Abstract

This paper presents recent developments in advanced biological treatment technologies for landfill leachate (LFL) treatment that are attracting increasing attention and have a high treatment potential in the near future. Landfills are designed to dispose high quantities of waste at economical costs with potentially less environmental effects; however, improper landfill management may pose serious environmental threats through discharge of high-strength polluted wastewater also known as leachate. The generated leachate must be appropriately treated before being discharged into the environment. LFL, is very difficult to treat using conventional biological processes. This paper focused on achievements on landfill leachate treatment by different advanced biological treatment technology. Study also explores the fundamental principles as well as the applicability of the advanced biological treatment technologies which are finding increasing application worldwide for their compactness, low footprint, and high efficiency.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Landfilling of municipal waste is still a very important issue of the waste management system in all over the world. Some alternative methods such as recycling, composting, and incineration are nowadays very much encouraged but even incinerations create residue of approximately 10–20% that must be ultimately landfilled (Wiszniowski et al. 2006). As the developing countries are beginning to adopt modern solid waste management practices with the up-gradation of the existing dumpsites and unsanitary landfills, leachate management would require a highly specialized approach in dealing with the constituent pollutants in it. Landfill leachate treatment is an integral part of municipal solid waste (MSW) management that in turn has a skin-blood relationship with urban infrastructure. To ensure the protection of our ecosystem, environmental health, and foster sustainable development, the waste generated by the increasing urban population requires treatment and disposal in an environmentally sound manner. MSW from the urban habitat is disposed off in dumpsites (a crude form of disposal) or in sanitary or engineered landfills. The constituents of the MSW undergo biological and chemical degradation after disposal resulting in emissions of landfill gas and discharge of leachate, which is a highly polluted form of wastewater when discharged into the environment, and would cause potential damages to environmental health and the ecosystem (Visvanathan et al. 2004).

Landfill leachate is the dark colored liquid with strong smell produced by natural humidity and water present in the residue of organic matter. It released as a result of the biological degradation of organic matter present and by water infiltration in the covering and inner layers of landfill cells, supplementing dissolved or suspended material originating from the residue mass (Yao 2017). Leachate is considered a very complex wastewater containing mixture of different heavy metals, organics, refractory organics, toxic, color, and odor. One of its characteristic features is an aqueous solution in which four groups of pollutant are present: dissolved organic matter (volatile fatty acid and more refractory organic matter such as humic substances), macro inorganic compounds (Ca2+, Mg2+, Na+, K+, NH4+, Fe2+, Mn2+, HCO−3), heavy metals (Cd2+, Cr3+, Cu2+, Pb2+, Ni2+, Zn2+), and xenobiotic organic compounds originating from chemical and domestic residue present at low concentrations (aromatic hydrocarbons, phenols, pesticides, etc.) (Christensen and Kjeldsen 1989), and microorganisms that indicate, predominantly total and thermotolerant coliform (Moravia et al. 2013).

As time proceeds, LFL goes through the successive aerobic, acetogenic, methanogenic, and stabilization stages of organic waste degradation, in which its properties such as the chemical oxygen demand (COD), biological oxygen demand (BOD), BOD/COD ratio, ammonium nitrogen (NH3–N), and pH vary widely (Kjeldsen et al. 2002). Table 5.1 summarizes the classification of landfill leachate according to the composition changes with age. As shown in Table 5.1, the parameters have their typical ranges in association with the age of LFL, which is commonly classified into three stages: young (<5 years), medium (5–10 years), and stabilized (>10 years). Among the different LFL properties, the ratio BOD/COD is commonly recognized to be the most representative of LFL age because it is directly related to the biodegradability of LFL. Young LFL is characterized by high concentrations of biodegradable organic matters such as volatile fatty acids (VFAs) and as a result, it has a high BOD/COD ratio. Most of the BOD, which is the biodegradable portion of the COD, would have been decomposed in the stabilization process. Therefore, the BOD/COD ratio decreases with time because the non-biodegradable portion of COD will largely stay unchanged in this process. The BOD/COD ratios of young, medium, and old LFL are in the ranges of 0.5–1.0, 0.1–0.5, and less than 0.1, respectively. It is, however, worth mentioning that there is not a clear cut off between the medium and old LFLs and BOD/COD ratios less than 0.2 may also be treated as old LFL by some researchers (Bohdziewicz and Kwarciak 2008). Stabilized leachate is also characterized by high concentrations of NH3–N and recalcitrant matter (e.g. humic acids), which has profound implications to the effectiveness of different biological treatment technologies.

It is, therefore, important to apply reliable and effective treatment technology for leachate treatment (Chaudhari and Murthy 2010). There are several methods for leachate treatment such as precipitation, electrocoagulation, membrane processes, adsorption, and biosorption or combination of the above (Gotvajn et al. 2009; Laitinen et al. 2006; Mohan and Gandhimathi 2009). Increasing pressure to meet more stringent discharge standards or not being allowed to discharge treated effluent has led to implementation of a variety of advanced biological treatment processes in recent years (Mittal 2011).

The principal biological process (activated sludge and biological filter) has been known quite well and is successfully applied for domestic wastewater. However, for leachate, the conventional approach for treatment requires some modifications. Depending on the wastewater and the standards which they have to meet, different process design and/or operational control parameters must be considered. At first, the laboratory-scale approach is needed.

Today, the strictness of landfill regulations, controls and managements hamper efficient conventional treatments which appears under-dimensioned or does not allow to reach the specifications required by the legislator. So that, advanced biological processes offers the best solution, and have been proved to be the more efficient, adaptable such as up-flow sludge blanket reactor (USBR), rotating biological contractor (RBC), membrane bioreactors (MBR) (aerobic/anaerobic), sequencing batch reactors (SBR), moving bed biofilm reactor (MBBR), and other emerging biological processes.

2 Evolution of Landfill Leachate Treatments

Conventional landfill leachate treatments can be classified into five major groups: (a) natural treatment system (b) leachate transfer: recycling and combined treatment with domestic sewage, (c) biological treatment: biodegradation by aerobic and anaerobic processes, and (d) chemical and (e) physical methods: chemical oxidation, adsorption, chemical precipitation, coagulation/flocculation, sedimentation/flotation and air stripping (Renou et al. 2008; Yu 2007) (Table 5.2).

Few years ago, a common solution was to treat the leachate together with municipal sewage in the municipal sewage treatment plant. It was preferred for its easy maintenance and low operating costs (Ahn et al. 2002). However, this option has been increasingly questioned due to the presence of organic inhibitory compounds in the leachate with low biodegradability and heavy metals that may reduce treatment efficiency and increase the effluent concentrations (Cecen and Aktas 2004). Recycling leachate back through the tip has been largely used in the past decade because it was one of the least expensive options available (Lema et al. 1988).

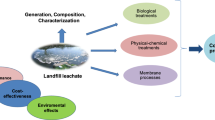

The schematic in Fig. 5.1 shows which parameters should be evaluated in the choice of a treatment for a landfill leachate. According to Fig. 5.1, for a leachate containing a high concentration of organic material (>10,000 mg L−1), the most appropriate approach is biological treatment. However, for leachates with a high concentration of ammoniacal nitrogen and a low biodegradability, the most suitable approach is a physical–chemical process, possibly in combination with biological treatment.

2.1 Biological Treatment Systems

Amongst the treatment classifications, biological treatment is worldwide and the most common practice for leachate treatment because of its reliability, simplicity and high cost-effectiveness. Biological treatment is commonly used for the removal of the bulk of leachate containing high concentrations of BOD. Biological systems can be divided in anaerobic and aerobic treatment processes. Both can be realized by using different plant concepts (Kumar et al. 2013). Biodegradation is carried out by microorganisms, which can degrade organics compounds to carbon dioxide and sludge under aerobic conditions and to biogas (a mixture comprising chiefly CO2 and CH4) under anaerobic conditions (Lema et al. 1988). Biological processes have been shown to be very effective in removing organic and nitrogenous matter from immature leachates when the BOD/COD ratio has a high value (>0.5). Biological processes are the most cost-effective means for reducing the organic content of leachate, particularly when complete onsite treatment is required.

2.1.1 Conventional Biological Treatment Processes

A Conventional aerobic treatment should allow a partial abatement of biodegradable organic pollutants and should also achieve the ammonium nitrogen nitrification. Aerobic biological processes based on suspended-growth biomass, such as aerated lagoons, conventional activated sludge processes (ASP) and SBR, have been widely studied and adopted (Abbas et al. 2009). However, this method has been shown in the more recent decades to be inadequate for handling landfill leachate treatment (Lin et al. 2000). Attached-growth systems have recently attracted major interest: MBBR and biofilters. The combination of membrane separation technology and aerobic–anaerobic bioreactors, most commonly called membrane bioreactor, has also led to a new focus on leachate treatment. Even if processes were proved to be effective for the removal of organic carbon, nutrients and ammonia content, too much disadvantages tend to focus on others technologies: inadequate sludge settleability and the need for longer aeration times, high energy demand and excess sludge production, microbial inhibition due to high ammonium nitrogen strength.

Anaerobic treatment is the biological treatment without use of air or elemental oxygen. Many applications are directed toward the removal of organic pollution in wastewater, leachate (containing high concentrations of organic acids), slurries, and sludge. An anaerobic digestion treatment of leachates allows to end the process initiated in the tip, being thus particularly suitable for dealing with high-strength organic effluents, such as leachate streams from young tips. Contrary to aerobic processes, anaerobic digestion conserves energy and produces very few solids, but suffers from low reaction rates. Moreover, it is possible to use the CH4 produced to warm the digester that usually works at 35 °C and, under favorable conditions, for external purposes. The main advantage of the anaerobic treatment processes is the low energy requirement, because no oxygen has to be supplied. Technical anaerobic processes need adequate temperatures of 35–55 °C (Kumar et al. 2013).

2.1.2 ASP

The activated sludge process is a suspended-growth and biological treatment process that uses aerobic microorganisms to biodegrade organic contaminants in leachate. With conventional activated sludge treatment, the leachate is aerated in an open tank basin with diffusers or mechanical aerators.

After the aeration phase, the mixed liquor (the mixture of microorganisms and the treated water) is pumped to a gravity clarifier to settle out the microorganisms. A high percentage of the settled biomass is recycled to the aeration tank to maintain the design mixed liquor suspended solids level, and the excess sludge is wasted. Variations in the conventional activated sludge process have been developed to provide greater tolerance for shock loadings, to improve sludge-settling characteristics, and to achieve higher BOD removals. Process modifications include complete mixing, step aeration, modified aeration, extended aeration, contact stabilization, and the use of pure oxygen (EPA 1982).

2.1.3 Trickling Filters

This method has been investigated for the biological nitrogen lowering from municipal landfill leachate. The trickling filter is an attached-growth; aerobic biological treatment process in which leachate is continuously distributed over a bed of rocks or plastic medium that supports the growth of microorganisms. The wastewater trickles through the filter bed, contacts the slime layer formed on the medium, and is collected by an under-drain system. The microorganisms assimilate and oxidize substances in the leachate; as the microorganisms grow, the slime layer increases. Periodic sloughing of the slime layer into the under-rain system results from organic and hydraulic loadings on the filter, and a new slime layer begins to grow. Sloughed solids are separated from the treated effluent by settling.

Trickling filters operate under short hydraulic retention times that do not allow for complete biodegradation of organics; as a result, effluent recirculation is required to increase the net contact time of the leachate with the biomass and achieve high organic removal efficiency. Recirculation also provides a constant hydraulic loading and dilutes high-strength leachates (EPA 1982). Effluent recirculation is essential for trickling filters constructed with plastic medium, which has a high percentage of void space, to ensure that the medium is thoroughly wetted and will sustain microbial growth and promote effective sloughing.

2.2 Advanced Biological Treatment Techniques

Due to main problems of sludge bulking or inadequate separability in conventional aerobic systems, a number of innovative treatment processes, called attached-growth biomass systems, using biofilm, have been recently developed. These systems present the advantage of not suffer from loss of active biomass (Renou et al. 2008).

2.2.1 Rotating Biological Contractor (RBC)

The RBC is an attached-growth, aerobic biological treatment process which consists of a series of closely spaced plastic disks on a horizontal shaft. The assemblage is mounted in a contoured-bottom tank containing the water to be treated so that the disks are partially (about 40%) immersed. The disks, which eventually develop a slime layer 2–4 mm thick over the entire wetted surface, rotate slowly through the water and alternately contact the biomass with the organic matter in the wastewater and then with the atmosphere for adsorption of oxygen. Excess biomass on the media is stripped off by rotational shear forces, and the stripped solids are held in suspension with the wastewater by the mixing action of the disks. The sloughed solids are carried with the effluent to a clarifier, where they are settled and separated from the treated waste (Abbas et al. 2009). A COD removal of about 52% is obtained at an HRT of 24 h and a rotational speed of 6 rpm. Even it is cheaper in operating it, so it is suitable for a developing country like India. However, it requires infinitesimal amount of energy for running the operation (Kumar et al. 2013).

2.2.2 SBR

The SBR is an activated sludge, biological nutrient removal (nitrification/denitrification) process, based on a cycle of operation. Unlike conventional, continuous-flow, activated sludge systems, which have separate tanks for equalization, aeration, and clarification, the SBR performs all operations in a single tank. According to E.P.A (1992), SBR process has widespread application where mechanical treatment of small wastewater flows is desired. Because it provides batch treatment, it is ideally suited for wide variations in flow rates operation in the “fill and draw” mode prevents the “washout” of biological solids that often occurs with extended aeration system. Another advantage of SBR systems is that they require less operator attention yet produce a very high quality effluent. SBR is ideally suited to nitrification–denitrification processes since it provides an operation regime compatible with concurrent organic carbon oxidation and nitrification. The greater process flexibility of SBR is particularly important when considering landfill leachate treatment, which has a high degree of variability in quality and quantity (Kennedy and Lentz 2000).

2.2.3 Moving Bed Biofilm Reactor (MBBR)

MBBR process is based on the use of suspended porous polymeric carriers, kept in continuous movement in the aeration tank, while the active biomass grows as a biofilm on the surfaces of them. During the operation process, characteristics of attached-growth media play a key role in MBBR performance. In recent years, different kinds of media have been employed in MBBRs for wastewater treatment, including plastic media, polyurethane foam, activated carbon (granular and powdered), natural occurring materials (e.g. sand, zeolite, earth, light expended clay aggregate, etc.), non-woven carriers, ceramic carriers, modified carriers (e.g. BIOCONS carrier), bioplastic-based moving bed biofilm carriers, and wood chips (Deng et al. 2016). MBBR provides a long biomass retention time and accommodates high loading rates without any problems of clogging. In a MBBR, the bacteria are fixed in a biofilm on a carrier. The carrier is suspended and moves freely in the reactor. The MBBR has been applied for organic matter removal, for nitrification, and for nutrient (N and P) removal (Tawfik et al. 2010). Mains advantages of this method compared to conventional suspended-growth processes seems to be: higher biomass concentrations, no long sludge-settling periods, lower sensitivity to toxic compounds, and both organic and high ammonia removals in a single process (Loukidou and Zouboulis 2001).

2.2.4 Up-Flow Anaerobic Sludge Blanket (UASB) Reactor

The UASB reactor technology is considered a breakthrough in the development and application of anaerobic high-rate technology for wastewater treatment UASB process is a modern anaerobic treatment that can have high treatment efficiency and a short hydraulic retention time. UASB reactors, when they are submitted to high volumetric organic loading rate values have exhibited higher performances compared to other kinds of anaerobic reactors. In addition, the UASB lends itself to a design where liquid, gas, and solid phases can be separated within the one vessel. The process temperatures reported have generally been 20–35 °C for anaerobic treatment with UASB reactors. These promising results show that high-rate treatment at low temperature may minimize the need for heating the leachate prior to treatment, which may thus provide an interesting cost-effective option. The main disadvantages of such a treatment stay sensitivity to toxic substances (Renou et al. 2008).

2.2.5 Membrane Bioreactors

Recently, membrane bioreactor (MBR) technology, an advanced biological treatment process that replaces the traditional secondary clarifier of an activated sludge process with a membrane separation unit, has emerged as a promising alternative. The combination of membranes to biological processes for treatment has led to the emergence of membrane bioreactors for the separation and retention of solids, for bubble-less aeration within the bioreactor, and for extraction of priority organic pollutants from industrial contaminated water (Stephenson et al. 2000). MBRs have been demonstrated to be particularly advantageous in treating old leachate. The advantages of MBRs over conventional biological processes are well known and include better effluent quality, process stability, smaller footprint, increased biomass or mixed liquor suspended solids (MLSS) retention, and low sludge production (Ahmed and Lan 2012). Several early research efforts investigated the potential of using MBRs for leachate treatment (Costa et al. 2019; Deng et al. 2016; Eldyasti et al. 2011; EPA Manual 1992). Recently, more research studies are being conducted on the feasibility and performance of MBRs for LFL treatment.

As shown in Table 5.3, high COD removals between 60 and 99% were achieved, regardless of the leachate age or the operating conditions used. Such high removal of the biodegradable organic matter is in accordance with most biological treatments of LFL.

2.2.6 Circulating Integrated Fluidized Bed Bioreactor (CFBBR)

Compared to conventional physical, chemical, and biological treatment processes for industrial wastewater, the CFBBR system has numerous advantages including small footprint with elimination of clarifiers, high biomass retention resulting in long solid residence times (SRTs) and relatively short hydraulic retention times (HRTs), enhanced mass transfer, and lower sludge production rate (Eldyasti et al. 2011). An extensive pilot-scale investigation of the patented CFBBR for biological nutrient removal (BNR) from municipal wastewater and landfill leachate has been reported by Nakhla et al. (2005). The CFBBR employs attached microbial films resulting from biodegradation of both organics and nutrients within an integrated system comprising an anoxic column in a fast fluidization regime and an aerobic column in a conventional fluidization regime. This new promising patented technology combines the compactness and efficiency of a fixed-film process with excellent organics, nitrogen, and phosphorus removal efficiencies of 85%, 80%, and 70%, respectively.

3 Conclusions

Optimal leachate treatment, in order to fully reduce the negative impact on the environment, is today’s challenge. But, the complexity of the leachate composition makes it very difficult to formulate general recommendations. Variations in leachates, in particular their variation both over time and from site to site, means that the most appropriate treatment should be simple, universal and adaptable. The various methods presented in the current study, offer their treatment technique with respect to certain facets of the problem. There has been a steady progress of new and advanced sustainable landfill leachate treatment which proven to be a promising alternative. Utilization of advanced biological treatment technologies may be suitable to mitigate the hazard created by landfill leachate. Though there are still uncertainties whether these techniques could enhance environmental sustainability and safety of human being, more efforts should be carried out to ensure a livelihood of human being and earth coexistence. Therefore, a holistic approach is essential for finding a suitable leachate treatment opportunity in order to safeguard environmental and human being livelihood, as a whole.

References

Abbas AA, Jingsong G, Ping LZ, Ya PY, Al-Rekabi WS (2009) Review on land fill leachate treatments. Am J Appl Sci 6(4):672–684

Ahmed FN, Lan CQ (2012) Treatment of landfill leachate using membrane bioreactors: a review. Desalination 287:41–54. https://doi.org/10.1016/j.desal.2011.12.012

Ahn WY, Kang MS, Yim SK, Choi KH (2002) Advanced landfill leachate treatment using an integrated membrane process. Desalination 149(1–3):109–114. https://doi.org/10.1016/S0011-9164(02)00740-3

Bohdziewicz J, Kwarciak A (2008) The application of hybrid system UASB reactor-RO in landfill leachate treatment. Desalination 222:128–134. https://doi.org/10.1016/j.desal.2007.01.137

Cecen F, Aktas O (2004) Aerobic co-treatment of landfill leachate with domestic wastewater. Environ Eng Sci 21:303–312

Chaudhari LB, Murthy ZVP (2010) Treatment of landfill leachates by nanofiltration. J Environ Manage 91(5):1209–1217. https://doi.org/10.1016/j.jenvman.2010.01.007

Chiemchaisri C, Chiemchaisri W, Nindee P, Chang CY, Yamamoto K (2011) Treatment performance and microbial characteristics in two-stage membrane bioreactor applied to partially stabilized leachate. Water Sci Technol 64:1064–1072

Christensen TH, Kjeldsen P (1989) Basic biochemical processes in landfills. In: Sanitary landfilling: process, technology, and environmental impact. Academic Press, New York, pp 29–49

Costa AM, Greice R, Marotta DS, Campos JC (2019) Land fill leachate treatment in Brazil—An overview. 232(October 2018):110–116

Deng L, Guo W, Ngo HH, Zhang X, Wang XC, Zhang Q, Chen R (2016) New functional biocarriers for enhancing the performance of a hybrid moving bed biofilm reactor-membrane bioreactor system. Biores Technol 208:87–93. https://doi.org/10.1016/j.biortech.2016.02.057

Eldyasti A, Andalib M, Hafez H, Nakhla G, Zhu J (2011) Comparative modeling of biological nutrient removal from landfill leachate using a circulating fluidized bed bioreactor (CFBBR). J Hazard Mater 187:140–149. https://doi.org/10.1016/j.jhazmat.2010.12.115

EPA (1982) Treatability Data. Volume 1 EPA-600/2-82-OOla

EPA Manual (September 1992) Wastewater treatment/disposal for small communities. Office of Research & Development, Office of water

Gotvajn AŽ, Tišler T, Zagorc-Končan J (2009) Comparison of different treatment strategies for industrial landfill leachate. J Hazard Mater 162(2–3):1446–1456. https://doi.org/10.1016/j.jhazmat.2008.06.037

Hasar H, Ipek U, Kinaci C (2009) Joint treatment of landfill leachate with municipal wastewater by submerged membrane bioreactor. Water Sci Technol 60:3121–3127

Kennedy KJ, Lentz EM (2000) Treatment of landfill leachate using sequencing batch and continuous flow upflow anaerobic sludge blanket (UASB) reactors. Water Res 34:3640–3656

Kjeldsen P, Barlaz MA, Rooker AP, Baun A, Ledin A, Christensen TH (2002) Present and long-term composition of MSW landfill leachate: a review. Crit Rev Environ Sci Technol 32(4):297–336. https://doi.org/10.1080/10643380290813462

Kumar S, Katoria D, Singh G (2013) Leachate treatment technologies 1, 4(5):439–444

Laitinen N, Luonsi A, Vilen J (2006) Landfill leachate treatment with sequencing batch reactor and membrane bioreactor. Desalination 191(1–3):86–91. https://doi.org/10.1016/j.desal.2005.08.012

Lema JM, Mendez R, Blazquez R (1988) Characteristics of landfill leachates and alternatives for their treatment: a review. Water Air Soil Pollution 40:223–250

Lin CY, Chang FY, Chang CH (2000) Co-digestion of leachate with septage using a UASB reactor. Biores Technol 73:175–178

Loukidou MX, Zouboulis AI (2001) Comparaison of two biological treatment process using attached-growth biomass for sanitary landfill leachate treatment. Environ Pollut 111:273–281

Mittal BA (2011) Biological wastewater treatment, 2–9

Mohan S, Gandhimathi R (2009) Removal of heavy metal ions from municipal solid waste leachate using coal fly ash as an adsorbent. J Hazard Mater 169(1–3):351–359. https://doi.org/10.1016/j.jhazmat.2009.03.104

Moravia WG, Amaral MCS, Lange LC (2013) Evaluation of landfill leachate treatment by advanced oxidative process by Fenton’s reagent combined with membrane separation system. Waste Manag 33(1):89–101. https://doi.org/10.1016/j.wasman.2012.08.009

Nakhla G, Zhu J, Cui Y (2005) Liquid–solid circulating fluidized bed wastewater treatment system for simultaneous removal of carbon, nitrogen, and phosphorus, US Patent No. 7261811 (2004) Int’l PCT patent awarded

Puszczało E, Bohdziewicz J, Świerczyńska A (2010) The influence of percentage share of municipal landfill leachates in a mixture with synthetic wastewater on the effectiveness of a treatment process with use of membrane bioreactor. Desalination Water Treat 14:16–20

Renou S, Givaudan JG, Poulain S, Dirassouyan F, Moulin P (2008) Landfill leachate treatment: review and opportunity. J Hazard Mater 150(3):468–493. https://doi.org/10.1016/j.jhazmat.2007.09.077

Robinson T (2007) Membrane bioreactors: nanotechnology improves landfill leachate quality. Filtr Sep 44:38–39

Stephenson T, Judd S, Jefferson B, Brindle K (2000) Membrane bioreactors for wastewater treatment. IWA Publishing, ISBN 1-90-022207-8

Tawfik A, El-Gohary F, Temmink H (2010) Treatment of domestic wastewater in an up-flow anaerobic sludge blanket reactor followed by moving bed biofilm reactor. Bioprocess Biosyst Eng 33(2):267–276

Visvanathan C, Tränkler J, Zhou G (2004) State of the art review landfill leachate treatment, 93

Wiszniowski J, Robert D, Surmacz-Gorska J, Miksch K, Weber JV (2006) Landfill leachate treatment methods: A review. Environ Chem Lett 4(1):51–61. https://doi.org/10.1007/s10311-005-0016-z

Yao P (2017) Perspectives on technology for landfill leachate treatment. Arab J Chem 10:S2567–S2574

Yu D (2007) Landfill leachate treatment case study, 82

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Burman, I. (2020). Environmental Impact of Landfill Leachate and Its Remediation Using Advanced Biological Methods. In: Singh, R., Shukla, P., Singh, P. (eds) Environmental Processes and Management. Water Science and Technology Library, vol 91. Springer, Cham. https://doi.org/10.1007/978-3-030-38152-3_5

Download citation

DOI: https://doi.org/10.1007/978-3-030-38152-3_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-38151-6

Online ISBN: 978-3-030-38152-3

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)