Abstract

Management of hazardous waste deals with the cost-effective, efficient, social, and environmental concern, and the concept of sustainability includes all of these issues. In this regard, new approaches are emerging to handle waste management according to the concept of smart city. In the current study, a mathematical model is developed for the hazardous waste location-routing problems to determine the best decisions in a hazardous waste Management (HWM) system. The proposed model aims to maximize the total profit of the HWM system and reduce the destructive effects of hazardous waste from the perspective of environmental and social impacts. In order to advance the efficiency and practicality of the proposed model, a solution method based on the non-dominated sorting genetic algorithm III, a recently presented metaheuristic procedure, is applied to efficiency solve the problem. The current study takes into account the concept of Information and Communications Technology ICT and Internet of Things technology in hazardous waste location-routing modeling. In addition, some sensitivity analyses are implemented to assess the behavior of the model and extract managerial insights.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The dramatic ever-increasing trend of urbanization, population, quality of life and change in lifestyle, also the substantial industrialization and the expansion of commercial areas has led to higher amounts of hazardous waste production. The big issue is that this high volume of hazardous waste produced in industrial and urban areas causes many dangers and concerns on the environment and social activities including air pollution, the inappropriate landscape of cities due to visual pollution and the enormous economic costs incurred to governments by mismanagement of the issue. Hence the importance of HWM has increased and gained the attention different countries all over the world. This issue has caused new challenges for decision-makers, municipalities and urban planners. By considering the issues as mentioned earlier, the necessity to implement the concept of a smart city with a sustainable approach becomes more indispensable. According to the authors, by implementing Information and Communications Technology (ICT) and pay attention to the issue of sustainability, we can achieve cleaner environments, prettier cities, and more economical HWM costs. According to the authors, by implementing Information and Communications Technology (ICT) and pay attention to the issue of sustainability, we can achieve cleaner environments, prettier cities, and more economical waste management costs. The way to achieve this is through the use of the IT-based infrastructure in the fleet of waste transportation, bins, and managing the location-routing of the problem.

Hazardous waste can be divided into two main groups: Municipal Hazardous Waste (MHW) and Industrial Hazardous Waste (IHW). Municipal Hazardous Waste (MHW) includes waste from Household Hazardous Waste (HHW), thinners, fluorescent tubes, heavy metal containing batteries, Chlorofluorocarbons (CFC) containing equipment, household cleaning products, and insecticides. MHW can also be caused by commercial and municipal solid waste (MSW) streams such as hospital, gas station, laboratory, laundry, car repair shops, photography centers and many other urban and social activities which are examined in the review paper by Slack et al. (2004). Industrial Hazardous Waste (IHW) is caused by industrial processes and products such as factories, electrical plumbing workshops, oil refineries, and so forth, have large dimensions and sizes. Because the scope of the smart city problem includes MHW and IHW types of waste and eliminating one of the them removes part of the model’s objective function, we consider both of them in the problem to use it to provide a more inclusive and broader vision. Hazardous waste has the characteristics of flammability, corrosivity, reactivity, and toxicity. The control of hazardous waste due to last long harms for the environment is generally heavily regulated in developed countries, and it has been the subject of controversy. A convenient Hazardous Waste Management (HWM) system that is addressed by Nema and Gupta (1999) Contains disposal and treatment facilities and Guaranteed safety and cost-efficiency. Another aspect of HWLRPs is that there are several types of hazardous wastes. Therefore, the compatibility between wastes, recycling, disposal, and treatment technologies, is essential. For instance, some chemical hazardous wastes are inflammable, so any model that is suggested should incorporate these real-world aspects of the HWM problems.

The concept of the smart city represents fundamental ingredient including sustainability, flexibility, productivity, people prosperity, and many meaning of this kind (Giffinger et al. 2007). By utilizing the appropriate infrastructure, wireless sensors, actuators, smart communication devices, and online data will enable technologies such as information and communication (ICT) and the Internet of Things (IoT) to build a bed which with the help of that smart city concept is created and effective optimization of urban activities are provided (Miorandi et al. 2012). One of the most acute aspects of achieving the concept of sustainability and satisfying the characteristics of the smart city is the suitable administration of hazardous wastes made as an outcome of increasing public welfare and population as well as the growth and expansion of industries. Although recent widespread research on the smart and sustainable city has been carried out, most of the related studies have focused on the areas such as energy management, transportation, infrastructure routing, surveillance, and dynamic scheduling, and still some remarkable issues have not yet been addressed. The objective of hazardous waste location-routing problems (HWLRPs) in a smart city with a sustainability approach is one of the significant issues on which not been well considered in the literature. Therefore, these concerns prompted us to answer the following questions with the help of smart city concepts and attention to sustainability:

-

How can the operational benefits of waste recycling be achieved by implementing smart city concepts and sustainability?

-

Where should the treatment, recycling, and disposal facilities be located to meet the sustainability requirements?

-

How can developing a sustainable and IT-based location-routing model help to reduce the visual pollution and greenhouse gas (GHG) emissions in the industrial and urban zones?

-

How to manage the uncertainty related to the volume of waste generated at each generation nodes and use it to optimize the model?

In this paper, we offer an optimization model to facilitate decision-making for optimal and sustainable Hazardous Waste Location-Routing problems (HWLRPs) in a smart city. The intentions of the proposed model are to (1) enhance the total income of the HWM system, (2) reduce the GHG emission from the fleet of collection vehicles and system facilities, (3) and minimize the visual pollution to contribute to the social aspect of sustainability. Information and ICT and IoT opened ample prospects for developing waste management (WM) models. Owing to the significance of the (HWLRPs) (Especially green routing), the necessity of using techniques and tools related to smart city, and also to consider three scopes to achieve sustainability including social, environmental, and economic aspects simultaneously, a novel structure of HWLRP in the case of smart and sustainable city is designed (Table 1).

2 Literature review

Newly, the idea of WM in the smart city has attracted the attention of researchers. By surveying the literature, we found that most of the works can be classified into studies that deal with online data and information and methods for their collection and analysis and articles that have proposed models to indicate the application of ICT and IoT technology for befitting WM. In the following, new WM operations in smart cities are discussed. Before addressing this discussion, it should be noted that there are related studies in the area of HWM whereas, there are few studies referring to concept of the smart city. (Faccio et al. 2011) described a scheme of the solid waste collection-routing model to decrease the travel time and enhance total covered distance. The work of Carli et al. (2013) made a comparison between traditional tools as a static manner of Hazardous waste collection and innovative devices such as actuators, sensors, and IoT technologies as a dynamic solution of (WM).

To be aware of the advantages of using ICT and IoT technologies in WM modeling, we need to analyze the conceptualization between the two conventional approaches in optimizing the decisions related to routes and travel time of waste muster vehicles that exist in the literature. In the first approach, researchers considered traditional tools in WM systems, which is in the static outlining models category. The static models do not find the real-time status of reservoirs contain waste or trash bins, on the contrary, in the second approach dynamic modeling is used to the ability system to acquisition up-to-date information received by IoT-enabled sensors Anagnostopoulos et al. (2015). Lella et al. (2017) addressed network analysis to set the best decisions of routing in the HW collection system in the proposed smart city. Jatinkumar Shah et al. (2018) developed a stochastic model to optimize the preparation of waste collection operations in smart cities. In their model, they minimized the total transportation cost by considering the fact that consequence of value recovery is the main criteria in their study. In addition, a multi-level IoT-based smart cities foundation architecture is proposed by Marques et al. (2019).

2.1 Sustainability

It is becoming increasingly important that an integrated approach for sustainable HWM systems has appropriately addressed. To achieve the broader goals of sustainability of a community such as a Smart City the economic, social and environmental sustainability factors should be balanced in harmony (Le Blanc 2015). The economic aspect of sustainability deals with the optimizing profit or cost of a system. The environmental aspect of sustainability includes a wide range of topics comprising life cycle assessment (LCA), gas emissions of the HWM systems and impurity of air, soil, and water resources. For example, Zhang et al. (2018) developed a location-routing model for minimization CO2 emissions, emergency relief cost, and maximization of vehicle route travel time. Habibi et al. (2017) designed a model with to minimize, simultaneously, the social impacts, greenhouse gas emissions, and total cost. The importance of sustainability in a reverse supply chain of perishable goods was addressed by Tavakkoli Moghaddam et al. (2018). Heidari et al. (2019) proposed a multi-objective robust possibilistic model with take into consideration environmental, economic, and social concern together. Maximizing the job creation opportunities, maximizing the profit, and minimizing the GHG emissions were the objective of their study.

2.2 HWM optimization problems

A significant part of the proposed models for optimizing HWM has addressed undesirable/obnoxious facility location problems or routing of hazardous wastes independently. In this regard, the first attempt for noxious centers location modeling is related to Ratick and White (1988). Kang and Batta (2014) introduced a Value-at-Risk (VaR) model for hazardous material (HAZMAT) shipment. Minimizing the shipment risks was the objective of their study. In addition, various studies have been presented in case of hazardous waste collection and routing problems. To point a few studies Hemmelmayr et al. (2013) developed a new hybrid algorithm for the periodic truck routing problem to collect solid wastes, in which a central facilities is considered. Reducing the number of vans and the traveling time, multi-demand system (e.g., residential, commercial, industrial), multi-periods and containers with various sizes were addressed by Wy et al. (2013).

Samanlioglu (2013) developed a multi-objective MIP model for IHW location-routing problem. His work shed light into decisions related to facilities locations with different technologies, routing diverse types of IHW and routing waste residues. The work of Rabbani et al. (2017) focused on application of waste collection phase in the problem. They used a case study was to suggest the environmental impacts of facilities location. Aydemir-Karadag (2018) addressed a MIP model for the HWLRPs to increase the profit of the system. Other contributions of the prementioned work includes temporary holding nodes in system and formulating model for long-term planning period. A comprehensive HWLR model with minimization various objective functions, including costs of the system, total shipment and location risks of IHW was addressed by Rabbani et al. (2018). Considering incompatible characteristics of variant types of hazardous wastes and the heterogeneous fleet of vehicles distinguishes this study from other studies in the literature.

Visual pollution deals with the traces of pollution that people are able to admire watching a view. It can make damaging impacts on the nature and frustrates the visual zones (Habibi et al. 2017). Nevertheless, there is presently no related research in the literature that focuses on visual pollution as the social aspect of sustainability in a HWLRPs. Most attempts to model the social perspective of sustainability are related to justice and equity in abominable facility location problems, minimizing population exposure risk that takes into account population who are in a path of carrying IHW, and minimizing the risk of disposal facilities that affects the peoples. By reviewing the literature on the topics discussed, and identifying the aforementioned research gaps, we distinguish our work from existing studies in the literature by bring up these contributions which we will outline below:

-

Application of ICT and IoT technology in HWLR modeling.

-

Proposing a new mathematical model that consider three conflicting objective functions Contains maximizing the total profit, minimizing the visual pollution and minimizing the GHG emissions, and also a new mathematical model for the social aspect of sustainability

-

According to Table 2, there is no study regarding sustainability aspects in a location-routing problem of HWM systems.

Table 2 Taxonomy of the most relevant literature

3 Problem description

Here, a novel multi-objective MIP model for HWLRPs with the aim of implementing a smart and sustainable city in an organized manner is formulated. In this regard, two main groups of hazardous wastes are generated, municipal hazardous waste (MHW) and industrial hazardous waste (IHW), and the generated hazardous waste includes recyclable and non-recyclable wastes which are well-matched with different technology types. In the municipal zone, waste produced at various waste generation nodes is gathered at the waste collection centers. This collection centers and also the source nodes in the industrial zone are considered as our generation nodes. To implement the concepts of smart cities hazardous waste reservoirs, have IoT-based sensors such as radio-frequency identification (RFID) tags, actuator, and other intelligent devices. In the case of the container’s fulfillment, the cloud-based system is notified, to administer the HWM system. Because of the priority of addressing environmental issues, visual pollution, and greenhouse gas emission, we do not use the GPS for identifying the location of generation nods/bins and facilities in our work.

In our work, in each decision-making horizon, a certain number of generation nodes (\( {\text{G}}_{\text{s}} \)) may reach the predefined threshold, and this has led us to consider different scenarios with different coefficient of scenarios occurrence for the problem. We show this approach by defining a matrix that members are binary parameters. It is important to note that, the advantage of using IoT-compatible devices in our work that is not to visit all the generation nodes and only visit the nodes that reach to the threshold, which reduces unnecessary visits. The collected waste from generation nodes is shipped by heterogeneous fleets of vehicles that are compatible with waste type, to recycling or treatment facilities, with compatible technology according to hazardous wastes type. For reaching the maximum profit of HWM, recycling of hazardous waste is another important subject that should be taking account of consideration.

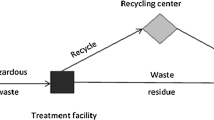

The collected waste from generation nodes is shipped by heterogeneous fleets of vehicles that are compatible with waste type, to recycling or treatment facilities, with compatible technology according to hazardous wastes type. For reaching the maximum profit of HWM, recycling of hazardous waste is another important subject that should be taking account of consideration. Processable wastes are moved to reprocessing centers, and others are shipped to removal centers. As we seek to reach a sustainable approach in our hazardous waste location-routing problem, we try to formulate a new model for the social aspect of sustainability with considering visual pollution for a heterogeneous fleet of collection vehicles and also for each system’s facilities. In the environmental side of sustainability, we need to formulate an objective function that minimizes the amount of GHG emissions from all of the system facilities and also amount of GHG emissions as a result of navigating our fleet of collection vehicles. Figure 1 depicts the framework of the hazardous waste management system of this study.

3.1 Mathematical model

Here, a novel multi-objective MIP model is developed for hazardous waste location-routing problem in a smart city with a sustainable approach regarding the assumptions mentioned above, developing the model introduced by (Rabbani et al. 2018) to determine the following decisions:

-

Routing the incompatible hazardous waste types from production centers and collection nodes to the facilities, and also the waste reminder generated at different facilities

-

Locating the treatment, reprocessing, and removal nodes.

-

Assigning the different technology types at treatment nodes.

Tables 3, 4 and 5 display the list of sets, parameters, and variables that are used in the mathematical formulation of the model. The proposed model of this problem includes three objective functions which are determined by applying a smart city concept and aspects of sustainability.

3.1.1 Objective functions formulation

The first objective function consists of four components that aim to increase the profit of the HWLR system. Equation (1a) is related to the income of the system. The opening cost of treatment, reprocessing, and removal centers is formulated by Eq. (1b). Equation (1c) represents the operating cost of facilities, waste collection, transportation, shipment from gathering centers and to treatment centers and transferring from gathering to recycling centers is formulated by Eq. (1d). The second objective function (2a)–(2b) minimizes the emissions. Equation (2a) is about the GHG gained from hazardous waste transportation, whereas Eq. (2b) corresponds to the amount of GHG caused by HWM system facilities. The third objective function is expressed with Eq. (3a)–(3b) and tries to satisfy the social aspect of sustainability in terms of minimizing the visual pollution due to shipping of vehicle(Eq. (3a)), and visual pollution due to HWM system facilities.

3.1.2 Constraints formulation

Equation (4) guarantees starting point of vehicles is a central node. Equation (5) guarantees the continuousness for vehicle’s path by incoming and leaving a constant generation node. Equation (6) ensures that the vehicles return to center by covering the treatment or recycling center. Equation (7) ensures about visiting all the nodes for each type of waste. Equation (8) confirms a vehicle assigned to a non-recyclable waste is allowed to unload in a treatment center. Equation (9) indicates that the collected wastes must be shipped to a reprocessing center before coming back to the main node. Equations (10)–(12) enforces the heterogeneous vehicles fleet does not neglect the acceptable traveling distance. Equations (13)–(16) are added to our constraints for ensuring that a cargo of gathering vehicles does not surpass the determined capacity and preventing the emergence of sub-tours. Equation (17) determines the amount of waste handled at a treatment node. Equations (18), (19), (20), (21), (22), and (23) examine the capacity limitations on HWM system facilities. Equation (24) indicates the flow from treatment facilities to the reprocessing centers. The number of reproducible waste handled at recycling centers is assessed by Eq. (25). Equation (26)–(27) indicates the flow from treatment and recycling centers to the disposal facilities. The amount of disposing waste remainder at each disposal center calculated by Eq. (28). Equation (29) makes sure about demands at each generation nodes and collection centers must be covered. Equation (30) guarantees that at most, one of the treatment technologies could be established at potential treatment nodes. Determining the existing treatment facilities is done by defined a binary parameter by Eqs. (31) and other existing system facilities are determined by Eqs. (32)–(33). Types of decision variables are denoted by Eqs. (34)–(35), respectively.

This model includes nonlinear terms in Eqs. (1c) of objective functions formulation as well as Eqs. (17), (26), (27) and (28) of constraints formulation subsection. Through using auxiliary variables and constraints, the model can be changed to a Mixed Integer Linear Programming (MILP) model. Appendix A shows how to linearize the model.

4 Methodology

This section introduces the proposed algorithm for solving the hazardous waste location-routing problem. Location-routing is an outstanding NP-hard Problem (Nagy and Salhi 2007). Because of the conflict between the objectives in our proposed model and complexity in finding optimal solutions for large-scale problems, it is natural to find a set of solutions depending on the non-dominance criterion. The newly offered metaheuristic algorithm based on the non-dominated sorting genetic algorithm III (NSGA- III) employs for the small and large test problem. Solutions which dominate the others but do not dominate themselves are entitled non-dominated solutions. The advantage of NSGA-III in holding the diversity fails to be inherited and a parameter-less approach is used based on (Bi and Wang 2017). NSGA-III is coded using MATLAB R2017b software and run on a personal computer with 2.4 GHZ CPU Intel Core i7 and 8.00-GB of RAM memory. The following subsections, firstly, express proposed NSGA-III algorithms in details, and then, solution representation is introduced.

4.1 NSGA-iii

This section is going to describe the process of the basic NSGA-III algorithm. The basic framework of NSGA-III is proposed by Deb and Jain (2014). In the following, a brief outline of the previous version of NSGA-III, NSGA-II, and then the details of NSGA-II will be described. NSGA-III is developed through a reference point-based selection system. Nevertheless, this algorithm has an inherent similarity to the NSGA-II algorithm. The pseudo-code of NSGA-III is depicted in Fig. 2 (Deb and Jain 2014). Here, we give the primary procedure of NSGA-III:

Step 1: Set the initial status of decision variables according to the given lower and upper limits. Each individual (solution) in the population \( P_{0} \) is represented by \( s_{i} = \left( {n_{i} , h_{i} , k_{i} } \right) \) for \( {\text{i}} = 1, \ldots ,N_{pop} \). It is important to note that, in this work, individuals (solution) of the initial population are randomly generated;

Step 2: Apply crossover and mutation operators to generate a new population \( Q_{t} \). In the crossover operator, two individuals \( s_{i} \) and \( s_{r} \) from the current population are randomly selected to generate two offspring \( q_{i} \) and \( q_{r } \)(Michalewicz 2013), as follows:

Where \( \gamma \) is an uniform random number in the range [0,1] which decision-maker decides on it. In the following, the parent population \( P_{t} \) and the offspring \( Q_{t} \) are merged to form \( R_{t} = P_{t} \cup Q_{t} \) with a size of \( 2*N_{pop} \);

Step 3: Categorize population to some non-dominated stages, i.e., \( F_{1} \), \( F_{2} \) and so on, based on the Pareto-dominance principle. After finding different levels of non-dominance levels \( F_{1} \),\( F_{2} \),…, the next generation \( P_{t + 1} \)(based on \( F_{1} \), \( F_{2} \) and so on) are generated. Starting from \( F_{1} \) until the size of \( S_{t} \) equals to \( N_{pop} \) or for the first time exceeds \( N_{pop} \). Assume that the non-dominance level is lth. Individuals (solutions) from the level l + 1 to the end are discarded. If \( \left| {S_{t} } \right| = N_{pop} \), let \( P_{t + 1} = S_{t} \), next apply for Step 7. Otherwise the other \( N_{pop} - \left| {P_{t + 1} } \right| \) individuals (solutions) will be nominated based on the further phases and from \( F_{1} \) based on reference points;

Step 4: The reference points are chosen during optimization by the use of systematic approach of Das and Dennis’s (Michalewicz 2013) to guarantee the diversity of solutions obtained on the Hyper-plan in objective space.

Step 5: By reaching the distance between solutions is allocated to an orientation point having the least perpendicular distance;

Step 6: First we will categorize the orientation points in an increasing order matching to the number of related followers in \( S_{t} \), and then choose a point with the least related followers and mark the number of related members as \( \theta_{i} \). Select the members with better results.

Step 7: Set \( t = t + 1 \) and go to Step 2.

4.1.1 Solution representation

The performance of evolutionary algorithms (here NSGA-III) is tremendously influenced by how the problem is encoded for the sake to obtain acceptable and interpretable answers at the appropriate time (Chen et al. 2013). Accordingly, each chromosome must be defined in a way that can cover all possible scenarios in the solution of the problem. So, order-based encoding is selected which defines chromosomes according to features and orders of the model. The first array is created of \( G + F - 1 \), for engage in the first stage, which is a location-routing problem (LRP). In which G denotes the number of source nodes, and F denotes the number of vehicles that are compatible with waste type in the waste collection state. The generation nodes accomplice numbers between 1 and G. Numbers between G +1 and \( G + F - 1 \) considered as a delimiter. The generation nodes at the beginning allocated to vehicles. So, the position of numbers in the initial string is related to generation nodes. Numbers of initial element in the string to the position of the delimiter are assigned to the initial vehicle and so on. Figure 2 illustrates an example of this encoding.

Here, eleven production nodes and four vehicles are considered. Numbers1-11 are related to generation nodes, and the location of these numbers are marked. Numbers 1, 3, 6, and 9 are related to vehicle 1. Number 8 assigned to the second vehicle. Since there is no number between 13 and 14, the third vehicle will not visit any generation node, and finally, numbers 2, 4, 5, 7, 10 and 11 are assigned to the fourth vehicle, and so all 11 of our generation nodes are visited in this example. In addition, a penalty function is used to regard capacity constraints and reach feasible solutions.

5 Parameter tuning

Initial parameters of metaheuristics algorithms can affect the performance of such metaheuristic algorithms. So, to improve the experimental results of such algorithms and reduces the runtime of them, a Taguchi method is applied. This can lead to reach the best combination of parameters. Four tuning parameters namely, the number of iterations \( \left( {{\text{Max}}_{\text{iter}} } \right) \), the size of the population \( (N_{\text{pop}} ) \), Crossover rate \( ({\text{C}}_{\text{r}} ) \) and mutation rate (\( M_{\text{r}} \)) are considered as the affecting parameters in Taguchi method. The value of the objectives and assassinate time of trials have been used as criteria to check the quality of trials. The results are given in Fig. 3 reached by MINITAB. Finally, the desirable value of NSGA-III evolutionary algorithms is expressed in Table 6.

6 Case Study

Tehran, with a large population, about 13,778,000, is the largest city and capital of Iran. Because of its steadily growing population, the city’s future HW handling and management is a major concern. The main challenge of Tehran’s HWM system is the large quantity of daily generated HW that must be collected, treated, recycled, and disposed of. In addition, controlling the large amounts of HW produced in the Tehran is related with social and environmental issues considering the population of this city. According to the statistics of Tehran Municipality Waste Management Organization, from 1997 to 2019, the size of Tehran’s HW generation has had increased at a steady rate. Thus, likely difficulty of handling future HW generation volumes can be expected to cause adverse effects such as decreased urban hygiene, increased rate of contamination and resulting diseases, increased vermin population, etc. Therefore, Taking into account the outdated technology and operations of Tehran’s HWM system, including collection fleet, treating, recycling, and disposal facilities, there is an absolute need to improve the efficiency of the HWM system of the city and utilize more updated approaches and facilities. In this regard, determining the location of facilities can meet the demand of public in terms of social and environmental concern too (Table 7).

To demonstrate the performance of the proposed model in practical cases, the model has been implemented in a case study to determine the proper HWM system for 22 districts of Tehran, and the collected data is from these 22 districts of Tehran cities. Distances between the nodes are based on the nearest distance between each node. Although Euclidean distance also could have been used. The transportation cost is considered to be proportional to the distances between nodes. Also, the establishment cost of a facility depends on the type of technology. The visual pollution factor related to each facility has been determined based on questionnaires that are completed by people living in regions. The weight of the strategic planning costs and occurrence coefficient of each scenario have been determined according to the decision-maker opinions. In this respect, the related results are depicted the sensitivity analysis section.

7 Results and numerical examples

7.1 Model validation

In order to validate the solution presented by NSGA-III algorithm, 20 sample problems of randomly generated data sets including small, medium and large-scale sample problems is chosen. Main characteristics of these problems are in Table 8. We have solved this problem with the GAMS software, version 24.1.3, and CPLEX solver, based on the Epsilon constraint method. Then we compare the result of this method with the result of the NSGA-III. In Table 8, G indicates number of generation nodes, R indicates total recycling nodes including potential and existing waste recycling facilities, ER indicates existing waste recycling facilities, T indicates total treatment facilities, ET indicates existing treatment nodes, L indicates total disposal nodes, EL indicates existing disposal facilities, and at last, F indicates the number of fleet of collection vehicles. In Table 9 solutions achieved from the GAMS software and NSGA-III algorithm are compared for the first five sample problems. For the first five sample problems, the minimum of the relative gap percentage is recorded as the minimum percentage of the relative gap (MPRG) and NSGA-III is compared with the optimal solutions as [\( \frac{{Z_{\text{Opt}} - Z_{\text{Alg}} }}{{Z_{\text{Opt}} }}*100 \)], where \( Z_{Opt} \) and \( Z_{Alg} \) denotes the results of GAMS and the metaheuristic algorithm, respectively. GAMS software is incapable to deal with large-sized instances. Figure 4 illustrates the summary of results.

7.2 Numerical examples and sensitivity analyses

Due to the lack of access to source data for such problem and due to the novelty of proposed model, sample problems including large scaled problems and small scaled problem are generated. Parameters of these problems were randomly created based on the judgment of related experts and other related articles (Rabbani et al. 2018) using the MATLAB software. AS mentioned before Gams software was applied to validate the model too. Figure 5 demonstrates the outcome of NSGA-III.

7.3 Effect of non-recyclable waste generated amount on the model

To examine the effect of the non-recyclable waste parameters on the model behavior a sensitivity analysis has been conducted. After solving the proposed model by changing the values of objective functions reached by varying ± 90% alteration in the value of non-recyclable waste were set. According to the results as that parameter values enhances; the costs and visual pollution of the model increases too. Figure 6 illustrates the effects of non-recyclable waste amount on the objective functions. As the figures show, the level of visual pollution increases dramatically with increasing rates of non-recyclable hazardous waste. Clearly, with the increase in the amount of non-recyclable waste, the decision variable F indicating the number of vehicles that are compatible with the waste increases.

7.4 Survey the effect of vehicles’ number on model sustainability and computational time

It is necessary to note that the optimization model can be lope according to agendas defined by decision makers. Due to changes in the number of vehicles carrying waste in a work calendar, we need to have a sensitivity analysis on parameter F. Figure 7 illustrates the effects of the number of vehicles on the computational time of the algorithm. As the figures show, the computational time increases dramatically with the distance from the optimal number of vehicles. Another significant result of this analysis is that by increasing the number of vehicles, the operation’s freedom is provided in the model. As shown in Fig. 8, the amount of visual pollution caused by these vehicles increases significantly, and in contrast, the amount of emissions is low.

7.5 Effect of recycling facility’s capacity on revenue and model’s variables

The parameter \( Cr_{i} \) indicates the capacity of recycling facility at node \( {\text{i}} \in R \). As can be seen from Fig. 9 after solving the proposed model variations in values of benefit and cost functions resulting from ± 50% change in the capacity of recycling facility, alteration of this parameter makes little change in cost against changes in benefit. In addition, according to the results depicted in Fig. 9 with increasing recycling facility capacity, profits are rising significantly, and this can have an impact on strategic decisions. Another meaningful change in the model is related to variable \( {\text{Yr}}_{\text{i}} \). As can be seen from Fig. 10, by increasing the recycling capacity, the value of this variable increases with the model increasingly.

7.6 Survey the effect of IoT components

Considering the uncertainty in the number activated generation nodes with IoT components, in other word the total amount of waste produced in waste generation sources, and in order to investigate the effect of waste amount on the objectives, a problem instance has been solved with different scenarios and the sensitivity analyses have run on different number of activated nodes by IoT components to provides a comparison with the state of the lack of ICT and IoT technology in hazardous waste location routing management. As Fig. 11 shows, the presence of IoT components reduces the total costs and thus increases the profitability of the WM system.

8 Conclusions and further research

This paper presents an optimization model for optimal and sustainable Hazardous Waste Location-Routing problems (HWLRPs) in a smart city. To design a sustainable system, environmental and social aspects are considered alongside with economic aspects of the problem simultaneously. In this respect, three objective functions are defined, including maximization of profit and minimization of GHG emission and visual pollution. In addition, it is possible to have a sustainable system by taking into consideration green and social aspects alongside with economic aims of the system. Furthermore, the presented model has considered smart city components including techniques and tools related to information and communication technologies (ICT) and the Internet of Things (IoT) to proper the administration of hazardous wastes generated as a result of urban and industrial activities. Next, a solution representation is proposed based on the NSGA-III algorithm and the parameters of the metaheuristic algorithm are tuned by using the Taguchi method. In order to deal with the uncertainties in the proposed problem, various scenarios are generated regarding the number of activated nodes by IoT components and solved in small, medium, and large scales. As shown in previous sections, the presence of IoT components reduces the total costs and thus increases the profitability of the HWM systems. Moreover, the advantage of using this system is economic transportation and reducing greenhouse gases. In this way, unnecessary visits are avoided, and the optimum fuel consumption will happen. Due to the features of a Smart City, the application of this model is noteworthy, because as it can be fined from the results, the breadth and integration of the objective functions make it possible for decision makers to be able to visually take a broader look at the issue and make their decisions on the satisfaction of the environmental, economic and social issues. For example, in the social dimension of the problem, the reduction of visual pollution caused by hazardous waste transportation fleet in the city has been significantly reduced. In addition to the advantage mentioned above, omnipresent availability of data stored in the cloud can be useful for different beneficiaries and entities including legislators, food industry, healthcare systems, researchers, department of environmental protection and related organizations, and many other organizations that are affecting or taking effect of this progress.

For future studies, developing a multi-period model, considering time window and implementing the model in a real case are good directions. In addition, using other approaches to deal with uncertainty of the model such as fuzzy approaches is appealing.

References

Alumur, S., & Kara, B. Y. (2007). A new model for the hazardous waste location-routing problem. Computers & Operations Research, 34, 1406–1423. https://doi.org/10.1016/j.cor.2005.06.012.

Anagnostopoulos, T., Kolomvatsos, K., Anagnostopoulos, C., Zaslavsky, A., & Hadjiefthymiades, S. (2015). Assessing dynamic models for high priority waste collection in smart cities. Journal of Systems and Software, 110, 178–192. https://doi.org/10.1016/j.jss.2015.08.049.

Aydemir-Karadag, A. (2018). A profit-oriented mathematical model for hazardous waste locating- routing problem. Journal of Cleaner Production, 202, 213–225. https://doi.org/10.1016/j.jclepro.2018.08.106.

Azadeh, A., Shafiee, F., Yazdanparast, R., Heydari, J., & Keshvarparast, A. (2017). Optimum integrated design of crude oil supply chain by a unique mixed integer nonlinear programming model. Industrial and Engineering Chemistry Research, 56, 5734–5746. https://doi.org/10.1021/acs.iecr.6b02460.

Bi, X., & Wang, C. J. M. C. (2017). An improved NSGA-III algorithm based on elimination operator for many-objective optimization. Memetic Computing, 9, 361–383. https://doi.org/10.1007/s12293-017-0240-7.

Carli, R., Dotoli, M., Pellegrino, R., & Ranieri, L. (2013). Measuring and managing the smartness of cities: A framework for classifying performance indicators. In Proceedings of 2013 IEEE International Conference on Systems, Man, and Cybernetics, SMC 2013 (pp 1288–1293). https://doi.org/10.1109/smc.2013.223

Chen, C.-F., Wu, M.-C., & Lin, K.-H. (2013). Effect of solution representations on Tabu search in scheduling applications. Computers & Operations Research, 40, 2817–2825. https://doi.org/10.1016/j.cor.2013.06.003.

Deb, K., & Jain, H. (2014). An evolutionary many-objective optimization algorithm using reference-point-based nondominated sorting approach, Part I: Solving Problems With Box Constraints. IEEE Transactions on Evolutionary Computation, 18, 577–601. https://doi.org/10.1109/TEVC.2013.2281535.

Faccio, M., Persona, A., & Zanin, G. (2011). Waste collection multi objective model with real time traceability data. Waste Management, 31, 2391–2405. https://doi.org/10.1016/j.wasman.2011.07.005.

Ghezavati, V., & Morakabatchian, S. (2015). Application of a fuzzy service level constraint for solving a multi-objective location-routing problem for the industrial hazardous wastes. Journal of Intelligent and Fuzzy Systems, 28, 2003–2013. https://doi.org/10.3233/IFS-141341.

Giffinger, R., Fertner, C., Kramar, H., Kalasek, R., Milanović, N., & Meijers, E. (2007). Smart cities—Ranking of European medium-sized cities. Centre of Regional Science, Vienna UT: Final Report.

Habibi, F., Asadi, E., Sadjadi, S. J., & Barzinpour, F. (2017). A multi-objective robust optimization model for site-selection and capacity allocation of municipal solid waste facilities: A case study in Tehran. Journal of Cleaner Production, 166, 816–834. https://doi.org/10.1016/j.jclepro.2017.08.063.

Heidari, R., Yazdanparast, R., & Jabbarzadeh, A. (2019). Sustainable design of a municipal solid waste management system considering waste separators: A real-world application. Sustainable Cities and Society, 47, 101457. https://doi.org/10.1016/j.scs.2019.101457.

Hemmelmayr, V., Doerner, K. F., Hartl, R. F., & Rath, S. (2013). A heuristic solution method for node routing based solid waste collection problems. Journal of Heuristics, 19, 129–156. https://doi.org/10.1007/s10732-011-9188-9.

Jatinkumar Shah, P., Anagnostopoulos, T., Zaslavsky, A., & Behdad, S. (2018). A stochastic optimization framework for planning of waste collection and value recovery operations in smart and sustainable cities. Waste Management, 78, 104–114. https://doi.org/10.1016/j.wasman.2018.05.019.

Kang, Y., Batta, R., & Kwon, C J Ao O R. (2014). Value-at-Risk model for hazardous material transportation. Annals of Operations Research, 222, 361–387. https://doi.org/10.1007/s10479-012-1285-0.

Le Blanc, D. (2015). Towards integration at last? The sustainable development goals as a network of targets. Sustainable Development, 23, 176–187. https://doi.org/10.1002/sd.1582.

Lella, J., Mandla, V. R., & Zhu, X. (2017). Solid waste collection/transport optimization and vegetation land cover estimation using Geographic Information System (GIS): A case study of a proposed smart-city. Sustainable Cities and Society, 35, 336–349. https://doi.org/10.1016/j.scs.2017.08.023.

Marques, P., et al. (2019). An IoT-based smart cities infrastructure architecture applied to a waste management scenario Ad Hoc Networks, 87, 200–208. https://doi.org/10.1016/j.adhoc.2018.12.009.

Michalewicz, Z. (2013). Genetic algorithms + data structures = evolution programs. Berlin: Springer.

Miorandi, D., Sicari, S., De Pellegrini, F., & Chlamtac, I. (2012). Internet of things: Vision, applications and research challenges. Ad Hoc Networks, 10, 1497–1516. https://doi.org/10.1016/j.adhoc.2012.02.016.

Nagy, G., & Salhi, S. (2007). Location-routing: Issues, models and methods. European Journal of Operational Research, 177, 649–672. https://doi.org/10.1016/j.ejor.2006.04.004.

Nema, A. K., & Gupta, S. K. (1999). Optimization of regional hazardous waste management systems: An improved formulation. Waste Management, 19, 441–451. https://doi.org/10.1016/S0956-053X(99)00241-X.

Rabbani, M., Farrokhi-Asl, H., & Asgarian, B. (2017). Solving a bi-objective location routing problem by a NSGA-II combined with clustering approach: Application in waste collection problem. Journal of Industrial Engineering International, 13, 13–27. https://doi.org/10.1007/s40092-016-0172-8.

Rabbani, M., Heidari, R., Farrokhi-Asl, H., & Rahimi, N. (2018). Using metaheuristic algorithms to solve a multi-objective industrial hazardous waste location-routing problem considering incompatible waste types. Journal of Cleaner Production, 170, 227–241. https://doi.org/10.1016/j.jclepro.2017.09.029.

Rathore, P., & Sarmah, S. P. (2019). Modeling transfer station locations considering source separation of solid waste in urban centers: A case study of Bilaspur city, India. Journal of Cleaner Production, 211, 44–60. https://doi.org/10.1016/j.jclepro.2018.11.100.

Ratick, S. J., & White, A. L. (1988). A risk-sharing model for locating noxious facilities. Environment and Planning B: Planning and Design, 15, 165–179. https://doi.org/10.1068/b150165.

Samanlioglu, F. (2013). A multi-objective mathematical model for the industrial hazardous waste location-routing problem. European Journal of Operational Research, 226, 332–340. https://doi.org/10.1016/j.ejor.2012.11.019.

Slack, R. J., Gronow, J. R., & Voulvoulis, N. (2004). Hazardous components of household waste. Critical Reviews in Environmental Science and Technology, 34, 419–445. https://doi.org/10.1080/10643380490443272.

Tavakkoli Moghaddam, S., Javadi, M., & Hadji Molana, S. M. (2018). A reverse logistics chain mathematical model for a sustainable production system of perishable goods based on demand optimization. Journal of Industrial Engineering International. https://doi.org/10.1007/s40092-018-0287-1.

Wy, J., Kim, B.-I., & Kim, S. (2013). The rollon–rolloff waste collection vehicle routing problem with time windows. European Journal of Operational Research, 224, 466–476. https://doi.org/10.1016/j.ejor.2012.09.001.

Xie, Y., Lu, W., Wang, W., & Quadrifoglio, L. (2012). A multimodal location and routing model for hazardous materials transportation. Journal of Hazardous Materials, 227–228, 135–141. https://doi.org/10.1016/j.jhazmat.2012.05.028.

Yilmaz, O., Kara, B. Y., & Yetis, U. (2017). Hazardous waste management system design under population and environmental impact considerations. Journal of Environmental Management, 203, 720–731. https://doi.org/10.1016/j.jenvman.2016.06.015.

Zhang, B., Li, H., Li, S., & Peng, J. (2018). Sustainable multi-depot emergency facilities location-routing problem with uncertain information. Applied Mathematics and Computation, 333, 506–520. https://doi.org/10.1016/j.amc.2018.03.071.

Zografos, K., & Samara, S. J. T. R. R. (1989). A combined location-routing model for hazardous waste transportation and disposal, 1245, 52–59.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1: Model linearization

Appendix 1: Model linearization

The developed model is initially a MINLP model that will be linearized in this Appendix using an exact linearization method(Azadeh et al. 2017). The nonlinearity of the model comes from the Eqs. (1c) of objective functions formulation as well as Eqs. (17) and (26) of constraints formulation subsection. A simple method to evade this nonlinearity caused by for example \( z_{ijf } lo_{if} \) is defining auxiliary variable \( zl_{ijf } \) and replacing \( z_{ijf } lo_{if} \) by it. Also, we must add additional constraints A.1-A.4 to the model.

By applying the same approach, the nonlinearities associated with \( t_{bi} Yt_{wi} \) and \( Yt_{wi} t_{bi} \) will be overcome, and the initial nonlinear formulation will be reduced to a MILP model.

Rights and permissions

About this article

Cite this article

Saeidi, A., Aghamohamadi-Bosjin, S. & Rabbani, M. An integrated model for management of hazardous waste in a smart city with a sustainable approach. Environ Dev Sustain 23, 10093–10118 (2021). https://doi.org/10.1007/s10668-020-01048-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-020-01048-7