Abstract

Economic and efficient materials for the shielding of electromagnetic interference are required by many applications. Electrically conducting composite materials based on wood sawdust modified by polypyrrole (PPy) with different morphology, globular and nanotubular, were prepared through in-situ polymerization of pyrrole with the use of iron (III) chloride as an oxidant. The effect of PPy morphology and content in composite with sawdust on the DC conductivity and shielding effectiveness (SE) were investigated. Composites of sawdust with globular PPy demonstrated higher DC conductivity as compared to those with PPy nanotubes as long as PPy content was less or equal to 18 vol.%. Above this concentration the opposite trend was observed. The SE of composites was evaluated theoretically in the radio-frequency range, and measured by waveguide method in the frequency range 5.85–8.2 GHz. The SE increased with increase in DC conductivity, and good agreement between the theoretically calculated SE and experimental results was achieved. The SE of the composites extended over 20 dB level above 18 vol.% PPy at the thickness of the order of 10 μm. Polypyrrole nanotubes perfomed better than globular PPy at high conducting polymer content. The composites are good candidates for the application as shielding materials in the microwave band.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Conducting polymers, such as polyaniline (PANI), polypyrrole (PPy) and their substituted derivatives absorb electromagnetic radiation and therefore are widely considered in design of materials shielding the electromagnetic interference (Sapurina et al. 2005; Gashti et al. 2015; Xie et al. 2015a, b; Mohan et al. 2016; Zhao et al. 2016). The SE of a material is defined as the ratio between the incident power (P i) and transmitted power (P o) of an electromagnetic wave:

and it is expressed in decibels (dB). High conductivity and dielectric constant of materials contribute to high SE. In spite of moderate conductivity of PANI and PPy, i.e. units of S cm−1 for classical globular morphology and tens of S cm−1 for nanotubes (Kopecká et al. 2014; Bober et al. 2015), materials with sufficiently high SE have been prepared on their base. These include the coating of textile with PPy and PANI (SE = 20–35 dB in the frequency range Δf = 100 MHz–2.2 GHz) (Maity et al. 2013)), PANI thin film with high extent of crystallinity (SE = 68 dB, Δf = 4–12 GHz) (Mohan et al. 2016), and composites of PANI with sawdust (SE = 10 dB, Δf = 100 MHz–3 GHz) (Sapurina et al. 2005). The improvement of SE of such type of composites was also reported for PANI and PPy intercalated by silver nanoparticles and other metals (Gashti et al. 2015; Zhao et al. 2016).

The processing ability of PPy and PANI alone is poor and this also applies to mechanical properties. Therefore, it is suitable to deposit these polymers on a suitable support. It is well known that virtually any surface, which is immersed in the reaction mixture used for the preparation of conducting polymers, becomes coated with a thin layer of these polymers (Stejskal et al. 2003). The deposition is based on the physical adsorption of oligomers followed by the polymerization rather than on chemical grafting (Stejskal and Sapurina 2005). Such surface modification has been investigated especially for PANI. During the oxidative polymerization of aniline in the presence of any substrate in the reaction medium, two processes can be distinguishing: so-called “surface” and “bulk” growth of polymer chains (Sapurina and Stejskal 2008). The “surface” process takes place at the beginning of the reaction starting from the adsorption of insoluble oligomers at the surface of substrate and continues with PANI chains growth resulting in PANI film formation. Depending on the polymerization conditions, PANI film has thickness from tens up to hundreds nanometers. Moreover, it is established that nature of substrate can influence significantly the PANI film morphology as well as PANI coating can change the electrical and magnetic properties of substrate (Moucka et al. 2008; Babayan et al. 2012). The “bulk” process is polymerization of aniline in the continuous liquid phase resulting in formation of PANI precipitate. This happens when the amount of conducting polymer is too large to be accommodated at substrate surface. This is equally applicable also to PPy (Blinova et al. 2007; Sasso et al. 2011).

Conducting polymers have been used for protection of wood, e.g., by the biodeterioration by fungae (Treu et al. 2014). There is another benefit in the application of conducting polymers in the composites with wood, the flame retardancy (Stejskal et al. 2005; Stejskal et al. 2007; Trey et al. 2012). Conducting polymers convert at elevated temperature to nitrogen-containing carbons (Trchová et al. 2009). When deposited on wood or cellulose fibers, the carbonized polymer surface restricts the access of oxygen to the interior, which becomes carbonized but does not burn by flame (Stejskal et al. 2007). The reduced flammability may be a welcome value-added property in electrical applications.

The present study demonstrates that wood sawdust can be used as an economic support for the deposition of polypyrrole and subsequently applied for electromagnetic radiation shielding. It is shown that by proper choice of PPy morphology, controlled by synthesis conditions, and PPy concentration in composite, the materials with SE above 30 dB and thickness not exceeding 1 mm can be obtained. The results suggest that both types of sawdust–PPy composites can be successfully utilized as shielding materials in the certain microwave band.

Experimental

Materials

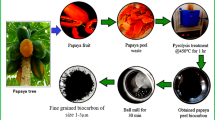

Sawdust was prepared with a 25 cm diameter circular saw operating at 1400 rpm from dry ash-tree wood (Fraxinus excelsior L.) and a sieve with 250 μm mesh size was used to remove larger particles. Globular PPy was prepared in the presence of sawdust by the oxidation 0.05 M pyrrole with 0.05 M iron(III) chloride in aqueous medium at room temperature (Bober et al. 2015). The reaction mixture for the synthesis of PPy nanotubes contained in addition 0.0025 M methyl orange. 1 L of the reaction medium generates under these conditions ≈2 g of PPy. Freshly prepared solution of pyrrole with methyl orange was poured over weighed portion of sawdust, the solution iron(III) chloride oxidant was added, and the mixture was stirred with a magnetic bar for 1 h. The composites containing various fractions of PPy were prepared by balancing the volume of reaction mixture and mass of sawdust. Solids were separated next day by filtration, rinsed with 0.2 M hydrochloric acid, followed by acetone, and left to dry in air at ambient temperature for several days.

Characterization

The morphologies of prepared materials were characterized with the scanning electron microscopy (SEM) using a JEOL 6400 microscope. The DC conductivity was measured by a four-point van der Pauw method, using a Keithley 6517A as a current meter and a Multimeter Keithley 2410 as a source and voltmeter. In order to measure the conductivity, PPy-coated sawdust particles were compressed into pellets at 200 MPa.

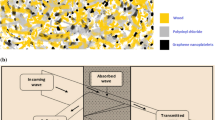

The SE of PPy−sawdust composites was measured in the frequency range of 5.85–8.2 GHz using Agilent N5230A vector network analyzer (VNA). An electromagnetic wave was injected directly into the composite using a waveguide set-up which is illustrated in Fig. 1.

To measure the scattering parameters (S ab, where a is the network analyzer port number that is receiving the scattered energy, and b is the network analyzer port number that is transmitting the incident energy) a full two-port VNA calibration was performed at the beginning of each test sequence. The values of measured scattering parameters are negative, and their absolute values are denoted as the attenuation on reflection (|S11|) and transmission (|S21|) of the radiation. In present study, the value of SE is equivalent to the attenuation on transmission (|S21|) of the radiation.

To calculate theoretical SE of PPy–sawdust composites in a broad frequency range (106–1010 Hz), the far-field shielding theory was applied and SE as a function of composite DC conductivity (σ), thickness (d) and frequency (f) was calculated by using the following equation (Colaneri and Shacklette 1992; Lee et al. 1999):

where

is the angular frequency, and

is the skin depth, i.e. the depth of material to which the radiation will penetrate within the material with a decrease in intensity to 1/e of its original strength, µ 0 is vacuum permeability and µ r is relative permeability of the composites. Since PPy-sawdust composites are nonmagnetic materials, µ r = 1.

Results and discussion

Sample preparation

PPy is typically prepared by the oxidation of pyrrole with ammonium peroxydisulfate (Blinova et al. 2007) or more frequently with iron(III) chloride (Xie et al. 2015b) (Fig. 2) in aqueous medium and obtained as powder with characteristic globular morphology (Fig. 3a). When the reaction mixture contains methyl orange dye, PPy nanotubes are obtained instead (Kopecká et al. 2014; Sapurina et al. 2017) (Fig. 3b).

DC conductivity

Electrical properties of composites are usually discussed on the bases of volume fractions of conducting component. Weight fractions were therefore converted to volume fractions by using densities of wood, 0.7 g cm−3, and PPy, 1.4 g cm−3, estimated from the mass and dimensions of compressed pellets used for the conductivity measurements. When a solid substrate, wood sawdust in this study, is present in the reaction mixture, it becomes coated with the PPy. The coating sawdust need not be complete when the amount of produced polymer is low, estimated to be less than 5 vol.% in the composite, or it can be accompanied by free PPy, when its content in the composite exceeds ca. 11 vol.%. We can only speculate that even when the coating is patchy, PPy can still produce a connective network between particles of wood after the composite is compressed to pellets. For that reason, no percolation threshold was observed even at the lowest 1 vol.% PPy content (Fig. 4). The composite can therefore be regarded as a conducting PPy matrix filled with non-conducting sawdust particles, i.e. different morphology than in the composite produced by simple mixing of PPy powder with sawdust. Similar dependence was also reported for the composites of PANI and sawdust (Sapurina et al. 2003).

It should be noted that up to the 18 vol.% content of PPy the composites with globular morphology of the polymer are characterized by higher conductivity than those with PPy nanotubes. However, at higher concentration of the conducting phase (above 18 vol.%) the conductivity of composites with PPy nanotubes is higher as compared to those with globular morphology.

Shielding effectiveness

The theoretical SE values of PPy−sawdust composites were calculated using Eq. 2 which implies a good conductor approximation, i.e. σ/ωε 0 ≫ 1, where ε 0 is the permittivity of free space. To satisfy this condition, the conductivity data of composites with PPy content corresponding to 4 vol.% and higher were used for SE calculation. Even if conductivity of composite was as low as 0.2 S cm−1 (4 vol.% of PPy nanotubes), then at frequency of 10 GHz, σ/ωε 0 was still equal to several tens of units.

Figure 5 depicts SE plots for two sets of composites with volume content of polypyrrole being in the first case below 18 vol.% and in the second case above this level. The measurement and calculation of SE was carried out on the samples with the thickness of 0.5 mm. Taking into account the scattering of the experimental data that is determined by re-reflections inside measurement setup, the theoretically calculated SE gives a reasonable fit to experimental results.

It is obvious that the composite with 5 vol.% of globular PPy demonstrates higher SE than its analogue with PPy nanotubes, whereas at 33 vol.% of PPy content, this is vice versa. Thus, the SE is determined by DC conductivity (Fig. 4).

Figure 6 demonstrates 3D plots of theoretical SE of the same composites calculated for the extended range of the frequency and composite thickness. The latter parameter was varied from x mm to 1 mm, where x corresponds to thickness of the respective composite assuring at least 10 dB of SE level (= 90% SE). The composites with globular PPy were more efficient (Fig. 6a) than with nanotubes (Fig. 6b), but even the sample with the lowest conductivity (σ = 0.4 S cm−1, 5 vol.% of PPy nanotubes in composite) is characterized by 20 dB SE level (= 99% SE) in the frequency range from 1 MHz to 10 GHz when its thickness approaches to 1 mm (Fig. 6b). The SE of this sample demonstrates virtually frequency independent behavior, whereas SE of the samples with higher concentration of PPy have both frequency-independent as well as frequency-dependent parts (Fig. 6c, d). It was demonstrated (Colaneri and Shacklette 1992), that for frequencies much lower than crossover frequency, i.e. the frequency at which the thickness of the composite equals the skin depth (“electrically thin” shield), Eq. 2 becomes independent of frequency and for the frequencies far above crossover frequency (“electrically thick” shield), the SE increases monotonically with frequency. The crossover frequency calculated for the sample with 5 vol.% PPy nanotubes content using Eq. 4 is rather high and equals to 6.3 GHz even at the largest considered thickness of 1 mm (Table 1). That is the reason of the frequency independent behavior of this sample. The crossover frequencies of the rest of the samples (Table 1) are much lower thus the frequency dependent part of SE is well pronounced there.

Based on conductivity data, the minimum theoretical thickness of PPy−sawdust composites was calculated which would assure 20 dB SE level in the frequency range of 106–1010 Hz (Fig. 7). Starting from 18 vol.% of PPy, the thickness of about tens of micrometers is sufficient to obtain highly efficient shielding materials.

It should be noted that PPy is substantially more effective in the electromagnetic radiation screening than PANI. The composite of PANI (33 wt%)–sawdust required at least 100 mm thickness for only 10 dB SE at GHz frequency range (Sapurina et al. 2005).

Conclusions

Based on the results of present study, the following conclusions can be drawn:

-

(1)

Electrically conducting composites of wood sawdust and PPy with different morphology, globular and nanotubular, were prepared. Composites with globular PPy have higher DC conductivity than those with PPy nanotubes when the polymer content was below 18 vol.%. Above this concentration the opposite trend is observed.

-

(2)

The shielding effectiveness of composites was evaluated theoretically by using of far-field shielding theory and measured by waveguide method in the frequency range from 5.85 to 8.2 GHz. Good agreement between experiment and theory was achieved.

-

(3)

The shielding effectiveness reached 20 dB above 18 vol.% PPy in the composite at the thickness tens of micrometers, and PPy nanotubes were more efficient at high PPy contents.

-

(4)

The SE of PPy was considerably better than that of PANI in similar composites with wood sawdust reported in the literature (Sapurina et al. 2005).

-

(5)

Considering all the advantages, i.e. high SE, small thickness, and low production cost, such composite materials could be of practical interest for the shielding of electromagnetic radiation in microwave band.

References

Babayan V, Kazantseva NE, Sapurina I, Moučka R, Vilčáková J, Stejskal J (2012) Magnetoactive feature of in-situ polymerised polyaniline film developed on the surface of manganese-zinc ferrite. Appl Surf Sci 258:7707–7716. doi:10.1016/j.apsusc.2012.04.126

Blinova NV, Stejskal J, Trchová M, Prokeš J, Omastová M (2007) Polyaniline and polypyrrole: a comparative study of the preparation. Eur Polym J 43:2331–2341. doi:10.1016/j.eurpolymj.2007.03.045

Bober P, Stejskal J, Šeděnková I, Trchová M, Martinková L, Marek J (2015) The deposition of globular polypyrrole and polypyrrole nanotubes on cotton textile. Appl Surf Sci 356:737–741. doi:10.1016/j.apsusc.2015.08.105

Colaneri NF, Shacklette LW (1992) EMI shielding measurements of conductive polymer blends. IEEE Trans Instrum Meas 41:291–297. doi:10.1109/19.137363

Gashti MP, Ghehi ST, Arekhloo SV, Mirsmaeeli A, Kiumarsi A (2015) Electromagnetic shielding response of UV-induced polypyrrole/silver coated wool. Fiber Polym 16:585–592. doi:10.1007/s12221-015-0585-9

Kopecká J, Kopecký D, Vrňata M, Fitl P, Stejskal J, Trchová M, Bober P, Morávková Z, Prokeš J, Sapurina I (2014) Polypyrrole nanotubes: mechanism of formation. RSC Adv 4:1551–1558. doi:10.1039/c3ra45841e

Lee CY, Song HG, Jang KS, Oh EJ, Epstein AJ, Joo J (1999) Electromagnetic interference shielding efficiency of polyaniline mixtures and multilayer films. Synth Met 102:1346–1349. doi:10.1016/S0379-6779(98)00234-3

Maity S, Singha K, Debnath P, Singha M (2013) Textiles in electromagnetic radiation protection. J Saf Eng 2:11–19. doi:10.5923/j.safety.20130202.01

Mohan RR, Varma SJ, Sankaran J (2016) Impressive electromagnetic shielding effects exhibited by highly ordered, micrometer thick polyaniline films. Appl Phys Lett 108:154101. doi:10.1063/1.4945791

Moučka R, Vilčáková J, Kazantseva NE, Lopatin AV, Sáha P (2008) The influence of interfaces on the dielectric properties of MnZn-based hybrid polymer composites. J Appl Phys 104:103718. doi:10.1063/1.3028272

Sapurina I, Stejskal J (2008) The mechanism of the oxidative polymerization of aniline and the formation of supramolecular polyaniline structures. Polym Int 57:1295–1325. doi:10.1002/pi.2476

Sapurina IY, Frolov VI, Shabsel’s BM, Stejskal J (2003) A conducting composite of polyaniline and wood. Russ J Appl Chem 76:835–839. doi:10.1023/A:1026050428908

Sapurina I, Kazantseva NE, Ryvkina NG, Prokeš J, Sáha P, Stejskal J (2005) Electromagnetic radiation shielding by composites of conducting polymers and wood. J Appl Polym Sci 95:807–814. doi:10.1002/app.21240

Sapurina I, Li Y, Alekseeva E, Bober P, Trchová M, Morávková Z, Stejskal J (2017) Polypyrrole nanotubes: the tuning of morphology and conductivity. Polymer 113:247–258. doi:10.1016/j.polymer.2017.02.064

Sasso C, Beneventi D, Zeno E, Chaussy D, Petit-Conil M, Belgacem N (2011) Polypyrrole and polypyrrole/wood-derived materials conducting composites: a review. BioResources 6:3585–3620

Stejskal J, Sapurina I (2005) Polyaniline: thin films and colloidal dispersions (IUPAC technical report). Pure Appl Chem 77:815–826. doi:10.1351/pac200577050815

Stejskal J, Trchová M, Fedorova S, Sapurina I, Zemek J (2003) Surface polymerization of aniline on silica gel. Langmuir 19:3013–3018. doi:10.1021/la026672f

Stejskal J, Trchová M, Sapurina I (2005) Flame-retardant effect of polyaniline coating deposited on cellulose fibers. J Appl Polym Sci 98:2347–2354. doi:10.1002/app.22144

Stejskal J, Trchová M, Brodinová J, Sapurina I (2007) Flame retardancy afforded by polyaniline deposited on wood. J Appl Polym Sci 103:24–30. doi:10.1002/app.23873

Trchová M, Konyushenko EN, Stejskal J, Kovářová J, Ćirić-Marjanović G (2009) The conversion of polyaniline nanotubes to nitrogen-containing carbon nanotubes and their comparison with multi-walled carbon nanotubes. Polym Degrad Stabil 94:929–938. doi:10.1016/j.polymdegradstab.2009.03.001

Treu A, Bardage S, Johansson M, Trey S (2014) Fungal durability of polyaniline modified wood and the impact of a low pulsed electric field. Int Biodeter Biodegr 87:26–33. doi:10.1016/j.ibiod.2013.11.001

Trey S, Jafarzadeh S, Johansson M (2012) In situ polymerization of polyaniline in wood veneers. ACS Appl Mater Interf 4:1760–1769. doi:10.1021/am300010s

Xie A, Jiang WC, Wu F, Dai XQ, Sun MX, Wang Y, Wang MY (2015a) Interfacial synthesis of polypyrrole microparticles for effective dissipation of electromagnetic waves. J Appl Phys. doi:10.1063/1.4936549

Xie AM, Wu F, Sun MX, Dai XQ, Xu ZH, Qiu YY, Wang Y, Wang MY (2015b) Self-assembled ultralight three-dimensional polypyrrole aerogel for effective electromagnetic absorption. Appl Phys Lett 106:222902. doi:10.1063/1.4921180

Zhao H, Hou L, Lu YX (2016) Electromagnetic interference shielding of layered linen fabric/polypyrrole/nickel (LF/PPy/Ni) composites. Mater Des 95:97–106. doi:10.1016/j.matdes.2016.01.088

Acknowledgments

The support of the Ministry of Education, Youth and Sports of the Czech Republic (NPU I, LO1504) and the Czech Science Foundation (16-02787S) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Babayan, V., Kazantseva, N.E., Moučka, R. et al. Electromagnetic shielding of polypyrrole–sawdust composites: polypyrrole globules and nanotubes. Cellulose 24, 3445–3451 (2017). https://doi.org/10.1007/s10570-017-1357-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1357-z