Abstract

Three carboxylic fibers including alginate fiber, polyacrylic acid-grafted polypropylene (PP), and polytetrafluoroethylene (PTFE) fibers were coordinated with Fe(III) ions, respectively, to prepare the different Fe(III)-carboxylic fiber complexes. On the basis of investigating their coordination with Fe(III) ions, the coordination number, surface morphology, and light adsorption property of the formed Fe(III)-carboxylic fiber complexes were characterized and compared. And the catalytic performance of the three complexes was then evaluated as the heterogeneous Fenton catalysts in the degradation of a typical azo dye, Reactive Red 195 in water. The results indicated that alginate fiber could react with Fe(III) ions more easily than the grafted PP or PTFE fibers containing similar amount of carboxyl groups to form Fe(III)-carboxylic fiber complexes. Higher concentration of Fe(III) ions led to a proportional increase in Fe content of the obtained complexes. Fe(III)-alginate fiber complex has the more unsaturated configuration than Fe(III)-grafted PP or PTFE fiber complex due to the changes in its coordination number. Moreover, the light adsorption of the complexes was affected by nature of fiber used. The incorporation of hydrophobic synthetic fiber, especially grafted PTFE fiber reduced the visible light absorption of the obtained complexes. Three Fe(III)-carboxylic fiber complexes could catalyze the dye degradation in the dark or under light irradiation. Fe(III)-alginate fiber complex showed better catalytic activity and reuse stability than the other two complexes with similar Fe content.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

During the last two decades, there has been an increasing interest in Fenton and photo-assisted Fenton technologies for the degradation of organic pollutants in industrial wastewaters owing to their low cost and high performance in treating processes. Moreover, active heterogeneous Fenton catalysis is gradually replacing the homogeneous system with its drawbacks of pH limitation and catalyst regeneration in catalysis research. The heterogeneous Fenton catalysts have been developed with the intention of (a) withstanding the corrosion due to the oxidative radicals produced in solution and (b) fixing the Fe ions on a support in a stable way so as not to allow them to leach out during the reaction [1–3]. In the recent years, metal coordination has been used as an effective method to immobilize Fe ions on the materials such as zeolite [4, 5], clay [6–9], nafion membrane [1–3, 10], resin [11], alginate microcapsules [12–14], and modified fibers [15–19] for preparing heterogeneous Fenton catalysts. Apart from the granulated and membrane materials, the fibers have been considered as good supporting materials. Moreover, Fe(III)-fiber complexes represent a kind of promising heterogeneous catalysts with unique properties, such as lower cost, easy separation, large surface area, suitable chemical and mechanical stability as well as convenient utility. Several fibrous materials including the modified polyacrylonitrile (PAN) fibers [15–19], collagen fiber [20], and the grafted polytetrafluoroethylene (PTFE) fiber [21] have been used to produce the Fe(III)-fiber complexes for the dye degradation in the dark or under irradiation. Moreover, our recent research found that the modified PTFE fiber or alginate fiber Fe complex could be served as heterogeneous photo-Fenton catalyst for the dye degradation, and they showed the accepted catalytic performance over a wide pH range [22, 23]. However, these catalysts haven’t been widely used because of relatively lower catalytic capacity and regenerative property, or high manufacture and operating costs. In our previous works [15–19, 21–23], the single fiber was often used to react with Fe(III) ions for the synthesis of the heterogeneous Fenton catalyst, little research has concerned with the effect of nature or structure of fibrous materials on catalytic activity of their Fe complexes. Hence, in order to investigate the relationship between structure and property of carboxylic fibers and their complexes as heterogeneous catalysts for the Fenton reactions, three carboxyl group containing fibers including alginate fiber, poly acrylic acid-grafted polypropylene (PP), and PTFE fibers were used as the polymer ligands in the present study. This is because there are a lot of carboxyl groups in the surface of alginate fiber [24]. Meanwhile, it is well known that the graft polymerization of acrylic acids can introduce the carboxyl groups into the surface of the fibrous matrix without affecting any bulk properties. The three fibrous ligands were used, respectively, to prepare the different Fe(III)-carboxylic fiber complexes, and their coordination with Fe(III) ions was examined. The coordination structure, surface performance, and light adsorption property of the formed complexes were then characterized. Finally, the catalytic performance of their complexes was evaluated and compared as the heterogeneous Fenton catalysts in the degradation of a typical azo dye, Reactive Red 195 by changing the nature of the fibrous ligands used during the process.

Experimental section

Materials and reagents

Alginate fiber, PP fiber, and PTFE monofilament were commercially available. Three fibers were washed twice with acetone and then dried at 60 °C before use. Acrylic acid, Fe (NO3)3, H2O2 (30 % w/w), and benzophenone (BP) were of analytical grade and used as received. A commercial azo dye, Reactive Red 195 (abbr. RR 195) was used after purification by re-precipitation method, and its molecular structure was presented in our previous works [17].

Graft polymerization of PP fibers

According to the procedure of the Park [25], the grafting solution was prepared using 80/20 (v/v) % water/ethanol and contained the given amount of acrylic acid, BP, and H2SO4. PP fibers were immersed into the grafting solution and then exposed to UV irradiation (2 × 300 W, 365 nm) for 3–4 h at 40 °C. After the irradiation, the grafted PP fibers (denoted as PAA-g-PP) were washed with methanol for 6 h and dried at 50 °C to constant weight. Its grafting degree was calculated by the percentage increase in weight.

Graft polymerization of PTFE fibers

According to the previous work [26], 5.0 g of the dried PTFE fibers were immersed into 150 ml of monomer aqueous solution containing the given amount of acrylic acid and Mohr’s salt in a flask. After being sealed and bubbled with nitrogen, the mixture was subjected to 60Co irradiation at a dose rate of 5.0 kGyh−1 for a given time. The resulting grafted PTFE fibers (denoted as PAA-g-PTFE) were washed with hot water and acetone repeatedly. Afterward, it was dried in a vacuum oven at 50 °C for 24 h and then weighed. Its grafting degree was also determined using the same method described above.

Determination of carboxyl group surface content

0.50 g of the dried carboxylic fiber pieces (about 0.50 cm) were submerged in 50 ml of 100 mmolL−1 NaOH aqueous solution under a nitrogen atmosphere, and stirred for 2 h at room temperature. Afterward, the amount of the unneutralized NaOH in solution was determined by titration with standardized 100 mmolL−1HCl aqueous solution using an automatic titrator (Shanghai Jingmi Instrumental Co. China). Phenolphthalein was used as the indicator. The carboxyl group surface content of the carboxylic fiber (Q COOH, mmolg−1) was calculated as: Q COOH = (V 1 M 1−V 2 M 2)/M, where M 1 and M 2 are molar concentration of NaOH and HCl aqueous solution (molL−1), respectively. V 1 is the volume of NaOH solution (50 ml). V 2 is the volume of HCl solution consumed in titration (ml), and M is the mass of dry carboxylic fiber used (g).

Specific surface area and contact angle measurements

Specific surface areas of the carboxylic fibers were determined at 77 °C by N2 adsorption using Micromeritics ASAP2010 equipment. Prior to adsorption experiments, the samples were degassed to 10−5 Torr at 573 K for 4 h. The contact angle of a water droplet on the carboxylic fiber surface was also measured using a liquid–solid contact angle analyzer (DSA100; Krüss, Germany) equipped with a high speed camera. Approximately 0.60 μL of deionization water was transferred to each fiber, and the contact angle was calculated by tangent method 2.

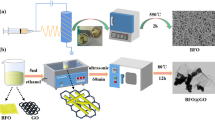

Coordination of carboxylic fibers with Fe(III) ions

5.0 g of carboxylic fiber was immersed in 150 ml of 0.10 molL−1 Fe(NO3)3 aqueous solution. The mixture was kept at 50 °C for 4 h under continuous agitation. The obtained Fe(III)-carboxylic fibrous complex (Fe-ALG for alginate fiber, Fe-PAA-g-PP for PAA-g-PP or Fe-PAA-g-PTFE for PAA-g-PTFE) was then taken out, washed with deionization water, and dried under vacuum at 60 °C for 3 h. The residual concentration of Fe(III) ions in the solution after coordination was determined using a Varian Vista-MPX inductively coupled plasma optical emission spectroscopy (ICP–OES), for calculating the Fe content (Q Fe ) of the complex.

Characterization of Fe(III)-carboxylic fibrous complexes

Determination of coordination number

A series of reaction systems were established by immersing various weight of carboxylic fiber into 100 ml coordination solution. These systems had different molar ratios of carboxyl group surface content of carboxylic fiber to the initial concentration of Fe(III) ions in coordination solution (denoted as Q COOH/[Fe3+]0). The coordination reactions in these systems were conducted at 50 °C until the reaction equilibrium was reached. The equilibrium concentrations of Fe(III) ions in solution (denoted as [Fe3+]e) were then measured using ICP–OES and plotted as a function of the corresponding Q COOH/[Fe3+]0. Finally, the coordination numbers for the resulting complexes were determined using the tangent method.

Light adsorption measurement

The light adsorption properties of three Fe(III)-carboxylic fibrous complexes were evaluated by measuring their diffuse reflectance UV–Vis spectra (DRS), which were recorded on a Varian Cary 500 UV–vis-NIR spectrometer (Varian Inc., USA) in the 200–800 nm range with BaSO4 as the reflectance standard.

Catalytic study

The catalytic activity of the Fe(III)-carboxylic fibrous complexes was evaluated in the dye degradation in the dark or under irradiation. All the photocatalytic experiments were carried out in a photoreaction system presented in our previous studies [17–19] at an initial pH of 6.0 and 25 °C. A 400 W high-pressure mercury lamp or UV 365 nm lamp was used as illuminating source for photocatalytic reaction. A cut-off filter was used to ensure irradiation only by visible light (λ > 420 nm) when the high-pressure mercury lamp being applied. The intensity of visible or UV irradiation over the test solution surface was measured to be 9.65 or 2.51 mWcm−2 using radiometer (BNU Light and Electronic Instrumental Co., China). 0.50 g of the complex was placed into 100 ml of test solution containing 0.05 mmolL−1 RR 195 and 6.0 mmolL−1 H2O2. At given irradiation time intervals, 1–2 ml of the test solution was taken and analyzed immediately on a UV-2401 Shimadzu spectrophotometer. The decoloration percentage of the dye was expressed as: D % = (1−C d/C d,0) × 100, where C d,0 and C d are the initial and residual concentration of the dye (mmolL−1), respectively. Moreover, The content of total organic carbon (TOC) was assayed in the dye degradation process using a Phoenix 8000 TOC analyzer (Tekmar-Dehrmann Inc., USA) and the TOC removal percentage of the dye was also calculated using the follow formula: TOC R % = (1−TOC t/TOC 0) × 100, where TOC 0 and TOC t are the TOC values (mgL−1) at reaction times 0 and t, respectively. ESR (Electron Spin Resonance) spectra of the radical spin trapped by DMPO (5,5-dimethyl pyridine N-oxide) were examined using a Bruker ESP 300E spectrometer equipped with an irradiation source of Quanta-Ray ND:YAG laser system (λ = 532 nm).

Results and discussion

Preparation of Fe(III)-carboxylic fibrous complexes

The Q COOH value of alginate fiber was firstly measured to be 2.23 mmolg−1 using titration method. PAA-g-PP and PAA-g-PTFE with similar Q COOH values were then obtained by controlling the acrylic acid initial concentration during the graft polymerization. Their Q COOH values, specific surface areas and water contact angles were given in Table 1. Each carboxylic fiber was coordinated with the varied initial concentration of Fe(III) ions ([Fe3+]0) to form Fe(III)-carboxylic fibrous complex. The Q Fe values of the complexes within 150 min were examined and shown in Fig. 1.

Figure 1 shows that Q Fe values of the Fe(III)-carboxylic fibrous complexes proportionally increased with [Fe3+]0 increasing. The reason is that the carboxyl groups on the carboxylic fibrous materials possess the effective coordination ability with multivalent metal ions [12, 25–28]. Since the oxygen of the carboxyl group has a pair of electrons, which can add themselves to a proton or a metal ion to form a complex [26]. The Fe(III) ion with empty orbitals function as a Lewis acid can accept electron pairs. In contrast, the carboxyl groups that have non-shared electron pairs function as Lewis bases donating their electrons pair in acid medium. On the other hand, at a given [Fe3+]0 level, Q Fe value of the resulting Fe-ALG is much higher than that of Fe-PAA-g-PP or Fe-PAA-g-PTFE. This is due mainly to a big difference in carboxyl group’s location on polymer molecular chains between two types of the carboxylic fibrous ligands described in Scheme 1.

PAA-g-PP and PAA-g-PTFE are the branched copolymers, in which grafted chains are composed of polyacrylic acids [25, 26]. Moreover, the carboxyl groups attached to grafted chains on the surface of the PP and PTFE fibers can react with Fe(III) ion by intermolecular and intramolecular coordination [29], and the proposed structure of the formed complexes is presented in Scheme 2.

While alginate fiber is a natural unbranched binary copolymer of b-(1-4)-linked-d-mannuronic acid (M) and a-l-guluronic acid (G) groups. Moreover, the carboxyl groups from alginate molecule prefer to react with metal ion by intermolecular coordination [25, 30]. However, the carboxyl groups of PAA-g-PP or PAA-g-PTFE are branched and more disordered compared to those of alginate fiber. Consequently, the space steric hindrance resulted by its branch chains can limit the coordination of Fe(III) ions with its carboxyl groups [31, 32].

Additionally, the surface properties of substrate fiber can effect the iron complex formation on the fiber. It is seen in Table 1 that the specific surface areas of three fibers are not larger than 0.30 m2g−1, This indicates that their surface areas are very low and nonporous. Besides, the contact angles of substrates are used to evaluate their hydrophilicity. As can also be seen in Table 1, the water contact angle of alginate fiber is much lower than that of PAA-g-PP or PAA-g-PTFE, which is similar to the results reported in the previous studies [30, 33, 34]. This reveals that alginate fiber is much hydrophilic than the grafted PP or PTFE fiber. Consequently, Fe(III) aqueous solution prefers to permeate and diffuse on alginate fiber surface during the reaction, thus enhancing the reaction between them.

Characterization of Fe(III)-carboxylic fibrous complexes

Coordination number

The coordination numbers of three Fe(III)-carboxylic fibrous complexes were determined through the variation curve of [Fe3+]e with Q COOH/[Fe3+]0 using tangent method, and the results are provided in Fig. 2.

Figure 2 shows that [Fe3+]e decreased remarkably with Q COOH/[Fe3+]0 increasing, and no further decline was found after Q COOH/[Fe3+]0 was above eight. This proposes that the coordination between fiber and Fe(III) ion achieved the equilibrium at the critical molar ratio. When the PAA-g-PP or PAA-g-PTFE reacting with Fe(III) ion, a corresponding Q COOH/[Fe3+]0 was obtained to be about 3 by the intersection between both the tangents. This demonstrated that one Fe(III) ion coordinated with three carboxyl groups of PAA-g-PP or PP-g-PTFE in the resulting complex. Hence, Fe(III) ion as a central cation that had the coordination number of 6 in Fe-PAA-g-PP or Fe-PP-g-PTFE. However, [Fe3+]e in the presence of alginate fiber is much lower than that in the presence of PAA-g-PP or PAA-g-PTFE. The coordination number of Fe(III) ion in Fe-ALG was measured to be 2, which is different from the coordination number (6) of Fe(III) ion in Fe alginate gel bead [12]. This is because alginate fibers are generally formed in the presence of Ca(II) ions as ionic bridges between l-guluronic acid residues on adjacent chain segments [35, 36]. These ionic bridges may block the combination of Fe(III) ion with carboxyl groups from l-guluronic acid residues.

Light adsorption properties

The DRS spectra of the Fe(III)-carboxylic fibrous complexes were measured and shown in Fig. 3.

Figure 3 shows that three complexes exhibited the strong absorption in the UV and visible region. The absorption band in the UV region is attributed to its transitions of π electrons to the π* excited state. While the absorption band in the visible region is owing to d–d transitions of the metal ions and the ligand-to-metal charge transfer (LMCT) transitions from fiber toward metal ion in the complexes [18]. It is a fact that LMCT transitions can cause strong absorption in the visible region, especially for the O-donor ligand complexes since one oxygen atom could provide two lone pair electrons [37, 38]. On the other hand, the d-orbital symmetry of the metal ions may be broken by the coordination effect of the ligands and their forbidden d–d transition is allowed [39], thus often leading to the weak adsorption in the visible region. Moreover, there is a band centered at 355 nm in the spectrum of Fe-ALG, which is broader and more intense than bands centered at 361 and 293 nm in the spectra of Fe-PAA-g-PP and Fe-PAA-g-PTFE, correspondingly. This suggests that a significant blue shift is found when two grafted synthetic fibers, especially PAA-g-PTFE were used. Furthermore, Fe-PAA-g-PTFE had a much reduced light absorption in the visible region, especially at higher position compared with Fe-ALG. The change in spectral features of three complexes indicates that the incorporation of hydrophobic fibrous ligands into the complexes leads to a less intensive and narrower absorption of light in the visible region. Hence, Fe-ALG is considered as a more effective photocatalyst than Fe-PAA-g-PP or Fe-PAA-g-PTFE under visible light irradiation, compared with the other complexes.

Catalytic activity of Fe(III)-carboxylic fibrous complexes

Nature of fibrous ligands

Three Fe(III)-carboxylic fibrous complexes with similar Q Fe values were prepared and compared as the heterogeneous Fenton photocatalysts for the degradation of RR 195 with H2O2, and the results were presented in Table 2.

It is found in Table 2 that little degradation of the dye was observed in the absence of the complex in the dark or under light irradiation. The insignificant D % and TOC R % values were obtained when any of the three complexes was used in the dark. Moreover, the addition of visible or UV irradiation significantly increased the dye decomposition and mineralization. This is consistent with our previous reports on the dye decomposition in the system of Fe(III)-modified PAN fiber complex and H2O2 [17, 18]. The main reason is that these complexes are activated in the UV and visible region mentioned above (Fig. 3). According to the D and TOC R % values at the same condition, three complexes were ranked in this order: Fe-ALG > Fe-PAA-g-PP > Fe-PAA-g-PTFE. This indicated that the catalytic activity was the lowest for Fe-PAA-g-PTFE; follow by Fe-PAA-g-PP, and the highest for Fe-ALG. This is ascribed to a big difference in the coordination structure and surface performance between these complexes. Firstly, the specific surface areas for three complexes were measured to be 0.151–0.30 m2g−1 (Their specific surface areas were provided in the Supplementary Material). Therefore, it is not believed that slight difference in specific surface area is the main reason for the higher catalytic ability of Fe-ALG. Secondly, Fe-ALG had a more unsaturated coordination structure than the other two complexes owing to its lower coordination number (see Fig. 2). Accordingly, Fe-ALG showed a higher catalytic activity than the other two complexes. Thirdly, it is well known that a good heterogeneous catalyst should have the ability to adsorb the reactant molecules strong enough for them to react. The adsorption amount of RR 195 on Fe-ALG was measured to be much higher than those for the other complexes at the same conditions (The adsorption amounts of RR 195 on three complexes were measured and presented in the Supplementary Material). This reveals that Fe-ALG could absorb much more dye molecules owing to its good hydrophilic property, which may enhance the dye heterogeneous degradation. Fourthly, the spin-tripping ESR technique was used to examine the active hydroxyl radicals involved in the dark and under visible irradiation (Fig. 4).

Figure 4 shows that the characteristic peaks of DMPO-·OH adducts clearly appeared for all the complexes, particularly under visible irradiation. These results confirmed that hydroxyl radicals (·OH) had been formed by the heterogeneous Fenton reaction in the presence of each complex in the dark or under visible irradiation. The similar results had been found in H2O2 decomposition with metal-loaded humic acid [40] or poly acrylic acid-Fe complexes [41] through the metal-driven Fenton reaction. The resulting ·OH radicals can destroy dye molecules into the colorless compounds. A possible reaction mechanism was illustrated in Scheme 3.

In the first step, H2O2 molecule coordinated to a Fe(III)-carboxylic fibrous complex (Fe3+fn) and formed an intermediate-mixed complex (Fe3+fn-1-H2O2). It was then activated to produce ·OH radicals by Fe ions and dissociates from the complex, which was regenerated to the original complex. Besides, RR 195 molecules adsorbed on the complexes may act as the sensitizer to cause a conversion of Fe(III) to Fe(II) ions due to its azo structure [17], The catalytic action of a Fe ion depends substantially on the nature of the ligands in the intermediate-mixed complex [41]. It is noticed that ESR signal intensities are ranked as follow: Fe-ALG > Fe-PAA-g-PP > Fe-PAA-g-PTFE, suggesting that more ·OH radicals were generated by H2O2 decomposition in the presence of Fe-ALG, which is responsible for the fast degradation of the dyes. The photo efficiency (ξ) of the dye degradation was also calculated using the method proposed in our previous work [19] within 90 min and listed in Table 3. Of these complexes, the ξ value with Fe-ALG was the highest under visible irradiation. While the ξ values showed the different trend under UV irradiation. This was mainly contributed to the difference in light adsorption property among these complexes. Moreover, the ξ value was higher under UV irradiation than under visible irradiation, implying that UV irradiation was preferably beneficial for the dye degradation in the presence of the complex. At the end of reaction, the final leached concentrations of Fe(III) ions in test solutions were measured to be lower than 1.0 mgl−1 for three complexes (The final leached concentration of Fe(III) ions for three complexes in test solution were presented in the Supplementary Material), which suggesting that three complexes can be regarded as effective and stable heterogeneous photocatalysts for dye degradation. This was attributed to a minimum threshold concentration of 3–15 mgl−1 of Fe ions, which allowed the homogeneous Fenton reaction to proceed within a reasonable period of time.

Effect of Fe content

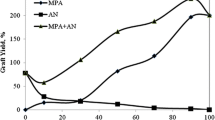

The Fe(III)-carboxylic fibrous complexes with different Q Fe values were used for catalyzing the degradation of RR 195 under visible irradiation, respectively. The D % levels within 60 min were shown in Fig. 5.

Figure 5 shows that the D % level became higher with Q Fe value increasing, which proposed that dye degradation was faster when the complexes with high Q Fe values were used as the catalysts. Furthermore, comparing three complexes with similar Q Fe values, the highest D % levels were found for Fe-ALG, suggesting that it still showed a much better catalytic ability than the other complexes at the similar condition.

Recycling capability

The recycling capability of three Fe(III)-carboxylic fibrous complexes with similar Q Fe values (approximately 2.20 mmolg−1) as the catalysts were evaluated by the additional degradation process of fresh RR 195 solution with the used complexes from the previous runs. The used complexes were thoroughly washed with a water–ethanol (1:1) mixed solution after each run, and RR 195 and H2O2 were added before the next run. Three complexes were reused up to five times. The dye degradation was carried out within 90 min for each reuse process, and the D % values were presented in Table 4.

Table 4 shows that little deactivation of Fe-ALG in four successive runs is observed when comparing with the first run. By contrast, Fe-AA-g-PP was reused five times, remained most of its catalytic activity. The catalytic activity of Fe-AA-g-PTFE significantly decreased after each cycle. This result confirms that Fe-ALG as a heterogeneous Fenton catalyst has better reuse capacity than the two synthetic fibrous Fe complexes.

Supplementary material

Experimental details on specific surface areas of three complexes, the adsorption amounts of RR 195 on them and the final leached concentration of Fe(III) ions for them in test solution were provided.

References

Fernandez J, Bandara J, Kiwi J, Lopez A, Albers P (1998) Efficient photo-assisted Fenton catalysis mediated by Fe ions on nafion membranes active in the abatement of non-biodegradable azo-dye. Chem Commun 14:1493–1494

Parra S, Guasaquillo I, Enea O, Mielczarski E, Mielczarki J, Albers P, Kiwi-Minsker L, Kiwi J (2003) Abatement of an azo dye on structured C-nafion/Fe-ion surfaces by photo-Fenton reactions leading to carboxylate intermediates with a remarkable biodegradability increase of the treated solution. J Phys Chem B 107:7026–7035

Parra S, Nadtotechenko V, Albers P, Kiwi J (2004) Discoloration of azo-dyes at biocompatible pH-values through an Fe-histidine complex immobilized on nafion via Fenton-like processes. J Phys Chem B 108:4439–4448

Russo AV, Toriggia LF, Jacobo SE (2014) Natural clinoptilolite–zeolite loaded with iron for aromatic hydrocarbons removal from aqueous solutions. J Mater Sci 49:614–620

Fan B, Li H, Fan W, Jin C, Li R (2008) Oxidation of cyclohexane over iron and copper salen complexes simultaneously encapsulated in zeolite Y. Appl Catal A 340:67–75

Yip AC-K, Lam FL-Y, Hu X (2007) Novel bimetallic catalyst for the photo-assisted degradation of acid black 1 over a broad range of pH. Chem Eng Sci 62:5150–5153

Destrée A, Long GJ, Vatovez B, Grandjean F, Fonseca A, Nagy JB, Fransolet A-M (2007) Synthesis and characterization of carbon nanotubes grown on montmorillonite clay catalysts. J Mater Sci 42:8671–8689

Wang Z, Ma W, Chen C, Zhao J (2009) Light-assisted decomposition of dyes over iron-bearing soil clays in the presence of H2O2. J Hazard Mater 168:1246–1252

Jia H, Zhao J, Fan X, Dilimulati K, Wang C (2012) Photodegradation of phenanthrene on cations-modified clays under visible light. Appl Catal B 123–124:43–51

Kiwi J, Denisov N, Gak Y, Ovanesyan N, Buffat P, Suvorova E, Gostev F, Titov A, Sarkisov O, Albers P, Nadtochenko V (2002) Catalytic Fe3+ clusters and complexes in nafion active in photo-Fenton processes: high-resolution electron microscopy and femtosecond studies. Langmuir 18:9054–9066

Ji H, Song W, Chen C, Yuan H, Ma W, Zhao J (2007) Anchored oxygen-donor coordination to iron for photodegradation of organic pollutants. Environ Sci Technol 41:5103–5107

Dong Y, Dong W, Cao Y, Han Z, Ding Z (2011) Preparation and catalytic activity of Fe alginate gel beads for oxidative degradation of azo dyes under visible light irradiation. Catal Today 175:346–355

Rosales E, Iglesias O, Pazos M, Sanromán M (2012) Decolourisation of dyes under electro-Fenton process using Fe alginate gel beads. J Hazard Mater 213:369–377

Iglesias O, Rosales E, Pazos M, Sanromán M (2013) Electro-Fenton decolourisation of dyes in an airlift continuous reactor using iron alginate beads. Environ Sci Pollut Res 20:2252–2261

Ishtchenko V, Huddersman K, Vitkovskaya R (2003) Production of a modified PAN fibrous catalyst and its optimisation towards the decomposition of hydrogen peroxide. Appl Catal A 242:123–137

Ishtchenko V, Vitkovskaya R, Huddersman K (2003) Investigation of the mechanical and physico-chemical properties of a modified PAN fibrous catalyst. Appl Catal A 242:221–231

Dong Y, Han Z, Liu C, Du F (2010) Preparation and photocatalytic performance of Fe(III)-amidoximated PAN fiber complex for oxidative degradation of azo dye under visible light irradiation. Sci Total Environ 408:2245–2253

Dong Y, Han Z, Dong S, Wu J, Ding Z (2011) Enhanced catalytic activity of Fe bimetallic modified PAN fiber complexes prepared with different assisted metal ions for degradation of organic dye. Catal Today 175:299–309

Han Z, Dong Y, Dong S (2011) Copper-iron bimetal modified PAN fiber complexes as novel heterogeneous Fenton catalysts for degradation of organic dye under visible light irradiation. J Hazard Mater 189:241–248

Liu X, Tang R, He Q, Liao X, Shi B (2007) Fe(III)-loaded collagen fiber as a heterogeneous catalyst for the photo-assisted decomposition of malachite Green. J Hazard Mater 174:687–693

Ding Z, Dong Y, Li B, Li M (2013) Preparation of grafted PTFE fiber metallic complexes and their photocatalytic degradation abilities. Acta Phys Chim Sin 29:157–166

Li B, Dong Y, Ding Z (2013) Photoassisted degradation of CI reactive red 195 using an Fe(III)-grafted polytetrafluoroethylene fibre complex as a novel heterogeneous Fenton catalyst over a wide pH range. Color Technol 129:403–411

Li B, Dong Y, Zou C, Xu Y (2014) Fe(III)-alginate fiber complex as a highly effective and stable heterogeneous Fenton photocatalyst for mineralization of organic dye. Ind Eng Chem Res 53:4199–4206

Kong Q, Wang B, Ji Q, Xia Y, Guo Z, Yu J (2009) Thermal degradation and flame retardancy of calcium alginate fibers. Chin J Polym Sci 27:807–812

Park H-J, Na C-K (2006) Preparation of anion exchanger by amination of acrylic acid grafted polypropylene nonwoven fiber and its ion-exchange property. J Colloid Interface Sci 301:46–54

Xiong C, Yao C (2009) Preparation and application of acrylic acid grafted polytetrafluoroethylene fiber as a weak acid cation exchanger for adsorption of Er(III). J Hazard Mater 170:1125–1132

Papageorgiou SK, Kouvelos EP, Favvas EP, Sapalidis AA, Romanos GE, Katsaros FK (2010) Metal–carboxylate interactions in metal–alginate complexes studied with FTIR spectroscopy. Carbohydr Res 345:469–473

Shu X, Zhu K (2002) The release behavior of brilliant blue from calcium–alginate gel beads coated by chitosan: the preparation method effect. Eur J Pharm Biopharm 53:193–201

El-Sawy NM, Ali Z (2007) Iron(III) complexed with radiation-grafted acrylic acid onto poly(tetrafluoroethylene-co-perfluorovinyl ether) films. J Appl Polym Sci 103:4065–4071

Cheng XS, Guan HM, Su YC (2000) Coordination structure of copper alginate film and its catalytic property for MMA polymerization. Acta Chim Sinica 58:407–413

Naja G, Mustin C, Berthelin J, Volesky B (2005) Lead biosorption study with Rhizopus arrhizus using a metal-based titration technique. J Colloid Interface Sci 292:537–543

Ray JR, Lee B, Baltrusaitis J, Jun Y-S (2012) Formation of iron (III)(Hydr) oxides on polyaspartate-and alginate-coated substrates: effects of coating hydrophilicity and functional group. Environ Sci Technol 46:13167–13175

Schönherr H, Hruska Z, Vancso GJ (1998) Surface characterization of oxyfluorinated isotactic polypropylene films: scanning force microscopy with chemically modified probes and contact angle measurements. Macromolecules 31:3679–3685

Park BH, Lee M-H, Kim SB, Jo YM (2011) Evaluation of the surface properties of PTFE foam coating filter media using XPS and contact angle measurements. Appl Surf Sci 257:3709–3716

Watthanaphanit A, Supaphol P, Tamura H, Tokura S, Rujiravanit R (2010) Wet-spun alginate/chitosan whiskers nanocomposite fibers: preparation, characterization and release characteristic of the whiskers. Carbohydr Polym 79:738–746

Watthanaphanit A, Supaphol P, Furuike T, Tokura S, Tamura H, Rujiravanit R (2008) Novel chitosan-spotted alginate fibers from wet-spinning of alginate solutions containing emulsified chitosan−citrate complex and their characterization. Biomacromolecules 10:320–327

Kunkely H, Vogler A (2005) Photoredox reaction of with PctsH 2=phthalocyaninetetrasulfonate induced by peroxide to Fe(III) charge transfer excitation. Inorg Chim Acta 358:4086–4088

Cotton FA, Wilkinson G, Gaus PL (1987) Basic inorganic chemistry, 2nd edn. John Wiley & Sons, New York

Li L, Jin J, Shi Z, Zhao L, Liu J, Xing Y, Niu S (2010) Cd (II)-M (II) hetero-nuclear coordination polymers: synthesis, structure and photo-electric properties (M=Fe Co, Cd). Inorg Chim Acta 363:748–754

Paciolla MD, Davies G, Jansen SA (1999) Generation of hydroxyl radicals from metal-loaded humic acids. Environ Sci Technol 33:1814–1818

Tsuchida E, Nishide H (1977) Polymer-metal complexes and their catalytic activity. Molecular Properties, Springer, Berlin Heidelberg

Acknowledgements

The authors thank the Tianjin Municipal Science and Technology Committee for a Research Program of Application Foundation and Advanced Technology (11JCZDJC24600). This research was also supported in part by a grant from the Natural Science Foundation of China (20773093).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, B., Dong, Y., Li, M. et al. Comparative study of different Fe(III)-carboxylic fiber complexes as novel heterogeneous Fenton catalysts for dye degradation. J Mater Sci 49, 7639–7647 (2014). https://doi.org/10.1007/s10853-014-8472-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8472-0