Abstract

Waste-to-energy is one effective waste management approach for a sustainable society. The purpose of this study was to clarify the potential for energy recovery and greenhouse gas (GHG) reduction that could be achieved by introducing anaerobic digestion (AD) facilities in the process of reconstructing aging incineration facilities in Japan. Using statistical data from 1068 incineration facilities, four future scenarios were considered and compared with the current situation. As results, compared with the current situation the amount of electricity generated could increase by 60 % in 2030, by combining AD facilities for food waste with new, high-efficiency incineration facilities for remaining municipal solid waste (MSW). From a life cycle perspective, net energy recovery in 2030 was approximately three times greater than in 2011, and GHG emission could be reduced by 27 %. The introduction of AD facilities is attractive for small authorities, which currently treat <100 t/day of MSW through incineration facilities without energy recovery. An AD facility is also beneficial for large authorities. On the contrary, in middle-scale authorities that treat 100–299 t/day of MSW, the reconstruction of incineration facilities to include electricity production capabilities requires careful consideration, because it will significantly influence energy recovery and GHG reduction effects.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In 2013, the EU incinerated 25 % of its municipal solid waste (MSW) [1]; in comparison, in 2014, Japan incinerated 81 % of its MSW [2]. Japan has historically adopted incineration as the MSW treatment method of choice, due to lack of landfill space. Approximately 1100 incineration facilities are currently in operation in Japan [3]. However, some aging incineration facilities will have to be reconstructed in the near future. Approximately one-third and two-thirds of all incineration facilities will need to be replaced by 2020 and 2030, respectively; at these points, these would have been in operation for approximately 30 years [3]. Future mid- and long-term MSW management strategies therefore need to be developed.

Food waste management is a global concern. The Food and Agriculture Organization (FAO) of the United Nations has estimated that roughly one-third of global food produced for human consumption is lost or wasted between production and consumption stages, the equivalent of approximately 1.3 billion t/year [4]. Food waste generation in the EU was estimated at 89 million t/year [5], compared to 60 million t/year in China and 17 million t/year in India [6]. In Japan, 17.1 million t of food waste were generated in 2010, of which 2.9 million t were derived from the industrial sector, 3.5 million t from the business sector, and the remaining 10.7 million t from households [7]. The Law for Promotion of Recycling and Related Activities for the Treatment of Cyclical Food Resources came into force in 2001 and was revised in 2007. However, it only covers businesses and industries that generate more than 100 t/year of food waste [8]. As per this law, in 2010, food waste recycled by feed production, composting, and energy recovery [including anaerobic digestion (AD)] accounted for 2.0, 0.6, and 0.4 million t, respectively [7].

Approximately 78.9 % of business food waste and 93.8 % of household food waste was not recycled in 2010; this was consequently incinerated as mixed waste without separation [7]. The management of food waste in MSW must therefore be carefully improved.

Waste-to-energy (WTE) is one effective waste management approach for a sustainable society. WTE contributes to the reduction of fossil fuel consumption and consequently of greenhouse gas (GHG) emissions. Incineration with power generation and/or heat recovery is one of the typical WTE methodologies. AD of food waste enables more efficient electricity and heat recovery than incineration alone. Landfill disposal of food waste can lead to large volumes of CH4 emissions. Although biogas could be collected from landfill sites for energy recovery, landfilling is known to result in negative impacts on the environment and human health, and should be avoided.

There have been case studies of life cycle assessment (LCA) of WTE conducted in Uppsala, Stockholm, Älvdalen [9], and Augustenborg in Sweden [10], in Aarhus [11, 12] and for Denmark in general [13], in Rome [14, 15] and Milan [12, 16] in Italy, in London in the UK [17], in Thessaloniki in Greece [18], in Barcelona in Spain [19], in Jungnang-gu in the Republic of Korea [20], and in Jakarta in Indonesia [21]. In Japan, some previous studies have estimated the reduction in environmental impacts achieved by the comanagement of incineration and AD facilities [22–24]. As shown in Table 1, the wide range of net GHG emissions reported in these studies points to the difficulty of comparing results, due to differences in assumptions related to aspects, such as type of waste, system boundary, and considered substitutions. However, comparisons conducted within studies indicate that WTE using incineration and AD is effective in reducing environmental impact. A review of 25 and 82 LCA studies on food/organic waste by Bernstad et al. [25] and Morris et al. [26], respectively, also indicated that AD showed good environmental performance.

Mid- and long-term MSW management strategies in Japan should therefore include the introduction of AD facilities and the renewal of incineration facilities. The purpose of this study was to clarify the potential for energy recovery and GHG reduction that could be achieved by introducing AD facilities in the process of reconstructing aging incineration facilities in Japan, based on a LCA perspective. Using statistical data from more than 1000 incineration facilities in Japan, the results highlight differences in waste generation and composition among the waste collection areas.

Materials and methods

Number of facilities

Statistical data from 1068 operational incineration facilities that treat MSW were used for the analysis [3]. Facility specifications, such as treatment capacity, electricity production efficiency, and the composition of treated MSW (as reported for 2011) were used as starting values.

For purposes of the time series, we considered conditions for Japan in 2011, 2020, and 2030. Statistical data [3] indicated the year of construction of each facility. The lifespan of incineration facilities was assumed to be 30 years. In scenarios for 2020 and 2030, incineration facilities at the end of their lifespan were assumed to have been reconstructed, with or without an AD facility. The total number of incineration facilities was assumed to be constant. Consequently, 324 and 825 incineration facilities would be reconstructed as of 2020 and 2030, respectively.

Scenarios construction

A total of four future scenarios were considered for the reconstruction of aging incineration facilities and were compared with the current situation (Inc2011). In two of the scenarios, only an incineration facility (Inc2020 and Inc2030) was reconstructed, while in the other two, an AD facility was constructed in addition to a high-efficiency incineration facility (IncAD2020 and IncAD2030). To estimate the maximum potential, all (100 %) food waste was assumed to be source separated and treated in AD facilities in IncAD2020 and IncAD2030 scenarios.

MSW composition

Table 2 shows the composition of MSW treated in incineration facilities. While MSW composition differs between facilities, it was assumed that composition remained constant during the period 2011–2030. In all scenarios, the mass (three components and each element) and energy (lower heating value; LHV) of MSW treated at each facility were balanced. Values for average moisture, combustible matter, and ash content of MSW in all 1068 facilities were 46.7, 44.2, and 9.2 %, respectively. Food waste accounted for 41.5 % of MSW. In IncAD2020 and IncAD2030, moisture content in remaining MSW after food waste separation was assumed to be constant at 21.4 %, to estimate moisture content in food waste. LHV was estimated using Steuer’s model [30] after excluding sulfur, as described in Eq. (1)

where LHV lower heating value (MJ/t-wet), C carbon content (wt%), H hydrogen content (wt%), N nitrogen content (wt%), O oxygen (wt%), W moisture content (wt%).

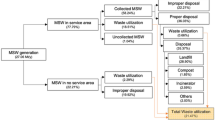

MSW generation

This study only considered MSW from household and business sectors sent to the incineration facility, because recycled components of MSW are already well managed. MSW generation and composition reported in statistical data [3] were used for Inc2011. In the case of four future scenarios, the amounts of MSW generated and treated in each facility were assumed to be proportional to the projected population in each managing authority domain (collection area) [31]. It is important to note that this assumption did not consider the effects of future waste prevention and source separation activities. Table 3 shows average population size in 2020 and 2030 in the collection area, compared with population in 2010. In 2030, the population decreased by only 6.0 % in the area where the facility treats over 300 t/day, while a reduction of 21.3 % can be seen in the area where the facility treats less than 50 t/day. It was found that the generated amount of MSW in smaller authorities tends to decline more rapidly. Table 4 lists the number of facilities and the amount of waste treated according to the treatment capacity of each scenario. The total amount of MSW treated was consequently estimated to decrease from 34.9 million t in 2011 to 31.9 million t in 2030, a reduction of 8.7 %. In IncAD2020 and IncAD2030, 4.0 and 9.0 million t/year of food waste were treated in AD facilities, respectively. This accounted for 29.2 and 69.5 % of the total amount of food waste generated.

Treatment capacity of facilities and energy recovery

It was found that incineration facilities in Inc2011 operated on average at 51.5 % of their maximum capacity, with a standard deviation of 16.7 % [3]. This value was assumed to be constant in all scenarios. The treatment capacity of the reconstructed incineration facilities was determined using this percentage and the amount of MSW incinerated. As shown in Table 4(a), the treatment capacity of each incineration facility tended to be scaled down following AD treatment of food waste.

As of 2011, 308 incineration facilities had electricity production equipment, with 11.7 % efficiency on average [3]. Efficiency in Japan was lower than in the EU (21.6 %) [32], due to the lower LHV of incinerated waste. The Japanese Government set an efficiency target for newly constructed incineration facilities of 21 % (average) for 2013–2017 [33]. For purposes of the four future scenarios, it was assumed that reconstructed incineration facilities with treatment capacity over 100 t/day could produce electricity, because as of 2011, almost all facilities that produce electricity treat over 100 t/day [3]. Electricity production efficiency at reconstructed incineration facilities in Inc2020 and Inc2030 was assumed to be 15 %. For IncAD2020 and IncAD2030, it was assumed to be 15 % for facilities that treat 100–299 t/day and 20 % for those that treat ≥300 t/day. This was because electricity production efficiency loosely correlates with treatment capacity, as shown in the electronic supplementary material. Additionally, the higher LHV of the remaining MSW following large-scale food waste separation in IncAD2020 and IncAD2030 was expected to result in better WTE performance. AD facilities can also produce electricity using gas engines, with efficiency of 40 %, regardless of treatment capacity. Surplus heat recovery is also a significant function of WTE facilities. However, heat recovery was not considered, because providing surplus heat outside the facility was more difficult than providing electricity, due to lack of infrastructure for heat transport and to regional and seasonal demand gaps.

Environmental impact

GHG emissions and fossil fuel consumption were considered to be environmental impacts. CO2, CH4, and N2O emissions were classified as GHGs and characterized using global warming potential (GWP) 100-year values of 1 for CO2, 25 for CH4, and 298 for N2O [34]. CO2 emissions derived from biomass were also excluded because of their carbon–neutral status.

Electricity and diesel fuel consumption were considered to comprise fossil fuel consumption. Both consumption and substituted electricity refer to commercial electricity from utility companies.

System boundary

Collection, treatment (incineration and AD), and final disposal (landfill of residue) were included within the system boundary. Construction of the facilities was not included. With regard to fossil fuel consumption, the system boundary considered the stages from raw material extraction to final use (combustion). The associated environmental impacts were allocated to the process consuming the fossil fuel.

Unit processes and data collection

Important parameters and assumptions employed in this study are listed in Table 5, and each process is briefly described. Uncertainties considered for some parameters are discussed in the “Sensitivity analysis” section.

Collection

Diesel fuel consumption units, obtained through a case study of Kyoto City using a grid city model [35], were used for calculating annual diesel fuel consumption. The frequency of collection was assumed to be twice a week for MSW. In case of source separated food waste, the collection frequency was assumed to be twice a week for both food waste and remaining MSW. Because more vehicles are required for the collection of food waste in IncAD scenarios, the total collection distances in these scenarios are longer than those in Inc scenarios. CO2 emissions from diesel combustion were then calculated.

Incineration

Direct emissions of CO2 from fossil-derived carbon contained in waste were considered, as well as CH4 and N2O in exhaust gas. Electricity consumption was also calculated using an empirical formula (Eq. 2), which reflects differences in waste composition in different facilities [36]. In IncAD2020 and IncAD2030 scenarios, the digestion residue after the AD process was incinerated with remaining MSW. Ash residue from incineration was landfilled after transportation.

When electricity production equipment was present, the amount of electricity produced was calculated by multiplying LHV of waste with electricity production efficiency according to treatment capacity, as discussed in the “Treatment capacity of facilities and energy recovery” section

where \(U_{{{\text{EL}}\_{\text{consump}}}} ,\) electricity consumption unit (kWh/t-waste), W weight of incinerated waste (t-waste), LHV lower heating value (MJ/t-waste), G amount of wet exhaust gas (Nm3/t-waste), \({\text{C}}_{\text{ash}}\) ash content (wt%).

Anaerobic digestion

The AD technology was assumed to be dry methane fermentation at 55 °C. Inventory data for this process was based on the results of a demonstration project (Bio-cycle Project) in Kyoto, Japan in FY 2007–2009 [40].

Electricity consumption in AD was divided into digestion and wastewater treatment processes. Electricity consumption during the digestion process was assumed to be proportional to the total solid (TS) fraction, while electricity consumption during the wastewater treatment process was assumed to be proportional to the amount of wastewater generated. One of the problems with AD is that the wastewater treatment step must be tightly controlled. NH3 concentration during digestion is a key parameter, because it counteracts the digestion of organic content. Volumes of digestive fluid and wastewater were therefore determined to maintain an NH3 concentration below 2500 ppm. To meet this condition, the amount of wastewater generated was estimated using Eq. (3). CH4 and N2O emissions from wastewater were also considered using emission factors shown in Table 5.

Biogas generation was calculated by multiplying the amount of carbon in food waste with the biodegradation rate (84 %). The CH4 concentration in biogas was assumed to be constant (57.9 %) [24]. Produced biogas was used for electricity production by means of a gas engine. It was assumed that there was no surplus heat removed from the facility

\(U_{\text{wastewater}}\): wastewater generation unit (t-wastewater/t-FW), FW: food waste, \({\text{C}}_{\text{N}}\): nitrogen content (wt%), \({\text{C}}_{\text{moi}}\): moisture content (wt%), \({\text{C}}_{\text{VS}}\): volatile solid content (wt%), \(R_{\text{biodeg}}\): biodegradation rate of food waste (%).

Transportation

Distances between incineration facilities and landfill sites differ between authorities. However, this study assumed that in all cases, incineration residues were transported to a landfill site 25 km (as one way distance) away from the incineration facility. CO2 emissions from diesel combustion were calculated.

Landfilling

For landfilling, electricity consumption for leachate treatment and diesel fuel consumption for heavy machinery were considered. It was assumed that the landfill was semi-aerobic and that there was no biogas generation, given that the majority of the biodegradable fraction in the residue would have been combusted before reaching the landfill.

Results and discussion

Fossil fuel consumption

The results in Table 6 show trends in electricity production as a function of facility renewal. Compared with the current situation (Inc2011), the amount of electricity generated could increase by 34 % in IncAD2020 and by 60 % in IncAD2030, through combining AD facilities for food waste with new, high-efficiency incineration facilities for remaining MSW. The energy recovery potential of AD in IncAD2020 and IncAD2030 was 1100 GWh/year (180 MW) and 2800 GWh/year (440 MW), respectively. The decrease in electricity production by the incineration facility between Inc2020 and IncAD2020 (or Inc2030 and IncAD2030) was smaller than the increase from AD.

From a life cycle perspective, total electricity consumption and production in the 1068 incineration and AD facilities (Fig. 1) contributed considerably to overall fossil fuel consumption. Through reconstruction of aging incineration facilities, the net amount of recovered energy increased from 27.2 PJ/year in Inc2011 to 53.6 PJ/year in Inc2020. If AD facilities were also introduced with new, high-efficiency incineration facilities, then a further 3.4 PJ/year could be recovered in IncAD2020. In 2030, the gaps between Inc2030 and IncAD2030 widened. Consequently, net energy recovery in IncAD2030 was estimated to be 80.5 PJ/year, approximately three times greater than in Inc2011. While the energy consumption of incineration and AD facilities did not differ greatly between the scenarios, electricity production gradually increased. Although recovered amounts from incineration facilities in IncAD2020 and IncAD2030 decreased compared with those in Inc2020 and Inc2030, the recovery amounts from AD facilities exceeded reduction amounts. It is important to note that net energy recovery could increase, even if MSW generation decreases in future. Considering that energy consumption in a household is approximately 38.4 GJ/year, the net amount of energy recovery in Inc2020, IncAD2020, Inc2030, and IncAD2030 equaled energy demand of 1.40, 1.49, 1.80, and 2.10 million households, respectively.

Greenhouse gas emissions

Table 7 presents summarized results of GHG emissions. Direct CO2 emissions from MSW combustion, mainly derived from carbon in plastics, gradually decreased between 2011and 2030, because MSW generation decreased. Other GHG emissions increased slightly through the introduction of AD facilities. However, more GHG reduction effects were expected. Detailed results are provided in Fig. 2. In addition to direct CO2 emissions, electricity consumption and other direct emissions (CH4 and N2O emissions from exhaust gas) in incineration contributed to GHG emissions. GHG emissions from electricity consumption in AD were relatively lower because the amount of treatment in AD facilities was lower than in incineration facilities. Reduced amounts of net GHG emissions (compared with Inc2011) were estimated to be 3.2 million t-CO2eq/year in Inc2030. If AD facilities were also introduced with new, high-efficiency incineration facilities, then a further reduction of 0.64 million t-CO2eq/year could be achieved by IncAD2030. Reduction ratios in IncAD2020 and Inc2030AD (compared with Inc2011) were 12.9 and 26.9 %; this indicates that the ratio could be doubled through reconstruction of incineration facilities during 2020–2030. Of these reductions, however, 2.9 and 8.6 % were derived from reductions in direct CO2 emissions due to reduced MSW generation.

Net GHG emissions per 1 t of MSW were 412, 376, 370, 350, and 330 kg-CO2eq/t-MSW in Inc2011, Inc2020, IncAD2020, Inc2030, and IncAD2030, respectively, with a 19.9 % reduction between Inc2011 and IncAD2030. These values were similar to those obtained by Cherubini et al. [14, 15], i.e., 297 kg-CO2eq/t-MSW (Table 1). Grosso et al. [16] indicate that AD can reduce GHG emissions by 30–60 kg-CO2eq/t-MSW compared with incineration. In our study, GHG reduction effect compared with incineration (Inc2011) resulted in 36–42 and 62–82 kg-CO2eq/t-MSW as of 2020 and 2030, respectively. From comparison with the results of Koroneos and Nanaki [18] and Gross et al. [16], further GHG reductions would be expected if heat recovery is achieved in addition to electricity substitution. It can be estimated in our model that 1 % of heat recovery (LHV basis) additionally contributes to the reduction of 6.7 kg-CO2eq/t-MSW.

More detailed information about distribution of fossil fuel consumption and GHG emissions of each facility is provided in electronic supplementary material.

Influence of treatment capacity

The results of fossil fuel consumption and GHG emissions of each facility differed with treatment capacity, or in other words, with the size of the authority. Figures 3 and 4 show the distributions of fossil fuel consumption and GHG emission units per 1 t of MSW, categorized by the treatment capacity of the incineration facility. Treatment capacity is not based on that of the renovated facility but on facilities available in 2011, because the MSW management strategy of each authority is considered from the standpoint of the current situation.

For incineration facilities with capacities of <50 and 50–99 t/day in 2011, reconstruction in Inc2020 and Inc2030 did not reduce either fossil fuel consumption or GHG emissions, because there were no electricity production facilities included. GHG emissions could be reduced with the introduction of AD facilities (IncAD2020 and IncAD2030). However, fossil fuel consumption units in both IncAD2020 and IncAD2030 had positive values; the amount of energy recovery could thus not equal energy consumption.

For incineration facilities with capacities of 100–299 t/day, results were more complex. When only the incineration facility was reconstructed (Inc2020 and Inc2030), fossil fuel consumption units had negative values; amounts of energy recovery thus exceeded energy consumption. On the other hand, units in IncAD2020 and IncAD2030 had wider distribution and their median values were positive because incineration facilities tended to be scaled down as a result of food waste separation, and electricity production capacity decreased. However, compared with the situation before reconstruction (“before rec.” in Fig. 3), introducing AD facilities also resulted in reduced fossil fuel consumption. Because most incineration facilities did not have electricity production facilities before reconstruction, GHG emission units of the reconstructed facilities (Inc2020, IncAD2020, Inc2030, and IncAD2030) could be also reduced. As of 2030, both fossil fuel consumption and GHG emission units of non-reconstructed facilities (“non-rec.” in Fig. 3) were lower than those of reconstructed facilities (“before rec.”). This indicates that incineration facilities that were already reconstructed between 2000 and 2011 and that did not need further reconstruction after 2011 had good energy and environmental performance.

For incineration facilities with capacities of over 300 t/day, introducing AD facilities (IncAD2020 and IncAD2030) provided the best outcome, because even if facilities were scaled down as a result of food waste separation, these had a large enough treatment capacity to produce electricity.

These results show that the introduction of AD facilities is attractive for small authorities, which currently treat <100 t/day of MSW through incineration facilities without energy recovery. An AD facility is also beneficial for large authorities. However, for middle-scale authorities that treat 100–299 t/day, the inclusion of electricity production facilities must be carefully considered because it will significantly influence energy recovery and GHG reduction effects.

Sensitivity analysis

As shown in Figs. 3 and 4, statistical data from 1068 incineration facilities was used to derive results, with the degree of variation indicated through error bars. These variations describe uncertainties related to waste generation and composition differences between treated areas, and to energy recovery and GHG emission/reduction effects related to the introduction of AD facilities.

However, several uncertainties were still noted in this analysis. Clavreul et al. [29] categorized uncertainties in LCAs for waste management systems using the framework introduced by Huijbregts [45]: model uncertainty, scenario uncertainty, and parameter uncertainty. With regard to parameter uncertainty, sensitivity analysis, which evaluates the influence of input changes on results, is useful [29]. Sensitive parameters for AD of food waste are related to the characteristics of food waste and energy recovery through biogas combustion and incineration [12, 16, 25, 46].

Perturbation analysis, a sensitivity analysis tool to assess the influence of parameter uncertainties [29, 47] (Heijungs and Kleijn, 2001; Clavreul et al. 2012), was applied in this study. Sensitivity ratios (SR) for fossil fuel consumption and GHG emission, defined in Eq. (4), were calculated. Table 8 lists the considered ten parameters. SRs were calculated when each parameter changed by 10 % against the default value

Calculated SRs for Japan in general are listed in Table 9 and more detailed information is provided in electronic supplementary material. If a parameter has a SR of 2, this implies that when changing its value by 10 %, the final result is changed by 20 %. Negative value means that result value is decreased when parameter is increased. Overall, parameters related to incineration facilities tended to show higher sensitivity because the amount of MSW treated in these was higher than in AD facilities. For fossil fuel consumption, the three highest sensitivity parameters among all scenarios were LHV of MSW, moisture content in MSW, and electricity consumption in the incineration facility. Electricity production efficiencies for incineration (for treatment capacities of 100–299 and ≥300 t/day) also showed higher SRs (exceeding 0.5) in Inc2030. Although a similar tendency was noted in case of GHG emission, SRs were lower than those of fossil fuel consumption. This was because the dominant emission source, direct CO2 emission from incineration of the plastic fraction in MSW, dulled sensitivity. In addition to three highest sensitivity parameters mentioned above, the CO2 emission factor of electricity also showed higher sensitivity in all scenarios except for Inc2011. Among the ten parameters, change of its value by 10 % resulted in 0.62 million t-CO2eq/year (19.6 kg-CO2 eq/t-MSW) in IncAD2030 as maximum case.

Discussions and limitations

This section discusses key results obtained and some limitations of the study:

-

The results indicate that net energy recovery could increase, even if MSW generation decreases in future, through reconstruction of aging incineration facilities. However, the effects of future waste prevention and source separation activities were not considered in the scenarios developed in this study. Food waste is generally given higher priority for waste prevention [48, 49]. If MSW generation decreases in future, net energy recovery would also decrease. However, this does not justify deterring waste prevention, because the latter produces several environmental benefits.

-

In this study, the residue remaining after digestion was assumed to be incinerated with MSW. However, the use of AD residue, which can be used as a chemical fertilizer, would contribute to a reduction in GHG emissions [27]. The supply and demand balance for each MSW treatment area needs to be considered; making use of AD residue would be more difficult in large local authorities than in small, rural authorities.

-

In 2011, 379 facilities were managed by multiple authorities, while the rest were managed by a single authority. The number of incineration facilities was assumed to be constant. However, this study showed that energy recovery from AD and incineration of remaining MSW after food waste separation were significant for reducing fossil fuel consumption and GHG emissions. To ensure energy recovery from the remaining MSW in incineration facilities, merging facilities managed by local authorities would therefore be one effective option.

-

This study assumed that all food waste was source separated and treated in AD facilities in IncAD2020 and IncAD2030 to estimate the maximum potential. It was acknowledged that the efficiency of source separation could significantly affect the results. However, it was found challenging to determine appropriate source separation efficiency because most of the local authorities in Japan incinerate food waste without source separation and there is a lack of knowledge in this regard. Nevertheless, it would be beneficial to clarify the effects of source separation efficiency in a further study.

-

The treatment methods considered in this study are only some of the options available. Dry methane fermentation could treat not only food waste but also paper and garden waste. Wet methane fermentation could also contribute to mid- and long-term MSW treatment strategies. In this case, instead of combining food waste with incineration, sewage treatment might be applicable. As mentioned before, the introduction of a heat recovery system could be considered, as this would also be effective for further energy recovery and GHG reductions. When considering available options, MSW management systems must therefore be independently evaluated for each area.

-

This study mainly focused on energy recovery and GHG reduction effects. However, WTE plants can contribute towards a sustainable society in a number of ways. Incineration could destroy hazardous organic substances and concentrate toxic metals in relatively small amounts of residue. Valuable metals could also be collected from residues [50]. Apart from energy recovery, WTE facilities can thus play a variety of additional roles in waste management.

Conclusions

The purpose of this study was to investigate the potential for energy recovery and GHG emission reduction that can be achieved by introducing AD facilities during reconstruction of aging incineration facilities in Japan. A total of four future scenarios were considered and compared with the current situation. The total amount of MSW treated was assumed to decrease by 8.7 % between 2011 and 2030.

Our conclusions are as follows:

-

Compared with the current situation (Inc2011), the amount of electricity generated could increase by 34 % in IncAD2020 and 60 % in IncAD2030, by combining AD facilities for food waste with new, high-efficiency incineration facilities for remaining MSW.

-

From a life cycle perspective, net energy recovery and GHG emissions in IncAD2030 were estimated to be 80.5 PJ/year and 10.5 million t-CO2eq/year, respectively. Net energy recovery was approximately three times greater than in Inc2011. A further 3.9 million t-CO2eq/year could be reduced, compared with Inc2011.

-

When 1068 facilities were compared based on their treatment capacities, it was found that energy recovery from AD of food waste and from incineration of remaining MSW significantly affected energy and GHG reductions. This was particularly true for middle-scale authorities that treat 100–299 t/day of MSW. In these authorities, the reconstruction of incineration facilities to include electricity production capabilities requires careful consideration, because it will significantly influence energy recovery and GHG reduction effects.

Currently, most household food waste is not utilized. Thus, from the perspective of energy recovery and GHG emission reduction, introducing AD facilities would be an attractive treatment option for local municipalities, where energy recovery is difficult with incineration. It would also be important for mid- and long-term national MSW management strategies.

References

European Union (2015) Sustainable development in the European Union. 2015 monitoring report of the EU sustainable development strategy

Ministry of the Environment (MOE), Japan (2016) Annual report on the Environment, the Sound Material-Cycle Society and Biodiversity in Japan. http://www.env.go.jp/policy/hakusyo/h28/pdf.html. Access Jun 2016 (in Japanese)

MOE, Japan (2013) Results of factual investigation of domestic waste disposal as of FY2011. http://www.env.go.jp/recycle/waste_tech/ippan/. Accessed Dec 2015 (in Japanese)

Food and Agriculture Organization of the United Nations (FAO) (2011) Global food losses and food waste. FAO, Rome

Monier V, Mudgal S, Escalon V, O’Connor C, Anderson G, Reisinger H, Dolley P, Ogilvie S, Morton G.G (2010) Preparatory study on food waste across EU27. Final report. European Commission (DG ENV) Directorate C-Industry (Ed), Contract #: 07.0307/2009/540024/SER/G4

IGES (2011) Practical Guide for improved organic waste management: climate benefits through the 3Rs in developing Asian countries. IGES Policy Report. IGES, Kanagawa. ISBN 978-4-88788-077-1

MAFF and MOE, Japan (2013) Progress of Food Recycling Law in Japan. Document 2, 1st joint meeting of Central Environment Council of recycling society sectional meeting of advisory committee of food recycling and Council of Food, Agriculture and Rural Area Policies of food industrial sectional meeting of subcommittee of food recycling. https://www.env.go.jp/council/03recycle/y031-01/mat02-1.pdf. Accessed Dec 2015 (in Japanese)

MAFF and MOE, Japan (2013) Law for promotion of recycling and related activities for the treatment of cyclical food cyclical resources. http://law.e-gov.go.jp/htmldata/H12/H12HO116.html. Accessed Dec 2015 (in Japanese)

Eriksson O, Reich MC, Frostell B, Björklund A, Assefa G, Sundqvist J-O, Granath J, Baky A, Thyselius L (2005) Municipal solid waste management from a system perspective. J Clean Prod 13:241–252

Bernstad A, Jansen J, La C (2011) A life cycle approach to the management of household food waste: a Swedish full-scale case study. Waste Manag 31(8):1879–1896

Kirkeby JT, Birgisdottir H, Hansen TL, Christensen TH (2006) Evaluation of environmental impacts from municipal solid waste management in the municipality of Aarhus, Denmark (EASEWASTE). Waste Manag Res 24(1):16–26

Turconi R, Butera S, Boldrin A, Grosso M, Rigamonti L, Astrup T (2011) Life cycle assessment of waste incineration in Denmark and Italy using two LCA models. Waste Manag Res 29(10):78–90

Fruergaard T, Astrup T (2011) Optimal utilization of waste-to-energy in an LCA perspective. Waste Manag 31(3):572–582

Cherubini F, Bargigli S, Ulgiati S (2008) Life cycle assessment of urban waste management: energy performance and environmental impacts. The case of Rome, Italy. Waste Manag 28(12):2552–2564

Cherubini F, Bargigli S, Ulgiati S (2009) Life cycle assessment (LCA) of waste management strategies: landfilling, sorting and incineration. Energy 34(12):2116–2123

Grosso M, Nava C, Testori R, Rigamonti L, Viganò F (2012) The implementation of anaerobic digestion of food waste in a highly populated urban area: an LCA evaluation. Waste Manag Res 30(9):78–87

Evangelisti S, Lettieri P, Borello D, Clift R (2014) Life cycle assessment of energy from waste via anaerobic digestion: a UK case study. Waste Manag 34(1):226–237

Koroneos CJ, Nanaki EA (2012) Integrated solid waste management and energy production—a life cycle assessment approach: the case study of the city of Thessaloniki. J Clean Prod 27:141–150

Güereca LP, Gassó S, Baldasano JM, Jiménez-Guerrero P (2006) Life cycle assessment of two biowaste management systems for Barcelona, Spain. Resour Conserv Recycl 49(1):32–48

Kim MH, Song HB, Song Y, Jeong IT, Kim JW (2013) Evaluation of food waste disposal options in terms of global warming and energy recovery: Korea. Int J Energy Environ Eng 4(1):1–12

Bastian L, Yano J, Hirai Y, Sakai S (2013) Greenhouse gas emissions from biogenic waste treatment: options and uncertainty. J Mater Cycles Waste Manag 15(1):49–60

Sakai S, Hirai Y, Yoshikawa K, Deguchi S (2005) Distribution of potential biomass/waste resources and GHG emission analysis for food waste recycling system. J Jpn Soc Waste Manag Experts 16(2):173–187 (in Japanese)

Takaoka M, Masuda T (2010) Intermediate treatment of municipal solid waste in relation to a sound material cycle and low-carbon society. Mater Cycles Waste Manag Res 21(6):368–379 (in Japanese)

Sakai S, Yano J (2013) Outlook for municipal solid waste management strategies for promoting reduction and recycling of food waste. Mater Cycles Waste Manag Res 25(1):55–68 (in Japanese)

Bernstad A, Jansen J, La C (2012) Review of comparative LCAs of food waste management systems: current status and potential improvement. Waste Manag 32(12):2439–2455

Morris J, Matthews HS, Morawski C (2013) Review and meta-analysis of 82 studies on end-of-life management methods for source separated organics. Waste Manag 33(3):545–551

Møller J, Boldrin A, Christensen TH (2009) Anaerobic digestion and digestate use: accounting of greenhouse gas and global warming contribution. Waste Manag Res 27(8):813–824

IPCC (2006) Guideline for national greenhouse gas inventories, prepared by National Greenhouse Gas Inventories Programme. In: Eggleston HS, Buendia L, Miwa K, Ngara T, Tanabe K (eds) IGES, Japan

Clavreul J, Guyonnet D, Christensen TH (2012) Quantifying uncertainty in LCA-modelling of waste management systems. Waste Manag Res 32(12):2482–2495

Liu J, Paode RD, Holsen TM (1996) Modeling the energy content of municipal solid waste using multiple regression analysis. J Air Waste Manag 46:650–656

NIPSSR (National institute of population and social security research) (2012) Population projection for Japan: 2011 to 2060. http://www.ipss.go.jp/site-ad/index_english/esuikei/gh2401e.asp. Accessed Dec 2015

Reimann DO, Scientific & Technical Advisor to CEWEP (2012) CEWEP energy report III (Status 2007–2010). CEWEP, Bamberg

MOE, Japan (2013) Maintenance plan for waste treatment facilities during 2013–2017 (in Japanese)

IPCC (2007) Climate change 2007 (AR4), Working group I report. The physical science basis

Ishikawa M (1996) A logistics model for post-consumer waste recycling. J Packag Sci Technol Jpn 5(2):119–130

NIES (2008) Technical development report of hydrogen production from biomass and biowaste. Tsukuba, Japan (in Japanese)

Yasuda K (1997) Greenhouse gas emissions from waste incineration in Japan. J Jpn Soc Waste Manag Experts 8(6):432–437 (in Japanese)

MOE, Japan (2009) Guideline for the estimation and its report on greenhouse gas emission Ver 2.4 (in Japanese)

ASTEM (2010) Production of green methanol for carbon-free BDF and development of efficient conversion technologies from by-product materials. (in Japanese)

MOE, GIO, CGER, NIES (2014) National greenhouse gas inventory report of Japan. http://www-gio.nies.go.jp/aboutghg/nir/nir-j.html. Access Dec 2015

Dote Y, Kurata Y, Maruyama T (1999) CO2 discharge by operation of non-industrial waste disposal site. In: Proceedings of the annual conference of the Japan Society of Waste Management Experts (in Japanese)

The Federation of Electric Power Companies of Japan (FEPCJ) (2013) Environmental action plan of electric utility (in Japanese)

Toyota Motor Corporation, Mizuho Information & Research Institutem, Inc. (2004) Well-to-wheel analysis of greenhouse gas emissions of automotive fuels in the Japanese context-well-to-tank Report

World Energy Council (WEC) (2010) 2010 survey of energy resources. WEC, London

Huijbregts MAJ (1998) Application of uncertainty and variability in LCA, a general framework for the analysis of uncertainty and variability in life cycle assessment. Int J Life Cycle Assess 3(5):273–280

Börjesson P, Berglund M (2007) Environmental systems analysis of biogas systems: Part II: the environmental impact of replacing various reference systems. Biomass Bioenergy 31(5):326–344

Heijungs R, Kleijn R (2001) Numerical approaches towards life cycle interpretation—five examples. Int J Life Cycle Assess 6(3):141–148

Reisinger H, van Acoleyen M, O’Connor C, Hestin M, Laureysens L, Morton G, Dolley P, Nelen D, Vanderreydt I (2011) Evolution of (bio-) waste generation/prevention and (bio-) waste prevention indicators Final Report, A project under the Framework contract ENV. G. 4/FRA/2008/0112

Watson D, Milios L, Bakas I, Herczeg M, Kjær B, Tojo N (2013) Proposals for targets and indicators for waste prevention in four waste streams. Nordic Council of Ministers, Copenhagen

Brunner PH, Rechberger H (2015) Waste to energy: key element for sustainable waste management. Waste Manag 37:3–12

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yano, J., Sakai, Si. Energy recovery and greenhouse gas reduction potential from food waste in Japan. J Mater Cycles Waste Manag 18, 631–645 (2016). https://doi.org/10.1007/s10163-016-0531-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-016-0531-y