Abstract

Hazardous Waste Management is defined as the safe and efficient handling of hazardous waste to decrease its toxicity to humans and the environment by means of proper transportation, processing, and disposal. Hazardous waste is generated by different sectors, including the medical sector, industrial sector, domestic sector, among others. Industrial hazardous waste consists of chemicals and compounds of a complex structure, which poses a great risk for public health and the environment alike. This potential risk heavily influences decision-makers when choosing a suitable location for establishing a waste processing facility. Therefore, the process of designing a hazardous waste transportation network comes with many challenges. This paper presents a profit-oriented mixed-integer linear programming model for the hazardous waste location-routing problem, with the main objective of maximizing the overall profit in the network and conditions focusing on minimizing the associated risk in terms of population exposure. The transportation network includes waste generators which are, in this case, factories, along with three different types of hazardous waste processing centers: treatment, recycling, and disposal centers. The formulated problem is coded in Python and optimally solved by Gurobi Optimizer. Furthermore, to deal with the NP-hard nature of the problem for large numerical instances, a metaheuristics algorithm based on non-dominated sorting genetic algorithm II (NSGA-II) is applied, and the model is solved with both NSGA-II and Gurobi to investigate the improvements done by utilizing the genetic algorithm. A case study is conducted for the textile industry in Jordan, as to put the proposed model into practice.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Hazardous Waste Management (HWM) has been a topic of concern in recent years. Hazardous materials (hazmat) generated by the industrial sector remain as one of the biggest threats to humans and the environment, as most manufacturers are located in developing countries with loose regulations on waste management and disposal.

Research on hazardous waste transportation has been mostly focused on the design of networks on a strategic level through the Facility Location Problem (FLP). Nonetheless, there have been many recent research efforts addressing HWM on an operational level through the Vehicle Routing Problem (VRP). The Location Routing problem (LRP) tackles the design of a transportation network on both strategic and operational levels. In this paper, we present a profit-oriented mixed-integer linear programming model (MILP) for the hazardous waste location-routing problem, with conditions focusing on the associated risk. The transportation network consists of factories along with three different types of waste processing centers: treatment, recycling, and disposal centers.

In general, there are two main sources of profit in hazmat transportation networks: income from the polluter pays principle, and income from sales of electricity generated by energy recovery [1]. However, this paper focuses on the profit generated from the repurposing of recycled hazardous waste, by reusing it in manufacturing processes or selling it commercially. In the case of developing countries, this would be an appealing approach to encourage companies to invest in waste recycling, by offering a new lens on how profit can be generated.

The formulated problem is coded in Python and optimally solved by Gurobi Optimizer. A non-dominated sorting genetic algorithm II (NSGA-II) is proposed to tackle the NP-hard nature of the problem and obtain the non-dominated Pareto solution in a reasonable time. Lastly, a case study is conducted for the textile industry in the North and Central regions of Jordan, as to put the proposed model into practice.

2 Literature Review

Interest in hazmat logistics has been rapidly increasing over the past two decades. One of the earliest known literature efforts in hazmat transportation management is Glickman [2] where they address the problem of railroad shipments of hazardous materials with the purpose of avoiding populated areas.

Holeczek [3] published a review on hazmat truck transportation problems where the following classification was proposed according to the contribution of the papers: (a) Risk assessment (b) Routing (c) Routing and location (d) Network design (e) Toll setting. Risk assessment and routing problems made up most of the research content, while LRP made up only 10% of the 290 papers included in the survey.

There have been many recent efforts to expand the research done on hazmat LRP. Zografos and Samara [4] remains one of the earliest studies where a multi-objective model was proposed aiming to minimize transportation risk, travel time, and disposal risk. Wang et al. [5] constructed a nonlinear integer open location-routing model for relief distribution considering travel time, total cost, and reliability. Beneventti et al. [6] considered different types of hazmat in a multi-objective model that maximizes the minimum weighted distance between hazardous facilities and the exposed population.

Heuristics are also heavily employed in hazmat LRP. Martínez-Salazar et al. [7] focused on solving the bi-objective LRP by metaheuristic algorithms by reduction of distribution cost and balance of workloads. Pichka et al. [8] addressed the two-echelon open location routing problem with hybrid heuristic, while Nedjati et al. [9] investigated a bi-objective integer linear programming model that minimizes the waiting time and lost demands.

When it comes to research focusing on potential profit, Boyer et al. [10] proposed the idea of minimizing the cost of the hazmat transportation network by considering the income from selling recycled waste, while Aydemir-Karadag [1] integrated the polluter pays principle and income from sales of electricity generated by energy recovery as means to maximize the profit.

Our proposed model considers both the profit generated by selling recycled waste, as well as the annual profit of factories as an indication of how the overall profit of the network is affected. To the best of our knowledge, our approach of tackling the overall profit in the hazmat transportation network is yet to be studied.

3 Problem Description and Formulation

3.1 Problem Framework

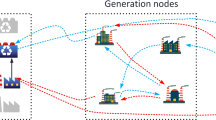

The proposed hazardous waste transportation network is shown in Fig. 1, where the generation points of hazardous waste are factories. In the first stage, the generated waste is classified into three main categories: (1) Recyclable (2) Treatable (3) Non-recyclable and non-treatable. In accordance with that, the waste gets transported to either a recycling center, treatment center, or a disposal center and in different directions.

In the case of waste transported to recycling centers, there are three possible outcomes: (1) Successfully recycled waste that can be repurposed or sold (2) Recycled waste that cannot be repurposed and goes to industrial landfills as non-hazardous residue (3) Waste that is not successfully recycled and gets transported to hazardous waste disposal centers.

In the case of treatment centers, the waste that is successfully treated can either be transported to recycling centers depending on the chemical composition or gets directly transported to industrial landfills. However, akin to the case of recycled waste, untreatable waste gets transported to hazardous waste disposal centers for its final disposal. Lastly, hazardous waste that is deemed as non-recyclable and non-treatable gets directly transported to a hazardous waste disposal center, where it is either stored in special containers or incinerated.

3.2 Mathematical Model

The proposed location-routing problem decides: (a) The number and locations of each type of waste facilities (b) The quantity of waste transported through different routes in the network. The main objective of the proposed model is to maximize the total profit of the network, with conditions focusing on limiting the transportation risk in terms of population exposure. the assumptions of the proposed model are as follows:

-

The problem is assumed to be a truck transportation problem.

-

The amount of the generated waste is known and deterministic.

-

The percentages of the three types of generated hazardous waste are known and fixed.

-

There are no capacity constraints for roads and vehicles, however, there are capacity constraints for waste facilities.

-

Transportation costs are based on the length of routes and fuel prices.

-

Every node can be a candidate location for all three types of waste facilities at the same time.

-

Population density is assumed to be non-uniformly distributed along a transportation link depending on a maximum set distance from the nearest city center.

-

There are budgetary constraints concerning the investment cost for establishing waste facilities.

Model formulation

The notations of the proposed mathematical model are shown in Table 1. The model formulation is as follows:

s.t.

Objective function (1) maximizes the total profit of the network. Constraint (2) controls the transportation risk. Constraint (3) ensures the flow balance of transported waste and that all generated waste is successfully transported. Constraint (4) ensures that all transportation routes start from a valid source node i and end at a valid destination node j. Constraints (5–7) indicate the allowed directions of transported waste. Constraint (8) is a budgetary constraint. Constraints (9–10) are capacity constraints, and constraints (11–13) are positivity and binary variable constraints.

4 Computational Results

The model was solved using Python via Gurobi 8.1.1 on Intel Core i5-8250U 1.60 GHz CPU and 8 GB RAM computer. Due to the NP-hard nature of LRP [11] a metaheuristic genetic algorithm was developed to solve different sizes of the problem.

The parameter \({\uplambda }_{{{\text{ij}}}}\) (level of maximum allowed risk) is integrated into the problem, which is represented as a percentage of the amount of transported waste. This is done to focus on controlling the transportation risk under a certain level. This value is set to 0.3 based on the conducted sensitivity analysis and the average value used in previous literature.

A non-dominated sorting genetic algorithm II (NSGA-II) is developed. This approach was chosen since it has been proven to be superior in solving LRP models [9]. Moreover, due to the complicated nature of the decision variables in our model, NSGA-II was chosen due to its flexibility in integrating other solution methods. For our problem, a combinational approach was developed where NSGA-II decides the binary decision variables, then in the evaluation part of the algorithm we solve a linear programming model to get the values of the continuous decision variables. The base algorithm was adopted from Pymoo library [12]. An overview of the implemented algorithm is shown in Fig. 2. Multiple experiments were conducted as shown in Table 2. The values of the parameters used are: (1) Half uniform crossover with 0.5 rate (2) Bit-flip mutation with 0.02 rate (3) Population size of 100 (4) 1500 generations.

As observed from the results, the GAP percentages indicate the superiority of the algorithm’s performance, especially as the size of the problem increases. In instances larger than 40 facilities, Gurobi solver was not able to achieve a good solution within the specified one-hour run time, while NSGA-II could get remarkably better results in less than half of the run time. With an average GAP of 5.7% and in accordance with the complexity of the model, the proposed algorithm has proved to yield satisfactory results for medium and large size problems.

Case study: Jordan

In order to investigate the solution for a large size problem, the model was applied to the waste management network in the North and Central regions of Jordan. Those regions were chosen due to the prominent presence of textile factories. According to the Netherlands Enterprise Agency [13] the textile sector in Jordan has grown by 35% in the span of five years between 2012 and 2017. However, the generated waste remains disposed of in an unmanaged manner.

The candidate locations were chosen according to the locations of pre-existing waste collection centers, as well as some additional locations in non-densely populated areas. The necessary information including the population densities, distances, and locations of existing facilities were taken from the report published by Japan International Cooperation Agency in 2016 [14]. Data on annual profits of textile factories were taken from Jordan textile incoming trade mission to the Netherlands report published in 2018 [15].

The problem was solved with a dataset of 54 factories and 18 candidate locations of waste facilities via the developed NSGA-II algorithm. Figure 3a illustrates the convergence curve of the algorithm, based on the best fitness value of each generation. The algorithm stabilizes after around 550 generations, noting that it was terminated after one hour of run time. A map showing the chosen locations of waste facilities and the corresponding population densities is shown in Fig. 3b.

The best solution found in terms of profit is around 31 million EUR annually. This value seems reasonable as a combined profit of the network, since most factories are small and medium size with an annual profit of less than 1–2 million EUR. Moreover, the chosen locations show the trade-off between the profit and potential transportation risk, where some locations were chosen in relatively densely populated areas due to the larger profit resulting from lower transportation cost. Nonetheless, it is worthy to mention that the highest populated areas shown in purple in Fig. 3b have been avoided while still choosing locations as close as possible to where most factories are located.

5 Conclusions

In this study, we proposed a profit-oriented mixed-integer linear programming model for the hazardous waste location routing problem. The main contribution of this research is to offer a new lens on how to consider the overall profit in hazmat transportation networks. The mathematical model was solved by Gurobi solver and NSGA-II algorithm due to its NP-hard nature. The computational results confirm the superiority of the proposed algorithm in solving medium and large size problems within an acceptable time. The model was then applied to real life case study in Jordan and yielded reasonable and applicable results.

References

Aydemir-Karadag, A.: A profit-oriented mathematical model for hazardous waste locating-routing problem. J. Cleaner Prod. 202, 213–225 (2018). https://doi.org/10.1016/j.jclepro.2018.08.106

Glickman, T.S.: Rerouting railroad shipments of hazardous materials to avoid populated areas. Accid. Anal. Prev. 15(5), 329–335 (1983)

Holeczek, N.: Hazardous materials truck transportation problems: a classification and state of the art literature review. Transp. Res. Part D 69, 305–328 (2019). https://doi.org/10.1016/j.trd.2019.02.010

Zografos, K., Samara, S.: Combined location-routing model for hazardous waste transportation and disposal. Transp. Res. Rec. 1245, 52–59 (1989)

Wang, H., Du, L., Ma, S.: Multi-objective open location-routing model with split delivery for optimized relief distribution in post-earthquake. Transp. Res. Part E 69, 160–179 (2014). https://doi.org/10.1016/j.tre.2014.06.006

Beneventti, G.D., Andres, B., German, P., Vladimir, M.: A multi-product maximin hazmat routing-location problem with multiple origin-destination pairs. J. Cleaner Prod. 240, 118193 (2019). https://doi.org/10.1016/j.jclepro.2019.118193

Iris Abril, M., Julian, M., Francisco, M., Trinidad, G., Rafael, C.: Solving a bi-objective transportation location routing problem by metaheuristic algorithms. Eur. J. Oper. Res. 234, 25–36 (2014). https://doi.org/10.1016/j.ejor.2013.09.008

Pichka, K., Bajgiran, H., Petering, H., Jang, J., Yue, X.: The two echelon open location routing problem: mathematical model and hybrid heuristic. Comput. Ind. Eng. 121, 97–112 (2018). https://doi.org/10.1016/j.cie.2018.05.010

Nedjati, A., Gokhan, I., Jamal, A.: Bi-objective covering tour location routing problem with replenishment at intermediate depots: formulation and meta-heuristics. Comput. Industr. Eng. 110, 191–206 (2017). https://doi.org/10.1016/j.cie.2017.06.004

Boyer, O., Hong, T., Pedram, A., Yusuff, R., Zulkifli, N.: A mathematical model for the industrial hazardous waste location-routing problem. J. Appl. Math. 2013, 435272 (2013). https://doi.org/10.1155/2013/435272

Zhong, S., Cheng, R., Jiang, Y., Wang, Z., Larsen, A., Nielsen, O.: Risk-averse optimization of disaster relief facility location and vehicle routing under stochastic demand. Transp. Res. Part E 141, 102015 (2020). https://doi.org/10.1016/j.tre.2020.102015

Blank, J., Deb, K.: Pymoo: multi-objective optimization in python. IEEE Access 8, 89497–89509 (2020). https://doi.org/10.1109/ACCESS.2020.2990567

Netherlands Enterprise Agency: Value Chain Analysis (VCA) Garments, Jordan (2019). Publication number: RVO-027–1901/CBI-RP

Japan International Cooperation Agency (JICA), Kokusai Kogyo Co., Ltd.: Data collection survey on waste management in northern region accepting Syrian refugees in The Hashemite Kingdom of Jordan. 7R-JR-16–010 (2016)

Nederlandse Export Combinatie: Jordan textile incoming trade mission to the Netherlands, March 18–23, Textile Companies (2018)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Junaidi, A., Irohara, T. (2023). Metaheuristics Based Profit-Oriented Optimization Model for the Hazardous Waste Location Routing Problem. In: Huang, CY., Dekkers, R., Chiu, S.F., Popescu, D., Quezada, L. (eds) Intelligent and Transformative Production in Pandemic Times. Lecture Notes in Production Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-18641-7_42

Download citation

DOI: https://doi.org/10.1007/978-3-031-18641-7_42

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-18640-0

Online ISBN: 978-3-031-18641-7

eBook Packages: EngineeringEngineering (R0)