Abstract

In this paper, the influence of SO2 on the performances of selective catalytic oxidation (SCO) of NH3 on Cr-Ce mixed oxide catalysts had been disclosed. Experimental results revealed that the existence of SO2 could greatly suppress the unselective catalytic oxidation of ammonia over Cr-Ce mixed oxide catalysts with strong redox capacity, though the ammonia conversion rate was somewhat lowered after SO2 introduction. As such, near or above 90% ammonia conversion and excellent N2 selectivity within 350–450 °C could be achieved on Cr10Ce sample after 20 h reaction running in the presence of 350 ppm SO2. Characterization results indicated that SO2 could induce the formation of surface sulfates on Cr10Ce catalysts and enhance its surface acidity, which would inhibit the over-oxidation of NH3. More importantly, the bulk-like sulfation of Cr10Ce samples was damped in the presence of SO2 compared to pure CeO2, which allowed certain active oxygens participating in NH3-SCO reaction. DFT results also confirmed that the adsorbed SO2 would preferentially interact with the oxygens around the interface of CeO2 and Cr2O3, thereby preventing the retained active oxygens from being further sulfation. Therefore, the Cr-Ce mixed oxide catalysts showed promising application potential for eliminating NH3 slip downstream NH3-SCR process.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

As the “haze promoter”, ammonia (NH3) has been included as a controlled indicator of air pollutants, which caused tremendous concerns on ecological environment and human health [1,2,3,4,5]. Apart from industrial production procedure, stock farming and agricultural fertilization, one of the primary sources of ammonia emissions is the ammonia slip during the industrial flue gas denitrification process when ammonia is used as reductant [6,7,8,9]. Owing to fluctuation of gaseous distribution and operational condition, over stoichiometric ratio of NH3 had been injected to ensure the deNOx efficiency during selective catalytic reduction (SCR) or selective non-catalytic reduction (SNCR) process, resulting in the emission of unreacted NH3 so-called ammonia slip [10, 11]. The NH3 slip would lead to the plug in the downstream air-preheater and form secondary inorganic aerosols [11].

Nowadays, the NH3-SCO (selective catalytic oxidation of NH3) catalyst installed at the tail-end of SCR units could be one promising way to solve the NH3 slip problem [2]. Commonly, the NH3-SCO reactions follow the internal SCR mechanism (i-SCR), which can be described as follows: the absorbed ammonia on catalysts is partly oxidized to NOx and the resulted NOx then reacts with NH3 to produce N2 and H2O [12, 13]. Generally, an excellent NH3-SCO catalyst should possess suitable redox ability, which could not only meet the requirement of deeply dehydrogenation of NH3 but also suppress the over-oxidation to avoid the formation of byproducts, including N2O, NO and NO2.

The most studied NH3-SCO catalysts included noble-metal based catalysts and transition metal-based catalysts [12, 13]. Although possessing excellent low-temperature NH3-SCO activity, noble-metal based catalysts with narrow temperature window could be hardly affordable in slip-NH3 control application [12, 14]. As for transition metal-based catalysts, Cu-based catalysts had attracted lots of researchers’ attention owing to the relatively well activity and N2 selectivity [12, 15]. However, the coexistence of gaseous SO2 in the flue gas is inevitable, which would exert serious deactivation effect on NH3-SCO activity due to the strong interaction between Cu active phase and SO2 [10, 16, 17].

In the previous literatures, chromic (Cr) based catalysts with excellent redox ability and exceptional resistance to sulfur and chlorine species, owing to its low interaction with HCl/SO2 [18, 19], had been widely reported in NH3-SCR [19,20,21], NO oxidation [22] and VOCs catalytic combustion [18, 23, 24], etc. Additionally, due to good oxygen storage capacity, CeO2 has been often applied as promoter or main active phase in NH3-SCR/SCO reactions [25,26,27,28]. Moreover, based on our previous works [29, 30], CeO2 could serve as the sacrificial sites to promote the SCR performance of Cu or Mn based catalysts in the presence of SO2. As such, the Cr-Ce mixed oxide catalysts might be one promising candidate to achieve well NH3-SCO performances, where the well redox capacity of Cr-Ce catalyst could effectively activate NH3 and sulfation would also provide acidic sites to inhibit the over-oxidation of NH3. However, what happens to the NH3-SCO performance of Cr-Ce mixed oxide catalysts in the presence of SO2 needs to be further investigated.

Therefore, in this manuscript, to deal with the challenges of NH3 slip elimination, the Cr-Ce mixed oxide catalysts prepared by impregnation method were employed to investigate their activities and stabilities in the presence of SO2 and H2O during NH3-SCO reaction process. Additionally, various characterizations and density functional theory (DFT) simulations were then conducted to reveal the inherent mechanism for NH3-SCO reaction behaviors over Cr-Ce mixed oxide catalysts.

2 Experimental Section

Firstly, pure Cr2O3 and CeO2 catalysts were prepared by the direct calcination of nitrate precursors. Then, various Cr-Ce mixed oxide catalysts were synthesized by impregnating Cr(NO3)3·9H2O on previous obtained CeO2 support. And the obtained Cr-Ce mixed oxide catalysts were denoted as CrxCe, where x represented Cr/Ce molar ratio (x = 1–20%). Moreover, the selected Cr10Ce catalyst after stability tests in the presence of 350 ppm SO2 at 350 °C were denoted as Cr10Ce-Uy, where y represented the duration of stability tests period (y = 10, 20 and 30 h). To investigate the intrinsic mechanism of SO2 influence on NH3-SCO performances, the samples before and after stability tests were subjected to various characterizations to disclose. And more detailed experimental illustration and computational method were given in the Supporting Information.

3 Results and Discussion

3.1 Catalytic Performances

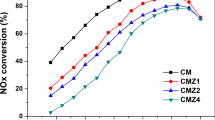

The NH3-SCO performances of various fresh CrxCe mixed oxide catalysts were depicted in Fig. 1. As shown in Fig. 1a, fresh CeO2 sample hardly converted ammonia efficiently within the investigated temperature window, while 100% NH3 conversion in the temperature range of 250–450 °C was achieved on pure Cr2O3. Unsurprisingly, NH3 oxidation activity of CrxCe catalysts lied between that of pure Cr2O3 and CeO2 samples. And the addition of Cr significantly promoted NH3 conversion of CeO2, where the NH3 conversion changed little when Cr/Ce ratio exceeded 10%. The well dispersion of Cr species owing to the interaction between Cr species and CeO2 could account for it. However, high amount of N2O and NOx species generated on CrxCe catalysts at low-medium and medium–high temperature range respectively, which resulted in rather poor N2 selectivity on all Cr-related samples (see Figs. 1b and S1). It could be due to the fact that CrxCe samples with strong redox ability but lack of surface acidity promoted the unselective oxidation of ammonia [13]. Moreover, Cr10Ce sample with approximative NH3 conversion and relative higher N2 selectivity compered to pure Cr2O3 was further applied in the investigation of the effect of SO2.

NH3 conversion (a) and N2 selectivity (b) of various samples; NH3 conversion and outlet SO2 concentration during SO2 resistance stability tests of Cr10Ce sample at 350 °C (c); NH3-SCO performance of Cr10Ce sample after 20 h SO2 poisoning reaction running under different temperature (d). NH3-SCO reaction conditions: [NH3] = 100 ppm, [O2] = [H2O] = 5 vol.%, [SO2] = 350 ppm (if applicable), N2 balance

As shown in Fig. 1c, in the presence of 350 ppm SO2 at 350 °C, Cr10Ce sample achieved complete NH3 conversion during the initial 5 h, but gradually decreased to about 88% NH3 conversion for the next 8 h and then maintained at this value for the later reaction time. In comparison, the introduction of SO2 would quickly decrease NH3 conversion of pure Cr2O3 from 100% to around 50%. The evolution in NH3 oxidation activity was in good accordance with that of outlet SO2 concentration detected, where it increased gradually to finally reached its inlet value in the final stage of tests. This observation indicated that the deposition of sulfur could somewhat lower the NH3 oxidation activity, as sulfation of metal oxides by SO2 would generally deteriorate their redox capacity [31, 32]. However, such poisoning effect was lessened greatly on Cr10Ce sample compared to pure Cr2O3, which deserved to be further investigation regarding the intrinsic mechanism. In addition, the NH3-SCO performances of Cr10Ce sample after 20 h SO2 poisoning under different temperature had also been investigated (see Fig. 1d). It could be seen that Cr10Ce sample possessed near or above 90% NH3 conversion and 100% N2 selectivity in the temperature range of 350–450 °C. Therefore, Cr-Ce mixed oxides could be suitable candidate of NH3 slip elimination catalysts downstream SCR units. It was noted that the existence of SO2 slightly decreased NH3 conversion of Cr10Ce sample but significantly promoted N2 selectivity at temperatures higher than 350 °C. For instance, N2 selectivity of Cr10Ce sample at 350 °C increased from less than 50% to 100%. Therefore, the existence of SO2 could greatly suppress the unselective catalytic oxidation of ammonia over Cr-Ce mixed oxide catalysts. And the promoted N2 selectivity in the SO2 stability tests might be attributed to the enhanced surface acidity but weakened redox ability with surface sulfation, where similar findings had been mentioned in previous works [31, 33]. To reveal the related mechanism regarding the effect of SO2 on NH3-SCO performances, various corresponding characterizations were conducted in the following sections.

3.2 The Physical Property Changes

To identify the physical property changes of Cr-Ce mixed oxide catalysts caused by SO2, the specific surface area, XRD and TEM/SEM characterizations had been conducted. As illustrated in Tables 1 and S1, a SBET of 69 m2/g was obtained on fresh CeO2 sample, and that decreased at an elevated molar ratio of Cr/Ce for fresh CrxCe samples. The introduction of certain Cr species into micro-channels of CeO2 during preparation process could be responsible for that [25]. Furthermore, after stability tests in the presence of SO2, the surface area of Cr10Ce sample would be deteriorated over time (from 57 m2/g of fresh Cr10Ce to 41 m2/g of Cr10Ce-U30), owing to the blockage effect derived from the formed sulfate species [31, 32]. Additionally, as shown in Figs. 2 and S2a, XRD patterns of various samples showed that various diffraction peaks located at 28.6°, 33.1°, 47.5°, 56.3°, 59.1°, 69.4°, 76.7°, 79.1° and 88.4° emerged, which could be assigned to CeO2 with cubic fluorite structure [PDF#43–1002]. However, characteristic diffraction peaks related to Cr species were hardly detected for Cr10Ce sample, indicating the high dispersion of Cr species [21, 34]. Furthermore, the intensity of characteristic diffraction peaks of Cr10Ce-Uy samples gradually decreased compared to fresh Cr10Ce sample, demonstrating that the crystal structure of CeO2 was damaged by SO2 poisoning. And similar findings could be observed for CeO2-U20 and Cr2O3-U20 samples (see Fig. S2b), however, it was found that better crystallinity of Cr2O3 reserved after SO2 resistance stability tests than CeO2. It might be implied that SO2 would preferentially interact on surface Ce sites to form cerium sulfate species compared to Cr species during stability tests, which had been similarly reported in the previous work [17].

In addition, the morphology and microstructure of fresh Cr10Ce and selected Cr10Ce-U20 samples were studied by TEM and SEM. As shown in Figs. 3 and S3, no obvious lattice stripes of Cr related crystals were found in Cr10Ce sample, suggesting the well dispersion of Cr species on CeO2 support, which was consistent with XRD patterns. Furthermore, slightly blurred edges of crystals were observed on Cr10Ce-U20 sample, indicating that the sulfation of catalysts occurred after SO2 introduction in NH3-SCO reaction [35]. As illustrated in Table S2, elements distribution analyzed by SEM EDS-Mapping indicated that there deposited certain amount of sulfur (S) species on Cr10Ce-U20 sample, while the content of surface O, Ce, Cr and nitrogen (N) species did not show evident changes compared to fresh Cr10Ce sample. The above phenomena indicated that the metal oxides sulfation but not ammonium sulfates accumulation is the main cause of sulfur deposition on Cr10Ce-U20 catalyst [31].

3.3 The Redox Ability and Surface Acidity Changes

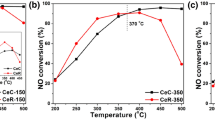

To investigate the changes in the redox ability of different samples before and after stability tests in the presence of SO2, H2-TPR and O2-TPD experiments were conducted and the results were presented in Fig. 4. As seen the H2-TPR results in Fig. 4a, the pristine CeO2 sample showed two reduction peaks of surface-active oxygen species related to ceria at 406 °C and 523 °C, respectively. After Cr addition, the reduction peaks shifted to a lower temperature range (349 °C and 445 °C), indicating the promoted reducibility derived from Cr species. Based on the previous works [19, 34], the two peaks could be ascribed to the reduction of Cr6+ to Cr3+ and active surface oxygen derived from Cr–O-Ce strong interactions, respectively. However, after reaction with SO2 poisoning, the reduction peaks of various samples shifted to higher temperature range (592 °C for CeO2-U20, 450 and 556 °C for Cr10Ce-U20), indicating the suppressed reducibility of catalysts caused by sulfation. As reported in the literatures [36, 37], the much stronger H2 consumption peaks emerged at above 550 °C on the two samples were subjected to the reduction of formed sulfate species. And the relatively lower reduction temperature of sulfate species observed on Cr10Ce-U20 sample compared to CeO2-U20 sample suggested that Cr addition would decrease the stability of sulfate species on CeO2. Notably, compared with CeO2-U20 sample, one small peak for the reduction of Cr-Ce species at 450 °C still could be found on Cr10Ce-U20 sample. It could be concluded that sulfation could not completely eliminate the active oxygens in Cr10Ce sample and the reserved active oxygens were still capable to participate in the NH3 oxidation reaction. And the O2-TPD results shown in Fig. 4b further confirmed this conclusion.

From Fig. 4b, one small oxygen desorption peak at 510 °C could be seen on fresh CeO2 sample, where Cr10Ce catalyst showed two stronger oxygen desorption peaks at 560 and 660 °C. As mentioned [31, 37], the much larger oxygen desorption peak of Cr10Ce sample indicated that the formed strong Cr-Ce interactions could bring about abundant active oxygen species (Oβ), inducing better activation ability of reactants during NH3-SCO reaction process. After reaction with SO2, CeO2-U20 sample showed one oxygen desorption peak at about 714 °C, while three oxygen desorption peaks located at 540, 630 and 730 °C emerged on Cr10Ce-U20 sample. Excluding these dramatically increased oxygen desorption peaks above 700 °C caused by thermal decomposition of sulfate species [31, 37], Cr10Ce-U20 sample could maintain more active oxygen species to participate in SCO reaction after SO2 introduction, which was in accordance with the H2-TPR results.

Figure 4c showed the NH3-TPD profiles of various samples. From the previous works [38, 39], the desorption peaks of NH3 could be divided into three sections within 50–250 °C, 250–400 °C and 400–500 °C, corresponding to NH3 desorbed from weak, moderate and strong acidic sites, respectively. It could be found that SO2 poisoning significantly enlarged the amount of the moderate/strong acidic sites of catalysts. It was reasonable that the sulfate species formed were of strong electronic attractive effect, which improved the surface acidity [36]. It was widely recognized that strong acidity could inhibit the over oxidation of ammonia in SCR reaction [40]. Therefore, the enhanced surface acidity after SO2 poisoning was account for the improved N2 selectivity of Cr10Ce sample for NH3-SCO reaction in the presence of SO2 (see Fig. 1).

3.4 The Influence of SO2 on Surface Chemical States

To further reveal the influences of SO2 on the existence states of surface elements in the catalyst, various Cr10Ce samples before and after stability tests in the presence of SO2 were subjected to XPS characterization (see Fig. 5). The surface atomic concentration distribution and detailed peak calculation results were given in Table 2. As shown, the characteristic peaks of Cr 2p XPS spectra could be deconvoluted into three categories, including Cr6+ (~ 578.7 eV for Cr 2p3/2 and ~ 588.4 eV for Cr 2p1/2), Cr3+ (~ 576.8 eV for Cr 2p3/2 and ~ 586.4 eV for Cr 2p1/2) and Cr2+ (~ 575.8 eV for Cr 2p3/2 and ~ 585.8 eV for Cr 2p1/2) [21, 41], while the Ce 3d XPS spectra were divided into two categories (u for Ce4+ and v for Ce3+) [33, 42, 43]. Compared with fresh Cr10Ce sample, positive shifts in the binding energy of Cr 2p and Ce 3d XPS peaks could be observed after SO2 poisoning. The strong electronic interaction of sulfate groups could be ascribed to the main reason for that [44]. However, the shift in Cr 2p and Ce 3d XPS peaks showed respective variations in different durations of SO2 poisoning reaction. It was evident that the displacement of Cr 2p XPS peaks occurred solely within the initial 10 h of SO2 poisoning reaction, whereas the deviation in Ce 3d XPS peaks mainly occurred in the Cr10Ce-U20 sample. It was suggested that the impact of SO2 poisoning on Cr species diminished over time, while it progressively affected Ce species.

Furthermore, focusing on the changes in the subpeaks of Cr and Ce species on various Cr10Ce-Uy samples, it could be seen that the proportion of Cr6+/Crtotal changed little except the increase during the initial 10-h reaction time, while Ce3+/Cetotal ratio continued to increase. The above results indicated that the presence of SO2 would significantly affect the existence states of Ce, whereas the impact on Cr was somewhat mitigated, which agreed with the results related to locations of XPS peaks. The increase of Ce3+/Cetotal resulted from the reduction effect caused by SO2 and the initial increase of Cr6+/Crtotal might be due to the electronic interaction with sulfate species [31]. From Fig. 5c, the O 1 s spectra of the catalysts were fitted into three sub-peaks: lattice oxygen (Oα, 528.6–530.0 eV), surface chemisorbed oxygen species (Oβ, 531.4–532.0 eV) and oxygen containing surface groups (Oγ, 532.6–533.5 eV) like carbonate and/or hydroxyl species [29, 43]. As listed in Table 2, SO2 poisoning reaction would promote the formation of surface chemisorbed oxygen species derived from surface formed sulfate species [29]. Notably, the Oβ/Ototal in Cr10Ce-Uy samples trended to be stable when the reaction time increased beyond 20 h, indicating that the sulfation became lessened, corresponding to its stable NH3-SCO activity. Additionally, the above findings of weakened sulfation process were further confirmed by various N 1s and S 2p XPS spectra (see Fig. S4 and Table 2), as the obvious increased S and N species only occurred within the initial 10 h of SO2 poisoning reaction. Furthermore, the surface atomic concentration of S was about 2.5 times higher than that of N on various CrxCe-Uy samples. It was implied that sulfate species existed as metal sulfate species rather than ammonium sulfates on the samples after stability tests.

3.5 Reaction Process Analysis

To identify the reaction process of NH3-SCO, TPSR studies had been also carried out on Cr10Ce sample before and after 20 h SO2 poisoning. As shown in Fig. 6, it could be seen that the ammonia could be converted on fresh Cr10Ce sample at relative low temperature (about 250 °C), where less N2 emission and higher amount of NO emerged compared to Ce10Ce-U20 sample. It was implied that the activation of NH3 could occur on Cr10Ce sample easily but mainly follow the unselective catalytic oxidation process. After 20 h reaction running in the presence of SO2, owing to the suppressed redox ability and enhanced surface acidity, the ammonia conversion onset temperature of Ce10Ce-U20 sample shifted to higher temperature range (about 300 °C), where the signals of released byproducts, including N2O, NO and NO2, obviously decreased, indicating the achievement of well N2 selectivity. The above results were in accordance with the previous obtained redox ability, surface acidity and activity test results.

3.6 SO2 Influential Mechanism Analysis

Based on the SEM EDS-mapping results above, it was indicated that less ammonium sulfates accumulated on catalysts after SO2 poisoning reaction running. Therefore, TP, FT-IR and TG analysis were further conducted to identify it. As shown in Fig. S5, no signals of NO, H2O and N2 species derived from NH4HSO4 decomposition and only SO2 emission due to sulfate species dissociation could be detected on the Cr10Ce-U20 sample. Then, FT-IR experiments in Fig. S6 indicated that almost no characterization peaks ascribed to NH4+ existed on Cr10Ce-U20 sample [38]. Finally, from TG analysis in Fig. S7, Cr10Ce-U20 sample did not show obvious weight loss at around 300 °C, where the temperature was related to the decomposition of NH4HSO4 [30, 45]. As such, it could be concluded that sulfur deposition on Cr10Ce-U20 sample was mainly sulfate species associated with metal cations.

Aiming to investigate the existences of sulfate species on Cr10Ce sample, SO2-TPD and SO2 + O2 DRIFT experiments were conducted (see Fig. 7). From SO2-TPD results in Fig. 7a, it could be observed that only one SO2 desorption peak emerged on Cr2O3, Cr10Ce and CeO2 samples, which located at 651, 721 and 735 °C, respectively. Obviously, the desorption peak area of sulfate species on various samples decreased as follows: Cr2O3 < < Cr10Ce < CeO2, indicating that Cr addition diminished the formation of sulfate species and its stability on CeO2. Although it was found that the sulfation of pure Cr2O3 was least severe among three samples, it lost about half of its activity by SO2 poisoning at 350 °C. As such, the sulfur aversion feature of Cr species could not explain the high NH3-SCO activity of Cr10Ce sample during the reaction in the presence of SO2, whose inherent reason need to be further clarified. In addition, DRIFT studies had been performed to further elucidate the states of adsorbed sulfate species. As shown in Fig. 7b, after exposure to 500 ppm SO2 + 5 vol% O2 at 350 °C for 1 h, various peaks located at 1624 (1618), 1520, 1402 ~ 1382, 1314 ~ 1273, 1170, 1032 and 956 cm−1 emerged, which could be ascribed to H2O (1624 ~ 1618 cm−1), pyrosulfate species (1520 cm−1), surface sulfate species (1402 ~ 1382 cm−1) and bulk-like sulfate species (1314 ~ 1273, 1170, 1032 and 956 cm−1), respectively [31, 32]. Although surface and bulk-like sulfate species were detected on various samples, the Cr10Ce sample exhibited a majority formation of surface sulfate species, whereas CeO2 sample predominantly generated bulk-like sulfate species. Based on previous literatures [37, 46], the bulk-like sulfate species usually possessed more harmful effect on the activity compared to surface sulfate species, which would greatly inhibit the redox cycle of Cr-Ce species. These results indicated that Cr addition significantly suppressed the deep sulfation of bulk phase in Cr10Ce sample, which should be the main reason of its well activity against SO2 poisoning. Moreover, little sulfate species formed on Cr10Ce-U20 sample was indicative of the saturation point being reached in the adsorption of SO2, which was related to its stable activity.

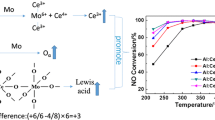

DFT studies were then performed to explore the intrinsic reason of such phenomena (see Fig. 8 and Table 3). The adsorption energies of SO2 molecule at atop Ce and O sites on the CeO2 surface were − 0.28 and − 1.40 eV, while that at atop Ce, O1 (Ce-O-Ce), O2 (Cr-O-Ce) and Cr sites on the Cr-doped CeO2 surface were − 0.83, − 1.93, − 1.66 and − 1.69 eV, respectively. It was confirmed that the SO2 preferred to bond with the O atoms of Ce-O-Ce model around Cr atoms compared to pure Ce-O-Ce model. It could explain that the sulfation of Ceria was more serious and prolonged compared with that of Cr species. As such, during the NH3-SCO reaction, the adsorbed SO2 would preferentially interact with the oxygens around the interface of CeO2 and Cr2O3. Different with the final deactivation of CuCeOx after SO2 introduction reported in the literature [17], CrOx possessed stronger aversion to SO2 than Cu species, combined with the spatial protection effect of the formed sulfate species on the interface of CeO2 and Cr2O3 [47], further SO2 poisoning on Cr2O3 could be greatly inhibited. Therefore, remained clean Cr species and active oxygens could still participate in the NH3-SCO reaction, which had been verified by H2-TPR and O2-TPD results in Fig. 4. This should be the main reason of superior SCO performances achieved on Cr10Ce mixed oxide catalyst in the presence of SO2.

4 Conclusion

In summary, the influence of SO2 on NH3-SCO performance of Cr-Ce mixed oxide catalysts had been disclosed. The existence of SO2 in flue gases would somewhat inhibit the NH3 oxidation ability due to the formation of surface sulfation but still could guarantee the fulfilled NH3-SCO reaction at high temperatures. In addition, the N2 selectivity was greatly improved due to the enhanced acidity. For instance, near or above 90% ammonia conversion with excellent N2 selectivity in the temperature range of 350–450 °C could be achieved on Cr10Ce sample after 20 h reaction running in the presence of 350 ppm SO2, while pure Cr2O3 quickly lost half of its activity. SO2 would preferentially attack the oxygens around the interface of CeO2 and Cr2O3 in Ce-Cr mixed oxides, the formed surface sulfate species created a protection structure for preventing the further sulfation of the metal oxides. As such, certain amount of active oxygens and clean Cr species were remained to fulfill the NH3-SCO reaction. Therefore, robust NH3-SCO performances in the presence of SO2 could be achieved on Cr10Ce sample, which showed promising application potential for eliminating NH3 slip downstream NH3-SCR process.

References

Liu Y, Liu Z, Wang C, Xu J, Ai J, Liu X, Zhang A, Zhao Y, Du C, Shan B (2023) Unraveling the lattice O assisted internal selective catalytic reduction mechanism on high N2 selectivity of CuOx/PtCu catalysts in NH3-SCO. ACS Catal 13:7178–7188

Wang H, Murayama T, Lin M, Sakaguchi N, Haruta M, Miura H, Shishido T (2022) Understanding the distinct effects of Ag nanoparticles and highly dispersed Ag species on N2 selectivity in NH3-SCO reaction. ACS Catal 12:6108–6118

Amblard M, Burch R, Southward BWL (2000) An investigation of the selective oxidation of NH3 to N2 in gasified biomass in the presence of excess CO and H2 using zeolite catalysts. Catal Lett 68:105–108

Fung WK, Claeys M, van Steen E (2012) Effective utilization of the catalytically active phase: NH3 oxidation over unsupported and supported Co3O4. Catal Lett 142:445–451

Ono Y, Wakita H, Inui T (1998) Relationship between oxidation states of copper supported on alumina and activities for catalytic combustion of NH3. Catal Lett 53:83–89

Wang H, Lin M, Murayama T, Feng S, Haruta M, Miura H, Shishido T (2021) Ag size/structure-dependent effect on low-temperature selective catalytic oxidation of NH3 over Ag/MnO2. ACS Catal 11:8576–8584

Liao Y, Liu Z, Li Z, Gao G, Ji L, Xu H, Huang W, Qu Z, Yan N (2022) The unique CO activation effects for boosting NH3 selective catalytic oxidation over CuOx-CeO2. Environ Sci Technol 56:10402–10411

Sun D, Liu Q, Liu Z, Gui G, Huang Z (2009) An in situ DRIFTS study on SCR of NO with NH3 Over V2O5/AC surface. Catal Lett 132:122–126

Xiao X, Xiong S, Li B, Geng Y, Yang S (2016) Role of WO3 in NO reduction with NH3 over V2O5-WO3/TiO2: a new insight from the kinetic study. Catal Lett 146:2242–2251

Yu Y, Wei D, Tong Z, Wang J, Chen J, He C (2022) Rationally engineered ReOx-CuSO4/TiO2 catalyst with superior NH3-SCO efficiency and remarkably boosted SO2 tolerance: synergy of acid sites and surface adsorbed oxygen. Chem Eng J 442:136356

Zhang Y, Zhang M, Zang Y, Wang H, Liu C, Wei L, Wang Y, He L, Wang W, Zhang Z, Han R, Ji N, Song C, Lu X, Ma D, Sun Y, Liu Q (2023) Elimination of NH3 by interfacial charge transfer over the Ag/CeSnOx tandem catalyst. ACS Catal 13:1449–1461

Gao F, Liu Y, Sani Z, Tang X, Yi H, Zhao S, Yu Q, Zhou Y (2021) Advances in selective catalytic oxidation of ammonia (NH3-SCO) to dinitrogen in excess oxygen: a review on typical catalysts, catalytic performances and reaction mechanisms. J Environ Chem Eng 9:104575

Li Z, Wang C, Qiu J, Ma Y, Wang C, Sun X, Li K, Ning P, Wang F (2023) Advances in selective catalytic oxidation of ammonia (NH3-SCO): a review of catalyst structure-activity relationship and design principles. Chin Chem Lett 108432

Lan T, Zhao Y, Deng J, Zhang J, Shi L, Zhang D (2020) Selective catalytic oxidation of NH3 over noble metal-based catalysts: state of the art and future prospects. Catal Sci Technol 10:5792–5810

Jabłońska M (2020) Progress on selective catalytic ammonia oxidation (NH3-SCO) over cu-containing zeolite-based catalysts. ChemCatChem 12:4490–4500

Chen C, Cao Y, Liu S, Jia W (2020) The effect of SO2 on NH3-SCO and SCR properties over Cu/SCR catalyst. Appl Surf Sci 507:145153

Li Z, Chen J, Jiang M, Li L, Zhang J, Duan W, Wen J, Wang H, Liu M, Zhang Q, Chen J, Ning P (2022) Study on SO2 poisoning mechanism of CO catalytic oxidation reaction on copper-cerium catalyst. Catal Lett 152:2729–2737

Su J, Yao W, Liu Y, Wu Z (2017) The impact of CrOx loading on reaction behaviors of dichloromethane (DCM) catalytic combustion over Cr-O/HZSM-5 catalysts. Appl Surf Sci 396:1026–1033

Guo M, Liu Q, Zhao P, Han J, Li X, Ha Y, Fu Z, Song C, Ji N, Liu C, Ma D, Li Z (2019) Promotional effect of SO2 on Cr2O3 catalysts for the marine NH3-SCR reaction. Chem Eng J 361:830–838

Liu H, Wei L, Yue R, Chen Y (2010) CrOx-CeO2 binary oxide as a superior catalyst for NO reduction with NH3 at low temperature in presence of CO. Catal Commun 11:829–833

Guo M, Liu Q, Liu C, Wang X, Bi Y, Fan B, Ma D, Liang X, Li Z (2021) Rational design of novel CrZrOx catalysts for efficient low temperature SCR of NOx. Chem Eng J 413:127554

Cai W, Zhao Y, Chen M, Jiang X, Wang H, Ou M, Wan S, Zhong Q (2018) The formation of 3D spherical Cr-Ce mixed oxides with roughness surface and their enhanced low-temperature NO oxidation. Chem Eng J 333:414–422

Su J, Liu Y, Yao W, Wu Z (2016) Catalytic combustion of dichloromethane over HZSM-5-supported typical transition metal (Cr, Fe, and Cu) oxide catalysts: a stability study. J Phys Chem C 120:18046–18054

Fei X, Ouyang W, Gu Z, Cao S, Wang H, Weng X, Wu Z (2021) Effect of Cr doping in promoting the catalytic oxidation of dichloromethane (CH2Cl2) over Cr-Co@Z catalysts. J Hazard Mater 413:125327

Wang X, Liu Y, Ying Q, Yao W, Wu Z (2018) The superior performance of Nb-modified Cu-Ce-Ti mixed oxides for the selective catalytic reduction of NO with NH3 at low temperature. Appl Catal A 562:19–27

Wang X, Liu Y, Wu Z (2021) Temperature-dependent influencing mechanism of carbon monoxide on the NH3-SCR process over ceria-based catalysts. ACS ES&T Eng 1:1131–1139

Liu W, Long Y, Liu S, Zhou Y, Tong X, Yin Y, Li X, Hu K, Hu J (2022) Promotional effect of Ce in NH3-SCO and NH3-SCR reactions over Cu-Ce/SCR catalysts. J Ind Eng Chem 107:197–206

Yan T, Chen J, Li K, Yin R, Peng Y, Li J (2023) CeO2/α-MnO2 nanorods as dual-functional catalyst for simultaneous abatement of nitric oxide and chlorobenzene. Catal Lett

Gu T, Liu Y, Weng X, Wang H, Wu Z (2010) The enhanced performance of ceria with surface sulfation for selective catalytic reduction of NO by NH3. Catal Commun 12:310–313

Jin R, Liu Y, Wang Y, Cen W, Wu Z, Wang H, Weng X (2014) The role of cerium in the improved SO2 tolerance for NO reduction with NH3 over Mn-Ce/TiO2 catalyst at low temperature. Appl Catal B 148–149:582–588

Wang X, Liu Y, Yao W, Wu Z (2019) Boosting the low-temperature activity and sulfur tolerance of CeZr2Ox catalysts by antimony addition for the selective catalytic reduction of NO with ammonia. J Colloid Interface Sci 546:152–162

Wang X, Liu Y, Wu Z (2019) Highly active NbOPO4 supported Cu-Ce catalyst for NH3-SCR reaction with superior sulfur resistance. Chem Eng J 382:122941

Yao W, Liu Y, Wu Z (2018) The promoting effect of CeO2@Ce-O-P multi-core@shell structure on SO2 tolerance for selective catalytic reduction of NO with NH3 at low temperature. Appl Surf Sci 442:156–163

Xue L, Wei N, Zhao C, Hu X, Yun J, Chen Z, Deng Z, Chen Z (2022) Promotion effect of Cr addition on the activity and SO2 tolerance of CeOx catalysts for the NH3-SCR at middle-low temperature. J Energy Inst 105:472–480

Qi K, Yi Q, Fang D, Gong P, Shi L, Gao L, Li X, He F, Xie J (2023) Temperature dependence of reaction mechanisms and SO2 tolerance over a promising monolithic CuY catalyst for NO removal. Appl Surf Sci 615:156473

Yang S, Guo Y, Chang H, Ma L, Peng Y, Qu Z, Yan N, Wang C, Li J (2013) Novel effect of SO2 on the SCR reaction over CeO2: mechanism and significance. Appl Catal B 136–137:19–28

Wang X, Liu Y, Wu Z (2020) The poisoning mechanisms of different zinc species on a ceria-based NH3-SCR catalyst and the co-effects of zinc and gas-phase sulfur/chlorine species. J Colloid Interface Sci 566:153–162

Chi R, Wang X, Liu Y, Wu Z (2023) Highly active alkali etching silica-modified Cu-Ce-Ti catalyst with superior water resistance for low temperature NOx reduction. Appl Surf Sci 627:157304

Wang X, Zhu Y, Liu Y, Weng X, Wu Z (2022) Tailoring the simultaneous abatement of methanol and NOx on Sb-Ce-Zr catalysts via copper modification. Front Environ Sci Eng 16:130

Liu F, Asakura K, He H, Shan W, Shi X, Zhang C (2011) Influence of sulfation on iron titanate catalyst for the selective catalytic reduction of NOx with NH3. Appl Catal B 103:369–377

Guo M, Liu C, Liu Q, Wang Y, Fan B, Wang H, Liu B, Cui S, Zhao Y (2022) Investigation of SO2 resistance on Novel Cr0.8Zr0.2Ox catalysts for marine low-temperature SCR of NO removal. ACS ES&T Eng 2:1825–1835

Yao W, Wang X, Liu Y, Wu Z (2019) Ce-O-P material supported CeO2 catalysts: a novel catalyst for selective catalytic reduction of NO with NH3 at low temperature. Appl Surf Sci 467–468:439–445

Liu Y, Yao W, Cao X, Weng X, Wang Y, Wang H, Wu Z (2014) Supercritical water syntheses of CexTiO2 nano-catalysts with a strong metal-support interaction for selective catalytic reduction of NO with NH3. Appl Catal B 160–161:684–691

Ying Q, Liu Y, Wang N, Zhang Y, Wu Z (2020) The superior performance of dichloromethane oxidation over Ru doped sulfated TiO2 catalysts: synergistic effects of Ru dispersion and acidity. Appl Surf Sci 515:145971

Guo K, Fan G, Gu D, Yu S, Ma K, Liu A, Tan W, Wang J, Du X, Zou W, Tang C, Dong L (2019) Pore size expansion accelerates ammonium bisulfate decomposition for improved sulfur resistance in low-temperature NH3-SCR. ACS Appl Mater Interfaces 11:4900–4907

Zhang L, Li L, Cao Y, Yao X, Ge C, Gao F, Deng Y, Tang C, Dong L (2015) Getting insight into the influence of SO2 on TiO2/CeO2 for the selective catalytic reduction of NO by NH3. Appl Catal B 165:589–598

Costa CN, Savva PG, Fierro JLG, Efstathiou AM (2007) Industrial H2-SCR of NO on a novel Pt/MgO-CeO2 catalyst. Appl Catal B 75:147–156

Acknowledgements

The authors acknowledge for the financial support of National Key R&D Program of China (No. 2022YFC3701600), National Natural Science Foundation of China (No. 22276162 and 22306072) and China Postdoctoral Science Foundation (No. 2023M731441).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhou, F., Wang, X., Sun, L. et al. Selective Catalytic Oxidation of Ammonia over Cr-Ce Mixed Oxide Catalysts in the Presence of Sulfur Dioxide. Catal Lett 154, 2841–2851 (2024). https://doi.org/10.1007/s10562-023-04535-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-023-04535-4