Abstract

Electromyographic signals (EMGs) are becoming important as a tool for muscle fatigue monitoring. EMGs measure the electric currents produced in muscle contractions providing information that can be analyzed and processed to evaluate the conditions of muscles. In this work, we proposed a real-time system that measures muscle fatigue levels based on Electromyographic signals. We used the Mean Frequency and the Power Spectral Density as features for muscle fatigue determination. A linear regression model determines the levels of muscle fatigue. Moreover, the system is composed of EMG wireless sensors allowing it to be used in common activities in the manufacturing industry as manual handling loads.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Most of the common injuries in the manufacturing industry are back injuries, which are related to the excess in the physical capacities of the workers [1]. Besides, studies [1, 2] reveal that these injuries can be prevented if an evaluation of the risk in working environments is carried out. Disciplines like ergonomics and occupational health, study and evaluate the risk in job activities to produce safer working environments. One crucial aspect to take into account is muscle fatigue since it is associated with a higher risk of developing musculoskeletal disorders [3]. Muscle fatigue can be determined using a variety of methods [4], as measuring the time during which an individual is able to perform a task with an ergonometric imposed load, keeping a posture during a certain time interval, or by measuring the concentration of lactic acid in muscle [5]. Moreover, various studies [6,7,8,9,10] have also shown that Electromyographic signals (EMGs) provide a method that allows continuous monitoring of muscle fatigue. This is due to EMGs measure the electric currents produced during muscle contractions, enabling the study of physiological muscle properties. The electric currents are known as muscle fiber potentials, and EMGs are composed of all muscle fiber potentials. As the above is related to the neuromuscular activity, EMGs also provide information to study neuromuscular disorders [11]. EMGs are becoming important in many fields because of their multiple applications as human-machine interfaces, biomedical-medicine [12]; sports [13]; occupational medicine [14], etc. In human-machine interfaces, EMG can be used to control a computer, to drive a car, or to control a robotic arm, among others [15]. In the sports field, EMG signals are used to measure the muscle activity of athletes. For example, in [16] is described a method to design a pilates training program based on a study of muscle response during exercise. In biomedical-medicine, EMG signals are studied to find patterns that characterize the signals corresponding to each hand-finger and in this way to control powerful prosthesis of upper and lower amputee limbs as it is described in [17].

EMG signals are generally recorded by non-invasive sensors placed on the surface of the skin over the muscle. Then, the recorded signals are studied through spectral analysis in order to extract information related to muscle fatigue. Considering the existing wireless technology of the non-invasive sensors combined with an analysis of features in real-time, is possible to develop a system to monitor muscle fatigue in real-time. Moreover, the wireless sensors allow the use of this system in working environments as the manufacturing industry, where the activities performed by the workers usually require total freedom of arms and legs.

In this paper, a system to monitor the level of muscle fatigue in real-time using EMG signals is developed. The system uses non-invasive wireless sensors. An application was implemented in python for muscle fatigue detection using a linear regression model for fatigue determination. Moreover, the system was evaluated in repetitive tasks similar to the manufacturing industry.

This paper is organized as follows: in Sect. 2, a description of the selected features is given; materials and experiment protocol are described in Sect. 3; features analysis is described in Sect. 4; the monitoring system is described in Sect. 5; experiment results are presented in Sect. 6, and Sect. 7 is dedicated to the discussion.

2 Theoretical background

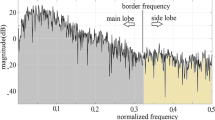

The EMGs are non-stationary signals [9]. Their values range go from micro to millivolts; therefore, they are usually studied in short-time windows where the properties of EMGs behave as quasi-stationary. In other words, the EMGs data are segmented into short-time intervals for their analysis. Then, frequency domain features are extracted from the data to obtain information about the muscle condition. The above method is widely used in the literature, as is described in various studies [10, 18, 19]. Moreover, these studies have reported a shift from higher to lower frequencies in the EMG signals as a manifestation of muscle fatigue [9, 10]. This is due to a decrease in the muscle fiber conduction velocity (CV) when one person gets tired, affecting the myoelectric signal [20]. This reduction in the frequency can be observed in the Mean Frequency (MNF), and the Median Frequency (MDF) parameters that are typically used to study muscle fatigue [21]. The MNF and MDF parameters are obtained from the EMG signals’ Power Spectral Density (PSD) [9].

The PSD is computed using the Fast Fourier Transform [22] . The MDF (see Eq. 1) can be described as the frequency at which the PSD of EMG signals is divided into two regions with equal amplitude, while MNF ( see Eq. 2) is described as half of the PSD of EMG signals.

where \(f_j\) is the frequency of the Power Spectral Density measured at the bin j and \(p_j\) is the PSD measured at the bin j, and M refers to the length of the frequency bin.

3 Materials

Figure 1 shows the schema of the developed system for monitoring muscle fatigue in real-time. The proposed method comprises EMG wireless sensors, a wireless base station, a server, and a client. The function of each element is described as follows: the system takes the EMG signals using the EMG wireless sensors placed over the skin of the volunteer. Then, the EMG signals are transmitted to a wireless base station connected to a local EMG server through a serial cable. The local server sends the data to a client through a TCP connection. Subsequently, the data is analyzed in real-time by the client.

The EMG wireless sensors and the wireless base station are integrated into the commercial Trigno Wireless System [23] (see Fig. 2). The Trigno system is composed of eight non-invasive electromyographic sensors that measure the electric currents of muscles. The body size of each Trigno sensor is 27x37x13 mm\(^3\), and the mass is 14 g. The measured EMG signals obtained by the Trigno sensors are transmitted to a receiving base machine station via a wireless protocol, which is optimized to minimize data latency across sensors. The wireless sensors’ coverage range is 20 m, allowing taking data without being close to the volunteer.

Trigno wireless system [23] for EMG signals collection. The wireless sensors allow taking data in working environments like manual handling loads without affecting the activity of workers

For real-time analysis of the data, a locally based machine is configured as a client. The device used for the data analysis is an NVIDIA Jetson Nano [24] (see Figs. 3, 4), which is a small computer that allows analyzing biomedical signals in real-time due to its low latency and less impact on overhead.

NVIDIA Jetson Nano [24] used for the analysis of the EMG signals in real-time

Illustration of the deltoid muscle. The sensor was placed in red zone. The figure was taken from [25]

The Jetson Nano was preconfigured with the operating system NVIDIA L4T based on Ubuntu 18.4, which provides the drivers, kernels, etc., needed for running the machine. The L4T is a light operative system that allows run applications that require high computing time performance.

3.1 Experiment protocol

According to the “Manual Handling at work: A brief guide” [26] by the Health and Safety Executive (HSE) agency of the UK, the weights recommended for manual handling of loads depend on the height. The maximum theoretical weight that one worker can handle without being exposed to an injury is shown in Fig. 5 for different body heights. The safest one is just below the elbow level.

Recommended weight for manual lifting. The information shown in this figure was taken from [26]

The chosen dynamic to test the system consists of handling the box shown in Fig. 6 and transporting it from one desk to another, taller desk. The height of the smaller desk is 93 cm, while the height of the taller desk is 150 cm. The procedure consists of that the volunteer performs the activity until the developed system emits an alert when the volunteer starts reaching the critical point of muscle fatigue. The critical point in this work is when the volunteer feels so exhausted.

The positions adopted by the volunteer are shown in Figs. 7 and 8. The volunteer holds the box, which is filled with books, and then he turns left and puts the box on the top level of the next desk. Then, immediately, the volunteer takes the box from the top-level desk, turns right, and puts the box on the top level of the lower desk. Thus, in this exercise, the volunteer has two positions: (1) holding the box just below elbow height and (2) holding the box just above eye height.

Several muscles can be monitored when performing the activity described above. However, in this study, it was found that the effort was mainly concentrated in the muscles of the shoulder, more specifically, in the deltoid muscle shown in Fig. 4. This is in agreement with studies reported in [27]. Accordingly, one sensor in the deltoid muscle of the right shoulder was placed on each volunteer. As a cross-check, a sensor was also placed in the deltoid muscle of the left shoulder.

In this work, three male students, ages 21, 22, and 21, participated in this study as volunteers. The volunteer’s heights are 1.65 cm, 1.72 cm, and 1.74 cm and weigh 56 kg, 60 kg, and 98 kg, respectively. All the participants signed an Informed Consent form indicating they agreed to take part in this study.

4 Feacture analysis

Features are computed and analyzed in real-time to determine the critical point of muscle fatigue. The criteria for the critical point of muscle fatigue determination were established after doing an offline analysis of PSD and MNF, and it is described below.

For the offline analysis, all the volunteers performed the activity described in Sect. 3.1 two times; each lasted 3 minutes. The weight box was varied each time as follows:

-

1.

Without weight: the box was empty. The box’s total weight was 100 g.

-

2.

With weight: the box was filled with books. The box’s total weight was 7 kg, which is 40 % above the recommended weight for eye height.

The PSD was computed for all the volunteers. The PSD for the first volunteer shows a shift from higher to lower frequencies when he performs the activity with weight(see Fig. 9). In the activity with the box weight of 7 kg, a narrower peak is observed, which means that the muscle gets fatigued more quickly when performing the heaviest task. The same behavior was observed for the second volunteer (see Fig. 10). The third volunteer does not show similar results (Fig. 11). However, this can be due to his physical condition.

Power Spectral Density computed from EMG signals of the second volunteer. The same behavior as the first volunteer one is observed here. There is a more significant peak at lower frequencies when the volunteer performs the activity with the box of 7 kg. The dotted line corresponds to the activity with the empty box

The mean frequency (MNF) was also computed for the three volunteers when they were doing the two activities. In this case, the manifestation of muscle fatigue was more visible with MNF (see Figs. 12 and 13) than the one with the PSD. Besides, the MNF shows a clear difference in both activities. The MNF of volunteer 1 performing the exercise without weight decreases slightly with time. On the other hand, when volunteer 1 performed the activity with the box of 7 kg, the reduction of the frequency is faster.

4.1 Linear regression

The MNF versus time plots are shown in Figs. 12 and 13. The graphs show a dispersion of MNF over time that makes it difficult to see the decrement of the frequency, and consequently, difficult to monitor the muscle fatigue. For this reason, the variation of MNF in time was studied using a linear regression model. This model assumes a linear relationship between the MNF and time. The slope of the linear regression was used to estimate fatigue as it is described in [28,29,30]. The equation of the linear regression is defined as:

where X is the independent variable, y is the dependent variable, \(\beta _{0}\) and \(\beta _{1}\) are the regression coefficients and \(\epsilon\) is the residual error. The linear regression method can be used to predict the value of the \(\text{ MNF}_{i}\) at \(\text{ time}_{i}\) and in this way not being affected by the data dispersion.

The data fit obtained with the linear regression model is shown in red in Figs. 12 and 13. The fit shows a clear downward trend of the frequency in Fig. 13, and it is still possible to see the slight reduction of the frequency as a function of time in Fig. 12.

5 Monitoring system

Figure 14 shows the flow of the monitoring system. The EMG signals are processed in the Jeton Nano Machine. The PSD and MNF features are computed every 0.255 seconds. For each iteration, the system compares the current MNF to a baseline to measure the reduction of the frequency over time. The lower frequency, the higher the muscle fatigue. The criteria for the determination of muscle is presented in Table 1. The system defines three levels of muscle fatigue: yellow, yellow phase 2, and critical point. The critical point represents the maximum level of tiredness of the volunteer. The values \(t_1min\), \(t_1max\), and \(t_2max\) are the thresholds for each level of fatigue.

The level of muscle fatigue is determined by using the algorithm 1. As mentioned in 4.1, the MNF and the baseline used to computed the level of fatigue are obtained from a linear regression model to be less sensitive to the data dispersion shown in Figs. 12 and 13. The way to fit the regression model is shown in Eq. 4.

where time = {\(t_i,t_{i+1}...t_n\)} and Y = {\(y_i,y_{i+1}...y_n\)}, \(y_i\) is the MNF computed at \(t{_i}\).

Once the regression model is fitted, the variables are predicted as follows:

The MNF sample collected in the first 30 seconds is fitted with a linear regression model, and the baseline is obtained by evaluating the fit at \(t_{0} = 0\). On the other hand, for the current MNF, the MNF data sample is fitted in every iteration. A sliding window, like the one shown in Fig. 15 is used to have the same statistic for the fit and not saturate the disk memory with data. Moreover, due to First-In, First-Out (FIFO) principle, the data sample length is always the same. In addition, it is important to mention that longer-size windows were tested at the beginning of this work. The difference in the accuracy of the features extraction was not significantly different.

6 Experimental results

For testing and validation of the developed real-time system, the three volunteers described in Sect. 3.1 were required again. The test of the system in real-time was carried out three days after the first data taking described in Sect. 4, and divided into two days. During the first day, the volunteers performed the activity with a box of 5 kg twice to monitor only one of the two (left and right) deltoid muscles at a time. During the activities, the system emitted alerts when reaching the three levels of muscle fatigue: yellow, yellow phase 2, and critical point. Besides, as a cross-chek, all the volunteers were asked if they were fatigued when entering the critical point.

Figure 4 shows the results obtained with the 5 kg box for the right deltoid muscle. The time values tell that each volunteer gets fatigued at different times, which can be since each of the volunteers has a different physical condition, as mentioned in Sect. 3.1. On the other hand, the results obtained when monitoring the left deltoid muscle (see Table 2, 3) show a decrease in the volunteers’ performance. This result can be due to two factors: (1) the volunteers only rested 20 min between the two tests, or (2) all the volunteers mentioned that due to the activity’s movements, they felt more tension in the left shoulder than the right one.

The results obtained for the activity with the 7 kg box are shown in Tables 4 and 5 for right and left deltoid muscle, respectively. The volunteers entering the critical zone more quickly agree with the recommended weight for manual lifting shown in 5. Moreover, a better agreement between the real-time system and the feeling of tiredness of volunteers was observed.

7 Discussion and future work

In this work, a real-time system that monitors muscle fatigue using electromyographic signals were developed. The Mean Frequency was used as a feature to determined muscle fatigue. The system uses a linear regression to analyse the variation in time of the Mean Frequency. The system used wireless sensors to be more portable and defines three levels of muscle fatigue. The activity chosen to validate the system was related to an activity commonly performed in the manufacturing industry as the manual handling loads, which the purpose of develops a tool that can be used to measure the risk in this kind of working environment.

The obtained results can be summarized as follows:

-

The analyzed data showed that the Mean Frequency could be used as a feature to monitor muscle fatigue as it showed a decrement due to muscle fatigue.

-

The variation in time of the Mean Frequency was studied using a linear regression approach to get less sensitive to the data dispersion.

-

During the testing phase, the system showed that it took longer to get fatigued when the volunteers performed the activity with the recommended weight by the HSE agency.

-

The system also showed that the volunteers get fatigued more quickly when performing with 43% above the recommended weight.

-

The developed system showed different results when monitoring the left and right deltoid muscles. The latter is interpreted as an effect of the designed activity, which requires more action from the left deltoid muscle. On the other hand, the level of muscle fatigue emitted by the system and each volunteer’s tiredness agrees in 60 %. However, more statistics are needed to give a more precise performance of the system.

Subsequent versions of the system can include an interface that sends data of the EMG signals to a cloud system allowing remote data analysis. The latter can open a research line in occupational health where one can monitor the muscle fatigue of workers in real-time even if they are in another city.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Deviani, Triyanti, V.: “Risk assessment of manual material handling activities (case study: PT BRS Standard Industry)”, IOP Conference Series: Materials Science and Engineering, 277, 012043 (2017). https://doi.org/10.1088/1757-899X/277/1/012043

Kiani, Fariba, Khodabakhsh, Mohammad, R.: Preventing injuries in workers: the role of management practices in decreasing injuries reporting. Int. J. Health Policy Manag. 3, 171-177 (2014). https://doi.org/10.15171/ijhpm.2014.83

Zenija, R., Henrijs, K., Inara, R.: Measuring muscle fatigue in relation to the workload of health care workers. Procedia Manufacturing: 6th International Conference on Applied Human Factors and Ergonomics (AHFE 2015) and the Affiliated Conferences, AHFE 2015, 3, 4189-4196 (2015). https://doi.org/10.1016/j.promfg.2015.07.394

Cifrek, M., Medved, V., Tonković, S., Ostojić, S.: Surface EMG based muscle fatigue evaluation in biomechanics. Clin. Biomech. 24, 327–340 (2009). https://doi.org/10.1016/j.clinbiomech.2009.01.010

Sahlin, K.: Muscle fatigue and lactic acid accumulation. Acta. Physiol. Scand. Suppl. 556, 83–91 (1986)

Vøllestad, K., Nina.: Measurement of human muscle fatigue. J. Neurosci. Methods. 74, 219-227 (1997). https://doi.org/10.1016/S0165-0270(97)02251-6

Kuthe, Chetan, D.: et al.: Surface electromyography based method for computing muscle strength and fatigue of biceps brachii muscle and its clinical implementation. Inform. Med. Unlocked 12, 34-34 (2018). https://doi.org/10.1016/j.imu.2018.06.004

Cifrek, M., et al.: Surface EMG based muscle fatigue evaluation in biomechanics. Clin. Biomech. 24, 327–340 (2009). https://doi.org/10.1016/j.clinbiomech.2009.01.010

Zhang, Z.G., et al.: Time-dependent power spectral density estimation of surface electromyography during isometric muscle contraction: methods and comparisons. J. Electromyogr. Kinesiol. 20, 89–101 (2010). https://doi.org/10.1016/j.jelekin.2008.09.007

Karthick, P.A., Ramakrishnan, S.: Muscle fatigue analysis using surface EMG signals and time-frequency based medium-to-low band power ratio. Electronics Letters 52, 185–186 (2015). https://doi.org/10.1049/el.2015.3460

Raez, M. B., Hussain, M. S., Mohd-Yasin, F.: Techniques of EMG signal analysis: detection, processing, classification and applications. Biol. Proced. Online 8, 11–35 (2006). https://doi.org/10.1251/bpo115

Farfán, F.D., Politti, J.C., Felice, C.J.: Evaluation of EMG processing techniques using information Theory. BioMed. Eng. OnLine 9, 72 (2010). https://doi.org/10.1186/1475-925X-9-72

Hande, T., Hasan, S.: Surface electromyography in sports and exercise. In: Hande Türker, Electrodiagnosis in New Frontiers of Clinical Research, pp. 175-194. (2013). https://doi.org/10.5772/56664

Marco, G., Babak, A., Roberto, M.: Surface EMG in ergonomics and occupational medicine. Surf. Electromyogr. Physiol. Eng. Appl. 361–391, (2016). https://doi.org/10.1002/9781119082934.ch13

Blanco, A., Catalán, J.M., Díez, J.A., García, J.V., Lobato, E., García-Aracil, N.: Electromyography assessment of the assistance provided by an upper-limb exoskeleton in maintenance tasks. Sensors (Basel, Switzerland) 19(15), 3391 (2019). https://doi.org/10.3390/s19153391

Steele, C.: Applications of EMG in clinical and sports medicine. IntechOpen (2012). https://doi.org/10.5772/2349

You, K-J., Rhee, K-W., Shin, H-C.: Finger motion decoding using EMG signals corresponding various arm postures 19(1), 54–61 (2010). https://doi.org/10.5607/en.2010.19.1.54

Knaflitz, M., Bonato, P.: Time-frequency methods applied to muscle fatigue assessment during dynamic contractions. J. Electromyogr. Kinesiol. 9(5), 337–50 (1999). https://doi.org/10.1016/s1050-6411(99)00009-7

Masuda, K., Masuda, T., Sadoyama, T., Inaki, M., Katsuta, S.: Changes in surface EMG parameters during static and dynamic fatiguing contractions. J. Electromyogr. Kinesiol. 9(1), 39–46 (1999). https://doi.org/10.1016/s1050-6411(98)00021-2

Merletti, R., Knaflitz, M., De Luca, C.J.: Myoelectric manifestations of fatigue in voluntary and electrically elicited contractions. J. Appl. Physiol. 69(5), 1810–20 (1990). https://doi.org/10.1152/jappl.1990.69.5.1810

Angkoon, P., et al.: The usefulness of mean and median frequencies in electromyography analysis. Computational Intelligence in Electromyography Analysis- A perspective on Current Applications and Future Challenges, 195-220 (2012). https://doi.org/10.5772/50639

Stulen, F.B., DeLuca, C.J.: Frequency parameters of the myelectric signal as a measure of muscle conduction velocity. IEE Trans. Biomed. Eng. 28(7), 515–23 (1981). https://doi.org/10.1109/tbme.1981.324738

Trigno Wireless System, https://delsys.com/trigno/. Accessed 7 Dec 2020

Jetson Nano NVIDIA, https://developer.nvidia.com/embedded/jetson-nano-developer-kit. Accessed 7 Dec 2020

Primal Pictures Ltd: Trigger point Deltoid 1. (2020)

Health And Safety Executive (HSE), Manual handling at work: a brief guide. HSE Books, London (2020)

Sung-kwang, J., Yoo, W-G: Electromyography activity of the deltoid muscle of the weight-bearing side during shoulder flexion in various weight-bearing positions. J. Phys. Ther. Sci. 27(10), 3285–3286 (2015). https://doi.org/10.1589/jpts.27.3285

Thongpanja, S., Phinyomark, A., Phukpattaranont, P., Limsakul, C.: Mean and median frequency of EMG signal to determine muscle force based on time-dependent power spectrum. Elektronika Ir Elektrotechnika 19(3), 51–56 (2013). https://doi.org/10.5755/j01.eee.19.3.3697

Oliveira, R.S., Pedro, R.E., et al.: Spectral analysis of electromyographic signal in supramaximal effort in cycle ergometer using Fourier and Wavelet transforms: a comparative study. Revista Andaluza de Medicina del Deporte 5(2), 48–52 (2012). https://doi.org/10.1016/S1888-7546(12)70008-4

Smith, L.H., Kuiken, T.A., Hargrove, L.J.: Evaluation of Linear Regression Simultaneous Myoelectric Control Using Intramuscular EMG. IEEE Trans. Biomed. Eng. 63(4), 737–746 (2016). https://doi.org/10.1109/TBME.2015.2469741

Acknowledgements

Authors thanks to The Mexican Council of Science and Technology, CONACYT, Mexico, for its support (Grant 236207, CB-2014-01).

Funding

This work was supported by the Consejo Nacional de Ciencia y Tecnología de México (Conacyt-México).

Author information

Authors and Affiliations

Contributions

All the authors in this paper contribute to the design and development of the system presented here. The full manuscript was written by P. González-Zamora, and all authors contributed with comments on the previous versions.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Ethical approval

All the participants signed an Informed Consent form indicating they accept to take part in this study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

González-Zamora, P., Benitez, V.H. & Pacheco, J. A feature-based processing framework for real-time implementation of muscle fatigue measurement. Cluster Comput 26, 385–394 (2023). https://doi.org/10.1007/s10586-021-03437-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10586-021-03437-7