Abstract

Landfill application is the most common approach for biowaste treatment via leachate treatment system. When municipal solid waste deposited in the landfills, microbial decomposition breaks down the wastes generating the end products, such as carbon dioxide, methane, volatile organic compounds, and liquid leachate. However, due to the landfill age, the fluctuation in the characteristics of landfill leachate is foreseen in the leachate treatment plant. The focuses of the researchers are keeping leachate from contaminating groundwater besides keeping potent methane emissions from reaching the atmosphere. To address the above issues, scientists are required to adopt green biological methods to keep the environment safe. This review focuses on the assorting of research papers on organic content and nitrogen removal from the leachate via recent effective biological technologies instead of conventional nitrification and denitrification process. The published researches on the characteristics of various Malaysian landfill sites were also discussed. The understanding of the mechanism behind the nitrification and denitrification process will help to select an optimized and effective biological treatment option in treating the leachate waste. Recently, widely studied technologies for the biological treatment process are aerobic methane oxidation coupled to denitrification (AME-D) and partial nitritation–anammox (PN/A) process, and both were discussed in this review article. This paper gives the idea of the modification of the conventional treatment technologies, such as combining the present processes to make the treatment process more effective. With the integration of biological process in the leachate treatment, the effluent discharge could be treated in shortcut and novel pathways, and it can lead to achieving “3Rs” of reduce, reuse, and recycle approach.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Management of solid waste from municipalities is one of the important facilities provided to the people by the government in every country of the world. According to the statistics in 2012, 1.3 billion tonnes of solid wastes have been produced by 3 billion urban residents in the world cities accounting to 1.2 kg capita−1 day−1 of municipal solid waste (MSW). Embracing the increase of population, world urbanization, and economic development, an increase in solid waste generation per capita is expected in the next decade. By 2025, it is estimated that 1.42 kg capita−1 day−1 of MSW will be generated by 4.3 billion urban residents which is equivalent to 2.2 billion tonnes year−1. For solid waste management, biowaste is the biggest portion found in the MSW especially in the developing country which has a fraction of 70% in the waste stream (Hoornweg and Bhada-Tata 2012). Biowaste is defined as an organic waste which is capable of decomposing by aerobic or anaerobic conditions. Biowaste is ranging from food and kitchen waste, yard waste originated from the households, and commercial and industrial sources (Rigby and Smith 2013; Schüch et al. 2016; DEFRA 2011).

Biowaste volumes are rapidly increasing, which can even grow higher than the urbanization rate. According to Hassan and Xie (2014), the growth of solid waste from household and commercial sources can be anticipated as much as 40% in 2020. GHG emission, ozone-depleting substances, and water pollution due to the uncontrolled leachate discharge could also bring the significant negative impacts to the environment. Improper waste collection and disposal could turn a land into a breeding area for insects and rodents which are potential disease-carrying vectors, and it can result in serious health concerns. The growing challenges require an effective and improving MSW management. Biowaste management is considered an urban issue because > 50% of the world’s population live in cities with fast-growing urbanization rate.

Various activities are involved in solid waste management right from waste generation until final disposal at prescribed facilities. Wastes could be segregated into biowaste and recyclable items (Hoornweg and Bhada-Tata 2012).

The best ways to decrease biowastes are (1) reduction of the waste at source and (2) recycling the waste instead of throwing it to the disposal site. Biodegradable waste can be composted into nutrition-rich soil conditioner. Composting of biowaste has received an encouraging attention especially in high-income countries as shown in Fig. 1.

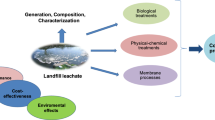

Based on the survey conducted in 90 countries worldwide, landfilling method has been widely applied and accepted as a major treatment option for the municipal waste (Hoornweg and Bhada-Tata 2012) as shown in Fig. 1. However, leachate treatment is the main concern of landfill application to avoid negative impacts to the environment. Biological process is used to remove the contaminants (especially the organic content and total Kjeldahl nitrogen (TKN) in the form of ammonium) from leachate to meet the compliance limits before being discharged into the environment (Hoang et al. 2012). Conventional biological treatment process usually consists of two stages viz., denitrification and nitrification. However, the conventional pathway involves higher operational cost due to the requirement of high amount of oxygen during nitrification and carbon during denitrification process. This review article emphasized the novel pathways combining the advanced biological technologies for biowaste treatment and the latest findings on aerobic and anaerobic treatment for removing nitrogen in the form of ammonium. The flow chart of the topics elaborated in the present review paper is presented in Fig. 2.

Leachate characteristics

Leachate is a liquid, which is a mixture of organic and inorganic contaminants which are harmful for the environment (Silva et al. 2013; Zhang et al. 2009). The leachate could be a mixture of personal care products (PCPs), pharmaceutical products, phthalates, complex aromatic molecules (Marttinen et al. 2003), polybrominated diphenyl ethers (PBDEs) (Oman and Junestedt 2008; Wu et al. 2011), pesticides (Oman and Junestedt 2008), heavy metals (Jensen et al. 1999; Christensen et al. 2001), etc. Leachate has high content of chemical oxygen demand (COD), biochemical oxygen demand (BOD), and ammoniacal nitrogen (Akkaya et al. 2010). Some specific components of leachate are shown in Table 1.

Dissolved organic matter encompasses 80% of the total organic carbon (TOC) concentration in the leachate with the concentration ranging from 800 to 20,000 mg L−1 or higher (Liu et al. 2015; Huo et al. 2008; Mohammadzadeh et al. 2005). Nevertheless, the leachate characteristics vary with seven factors which are site hydrogeology, weather conditions, moisture traversing through the landfill, landfill age, waste composition, landfill design, and operational practice (Oulego et al. 2016; Kurniawan et al. 2006b; Zainol et al. 2012; Ghafari et al. 2010).

Once the leachate is collected in the leachate collection pond, the landfill age will be the key factor determining the waste composition throughout the landfill operation (Aziz et al. 2009; Aziz et al. 2004; Nazrieza et al. 2015). Leachate can be characterized based on its age; (i) young, (ii) intermediate, and (iii) old leachates. The characteristics of the leachate on the basis of age are shown in Table 2.

For the first 10 years of the leachate generation, the leachate is considered young and it undergoes acidogenic phase with high organic carbon (Oulego et al. 2016; Kulikowska and Klimiuk 2008). Aerobic degradation of the organic matter takes place in the presence of the aerobic bacteria (i.e., hydrolytic and fermentative bacteria as well as acetogenic bacteria (Taha et al. 2011)), utilizing the oxygen present in the organic matter (Oulego et al. 2016). Acideognic phase will convert the carbon sources present in the leachate into a substantial amount of volatile fatty acid such as formic, acetic, and lactic acids. At this phase, high biodegradability of organic matter could be seen by measuring the BOD5 to COD ratio experimentally (typically it should be BOD5/COD > 0.3) (Zainol et al. 2012; Nazrieza et al. 2015; Umar et al. 2010; Kurniawan et al. 2006a; Christensen et al. 2001). Young leachate has high BOD5 and COD which subsequently decrease with increasing the age of landfill > 10 years as it goes to the methanogenic phase (Oulego et al. 2016; Lee et al. 2010).

At the methanogenic phase, anaerobic degradation takes place due to depletion of oxygen. The methanogenic phase continues for a very long period over 20 years (Leachater 2011). During the methanogenic phase, methanogenic bacteria convert volatile fatty acids (which are gathered in acidogenic phase) into methane gas and carbon dioxide. In the methanogenic phase, the methane gas production rate reaches a maximum depending upon the rate of hydrolysis cellulose and hemicellulose. The pH of the intermediate leachate increases up to 6.6–9.0 as the acids are consumed (Alvarez-Vazquez et al. 2004; Christensen et al. 2001). At this point, BOD5 to COD ratio also decreases to 0.1–0.58 as the volatile fatty acids are consumed in the intermediate leachate during the period of 10 to 20 years. Volatile fatty acids remains 5–30% as refractory organic which are humic substance and fulvic fraction represented as COD (Oulego et al. 2016; Kulikowska and Klimiuk 2008; Aziz et al. 2009; Zainol et al. 2012). Humic acid is a compound that comprises many different acids like carboxyl (COOH), carbonyl (C=O), and phenolate groups (Silva et al. 2017; Park and Yoon 2007). The presence of humic substances and ferric iron caused the dark brown or black coloration of the leachate (Oulego et al. 2016; Zouboulis et al. 2004; Tatsi and Zouboulis 2002).

An increase in the landfill age increased the ammonium concentration in leachate (Aziz et al. 2007; Aziz et al. 2009; Bashir et al. 2009), while biodegradability of the leachate reduces (Akkaya et al. 2010). Ammoniacal nitrogen can have the value of 10–10,000 mg NH4 N L−1 (Tatsi and Zouboulis 2002; Statom et al. 2004; Marttinen et al. 2003). Ammoniacal nitrogen and TKN have marginal differences in raw leachate. Leachate content is well stabilized under alkaline pH conditions (Akkaya et al. 2010). Therefore, COD fractionation is a very crucial factor to improve the biodegradable, soluble, and biodegradable soluble COD in the leachate (Amr et al. 2014).

Table 3 shows the laboratory results for the leachate characteristics of biowaste from the selected landfills in Malaysia. Most of the landfills in Malaysia are in operation for more than 10 years. The most chosen landfill sites in the previous research studies (Zainol et al. 2012, 2013; Aziz et al. 2009, 2010, 2015; Nazrieza et al. 2015; Umar et al. 2010; Jayanthi et al. 2016; Zin et al. 2012) were Matang Landfill, Kuala Sepetang Landfill, Kulim Landfill, Pulau Burung Landfill, Panchang Bedena Landfill, Bukit Beruntung Landfill, and Batang Padang Landfill. Analysis of the leachate of the above-mentioned landfills revealed that the leachate of these landfill sites can be categorized under the type of intermediate leachate. Two landfills (i.e., Ampang Jajar Lanfill and Taman Beringin Landfill) which were already closed for more than 10 years were also studied by Umar et al. (2010) and Jayanthi et al. (2016), and the leachate characteristics were found congruent with the old leachate category. Nevertheless, both well-engineered sanitary landfills (Jeram Sanitary Landfill and Bukit Tagar Sanitary Landfill) have the least operational years as compared with the other mentioned landfills. The landfill age for both of them is less than 10 years and are considered young leachate (Agamuthu and Masaru 2014; Europasia Engineering Services Sdn. Bhd 2016).

The fluctuation of landfill leachate characteristics is the challenge to be tackled in the leachate treatment plant currently. Therefore, the conventional method of the leachate treatment system would not work completely to remove the pollutants from the leachate in compliance to the Department of Environment (DOE) standard discharge limits. Hence, this review paper focusing on the advantages of biological treatment for landfill leachate treatment.

Principle of biological treatment of landfill leachate to remove ammonia

Biological treatment could not be replaced by the oxidation process, but VFA are easily removed by traditional biological treatment (Oulego et al. 2016). Two conventional steps to treat nitrogen in wastewater are denitrification (conversion of nitrate to nitrogen gas) and nitrification (conversion of ammonium to nitrate) (Kim et al. 2007; Sadri et al. 2008; Kornboonraksa et al. 2009; Zhu et al. 2016). Removal of nitrogen can occur either by heterotrophically, autotrophically, or methylotrophically. By definition, the autotrophic bacteria derive carbon by reduction and fixation of inorganic carbon from CO2 and heterotrophic bacteria obtains cell biomass from reduced organic molecules. Methylotrophic denitrifying bacteria plays an important role for the connection of methane and nitrogen cycle in nature (Zhu et al. 2016). In many cases, denitrifying bacteria derives carbon from reduced molecules also called C1 compounds (which have no C–C bond). Methane and NO3− are generally consumed by mixed microbial community not by a single microbe. For example, Achromobacter species consumes NO2− but cannot reduce NO3− because of absence of nitrate reductase (Nar) (Zhu et al. 2016).

Denitrification process can occur under anaerobic and aerobic conditions (Zhu et al. 2016). On the basis of oxygen tolerance of the bacteria, denitrifiers are categorized into two categories.

-

a)

Anaerobic denitrifier (NO3−/NO2− respiration under anoxic conditions)

-

b)

Aerobic denitrifier (NO3−/NO2− respiration under oxygen conditions)

Conventional biological treatment processes

Anaerobic process

Nitrogen treatment via nitrification and denitrification process is practiced in the biological treatment for biowaste since a very long time (Lackner et al. 2014). Denitrifiers have wide distribution among bacteria, archaea, and fungi. Sequential reduction of NO3−, NO2−, NO, and N2O to dinitrogen (N2) through cytoplasmic membrane is followed by denitrification process. This whole process generates the electrochemical gradient through the cytoplasmic membrane which creates energy for denitrifiers (Zhu et al. 2016). For complete nitrogen removal, the ammoniacal nitrogen was oxidized to NO3− followed with denitrification (Herbert Jr et al. 2014). It uses carbon source from organic matter (CH2O) while reducing NO3− to N2 under anaerobic process as shown in the stoichiometric equation (Reaction 1).

The consumption of organic carbon in the leachate could promote the reduction of organic pollutants while removing the ammonium content. The understanding of the mechanism behind the nitrification and denitrification process will help to select an optimized biological treatment for treating the leachate waste.

Corresponding enzyme for complete denitrification to release nitrogen gas as terminal product are Nar for NO3−, nitrite reductase (Nir) for NO2−, nitric oxide reductase (Nor) for NO, and nitrous oxide reductase (N2OR) for N2O (Zhu et al. 2016). There are two different types of Nar which are categorized as (a) periplasmic reductase (Nap) and (b) membrane-bound reductase (Nar). Nap are found in proteobacteria while the Nar are distributed in proteobacteria, actinobacteria, archaea, etc. (Zhu et al. 2016; Bru et al. 2007; Richardson et al. 2001).

narG and napA genes are responsible for controlling the Nap and Nar, respectively, for protein expression of catalytic subunits (Zhu et al. 2016). Denitrification is also called “sensu stricto” which is the process of nitrite reduction (Herbert Jr et al. 2014). The genes nirK or nirS has the genetic potential for denitrification. The fraction of nosZI and nosZII (nitrous reduction) to nirS and nirK required for reducing nitric oxide to nitrous oxide is 39.6 ± 9.7%. The fraction specifies that denitrifiers produce more nitrous oxide than their reduction rate. Nir genes are abundant than nos. Moreover, nosZ/(nirS + nirK) decreases with increasing the temperature (Herbert Jr et al. 2014). However, all denitrifiers do not possess all four types of enzyme (Nar, Nir, Nor, and N2OR). In Alcaligenes eutrophus H16, Nap is responsible for aerobic aspiration and anaerobic denitrification (Zhu et al. 2016). While in Thiosphaera pantotropha, the reduction of aerobic aspiration is facilitated by Nap. Denitrifying methylotrophs like Hyphomicrobium and Methylotenera are obligate aerobes (Kalyuhznaya et al. 2009) which uptake methanol for reducing NO3− in the presence of oxygen. Therefore, they can utilize oxygen and NO3− or NO2− as their terminal electron acceptors (Zhu et al. 2016).

All reductases (Nar, Nir, Nor, and N2OR) except Nap are sensitive to oxygen, and their activity may be suppressed in the presence of oxygen. Conventional way of Nar for reduction of NO3− is under anaerobic conditions (Zhu et al. 2016). Under anaerobic reactor, reduction of NO3− to N2 is stimulated by denitrifiers (Herbert Jr et al. 2014; Jones et al. 2008; Philippot et al. 2011). Increase of oxygen (2–8%) will degrade the denitrification process due to suppression of genes which carry out the denitrification and critical cellular function (Zhu et al. 2016; Luesken et al. 2012). It could also be terminated by N2O due to unfavorable environmental conditions (Herbert Jr et al. 2014; Elgood et al. 2010). Therefore, it will cause an incomplete denitrification (Zhu et al. 2016). Lower denitrification rates are linked to longer residence times for the limited supply of nitrate (Herbert Jr et al. 2014). Proliferation of denitrifier community is also supported by degree of water saturation in deeper area which has limited oxygen. Oxygen and NO3− compete with each other to perform as terminal electron acceptor for oxidation. Therefore, oxygen diffusion into the bioreactor and supply of required substrates affects the distribution of denitrification process. The spatial distribution of denitrifier community is related to the aspects of hydraulic condition which are flow paths, hydraulic retention times (HRT), and water saturation (Herbert Jr et al. 2014). The increased depth of bioreactor and continuous water saturation provides the homogeneous microbial community where exposure of oxygen is low and organic carbon is highly available (Andrus et al. 2014).

nirS and nirK denitrifiers belong to the different niche for instance, nirS decreases with increasing distance from the inlet while nirK is abundant at the central region of the bioreactor. nirS is more predominant with increase of temperature. nirS shows the denitrification activity in soil (Warneke et al. 2011). An increase in denitrifier community (nirS, nirK, nosZ) with depth was observed. It coincides with the increase of NO3− removal as demonstrated by Warneke et al. (2011). High population of nirK and nirS found in the bioreactor could increase the alkalinity and favored denitrifier system (Herbert Jr et al. 2014). As the depth of the reactor increases, the nitrous oxide reduction capacity of nosZI increases. nosZII dominates non-denitrifying nitrous oxide-reducing bacteria (Herbert Jr et al. 2014). Overall genetic potential for nitrous oxide reduction favors upper sampling horizon as compared with the lower. However, there is no difference in flow paths or distance from the inlet.

Heterotrophic denitrification

Organic carbon works as an electron donor for heterotrophic bacteria during nitrate and nitrite conversion to nitrogen gas in anoxic conditions. Complete nitrate reduction requires 2.7–3 C/N ratio (Chung et al. 2014). If sufficient carbon is not present in the system, additional carbon source is required, such as in an old landfill’s leachate (Chung et al. 2014; Bai et al. 2009; Manconi et al. 2007). As there is increase of landfill age, COD decreases while concentration of ammonia increases (Price et al. 2003). Moreover, adding extra carbon source during the denitrification fluctuation of nitrogen loading process will create secondary pollutant from incomplete oxidation of carbon (Chung et al. 2014).

Autotrophic denitrification

If the landfill leachate will have high nitrogen content and low carbon content, autotrophic denitrification occurs instead of heterotrophic denitrification. Autotrophic bacteria are identified as Thiobacillus denitrificans or Thiomicrospira denitrificans. External carbon source like ethanol/methanol is not required for these bacteria (Chung et al. 2014) as they obtain energy by the oxidation of reduced inorganic compounds (H2S, S2O32−, S, S4O62−, SO32−) in combination of reduction of nitrate or nitrite. Sludge generation could be subsequently decreased and cost of sludge handling could also be reduced. Therefore, these microorganisms can grow mixotrophically by using inorganic and organic carbon for biosynthesis. Sulfur-limestone autotrophic denitrification has the same effect as heterotrophic denitrification but has the disadvantage of the increasing dissolved solids and hardness in the leachate (Chung et al. 2014; Liu and Koenig 2002; Wang and Qu 2003; Moon et al. 2004). Based on the following stoichiometric equation (Reaction 2), 1 g of NO3− requires 12.15 g of sulfate content (Chung et al. 2014).

High sulfate generation and low alkalinity is a disadvantage of autotrophic denitrification of nitrate. The considerable cost is required to maintain a neutral pH (Chung et al. 2014; Liu and Koenig 2002). Optimum pH for denitrification is 8.0 as studied by Chung et al. (2014). A comparative study revealed that the biomass yield of denitritation process (i.e., 0.34 mg VSS mg−1 N) was 36% less compared with the biomass yield of the denitrification process (i.e., 0.53 mg VSS mg−1 N) while at the same time, a reduction of 50% sulfate generation under the denitritation process due to 20% lesser thiosulfate was applied. Therefore, the denitritation process is the preferable option to convert the ammonium to nitrogen gas instead of the denitrification process which is also known as nitritation–denitritation process (Fig. 3). Nevertheless, it is important to study the kinetic of the autotrophic denitrification due to sulfate production and low alkalinity. In view of this reaction, high strength of ammonium wastewater with excessive sulfate as carbon source could be easily removed by the autotrophic bacteria especially in the leachate waste (Chung et al. 2014).

Autotrophic and heterotrophic denitrification in combination

Various researchers have used combined heterotrophic and autotrophic denitrification for water treatment (Chung et al. 2014; Kim et al. 2004; Liu et al. 2009). Shortcut nitrification and denitrification (also known as nitritation and denitritation) was successfully carried out by using autotrophic and heterotrophic bacteria (Ruiz et al. 2006; Wang et al. 2008). Where, instead of completing the conventional cycle of nitrification and denitrification process, oxidation of ion NH4+ to NO2− takes place by suppressing the nitrite-oxidizing bacteria. It is then followed by the denitrifying bacteria for nitrite reduction to nitrogen gas (Chung et al. 2014; Ruiz et al. 2003). However, the above combination process requires inhibition of free ammonia and nitrous acid concentration which depends on pH, temperature, dissolved oxygen, and sludge retention time (Pollice et al. 2002; Yang et al. 2007).

Inhibition of nitrite-oxidizing bacteria is caused by free ammonia at a concentration range of 0.1–1.0 mg L−1 while, ammonium-oxidizing bacteria requires free ammonia 10–150 mg L−1 (Wang et al. 2016). Another study concluded that nitrite-oxidizing bacteria could be inhibited completely under the concentration of 6.0 and 0.02 mg L−1 for free ammonia and free nitrous acid, respectively (Wang et al. 2016; Vadivelu et al. 2007).

In contrast with nitritation and denitritation-based process, anaerobic ammonium-oxidizing (anammox) autotrophic bacteria work on overall nitrogen removal for NO2− and NH4+ (Herbert Jr et al. 2014) where NH4+ is used as an electron donor and NO2− as an electron acceptor to convert NH4+ into nitrogen gas (N2) as shown in Fig. 3. Anammox microorganisms belong to phylum Planctomycetes, and currently, five anammox genera have been discovered which are Candidatus (Ca) Brocadia, Ca Kuenenia, Ca Anammoxoglobus, Ca Jettenia (all fresh water species), and Ca Scalindua (marine species) (Lackner et al. 2014; Jetten et al. 2001; Kartal et al. 2007). Characteristics of anammox bacteria is inhibited by low concentration of dissolved oxygen, but intermittent aeration makes partial nitritation and anammox process possible in single reactor (Lackner et al. 2014; Third et al. 2005). Due to the anammox bacteria, the aerobic ammonium-oxidizing bacteria can develop with suppression and out-selection of nitrite-oxidizing bacteria. As the growth rate of aerobic-oxidizing bacteria is higher than nitrite-oxidizing bacteria at the temperature above 30 °C, the removal of nitrite-oxidizing bacteria at suspended biomass systems for partial nitritation with minimum sludge retention time (SRT) is possible (Lackner et al. 2014).

Anammox bacteria are more conducive with higher NO2− concentration (Herbert Jr et al. 2014). However, nitrite concentration showed inhibitory effect to the reactor at more than 10 mg N L−1, though it is an essential substrate (Lackner et al. 2014; Wett 2007). Threshold concentration could spread over a wide range as summarized in Table 4.

Anammox bacteria can also be repressed by free nitrous acid. However, if pH range is above 7.0, nitrite is predominantly responsible for inhibition of anammox (Lackner et al. 2014; Puyol et al. 2014). As reported, 50% inhibition of anammox bacteria can be caused by free ammonium with the concentration of 35–40 mg N L−1 (Fernández et al. 2012). Some researchers reported the suppression of anammox activity by methanol (Lackner et al. 2014; Güven et al. 2005; Isaka et al. 2008). Though nitrate build-up is not essential for inhibition, it reflects imbalance in microbial community due to the accumulation of nitrite-oxidizing bacteria (Lackner et al. 2014).

Aerobic process

Aerobic methanotrophic bacteria and denitrifying bacteria are primarily linked to biogeochemical methane and nitrogen cycles (Zhu et al. 2016; Modin et al. 2008).

Examples of aerobic methanotrophic bacteria are given below:

-

a.

Crenothrix polyspora (filamentous aerobic methanotrophic g-proteobacteria) (Zhu et al. 2016; Stoecker et al. 2006)

-

b.

Proteobacterial origin (Methylococcaceae (14 genera), Methylocystaceae (2 genera), and Beijerinckiaceae (3 genera))

-

c.

Acidimethylosilex fumarolicum SolV, Methylokorus infernorum V4, and Methyloacida kamchatkensis Kam1), belongs to Verrucomicrobial methanotrophs from extremely acidic habitats (Zhu et al. 2016; Dunfield et al. 2007; Islam et al. 2008; Pol et al. 2007)

Verrucomicrobial methanotrophs are acidic habitants, and they consume CO2 and methane as sources of carbon and energy. There are also aerobic methanotrophic bacteria which are culturably divided into three assemblages (types I, II, and X). Dominant phospholipid fatty acids (PLFAs) are associated with type I, C18 fatty acid are present in type II. C14, C16, C17, and C18 fatty acids for PLFAs were also detected prominently in uncultured aerobic methanotrophs (Zhu et al. 2016).

Aerobic methanotrophic bacteria are oxygen dependent, and they perform methane oxidation to be converted into carbon dioxide (CO2) in the presence of oxygen. The process is initiated by methane monooxygenase (MMO) where methanol is produced as an intermediate. The produced methanol is oxidized by pyrroloquinoline quinone (PQQ)-dependent methanol dehydrogenase (MDH) to form formaldehyde (Zhu et al. 2016). Some of the formaldehyde is utilized in ribulose monophosphate (RuMP) pathway to produce intermediates such as acetate and citrate. Remaining part of formaldehyde is converted to CO2 through formate pathway which reduces equivalent nicotinamide adenine dinucleotides (NADHs) for the initial methane oxidation step (Zhu et al. 2016; Lieberman and Rosenzweig 2004).

pMMO is a well-known methanotrophs that belong to proteobacterial which could oxidize ammonium (Zhu et al. 2016; Trotsenko and Murrell 2008). pMMO and AMO have the same properties as they are reductant, inhibitor, and having active site; as a result, both could have same pathway for methane and ammonium oxidation (Zhu et al. 2016). Due to these features, type I methanotrophs which are predominant in environments of high nitrogen contents, can oxidize ammonium and other by-products such as hydroxylamine, NO, and NO2− (Zhu et al. 2016; Tamas et al. 2014). NO2− could inhibit bacterial growth, therefore the reduction of NO2− to N2O by aerobic methanotrophic bacteria would be a strategy for survival under high concentration of NO2− (Zhu et al. 2016). There is another study carried out where nirK, narG, norC, and norB were observed to raise up in aerobic methanotrophic bacteria under hypoxic condition with high concentration of NOx. They can survive there because of their diverse nitrogen metabolism. They use NO3− as electron acceptor for respiration process for methane oxidation and production of N2O as terminal products (Zhu et al. 2016; Kits et al. 2015). N2O could be derived from two important habitats viz., high nitrogen loading and from the area with diverse methanotrophic bacteria (Zhu et al. 2016; Lee et al. 2009; Mandernack et al. 2000; Wang et al. 2008).

It is also noticed that aerobic methanotrophic bacteria with some denitrifying genes work in cooperation to perform the denitrification process. For instance, NO3− to N2O was performed by Methylobacter tundripaludum (aerobic methanotrophic bacteria) with narG and nirS genes followed by Methylomonas methanica or Methylomicrobium alcaliphilum (aerobic methanotrophic bacteria) with norB gene (Zhu et al. 2016; Dumont et al. 2013) Methylococcaceae shows notable positive response for their activity after adding oxygen and NO3− (Zhu et al. 2016; Beck et al. 2013). Aerobic methanotrophic bacteria utilize methane as their carbon source and energy while the intermediate soluble organic metabolites such as methanol, acetate, citrate, polysaccharides, and proteins are released to denitrifiers to be used as electron donor to reduce NO3− or NO2−. Theoretically, a minimum of 40% methanol is utilized by aerobic methanotrophs themselves, and the remaining maximum of 60% could be used by denitrifiers for their metabolism. Nevertheless, 60% methanol which is captured by denitrifiers will become lower if the aerobic methanotrophs work under rich content of oxygen. This is because the remaining portion of methanol is utilized for synthesis of cells (Zhu et al. 2016). If the ratio of methane (mol)/NO3− (mol) consumption (C/N) is around 1.39 maximum percentage of methanol will be utilized by denitrifier. The lower the C/N value, higher the percentage of methanol utilization by denitrifiers (Zhu et al. 2016; Modin et al. 2007). It is better to measure methane and NO3− than to measure methanol (used by the denitrifiers) because the other substrates will only be produced after the formation of methanol. However, the possibility of methanol excretion in bulk medium is very less because it is captured by MDH to convert it into formaldehyde. Methylococcus capsulatus converts methane to formaldehyde without methanol intermediate (Zhu et al. 2016). Acetate is added to increase the carbon and thereby increasing the NO3− removal rate. Addition of acetate will help to remove NO3− and NO2− by more than 95% (Herbert Jr et al. 2014). Under oxygen limited conditions (5%), methane dependent denitrifying bioreactor consist of major bacteria which are Methylocystis parvus and Mesorhizobium plurifarium where M. parvus is electron donor to M. plurifarium via production of acetate which is the main trophic link (Zhu et al. 2016; Costa et al. 2000). The concentration of NO3− and acetate does not limit the reaction rate (Herbert Jr et al. 2014).

Citrate is another key metabolite which links the Methylomonas (methanotroph) and P. stutzeri (non-methylotrophic denitrifier) (Zhu et al. 2016). Methanol-utilizing denitrifiers are less populated compared with acetate-dependent denitrifiers (Costa et al. 2000) due to the less possibility for aerobic methanotroph to live upon methanol. However, under specific environment, aerobic methanotrophs excrete methanol for survival. Acetate-degrading denitrifier could be predominant in growth phase under short SRT with/without sufficient substrate as compared with methanol-degrading denitrifiers which could dominate in the maintenance phase under long retention time with/without dilute substrate. In short, SRT and substrate are two important factors determining the population of aerobic methanotrophic bacteria (Zhu et al. 2016).

Advanced biological treatment technology

With the recent emerging of new technologies, biological process becomes one of the important elements in treating the leachate originated from biowaste. The mechanism of color removal in the biological treatment is due to the absorption or partial assimilation of colloidal matter by the biomass (Oulego et al. 2016; Sawyer et al. 2003). However, effluent from the aerobic process and anaerobic process alone could not meet the limit. For example, removal efficiency for COD under aerobic and anaerobic process could be achieved at 40 and 30%, respectively (Akkaya et al. 2010). COD is 400–1500 mg L−1 after biological treatment due to non-biodegradable matter in the leachate and should be removed to comply with the discharged limit (Oulego et al. 2016; Kulikowska and Klimiuk 2008). Humic acid and fulvic acid fraction are the main non-biodegradable substances which are responsible for the coloration in the leachate. The other drawbacks of biological treatment are foam formation, metal contamination, lack of nutrients, and sludge settling (Oulego et al. 2016). It should be integrated with the chemical and physical processes to meet the effluent discharge limit. Among the recent widely studied technologies for the biological treatment process are aerobic methane oxidation coupled to denitrification (AME-D) process and partial nitritation–anammox (PN/A) process.

Generally, nitrifying and denitrifying bioreactors depend on hydraulic conditions, geochemical conditions, microbiological characteristics, and partially dependent to organic matters. The preferential flow should happen at the central region. Limitation of substrate occurs at the edges of the bioreactor with higher fraction of steady water and results in the poor performance of bioreactor (Herbert Jr et al. 2014). Preferential flow could lead to short HRT and deplete the labile organic carbon reserve in the substrate. It results in lower removal rates of contaminants (Herbert Jr et al. 2014; Christianson et al. 2013). Due to this factor, a supplemental feeding for carbon and energy source is needed in the bioreactor (Herbert Jr et al. 2014). If water saturation is maintained at all depths and flow maintained evenly in the reactor, overall removal of nitrite and nitrous oxide will be enhanced. The design of bioreactor should also consider the distribution of denitrifying community as well as nitrifying community. For heterogeneous community distribution, further investigation should be carried out if it is due to water saturation, flow field, competition with other functional group, or poor water chemistry. The design of bioreactor shall also consider the emission of nitrous oxide (Herbert Jr et al. 2014).

Aerobic methane oxidation-denitrification process

Major source of methane is not from fuel consumption but from uncontrolled anaerobic degradation of organic compounds from natural and anthropogenic activities (Zhu et al. 2016; Bousquet et al. 2006). Biogeochemical methane and nitrogen cycle happens via methane oxidation and denitrification (Zhu et al. 2016). AME-D provides an alternative solution for nitrogen removal of NO3 and NO2 in landfill biowaste, wastewater, and drinking water (Zhu et al. 2016; Modin et al. 2007). AME-D could be applied for nitrogen removal by offsetting eutrophication and atmospheric methane concentrations simultaneously (Knittel and Boetius 2009). Removal of nitrogen is 0.6 g NO3–N g−1 VSS day−1 through AME-D process and accounted for 5–75% removal rate. It also links for the consumption and production of methane and N2O, respectively. Aerobic methanotrophs has dual functionalities that are methane oxidation and partial denitrification, which makes the understanding of AME-D process challenging (Zhu et al. 2016).

AME-D could be divided into two separate pathways by considering the biogeochemical cycle of methane and nitrogen cycle.

-

a.

N2O production by partial denitrification (i.e., incomplete denitrification with aerobic methanotrophs (novel pathway)) (Stein and Klotz 2011).

-

b.

Methanotrophs and denitrifiers work in cooperative metabolism (Zhu et al. 2016; Modin et al. 2007) where aerobic methanotrophs oxidized methane to methanol with methane monooxygenase (MMO) and continued to metabolize a part of methanol as carbon source and energy. Remaining methanol was excreted out from aerobic methanotrophs into the extracellular part to be utilized by denitrifier for NO3−/NO2− reduction (Zhu et al. 2016).

Methylobacter (aerobic methanotrophic bacteria) and Methylotenera (denitrifying methylotrophs) are the major microbial community present in the AME-D systems. Among which M. tundripaludum, M. methanica, and M. alcaliphilum are the majorly involved microorganisms in methane metabolism. The above said species transcribe the denitrifying genes (narG, nirS, and norB) to accomplish few steps of denitrification (Zhu et al. 2016). Methanol is primary substrate utilized by aerobic methanotrophs to produce a reducing agent for methane oxidation (Zhu et al. 2016; Trotsenko and Murrell 2008). It is considered the most critical substrate for the operation of AME-D process among the other identified substrate (formaldehyde, formate, acetate, and citrate). Under mixed methylotrophs, denitrifier (Hyphomicrobium sp.) and type II methanotroph (M. capsulatus) are observed to perform low level of methanol production, NO3− consumption, and dinitrogen accumulation in presence of methane and oxygen (Zhu et al. 2016). In real conditions due to insufficient carbon source in the wastewater, additional methanol and simple organic matter is needed to support denitrification. Additional cost will be incurred and can cause pollution if it is added in excess. Cooperative AME-D is also performed by aerobic methanotrophs and denitrifiers where acetate and citrate were identified as probable trophic links (Zhu et al. 2016; Costa et al. 2000). However, the abundance of acetate-utilizing denitrifier in AME-D system could cause toxicity towards methanotrophs due to the organic acid formed as acetate (Zhu et al. 2016; Bothe et al. 2008).

Methane can be utilized as carbon source by methanotrophs in the denitrification process. The methanotroph include aerobic methanotrophic bacteria (Zhu et al. 2016; Kits et al. 2015), bacteria of NC10 phylum (Zhu et al. 2016), and anaerobic methane-oxidizing archaea (Zhu et al. 2016; Haroon et al. 2013). Methane gas is inexpensive and could be obtained via anaerobic digestion (Zhu et al. 2016; Modin et al. 2007). Methane gas unlikely induces secondary pollution to drinking water and groundwater (Eisentraeger et al. 2001). Supply of methane and oxygen (two flammable gases) can be provided in two separate media. The supply of gas in the system should be optimum and monitored to balance the nitrogen removal managing the low operating cost. Supply of methane and oxygen to activated sludge system was carried out by Zhu et al. (2016), Liu et al. (2014), and Waki et al. (2005). It was studied that, due to the low solubility and difficulty of controlling DO, C/N ratio in the activated sludge ranged from 4 to 12. The C/N ratio was higher than theoretical value of 1.27 to 1.39 (Zhu et al. 2016; Modin et al. 2007). Optimization of the operation parameter is required due to wide gap of theoretical value and experimental value for C/N (Zhu et al. 2016).

AME-D combined with membrane biofilm reactor (MBfR) has very high potential for removal of nitrogen in wastewater. Current study on MBfR with AME-D emphasizes on nitrogen removal. Complete denitrification with small amount of N2O was achieved by Zhu et al. (2016). Supply of methane and oxygen gas through membrane lumen increased the mass transfer efficiency towards removal of nitrogen, COD and other contaminants (Zhu et al. 2016). Modin et al. (2010) reported the lower C/N ratio of 2.8–4.0 in such systems while the specific nitrogen removal rates increased to 1.55–1.78 g NO3–N g−1 VSS day−1 (Zhu et al. 2016; Sun et al. 2013). This might be the contribution of a part of methanol from aerobic methanotrophs to an abundance of methanol utilizing denitrifier in MBfR (Zhu et al. 2016). Several studies monitored the release of N2O to environment during the operation of MBfR, and membrane fouling could be resolved with anaerobic fluidized-bed membrane reactor to reduce high energy cost to deliver the gas substrate (Zhu et al. 2016; Martin and Nerenberg 2012). Anaerobic fluidized-bed membrane bioreactor (AFMBR) is a filtration system with fluidization-induced sheer force. It should be further integrated with gas permeable membrane reactor to get the membrane to act as active AME-D biofilm to get high mass transfer while avoiding membrane fouling. New techniques like meta-omic, FISH-SIMS, and Nano-SIMS can provide a better understanding of AME-D pathway (Zhu et al. 2016). Economic aspect should be assessed for the proposed technology. Development of cost-effective membrane will promote the membrane technology (Zhu et al. 2016; Martin and Nerenberg 2012). Solution for the above limitations should be addressed before proceeding with engineering consideration to capitalize the AME-D process.

Partial nitritation/anammox process

The recent technology in the biological treatment for ammonium-contained leachate from biowaste is PN/A process where partial oxidation of ammonium to nitrite (nitritation) takes place (Lackner et al. 2014). For controlled nitritation, early PN/A implementation used two-stage reactor configuration (i.e., SHARON type reactors). For applicability to the full-scale experience, the focus is shifted to single stage system, e.g., moving bed biofilm reactor (MBBR) (Rosenwinkel and Cornelius 2005), sludge blanket reactor (SbR) (Joss et al. 2009; Wett 2007), granular sludge processes (Abma et al. 2010), rotating biological contactors (RBC) (Hippen et al. 1997), and activated sludge systems (Lackner et al. 2014; Desloover et al. 2011). Based on the existing operated full-scale plants, the effluent characteristics have the ammonium concentration from 500 to 5000 mg N L−1 and COD/N ratio was less than 2 (Lackner et al. 2014). It means that the N removal is the dominant electron acceptor. Total soluble solids (TSS) mean was 200–300 mg L−1. The treated ammonium ranged from 5 to 200 mg N L−1. The PN/A process requires less organic carbon by 100%, less oxygen requirement by 60%, and less sludge production by 90%. Therefore, this process is suitable for high ammonium concentration and low C/N ratio (Mulder 2003; Siegrist et al. 2008; van Loosdrecht and Salem 2006).

The successful application of PN/A process requires online measurement and the troubleshooting of the matters arisen. Online measurement requires the measurement of pH, DO, air flow rate and nitrogen species (i.e., ammonium and nitrate except for nitrite in some cases). If pH is too high (> 8.0), it can cause the anammox activity inhibition and subsequently increase the nitrite. However, if pH is too low (< 6.8), it can cause the limitation of ammonium-oxidizing bacteria. When the DO requirement is too low, measurement of air flow rate instead of DO concentration is a more reliable control parameter. If the aeration intensity is not detected immediately, it could lead to increase the nitrate production from 10 to 40% (Lackner et al. 2014).

For troubleshooting, one of the issues is the accumulation of N species especially the build-up of nitrate and nitrite. To have a good performance of ammonium removal, nitrate and nitrite should not be present in PN/A plants. Therefore, one should be more cautious during the start-up as ammonium-oxidizing bacteria grow faster than anammox bacteria, it will lead to inhibit nitrite (NO2−) concentration. Inhibition of ammonium-oxidizing bacteria and subsequent increase of DO in the reactor causes the inhibition of anammox bacteria (Lackner et al. 2014; Joss et al. 2011). Free ammonia and nitrite concentration have also to be limited due to potential inhibitory effects. This issue could be counter-measured by decreasing or completely stopping the aeration and being left with mixing only for an extended time. Biomass removal and reduced flow of influent could be another way to solve the accumulation of N species (Lackner et al. 2014). Besides, other issues related to the operation of the plant are foam formation, scaling, solids retention, settling, and separation (Lackner et al. 2014).

Sequential batch reactor (PN/A)

NH4+-controlled PN/A process is one of the well-known sequential batch reactor (SBR) technology. The feeding can be done in parts or during the aeration phase. Feeding continuously during the aeration phase gives more stable operation. Therefore, the feed rate is controlled by NH4+ concentration and conductivity signal is used to monitor the NH4+. The aeration is also controlled volumetrically to allow simultaneous nitritation and anammox, resulting DO of 0.1 mg L−1 (Lackner et al. 2014). Volumetric loading rates varied for the surveyed SBR from 0.04 to 0.65 kg N m−3 day−1, TSS ranged from < 1.0 to > 4.5 g L−1. HRT was 1–5 days, and sludge loading rate was 71–155 g N kg−1 TSS day−1. The energy requirement for SBR-PN/A side-stream treatment system is 0.8–2 kWh kg−1 N (Lackner et al. 2014). A similar value (1.2 kWh kg−1 N) is also reported by Wett et al. (2010). Whereas, energy consumption in conventional nitrification/denitrification (N/DN) side stream treatment is 4.0 kWh kg−1 N. The energy saving is 50% in SBR-PN/A system due to oxygen transfer efficiency and bubble aeration (Lackner et al. 2014).

Few strategies for the operation of SBR-PN/A system are selected and applied in the current full-scale plants by Lackner et al. (2014). Generally, one of the strategies may choose the continuous feeding which is automatic activation of the aeration when ammonium concentration exceed the upper limit and it stops when either pH or ammonium concentration falls below a lower limit. In the above said system, DO was kept below 0.5 mg L−1. Another strategy is to run the 8-h reaction cycle. Sixty percent reaction time is for the aerated phase (0.3–0.8 mg O2 L−1) followed by an anoxic stirred phase for about 40% of the reaction time (Lackner et al. 2014; Jeanningros et al. 2010). Continuous aeration is preferred at very low DO levels. Intermittent aeration can also be provided with pulses of 5–10 min or shorter period (if higher DO is present). Fine tuning of NO2−/NH4+ ratio was assisted by online ammonium and nitrite/nitrate measurement (Lackner et al. 2014). The above-mentioned strategies used one-stage system instead of two-stage reactor like SHARON/anammox process with a granular sludge bed in two reactor compartments on top of each other. After 3.5 years of start-up, the second stage converted 90–95% of the nitrogen load of 20 kg m−3 day−1 (Lackner et al. 2014; Abma et al. 2007). Eventually, it was redesigned into a one-stage system. DEMON system is the most common configuration used in the SBR. It uses cyclone to remove fine particulate and retain large anammox granules in the system. For conventional SBR system, due to the reduced settling time, sludge is wasted with the effluent discharge (Lackner et al. 2014).

Rotating biological contactors system

Traditional biofilm technologies have been successfully used for PN/A such as RBC. Though the operational cost was low, the flexibility for the process control was limited. Where, variation of rotation speed and disk submersion level strategy was used to control DO. The treatment efficiency is expected to be 150 kg N day−1. Therefore, 1–4 rpm rotation speed of RBC was required to achieve DO concentration target at 0.60–0.65 mg L−1 in the bulk liquid and pH was set at 7.0–7.5 with caustic soda (NaOH) addition. Other control method was the online ammonium measurement (Lackner et al. 2014).

Moving bed biofilm reactor

Unlike SBR system, MBBR is occupied with 40–50% carriers (AnoxKaldnes K1) and equipped with aeration, stirrers, and settler (Lackner et al. 2014; Rosenwinkel and Cornelius 2005; Szatkowska et al. 2007). Aeration, DO, pH, temperature, and SRT are monitored. It can be a single-stage PN/A process known as ANITAMOX (Lackner et al. 2014) or a multistage combination PN/A and N/DN by using activated sludge concept. Multistage configuration of PN/A consists of an aerated reactor, mixed reactor, and settlers (Lackner et al. 2014). If the integrated fixed film sludge (IFAS) with a settler is installed in the MBBR system, the suspended sludge retained from effluent holds 90% of the aerobic-oxidizing ammonium bacteria and have better performance than the pure biofilm system (Lackner et al. 2014; Veuillet et al. 2014). Similar to IFAS, bentonic clays (patented as TERRANA) is added to the suspended sludge in SBR or two-stage activated sludge process (ASP). TERRANA serves as substrate for attached growth to help to retain anammox bacteria and improved settling ability. It also can serve as a source of alkalinity and treat the poorly buffered wastewater (Lackner et al. 2014).

Biofilm/granular system

For granular system, lamella separator is used for granule retention. For IFAS, fine particle sludge is retained with a settler. According to Lackner et al. (2014), high volumetric loading rates were observed from 1.0 to 7.0 kg N m−3 day−1 in the anammox stage of the two-stage system. This is due to higher biomass concentration (15–20 g L−1) in carrier-based biofilm systems and granular systems (25–35 g L−1). Bentonite clays can function as carrier and pH stabilizer. Sludge loading rate is less than 100 kg N g−1 TSS day−1. HRT is less than 24 h. More robust behavior of biofilm/granular-based system compared with SBR, however energy demand seems higher for the biofilm/granular system (Lackner et al. 2014).

Performance comparison of PN/A process with other selected biological treatment process

Comparison of the performance of PN/A process with other selected biological treatment technologies such as membrane bioreactor (MBR), internal circulation of upflow sludge blanket reactor (ICUSbR), and sequencing batch biofilter granular reactor (SBBGR), and it is shown in Table 5. The chosen biological treatment technology for PN/A process is a two-stage treatment via anoxic/aerobic (A/O) reactor and upflow anaerobic sludge blanket (UASB-anammox) (Wang et al. 2016). The advantage of a two-stage process over one-stage process is high nitrogen removal in the lab scale experiment. Nitrogen removal rate for one-stage process and two-stage process is 76.7 and 0.06–1.80 kg N (m3 day)−1, respectively, as reported in the UASB process (Wang et al. 2016; Tang et al. 2011; Van Hulle et al. 2010).

Nitrification process is developed in the MBR whereby ammoniacal nitrogen is converted to nitrate. Though ammoniacal nitrogen removal was 98.2%, nitrate accumulation was observed in the leachate (Zolfaghari et al. 2016). Unlike the MBR process, simultaneous denitrification process takes place in SBBGR as the total content of nitrate and nitrite concentration is also reduced by 98%. A similar reduction performance of ammoniacal nitrogen was achieved in MBR and SBBGR. The removal of ammoniacal nitrogen and nitrite in anammox process is not affected by the presence of COD in A/O reactor–UASB which has strong COD-shock resistance. Both the processes have removal rates around 98%. However, the anammox process is not favorable for removal of recalcitrant compound which could be seen in low COD removal rate (i.e., 17.6%) for the stabilized leachate as shown in the research by Wang et al. (2016). COD is closely related to the recalcitrant compounds which is removed in MBR by 63.4% (Zolfaghari et al. 2016). The biological process can remove most of the biodegradable compounds which are represented by BOD5 with low value at the effluent discharge as compared with COD (Zolfaghari et al. 2016; Cassano et al. 2011). DO has a significant effect on removal of ammoniacal nitrogen than COD. This is due to the occurrence of nitrification process in the aerobic condition where high removal of ammoniacal nitrogen is observed under 4.0 mg L−1 of DO (Abood et al. 2013). However, the anammox reactor is separated from the nitrification reactor as the existence of DO can act as inhibitor to the anammox activity (Wang et al. 2016).

It can be concluded that SRT cannot be used as the only selection criteria for combined PN/A due to the slower growth rate of the anammox biomass (Lackner et al. 2014). The most practical approach is to operate PN/A at low oxygen concentration which favors the growth of aerobic ammonium oxidizing bacteria instead of nitrite oxidizing bacteria (Blackburne et al. 2008; Wyffels et al. 2004). The selective biomass enable wash-out of nitrite oxidizing bacteria in small flocs and retains the anammox bacteria in larger aggregates (Lackner et al. 2014).

Challenges and perspectives

With the concern of the government of Malaysia, landfills should be properly designed as sanitary landfills with suitable leachate treatment system, a gas ventilation system for waste treatment before disposal (Manaf et al. 2009). The challenge is to establish an efficient treatment for the leachate management especially dealing with the disposed biowaste into the landfill (Amr et al. 2014). The complexity of the leachate characteristics of biowaste depends on the habit of segregation of the recyclable domestic wastes before ending up to the landfills. Recycling can reduce the operational cost of the leachate treatment plants. Biowaste contribute organic compounds that are required to be further treated in the leachate treatment system. Therefore, the fluctuation of the landfill leachate composition is one of the challenges in operation of the leachate treatment plant. Further research is required to study the microorganism behaviour in the anammox activity in terms of its interaction and relationship with the other microorganisms including ammonium oxidizing bacteria and nitrite oxidizing bacteria for performance stability of the process. Rapid cultivation method needs to be developed for anammox bacteria in the commercial application. The remaining challenges are to solve the solids regime and unknown inhibitory effect. Focus should be given to discover novel pathways including the kinetic process and SRT for comprehensive understanding of the AME-D and PN/A process. In the AME-D process, excess dosage of methanol to support the denitrification could cause the secondary pollution. Understanding of optimum gas supplies of methane and oxygen needs to be studied comprehensively. Integration of MBfR and AFMBR could increase the mass transfer of the gas to the microorganism while solving the issue of membrane fouling. Additional usage of chemical and gas supply could incur high operation cost in a long run. Better understanding in biodegradability kinetics is required to know the leachate characteristic of the biowaste (Amr et al. 2014).

Conclusions

The recycling process in Malaysia is still at the infant stage and landfilling rate high; it causes the complexity of the leachate composition. Most of the treatment options used in the leachate treatment system are based on the non-renewable source of physicochemical treatment and the energy-intensive of biological process. In this review, the biological process using the combination of the microorganism community resulting in the novel shortcut pathway is studied. This pathway can replace the conventional nitrification-denitrification process. In future researches, integration of different best available technologies could further enhance the contaminants removal rate from leachate-generated form biowaste. That will be helpful in order to meet the national water quality standards applied for the river water quality monitoring for Malaysia. Finally, the goals of national solid waste management policy could successfully be implemented using proper leachate treatment systems. The aim of the proper waste management is to generate a universal system which is cost effective, sustainable, and acceptable to the community. The emphasis of the system should be the environmental conservation with adopting the technology which are affordable and assure public health. Implement of the solid waste management and treatment system should be based on the waste management hierarchy that gives the priority to waste reduction through 3R (reduce, reuse and recycle) principle, intermediate treatment, and final disposal. Adaptation of this strategy will protect the environment keeping control on resource and energy consumption to the most favorable actions.

References

Abbas, A. A., Jingsong, G., Ping, L. Z., Ya, P. Y., & Al-Rekabi, W. S. (2009). Review on landfill leachate treatments. Journal of Applied Sciences Research, 5, 534–545.

Abma, W. R., Schultz, C. E., Mulder, J. W., Van der Star, W. R., Strous, M., Tokutomi, T., & Van Loosdrecht, M. C. (2007). Full-scale granular sludge anammox process. Water Science and Technology, 55, 8–9.

Abma, W. R., Driessen, W., Haarhuis, R., & Van Loosdrecht, M. C. (2010). Upgrading of sewage treatment plant by sustainable and cost-effective separate treatment of industrial wastewater. Water Science and Technology, 61, 1715–1722.

Abood, A. R., Bao, J., & Abudi, Z. N. (2013). Biological nutrient removal by internal circulation upflow sludge blanket reactor after landfill leachate pretreatment. Journal of Environmental Sciences, 25, 2130–2137.

Agamuthu, P., & Masaru, T. (2014). Municipal solid waste management in Asia and the Pacific Islands: challenges and strategic solutions. Singapore: Springer.

Akkaya, E., Demir, A., Karadag, D., Varank, G., Bilgili, M. S., & Ozkaya, B. (2010). Post-treatment of anaerobically treated medium-age landfill leachate. Environmental Progress & Sustainable Energy, 29, 78–84.

Alvarez-Vazquez, H., Jefferson, B., & Judd, S. J. (2004). Membrane bioreactors vs conventional biological treatment of landfill leachate: a brief review. Journal of Chemical Technology and Biotechnology, 79, 1043–1049.

Amr, A. S. S., Aziz, H. A., Adlan, M. N., & Alkasseh, J. M. (2014). Effect of ozone and ozone/persulfate processes on biodegradable and soluble characteristics of semiaerobic stabilized leachate. Environmental Progress & Sustainable Energy, 33, 184–191.

Andrus, J. M., Porter, M. D., Rodríguez, L. F., Kuehlhorn, T., Cooke, R. A., Zhang, Y., Kent, A. D., & Zilles, J. L. (2014). Spatial variation in the bacterial and denitrifying bacterial community in a biofilter treating subsurface agricultural drainage. Microbial Ecology, 67, 265–272.

Aziz, H. A., Yusoff, M. S., Adlan, M. N., Adnan, N. H., & Alias, S. (2004). Physico-chemical removal of iron from semi-aerobic landfill leachate by limestone filter. Waste Management, 24, 353–358.

Aziz, H. A., Alias, S., Adlan, M. N., Asaari, A. H., & Zahari, M. S. (2007). Colour removal from landfill leachate by coagulation and flocculation processes. Bioresource Technology, 98, 218–220.

Aziz, H. A., Yusoff, M. S., Aziz, S. Q., Umar, M., & Bashir, M. J. (2009). A leachate quality at Pulau Burung, Kuala Sepetang and Kulim landfills—a comparative study. Proceedings Civil Engineering Conference (AWAM 09), 978-983.

Aziz, S. Q., Aziz, H. A., Yusoff, M. S., Bashir, M. J., & Umar, M. (2010). Leachate characterization in semi-aerobic and anaerobic sanitary landfills: a comparative study. Journal of Environmental Management, 91, 2608–2614.

Aziz, S. Q., Aziz, H. A., Bashir, M. J., & Mojiri, A. (2015). Assessment of various tropical municipal landfill leachate characteristics and treatment opportunities. Global NEST Journal, 17, 439–450.

Bai, T., Lei, H., Yu, G., Yu, Q., Li, Z., & Li, H. (2009). High nitrite accumulation and strengthening denitrification for old-age landfill leachate treatment using an autocontrol two-stage hybrid process. Process Safety and Environment Protection, 87, 307–314.

Bashir, M. J., Isa, M. H., Kutty, S. R., Awang, Z. B., Aziz, H. A., Mohajeri, S., & Farooqi, I. H. (2009). Landfill leachate treatment by electrochemical oxidation. Waste Management, 29, 2534–2541.

Beck, D. A., Kalyuzhnaya, M. G., Malfatti, S., Tringe, S. G., del Rio, T. G., Ivanova, N., Lidstrom, M. E., & Chistoserdova, L. (2013). A metagenomic insight into freshwater methane-utilizing communities and evidence for cooperation between the Methylococcaceae and the Methylophilaceae. PeerJ., 9, 23.

Bettazzi, E., Caffaz, S., Vannini, C., & Lubello, C. (2010). Nitrite inhibition and intermediates effects on anammox bacteria: a batch-scale experimental study. Process Biochemistry, 45, 573–580.

Blackburne, R., Yuan, Z., & Keller, J. (2008). Partial nitrification to nitrite using low dissolved oxygen concentration as the main selection factor. Biodegradation, 19, 303–312.

Bothe, H., Jensen, K. M., Mergel, A., Larsen, J., Jørgensen, C., Bothe, H., & Jørgensen, L. (2008). Heterotrophic bacteria growing in association with Methylococcus capsulatus (Bath) in a single cell protein production process. Applied Microbiology and Biotechnology, 59, 33–39.

Bousquet, P., Ciais, P., Miller, J. B., Dlugokencky, E. J., Hauglustaine, D. A., Prigent, C., Van der Werf, G. R., Peylin, P., Brunke, E. G., Carouge, C., & Langenfelds, R. L. (2006). Contribution of anthropogenic and natural sources to atmospheric methane variability. Nature, 443, 439–443.

Bru, D., Sarr, A., & Philippot, L. (2007). Relative abundances of proteobacterial membrane-bound and periplasmic nitrate reductases in selected environments. Applied and Environmental Microbiology, 73, 5971–5974.

Cassano, D., Zapata, A., Brunetti, G., Del Moro, G., Di Iaconi, C., Oller, I., Malato, S., & Mascolo, G. (2011). Comparison of several combined/integrated biological—AOPs setups for the treatment of municipal landfill leachate: minimization of operating costs and effluent toxicity. Chemical Engineering Journal, 172, 250–257.

Christensen, T. H., Kjeldsen, P., Bjerg, P. L., Jensen, D. L., Christensen, J. B., Baun, A., Albrechtsen, H. J., & Heron, G. (2001). Biogeochemistry of landfill leachate plumes. Applied Geochemistry, 16, 659–718.

Christianson, L., Helmers, M., Bhandari, A., & Moorman, T. (2013). Internal hydraulics of an agricultural drainage denitrification bioreactor. Ecological Engineering, 52, 298–307.

Chung, J., Amin, K., Kim, S., Yoon, S., Kwon, K., & Bae, W. (2014). Autotrophic denitrification of nitrate and nitrite using thiosulfate as an electron donor. Water Research, 58, 169–178.

Costa, C., Dijkema, C., Friedrich, M., Garcia-Encina, P., Fernandez-Polanco, F., & Stams, A. J. (2000). Denitrification with methane as electron donor in oxygen-limited bioreactors. Applied Microbiology and Biotechnology, 53, 754–762.

Dapena-Mora, A., Fernandez, I., Campos, J. L., Mosquera-Corral, A., Mendez, R., & Jetten, M. S. (2007). Evaluation of activity and inhibition effects on anammox process by batch tests based on the nitrogen gas production. Enzyme and Microbial Technology, 40, 859–865.

DEFRA. (2011). Government review of waste policy in England, Department of Environment-Food and Rural Affairs.

Desloover, J., De Clippeleir, H., Boeckx, P., Du Laing, G., Colsen, J., Verstraete, W., & Vlaeminck, S. E. (2011). Floc-based sequential partial nitritation and anammox at full scale with contrasting N2O emissions. Water Research, 45, 2811–2821.

Dumont, M. G., Pommerenke, B., & Casper, P. (2013). Using stable isotope probing to obtain a targeted metatranscriptome of aerobic methanotrophs in lake sediment. Environmental Microbiology Reports, 5, 757–764.

Dunfield, P. F., Yuryev, A., Senin, P., Smirnova, A. V., Stott, M. B., Hou, S., Ly, B., Saw, J. H., Zhou, Z., Ren, Y., & Wang, J. (2007). Methane oxidation by an extremely acidophilic bacterium of the phylum Verrucomicrobia. Nature, 450, 879–882.

Egli, K., Fanger, U., Alvarez, P. J., Siegrist, H., van der Meer, J. R., & Zehnder, A. J. (2001). Enrichment and characterization of an anammox bacterium from a rotating biological contactor treating ammonium-rich leachate. Archives of Microbiology, 175, 198–207.

Eisentraeger, A., Klag, P., Vansbotter, B., Heymann, E., & Dott, W. (2001). Denitrification of groundwater with methane as sole hydrogen donor. Water Research, 35, 2261–2267.

Elgood, Z., Robertson, W. D., Schiff, S. L., & Elgood, R. (2010). Nitrate removal and greenhouse gas production in a stream-bed denitrifying bioreactor. Ecological Engineering, 36, 1575–1580.

Europasia Engineering Services Sdn. Bhd. (2016). Detailed EIA for the Proposed Expansion of 130.55 Acres Sanitary Landfill in Mukim Jeram, District of Kuala Selangor, Selangor Darul Ehsan.

Fernández, I., Dosta, J., Fajardo, C., Campos, J. L., Mosquera-Corral, A., & Méndez, R. (2012). Short-and long-term effects of ammonium and nitrite on the anammox process. Journal of Environmental Management, 95, S170–S174.

Foo, K. Y., & Hameed, B. H. (2009). An overview of landfill leachate treatment via activated carbon adsorption process. Journal of Hazardous Materials, 171, 54–60.

Fux, C., Huang, D., Monti, A., & Siegrist, H. (2004). Difficulties in maintaining long-term partial nitritation of ammonium-rich sludge digester liquids in a moving-bed biofilm reactor (MBBR). Water Science and Technology, 49, 11–12.

Ghafari, S., Aziz, H. A., & Bashir, M. J. (2010). The use of poly-aluminum chloride and alum for the treatment of partially stabilized leachate: a comparative study. Desalination, 257, 110–116.

Güven, D., Dapena, A., Kartal, B., Schmid, M. C., Maas, B., van de Pas-Schoonen, K., Sozen, S., Mendez, R., den Camp, H. J., Jetten, M. S., & Strous, M. (2005). Propionate oxidation by and methanol inhibition of anaerobic ammonium-oxidizing bacteria. Applied and Environmental Microbiology, 71, 1066–1071.

Haroon, M. F., Hu, S., Shi, Y., Imelfort, M., Keller, J., Hugenholtz, P., Yuan, Z., & Tyson, G. W. (2013). Anaerobic oxidation of methane coupled to nitrate reduction in a novel archaeal lineage. Nature, 500, 567–570.

Hassan, M., & Xie, B. (2014). Use of aged refuse-based bioreactor/biofilter for landfill leachate treatment. Applied Microbiology and Biotechnology, 98, 6543–6553.

Herbert, R. B., Jr., Winbjörk, H., Hellman, M., & Hallin, S. (2014). Nitrogen removal and spatial distribution of denitrifier and anammox communities in a bioreactor for mine drainage treatment. Water Research, 66, 350–360.

Hippen, A., Rosenwinkel, K. H., Baumgarten, G., & Seyfried, C. F. (1997). Aerobic deammonification: a new experience in the treatment of waste waters. Water Science and Technology, 35, 111–120.

Hoang, V. Y., Jupsin, H., Le, V. C., & Vasel, J. L. (2012). Modeling of partial nitrification and denitrification in an SBR for leachate treatment without carbon addition. Journal of Material Cycles and Waste Management, 14, 3–13.

Hoornweg, D., Bhada-Tata, P. (2012). What a waste: a global review of solid waste management. World Bank’s Urban Development and Local Government Unit of the Sustainable Development Network.

Huo, S., Xi, B., Yu, H., He, L., Fan, S., & Liu, H. (2008). Characteristics of dissolved organic matter (DOM) in leachate with different landfill ages. Journal of Environmental Sciences, 20, 492–498.

Isaka, K., Suwa, Y., Kimura, Y., Yamagishi, T., Sumino, T., & Tsuneda, S. (2008). Anaerobic ammonium oxidation (anammox) irreversibly inhibited by methanol. Applied Microbiology and Biotechnology, 81, 379–385.

Islam, T., Jensen, S., Reigstad, L. J., Larsen, O., & Birkeland, N. K. (2008). Methane oxidation at 55°C and pH 2 by a thermoacidophilic bacterium belonging to the Verrucomicrobia phylum. Proceedings of the National Academy of Sciences of the United States of America, 105, 300–304.

Jayanthi, B., Emenike, C. U., Agamuthu, P., Simarani, K., Mohamad, S., & Fauziah, S. H. (2016). Selected microbial diversity of contaminated landfill soil of Peninsular Malaysia and the behavior towards heavy metal exposure. Catena, 147, 25–31.

Jeanningros, Y., Graveleau, L., Kaldate, A., Vlaeminck, S. E., & Verstraete, W. (2010). Fast start-up of a pilot-scale deammonification sequencing batch reactor from an activated sludge inoculum. Water Science and Technology, 61, 1393–1400.

Jensen, D. L., Ledin, A., & Christensen, T. H. (1999). Speciation of heavy metals in landfill-leachate polluted groundwater. Water Research, 33, 2642–2650.

Jetten, M. S., Wagner, M., Fuerst, J., van Loosdrecht, M., Kuenen, G., & Strous, M. (2001). Microbiology and application of the anaerobic ammonium oxidation (‘anammox’) process. Current Opinion in Biotechnology, 12, 283–288.

Jones, D. L., Williamson, K. L., & Owen, A. G. (2006). Phytoremediation of landfill leachate. Waste Management, 26, 825–837.

Jones, C. M., Stres, B., Rosenquist, M., & Hallin, S. (2008). Phylogenetic analysis of nitrite, nitric oxide, and nitrous oxide respiratory enzymes reveal a complex evolutionary history for denitrification. Molecular Biology and Evolution, 25, 1955–1966.

Joss, A., Salzgeber, D., Eugster, J., König, R., Rottermann, K., Burger, S., Fabijan, P., Leumann, S., Mohn, J., & Siegrist, H. (2009). Full-scale nitrogen removal from digester liquid with partial nitritation and anammox in one SBR. Environmental Science & Technology, 43, 5301–5306.

Joss, A., Derlon, N., Cyprien, C., Burger, S., Szivak, I., Traber, J., Siegrist, H., & Morgenroth, E. (2011). Combined nitritation-anammox: advances in understanding process stability. Environmental Science & Technology, 45, 9735–9742.

Kalyuhznaya, M. G., Martens-Habbena, W., Wang, T., Hackett, M., Stolyar, S. M., Stahl, D. A., Lidstrom, M. E., & Chistoserdova, L. (2009). Methylophilaceae link methanol oxidation to denitrification in freshwater lake sediment as suggested by stable isotope probing and pure culture analysis. Environmental Microbiology Reports, 1, 385–392.

Kartal, B., Rattray, J., van Niftrik, L. A., van de Vossenberg, J., Schmid, M. C., Webb, R. I., Schouten, S., Fuerst, J. A., Damsté, J. S., Jetten, M. S., & Strous, M. (2007). Candidatus Anammoxoglobus propionicus a new propionate oxidizing species of anaerobic ammonium oxidizing bacteria. Systematic and Applied Microbiology, 30, 39–49.

Kim, S., Jung, H., Kim, K. S., & Kim, I. S. (2004). Treatment of high nitrate-containing wastewaters by sequential heterotrophic and autotrophic denitrification. Journal of Environmental Engineering, 130, 1475–1480.

Kim, D., Ryu, H. D., Kim, M. S., Kim, J., & Lee, S. I. (2007). Enhancing struvite precipitation potential for ammonia nitrogen removal in municipal landfill leachate. Journal of Hazardous Materials, 146, 81–85.

Kits, K. D., Klotz, M. G., & Stein, L. Y. (2015). Methane oxidation coupled to nitrate reduction under hypoxia by the Gammaproteobacterium Methylomonas denitrificans, sp. nov. type strain FJG1. Environmental Microbiology, 17, 3219–3232.

Kjeldsen, P., Barlaz, M., Rooker, A., Baun, A., Ledin, A., & Christensen, T. (2002). Present and long-term composition of MSW landfill leachate: a review. Critical Reviews in Environment Science and Technology, 32, 297–336.

Knittel, K., & Boetius, A. (2009). Anaerobic oxidation of methane: progress with an unknown process. Annual Review of Microbiology, 63, 311–334.

Kornboonraksa, T. H., Lee, S., Lee, S. H., & Chiemchaisri, C. (2009). Application of chemical precipitation and membrane bioreactor hybrid process for piggery wastewater treatment. Bioresource Technology, 100, 1963–1968.

Kulikowska, D., & Klimiuk, E. (2008). The effect of landfill age on municipal leachate composition. Bioresource Technology, 99, 5981–5985.

Kurniawan, T. A., Lo, W. H., & Chan, G. Y. S. (2006a). Physico-chemical treatments for removal of recalcitrant contaminants from landfill leachate. Journal of Hazardous Materials, 129, 80–100.

Kurniawan, T. A., Lo, W. H., & Chan, G. Y. S. (2006b). Radicals-catalyzed oxidation reactions for degradation of recalcitrant compounds from landfill leachate. Chemical Engineering Journal, 125, 35–57.

Lackner, S., Gilbert, E. M., Vlaeminck, S. E., Joss, A., Horn, H., & van Loosdrecht, M. C. (2014). Full-scale partial nitritation/anammox experiences—an application survey. Water Research, 55, 292–303.

Leachater. (2011). How leachate changes in a landfill over time. The Leachate Expert Website.

Lee, S. W., Im, J., DiSpirito, A. A., Bodrossy, L., Barcelona, M. J., & Semrau, D. (2009). Effect of nutrient and selective inhibitor amendments on methane oxidation, nitrous oxide production, and key gene presence and expression in landfill cover soils: characterization of the role of methanotrophs, nitrifiers, and denitrifiers. Applied Microbiology and Biotechnology, 85, 389–403.

Lee, A. H., Nikraz, H., & Hung, Y. T. (2010). Influence of waste age on landfill leachate quality. International Journal of Environmental Science and Development, 1, 347–350.

Li, X. Z., & Zhao, Q. L. (2002). MAP precipitation from landfill leachate and seawater bittern waste. Environmental Technology, 23, 989–1000.

Lieberman, R. L., & Rosenzweig, A. C. (2004). Biological methane oxidation: regulation, biochemistry, and active site structure of particulate methane monooxygenase. Critical Reviews in Biochemistry and Molecular Biology, 39, 147–164.

Lim, C. K., Seow, T. W., Neoh, C. H., Nor, M. H. M., Ibrahim, Z., Ware, I., & Sarip, S. H. M. (2016). Treatment of landfill leachate using ASBR combined with zeolite adsorption technology. Biotech, 6, 1–6.

Liu, L. H., & Koenig, A. (2002). Use of limestone for pH control in autotrophic denitrification: batch experiments. Process Biochemistry, 37, 885–893.

Liu, H. J., Jiang, W., Wan, D. J., & Qu, J. H. (2009). Study of a combined heterotrophic and sulfur autotrophic denitrification technology for removal of nitrate in water. Journal of Hazardous Materials, 169, 23–28.

Liu, J., Sun, F., Wang, L., Ju, X., Wu, W., & Chen, Y. (2014). Molecular characterization of a microbial consortium involved in methane oxidation coupled to denitrification under micro-aerobic conditions. Microbial Biotechnology, 7, 64–76.

Liu, Z. P., Wu, W. H., Shi, P., Guo, J. S., & Cheng, J. (2015). Characterization of dissolved organic matter in landfill leachate during the combined treatment process of air stripping, Fenton, SBR and coagulation. Waste Management, 41, 111–118.

Lotti, T., van der Star, W. R. L., Kleerebezem, R., Lubello, C., & van Loosdrecht, M. C. M. (2012). The effect of nitrite inhibition on the anammox process. Water Research, 46, 2559–2569.

Luesken, F. A., Wu, M. L., Op den Camp, H. J. M., Keltjens, J. T., Stunnenberg, H., Francoijs, K., Strous, M., & Jetten, M. S. M. (2012). Effect of oxygen on the anaerobic methanotroph Candidatus Methylomirabilis oxyfera: kinetic and transcriptional analysis. Environmental Microbiology, 14, 1024–1034.

Manaf, L. A., Samah, M. A. A., & Zukki, N. I. M. (2009). Municipal solid waste management in Malaysia: practices and challenges. Waste Management, 29, 2902–2906.

Manconi, I., Carucci, A., & Lens, P. (2007). Combined removal of sulfur compounds and nitrate by autotrophic denitrification in bioaugmented activated sludge system. Biotechnology and Bioengineering, 98, 551–560.

Mandernack, K. W., Kinney, C. A., Coleman, D., Huang, Y. S., Freeman, K. H., & Bogner, J. (2000). The biogeochemical controls of N2O production and emission in landfill cover soils: the role of methanotrophs in the nitrogen cycle. Environmental Microbiology, 2, 298–309.

Martin, K. J., & Nerenberg, N. (2012). The membrane biofilm reactor (MBfR) for water and wastewater treatment: principles, applications, and recent developments. Bioresource Technology, 122, 83–94.

Marttinen, S. K., Kettunen, R. H., & Rintala, J. A. (2003). Occurrence and removal of organic pollutants in sewages and landfill leachates. The Science of the Total Environment, 301, 1–12.

Modin, O., Fukushi, K., & Yamamoto, K. (2007). Denitrification with methane as external carbon source. Water Research, 41, 2726–2738.

Modin, O., Fukushi, K., Nakajima, F., & Yamamoto, K. (2008). Performance of a membrane biofilm reactor for denitrification with methane. Bioresource Technology, 99, 8054–8060.

Modin, O., Fukushi, K., Nakajima, F., & Yamamoto, K. (2010). Nitrate removal and biofilm characteristics in methanotrophic membrane biofilm reactors with various gas supply regimes. Water Research, 44, 85–96.

Mohammadzadeh, H., Clark, I., Marschner, M., & St-Jean, G. (2005). Compound Specific Isotopic Analysis (CSIA) of landfill leachate DOC components. Chemical Geology, 218, 3–13.

Moon, H. S., Ahn, K. H., Lee, S., Nam, K., & Kim, J. Y. (2004). Use of autotrophic sulfur-oxidizers to remove nitrate from bank filtrate in a permeable reactive barrier system. Environmental Pollution, 129(3), 499–507.

Mulder, A. (2003). The quest for sustainable nitrogen removal technologies. Water Science and Technology, 48, 67–75.

Nazrieza, N., Siti Rohana, M. Y., Subramaniam, K., & Hazilia, H. (2015). Characterization of leachate from panchang bedena landfill, Batang Padang Landfill and Matang Landfill: a comparative study. Malaysian Journal of Science, 34, 69–77.

Oman, C. B., & Junestedt, C. (2008). Chemical characterization of landfill leachates—400 parameters and compounds. Waste Management, 28, 1876–1891.

Oulego, P., Collado, S., Laca, A., & Díaz, M. (2016). Impact of leachate composition on the advanced oxidation treatment. Water Research, 88, 389–402.

Park, S., & Yoon, T. (2007). The effects of iron species and mineral particles on advanced oxidation processes for the removal of humic acids. Desalination, 208, 181–191.