al., 2020). The region (113.5oE-119.8oE and 36.1oN-42.7oN) occupies a total land area of 218 thousand square kilometers. The region contributes 9.44% of China's real GDP (Yang et al., 2020a, 2020b). The total amount of municipal solid waste collected in the region from 2004 to 2018 for disposal was 232.73 Mt. The main municipal solid waste treatment methods in the region are landfilling, incineration, and composting (NBS, 2018). Figure 1 depicts the maps of China and the Beijing-Tianjin-Hebei region.

4 Methodology

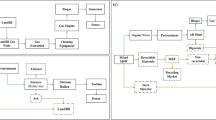

The methodological framework of this study is presented in Fig. 2.

4.1 Allocation of waste composition to the waste-to-energy technologies

Typical municipal solid waste in China is organic waste (food waste), paper, plastic, metal, glass, textile, wood, and inert materials (Cudjoe et al., 2020). Waste-to-energy technologies require a particular municipal solid waste composition for efficient operation and energy generation potential. In this study, food waste is allocated to anaerobic digestion technology. Food waste's high moisture content and composition rate make it a suitable feedstock for anaerobic digestion technology (Ayodele et al., 2018). The mixed waste except recyclables is allocated to the landfill gas to energy technology, while combustible waste is assigned to the incineration technology. The amount of municipal solid waste that can be utilized by each of the waste-to-energy technologies for electricity generation can be obtained as:

where \({\mathrm{MW}}_{(\mathrm{col})}\) is the amount of municipal solid waste collected for disposal in the region from 2004 to 2018 (see Table 8 in the appendix), \({\mathrm{COMP}}_{\left(\mathrm{waste}\right)t}\) is the percentage composition of typical municipal solid waste generated in China, which are given as food (52.6%), paper (6.9%), plastic (7.3%), metal (0.5%), glass (1.6%), textiles (4.7%), wood (6.9%), and inert materials (19.2%) (Cudjoe et al., 2020), and \(t\) is the type of waste-to-energy technology (anaerobic digestion, landfill gas to energy or incineration).

4.2 Electricity generation potential of the integrated waste-to-energy technologies

The integrated WtE technologies considered in this study are the integration of anaerobic digestion and landfill gas to energy technologies (AD/LFGTE), anaerobic digestion and incineration technologies (AD/INC), and incineration and landfill gas to energy technologies (INC/LFGTE). The composition of food waste and mixed waste (except recyclables) was utilized in the AD/LFGTE for electricity generation. The electricity generation potential (kWh/year) of the AD/LFGTE technology could be determined as:

where \({E}_{(\mathrm{AD})}\) is the electricity generation potential (kWh/year) of the anaerobic digestion technology and \({E}_{(\mathrm{LFGTE})}\) is the electricity generation potential (kWh/year) of the landfill gas to energy technology.

The electricity generation potential of the anaerobic digestion technology can be evaluated as:

where \({\mathrm{LHV}}_{(\mathrm{methane})}\) is the lower heating value of methane, which is taken as 37.2 MJ/m3 (Cudjoe et al., 2021b), \({\in }_{(\mathrm{eff})}\) is the electricity generation efficiency of biogas-fired generator and is given as 0.26 (Ogunjuyigbe et al., 2017), \({\mu }_{(\mathrm{cap})}\) is the capacity factor, which is given as 0.85 (Ayodele et al., 2018), \(\beta\) is the conversion factor from MJ to kWh and is taken as 3.6 (Cudjoe et al., 2020), and \({{P}_{\mathrm{bio}}}_{({\mathrm{CH}}_{4})}\) is the purified biogas (bio-methane) obtained via the anaerobic process. The volume of theoretical methane should be known to calculate the actual bio-methane. Buswell’s equation (Eq. 3 and 4) was used to calculate the digester's theoretical bio-methane production potential.

The normalized mole ratio equation (Ayodele et al., 2019) was used to determine the constants d, e, f, and g.

where \(\mathrm{EL}\) is the composition of carbon, hydrogen, oxygen, and nitrogen, which is obtained from the ultimate analysis of food waste in China (see Table 9), \(\mathrm{ML}\) is the molar mass (oxygen = 16.00, carbon = 12.01, nitrogen = 14.01, hydrogen = 1.01, and sulfur = 32.06) of the elements (Ogunjuyigbe et al., 2017), and \(k\) is the mole ratio of nitrogen.

At a standard temperature of 0 \(^\circ{\rm C}\) and pressure of 1 atm, the theoretical methane (m3/t) and carbon dioxide (m3/t) can be evaluated using Eq. (6)-(7):

The theoretical volume of biogas can be calculated as:

Practically, a portion (about 10%) of the digester's organic matter does not decompose (Cudjoe et al., 2022b). Besides, about 5–10% of the organic matter in the waste stream is used to synthesize the cell tissue of the organism that influences microbial degradation (Ayodele et al., 2019). The raw biogas yield should be purified to obtain methane (bio-methane) for electricity generation. Following Ayodele et al. (2018), it is assumed that the theoretical biogas after purification is upgraded to 70% of methane and 30% of carbon dioxide. Therefore, the purified biogas (bio-methane) yield can be estimated as:

where \({\mathrm{TBio}}_{(\mathrm{volume})}\) is the volume of the theoretical biogas, \({\mathrm{SW}}_{\left(\mathrm{AD}\right)}\) is the amount of waste (food waste) utilized in the anaerobic digestion technology, and \(0.85\) is the fraction of organic matter utilized for cell tissue synthesis (Salami & Susu, 2011).

The electricity prospects of the landfill gas to energy technology can be obtained as:

where \({A}_{{(\mathrm{CH}}_{4})}\) is the volume (m3/year) of landfill gas (methane) captured from the landfills, \(xf\) is the oxidation factor of the landfill and is taken as 10% (IPCC, 2006), and \(\in\) is the electricity generation efficiency of the conversion device, which is taken as 35% (Ayodele et al., 2018). The volume of landfill gas (methane) that can be produced annually from the landfills was calculated using the Landfill Gas Emission Model (LandGEM) software version 3.02 (US EPA, 2005):

where \(i\) is the 1-year time increment, \(y\) is the (year of the calculation) -(initial year of waste acceptance), \(j\) is the 0.1-year time increment, \(k\) is the methane generation rate (y−1), \({\mathrm{L}}_{\mathrm{O}}\) is the potential methane generation capacity (m3/t),\({\mathrm{SW}}_{(\mathrm{LFGTE})}\) is the amount of waste that was utilized in the landfill gas to energy technology, \({t}_{ij}\) is the age of the jth section of waste in year \(i\), and \(\pi\) is the landfill methane collection efficiency, which is assumed to be 75%, following Cudjoe et al. (2021a).

To ascertain the electricity generation potentials of integrating anaerobic digestion and incineration technologies (AD/INC), the food waste and the combustible fraction in the waste stream of the Beijing-Tianjin-Hebei region were utilized. The electricity generation prospects (kWh/year) of the integrated technologies could be determined as:

where \({E}_{(INC)}\) is the electricity generation potential of the incineration technology and is obtained as:

where \({\mathrm{SW}}_{\left(\mathrm{INC}\right)}\) is the amount of combustible waste (t/year) utilized in the incineration technology, \(\tau\) is the electrical efficiency of the steam turbine and is taken as 29% (Cudjoe et al., 2022a; Ogunjuyigbe et al., 2017), \({\mathrm{INC}}_{(\mathrm{LHV})}\) is the lower heating value of the waste incinerated, \({\mathrm{INC}}_{(\mathrm{HHV})}\) is the higher heating value of the waste incinerated, \(\%H\) is the weight percentage of atomic hydrogen, \({\%H}_{2}O\) is the weight percentage of atomic water, and \(C\),\(H\), \(S\), \(O\), \(N\), and \(A\) stand for carbon, hydrogen, sulfur, oxygen, nitrogen, and ash content obtained from the ultimate analysis of municipal solid waste generated in China.

The electricity generation potential of integration of incineration and landfill gas to energy technologies (INC/LFGTE) was estimated as:

The estimated electricity needs by the Beijing-Tianjin-Hebei region and the percentage contribution of electricity generation from the integrated waste-to-energy projects to the needs were determined using Eq. (17) and (18):

where \({E}_{(c)}\) and \(\mathrm{Pop}\) are the per capita electricity consumption in China and the population of the Beijing-Tianjin-Hebei region from 2004 to 2018 (see Table 10), and \(\Delta\) is the percentage contribution of energy from the integrated waste-to-energy projects.

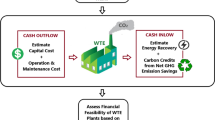

4.3 Economic feasibility and investment analysis

4.3.1 Initial investment cost (IIC)

The initial investment cost of the integrated anaerobic digestion and landfill gas to energy (AD/LFGTE) can be calculated as:

where \({\mathrm{IN}}_{(\mathrm{AD})\mathrm{cost}}\) is the initial investment cost of the anaerobic digestion project, \({\mathrm{IN}}_{\left(\mathrm{LFGTE}\right)\mathrm{cost}}\) is the initial investment cost of the landfill gas to energy project, \({\mathrm{PL}}_{(\mathrm{cost})}\) is the anaerobic digestion plant’s equipment and installation cost per kW, which is taken as US$4,339 (Cudjoe et al., 2021b), \({\mathrm{AD}}_{(\mathrm{size})}\) is the size of the anaerobic digestion plant in kilowatt (kW), \({V}_{(\mathrm{cost})}\) is the capital cost of the installed vertical gas extraction wells, \({W}_{(\mathrm{cost})}\) is the cost of fixing wellheads and pipes gathering, \({K}_{(\mathrm{cost})}\) is the cost of installation of a blower, flare system, and knockout, \({G}_{(\mathrm{cost})}\) is the permitting, surveying, and engineering cost, \({IE}_{(\mathrm{cost})}\) is the cost of installation of the landfill gas to energy’s internal combustion engine, \(Xft\) is the well’s depth, \(h\) is the number of wells dug at the site, \({M}_{(\mathrm{flow})}\) is the rate at which the landfill methane flow, and \({\mathrm{LFGTE}}_{\left(\mathrm{size}\right)}\) is the size of the internal combustion engine in kilowatt (kW).

The initial investment cost of the hybrid of anaerobic digestion and incineration technology is determined as:

where 4,900 Euro is the specific cost of the incineration plant (Tsilemou & Panagiotakopoulos, 2006) \({\mathrm{IN}}_{\left(\mathrm{INC}\right)\mathrm{cost}}\) is the initial investment cost of the incineration project, \({\mathrm{Con}}_{\left(\mathrm{rate}\right)}\) is the conversion rate from Euro to US$, \({\mathrm{In}}_{\left(\mathrm{rate}\right)}\) is the inflation rate (CPI), and \(\rho\) is the purchasing power parity (PPP) adjustment from Euro to US$.

Similarly, the initial investment cost of the integration of incineration and landfill gas to energy project was estimated as:

4.3.2 Operations & maintenance cost (OMC)

The operations & maintenance cost of the hybrid of anaerobic digestion and landfill gas to energy projects (AD/LFGTE) can be ascertained as:

where \({\mathrm{AD}}_{(\mathrm{O}\&\mathrm{M})}\) and \({\mathrm{LFGTE}}_{(\mathrm{O}\&\mathrm{M})}\) are the operations & maintenance costs of anaerobic digestion and landfill gas to energy projects. The factor, \(0.005\), is the assumed percentage (0.5%) of the energy generated (Hadidi & Omer, 2017), while \(0.03\) is the percentage (3%) of the assumed capital cost (Ayodele et al., 2018). \({\mathrm{LFS}}_{(\mathrm{O}\&\mathrm{M})}\) is the operations and maintenance cost of operating the landfill site, and \({\mathrm{LIN}}_{(\mathrm{O}\&\mathrm{M})}\) is the cost of operating and maintaining the internal combustion engine.

The operations and maintenance cost of the integration of anaerobic digestion and incineration (AD/INC) can be evaluated as:

where \({\mathrm{INC}}_{(\mathrm{O}\&\mathrm{M})}\) is the operations & maintenance cost of the incineration plant.

The operations & maintenance cost of the integrated incineration and landfill gas to energy project (INC/LFGTE) is calculated as:

4.3.3 Net present value (NPV)

NPV of a project is the sum of the discounted cash flows incurred during the project's lifetime (Creemers, 2018). The NPV enables cost–benefit analysis by comparing different aspects of benefits and costs among several projects. It utilizes discounting to compute the present values of future net benefits. This ensures that the net benefits that appear at different levels within a period become comparable (Knoke et al., 2020). For a project to be economically viable, its net present value should be positive. The NPV of the integrated waste-to-energy projects was calculated as:

where \({\mathrm{H}}_{\mathrm{n}}\) is the net cash flow, \({\mathrm{Rev}}_{(\mathrm{InT})}\) is the revenue gained from the projects, \(\mathrm{r}\) is the annual real discount rate, \({\mathrm{T}}_{(\mathrm{InT})}\) is tax paid on the project, \(\mathrm{FIT}\) is the feed-in tariff, which is taken as US$0.12/kWh (Winston & Strawn, 2014), \({\mathrm{T}}_{(\mathrm{rate})}\) is the marginal tax rate, which is taken from World Bank Group (2019), \({\mathrm{PF}}_{(\mathrm{InT})}\) is the profit from the integrated project, \({N}_{(\mathrm{rate})}\) is the inflation rate taken from World Bank Group (2019), and \(p\) is the economic period (15 years) of the project, \(\mathrm{InT}\) is the integrated project, which could be AD/LFGTE, AD/INC or INC/LFGTE, and \(\mathrm{\alpha }\) is the nominal discount rate and is given as 10% (IRENA, 2012).

4.3.4 Levelized cost of energy (LCOE)

LCOE depicts the lowest cost at which the power generated should be sold to achieve break-even over the project life cycle (Berrada & Loudiyi, 2019). LCOE is regarded as a cost indicator that compares energy storage systems with different characteristics on a comparable basis. The LCOE of the hybrid waste-to-energy systems in this study was estimated as:

where \({\mathrm{TLCC}}_{(\mathrm{InT})}\) and \({\upchi }_{(\mathrm{InT})}\) are the total life cycle cost and the capital recovery factor (CRF) of the integrated waste-to-energy systems.

4.3.5 Investment payback period (IPP)

The investment payback period is when the investment in the project begins to yield returns. This is also an essential economic indicator that can ascertain the viability of waste-to-energy projects. The discounted investment payback period of the integrated waste-to-energy projects was calculated as:

4.3.6 Amortization system

Amortization refers to the process of paying off a debt over a period in equal installments. The loan payment goes to different areas (principal and interest). An amortization system through the credit lines was simulated for a robust integrated waste-to-energy project investment analysis. Using the excel sheet, an amortization table was scheduled. The table lists each monthly loan payment and how much goes into interest and principal.

4.4 Environmental benefits of the integrated waste-to-energy technologies

4.4.1 Amount of coal consumption saved

Electricity generation from the various municipal solid waste components using integrated waste-to-energy technologies could significantly save a considerable amount of coal consumption. The amount of coal saved due to power generation from integrated waste-to-energy technologies can be evaluated as:

where \(\varphi\) is the density of coal and is given as 1100–1800 kg/m3 (The Engineering ToolBox, 2021), \({\gamma }_{(\mathrm{ef})}\) is the efficiency of the coal power plant in China and is taken as 38.4% (NS Energy, 2019), and \({\mathrm{LHV}}_{(\mathrm{coal})}\) is the lower heating value of coal and is taken as 25.86 MJ/kg (Claverton-energy, 2011).

4.4.2 The amount of greenhouse gas (GHG) emissions saved

In this study, only CO2, CH4, and N2O emissions were considered. This is because of the significant contributions of these GHGs to global warming. Therefore, the emission of GHG emissions avoided due to electricity generation from integrated waste-to-energy technologies are estimated as:

where \({\mathrm{EF}}_{(\mathrm{pol})}\) is the emission factor of coal for the GHGs considered in this study, which is given as 1.88 kg for CO2 (Ministry for the Environment, 2015), 0.258 kg for CH4, and 0.0387 kg for N2O (IPCC, 2006), \(\mathrm{pol}\) is the pollutant of calculation (CO2, CH4 or N2O), and \({\mathrm{CS}}_{(\mathrm{InT})}\) is the amount of coal saved by each of the integrated waste-to-energy technologies.

5 Results and discussion

5.1 The amount of MSW utilized and the electricity generation potential of IWtE

The analysis of the quantity of municipal solid waste allocation to the integrated waste-to-energy technologies is presented in Fig. 3. The figure shows that the highest amount of waste (271.83 Mt) was utilized in the AD/LFGTE. Following the AD/LFGTE was INC/LFGTE with 214.34 Mt, while the lowest 187.35 Mt was utilized in the AD/INC. The highest amount of waste for the AD/LFGTE could be attributed to the increased food waste composition in the region's waste stream. Besides, the composition of all wastes except recyclables, inert materials, and food waste were disposed of in the landfills for AD/LFGTE. This was the same scenario for INC/LFGTE (all wastes except recyclables, inert materials, and combustibles). A careful observation of Fig. 3 shows that the amount of waste allocated to the integrated waste-to-energy technologies for power generation annually experienced fluctuations during the project period. For instance, compared to 2004, the amount of waste utilized in the IWtE decreased from 2005 to 2006. Also, relative to 2009, the amount of MSW decreased from 2010 to 2013. The reduction in the amount of waste in those years could be attributed to the region’s poor economic performance during those years. This is consistent with Ayodele et al. (2017) findings that the poor economic development in some locations in Nigeria contributed to generating less MSW. Besides, a decrease in the region's waste collection rate during those years significantly impacted the decline of the amount of MSW allocated to the IWtE. This agrees with Cudjoe et al. (2020), who found that an increase in waste collection rate contributed massively to the amount of MSW utilized in anaerobic digestion and landfill gas to energy technologies for electricity generation in China’s provinces.

Table 2 lists the findings of the electricity generation potential of the integrated waste-to-energy technologies in the Beijing-Tianjin-Hebei region. It can be seen from Table 2 that AD/LFGTE had the highest total electricity generation potential in the region during the period. The AD/LFGTE demonstrated the highest electricity production potential because of the AD technology’s high bio-methane yield from highly degradable food waste. Besides, the quantity of the mixed waste utilized in the LFGTE technology had a high food waste composition, which yielded a high volume of landfill gas (methane) after decomposition for power generation. Compared to the AD/LFGTE, the AD/INC had less power generation potential. This is because the composition of combustible waste in China’s waste stream is less, resulting in lower waste in the INC technology for power generation. This finding is inconsistent with Ayodele et al. (2017) study, which found that the hybrid of anaerobic digestion and incineration (AD/INC) had the highest electricity generation potential in Nigeria. Similarly, our finding disagrees with Abdallah and Elfeky (2021), whose life cycle assessment discovered integrating anaerobic digestion and incineration (AD/INC) is the highest electricity generator. The finding also conflicts with Tan et al. (2015) finding that AD and INC are the two potential technologies in terms of power generation in Malaysia. The differences in this study’s findings and existing literature could be attributed to the composition of municipal solid waste discarded in landfills. The high proportion of nondegradable waste such as plastic in landfills only occupies space in the landfill and hinders methane generation. As an agricultural country, China produces a lot of food waste, and the larger portion is discarded in landfills. Therefore, this study assumed that the same amount of food waste utilized in the AD technology could be used in LFGTE technology. The high amount of food waste in the LFGTE contributed to high landfill gas. The landfill gas primarily has the same chemical reaction as anaerobic digestion and uses the same conversion technology (internal conversion engine), resulting in high power generation. The total electricity generation potential of AD/LFGTE during the period was 147,935.08 GWh, and that of AD/INC and INC/LFGTE was 134,586.01 GWh and 13,588.09 GWh, respectively. The findings further show that according to the region’s total electricity needs (695,764.12 GWh) from 2004 to 2018, AD/LFGTE could contribute 24.52% on average, while AD/INC and INC/LFGTE could contribute 22.68% and 1.88%, respectively. This indicates that the AD/LFGTE can highly contribute to the region's energy needs than AD/INC and INC/LFGTE. The lesson learned here is that when the organic composition of municipal solid waste in the region is high, the hybrid of AD/LFGTE technology could be used. However, if there is high nondegradable or combustible waste, such as plastics and paper with a considerable amount of degradable content, the hybrid of AD/INC could be utilized.

5.2 Economic feasibility and investment analysis

The findings of the economic analysis of the integrated waste-to-energy projects are presented in Table 3. It could be seen from Table 3 that all the IWtE projects in the region have positive net present value. This indicates that all the integrated projects are feasible during the period. According to the National Renewable Energy Laboratory (2011), a project is considered economically viable when its net present value is positive. The AD/LFGTE project proved more economically feasible in the region. This is because compared to the AD/INC and INC/LFGTE, the AD/LFGTE has a higher net present value, a lower initial investment cost, a less levelized cost of energy, a payback period, and higher profit on the investment. Compared to the other IWtE projects considered in this study, INC/LFGTE is less economical. Even though it has the lowest investment and operations & maintenance cost, its net present value and profit on the investment are very low. Besides, the INC/LFGTE project presents the highest levelized cost of energy and investment payback period. The lower levelized cost of energy, shorter investment payback period, and the high profit on investment displayed by the AD/LFGTE could be attributed to the high electricity generation potential of the project in the region. The low profit on an investment and the high levelized cost of energy and investment payback period recorded by the INC/LFGTE and AD/INC are because of the lower electricity generation potential of INC in the region and the capital-intensive nature of the INC project. This is in line with the study by Ogunjuyigbe et al. (2017), which found that compared to anaerobic digestion (AD) and landfill gas to energy projects (LFGTE), incineration (INC) was more capital intensive, and that made it not economical for electricity generation in Nigeria. This also confirms the findings of Cui et al. (2020), which stated that factors such as high initial investment costs have made it difficult for local governments in developing countries to solely invest, construct, and operate incineration projects.

The payment function was used to compute the monthly payment on a loan with an annual interest rate of 4.35% (World Bank Group, 2019). The projects have 180 periods (i.e., 15 years). The amount borrowed for the AD/LFGTE project was US$477,310,000, that for the AD/INC project was US$647,720,000, and US$194,510,000 for the INC/LFGTE project. The results of the amortization schedule for the IWtE projects in the Beijing-Tianjin-Hebei are listed in Table 4 (AD/LFGTE project), Table 5(AD/INC project), and Table 6 (INC/LFGTE project). The findings indicate that the AD/INC project requires a high loan amount, and a lot of interest is paid on loan compared to the AD/LFGTE and INC/LFGTE projects. This is because the AD/INC project is more capital intensive and requires a high amount for the initial investment. Table 4 shows that a total amount of US$173,372,856 was paid as interest on the amount borrowed for the AD/LFGTE project in the region. It could be seen from Table 5 that the amount of interest paid on loan for the AD/INC project during the period was US$235,270,718. Besides, it can be realized from Table 6 that the total interest paid on the amount borrowed for the INC/LFGTE project was US$70,651,682.

5.3 Environmental benefits of the integrated waste-to-energy technologies

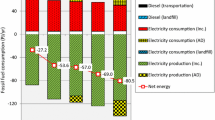

This section of the study presents and discusses the amount of coal saved due to electricity generation from municipal solid waste via integrated waste-to-energy technologies. The section also presents and discusses the amount of greenhouse gas emissions avoided due to electricity generation from integrated waste-to-energy technologies. The amount of coal consumption saved is depicted in Table 7. The Table shows that electricity generation from municipal solid waste using AD/LFGTE technology avoided the region's highest total coal consumption (8,699.37 Mt). Following the AD/LFGTE was the AD/INC, with a total of 7,914.40 Mt coal consumption saved, while the lowest amount of coal consumption (799.02 Mt) was saved by the INC/LFGTE technology. The highest coal consumption saving capability of the AD/LFGTE technology was because much electricity was generated from the technology. This reduced the combustion of a huge amount of coal for electricity generation in the region during the project period. The annual coal consumption savings by the AD/LFGTE technology range from 451.23 to 765.13 Mt/year, while that of the AD/INC and INC/LFGTE technologies range from 435.29 to 688.98 Mt/year and 8.80 to 85.40 Mt/year. A critical observation of Table 7 shows that the annual coal consumption saving by the IWtE technologies experienced some level of variation during the project period. The decline in the amount of coal consumption saved during certain periods was because of the drop in electricity generation potential by the IWtE technologies resulting from lower amounts of municipal solid waste allocation.

The amount of some essential greenhouse gas (GHG) emissions avoided due to electricity generation using the integrated waste-to-energy projects in the region were evaluated. The GHGs considered are carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O). The results are presented in Fig. 4 (for CO2), Fig. 5(for CH4), and Fig. 6 (for N2O). Figure 4 shows that the total CO2 emissions avoided by the AD/LFGTE, AD/INC, and INC/LFGTE during the project period were 16,354.81 Mt, 14,879.07 Mt, and 1,502.16 Mt, respectively. From Fig. 5, it could be seen that the total annual CH4 emissions avoided by the AD/LFGTE from 2004 to 2018 were 2,244.44 Mt, while that of AD/INC and INC/LFGTE were 2,041.92 Mt and 206.15 Mt. In Fig. 6, it can be observed that the INC/LFGTE avoided the lowest N2O emission (30.92 million kg), while the highest (336.67 million kg) was avoided by the AD/LFGTE. Following the AD/LFGTE is the AD/INC, which avoided N2O emissions of 306.29 million kg. It can be realized that the AD/LFGTE and AD/INC avoided the highest GHG emissions. This is due to the contribution of the anaerobic digestion technology (AD), a known contributor to reducing GHG emissions. This is consistent with Ayodele et al. (2018) study, which found that compared to landfill gas to energy technology (LFGTE), AD was the best technology in terms of GHG emission reduction in Nigeria. This also confirms the findings of Cudjoe et al. (2020) that AD performed better in reducing global warming in provinces of China than landfill gas to energy. Compared to AD/INC, the AD/LFGTE avoided a higher amount of GHGs emissions. This is because the amount of waste disposed of in the landfills had a high composition of the degradable waste (food waste), resulting in a high amount of landfill gas for power generation. This increased the GHGs emission avoidance strength of the LFGTE. This finding is inconsistent with Ayodele et al. (2017) study, which found the hybrid of anaerobic digestion and incineration (AD/INC) as potentially viable in terms of global warming reduction than other integrated systems.

6 Conclusions and policy recommendations

6.1 Conclusions

The present study assessed the electricity generation potential of municipal solid waste generated in China's Beijing-Tianjin-Hebei region from 2004 to 2018 using integrated waste-to-energy technologies. The results show that the total amount of municipal solid waste utilized in the AD/LFGTE during the project period was 271.83 Mt, while that of INC/LFGTE was 214.34 Mt and AD/INC was 187.35 Mt. Compared to the other integrated waste-to-energy systems in this study, AD/LFGTE had the highest electricity generation potential from the region's municipal solid waste. From 2004 to 2018, it was realized that the electricity needs of the Beijing-Tianjin-Hebei region was 695,764.12 GWh. The AD/LFGTE had the highest contribution of 24.52% to the region’s electricity needs, while AD/INC and INC/LFGTE contributed 22.68% and 1.88%, respectively.

The economic analysis showed that all the integrated waste-to-energy projects are feasible in the region. This is because they all presented a positive net present value during the period. The AD/LFGTE was more economical than AD/INC and INC/LFGTE. This is because AD/LFGTE project had the highest net present value, lowest levelized cost of energy (US$0.0915/kWh), a shorter investment payback period (9.1 years), and a higher profit (US$1,331.19 million) on investment. Compared to AD/LFGTE and INC/LFGTE projects, the amortization schedule showed that AD/INC was more capital intensive. This is because it required a higher loan amount and higher interest payment on the amount borrowed. It was evident from the environmental analysis that a considerable amount of coal consumption and greenhouse gas (CO2, CH4, and N2O) emissions could be avoided by using integrated waste-to-energy technologies for electricity generation in the region.

6.2 Policy recommendations

It is evident from the findings that using integrated waste-to-energy technologies, especially AD/LFGTE and AD/INC for power generation, can contribute to solid waste management, clean energy, and climate change mitigation in the region. The environmental benefits and economic advantages of the AD/LFGTE hybrid technology over the others are proportional to its electricity generation capacity. Therefore, it is recommended that the waste collection rates be improved in all the cities across the region through adequate and appropriate waste collection facilities. All the provinces and cities in the region should establish a sound institutional framework to ensure that the wastes generated are collected and disposed of as expected. Private waste collectors should be encouraged by empowering public financial institutions to support them through flexible loans. This should be accompanied by constant monitoring and evaluation to ensure professionalism and efficiency.

It was found from the study that integrated waste-to-energy technologies demand a specific type of wastes to be able to generate electricity efficiently. This means that improper waste sorting behavior in the region may minimize their electricity generation efficiency. It is recommended that policymakers at both the provincial and city level in the region adequately promote the residents’ awareness of waste sorting benefits to ensure that waste sorting has become a widely accepted behavior among residents. The appropriate waste sorting facilities should be provided by authorities to enable easy waste sorting among residents. Policymakers should consider the generation gaps in the region, which could be an obstacle to waste sorting. The elderly must be able to participate in waste sorting with little or no difficulties. The provincial and city government in the region should implement stringent punishment policies for residents who violate waste sorting laws.

It was realized from the study that the integrated waste-to-energy project may confront some economic obstacles such as high investment and/or operations & maintenance costs. More political intent and financial assistance will ensure the projects grow before realizing vital technological breakthroughs and cost reductions. Given the region’s current social and economic situation, a solid investment framework is proposed to be established. The region’s provincial and city governments should establish a high-level strategy roadmap for developing integrated waste-to-energy projects, particularly according to their geographical, economic, and commercial advantages. This should fit with the overall decarbonization strategy and tie China’s National Determined Contributions (NDCs) in line with climate actions. Investment in the projects should be encouraged at the provincial and city level through incentives such as subsidies, tax holidays, and carbon credits.

Data availability

All data generated or analyzed during this study are included in this article [and its supplementary information files].

Abbreviations

- \(A_{{({\text{CH}}_{{4}} )}}\) :

-

Volume of landfill gas (methane) captured from the landfills (m3/year)

- \({\rm{AD}_{( {O} \& {M})}}\) :

-

Operations & maintenance costs of anaerobic digestion project

- \({\text{AD}}_{{\left( {{\text{size}}} \right)}}\) :

-

Size of the anaerobic digestion plant in kilowatt (kW)

- CH4 :

-

Methane

- CO2 :

-

Carbon dioxide

- \({\text{COMP}}_{{\left( {{\text{waste}}} \right)t}}\) :

-

Composition of typical municipal solid waste generated in China (%)

- \({\text{CS}}_{{\left( {{\text{InT}}} \right)}}\) :

-

Amount of coal saved by each of the integrated technologies (t/year)

- \(E_{{\left( {{\text{AD}}} \right)}}\) :

-

Electricity generation potential of the anaerobic digestion technology(kWh/year)

- \({\text{EF}}_{{\left( {{\text{pol}}} \right)}}\) :

-

Emission factor of coal for the GHGs

- \(E_{{\left( {{\text{LFGTE}}} \right)}}\) :

-

Electricity generation potential of the landfill gas to energy technology(kWh/year)

- \(E_{{\left( {{\text{INC}}} \right)}}\) :

-

Electricity generation potential of the incineration technology (kWh/year)

- \({\text{FIT}}\) :

-

Feed-in tariff (US$/kWh)

- \(G_{{\left( {{\text{cost}}} \right)}}\) :

-

Permitting, surveying, and engineering cost

- \(h\) :

-

Number of wells dug at the site

- \({\text{H}}_{{\text{n}}}\) :

-

Net cash flow

- H2S:

-

Hydrogen sulfide

- \(IE_{{\left( {{\text{cost}}} \right)}}\) :

-

Cost of installation of the landfill gas to energy’s internal combustion engine

- \({\text{IN}}_{{\left( {{\text{LFGTE}}} \right){\text{cost}}}}\) :

-

Initial investment cost of the landfill gas to energy project

- \({\text{IN}}_{{\left( {{\text{INC}}} \right){\text{cost}}}}\) :

-

Initial investment cost of the incineration project

- \({\text{InT}}\) :

-

The integrated project

- \(k\) :

-

Mole ratio of nitrogen

- \(K_{{\left( {{\text{cost}}} \right)}}\) :

-

Cost of installation of a blower, flare system, and knockout

- \(L_{O}\) :

-

Potential methane generation capacity (m3/t)

- \({\rm{LFGTE}}_{\rm{( {{{O\& M}}} )}} {\multimap }\) :

-

Operations & maintenance costs of landfill gas to energy project

- \({\text{LFGTE}}_{{\left( {{\text{size}}} \right)}}\) :

-

Size of the internal combustion engine in kilowatt (kW)

- \({\text{LHV}}_{{\left( {{\text{methane}}} \right)}}\) :

-

Lower heating value of methane (MJ/m3)

- \(M_{{\left( {{\text{flow}}} \right)}}\) :

-

Rate at which the landfill methane flow

- \({\text{MW}}_{{\left( {{\text{col}}} \right)}}\) :

-

Amount of municipal solid waste collected (t/year)

- \(N_{{\left( {{\text{rate}}} \right)}}\) :

-

Inflation rate (%)

- NH3 :

-

Ammonia

- \(p\) :

-

Economic period (years)

- \({\rm{P}}_{{\rm{bio}} {({\rm{CH}}_{4})}}\) :

-

Purified biogas (bio-methane) obtained via the anaerobic process (m3/year)

- \({\text{PF}}_{{\left( {{\text{InT}}} \right)}}\) :

-

Profit from the integrated project

- \({\text{PL}}_{{\left( {{\text{cost}}} \right)}}\) :

-

Actual cost of the anaerobic digestion plant

- \({\text{pol}}\) :

-

Pollutant of calculation

- \(r\) :

-

Annual real discount rate (%)

- \({\text{Rev}}_{{\left( {{\text{InT}}} \right)}}\) :

-

Revenue gained from the projects

- \({\text{SW}}_{{\left( {{\text{AD}}} \right)}}\) :

-

Amount of food waste utilized in the anaerobic digestion technology (t/year)

- \({\text{SW}}_{{\left( {{\text{LFGTE}}} \right)}}\) :

-

Amount of waste that was used in the landfill gas to energy technology (t/year)

- \({\text{SW}}_{{\left( {{\text{INC}}} \right)}}\) :

-

Amount of combustible waste utilized in the incineration technology(t/year)

- \(t\) :

-

Type of waste-to-energy technology

- \({\text{T}}_{{\left( {{\text{InT}}} \right)}}\) :

-

Tax paid on the project

- \({\text{T}}_{{\left( {{\text{rate}}} \right)}}\) :

-

Marginal tax rate (%)

- \({\text{TBio}}_{{\left( {{\text{volume}}} \right)}}\) :

-

Volume of the theoretical biogas (m3/year)

- \({\text{TLCC}}_{{\left( {{\text{InT}}} \right)}}\) :

-

Total life cycle cost

- \(V_{{\left( {{\text{cost}}} \right)}}\) :

-

Capital cost of the installed vertical gas extraction wells

- \(W_{{\left( {{\text{cost}}} \right)}}\) :

-

Cost of fixing wellheads and pipes gathering

- \(xf\) :

-

Oxidation factor of the landfill (%)

- \(Xft\) :

-

Well’s depth

- \(\in_{{\left( {{\text{eff}}} \right)}}\) :

-

Electricity generation efficiency of biogas-fired generator (%)

- \({\upchi }_{{\left( {{\text{InT}}} \right)}}\) :

-

Capital recovery factor (CRF)

- \(\gamma_{{\left( {{\text{ef}}} \right)}}\) :

-

Efficiency of the coal power plant (%)

- \(\mu_{{\left( {{\text{cap}}} \right)}}\) :

-

Capacity factor (%)

- \(\in\) :

-

Electricity generation efficiency of the conversion device (%)

- \(\alpha\) :

-

Nominal discount rate (%)

- \(\beta\) :

-

Conversion factor from MJ to kWh

- \(\pi\) :

-

Landfill methane collection efficiency (%)

- \(\tau\) :

-

Electrical efficiency of the steam turbine (%)

- \(\varphi\) :

-

Density of coal (kg/m3)

- AD:

-

Anaerobic digestion technology

- BMT:

-

Biological and mechanical treatment

- GHGs:

-

Greenhouse gases

- HSWM:

-

Hybrid solid waste management

- IEA:

-

International energy agency

- INC:

-

Incineration technology

- IPP:

-

Investment payback period

- IWtE:

-

Integrated waste-to-energy technologies

- LCOE:

-

Levelized cost of energy

- LFGTE:

-

Landfill gas to energy technology

- MSW:

-

Municipal solid waste

- NPV:

-

Net present value

- OMC:

-

Operations & maintenance cost

- WtE:

-

Waste-to-energy

References

Abdallah, M., & Elfeky, A. (2021). Impact of waste processing byproducts on the carbon footprint of integrated waste-to-energy strategies. Journal of Environmental Management, 280, 111839. https://doi.org/10.1016/j.jenvman.2020.111839

Ahmad, S. I., Ho, W. S., Hassim, M. H., Elagroudy, S., Kohar, R. A. A., Bong, C. P. C., Hashim, H., & Rashid, R. (2020). Development of quantitative SHE index for waste to energy technology selection. Energy, 191, 116534. https://doi.org/10.1016/j.energy.2019.116534

Alao, M. A., Ayodele, T. R., Ogunjuyigbe, A. S. O., & Popoola, O. M. (2020). Multi-criteria decision based waste to energy technology selection using entropy-weighted TOPSIS technique: The case study of Lagos Nigeria. Energy, 201, 117675. https://doi.org/10.1016/j.energy.2020.117675

Atelge, M. R., Atabani, A. E., Banu, J. R., Krisa, D., Kaya, M., Eskicioglu, C., et al. (2020). A critical review of pretreatment technologies to enhance anaerobic digestion and energy recovery. Fuel, 270, 117494. https://doi.org/10.1016/j.fuel.2020.117494

Ayodele, T. R., Alao, M. A., & Ogunjuyigbe, A. S. O. (2020). Effect of collection efficiency and oxidation factor on greenhouse gas emission and life cycle cost of landfill distributed energy generation. Sustainable Cities and Society, 52, 101821. https://doi.org/10.1016/j.scs.2019.101821

Ayodele, T. R., Alao, M. A., Ogunjuyigbe, A. S. O., & Munda, J. L. (2019). Electricity generation prospective of hydrogen derived from biogas using food waste in South-western Nigeria. Biomass and Bioenergy, 127, 105291. https://doi.org/10.1016/j.biombioe.2019.105291

Ayodele, T. R., Ogunjuyigbe, A. S. O., & Alao, M. A. (2017). Life cycle assessment of waste-to-energy (WtE) technologies for electricity generation using municipal solid waste in Nigeria. Applied Energy, 201, 200–218. https://doi.org/10.1016/j.apenergy.2017.05.097

Ayodele, T. R., Ogunjuyigbe, A. S. O., & Alao, M. A. (2018). Economic and environmental assessment of electricity generation using biogas from organic fraction of municipal solid waste for the city of Ibadan Nigeria. Journal of Cleaner Production, 203, 718–735. https://doi.org/10.1016/j.jclepro.2018.08.282

Ba, Z., Zhao, J., Li, C., Huang, J., Fang, Y., Zhang, L., Kong, L., & Wang, Q. (2020). Developing efficient gasification technology for high-sulfur petroleum coke to hydrogen-rich syngas production. Fuel, 267, 117170. https://doi.org/10.1016/j.fuel.2020.117170

Berrada, A., & Loudiyi, K. (2019). Economic evaluation and risk analysis of gravity energy storage. Gravity Energy Storage. https://doi.org/10.1016/B978-0-12-816717-5.00003-7

Brunner, P. H., & Rechberger, H. (2015). Waste to energy–key element for sustainable waste management. Waste Management, 37, 3–12. https://doi.org/10.1016/j.wasman.2014.02.003

Chakraborty, M., Sharma, C., Pandey, J., & Gupta, K. P. (2013). Assessment of energy generation potentials of MSW in Delhi under different technological options. Energy Conversion and Management, 75, 249–255. https://doi.org/10.1016/j.enconman.2013.06.027

Chen, H., Zhang, M., Xue, K., Xu, G., Yang, Y., Wang, Z., Liu, W., & Liu, T. (2020). An innovative waste-to-energy system integrated with a coal-fired power plant. Energy, 194, 116893. https://doi.org/10.1016/j.energy.2019.116893

Chen, Z., Gong, H., Jiang, R., Jiang, Q., & Wu, W. (2010). Overview on LFG projects in China. Waste Management, 30, 1006–1010. https://doi.org/10.1016/j.wasman.2010.02.001

Cheng, J., Shi, F., Yi, J., & Fu, H. (2020). Analysis of the factors that affect the production of municipal solid waste in China. Journal of Cleaner Production, 259, 120808. https://doi.org/10.1016/j.jclepro.2020.120808

Chew, K. W., Chia, S. R., Chia, W. Y., Cheah, W. Y., Munawaroh, H. S. H., & Ong, W.-J. (2021). Abatement of hazardous materials and biomass waste via pyrolysis and co-pyrolysis for environmental sustainability and circular economy. Environmental Pollution, 278, 116836. https://doi.org/10.1016/j.envpol.2021.116836

China’s National Bureau of Statistics. (2018). 2017 China Statistical Yearbook (in Chinese).

Claverton-energy. (2011). The Energy and Fuel Data Sheet, Iain Staffell, University of Birmingham, UK. Available at: https://www.claverton-energy.com/wordpress/wp-content/uploads/2012/08/the_energy_and_fuel_data_sheet1.pdf (Accessed: 22 January 2021).

Creemers, S. (2018). Moments and distribution of the net present value of a serial project. European Journal of Operational Research, 267, 835–848. https://doi.org/10.1016/j.ejor.2017.12.039

Cudjoe, D., & Acquah, P. M. (2021). Environmental impact analysis of municipal solid waste incineration in African countries. Chemosphere, 265, 129186. https://doi.org/10.1016/j.chemosphere.2020.129186

Cudjoe, D., Chen, W., & Zhu, B. (2022b). Valorization of food waste into hydrogen: Energy potential, economic feasibility and environmental impact analysis. Fuel, 324, 124476. https://doi.org/10.1016/j.fuel.2022.124476

Cudjoe, D., & Han, M. S. (2021). Economic feasibility and environmental impact analysis of landfill gas to energy technology in African urban areas. Journal of Cleaner Production, 284, 125437. https://doi.org/10.1016/j.jclepro.2020.125437

Cudjoe, D., Han, M. S., & Chen, W. (2021a). Power generation from municipal solid waste landfilled in the Beijing-Tianjin-Hebei region. Energy, 217, 119393. https://doi.org/10.1016/j.energy.2020.119393

Cudjoe, D., Han, M. S., & Nandiwardhana, A. P. (2020). Electricity generation using biogas from organic fraction of municipal solid waste generated in provinces of China: Techno-economic and environmental impact analysis. Fuel Processing Technology, 203, 106381. https://doi.org/10.1016/j.fuproc.2020.106381

Cudjoe, D., Nketiah, E., Obuobi, B., Adu-Gyamfi, G., Adjei, M., & Zhu, B. (2021b). Forecasting the potential and economic feasibility of power generation using biogas from food waste in Ghana: Evidence from Accra and Kumasi. Energy, 226, 120342. https://doi.org/10.1016/j.energy.2021.120342

Cudjoe, D., Wang, H., & Zhu, B. (2022a). Thermochemical treatment of daily COVID-19 single-use facemask waste: Power generation potential and environmental impact analysis. Energy, 249, 123707. https://doi.org/10.1016/j.energy.2022.123707

Cui, C., Liu, Y., Xia, B., Jiang, X., & Skitmore, M. (2020). Overview of public-private partnerships in the waste-to-energy incineration industry in China: Status, opportunities, and challenges. Energy Strategy Reviews, 32, 100584. https://doi.org/10.1016/j.esr.2020.100584

da Silva, B. V. J. L., dos Santos, I. F. S., Mensah, J. H. R., Gonçalves, A. T. T., & Barros, R. M. (2020). Incineration of municipal solid waste in Brazil: An analysis of the economically viable energy potential. Renewable Energy, 149, 1386–1394. https://doi.org/10.1016/j.renene.2019.10.134

dos Santos, E. R., Santos, I. F. S., Barros, R. M., Bernal, A. P., Tiago Filho, G. L., & Silva, F. B. G. (2019). Generating electrical energy through urban solid waste in Brazil: Economic and energy comparative analysis. Journal of Environmental Management, 231, 198–206. https://doi.org/10.1016/j.jenvman.2018.10.015

Duan, N., Li, D., Wang, P., Ma, W., Wenga, T., Zhong, L., & Chen, G. (2020). Comparative study of municipal solid waste disposal in three Chinese representative cities. Journal of Cleaner Production, 254, 120134. https://doi.org/10.1016/j.jclepro.2020.120134

NS Energy. (2019). China’s coal plants: New efficiency benchmarks. Available at: https://www.nsenergybusiness.com/features/chinas-coal-plants-new-efficiency-benchmarks/#:~:text=Summer%202019%20has%20seen%20the,the%20temperature%20of%20the%20main (Accessed: 22 January 2021).

US EPA. (2005). Landfill Gas Emission Model (LandGEM) version 3.02. National Risk Management Research Laboratory (NRMRL), Research Triangle Park, North Carolina.

EPS China Data. (2019). Per capita electricity consumption in China (China Energy Yearly (Nationwide)), Available at: http://www.epschinadata.com/auth/platform.html?sid=C0FDAE765EA16CCAC5639D9488998863_ipv490646867 (Accessed: 24 January 2021)

Escamilla-García, P. E., Camarillo-López, R. H., Carrasco-Hernández, R., Fernández-Rodríguez, E., & Legal-Hernández, J. M. (2020). Technical and economic analysis of energy generation from waste incineration in Mexico. Energy Strategy Reviews, 31, 100542. https://doi.org/10.1016/j.esr.2020.100542

Fei, F., Wen, Z., & Clercq, D. D. (2019). Spatio-temporal estimation of landfill gas energy potential: A case study in China. Renewable and Sustainable Energy Reviews, 103, 217–226. https://doi.org/10.1016/j.rser.2018.12.036

Fetanat, A., Mofid, H., Mehrannia, M., & Shafipour, G. (2019). Informing energy justice based decision-making framework for waste-to-energy technologies selection in sustainable waste management: A case of Iran. Journal of Cleaner Production, 228, 1377–1390. https://doi.org/10.1016/j.jclepro.2019.04.215

Friesenhan, C., Agirre, I., Eltrop, L., & Arias, P. L. (2017). Streamlined life cycle analysis for assessing energy and exergy performance as well as impact on the climate for landfill gas utilization technologies. Applied Energy, 185, 805–813. https://doi.org/10.1016/j.apenergy.2016.10.097

Giglio, E., Vitale, G., Lanzini, A., & Santarelli, M. (2021). Integration between biomass gasification and high-temperature electrolysis for synthetic methane production. Biomass and Bioenergy, 148, 106017. https://doi.org/10.1016/j.biombioe.2021.106017

Gong, Y., Li, J., & Li, Y. (2020). Spatiotemporal characteristics and driving mechanisms of arable land in the Beijing-Tianjin-Hebei region during 1990–2015. Socio-Economic Planning Sciences, 70, 100720. https://doi.org/10.1016/j.seps.2019.06.005

Gu, B., Li, Y., Jin, D., Yi, S., Gu, A., Bu, X. Y., Zhou, H., He, S., Cheng, R., & Jia, R. (2018). Quantizing, recognizing, and characterizing the recycling potential of recyclable waste in China: A field tracking study of Suzhou. Journal of Cleaner Production, 201, 948–957. https://doi.org/10.1016/j.jclepro.2018.08.085

Gu, T., Yin, C., Ma, W., & Chen, G. (2019). Municipal solid waste incineration in a packed bed: A comprehensive modeling study with experimental validation. Applied Energy, 247, 127–139. https://doi.org/10.1016/j.apenergy.2019.04.014

Hadidi, L. A., & Omer, M. M. (2017). A financial feasibility model of gasification and anaerobic digestion waste-to-energy (WTE) plants in Saudi Arabia. Waste Management, 59, 90–101. https://doi.org/10.1016/j.wasman.2016.09.030

Hameed, Z., Aslam, M., Khan, Z., Maqsood, K., Atabani, A. E., Ghauri, M., Khurram, M. S., Rehan, M., & Abdul-Sattar Nizami, A. S. (2021). Gasification of municipal solid waste blends with biomass for energy production and resources recovery: Current status, hybrid technologies and innovative prospects. Renewable and Sustainable Energy Reviews, 136, 110375. https://doi.org/10.1016/j.rser.2020.110375

Harris, P. W., & McCabe, B. K. (2015). Review of pre-treatments used in anaerobic digestion and their potential application in high-fat cattle slaughterhouse wastewater. Applied Energy, 155, 560–575. https://doi.org/10.1016/j.apenergy.2015.06.026

Hong, R. J., Wang, G. F., Guo, R. Z., Cheng, X., Zhang, Q. L., & Qian, G. R. (2006). Life cycle assessment of BMT-based integrated municipal solid waste management: Case study in Pudong, China. Resources, Conservation and Recycling, 49, 129–146. https://doi.org/10.1016/j.resconrec.2006.03.007

Hwangbo, S., Sin, G., Rhee, G., & Yoo, C. (2020). Development of an integrated network for waste-to-energy and central utility systems considering air pollutant emissions pinch analysis. Journal of Cleaner Production, 252, 119746. https://doi.org/10.1016/j.jclepro.2019.119746

IPCC. (2006) Waste. In: Pipatti R. (Ed), Biological treatment of solid waste. Inter-governmental panel on climate change: Geneva, Switzerland, Guidelines for National Greenhouse Gas Inventories, Vol. 5.

Iqbal, A., Zan, F., Liu, X., & Chen, G. H. (2019). Integrated municipal solid waste management scheme of Hong Kong: A comprehensive analysis in terms of global warming potential and energy use. Journal of Cleaner Production, 225, 1079–1088. https://doi.org/10.1016/j.jclepro.2019.04.034

IRENA. (2012). Renewable Energy Technologies: Cost Analysis Series of Biomass for power generation. IRENA. Bonn. Germany, pp.60.

Jeswani, H., Krüger, C., Russ, M., Horlacher, M., Antony, F., Hann, S., & Azapagic, A. (2020). Life cycle environmental impacts of chemical recycling via pyrolysis of mixed plastic waste in comparison with mechanical recycling and energy recovery. Science of the Total Environment, 769, 144483. https://doi.org/10.1016/j.scitotenv.2020.144483

Kapoor, R., Ghosh, P., Kumar, M., & Vijay, V. K. (2019). Evaluation of biogas upgrading technologies and future perspectives: A review. Environmental Science and Pollution Research, 26, 11631–11661. https://doi.org/10.1007/s11356-019-04767-1

Knoke, T., Elizabeth Gosling, E., & Paul, C. (2020). Use and misuse of the net present value in environmental studies. Ecological Economics, 174, 106664. https://doi.org/10.1016/j.ecolecon.2020.106664

Kumar, A., & Samadder, S. R. (2020). Performance evaluation of anaerobic digestion technology for energy recovery from organic fraction of municipal solid waste: A review. Energy, 197, 117253. https://doi.org/10.1016/j.energy.2020.117253

Liu, M., Li, F., Liu, H., & Wang, C.-H. (2020). Synergistic effect on co-gasification of chicken manure and petroleum coke: An investigation of sustainable waste management. Chemical Engineering Journal, 417, 128008. https://doi.org/10.1016/j.cej.2020.128008

Luo, H., Cheng, Y., He, D., & Yang, E.-H. (2019). Review of leaching behavior of municipal solid waste incineration (MSWI) ash. Science of the Total Environment, 668, 90–103. https://doi.org/10.1016/j.scitotenv.2019.03.004

Ma, H., Cao, Y., Lu, X., Ding, Z., & Zhou, W. (2016). Review of typical municipal solid waste disposal status and energy technology. Energy Procedia, 88, 589–594. https://doi.org/10.1016/j.egypro.2016.06.083

Manasaki, V., Palogos, I., Chourdakis, I., Tsafantakis, K., & Gikas, P. (2021). Techno-economic assessment of landfill gas (LFG) to electric energy: Selection of the optimal technology through field-study and model simulation. Chemosphere, 269, 128688. https://doi.org/10.1016/j.chemosphere.2020.128688

Ministry for the Environment. (2015). Summary of Emissions Factors for the Guidance for Voluntary Corporate Greenhouse Gas Reporting—2015. Available at: https://www.mfe.govt.nz/sites/default/files/media/Climate%20Change/voluntary-ghg-reporting-summary-tables-emissions-factors-2015.pdf (Accessed: 24 January 2021).

Mohammadi, M., & Harjunkoski, I. (2020). Performance analysis of waste-to-energy technologies for sustainable energy generation in integrated supply chains. Computers & Chemical Engineering., 140, 106905. https://doi.org/10.1016/j.compchemeng.2020.106905

Montorsi, L., Milani, M., & Venturelli, M. (2018). Economic assessment of an integrated waste to energy system for an urban sewage treatment plant: A numerical approach. Energy, 158, 105–110. https://doi.org/10.1016/j.energy.2018.06.026

Murphy, C. A., Schleifer, A., & Eurek, K. (2021). A taxonomy of systems that combine utility-scale renewable energy and energy storage technologies. Renewable and Sustainable Energy Reviews, 139, 110711. https://doi.org/10.1016/j.rser.2021.110711

Mutz, D., Hengevoss, D., Hugi, C., Gross, T. (2017). Waste-to-energy options in municipal solid waste management: A guide for decision makers in developing and emerging countries. Deutsche Gesellschaft für, Internationale Zusammenarbeit (GIZ) GmbH, pp. 1e58.

National Renewable Energy Laboratory (NREL). (2011). Technical Manual for SAM Biogas Power Generation Model (p. 40). Oak Ridge.

NBS. (2018). National Data: National Bureau of Statistics of China. Available at: http://data.stats.gov.cn/english/easyquery.htm?cn=E0103 (Accessed: 16 February 2021).

Ogunjuyigbe, A. S. O., Ayodele, T. R., & Alao, M. A. (2017). Electricity generation from municipal solid waste in some selected cities of Nigeria: An assessment of feasibility, potential and technologies. Renewable and Sustainable Energy Reviews, 80, 149–162. https://doi.org/10.1016/j.rser.2017.05.177

Ouda, O. K. M., Raza, S. A., Nizami, A. S., Rehan, M., Al-Waked, R., & Korres, N. E. (2016). Waste to energy potential: A case study of Saudi Arabia. Renewable and Sustainable Energy Reviews, 61, 328–340. https://doi.org/10.1016/j.rser.2016.04.005

Parku, G. K., Collard, F.-X., & Görgens, J. F. (2020). Pyrolysis of waste polypropylene plastics for energy recovery: Influence of heating rate and vacuum conditions on composition of fuel product. Fuel Processing Technology, 209, 106522. https://doi.org/10.1016/j.fuproc.2020.106522

Passos, F., Ortega, V., & Donoso-Bravo, A. (2017). Thermochemical pretreatment and anaerobic digestion of dairy cow manure: Experimental and economic evaluation. Bioresource Technology, 227, 239–246. https://doi.org/10.1016/j.biortech.2016.12.034

Purmessur, B., & Surroop, D. (2019). Power generation using landfill gas generated from new cell at the existing landfill site. Journal of Environmental Chemical Engineering, 7(3), 103060. https://doi.org/10.1016/j.jece.2019.103060

Salami, L., & Susu, A. A. (2011). Characterization study of solid wastes: A case study of lagos state. International Journal of Applied Science and Technology, 3, 47–52.

Sipra, A. T., Gao, N., & Sarwar, H. (2018). Municipal solid waste (MSW) pyrolysis for bio-fuel production: A review of effects of MSW components and catalysts. Fuel Processing Technology, 175, 131–147. https://doi.org/10.1016/j.fuproc.2018.02.012

Tan, T. S., Ho, S. W., Hashim, H., Lee, T. C., Taib, M. R., & Ho, C. S. (2015). Energy, economic and environmental (3E) analysis of waste-to-energy (WTE) strategies for municipal solid waste (MSW) management in Malaysia. Energy Conversion and Management, 102, 111–120. https://doi.org/10.1016/j.enconman.2015.02.010

Tao, J., Wang, J., Zhu, L., & Chen, X. (2019). Integrated design of multi-stage membrane separation for landfill gas with uncertain feed. Journal of Membrane Science, 590, 117260. https://doi.org/10.1016/j.memsci.2019.117260

The Engineering ToolBox (2021). Classification of Coal. Available at: https://www.engineeringtoolbox.com/classification-coal-d_164.html (Accessed: 22 January 2021).

Tsilemou, K., & Panagiotakopoulos, D. (2006). Approximate cost functions for solid waste treatment facilities. Waste Management Research, 24, 310–322. https://doi.org/10.1177/0734242X06066343

Wainaina, S., Awasthi, M. K., Sarsaiya, S., Chen, H., et al. (2020). Resource recovery and circular economy from organic solid waste using aerobic and anaerobic digestion technologies. Bioresource Technology, 301, 122778. https://doi.org/10.1016/j.biortech.2020.122778

Wang, K., & Nakakubo, T. (2020). Comparative assessment of waste disposal systems and technologies with regard to greenhouse gas emissions: A case study of municipal solid waste treatment options in China. Journal of Cleaner Production, 260, 120827. https://doi.org/10.1016/j.jclepro.2020.120827

Wang, Z., Lv, J., Gu, F., Yang, J., & Guo, J. (2020). Environmental and economic performance of an integrated municipal solid waste treatment: A Chinese case study. Science of the Total Environment, 709, 136096. https://doi.org/10.1016/j.scitotenv.2019.136096

Winston and Strawn. (2014). Feed-in-tariff handbook for Asian renewable energy systems. Available at: https://www.winston.com/images/content/9/1/v2/91697/Feed-In-Tariff-Handbook-for-Asian-Renewable-Energy-Systems.pdf (Accessed : 16 December 2019).

World Bank Group (US). (2019). Population, total, GDP per Capita growth rate (annual %), Population growth rate (annual %). Available at: https://data.worldbank.org/indicator/SP.POP.TOTL?locations=MO (Accessed: 29 September 2019).

Yang, Y., Bao, W., & Liu, Y. (2020a). Scenario simulation of land system change in the Beijing-Tianjin-Hebei region. Land Use Policy, 96, 104677. https://doi.org/10.1016/j.landusepol.2020.104677

Yang, Z., Yang, H., & Wang, W. (2020b). Evaluating urban sustainability under different development pathways: A case study of the Beijing-Tianjin-Hebei region. Sustainable Cities and Society, 61, 102226. https://doi.org/10.1016/j.scs.2020.102226

Zeaiter, J., Azizi, F., Lameh, M., Milani, D., Ismail, H. Y., & Abbas, A. (2018). Waste tire pyrolysis using thermal solar energy: An integrated approach. Renewable Energy, 123, 44–51. https://doi.org/10.1016/j.renene.2018.02.030

Zhang, Y., Ji, G., Ma, D., Chen, C., Wang, Y., Wang, W., & Li, A. (2020a). Exergy and energy analysis of pyrolysis of plastic wastes in rotary kiln with heat carrier. Process Safety and Environmental Protection, 142, 203–211. https://doi.org/10.1016/j.psep.2020.06.021

Zhang, Y., Ma, Z., Fang, Z., Qian, Y., Zhong, P., & Yan, J. (2020b). Review of harmless treatment of municipal solid waste incineration fly ash. Waste Disposal & Sustainable Energy, 2, 1–25. https://doi.org/10.1007/s42768-020-00033-0

Zhang, Y., Xu, P., Liang, S., Liu, B., Shuai, Y., & Li, B. (2019). Exergy analysis of hydrogen production from steam gasification of biomass: A review. International Journal of Hydrogen Energy, 44, 14290–14302. https://doi.org/10.1016/j.ijhydene.2019.02.064

Zhou, H., Meng, A., Long, Y. Q., Li, Q. H., & Zhang, Y. G. (2015). An overview of characteristics of municipal solid waste fuel in China: Physical, chemical composition and heating value. Renewable and Sustainable Energy Reviews, 36, 107–122. https://doi.org/10.1016/j.rser.2014.04.024

Funding

The authors gratefully acknowledge the financial support of the National Natural Science Foundation of China (Grant No. 72050410354), and The Startup Foundation for Introducing Talent of NUIST (Grant No. 2021r111).

Author information

Authors and Affiliations

Contributions

D.C.: Conceptualization, Methodology, Software, Writing—Original draft, Validation, Investigation, Writing—Reviewing and Editing, Supervision, and Funding Acquisition.

Corresponding author

Ethics declarations

Conflict of interest