Nanocrystalline MgAl2O4 was found to be a highly efficient catalyst for the preparation of 2,4,6-triaryl-pyridines from the reaction of acetophenone derivatives, aryl aldehydes, and ammonium acetate under sonic condition for the first time. The present methodology offers several advantages, such as excellent yields, simple procedure, shorter reaction times, and milder conditions; the catalyst also exhibited remarkable reusable activity. This procedure is much simpler and faster than the protocols published to date.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Ultrasound-accelerated organic chemical reactions have been increasingly developed by researchers across the globe for the synthesis of organic compounds. Ultrasound irradiation offers an alternative energy source for organic synthesis which are ordinarily accomplished by heating. Ultrasound-mediated reactions proceed by the formation, growth, and collapse of acoustic bubbles in the reaction medium. These directly help in shortening the time span of reactions and increasing the yield of products [1].

The pyridine ring system is present in various natural compounds, and many pyridines exhibit a broard range of biological activities [2]. Due to their π-stacking ability, some pyridine derivatives are used in supramolecular chemistry [3]. Recently, these heterocyclic compounds have also evoked considerable attention, being endowed with a wide range of pharmaceutical activities such as anticonvulsant, antimalarial, anesthetic, vasodilator, and antiepileptic, and they have been used as agrochemicals such as pesticides, fungicides and herbicides [4, 5]. Therefore, it is of continuous interest to develop procedures for the synthesis of 2,4,6-tri-arylpyridines, Kröhnke pyridines. Since Kröhnke’s original report on the preparation of 2,4,6-triarylpyridines [6], there has been a plethora of research targeting their syntheses [7–12]. Recently, much effort has been devoted to developing more efficient protocols for the synthesis of 2,4,6-triarylpyridines, for example solid-phase synthesis [7], one-pot synthesis under microwave irradiation [8], and solvent-free reaction between acetophenones, benzaldehydes, and ammonium acetate in the presence of various catalyst such as I2 [9], heteropolyacid [10], HClO4–SiO2 [11], and ionic liquid [12]. However, many of these processes suffer from drawbacks such as long reaction time, expensive catalyst, undesired side products in reaction with harsh reagents, special care in handling and storing the reagents, cumbersome product isolation procedures and environmental pollution. Therefore, a need still exists for further development of versatile reaction conditions in the synthesis of 2,4,6-triarylpyridine using an efficient, reusable, inexpensive, eco-friendly, and selective catalyst.

In recent years, nanostructures have emerged as powerful catalysts in various organic synthesis such as cobalt nanoparticles for synthesis of 1,4-dihydropyridines [13], nanocrystalline MgO for synthesis of 2,4,5-tri-substituted imidazole derivatives [14], silica nanoparticles for the preparation of highly substituted pyridines [15] and ZnO nanopowder for the preparation of 2,4,6-triarylpyridines [16]. In recent years, the use of MgAl2O4 nanostructures has become a significant area of research in organic reactions and has been shown to improve yield and purity of the products. It has catalytic properties because of its unique properties such as chemical inertness, high surface area, small crystallite size, and more active sites [17–19].

However, despite extensive studies on the synthesis of 2,4,6-triarylpyridines reported in the literature, to the best of our knowledge there is no report focusing on the development of one-pot synthesis of Kröhnke pyridines using nanocatalyst under ultrasound conditions. Therefore, this report describes a convenient and facile synthesis of 2,4,6-triarylpyridines in high yields using nanocrystalline magnesium aluminate spinel as nanocatalyst under ultrasound irradiation.

To achieve suitable conditions for the synthesis of 2,4,6-triarylpyridines, various reaction conditions have been investigated in the reaction of acetophenone (1a), benzaldehyde (2a), ammonium acetate, and nanocrystalline MgAl2O4 (4 mol%) as a model reaction. We examined the effect of different solvents such as EtOH, DMSO, THF, DMF, AcOH, and MeCN on the model reaction under ultrasound irradiation (power intensity 50 W) at 70°C (Table 1). Comparing the yields of 2,4,6-triphenylpyridine (3a), AcOH was chosen as the best solvent for further experiments.

The reaction was performed in the presence of different amounts of catalyst (Table 2) with and without ultrasonic irradiation. In all cases, the experimental results show that the reaction times are shorter and the yields of the products are higher under ultrasound irradiation. With the application of ultrasound, compression of the liquid is followed by rarefaction, in which a sudden pressure drop forms small, oscillating bubbles of the gaseous substances. These bubbles are small and rapidly collapse, and they can be regarded as microreactors that offer the opportunity of speeding up certain reactions and allowing mechanistically novel reactions to take place in an absolutely safe manner [20]. The best results were obtained using 5 mol% of the nanocatalyst under both conditions (Table 2, entry 6). As shown, in the absence of catalyst the yield of the product was found to be low (Table 2, entry 1).

In order to further improve the yield of the reaction, we performed five experiments carrying out the model reaction under ultrasound irradiation (50 W) at 30, 50, 70, 90, and 100°C. It was observed that lower reaction temperature led to lower yield of the product. As shown in Table 3, increasing the reaction temperature improves the reaction yield, with the best result obtained at 90°C (entry 4). So, further experiments were performed at this temperature. In order to determine the effect of ultrasonic irradiation power on the reaction course, the model reaction was also performed at irradiation power of 20, 40, 60, 80 and 100 W (Table 3, entries 6-10). Increase in ultrasonic power led to relatively higher yield and shorter reaction time until the ultrasound power reached 80 W, at which further increase in ultrasound power to 100 W caused a slight decrease in yield of the model reaction. These results indicated that there was a remarkable ultrasonic temperature effect on this reaction.

Encouraged by the results obtained in the reaction of acetophenone (1a), benzaldehyde (2a), and NH4OAc, we performed the reaction of acetophenones 1a,b with a series of aromatic aldehydes 2a-j (Table 4). All the reactions proceeded very cleanly at the optimized reaction conditions, and no undesirable side reactions were observed. The experimental results show that the course of this reaction obviously does not depend on the substituent at the aromatic rings in both acetophenone and aldehyde: all the products 3a-p, including furyl-substituted derivatives 3e,f,o, were obtained in high yields with short reaction time. Compared to other methodologies reported for the synthesis of 2,4,6-triarylpyridines via one-pot reaction, the present methodology offers suitable conditions with respect to reaction times and yields.

On the other hand, ultrasound enhanced the rate of the reaction and, consequently, reduced energy consumption. The driving force for the increased efficiency of formation of 2,4,6-triarylpyridines by ultrasound is the increase in temperature due to the formation of hot spots, as well as the increase in reactant contact surface area through a cavitation phenomenon. Upon irradiation with ultrasound, the formation, growth, and implosive collapse of bubbles can create extreme chemical and physical conditions in solid/liquid systems, leading to short-lived localized hotspots that produce relatively high temperature for this one-pot condensation reaction to occur, and the rate of the reaction was well accelerated under sonic condition. Moreover, when cavitation phenomenon occurs near the solid catalyst surface, cavity collapse is nonspherical, and as a result of this, a liquid jet will be formed, which is targeted at the surface, and this effect is equivalent to a high-pressure/high-velocity liquid. These jets activate the heterogeneous catalyst and increase the mass transfer to the surface by disrupting the interfacial boundary layers as well as dislodging the material occupying the inactive sites [23].

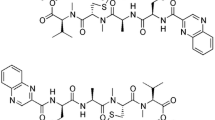

The suggested mechanism of the reaction is shown below. First, the aldol condensation of acetophenone 1 and aldehyde 2 occurred, and the second molecule of acetophenone 1 condensed with ammonia, forming enamine. The Michael addition of the enamine to the aldol product followed by cyclization produced dihydropyridine. Finally, air oxidation afforded the final product. The reaction involves three major stages: aldol condensation, Michael addition, and cyclization and oxidation. Nanocrystalline MgAl2O4 facilitates aldol condensation, Michael addition, and subsequent oxidation of dihydropyridine to the final product. An interesting point is that aromatic aldehydes carrying either electron-donating or electron-withdrawing substituents reacted very well to give the corresponding products in moderate to excellent yields with high purity.

The reusability of the catalyst is one of the most important benefits and makes it useful for commercial applications: thus, the recovery and reusability of nano-MgAl2O4 as a heterogeneous catalyst was investigated. For this purpose, the model reaction of acetophenone (1a) with benzaldehyde (2a) and NH4OAc was studied under optimized conditions. After the completion of the reaction, the mixture was evaporated and then diluted with hot ethanol. The catalyst was separated by filtration, washed with hot ethanol, and dried. The recovered nano-MgAl2O4 was reused in subsequent reactions without significant decrease in activity even after six runs (Fig. 1).

In conclusion, we have developed a new and facile procedure for the one-pot synthesis of 2,4,6-tri-arylpyridines in the presence of nano-MgAl2O4 as a heterogeneous nanocatalyst under ultrasonic condition. The present methodology offers very attractive features such as shorter reaction time and higher yields and will have wide applications in organic synthesis. This simple method combined with ease of recovery and reuse of the nanocatalyst makes this protocol economic, benign, and a waste-free chemical process for the synthesis of 2,4,6-triarylpyridines.

Experimental

IR spectra were recorded on a Perkin–Elmer 781 spectrophotometer in KBr pellets. 1H and 13C NMR spectra were recorded on a Bruker DPX-400 Avance spectrometer (400 and 100 MHz, respectively) in DMSO-d6, internal standard was TMS. Elemental analysis (C, H, N) was performed on a Carlo Erba model EA 1108 analyzer or a Perkin–Elmer 240c analyzer. Melting points were determined on a Yanagimoto micromelting point apparatus. The purity determination of the substrates and reaction monitoring were accomplished by TLC on silica gel polygram SILG/UV 254 plates. Transmission electron microscopy (TEM) was performed with a Jeol JEM-2100UHR apparatus operating at 200 kV. Sonication was performed in a Shanghai Branson-BUG40-06 ultrasonic cleaner (with a frequency of 35 kHz and a nominal maximal power 100 W). A circulating water bath (DC2006, Shanghai Hengping Apparatus Factory) with an accuracy of 0.1 K was adopted to keep the reaction temperature constant.

Chemicals were purchased from Merck and Fluka in high purity. All of the materials were of commercial reagent grade.

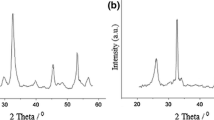

Preparation of Nanocrystalline MgAl 2 O 4 . Nanocrystalline magnesium aluminate spinel was synthesized using a procedure reported in [18]. In short, stoichiometric amounts of magnesium nitrate and aluminum nitrate and the desired amount of cetyl trimethylammonium bromide were added to well-stirred deionized water. Then ammonia solution was added dropwise to the well-stirred slurry to adjust the pH value to ~9. After precipitation, the slurry was stirred for another 30 min and refluxed at 80°C for 24 h under continuous stirring. The mixture was then cooled and filtered. The final product was dried at 100°C for 24 h under flowing air and calcined at 700 and 800°C. The crystallite sizes of the magnesium aluminate determined by TEM analysis at 700°C was 3-10 nm. The pore volume, calculated from the N2 adsorption/desorption isotherm, was approximately 1.10 cm3·g-1. The surface area was determined as ~201 m2·g-1 [18]. The crystallite sizes of MgAl2O4 increased to 4-12 nm after calcinations at 800°C. These results revealed that MgAl2O4 nanoparticles have high thermal stability toward high temperatures. Moreover, the particles are closely sintered together, and most of the particles have a slightly irregular, rounded shape [18].

Preparation of 2,4,6-Triarylpyridines 3a-p Using Nanocrystalline MgAl 2 O 4 under Sonication (General Method). A 25-ml Erlenmeyer flask was charged with acethophenone 1a,b (2 mmol), aromatic aldehyde 2a-j (1 mmol), NH4OAc (308 mg, 4 mmol), nano-MgAl2O4 (7 mg, 5 mol%), and AcOH (5 ml). The reaction flask was located in the ultrasonic bath, where the surface of the reactants was slightly lower than the level of the water, and irradiated with ultrasound at 80 W power during 55-70 min (Table 4), keeping the temperature inside the reactor at 90°C. The reaction was monitored by TLC (eluent petroleum ether – EtOAc, 7:3). After the reaction was completed, the reaction mixture was concentrated on a rotary evaporator under reduced pressure, the obtained solid product was dissolved in hot EtOH, and the insoluble catalyst was filtered off. The pure products were obtained by recrystallization from EtOH.

2,4,6-Triphenylpyridine (3a). White solid. IR spectrum, ν, cm-1: 3069, 1597, 1552, 1494, 1440, 1398, 1178, 1074, 1027, 867, 759, 692. 1H NMR spectrum, δ, ppm (J, Hz): 8.37 (2H, d, J = 7.2, H Ar); 8.33 (2H, d, J = 7.5, H Ar); 8.20 (2H, s, H Ar); 8.06 (2H, d, J = 7.4, H Ar); 7.60-7.50 (9H, m, H Ar). 13C NMR spectrum, δ, ppm: 157.0; 150.1; 139.3; 139.2; 129.7 (2C); 128.7; 128.4; 127.8; 127.4; 117.0. Found, %: C 89.82; H 5.55; N 4.51. C23H17N. Calculated, %: C 89.87; H 5.57; N 4.56.

4-(4-Chlorophenyl)-2,6-diphenylpyridine (3b). White solid. IR spectrum, ν, cm-1: 3061, 1599, 1543, 1489, 1449, 1414, 1384, 1237, 1090, 1013, 825, 773, 692. 1H NMR spectrum, δ, ppm (J, Hz): 8.39 (2H, d, J = 7.1, H Ar); 8.34 (2H, d, J = 7.8, H Ar); 8.14 (2H, s, H Ar); 7.81 (2H, d, J = 7.9, H Ar); 7.62 (2H, d, J = 7.9, H Ar); 7.56-7.53 (6H, m, H Ar). 13C NMR spectrum, δ, ppm: 157.1; 148.6; 139.2; 136.9; 134.7; 129.6; 129.5; 129.4; 129.2; 116.9. Found, %: C 80.75; H 4.70; N 4.08. C23H16ClN. Calculated, %: C 80.81; H 4.72; N 4.10.

4-(3-Methoxyphenyl)-2,6-diphenylpyridine (3c). White solid. IR spectrum, ν, cm-1: 3034, 2936, 1596, 1547, 1486, 1444, 1398, 1285, 1255, 1204, 1171, 1037, 872, 775, 692. 1H NMR spectrum, δ, ppm (J, Hz): 8.36 (2H, d, J = 7.5, H Ar); 8.30 (2H, d, J = 7.6, H Ar); 8.14 (2H, s, H Ar); 7.59-7.50 (8H, m, H Ar); 7.46 (1H, d, J = 7.4, H Ar); 6.89 (1H, t, J = 7.4, H Ar); 3.70 (3H, s, OCH3). 13C NMR spectrum, δ, ppm: 160.4; 157.0; 150.0; 139.8; 139.3; 130.6; 129.7; 129.2; 127.5; 120.1; 117.2; 115.4; 113.2; 55.8. Found, %: C 85.39; H 5.59; N 4.12. C24H19NO. Calculated, %: C 85.43; H 5.68; N 4.15.

4-(2-Fluorophenyl)-2,6-diphenylpyridine (3d). White solid. IR spectrum, ν, cm-1: 3031, 1591, 1544, 1490, 1451, 1395, 1288, 1209, 1204, 1114, 1074, 1025, 878, 759, 694. 1H NMR spectrum, δ, ppm (J, Hz): 8.36 (2H, d, J = 7.5, H Ar); 8.31 (2H, d, J = 7.3, H Ar); 8.10 (2H, s, H Ar); 7.85 (1H, d, J = 6.9, H Ar); 7.49-7.45 (8H, m, H Ar); 7.07 (1H, d, J = 7.9, H Ar). Found, %: C 84.85; H 4.85; N 4.23. C23H16FN. Calculated, %: C 84.90; H 4.96; N 4.30.

4-(5-Methylfuran-2-yl)-2,6-diphenylpyridine (3e). Light-brown solid. IR spectrum, ν, cm-1: 3058, 2927, 1591, 1548, 1495, 1447, 1394, 1237, 1122, 1204, 1114, 1075, 1027, 878, 758, 691. 1H NMR spectrum, δ, ppm (J, Hz): 8.35 (2H, d, J = 7.7, H Ar); 8.27 (2H, d, J = 7.5, H Ar); 8.18 (2H, s, H Ar); 7.57-7.47 (7H, m, H Ar); 6.34 (1H, d, J = 7.9, H Ar); 2.50 (3H, s, CH3). 13C NMR spectrum, δ, ppm: 155.3; 151.4; 146.1; 136.2; 129.3; 127.6; 127.4; 118.6; 107.8; 101.8; 14.1. Found, %: C 84.83; H 5.45; N 4.45. C22H17NO. Calculated, %: C 84.86; H 5.50; N 4.50.

4-(Furan-2-yl)-2,6-diphenylpyridine (3f). Light-brown solid. IR spectrum, ν, cm-1: 3058, 1606, 1541, 1487, 1454, 1414, 1244, 1158, 1073, 1010, 868, 772, 690. 1H NMR spectrum, δ, ppm (J, Hz): 8.30 (2H, d, J = 7.6, H Ar); 8.20 (2H, d, J = 7.5, H Ar); 8.14 (2H, s, H Ar); 7.96 (1H, s, H Ar); 7.57-7.47 (7H, m, H Ar); 6.75 (1H, d, J = 8.1, H Ar). 13C NMR spectrum, δ, ppm: 157.0; 151.4; 145.2; 139.6; 130.0; 129.8; 129.2; 127.2; 113.1; 113.0; 110.9. Found, %: C 84.78; H 5.02; N 4.68. C21H15NO. Calculated, %: C 84.82; H 5.08; N 4.71.

4-(4-Methylphenyl)-2,6-diphenylpyridine (3g). White solid. IR spectrum, ν, cm-1: 3034, 2936, 1598, 1548, 1442, 1398, 1286, 1254, 1203, 1170, 1036, 871, 775, 691. 1H NMR spectrum, δ, ppm (J, Hz): 8.35 (2H, d, J = 7.3, H Ar); 8.29 (2H, d, J = 7.5, H Ar); 8.14 (2H, s, H Ar); 7.93 (2H, d, J = 7.8, H Ar); 7.58 (2H, t, J = 7.6, H Ar); 7.50 (2H, t, J = 7.6, H Ar); 7.47 (2H, t, J = 7.7, H Ar); 7.35 (2H, d, J = 7.8, H Ar); 2.48 (3H, s, CH3). 13C NMR spectrum, δ, ppm: 157.0; 149.0; 139.4; 135.2; 130.1; 129.6; 129.2; 127.5; 127.4; 116.7; 21.3. Found, %: C 89.63; H 5.93; N 4.30. C24H19N. Calculated, %: C 89.68; H 5.96; N 4.36.

4-(4-Methoxyphenyl)-2,6-diphenylpyridine (3h). White solid. IR spectrum, ν, cm-1: 3035, 2936, 1596, 1547, 1486, 1444, 1398, 1285, 1255, 1204, 1171, 1037, 750, 691. 1H NMR spectrum, δ, ppm (J, Hz): 8.38 (2H, d, J = 7.6, H Ar); 8.30 (2H, d, J = 7.3, H Ar); 8.14 (2H, s, H Ar); 8.03 (2H, d, J = 7.1, H Ar); 7.50 (4H, t, J = 6.8, H Ar); 7.48 (2H, d, J = 7.3, H Ar); 7.10 (2H, d, J = 7.1, H Ar); 3.82 (3H, s, OCH3). 13C NMR spectrum, δ, ppm: 160.8; 156.9; 149.5; 139.4; 130.4; 130.3; 129.6; 129.1; 127.4; 116.4; 115.0; 55.8. Found, %: C 85.41; H 5.64; N 4.11. C24H19NO. Calculated, %: C 85.43; H 5.68; N 4.15.

N , N -Dimethyl-4-(2,6-diphenylpyridin-4-yl)benzenamine (3i). Yellow solid. IR spectrum, ν, cm-1: 3037, 2936, 1598, 1525, 1489, 1442, 1398, 1352, 1233, 1199, 1168, 1066, 1023, 818, 773, 695. 1H NMR spectrum, δ, ppm (J, Hz): 8.35 (2H, d, J = 7.4, H Ar); 8.20 (2H, d, J = 7.6, H Ar); 8.10 (2H, s, H Ar); 7.92 (2H, d, J = 6.8, H Ar); 7.55-7.44 (6H, m, H Ar); 6.83 (2H, d, J = 7.4, H Ar); 3.19 (6H, s, N(CH3)2). 13C NMR spectrum, δ, ppm: 155.2; 152.0; 150.1; 136.2; 129.3; 128.3; 127.6; 127.4; 118.0; 114.8; 40.2. Found, %: C 85.65; H 6.28; N 7.95. C25H22N2. Calculated, %: C 85.68; H 6.33; N 7.99.

2,6-Bis(4-chlorophenyl)-4-phenylpyridine (3j). White solid. IR spectrum, ν, cm-1: 3052, 1598, 1544, 1490, 1449, 1413, 1384, 1239, 1174, 1091, 1012, 829, 761, 694. 1H NMR spectrum, δ, ppm (J, Hz): 8.42 (2H, d, J = 7.6, H Ar); 8.33 (2H, d, J = 7.5, H Ar); 8.23 (2H, s, H Ar); 8.04 (2H, d, J = 7.7, H Ar); 7.61-7.50 (7H, m, H Ar). 13C NMR spectrum, δ, ppm: 155.8; 150.3; 137.9; 134.7; 129.9; 129.6; 127.9; 117.3. Found, %: C 73.36; H 4.01; N 3.67. C23H15Cl2N. Calculated, %: C 73.42; H 4.02; N 3.72.

2,6-Bis(4-chlorophenyl)-4-(4-methoxyphenyl)pyridine (3k). White solid. IR spectrum, ν, cm-1: 3052, 2928, 1602, 1543, 1512, 1489, 1426, 1381, 1291, 1247, 1177, 1088, 1011, 824. 1H NMR spectrum, δ, ppm (J, Hz): 8.40 (2H, d, J = 7.6, H Ar); 8.29 (2H, d, J = 7.6, H Ar); 8.17 (2H, s, H Ar); 7.60 (2H, d, J = 6.8, H Ar); 7.50 (2H, d, J = 6.8, H Ar); 7.48 (2H, d, J = 7.3, H Ar); 7.12 (2H, d, J = 7.3, H Ar); 3.84 (3H, s, OCH3). 13C NMR spectrum, δ, ppm: 161.1; 155.8; 134.3; 132.9; 130.2; 129.3; 129.0; 128.4; 118.0; 114.8; 50.80. Found, %: C 70.91; H 4.18; N 3.41. C24H17Cl2NO. Calculated, %: C 70.95; H 4.22; N 3.45.

2,6-Bis(4-chlorophenyl)-4-(2-methoxyphenyl)pyridine (3l). White solid. IR spectrum, ν, cm-1: 3049, 2948, 1601, 1542, 1512, 1491, 1411, 1383, 1263, 1245, 1175, 1126, 1090, 1014, 827, 749. 1H NMR spectrum, δ, ppm (J, Hz): 8.32 (2H, d, J = 7.6, H Ar); 8.20 (2H, d, J = 7.4, H Ar); 8.04 (2H, s, H Ar); 7.63 (1H, d, J = 7.9, H Ar); 7.55-7.53 (4H, m, H Ar); 7.45 (1H, t, J = 7.2, H Ar); 7.22 (1H, d, J = 7.2, H Ar); 7.09 (1H, t, J = 7.9, H Ar); 3.84 (3H, s, OCH3). 13C NMR spectrum, δ, ppm: 161.1; 155.8; 134.3; 132.9; 130.2; 129.3; 129.0; 128.4; 118.0; 114.8; 55.8. Found, %: C 71.03; H 4.18; N 3.51. C24H17Cl2NO. Calculated, %: C 70.95; H 4.22; N 3.45.

2,6-Bis(4-chlorophenyl)-4-(3-methoxyphenyl)pyridine (3m). White solid. IR spectrum, ν, cm-1: 3062, 2932, 1595, 1546, 1490, 1460, 1411, 1383, 1265, 1211, 1176, 1089, 1012, 833, 787. 1H NMR spectrum, δ, ppm (J, Hz): 8.40 (2H, d, J = 7.5, H Ar); 8.31 (2H, d, J = 7.4, H Ar); 8.20 (2H, s, H Ar); 7.62 (2H, d, J = 7.6, H Ar); 7.55-7.52 (4H, m, H Ar); 7.42 (1H, d, J = 7.3, H Ar); 7.05 (1H, d, J = 7.4, H Ar); 3.88 (3H, s, OCH3). 13C NMR spectrum, δ, ppm: 161.2; 155.2; 152.0; 138.9; 134.3; 132.9; 130.3; 129.3; 129.0; 119.7; 118.0; 114.8; 111.1; 55.8. Found, %: C 70.93; H 4.20; N 3.48. C24H17Cl2NO. Calculated, %: C 70.95; H 4.22; N 3.45.

2,6-Bis(4-chlorophenyl)-4-(2-fluorophenyl)pyridine (3n). White solid. IR spectrum, ν, cm-1: 3061, 1599, 1543, 1490, 1460, 1411, 1383, 1265, 1211, 1176, 1089, 1012, 833, 787. 1H NMR spectrum, δ, ppm (J, Hz): 8.38 (2H, d, J = 7.2, H Ar); 8.30 (2H, d, J = 7.5, H Ar); 8.18 (2H, s, H Ar); 7.59-7.55 (6H, m, H Ar); 7.35-7.43 (2H, m, H Ar). 13C NMR spectrum, δ, ppm: 116.0; 118.0; 124.9; 129.0; 129.3; 130.9; 132.8; 134.3; 152.0; 155.2; 158.2. Found, %: C 70.11; H 3.52; N 3.60. C23H14Cl2FN. Calculated, %: C 70.07; H 3.58; N 3.55

2,6-Bis(4-chlorophenyl)-4-(furan-2-yl)pyridine (3o). White solid. IR spectrum, ν, cm-1: 3061, 1609, 1544, 1488, 1422, 1374, 1265, 1216, 1176, 1090, 1012, 826, 736. 1H NMR spectrum, δ, ppm (J, Hz): 8.38 (2H, d, J = 7.6, H Ar); 8.30 (2H, d, J = 7.5, H Ar); 8.21 (2H, s, H Ar); 7.96 (1H, s, H Ar); 7.68-7.52 (5H, m, H Ar); 6.76 (1H, d, J = 8.1, H Ar). 13C NMR spectrum, δ, ppm: 155.3; 154.0; 146.1; 142.9; 134.3; 132.9; 129.3; 129.0; 118.0; 107.0; 105.0. Found, %: C 68.86; H 3.54; N 3.75. C21H13Cl2NO. Calculated, %: C 68.87; H 3.58; N 3.82.

4-[2,6-Bis(4-chlorophenyl)pyridin-4-yl]- N , N -dimethylbenzenamine (3p). Yellow solid. IR spectrum, ν, cm-1: 3061, 2932, 1597, 1527, 1432, 1359, 1265, 1201, 1189, 1090, 945, 814. 1H NMR spectrum, δ, ppm (J, Hz): 8.38 (2H, d, J = 7.5, H Ar); 8.31 (2H, d, J = 7.3, H Ar); 8.12 (2H, s, H Ar); 7.95 (2H, d, J = 6.8, H Ar); 7.56 (2H, d, J = 7.5, H Ar); 7.52 (2H, d, J = 7.5, H Ar); 6.84 (2H, d, J = 6.8, H Ar); 2.98 (6H, s, N(CH3)2). 13C NMR spectrum, δ, ppm: 155.2; 152.0; 150.1; 134.3; 132.9; 129.0; 128.3; 127.4; 118.0; 114.8; 40.2. Found, %: C 71.55; H 4.78; N 6.63. C25H20Cl2N2. Calculated, %: C 71.60; H 4.81; N 6.68.

References

D. Nagargoje, P. Mandhane, S. Shingote, P. Badadhe, and C. Gill, Ultrason. Sonochem., 19, 94 (2012).

R. D. Allen and G. A. R. Johnston, Med. Res. Rev., 3, 91 (1983).

E. C. Constable, C. E. Housecroft, M. Neuburger, D. Phillips, P. R. Raithby, E. Schofield, E. Sparr, D. A. Tocher, M. Zehnder, and Y. Zimmermann, J. Chem. Soc., Dalton Trans., 2219 (2000).

B. Y. Kim, J. B. Ahn, H. W. Lee, S. K. Kang, J. H. Lee, J. S. Shin, S. K. Ahn, C. I. Hong, and S. S. Yoon, Eur. J. Med. Chem., 39, 433 (2004).

I. J. Enyedy, S. Sakamuri, W. A. Zaman, K. M. Johnson, and S. Wang, Bioorg. Med. Chem. Lett., 13, 513 (2003).

F. Kröhnke, Synthesis, 1 (1976).

C. Chiu, Z. Tang, and J. W. Ellingboe, J. Comb. Chem., 1, 73 (1999).

X. Q. Huang, H. X. Li, J. X. Wang, and X. F. Jia, Chin. Chem. Lett., 16, 607 (2005).

Y. M. Ren and C. Cai, Monatsh. Chem., 140, 49 (2009).

M. M. Heravi, K. Bakhtiari, Z. Daroogheha, and F. F. Bamoharram, Catal. Commun., 8, 1991 (2007). L. Nagarapu, Aneesa, R. Peddiraju, and S. Apuri, Catal. Commun., 8, 1973 (2007).

A. Davoodnia, M. Bakavoli, R. Moloudi, M. Khashi, and N. Tavakoli-Hoseini, Monatsh. Chem., 141, 867 (2010).

J. Safari, S. H. Banitaba, and S. Dehghan Khalili, Chin. J. Catal., 32, 1850 (2011).

J. Safari, S. Dehghan Khalili, M. Rezaei, S. H. Banitaba, and F. Meshkani, Monatsh. Chem., 141, 1339 (2010).

S. Banerjee and G. Sereda, Tetrahedron Lett., 50, 6959 (2009).

M. Reza, M. Shafiee, R. Moloudi, and M. Ghashang, APCBEE Procedia, 1, 221 (2012).

J. Guo, H. Lou, H. Zhao, X. Wang, and X. Zheng, Mater. Lett., 58, 1920 (2004).

E. Navaei Alvar, M. Rezaei, and H. Navaei Alvar, Powder Technol., 198, 275 (2010).

N. Jeong, J. Yeo, and K. Song, Material. Lett., 109, 34 (2013).

D. Nagargoje, P. Mandhane, S. Shingote, P. Badadhe, and C. Gill, Ultrason. Sonochem., 19, 94 (2012).

B. Maleki, D. Azarifar, H. Veisi, S. F. Hojati, H. Salehabadi, and R. N. Yami, Chin. Chem. Lett., 21, 1346 (2010).

M. Adib, H. Tahermansouri, S. A. Koloogani, B. Mohammadi, and H. R. Bijanzadeh, Tetrahedron Lett., 47, 5957 (2006).

J. Safari and Z. Zarnegar, Ultrason. Sonochem., 20, 740 (2013).

We gratefully acknowledge financial support from the Research Council of the University of Kashan, grant No. 256722/28.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Khimiya Geterotsiklicheskikh Soedinenii, No. 12, pp. 1832-1840, December, 2014.

Rights and permissions

About this article

Cite this article

Zarnegar, Z., Safari, J. & Borjian-borujeni, M. Ultrasound-Mediated Synthesis of 2,4,6-Triaryl-Pyridines Using MgAl2O4 Nanostructures. Chem Heterocycl Comp 50, 1683–1691 (2015). https://doi.org/10.1007/s10593-015-1638-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10593-015-1638-0