Abstract

Polycarboxylic acid (PCA) modified cotton fiber Fe complex (Fe-PCA-Cotton) was created by the surface modification of cotton fabric with tartaric acid (TA), citric acid (CA) or 1,2,3,4-butanetetracarboxylic acid (BTCA) and subsequent Fe(III) ion coordination to meet the “4-E” criteria: efficient, economical, environmentally friendly and easily-produced. Effect of PCA structure on sunlight-driven catalytic and antibacterial activities, mechanical and thermal properties of the obtained Fe-PCA-Cotton was investigated, which showed that Fe-TA-Cotton had higher photocatalytic ability than other two complexes under different weather conditions. The best antibacterial activity was achieved when CA was used for the complex preparation. Increasing their Fe contents over critical values led to the complexes with excellent catalytic and mechanical performance. A little difference in thermal property between three complexes was found. This study indicated that Fe-CA-Cotton is possibly one of the few solar-driven heterogeneous Fenton photocatalyst that can be produced and applied in industrial scale.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polymer metal complexes (PMCs) have received an increasing attention owing to their unique structures with potential applications in electric magnetism, catalysis, drug delivery, and environmental purification. Over the last decade years, the use of fibrous ligands is a cost-effective alternative to the traditional methods of PMCs fabrication. Moreover, these fibrous ligands exhibit major advantages as compared to other types of polymer ligands, namely, high specific surface area, excellent adsorption capacity and being easy to design and tailor-made for almost any geometric shape suitable for placing in equipment (Moroi et al. 2001; Dong et al. 2010). Several synthetic fibrous ligands including the modified polyacrylonitrile (Dong et al. 2010), polypropylene and polytetrafluoroethylene fibers (Li et al. 2014) have been coordinated with Fe(III) ions to developed fibrous PMCs used as the efficient heterogeneous Fenton catalysts for the degradation of organic dyes in order to avoid some drawbacks of homogeneous catalysts. However, it is unbelievable that these synthetic fibrous PMCs as the catalysts can meet the “4-E” criteria: Efficient, Economical, Environmentally friendly, and Easily-produced (Feng et al. 2017) because mainly of non-biodegradable performance or high cost-effectiveness of these synthetic fibers used. Also, the chemical modification of the synthetic fibers is usually expensive or poses an environmental hazard for future industrialized application. Polycarboxylic acids (PCAs) as the common carboxylic ligands have been widely used in the fabrication of different PMCs because of their diversity of coordination modes and high structural stability (Du et al. 2013; Wang et al. 2015). Furthermore, aliphatic PCAs, especially tartaric acid (TA), citric acid (CA) and 1,2,3,4-butanetetracarboxylic acid (BTCA) have been proved to be safe in process and use, and can be applied easily and economically on textile fabrics in industrial scale (Bischof Vukušić et al. 2011; Feng et al. 2017). And they can be derived from natural products with large availability, and have low toxicity for environment and human health (Shen et al. 2015a; Soleimani-Gorgani and Karami 2016). On the other hand, cotton fiber as an important biomass is the commonly used cellulose fiber in the modern textile industry. Cotton fiber with production of more than 27 million tons per year, accounts for 30% of total fiber production worldwide (Wanassi et al. 2016). More importantly, some previous works (Welch 1992, 1988; Dehabadi et al. 2013; Liu et al. 2016; Qi et al. 2016) reported that several PCAs, especially CA and BTCA were used as the prospective non-toxic alternative cross-linkers to enhance the crease resistant property of cotton fabric by a conventional pad-dry-cure process. It was found by infrared spectrum that these PCAs first forms a cyclic anhydride at high temperatures, which then reacts with hydroxyl groups of cotton fiber to cause the crosslink (Mao and Yang 2001). Meanwhile, at least one carboxyl group was remained on the surface of cotton fabric during the reaction. In our recent studies (Li et al. 2015; Liu et al. 2018), the carboxyl groups introduced on cotton fiber using the same padding process were coordinated with Fe(III) ions for preparing the aliphatic PCAs-modified cotton fiber Fe complex as catalyst or activator for the fast degradation of organic dyes in water. The production procedure of the novel complex is not only manageable, but also less expensive to conduct for industrial application. TA modified cotton fiber Fe complex showed a better enhanced effect of activated Na2S2O8 for dye degradation than the other two complexes. In consideration of the environmental friendliness, virtually inexhaustible supply of aliphatic PCAs, cotton and Fe salt, highly efficient catalysis and easy industrial application to cotton fiber, the aliphatic PCAs-modified cotton fiber Fe complex could be regarded to meet the “4-E” criteria. Additionally, it should be stressed that better mechanical performance is necessary for effective using of these fibrous complexes as the catalysts or activators for different oxidative systems, since mechanical performance usually plays a great role in their durability and regenerative property (Han et al. 2010). It is known that cotton fiber is more susceptible to bacterial attacks than synthetic fibers owing to its porous hydrophilic structure and its ability to retain water, oxygen and nutrients, hence providing a perfect environment for bacterial growth (Lane et al. 2006; Soleimani-Gorgani and Karami 2016), thus possibly lead to serious damage to its mechanical performance when its complex being used as the heterogeneous Fenton catalyst in aqueous media for long period.

In this present work, three aliphatic PCAs including TA, CA and BTCA were used for the surface introduction of carboxyl groups of cotton woven fabric through an industrialized pad-dry-cure process. And the introduced carboxyl groups were then coordinated with Fe(III) ions to produce three carboxylic cotton fiber Fe complexes in order to investigate their feasibility as solar light-driven photocatalyst in future practical applications. Also, antibacterial activities of three complexes were examined to expect a reduced bacterial contamination for preventing their damage to cotton fiber. Besides, the mechanical properties including breaking strength and elongation at break of three complexes were evaluated and compared in dry and wet states. Finally, their thermal properties were studied for the identification of the fibrous Fe complexes and assessment of their structural variation as a result of modification or coordination. More importantly, the effect of different PCAs on solar light-driven photocatalytic ability under different weathers, antibacterial activities, mechanical and thermal properties of the three complexes was investigated in details for obtaining a catalyst that meets the “4-E” requirements and to be applied on an industrial scale.

Experimental section

Materials and chemicals

A commercially pretreated cotton woven fabric with a weight of 112.9 gm−2 was employed in this work. The cotton fabric was further treated with a solution containing 10.0 g L−1 NaOH and 2.0 g L−1 soap at the boil for 30 min, then thoroughly washed with cold water and dried at room temperature before use. Tartaric acid (TA), citric acid (CA), 1,2,3,4-butanetetracarboxylic acid (BTCA), NaH2PO2, Fe2(SO4)3 and H2O2 (30wt%) were of analytical reagent grade and used as received. The molecular structures of three polycarboxylic acids (PCAs) were presented in Scheme 1a. 5,5-dimethyl-1-pyrroline-N-oxide (DMPO) was provided from Micklin Biochemical Technology Co., Ltd (Shanghai, China). A typical commercial azo dye, Reactive Red 195 (RR 195, CAS: 93050-79-4) was used and the molecular structure of which was described in our previous study (Dong et al. 2010). Distilled water was further cleaned prior to its use using a quartz sub-boil high purity water system and used throughout the study.

Preparation of PCA modified cotton fiber Fe complexes

According to our previous works (Li et al. 2015; Liu et al. 2018), PCA modified cotton fiber Fe complexes were fabricated through two steps including modification and coordination processes. Briefly, cotton fabric was first padded with an aqueous modifying solution containing various concentration of PCA and NaH2PO2 (5.0w/w%) at room temperature on a laboratory mangle. The padded fabric was then dried at 100 °C for 3 min, and cured at 180 °C for 1.5 min to complete its modification for obtaining a carboxylic cotton fiber (denoted as PCA-cotton). And then obtained PCA-cotton was thoroughly washed with distilled water until washings were neutral and dried under vacuum. Carboxyl group content in the resulting PCA-Cotton (QCOOH, mmol g−1) was measured through an acid–base titration method reported in our previous studies (Li et al. 2015; Liu et al. 2018). Afterward, PCA-Cotton was immersed in a dyeing jigger containing an aqueous solution of Fe2(SO4)3 under continuous agitation at 50 °C for 2 h to produce the PCA modified cotton fiber Fe complex (denoted as Fe-PCA-cotton). The residual concentration of Fe(III) ions in the coordinating solution was analyzed by a Varian Vista-MPX inductively-coupled plasma optical emission spectroscopy (ICP-OES). Fe content (Q Fe , mmol g−1) of the resulting complex was calculated through Eq. (1).

where C0 and Ct are the initial and residual concentrations of Fe(III) ions in the coordinating solution (mmol L−1), respectively. V0 and Vt are the initial and residual volume of coordinating solution (L), respectively. m is the mass of the resulting Fe-PCA-cotton (g). The detailed reaction mechanism was shown in Scheme 1b.

Sunlight-driven photocatalytic procedure and analysis

The photocatalytic activity of Fe-PCA-cotton samples was assessed by analyzing the decomposition of RR 195 under sunlight irradiation on the top of Textile Engineering Building at the campus of Tianjin Polytechnic University (located at Xiqing District, Tianjin, about 9 m above sea level). The ambient temperature was 25–33 °C. The sunlight intensity was recorded using FZ-A radiometer and UV-A radiometer, respectively. 0.50 g of sample were cut into 1 cm × 1 cm pieces, and then immersed to 100 ml test solution containing 0.05 mmol L−1 RR 195 and 6.0 mmol L−1 H2O2. The photocatalytic degradation of test solution was initialized after the adsorption/desorption equilibrium of RR 195 on sample had been reached in the dark for 2 h. At given irradiation time intervals, 1–2 mL of the test solution was taken out and centrifuged to precipitate cotton fibers at the bottom of the tube, and the upper clear test solution was analyzed immediately by a UV-2401 Shimadzu spectrophotometer at 523 nm (maximum absorption wavelength of RR 195) for the determination of the change in dye concentrations before and after visible irradiation. The decoloration percentage of RR 195 was described as:

where Cd,0 and Cd are the initial and residual concentration of RR 195 (mmol L−1), respectively.

Antibacterial activity study

Escherichia coli (E. coli, Gram-negative) and Staphylococcus aureus (S. aureus, Gram-positive) were used as model bacteria to examine the antibacterial performance of PCA-cotton and its Fe complex according to modified ASTM E2149-2013 method in this work because E. coli resist common antimicrobial agents and causes urinary tract as well as wound infections, and S. aureus is the major cause of cross-infection in hospitals (Montazer et al. 2011). The antibacterial activity was expressed through the percentage of bacterial reduction after contact with PCA-cotton and its Fe complex compared to the number of bacterial colonies surviving after contact with the original cotton fabric as control sample. After the antibacterial experiment, bacteria colonies were counted using Scan 500 Colony Counter (Interscience, France), and the percentage of reduction was calculated by Eq. (3).

where R(%) is the percentage of bacterial reduction. A and B are the number of the visual bacterial colonies for the plates containing PCA-cotton and its Fe complex and control cotton fabrics, respectively, after 12 h contact time under visible radiation.

Mechanical performance test

The breaking strength and elongation at break of fabric sample on a YG 065 laboratory fabric tensile tester (Laizhou Electronic Instrument Co., China) under ambient atmosphere conditions according to the Chinese Standard GB/T3923.1-2013 based on ISO/DIS 13934.1-94. All tests were performed on dry as well as wet samples. Before testing, dry samples were conditioned at 25 °C and 65% RH for at least 48 h. Wet samples were prepared by immersion in water for 1 h prior to testing, and excess water of the samples was removed by laboratorial VF 15685 Padder (Werner Mathis AG Co., Switzerland). The data shown correspond to averages of at least five individual tests for each sample.

Thermal property evaluation

Thermo-gravimetric analysis (TGA) and Differential scanning calorimetry (DSC) measurement for original cotton fabric, PCA-Cotton and their Fe complexes was carried out by Q600 SDT Simultaneous DSC-TGA thermal analyzer under nitrogen atmosphere at heating rate of 10 °C/min using a sample weight of 10 mg.

Results and discussion

Comparison and preparation of three PCA-Cotton Fe complexes

Three PCA-Cotton samples with similar QCOOH values (approximately 0.85 mmol g−1) were fabricated and coordinated with Fe(III) ions (0.10 mol L−1), respectively and Q Fe values of the resulting complexes were measured during the reaction. For comparison, a control experiment, in which the untreated cotton fabric was used, and the results were shown in Fig. 1a.

Figure 1a shows that Q Fe value was very small (0.001 mmol g−1) within 90 min for the untreated cotton fabric, indicating that little Fe(III) ions was absorbed by cotton fabric. Moreover, Q Fe values for three PCA-Cotton gradually increased with the prolongation of reaction time, and then the increasing tendency became level after 30 min, proposing the Fe(III) ions could react with PCA-Cotton and more Fe(III) ions were fixed on cotton fiber. Moreover, the coordination between them reached the equilibrium due to unchanged Q Fe values after 30 min of reaction time. TA-Cotton reacted with Fe(III) ions more rapidly than the other PCA-Cotton samples at the same conditions because of its short equilibrium duration. Beside, Q Fe values of the resulting complexes at equilibrium ranked this order: Fe-TA-Cotton (0.756 mmol g−1) > Fe-CA-Cotton (0.587 mmol g−1) > Fe-BTCA-Cotton (0.483 mmol g−1). This was because the aliphatic PCAs with more than two carboxyl groups have better crosslink ability than dicarboxylic acids, and BTCA with 4 carbons in its backbone and 4 carboxyl groups showed the better crosslinking effects than CA with 3 carbons in its backbone and 3 carboxyl groups (Shen et al. 2015b; Song et al. 2016), leading to the higher crosslink degree of BTCA-Cotton and CA-Cotton than TA-Cotton. The complicated crosslink structure of the two PCA-Cotton could hinder the coordination of Fe(III) ions with their carboxyl groups. Figure 1b presented the FTIR spectra of three PCA-Cotton samples before and after coordination with Fe(III) ions. Several characteristic absorption peaks of original cotton fiber were observed at 3340, 2900, 1431, 1316, 1158, 1061, 1033 and 903 cm−1, owing to the stretching of OH, CH, CO and C–O–C, respectively (Li et al. 2015; Sun et al. 2008). A peak around 1723 cm−1 representing carbonyl stretching vibration of the carboxyl groups and ester carbonyl bands was apparent in the spectra of three PCA-Cotton samples, indicating that the carboxyl groups have been incorporated into surface structure of cotton fiber by esterification with PCAs. More importantly, this peak became much less intensive, and a new peak centered at 1638 cm−1 appeared in the spectra of three complexes, especially Fe-TA-Cotton and Fe-CA-Cotton, confirming that Fe(III) ions have involved in the coordination with hydroxyl groups of cellulose chains.

Photocatalytic activity for dye degradation

Three Fe-PCA-Cotton samples containing similar QFe values (about 0.38 mmol g−1) were prepared by optimizing their preparation processes and then evaluated as the heterogeneous Fenton photocatalysts for the degradation of RR 195 under solar irradiation. D% values of RR 195 during the reactions were measured and shown in Fig. 2a.

a Degradation efficiency of RR 195 in the presence of Fe-PCA-Cotton under different weather conditions (average intensities of solar irradiation are 0.32 mW cm−2 at 365 nm and 8.28 mW cm−2 at 400–1000 nm for cloudy day; or 4.97 mW cm−2 at 365 nm and 21.75 mW cm−2 at 400–1000 nm for sunny day): (a) H2O2/cloudy, (b) H2O2/sunny, (c) H2O2/Fe-BTCA-Cotton/cloudy, (d) H2O2/Fe-BTCA-Cotton/sunny, (e) H2O2/Fe-CA-Cotton/cloudy, (f) H2O2/Fe-TA-Cotton/cloudy, (g) H2O2/Fe-CA-Cotton/sunny, (h) H2O2/Fe-TA-Cotton/sunny, b effect of their QFe on D30% value during sunny day, c ESR spectra of free radicals generated in H2O2/Fe-PCA-Cotton system and d Changes in the D30% value during the reuse process of Fe-PCA-Cotton under sunny irradiation

Figure 2a shows that D% values in the presence of only H2O2 within 50 min during cloudy or sunny day were less than 5% (curves a–b), suggesting that little degradation of RR195 was found. When any of three Fe-PCA-Cotton was used, D% values increased with the prolonging of irradiation time (curves c-h), especially during sunny day. This indicated that Fe-PCA-Cotton is photochemically active under sunlight irradiation to catalyze the degradation of RR195. A main reason for this is that d–d transitions of the Fe(III) ions and the ligand-to-metal charge transfer (LMCT) transitions from PCA-Cotton toward Fe(III) ions in the complex often lead to the adsorption in the near UV and visible region (Cotton et al. 1995; Li et al. 2015). Furthermore, according to previous studies (Li et al. 2015; Zhu et al. 2008), the binding of Fe(III) ions with carboxyl groups of PCA-Cotton may significantly enhance the distortion of the resulting Fe-PCA-Cotton owing to the twist of cellulosic fiber chains, thus resulting in the creation of defects and unsaturated coordination. And then Fe-PCA-Cotton can react with H2O2 to generate OH radicals through a heterogeneous Fenton-like reaction to generate OH radicals with high oxidative ability, which is responsible for the degradation of RR195. More importantly, at a given irradiation time, D% values in the presence of three complexes were ranked as follow: Fe-TA-Cotton > Fe-CA-Cotton > Fe-BTCA-Cotton during cloudy and sunny days. It should be noticed from Fig. 2b that D% values within 30 min (D30%) for three complexes exhibited the same order at different QFe values. D30% values for Fe-CA-Cotton and Fe-BTCA-Cotton slightly declined over their critical QFe values (QFe-C). These results demonstrated that Fe-TA-Cotton and Fe-CA-Cotton have the much higher photocatalytic effect for dye degradation than Fe-BTCA-Cotton at the same conditions. And with increasing the number of carboxyl groups from 2 to 4 and the number of carbons in the backbone from 2 to 4 of the PCAs used, the sunlight driven photocatalytic activity of the resulting Fe-PCA-Cotton significantly decreased. It was report that the uncoordinated carboxyl groups of the complexes constructed from PCAs may capture OH radicals, limiting the catalysis (Song et al. 2017). It was clearly seen in Fig. 2c that the intensity of OH radicals produced presence of Fe-TA-Cotton or Fe-CA-Cotton was much higher than that presence of Fe-BTCA-Cotton. Also, as mentioned earlier, BTCA-Cotton and CA-Cotton have higher crosslink degree of than TA-Cotton owing to their better crosslink ability with cotton fibers, which reduced the coordination of Fe(III) ions with their carboxyl groups, thus the resulting Fe-BTCA-Cotton and Fe-CA-Cotton had more uncoordinated carboxyl groups as the scavengers for OH radicals than Fe-TA-Cotton. Besides, Our recent work (Liu et al. 2016) confirmed that increasing Fe(III) ion concentration caused a higher hydrophobic surface of the complexes after Fe(III) ion coordination. And Fe-BTCA-Cotton had a highest hydrophobic surface, thus which decreased the adsorption of H2O2 or dyes onto its surface, and limiting the dye degradation.

The recycling capacity of three complexes was evaluated and compared as a stable photocatalyst by the additional degradation process of fresh RR195 solution with the complex used from the previous runs. The used complex was thoroughly washed with distilled water after each run, and RR 195 and H2O2 were added before the next run. They were reused up to five times, respectively and the results given in Fig. 2d. D30% values for Fe-TA-Cotton and Fe-CA-Cotton in four successive runs in four successive runs were insignificantly lower than that in the first run, proposing that the catalytic activity of the two complexes had small deactivation in four successive runs. This was possibly because the excessive adsorption of dye molecules and their intermediates generated during the reaction may reduce their activity of the catalyst by the poisoning effect (Moulijn et al. 2001; Soon and Hameed 2011). It is known that in a heterogeneous Fenton reaction catalyzed by Fe(III)-carboxylic fibrous complex, the adsorption as well as coordination of H2O2 is a crucial step to generate OH radicals by Fe ions on the catalyst (Li et al. 2014). The most strongly adsorbing dyes or organic species may hinder the adsorption of less strongly adsorbing H2O2, thus reducing its decomposition on the fiber. Besides, metal ions leaching from the metallic complexes as the heterogeneous catalysts may cause secondary pollution to wastewater in the practical application. To evaluate the extent of Fe(III) ions leaching from three Fe-PCA-Cotton samples used, the final concentration of Fe(III) ion leached from 0.50 g of the complexes in the 100 mL test solution after 50 min for each run was measured by ICP-OES method to be 0.836 mgL−1 for Fe-TA-Cotton, 1.039 mgL−1 for Fe-CA-Cotton and 0.377 mgL−1 for Fe-BTCA-Cotton, which was proven to lead to little homogeneous photocatalytic degradation of RR 195(D% value within 50 min < 2.0%). These results confirmed that Fe-PCA-Cotton can be regarded as long-term stable heterogeneous photo-Fenton catalyst.

Antibacterial assessments

Antibacterial activities of three PCA-Cotton (about 0.85 mmol g−1) and their Fe complexes containing similar QFe values (about 0.38 mmol g−1) against E. coli and S. aureus as the model bacteria were investigated in this work. For comparison, a control experiment was conducted, in which original cotton fabric was used, and the results were given in Table 1 and Fig. 3.

Figure 3 shows that the numbers of bacteria colonies from three complexes were much less than that from original cotton fabric. As seen in Table 1, R% values for three PCA-Cotton samples against two bacteria did not reach 50%, which were much lower than those for their Fe complexes, correspondingly. These results indicated that after coordination with Fe(III) ions, the resulting Fe-PCA-Cotton exhibited higher antibacterial activity. It is well known that weak organic acids are popular preservative agents as they can sufficiently lower the internal pH level of microorganism cells for preventing their growth. Moreover, the organic acids can form ester bonding with the cellulose hydroxyls, which may make contact with the negatively charged protoplasm of the bacteria and then destroy their cell membrane, thus leading to their death (Bischof Vukušić et al. 2011; Soleimani-Gorgani and Karami 2016). Furthermore, the Fe(III)-complexes showed more activity than free ligand (Pansuriya and Patel 2008). A possible reason for increase in antibacterial activity after Fe ion coordination may mainly be from Tweedy’s chelation theory (Panchal et al. 2006). Generally, chelation can considerably reduce the polarity of the metal ion, owing mainly to the partial sharing of its positive charge with donor groups, which in turn favors the interaction between metal ion and the lipid as an important constituent of bacteria cell wall and membranes. This may lead to the breakdown of the permeability barrier of the cell, thus resulting in interference with normal cell processes (El-Habeeb 2014; Panchal et al. 2006). Besides, iron complexes are known for its DNA damaging property because of the binding of the complexes with base pair of DNA helix (Hemmert et al. 2001; Pedreño et al. 2005). Accordingly, a synergistic effect of the PCA ligand and the Fe ions acting together could take place, thus enhancing the antibacterial activity of the PCA-Cotton Fe complexes in this work. Also it was clear in Table 1 that Fe-TA-Cotton and Fe-CA-Cotton had greater antibacterial activity than Fe-BTCA-Cotton against S. aureus. While Fe-CA-Cotton was used, the highest antibacterial activity against E. coli was achieved. This could be mainly associated with differences between three PCAs with respect to dissociation, functionality, solubility, location and acidity. In particular, because TA and CA have lower acidity, both of them can have better antibacterial properties and can kill the bacteria. Additionally, Fe-BTCA-Cotton had a higher hydrophobic surface than the other complexes, which decreased the contact between Fe-BTCA-Cotton and bacteria, thus, inhibiting its antibacterial activity against two bacteria. On the other hand, the final concentrations of Fe iron leaching from three Fe-PCA-Cotton samples into bacterial medium were measured to be less than 1.0 mg L−1 after the antibacterial experiment. Moreover, the antibacterial activity of 1.0 mg L−1 of Fe(III) ions in bacterial medium was assessed against two bacteria, and the obtained R% values were only 2.86 and 6.32% for S. aureus and E. coli, correspondingly. This confirmed that high antibacterial activity of Fe-PCA-Cotton was attributed greatly to PCA-Cotton and its coordination with Fe(III) ions.

Mechanical properties

Effect of PCA structure and concentration

The modifying solutions were prepared by adding given concentration of NaH2PO2 and various molar concentrations (CPCA) of PCA into water, and pH values of which were then measured. Cotton fabrics were treated with the modifying solutions to obtain the PCA-Cotton samples, and their QCOOH, breaking strength and elongation at break in dry or wet state were then tested. The experimental results were shown in Table 2 and Fig. 4.

As shown in Table 2, increasing CPCA caused a gradual decrement in pH values of three modifying solutions. Moreover, pH values of three modifying solutions containing same CPCA ranked in this order: TA > CA > BTCA, which is determined by their ionization constants (Haynes 2014). While QCOOH values of PCA-Cotton exhibited a reversed trend, and at the given CPCA, BTCA-Cotton has a higher QCOOH value than TA-Cotton and CA-Cotton. A major reason for this was that aliphatic PCAs with more than two carboxyl groups have better crosslink ability than dicarboxylic acids, and BTCA has a higher crosslink degree than CA (Shen et al. 2015b). BTCA or CA first forms a cyclic anhydride by dehydration of the adjacent two carboxyl groups at high temperature, which then reacts with one or two hydroxyl groups of cotton fiber to form PCA-Cotton containing one or two carboxyl groups for causing the crosslink (Li et al. 2015). Whereas, dicarboxylic acids are unable to crosslink celluloses because their short backbone and restricted their range of crosslinking (Ji et al. 2016; Song et al. 2016). However, TA with 2 carbons in its backbone and 2 carboxyl groups is able directly to react with cellulose molecule to impart only one carboxyl group (Ji et al. 2016).

More importantly, Fig. 4a, b shows that the breaking strength of three PCA-Cotton samples almost linearly decreases with their QCOOH values increasing. This suggests that increased modification with PCAs can impart original cotton fabric strength loss. The major reasons include ester crosslinking between PCA molecule and cellulose chains and acidic degradation of cellulose macromolecules (Ji et al. 2016). It should be noticed that in the case of TA-Cotton, its strength loss was purely caused by acid damage to cellulose because TA is unable to crosslink cellulose chains mentioned above. Besides, the strength of all samples in wet state is higher than that of the ones in dry state, which could be explained by structural changes in cellulose by absorbed water. Two authors (Creely and Tripp 1971; Seitsonen and Mikkonen 1972) reported that higher relative humidity increased crystallinity of native cellulose. Another possible reason is that water molecules also have the effect of making possible a more uniform sharing of the load between the cellulose molecules in cotton fiber. Generally, the less molecular uniformity and the microcracks and microvoids on the surface of the fiber lead to a decrease of breaking strength (Han et al. 2010). Specially, TA-Cotton exhibited a lower strength than CA-Cotton or BTCA-Cotton, and increasing QCOOH value led to a big difference in strength between them, which are mainly due to lower pH values of TA modifying solution than the two PCAs modifying solution at the same conditions (Table 2). Also, TA molecules may diffuse into the deeper section of the cotton fibers because of smaller molecular sizes, and consequently destroy cellulose chains in deeper level (Ji et al. 2016).

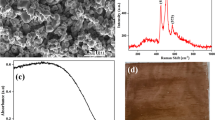

Additionally, Fig. 5a displays the XRD patterns of original cotton fiber before and after modification with three PCAs. The peaks centered at 22.81° of CA-Cotton and BTCA-Cotton exhibited a stronger intensity than original cotton fiber and CA-Cotton. This proposed that both of them had the higher crystallinity due to the significant crosslink degree (Parikh et al. 2007; Xu 2003), thus increasing their mechanical properties, especially for BTCA-Cotton. On the other hand, Fig. 4c, d shows that the elongation at break of thee samples insignificantly decreased as their QCOOH values increased. And their elongation at break in wet state was slightly higher than that in dry state at the same QCOOH values. Moreover, the elongation at break of three samples still showed a similar rank order as breaking strength as mentioned earlier. These results indicated that PCA structure and the QCOOH value of their modified cotton has a relatively small impact on their elongation at break.

Effect of Fe(III) ion initial concentration

Three PCA-Cotton with similar QCOOH values (about 0.52 mmol g−1) were selected to react with different initial concentration (CFe) of Fe(III) ions to fabricate a series of Fe-PCA-Cotton. Before the reaction, the pH values of the aqueous solutions containing different CFe were measured, and the QFe values of the obtained Fe-PCA-Cotton were also evaluated. The breaking strength and elongation at break of Fe-PCA-Cotton in both dry and wet states were then tested, and the results are shown in Table 3 and Fig. 6.

It was clear in Table 3 that higher CFe value reduced the pH level of Fe(III)ion solution. Besides, increasing CFe value caused a gradual increment in QFe value of three Fe-PCA-Cotton samples, and increasing tendency becomes level at high CFe of Fe(III) ion being used. Moreover, at a given CFe level, QFe values of three samples were ranked as follow: Fe-TA-Cotton > Fe-CA-Cotton > Fe-BTCA-Cotton, mainly owing to the big difference in the crosslink degree between modified cotton fabrics with different PCAs. More importantly, a significant reduction in the breaking strength of Fe-PCA-Cotton was observed from Fig. 6a, b with increasing their QFe values. Their minimum values of breaking strength and elongation at break were obtained at different critical QFe values (QFe-c: 0.43 mmol g−1 (dry) and 0.37 mmol g−1 (wet) for Fe-TA-Cotton, 0.46 mmol g−1 (dry) and 0.42 mmol g−1 (wet) for Fe-CA-Cotton and 0.47 mmol g−1 (dry) and 0.47 mmol g−1 (wet) for Fe-BTTA-Cotton). The breaking strength of the samples gradually increased above the minimum values. This was because when QFe was below critical value, Fe(III) ions were unevenly immobilized on Fe-PCA-Cotton, thus decreasing the breaking strength, as a result of the less uniformity of fiber molecular structure. In addition, the strong acidity of Fe(III) ion solution could give rise to a severe acidic degradation of cellulose macromolecules, and increasing Fe(III) ion concentration enhanced the acidic degradation due to the lower pH (Table 3). Also, it was found from Fig. 5b that the peaks at 22.81° of PCA-Cotton were reduced by subsequent coordination, correspondingly. This indicated that Fe(III) ion coordination decreased their crystallinity (Xu 2003), thus possibly enhancing the reduction in their strength. On the other hand, our previous study (Li et al. 2015) found that when the coordination of CA-Cotton with Fe(III) ion being used to prepare Fe-CA-Cotton, a Fe(III) ion on the surface of the fiber preferred to react with oxygen atoms in the carboxyl groups on adjacent cellulose chains in the amorphous regions of the cotton fibers to link the chains to each other, thus forming intermolecular coordination of Fe(III) ion with CA-Cotton chains. Therefore, when their QFe were above critical values, correspondingly, Fe(III) ions was effectively able to combine with different cellulose chains in the fibers and almost fully cover the fiber surface, thus balance off the decrease in their strength due to the uneven distribution of Fe(III) ions on the surface of the fiber and the acidic degradation.

Thermal behaviour

Thermo-gravimetric analysis

The thermal stability of the PCA modified cotton fabrics and their Fe complexes was examined by thermo-gravimetric analysis, and compared with that of untreated cotton fabric. Their TG and DTG curves were plotted in Fig. 7a, b, and the resulting data were collected in Table 4.

It was apparent from Fig. 7 and Table 4 that the thermal decomposition of cotton fiber in nitrogen proceeds by only one step, and during which a maximum weight loss was observed at 370.7 °C. Similar results have been confirmed by the previous works (Alongi et al. 2013; Bosco et al. 2013). According to these documents, cotton cellulose pyrolyzes in nitrogen may involve two alternative pathways: (1) the decomposition of the glycosyl units to char at lower temperature and (2) the depolymerization of such units to volatile species at higher temperature. It was noticed that the PCA modified cotton fabrics and their Fe complexes exhibited a similar weight loss behavior to original cotton fabric. The weight loss at low temperature (from 50 to 200 °C) was slight. However, Loss temperature of 5 wt% (T5wt%) of the PCA modified cotton fabrics, particularly their Fe complexes was lower than that of original cotton fabric, which may be attributed to their small moisture adsorption after the modification of PCA and Fe(III) ion coordination leading to an enhanced hydrophobic surface (Liu et al. 2018). From 240 to 400 °C, the weight loss was the most, which was due to the decomposition of cellulose chains. The maximum decomposition rate temperature (Tmax) of cotton fiber decreased from 370.7 to 358.3–359.7 °C after the modification of PCA. And Fe(III) ion coordination caused a further reduction in Tmax levels (340.0–355.5 °C). Over 600 °C, the decomposition nearly finished, and the thermally stable residue was remained. Thus it was concluded that the modification of PCA and Fe(III) ion coordination resulted in a slight reduction in the thermal behaviour of cotton fabric.

DSC characterization

DSC analysis of the sample was carried out to get further insights about the thermal stability of the samples. The DSC curves of original cotton fiber, the modified cotton fibers and their Fe complexes were presented in Fig. 7c, d. Seven samples especially original cotton fiber, TA-cotton and its complex showed an endothermic peak below 100 °C corresponding to the liberation of absorbed water molecules in the intercellular region of the cotton fiber. The major endothermic peak in the original cotton at 378.7 °C may be owing to the decomposition of cellulose leading to the formation of levoglucosan and other volatile products (Abkenar et al. 2013; Potter 2012). In the case of PCA-cotton, cotton decomposition peaks were shifted to the lower temperature of 369.8–371.5 °C and appeared as a broad peak, suggesting that the almost simultaneous decomposition of PCA grafted or crosslink chains and cellulose fiber. Moreover, the lower decomposition peaks of three complexes were found at a range of 339.5–363.2 °C and ascribed to some chemical or physical interactions taking place among the species produced through the degradation of cotton cellulose and modified PAC and Fe(III) ions. Accordingly, the DSC studies also confirm the insignificant decrease in the thermal stability of cotton fiber due to PCA modification and Fe(III) ions coordination.

Cost analysis and sustainable cycle evaluation

The cost of catalysts is a key parameter when applied in a large scale. In order to estimate the costs of these Fe-PCA-Cotton applied on an industrial scale, the similar fabrication conditions should be used. It is reasonable that the cost of Fe-PCA-Cotton mainly depends on the price of PCA and Fe2(SO4)3 as well as the cost of electric operation because waste cotton materials may be used in practical application. In recent years, rapid development and huge production capacity of cotton textile industries has lead to higher output of waste cotton fibers because different cotton wastes are generated from the initial stage of harvesting cotton crop to the final stage of finished textile product. BTCA shouldn’t be used since its price (about 26.8 USD/Kg) is much higher than that of TA (about 1.8 USD/Kg) or CA (about 0.75 USD/Kg). While the price of Fe2(SO4)3 is only about 0.22 USD/Kg. Additionally, Fe-TA-Cotton was not ideal when considering the cost, which would not be cost-effective in future application. Cotton fabric was economically modified with CA using an industrialized pad-dry-cure process widely applied in modern textile manufactory. On the other hand, Fe-PCA-Cotton as the catalysts has a better recycle performance, and the regeneration of the used catalyst using distilled water or its mixture with alcohol is also inexpensive. However, a sustainable economy-environment cycle for Fe-PCA-Cotton as the catalyst is crucial for their application on a large scale since improper disposal of depleted catalysts will cause secondary pollution to the environment. TG and DTG analysis mentioned above reveals that Fe-CA-Cotton was effectively decomposed to fly ash over 500 °C, suggesting that it is possible that the unavailable catalyst after reusing many time could be burned to generate electricity.

Conclusions

Three Fe-CA-Cotton samples were produced and showed the sunlight-driven photocatalytic and antibacterial activities. The two activities of three complexes varied with structure of PCAs used. Better catalytic and antibacterial activities were obtained when CA was used for the complex preparation. The complexes with excellent mechanical property and catalytic activity could be achieved through appropriately increasing their Fe contents over critical values. Besides, modification of PCA and Fe(III) ion coordination caused a slight reduction in the thermal behaviour of cotton fabric. Fe-CA-Cotton is regarded as a promising solar-driven heterogeneous Fenton photocatalyst that meets the “4-E” requirements for an industrial application in the future.

References

Abkenar SS, Malek RMA, Mazaheri F (2013) Thermal properties of cotton fabric modified with poly(propylene imine) dendrimers. Cellulose 20:3079–3091

Alongi J, Camino G, Malucelli G (2013) Heating rate effect on char yield from cotton, poly(ethylene terephthalate) and blend fabrics. Carbohydr Polym 92:1327–1334

Bischof Vukušić S, Flinčec Grgac S, Budimir A, Kalenić S (2011) Cotton textiles modified with citric acid as efficient antibacterial agent for prevention of nosocomial infections. Croat Med J 52:68–75

Bosco F, Carletto RA, Alongi J, Marmo L, Blasio AD, Malucelli G (2013) Thermal stability and flame resistance of cotton fabrics treated with whey proteins. Carbohydr Polym 94:372–377

Cotton FA, Wilkinson G, Gaus PL (1995) Basic inorganic chemistry. Wiley, London

Creely JJ, Tripp VW (1971) The effect of humidity on the crystallinity of cellulose. Text Res J 41:371–373

Dehabadi VA, Buschmann HJ, Gutmann JS (2013) Durable press finishing of cotton fabrics: An overview. Text Res J 83:1974–1995

Dong Y, Han Z, Liu C, Du F (2010) Preparation and photocatalytic performance of Fe(III)-amidoximated PAN fiber complex for oxidative degradation of azo dye under visible light irradiation. Sci Total Environ 408:2245–2253

Du M, Li C, Liu C, Fang S (2013) Design and construction of coordination polymers with mixed-ligand synthetic strategy. Coord Chem Rev 257:1282–1305

El-Habeeb AA (2014) Synthesis, spectroscopic, thermal, electrical conductivity and antimicrobial interpretations of new VO(II), Zn(II), Pd(II), Au(III) and Pt(IV) complexes with hypertensive atenolol drug. Orient J Chem 30:1441–1462

Feng Y, Liu Y, Xue L, Sun H, Guo Z, Zhang Y, Yang L (2017) Carboxylic acid functionalized sesame straw: a sustainable cost-effective bioadsorbent with superior dye adsorption capacity. Bioresour Technol 238:675–683

Han Z, Dong Y, Dong S (2010) Comparative study on the mechanical and thermal properties of two different modified PAN fibers and their Fe complexes. Mater Des 31:2784–2789

Haynes WM (2014) CRC handbook of chemistry and physics. CRC Press, Boca Raton, pp 5–93

Hemmert C, Pitié M, Renz M, Gornitzka H, Soulet S, Meunier B (2001) Preparation, characterization and crystal structures of manganese(II), iron(III) and copper(II) complexes of the bis[di-1,1-(2-pyridyl) ethyl] amine (BDPEA) ligand; evaluation of their DNA cleavage activities. J Biol Inorg Chem 6:14–22

Ji B, Zhao C, Yan K, Sun G (2016) Effects of acid diffusibility and affinity to cellulose on strength loss of polycarboxylic acid crosslinked fabrics. Carbohydr Polym 144:282–288

Lane SR, Sewell RDE, Jiang R (2006) Biological contamination parameters of cotton lint as biomarkers for fibre quality: a preliminary study. Fibers Polym 7:8–11

Li B, Dong Y, Li M, Ding Z (2014) Comparative study of different Fe(III)-carboxylic fiber complexes as novel heterogeneous Fenton catalysts for dye degradation. J Mater Sci 49:7639–7647

Li B, Dong Y, Li L (2015) Preparation and catalytic performance of Fe(III)-citric acid-modified cotton fiber complex as a novel cellulose fiber-supported heterogeneous photo-Fenton catalyst. Cellulose 22:1295–1309

Liu J, Wang B, Xu X, Chen J, Chen L, Yang Y (2016) Green finishing of cotton fabrics using a xylitol-extended citric acid cross-linking system on a pilot scale. ACS Sustain Chem Eng 4:1131–1138

Liu G, Dong Y, Wang P, Bian L (2018) Activation of Na2S2O8 for dye degradation by Fe complexes fixed on waste cotton modified with polycarboxylic acids. Carbohydr Polym 181:103–110

Mao Z, Yang CQ (2001) IR spectroscopy study of cyclic anhydride as intermediate for ester crosslinking of cotton cellulose by polycarboxylic acids. V. Comparison of 1,2,4-butanetricarboxylic acid and 1,2,3-propanetricarboxylic acid. J Appl Polym Sci 81:2142–2150

Montazer M, Pakdel E, Behzadnia A (2011) Novel feature of nano-titanium dioxide on textiles: antifelting and antibacterial wool. J Appl Polym Sci 121:3407–3413

Moroi G, Bılba D, Balba N (2001) Thermal behaviour of palladium complexing polyacrylamidoxime polymer. Polym Degrad Stab 72:525–535

Moulijn JA, Van Diepen AE, Kapteijn F (2001) Catalyst deactivation: is it predictable? What to do? Appl Catal A 212:3–16

Panchal PK, Parekh HM, Pansuriya PB, Patel MN (2006) Bactericidal activity of different oxovanadium(IV) complexes with Schiff bases and application of chelation theory. J Enzyme Inhib Med Chem 21:203–209

Pansuriya PB, Patel MN (2008) Iron(III) complexes: preparation, characterization, antibacterial activity and DNA-binding. J Enzyme Inhib Med Chem 23:230–239

Parikh DV, Thibodeaux DP, Condon B (2007) X-ray crystallinity of bleached and crosslinked cottons. Text Res J 77:612–616

Pedreño E, López-Contreras AJ, Cremades A, Peñafiel R (2005) Protecting or promoting effects of spermine on DNA strand breakage induced by iron or copper ions as a function of metal concentration. J Inorg Biochem 99:2074–2080

Potter C (2012) Thermal analysis of textile fibers. AATCC Rev 12:39–45

Qi H, Zhao C, Qing F, Yan K, Sun G (2016) Antiwrinkle finishing of cotton fabrics with 5-(Carbonyloxy succinic)-benzene-1,2,4-tricarboxylic acid: comparison with other acids. Ind Eng Chem Res 55:11850–11856

Seitsonen S, Mikkonen I (1972) X-ray study on the effect of moisture on the crystalline state of cellulose. J Polym Sci Part B Polym Phys 10:1743–1748

Shen L, Xu H, Yan Y (2015a) Quantitative correlation between cross-linking degrees and mechanical properties of protein films modified with polycarboxylic acids. Macromol Mater Eng 300:1133–1140

Shen L, Xu H, Kong L, Yang Y (2015b) Non-toxic crosslinking of starch using polycarboxylic acids: Kinetic study and quantitative correlation of mechanical properties and crosslinking degrees. J Polym Environ 23:588–594

Soleimani-Gorgani A, Karami Z (2016) The effect of biodegradable organic acids on the improvement of cotton ink-jet printing and antibacterial activity. Fibers Polym 17:512–520

Song K, Xu H, Xie K, Yang Y (2016) Effects of chemical structures of polycarboxylic acids on molecular and performance manipulation of hair keratin. RSC Adv 6:58594–58603

Song X, Wang C, Xu X, Jing H, Wang P, Gao S (2017) Syntheses and photocatalytic performances of four coordination complexes constructed from 1,10-phenanthroline and polycarboxylic acids. Transit Metal Chem 42:181–191

Soon A, Hameed BH (2011) Heterogeneous catalytic treatment of synthetic dyes in aqueous media using Fenton and photo-assisted Fenton process. Desalination 269:1–16

Sun Y, Lin L, Deng H, Li J (2008) Structural changes of bamboo cellulose in formic acid. BioResources 3(2):297–315

Wanassi B, Azzouz B, Wanassi MB (2016) Value-added waste cotton yarn: optimization of recycling process and spinning of reclaimed fibers. Ind Crops Prod 87:27–32

Wang Z, Wang X, Wei X, Wang J, Bai F, Xing Y, Sun L (2015) Triazine-polycarboxylic acid complexes: synthesis, structure and photocatalytic activity. New J Chem 39:4168–4177

Welch CM (1988) Tetracarboxylic acids as formaldehyde-free durable press finishing agents: part I: catalyst, additive, and durability studies. Text Res J 58:480–486

Welch CM (1992) Formaldehyde-free durable-press finishes. Color Technol 22:32–41

Xu W (2003) Effect of crosslinking treatment on the crystallinity, crystallite size, and strength of cotton fibers. Text Res J 73:433–436

Zhu J, Gao Q, Chen Z (2008) Preparation of mesoporous copper cerium bimetal oxides with high performance for catalytic oxidation of carbon monoxide. Appl Catal B 81:236–243

Acknowledgments

This research was supported by Innovation & Pioneering Talents Plan of Jiangsu Province (2015-340).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, P., Dong, Y. & Liu, G. Green and cost-effective carboxylic acid Fe complex functionalized cotton fabrics: sunlight-driven catalytic and antibacterial activities, mechanical and thermal properties. Cellulose 25, 3663–3678 (2018). https://doi.org/10.1007/s10570-018-1812-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-1812-5