Abstract

The biotechnology industry is currently seeking increased or improved enzyme efficiency and the emergence of new methods to maximize their shelf-life. Enzyme immobilization on solid supports offers characteristic features, such as recyclability, easy product recovery, improved enzyme stability, and biocatalytic properties. Biopolymers-based support materials provide cost-effective, and stability attributes to immobilized enzymes due to non-toxicity, biodegradability, biocompatibility, and the presence of multiple functional moieties. In addition, nanostructured materials with large specific surface areas and unique structural, physical, chemical, and operating characteristics have significantly contributed to biocatalytic systems for diverse biotechnological applications. Urease is a ubiquitous metalloenzyme that displays a high ability to catalyze urea's decomposition into ammonia and carbamate. This review provides information on urease immobilization using various biopolymers-based support matrices to develop nano-biocatalytic systems for biotechnological, medical, and industrial fields.

Graphic Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Enhancing enzymes’ efficiency and designing new methods for their longevity are the world’s biotechnological industries’ requirements. These conditions are inevitable if the broad and economic formulation is to be made simpler. Immobilization of enzymes is an outstanding source of increased accessibility of enzymes to the substrate. Numerous natural and synthetic support materials have been assessed for their enzyme immobilization efficacy [1]. Immobilized enzymes are currently ideal over their free equivalent due to their extended supply, reducing inefficient downstream and cleaning processes. Future research should seek to implement measures and innovatively amended assistance to improve the immobilization of enzymes and provide the industry with a new perspective [2, 3].

Enzyme immobilization means combining the carrier's physicochemical properties in a specialized formulation that maximizes the biocatalyst's physical and enzyme stability as a primary function. There are many techniques for immobilizing enzymes, including physical (adsorption, entrapment) and chemical (covalent bonding, cross-linking) methods (Fig. 1) [4], but the industry still chooses economical and straightforward techniques. Physical (adsorption or entrapment) immobilization and chemical (covalent binding and interconnection) are the most popular approaches [5].

Techniques to immobilize enzymes on solid supports. Reprinted from Bilal et al. [4] with permission from Elsevier

In some cases, soluble enzymes are immobilized on stable insoluble products reused in continuous processes so that the enzyme is retrieved economically after the reaction without significant losses to its biochemical results. In the face of temperature fluctuations and organic solvents, immobilization gives enormous stability. Covalent enzyme attachments on correctly functionalized connector support, with multiple and multi-unit connections, offer rigidity to the enzyme’s immobilized structure, which gradually improves the enzyme’s stability. Sequential and compatible enzyme modification approaches modification are protein engineering and immobilization strategies [6].

Soluble enzymes usually have to be trapped for durable use. Additionally, other essential characteristics, such as stability, activity, inhibition of reactions, and selectivity to non-natural substrates, need to be strengthened. Immobilization is by far the preferred progression to attain these objectives [7]. Although the Michaelis–Menten method has been continuously improved to study immobilized enzymes' behavior, its application to the immobilized state is constrained by the immobilization matrix obstacles to the components used as models of enzyme kinetics. The approximate value of the coefficients of Michaelis–Menten (e.g., Vmax, Km) will then be used to estimate the effects of immobilization on enzymes’ behavior in the immobilized state under supervision. This analysis addresses enzyme function and kinetics in the sense of immobilization and proposes several new protocols to discuss some of the immobilization barrier's specific limitations [8].

Urease is a highly potent catalyst for urea hydrolysis. Uric acid converts urea and CO2 to NH3. Urea is the major toxic biochemical agent, and eliminating this waste is a significant concern in patients with a renal disorder [9]. The enzyme is present in several bacteria, fungi, and plants, which play a substantial role in normal nitrogen management. The use of urease in biotechnology is an analysis of the urea content of blood, urine, beer, natural water, and environmental wastewater. The efficient way to extract urea from aqueous solutions is to use bonded urease for urea removal as no effective adsorbent is available. The urease enzyme is used to produce CO2 and NH3 in many analytical applications [3]. However, the enzyme cannot be extracted from a mixture of reactions. In this concern, the urease-tagged magnetic nanoparticle is very useful in replacing the pure enzyme and can be isolated from the external magnetic field’s reaction mixture. In this concept, the most potent support for enzyme immobilization is found in FeO nanoparticles with remarkable magnetic properties. Many polymers have been used for urease immobilization and applied in analytics and biomedicine [10], Senel et al. 2010).

Urea is a uremic poison that affects human health. Zhang et al. [11] constructed a type of urease-immobilized urea bead with strong blood affinity and high urea elimination proficiency. Urease was covalently grafted onto the polyethersulfone bead prepared by in-situ cross-linking polymerization and reversal processes using carboxyl group-operated beads. The blood compatibility of urease immobilized beads with low protein absorption levels, lower- coagulation times, low hemolysis ratio, and inhibited activation of the complement system and contact activation was adequate. After incubation in 80 mg/dL of urea solution for 480 min, urease-immobilized beads showed a strong potential for urea elimination with the elimination level of 75.1 mg/g. Besides, after five cycles, prepared immobilized beads have been used to maintain urea removal activity. They have shown adequate activity even if they are stored in a saline phosphate buffer for 15 days. The urease-immobilized beads will satisfy the future need for healthy and efficient detoxification of the blood.

2 Ureases Immobilization on (bio) Polymers

Biopolymers extracted naturally received considerable interest due to their surplus and varied resources over the last few years. Several biopolymers currently available show an ideal and promising support/composition potential in biomedical, agricultural, medicinal areas, food, biofuels, and electricity sectors [12]. Biopolymers enhanced biocatalytic efficiency by ensuring the best possible response trends in the biocompatible micro-environment surrounding the enzyme molecule. To date, a considerable number of biopolymers and their derived materials have been used as support materials for the production of multifunctional biocatalysts, including alginate, chitosan, cellulose, dextran, agarose, agar–agar, carrageenan, gelatin, guar gum, pectin, etc. (Table 1). The promotion of the construction of new composites of biopolymer-based materials with uniquely structured and innovative features emerges from their deep interest in biotechnology [13].

2.1 Alginate, chitosan, and carrageenan

Alginate has many business applications, but its particular characteristics are of interest to researchers because it is used in biomaterial sciences [14]. It is used efficiently in the preparation of nanoparticles to release substances. This polymer is also used to attach a biocatalyst and recycle the enzyme successfully. A study used a matrix for the trapping of biocatalyst dextranase of major industrial importance [15]. Alginate supported by a combination of carboxyl in the guluronic acid solution with a cationic crosslinking system including CaCl2, BaCl2, or poly(l-lysine) is generally obtained a crosslinking process. Ca2+ ion-linked alginate matrices are unstable in a physiological or standard buffer solution with high PO4−3 and citrate ion concentrations capable of extracting Ca2+ from the alginate and liquefying the system [16]. Danial et al. [17] assessed the biotic value of the immobilized urease against un-immobilized urease. The material used for the immobilization of urease was alginate. Urease immobilization shows a remarkable rise in Km and Vmax, typically in alginate gel. Thermal stability, however, was greater than that of free enzymes in immobilized urease. The inactivation rate of the bonded enzyme was reduced owing to implantation in the gel matrix. Besides, such enzyme activity during preservation was firmer than that of an un-bonded enzyme throughout the solution storage. In contrast, its activity was lower than that of an un-bonded enzyme. A robust restrained system and a long shelf life are suitable for implementations that are not possible with a soluble enzyme system. The findings showed that immobilized urease has technological and biochemical advantages over the free enzyme.

Urea sensors based on direct medium-contact electrodes have reduced long-term reliability in complex media exposures. The urea biosensors presented by Fapyane et al. [18] are based on ureases immobilized in polymer alginate, buffered at pH 6.0, and placed in front of a newly developed single, responsive CO2 microsensor with gas-permeable membrane shielding electrodes. The carbon dioxide emitted by the urease is diffused to the microsensor in the presence of urea. A Cr2+ trap prevents the intrusion of oxygen. The response time of 95% to urea shifts was 120 s, with a linear 0–1000 μM curve and a limit detection of 1 μM. The cofactor of the Ni2 + sensor was continuously supplied from behind the tip of the sensor from the reservoir. By incorporating bovine serum albumin, which was cross-linked to glutaraldehyde and Ca2+ ion, the urea sensors’ balance was optimized. The mixture of urea was well balanced. After two weeks of continuous service, this immobilization technique culminated in about 70% of the original urea sensitivity. The sensor was successfully checked in the blood serum.

Chitosan is another naturally occurring polymer that has become extremely popular with immobilization technology. Chitosan is derived from the N-deacetylation of chitin, the second most profuse natural polymer in marine exoskeletons. The major drawback of chitosan is its total insolubility close to physiological pH. Due to pKa residues of d-glucosamine (pKa 6.5), chitosan can only be soluble with diluted CH3COOH or HCl solutions [19]. This chitosan property could restrict its use in the immobilization of enzymes because many enzymes are not stable at such low pH levels. Several researchers have proposed the ion complexation of chitosan with alginate to form gel or microcapsule systems to overcome these limitations [16]. The physicochemical properties of chitosan are strange. Chitosan enhances biological functionality, including biocompatibility, mucosal adherence, regenerative effects, bone formation, fungicide, spermicide, antitumor, central nervous system depressant, immunocompromising agents, emulsifiers, improved permeation, anticholesterol, and antimicrobial activity [20, 21].

Chitosan is used explicitly to deliver drugs, tissue engineering, functional foods, preservatives, biocatalyst immobilization, wastewater treatment, molecular impressions, and metal reduction. Chitosan is, therefore, a versatile, low-cost biomaterial [22]. Feng et al. [23] prepared chitosan-coated cellulose dialdehyde (CDAC) and immobilized urease in the membrane of gelatin (IE). Batch systems were studied in CDAC urea nitrogen adsorption during IE biocatalysis. Balance isotherm of CDAC urea nitrogen adsorption (53, 78 and 95%), CDAC/IE weight ratio (30:4, 50:5, and 50:6), initial amounts of urea nitrate (395.2, 648.8 and 767.3 mg/L), and temperature (37, 42 and 47 °C), as well as adsorption kinetics about CDAC DOs (53 and 75%), were monitored. The experimental isotherm and isothermic constants were defined by the Langmuir and Freundlich adsorption models. Balance data were very well suited to the Langmuir model for the entire concentration range (128.2–708.2 mg/L). For CDACs with DO 53, 78, and 95%, the maximum single-clay adsorption potential obtained from Langmuir models is 70.18, 79.56, and 90.42 mg/g with CDACs at 10:1 and 37 °C. Kinetic data was represented by pseudo-first-order and pseudo-second-order models, and the rate constants were evaluated. The findings show that the urea nitrogen adsorption mechanism on the CDAC followed the pseudo-kinetic second-order paradigm. Adsorption ability was strongly influenced by CDAC, CDAC/IE weight ratios, first urea nitrogen content, and temperature.

Carrageenan is a linear sulphate polysaccharide composed of D-galactose and 3,6-anhydrous-galactose alternative units, connected by glycoside a-1,3 and b-1,4 connections. Kappa-carrageenan has the properties of forming solid and rigid gels and has a single sulfate group per galactose molecule. Kappa-carrageenan polyelectrolytes may develop hydrogels through chains that result in efficient encapsulation in the presence of divalent cations (Ca+2) by increasing the mechanical and chemical stability of beads that overcome the problem of enzyme leakage [24]. Urease was embodied in kappa-carrageenan beads by Baysal and Karagöz [25]. Several parameters were designed for urease immobilization, including the volume of kappa-carrageenan and the enzyme’s function. The immobilized urease properties for pH, tempering, and storage stability have been extensively characterized and compared to the free enzyme. Un-bonded urease activity decreased steadily. The half-time decrease was approximately 3 days at 4 °C. Restrained urease was incredibly active for a long time and lost about 70.43% of its initial operation during the 26-day storage period at 4 °C. Lineweaver–Burk plots determined Michaelis constant and maximum reaction velocity were determined by Lineweaver–Burk plots. A slight decrease in enzyme-specific activity and improvement in substrate affinity was shown for immobilized urease. Kara et al. [26] trapped urease (urea aminohydrolase, E.C. 3.5.1.5) using poly(acrylamide co-acrylic acid)/kappa-carrageenan (P(AAm-co-AA)/carrageenan) hydrogels. The pH, temperature, storage stability, reusability, and thermal stability of free and immobilized urease have been studied. Optimum pH was observed to be 7.5 and 8 for free and immobilized ureases, respectively. Optimum enzyme temperatures were 55 and 60 °C for free and immobilized counterparts. The Michaelis constant value was also found to be less than the free enzyme for both immobilized ureases. Storage stability values for 48% and 70% of immobilized systems were observed after 70 days. Besides, on the 5th day after 20 times use, retained immobilized enzyme activity was found to be 55% and 89% respectively in C-A PEC and P(Aam-co-AA)/carrageenan matrixes. As a result of immobilization, the heat-sensitive strength of the free urease was further improved.

3 Cellulose

Cellulsose has been extensively examined with theoretical and scientific methods due to its biocompatibility, biodegradability, chemical stability, and low-risk contamination of the environment. Cellulose is one of the world’s largest biopolymers of wood, cotton, hemp, and others and is a significant strengthening factor in plants’ development [27]. Bacteria, algae, and tunicates also synthesize cellulose. Durable, double hydrophilic, neurotoxic, and chemical inert cellulose helps survive enzymes under physiological conditions. Cellulose materials are therefore appropriate for the immobilization of the enzyme. Cellulose, apart from the use of cellulose, is transformed into its derivatives by chemical, enzymatic or microbiological processes [28]. Cellulose derivatives, such as carboxymethylcellulose (CMC), cellulose-cellulose acetate (CA), and cellulose nitrate, are the major commercial raw materials used in the chemical and biological industries since they are cheap, non-toxic, organic, biodegradable, and biocompatible. More specifically, cellulose derivatives have functional enzyme-binding groups. Cellulose derivatives are also suitable substrates for enzyme immobilization [29].

As an economical and biodegradable carrier, urease immobilization cellulose spheres have been selected [30]. Cellulose spheres (Ces) with high crystallization have been bound to citric acid and oxidized with sodium periodate to form aldehyde groups on the Ces surface that covalently bind to the amino urease groups via the Schiff base reaction. These spheres have been distinguished by FTIR, XRD, SEM, and TG and dialdehyde cellulose cells (DACs) and urea immobilized spheres (UrCes). The results show that Ces and urease immobilization have been successfully adjusted, the original spherical morphology preserved, and thermal stability increased. UrCes had better urea adsorption and more selective adsorption than DACs as an adsorbent. To generate UrCes1, UrCes2, and UrCes3, Urease was immobilized with 19, 31, and 40% aldehyde content on DAC. Urea gross elimination potential was 243.3, 276.2, and 187.6 mg g−1, with L-phenylalanine adsorption being 10.71, 15.08, and 20.50 mg−1, respectively.

Urease Pigeonpea (Cajanus cajan) was immobilized on paper strips of 1 cm × 1 cm DEAE-cellulose [31]. Optimum immobilization of 51% interaction with a protein concentration of 1.0 mg/strip was measured at 4 °C. The deceptive ideal pH was changed from 7.3 to 6.8. The optimum stability temperature for immobilized urease was 67 °C compared to soluble urease (47 °C). In contrast to the biphasic soluble enzyme, time-dependent kinetics have been investigated and shown to be monophasic in thermal inactivation of immobilized urease. For DEAE-cellulose-immobilized urease, Km was estimated to be 4.75 mM which was 1.5 times greater than the soluble enzyme. Strips kept at 4 °C showed an increase in half-life (t1/2 = 150 days). The immobilized strips were essentially free of leaching for 2 weeks of the enzyme. The findings were well consistent with those obtained by the clinical laboratory’s Autoanalyzer to assess blood urea levels. It is ideal for potential diagnostic applications due to the ease of access to pigeonpea urease, the ease of immobilization of DEAE-cellulose strips, and the significantly low urea cost.

3.1 Starch and Gelatin

Starch is a significant natural resource, sustainable, biodegradable, and low-cost. Modified starches are widely used for enzyme immobilization. Cross-linked 35 (CM-HASCL-35) carboxymethyl high amylose starch is ideal as a carrier for uricase immobilization [32]. Starch-g-polyacrylonitrile copolymers hydrolyzed by acid will bind and retain significant amounts of active glucoamylase. Glucose productivity with immobilized glucoamylase was observed at 2.7 g/g carrier/hour and a half-life of up to 1800 h [33]. Enzymatic hydrolysis and periodic oxidation were introduced by Luo and Fu [32]. DPS Urease has been immobilized by many techniques, including physical adsorption and covalent bonding. Maximum enzyme -function and optimum urease immobilization conditions were shown as follows: pH immobilization 6.0, immobilization time 25 h, immobility temperature 25 °C, aldehydrogen content group 79.6%, and support-to-urease ratio 1:2 (w/v in g/mL). Optimal temperatures in free and bonded urease were 60 and 70 °C, respectively. The temperature curve of the immobilized urease was longer than the un-bonded urease. The bonded urease reserved almost all of its original operation after being kept at ambient temperatures for 42 days. DPS has been shown to retain the urease enzyme 10-times in a recurrent cyclical test. A rise in the Km value of bonded urease has been identified. DPS is a sufficient sponsor of urease and was the foundation for biosensors or bioreactors' production with reduced costs and longer shelf life. Gelatin is one of the most commonly used products of natural origin for the stabilization of the enzyme, such as β-galactosidase, α-amylase, and urease. The uniqueness of gelatin solutions can be demonstrated by forming a thermally reversible network at approximately 30 °C below the sol–gel transition point. The substances of interest are trapped in protein chains during gel formation. The basic idea behind immobilization was to capture the protein in semi-permeable material, preventing an enzyme from escape while allowing substrates, products, and co-factors to move through [23].

3.2 Cotton Fibers/Fabric and Silk Fibroin

Cotton is a well-characterized, durable fiber that has been used for medical and hygienic use throughout history and is attractive as a biologically active fiber carrier due to its highly absorbing and non-toxic properties. The potential use of the immobilization of numerous cotton-based enzymes as origins of biologically active textile surfaces would have highly selective functional properties and environmentally sustainable textile finishing [34]. Cotton fibers were adjusted by Monier and El-Sokkary [35] and used to immobilize urease. In the presence of KMnO4 and oxalic acid, polyacrylonitrile was first grafted as a combined redox initiator of cotton fibers. Besides, modifications of the grafted cotton fibers were made to the nitrile group (–CN) of hydrazine. Glutaraldehyde activated the fibers to create free aldehyde groups that can react with urease amino groups to form the Schiff's base and result in urease immobilization of the cotton fibers. The outcomes revealed that the maximum urease thermal stability was increased up to 5 degrees. The relative activity of immobilized urease was greater than that of free urease above 35 °C. The immobilized urease showed activity at pH 6.5, which was less than pH 7.0, and the stable enzyme was stabilized over a broader pH spectrum. The immobilized urease’s Km was more significant than the free urease.

Pigeonpea urease was immobilized on a polyethylene cotton fabric, followed by a cross-linking with dimethyl suberimidate by Das and Kayastha [36]. Optimal immobilization (56%) was achieved at a protein loading of 1.2 mg/5 × 5 cm2. The immobilized enzyme had a t1/2 of 70 days at 4 °C in 0.1 M Tris/acetate buffer (pH 6.5). In 15 days, the immobilizing matrix had almost no enzyme leakage. In 24 h, the immobilized enzyme was used 7 times with 75% retained activity at the time of termination. For some clinical samples, a blood urea test was performed with immobilized urease.

Silks are protein polymers woven into the fiber by Lepidoptera larvae, such as silkworms and spiders. Fibroin is the essential structural protein of silk fiber and is responsible for silk and sericin’s particular physical and chemical characteristics (Lv et al. 2020). Glycine, alanine, and serine, which are antiparallel sheets in spun fibers, dominate the amino acid composition of the fibroins. Silk fibroin has remarkable mechanical and biocompatible characteristics; therefore, these proteins are currently being examined for use in biomaterials [37] and tissue engineering. Silk fibroin was also used to aid in the immobilization of enzymes. Due to its chemical and physical properties, enzymes immobilized in fibroin matrices have been found in the production of biosensors [38]. Moon et al. [39] developed and tested their comparative efficacy in the urea regeneration system with a PVDF filter system using an immobilized urease silk fibroin filter. The percentage of urea removal in 50 mg/dL urea solution was between 40 and 60% under conditions to maximize urease activity. The test batch showed that greater than 50% urea was extracted in 50 mg/dL urea solution with an immobilized filter. Besides, 90% of urea was removed from silk fibroin after 24-h peritoneal dialysate filtration. They propose a more successful application of silk fibrin with a urease fixation filter with hydrophilic properties and sustained enzyme activity for peritoneal dialysate regeneration.

3.3 DEAE–Sepharose

Ionic/electrostatic mobility is an immobilization-adsorption technique that uses the same guidelines as ion-exchange chromatography. The loaded groups on the protein surface interact with opposite resin charges [40]. Total protein load depends directly on average pH (operational pH). The isoelectric point is the pH of which the global protein charge is null. If the operating pH is higher than that of the protein, the net charge is negative and interacts with positively charged media. If the pH is below the isoelectric point of the protein, a positive net charge will be maintained, and the negative charge groups will interact [41].

Several forms of resins, such as diethylaminoethylcellulose (DEAE-C), Amberlite IRA-94, Amberlite IRC-50, QSepharose, carboxymethylcellulose (CMC), DOWEX, and various other resins, have been investigated for enzymatic immobilization. Due to their high ion exchange capability and their long history of use in the industry and the laboratory, these resins have great application opportunities, especially for protein separation and purification chromatography columns. As carriers for enzyme immobilization and applications in different industries, ion exchange resins have been extensively examined [42]. The use of immobilization in the food industry has attracted consideration among the various applications proposed. Glucose isomerase immobilization in DEAE cellulose for glucose and fructose isomerization and (β)-galactosidase Immobilization in lactose-free commodity lactose resin Duolite A568 is among the most effective and useful studies [43]. Krishna et al. [44] documented urease purification, characterization, and a simple urease immobilization of Momordica charantia seeds. The enzyme is purified in two phases by chromatography of DEAE–Sepharose followed by chromatography. FTIR spectrometry and SEM confirmed the activation and immobilization of chitosan beads. In comparison, the EDX study found that the proportion of nitrogen improved to ensure immobilization. The productivity of immobilization is about 97%. Until fourteen successive batches of enzyme reactions, the immobilized enzymes maintain 60% of their activity and are therefore highly stable. The enzyme presents the desired characteristics in detail for many applications.

3.4 Polytetrafluoroethylene

Polytetrafluoroethylene (PTFE) components are commonly used in several chemical and biotechnological fields. PTFE membranes are widely used as gas permeable membranes in filtration and diffusion cells [45]. PTFE is also the material of choice in oxygen electrodes due to its inertness, relative strength, and thermal resistance. Another significant benefit is that PTFE can be produced in thin sheets (less than one micron) with a high level of oxygen permeability. Protein immobilization on the surface of the PTFE, however, involves the development of reactive surface groups. This can be achieved using chemical or physical methods such as radiation or plasma therapy [46].

Kim et al. [47] developed a convenient urea biosensor for real-time flow control of physiological fluids using interlinked disuccinimidyl urease immobilization (Fig. 2). Urease was immunized with solid porous polytetrafluoroethylene (PTFE) assisted by a sequence of disuccinimidyl cross-linkers, i.e., disuccinimidyl glutarate (DSG), disuccinimidyl suberate (DSS). A review of urease behavior found that DSS showed full immobilizing urease efficiency. In contrast, FT-IR research showed that urease was immobilized by a DSS cross-linking of the PTFE membrane. In the presence of urea solvent, a membrane was implanted into a polydimethylsiloxane (PDMS) fluid slot, which produced an electrochemical signal. The DSS urea biosensor's sensitivity was the maximum of all biosensors tested and the GA cross-linking was found to be better than the most widely used. In order to simulate real-time tests for the human patient, it was assessed, and the DSS urea biosensors were reported to have effectively immobilized urease. Repetitiveness and urea bio-sensor intervention is usually seen in humans to control urea levels.

Schematic illustration of a the configuration of the urease-immobilized membrane; the configuration of the fluidic compartment of the urea biosensor b before and c after assembly. Reprinted from Kim et al. [47] with permission under the terms and conditions of the creative commons attribution (CC BY) license

3.5 Egg Shell Membrane

Eggshell membranes have been used in various applications today. The eggshell membrane has many distinctive properties, such as high porosity, antibacterial, anti-inflammatory effects. High amounts of minerals and amino acids can be found in the eggshell membrane. As a result, eggshell membranes have many uses in therapeutic, nutraceutical, metallurgical, and bioremediation fields. Besides, the egg-shell membrane was chosen as good support for bio-sensor construction due to its large surface area, porous structure, and lack of analysis interference [48].

Collagen and mineral overlap are less accessible for enzymatic coupling due to inert structure and presence. Poly-functional groups have been adsorbed to address these problems by cross-linking the surface membrane to improve the coupling of protein molecules. However, adsorption becomes less robust and, at the same time, less stable over the supporting surface of the immobilized enzyme. In addition, these membranes are often susceptible to a microbial attack due to the presence of hyaluronic acid and protein [49], Girelli and Scut 2020).

The eggshell membrane is a natural substance consisting mainly of protein fibers with stability in the aqueous solution and gas and water permeability. It was used as a biomembrane to immobilize urease for the production of a potentiometric urea biosensor [50]. Polyethyleneimine (PEI) has been treated to transmit polycation properties to the eggshell membrane. Adsorption of the PEI-treated eggshell membrane was immobilized with urease. SEM analysis was carried out to track changes in surface morphology after immobilization. FTIR membrane analysis was performed to track improvements in the IR spectrum following enzyme immobilization. The selective ammonium ion electrode was associated with the immobilized membrane. The biosensor observed the sigmoidal urea concentration of 0.5–10 mM. The biosensor's response time was 120 s.

3.6 (Poly)Acrylonitrile/Chitosan Composite Membranes

Synthetic polymer membranes are suitable for the immobilization of enzymes. They have good mechanical stability, reactive functional groups can be readily available for direct enzyme reactions, and easy preparation in various geometric configurations. A (poly)acrylonitrile membrane with excellent characteristics, such as good thermal and mechanical stability, was successfully used as a membrane matrix for the immobilization of enzymes [51]. In addition, some comonomers have been copolymerized to increase their acrylonitrile suitability [52, 53].

Gabrovska et al. [51] have prepared acrylonitrile/chitosan (PANCHI) composite membrane. Both the surface and the pores of the base limben were deposited with a layer of chitosan. As a result, the pores of the membrane were reduced and showed an improved affinity for water. The porous configuration of the PAN and PANCHI membranes was determined by transmission and scanning electron microscopy analysis. The mean pore sizes for the selective PAN membrane layer were 7 microns. The chitosan-coated membrane showed decreased pore sizes by 5 microns or equal to 0.35% and approximately 4 microns, respectively. The number of functional groups, the degree of hydrophilicity of the PAN/Chitosan composite membranes, and their transport characteristics have been determined. In all types of PAN/chitosan composite membranes, urease was covalently immobilized. Both the binding protein quantity and the comparative urease activity were determined. PANCHI2 urease-based membranes with 0.25% chitosan were tested with the most significant value (94%). The key characteristics: pH(optimum), pH stability, Temperature stability, thermal immobility, and storage ability of immobilized urease were described. The findings show that polyacrylonitrile composite membranes are ideal for the immobilization of enzymes.

3.7 Eupergit® C 250 L

Commercial acrylic resins epoxy-activated as Eupergit® C and Eupergit® C 250 L have strong covalent protein immobilizing properties. In some cases, suitable biomolecules can be stabilized. These supports consist of spherical macroporous particles with large internal surfaces and low water consumption. They vary in internal morphology and in epoxy groups, determining significant variations in properties. Eupergit C 250 L is more porous and contains fewer oxyrane groups than Eupergit C. [54], Martin et al. 2003). Fidaleo and Tavilli [55] immobilized Lactobacillus fermentum distilled acid urease on Eupergit® C 250 L generating 109.7 ± 2.4 mg, 677 ± 39 IU biocatalysts with enzyme loading and relevant activity, respectively. A two-phase deactivation process with residual asymptotic activation at approximately 180 h of 67% and 24% resulted from incubation of the biocatalyst produced at 20 °C in the rosé and red vines. The biocatalyst was used to effectively extract urea from red and pink wines in a recycled bed reactor. An apparent pseudo-first-order kinetic constant was measured for urea hydrolysis by a biologic reactor model ranging from 2.8–4.1 cm3 g−1 to 1.1–2.7 cm3 and from 1.1–2.7 cm3 g−1 to red wine for three repeated bioconversion cycles. Results of repetitive bioconversion cycles have shown that the fundamental cause of low urease production in high polyphenol vines is the deactivation of phenolic enzymes. The use of immobilization to address the current deficiencies of the free enzyme has been proposed.

3.8 Poly(Ethyleneglycol Dimethacrylate/2-Hydroxyethylmetacrylate) Microbeads

Poly(ethylene glycol dimethacrylate/2-hydroxyethyl methacrylate) [poly(EGDMA/HEMA)] poly microbeads. Ayhan et al. [56] conducted blood compatibility tests for immobilized urease (Fig. 3). 12% of HEMA integrated 105–125-micron non-porous particles were used in the study. Chemically modifying hydroxyl groups on microbeads through a three-stage process consisting of activation, spacer-arm integration (hexamethylene diamine), and glutaraldehyde binding. Enzyme urease has been restrained on microbeads, and blood protein adsorption in serum and plasma has been checked for blood coagulation and adherence to leukocyte and platelets. Adsorbed albumin is even higher than fibrinogen and the total volume of globulin per gram of microbeads. Urease immobilization decreased the adsorption times of protein and blood coagulation relative to microbeads. Prothrombin time has not been modified too much, while microbead poly(EGDMA/HEMA) has developed a substantial rise in the active time of the thromboplastin component. With poly(EGDMA/HEMA) modification, platelet and leukocyte adhesion increased marginally and decreased with urease introduction. Patient BUN values have been reduced to almost adequate levels since blood samples have been processed using urease-immobilized microbeads.

Modification of poly(EGDMA/HEMA) microbeads for enzyme immobilization. Reprinted from Ayhan et al. [56], with permission from John Wiley and Sons

3.9 PAN [Poly(Acrylonitrile-Methylmethacrylate-Sodium Vinylsulfonate)] Membrane

Polymer membranes are widely used for enzyme immobilization. Acrylonitrile (AN) copolymer membranes which are unmodified are not acceptable as a carrier. These membranes are typically modified in addition to improving their comfort. Some articles deal with the covalent immobilization of chemically modified AN copolymer membrane enzyme [57]. The extracellular urease of Arthrobacter creatinolyticus was partially purified by precipitation of ammonium sulfate and immobilized by PAN [poly(acrylonitrile-methylmethacrylate-sodium vinyl sulfonate)] membrane of Ramesh et al. [58]. Under optimal conditions with an enzyme concentration of 1.0%, glutaraldehyde 15%, 24-h immobilization time, and 4 °C temperature, the immobilized PAN membrane ureases showed an activity of 97.92 U/cm (2). SEM and ATR-FTIR analysis were used to investigate improvements in membrane surface morphology following immobilization. The immobilized membrane was paired with a potentiometric biosensor electrode, and the results indicated a linear reaction of 1 to 100 mM for a wide range of urea concentrations. The immobilized urease had reasonable storage stability at 4 °C and was reused for 13 cycles for 70 days.

3.10 Clay Matrix

Clay minerals are a class of naturally abundant hydro-aluminum or magnesium phyllosilicate. Minerals have a nanometre-scale, two-dimensional layered structure. For example, one or two sheets of Tetrahedral Silicate (Si–O) [59] sandwiched with octahedral metal oxide (M–O or M–OH, MMg, Al, etc.) are produced in each layer of Montmorillonite (Mt). This structure enables clay minerals to have physical properties, including a wide area, swelling, and ion exchangeability [60, 61]. In addition, functional groups such as Si–O-Si-, Si–O–OH, and Al (M)–OH have a vast surface of clay minerals. In tetrahedral silicate (Si–O) sheet hydrophobic -Si–O–Si- groups may contribute to the interaction between clay and organic enzyme molecules through hydrophobic activity. Hydroxyl groups are ideal for hydrogen bonds with enzyme molecules on broken edges of tetrahedral and octahedral sheets [62]. For smectites, cations that are replaced by positively charged enzyme molecules, such as Na+ and Ca2+ located in the interlayer region, may be replaced by cation exchange reactions. These characteristics make clay minerals an excellent source of support for immobilizing enzymes. In addition, the structural and compositional characteristics of the layered minerals of clay make various possible modifications of the minerals of clay by organic, polymer, or biological molecules [63].

De Melo et al. [64] developed field-effect transistors (ENFETs) based on enzymes for the determination of urea. These transistors are based on the immobility of urease in two separate clay matrices, one cationic (Laponite) and the other anionic (double layered hydroxide, LDH). A bio-sensor based on the laponite-immobilized enzyme is more resilient and has a narrower linear dynamic spectrum. The enzyme reaction is shielded from the buffer strength of the external medium. For both biosensors, the apparent constant of Michaelis − Menten is very similar. Enzyme inhibition of sodium tetraborate has been studied. Tetraborate functions as a competitive urease inhibitor in two distinct forms of clay. Inhibitor activity is much higher for the LDH/urease biosensor. In fact, in the absence of an inhibitor, the maximum linear dynamic range varies from 1.4 mM to 12 mM when 0.5 mM of tetraborate is present. The standards for laponite and LDH biomembranes with 0.5 mM tetraborate were 10 mM and 62 mM. A higher association of the enzyme-inhibitor with LDH/urease biomembrane shows an association of the constant inhibitory values, Ki 0.16 or 0.05 mM for biosensor laponite and LDH explicitly.

3.11 Macroporous Polypyrrole and Pyrrole

Biosensing of urea through a biosensor as a direct detection tool at room temperature and pressure rather than chromatography significantly reduces production costs. Hosseinian et al. [65] have developed an amperometric biosensor based on the immobilization of urease with macroporous polypyrrole (MPPy) and pyrrole on the Pt electrode surface. The synthesis of MPPy was illustrated using monodispersed polystyrene (460 nm) spheres as a prototype using cyclic voltammetry (CV) technology. The electrochemical current of the modified electrodes was evaluated by CV and chronoamperometric studies. The biosensor output was linear for polypyrrole electrodes (PPy) in the region of 1.67 to 832 mM (R2 = 0.99). The biosensor showed a sensitivity rate of 0.0035 mA/mM and an identification rate of 2.57 mM in a response time of 7 s. The linear range was 0.5–10.82 mM for the MPPy electrode (R2 = 0.99). Sensitivity and identification rates were 0.0432 mA/mM and 0.208 mM respectively at 5 s response time. The updated MPPy biosensor showed higher durability and urea specificity.

3.12 Byssus Thread

The Mussel Byssus is a complex structure divided into three regions, the stem, thread, and plaque. The stem is the frame that supports each byssal film, while the plaque is the stick pad at the end of the film. In the Mytilus genus, Byssus is the result of the secretions of nine separate glands produced by the fusion of the retractor mussel stems located at the base of the foot [66]. This thread is the core of collagen-like proteins that are steeper at one end because they are elastin (proximal) or silk (distal) copolymers of both blocks. Studies of Mytilus edulis byssal threads have identified three distinct types of collagen, namely Byssal precollagen-P, Byssal procollagen-D, and Precollagen-NG [67, 68].

The enzyme of urease in byssus threads has been immobilized by Mishra et al. [67]. Byssus threads are long-lasting biopolymer mussels (Mytilus viridis) to bind to rock. The selection was novel in favor that threads were collected from mussels grown in their natural environment and animals kept in a laboratory environment. SEM research, chemically modified and used for urease adsorption, distinguishes Byssus thread surfaces. The efficacy of immobilization was determined by comparing free and immobilized enzyme activities. The stability of PH for immobilized urease was more significant (0.5 unit) than that of the free enzyme. Immobilized byssus enzymes (N and L) maintained 50% of their function after 30 days, at 6 °C, but were stabilized in a dry state. The ideal temperature of the immobilized enzymes (25 °C) increased. An increase in Km value (2.08 mol) was observed for immobilized urease.

3.13 Hydrogel

Hydrogels are well known to provide biocompatible environments in the ideal composite structure for bio-substance immobilization. The product has been used in various medical and industrial applications, such as drug delivery [69], tissue engineering, biosensor, food industry, manufacturing, and processing of slow-release fertilizers [70]. Hydrogels can also be used as an enzyme immobilization matrix to increase the efficiency of biocatalytic reactions [71]. Chen and Chiu [72] synthesized a hydrogel in a polyester nonwoven aid with a composite membrane made of cross-linked poly(n-isopropyl acrylamide-co–N-acryloxisuccinimide-co-2-hydroxyethyl)(p(NIPAAm-NAS-HEMA)). The composite diaphragm has temperature tolerance features close to normal PNIPAAm hydrogel beads, which reversibly swell below the critical PNIPAAm solution temperature and de-swell below (approx. 32–33 °C). The urea diffusion membrane was heated dependent with a potent diffusion coefficient of 20 °C, 18 times that of a diffusion coefficient of 60 °C. Urease was instantly bonded in the membrane, creating covalent associations between its amino groups with the membrane's succinimide ester. After immobilization at a constant first-order inactivation rate of 70 °C, Urease shows improved thermal stability reduced to 1/8 of the free urea. Membrane-immobilized urease could be used to dramatically increase urea hydrolysis in a 2-compartment membrane reactor with temperature swing. With a cycle time of 60–20 °C and a temperature change every 10 min, the best operating state of the membrane reactor was when ammonia concentrations of the product increased 3.8-fold after a 3-h reaction compared to isothermal activity at 60 °C.

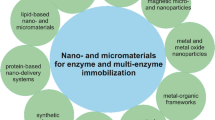

4 Urease Immobilization on Nanomaterials

Enzyme catalysis depends on the existence of substrate, enzyme concentration, temperature, pH, and active inhibitors. Stable and consistent particles with a size of 10–1000 nm are called nanoparticles. They boost particle flexibility, increase diffusion, thermal stability, storage space, increase surface area and restrain the catalytic activity of the enzymes bonded to them. Enzymes may be restrained by simple adsorption or chemical interactions with nanoparticles. The Immobilization system is commercially feasible and convenient, as it typically results in increased enzyme thermal and pH reliability, lower manufacturing costs, reusable activity, and better separation [73, 74]. Several compounds have been used in the immobilization of enzymes via polymer membranes, silica, chitosan-siloxane zeolites, and molecular sieves to make enzymes economical and sustainable. In a broad range of applications, solid media immobilization is the common rule because of low cost, recycling, rapid product segmentation, improved enzyme stability, and intact catalysts [75]. The nanomaterials can provide superior support to the immobilization of enzymes due to their high surface-to-volume nanomaterial ratios compared to traditional macro-based materials (Table 2). The smaller sizes of the substrate may cause deactivation enzyme desorption during enzymatic reactions. Magnetic nanoparticles are promising not only for the immobilization of enzymes on the surface but also for faster isolation from the external magnetic field, to be stronger than micro resistors. Besides, the successful isolation of the substance using the suspended small solid enzyme carrier’s external magnetic field is also of great interest [76, 77].

4.1 Metal Oxide Nanoparticles

Metal oxide nanoparticles have attracted increasing research interest in recent decades because of their enormous applications in these fields. In recent years, biological application areas have been dedicated to the nano-sized sections of iron oxide [78]. In addition to conventional electrical, optical, and magnetic fields, the use of these magnetic iron oxide nanoparticles broadens the scope of biotechnology applications. These nano-sized particles have been commonly cast-off in enzyme immobilization, immunosuppression, bioseparation, biosensor, selective drug delivery, and environmental studies [79,80,81]. It is economical, non-hazardous, bio-friendly, and quick to formulate. The superficial characteristics of magnetic nanoparticles consent different featured groups to operate magnetic nanoparticles for various applications. Although some observations of water-soluble magnetic nanoparticles are available, most approaches are poorly distributed with aqueous solutions. Hydrophilic molecules are also a prerequisite for altering magnetic nanoparticles' surfaces before they are used in biological systems [3].

For the quantifiable reduction of urea in an aqueous medium, an amperometric biosensor was produced using hematein, a pH-sensitive natural colorant by Tiwari et al. [82]. The urease was implanted on a gold-nanoparticle, covalent electrode, which functions on glass surfaces of indium-tin-oxide (ITO) coated with polyester-Boltron® H40 (H40–Au). The covalent relationship between the enzyme Urs and the nanoparticles H40–Au produced an increased degree of enzyme immobilization and a higher lifetime of the resulting enzyme electrode (Urs/H40–Au/ITO). Reaction experiments were conducted on an amperometric and photometric basis for urea concentration. The Urs/H40-Au/ITO biosensor exhibited a linear current reaction at the urea level from 0.01 to 35 mM as the operating electrode. The sensitivity of the urea biosensor was 7.48 nA/mM with a response time of 3 s. For the Urs/H40–Au/ITO biosensor, the Michaelis–Menten constant was measured at 0.96 mM, demonstrating that the immobilized enzyme on the electrode was very closely linked to the urea.

The terminated carboxylic exterior of glutathione-coated gold nanoparticles was used as a strong base for the covalent bonding of urease (Fig. 4) [83]. Immobilization has occurred under various pH conditions to explain its consequence on the efficacy of the enzymes’ immobilization and bioactivity. The attachment of the enzyme was studied quantitatively and qualitatively using methods. In different thermal conditions, the bonded enzyme's bioactivity was studied concerning the unbonded enzyme. The findings show that pH 7.4 immobilization is the most successful and less effective in the alkaline environment, followed by the acid medium. The immobilized enzyme often increases activation at physiological temperature relative to the unbonded form [83].

Covalent immobilization of urease on the surface of gold glutathione nano-conjugates. Reprinted from Garg et al. [83], with permission from John Wiley and Sons

Eghbali et al. [84] tested the immobilized urease enzyme's properties on nanostructured zinc oxide particles under different conditions. Thick zinc oxide film has been deposited with organic additives and urease in different pHs (6, 7, and 8). The behavior of the biosensors generated at different urea levels has been evaluated (10−6, 10−7, and 10−8 M). The results show that the biosensor has an optimum reaction at pH = 7 as its pH increases from 6.0 to 8.0. Besides, the response of the biosensor at pH = 6 is lower than pH = 8. As the concentration of urea increases, the reaction of the biosensor is increased, and this pattern is the same for 3 pHs of solution. The findings show that the maximum current of ZnO film impacted on Au is 18.4 mA under optimal conditions (pH = 7, 10−6 M), while the maximum current on Au sheet without ZnO film for immobilized urease is 6.06 mA. Nanowire arrays of well-aligned zinc oxide (ZnO) are manufactured using the low-temperature aqueous chemical growth method for gold-plated plastic substrates by Ali et al. [85]. In enzyme-based urea sensors, ZnO nanowire arrays of 50–130 nm in diameter and ~ 1 µm in length have been exploited by immobilizing the urease, sensitive enzyme at urea levels from 0.1 to 100 mM. The suggested sensor was 52.8 mV/decade sensitive to 0.1–40 mM urea and achieved a rapid response of less than 4 s with high selectivity, reproductivity, and inadequate response to typical interference elements ascorbic acid and uric acid.

4.2 Magnetite Nanoparticles

MNPs are known for their wide area and the abundance of hydroxyl groups on their surfaces, making them easy to modify and good (covalent) enzyme binding. These characteristics are essential. However, high mechanical stability and low porosity are vital in forming a stable bio-catalytic enzyme matrix system that eliminates steric obstructions [86]. According to Netto et al. [87], many enzymes grouped within oxidoreductases can be immobilized to generally build stable systems that provide high reusability and easy separation from the reaction mixture on magnetic nanoparticle surfaces. Magnetic regenerative urease formulations promising for biomedical and environmental uses have been developed by immobilizing the enzyme on the exterior of magnetite nanoparticles operated by Pogorilyi et al. [88]. Later tetraethoxysilane was either 3-mercaptopropyltrimethoxysilane and methyltriethoxysilane, or n-propyltriethoxysilane with a hydrolytic polycondensing agent. To compare this immobilization of urease, adsorption, inadequacy during a hydrolytic polycondensation reaction or covalent bonding has been performed in various ways. The enzyme was inserted into the entanglement solution until magnetite functionalization. Entrapment has bound high concentrations of enzymes, but its activity has dropped to between 18 and 10% as opposed to the original form. When urease is covalently bound using Ellman's Reagent, the enzyme's binding was almost as potent as when stuck with urease,however, its residual activity was 75%. The residual urease activity of the thiol-function particles was higher than that of the native enzyme (97%). Still, its binding efficiency was slightly lower than that of the native enzyme (46%). Alkyl functions have increased the sum of the adsorbed enzyme, but its activity has decreased considerably.

Modification and use of magnetic nanoparticles for the urease enzyme's immobilization have been demonstrated by Sahoo et al. [3]. Magnetite particles were prepared with the basic aqueous co-precipitation process and then filled with phosphonomethyl-iminodiacetic acid. Urease was affected by a carbodiimide reaction on the magnetic- nanoparticles. FTIR and TGA studied surface functional groups and surface structure. XRD analyzed the structural properties of the powders. DLS and HRTEM demonstrated the features of the modified nanoparticles. The particles' superparamagnetic structure at room temperature was shown by measurements of the vibration of the sample magnetometry (VSM). The catalytic activity of the bonded urease was equal to that of the enzyme-free solution. The bounded urease showed approximately six times outstanding catalytic activity and stability. Using immobilization methods in this magnetic nanoproduct, it is convenient to separate the product from the reaction mixture so that the reaction can be regulated and the cost of the enzyme at the same time minimized.

Urease was immobilized on functionalized magnetic nanoscale particles in the presence of cationic/anionic polyelectrolytes, BSA, and glutaraldehyde as coupling agents to fabricate a novel urea capacitive biosensor. Incorporating magnetic nanostructured beads showed exceptional sensitivity to change in pH for urea addition. The as-fabricated biosensor displayed good reproducibility, superior sensitivity, and substantial lifespan [89]. Zhang et al. [90] prepared a recyclable urea-immobilized magnetic graphene oxide nanocatalyst to successfully remove urea during blood purification, demonstrating a high potential for urea removal (2194 ± 110 mg/g). For a high urea solution of 80 mg/mL, the clearance ratio is over 80% and 77% for laboratory dialysis collected. The nanocatalyst is stable and resistant to storage. Besides, according to a variety of blood tests, the formulated nanocatalyst has strong blood compatibility. Therefore, there is an excessive potential for effective and stable urea removal by urease-immobilized recyclable nanocatalyst in blood purification.

4.3 Nanoceria

Nanoceria has been seen as a promising nanozyme for colorimetric screening because it catalyzes the rapid oxidation of colorimetric substrates, producing colorful products even without the need for additional oxidants (e.g., H2O2). The transition from white/light yellow to extreme yellow/orange properties is special due to changes in the H2O2-induced oxidation status of the nanoparticle Surface from Ce3+ to Ce4+ [91]. Several color tests for the detection of H2O2 and other biomolecules, including glucose and cholesterol, have been reported in aid of appropriate oxidases since nanoceria changes in their auto color by H2O2 alone without any color dye and due to the recovery of ion valence between Ce3+ and Ce4+ nanoceria [92, 93].

Al-Hakeim et al. [94] investigated nanoceria's synthesis and interaction with urease enzymes using a hydrothermal approach in their research. The findings revealed a cubic form nanoceria, 15 nm in size, measured by Transmission Electron Microscopy. Urease has been immobilized on nanoceria by adsorption. After interactions, the Vmax and Km of bonded and unbonded urease decreased, and the Lineweaver–Burk plot revealed an uncompetitive inhibition. Thermodynamic adsorption analysis showed an endothermic reaction. The relationship modified secondary and tertiary urease structures as seen in the circular dichroism analysis. A shift in the tertiary structure was observed in the fluorescence analysis. The FTIR of this complex did not show changes in covalent bonds that suggested the relationship between urease and nanoceria between the physical forces.

Gabrovska et al. [95] have developed a new matrix for enzyme urease immobilization using Rhodium Nanoparticles (5% activated carbon) and chemical bonds in the previously modified AN copolymer membrane at different concentrations (0.15%, 0.30%, 0.5%). The modified membranes of chitosan have been studied in their fundamental characteristics. In the various modified membranes, the SEM studies showed a significant shift in morphology. Both the volume of the binding protein and the relative enzyme activity was measured. Higher urease activity associated with the 1.0% AN copolymer membrane containing rhodium nanoparticles (77.44%) was assessed. KALE et al. [96] prepared a highly sensitive and high-efficiency biosensor for the respective biosensor using nickel ferrite (NiFe2O4) and a biological agent (urease). The Sol–Gel system was used to generate nanoparticles of nickel ferrite (niFe2O4). Prepared nanoparticles have been dispersed into polyvinyl alcohol (PVA) solution to create nanocomposite film on the gold (au) tray. In this nanocomposite film (PVA/NanoNiFe2O4/Au), urease was immobilized by physical adsorption. With the use of electron microscopy scanning (SEM), electrochemical spectroscopy (EIS), and cyclic voltammeter (CV), PVA/Nanospe2O4/Au electrode, and ur/PVA-nanoNiFe2O4/Au bioelectrode have been identified. XRD and FT-IR spectroscopy characterized the synthesized nanoparticles. The NiFe2O4 XRD shows the spinel ferrites’ crystal structure and the NiFe2O4 NPs with a typical particle size of ~ 40 nm. The formation of NiFe2O4 was confirmed by FT-IR. Nanocrystalline NiFe2O4 detective efficiency results in increased active PVA-nanoNiFe2O4/Au bioelectrode surface area for enzyme immobilization (Ur), improved electron transfers, and increased shelf life of bioelectrodes. Ur/PVA-nanoNiFe2O4/Au biochemical shows exciting features, including a 5–50 mg/dl detection scale, regression time 2 s with a regression coefficient of 0.951. The enzymatic affinity for urease (Ur) identification is suggested by a Michalis-Menten (km) constant of 2 mg/dl. Results from this analysis show that Ur/PVA-nanoNiFe2O4/Au bioelectrode leads to enhanced interactions between enzyme (urease)-substrate (urea) and other matrices used to produce urea biosensors. This electrode can be used to detect urea in the blood serum.

The industrial Jack beans urease nanoparticles (Canavalia ensiformis) aggregates were produced by the desolation and crosslinking of glutaraldehyde and functionalized by cysteamine dihydrochloride by Jakhar and Pundir [97]. TEM, UV, and FTIR Spectroscopy have characterized these enzyme nanoparticles (ENPs). TEM observations of urease NPs showed a size of 18-100 nm and an average size of 51.2 nm. The ENPs had a longer shelf life than the native enzyme molecules and were more active and stable. The bio-sensor was used to evaluate the potential urea in sera of apparently stable individuals and people with renal disorders. The serum urea recovery study was 106.33%. The new biosensor coefficient is 0.18% and 0.32%, respectively. The correlation between sera urea values (the enzyme-colorimetric package method) and the biosensor was strong (r = 0.99). The biosensor had limited interference with sodium, potassium, ammonium, and calcium ions, while some selective ion electrodes resolved interference with Mg2+, Cu2+, and ascorbic acid.

4.4 Carbon-Based Nanomaterials

The support materials used for the immobilization, particularly in the past two decades, were carbon-based materials such as activated carbon and unchanged and modified carbon. With their size and volume of pores and a large surface area (up to 1000 m2/g), these compounds have a well-developed pore structure that requires multiple contact points on the surface to immobilize enzymes [98]. High adsorption potential, the abundance of numerous functional groups, and the minimum release of fine particulate matter make carbon-based materials an adsorption carrier of different enzymes [99]. For instance, unmodified carbon support for amyloglucosidase has been used to immobilize it. The immobile enzyme produced was used to maintain more than 90% of the free enzyme catalytic function for starch hydrolysis without additional treatment. According to Silva et al. [100], the adsorption of pancreatin by activated carbon allows complete immobilization resulting in the development of biocatalytic systems with strong catalytic properties.

Meshram et al. [101] documented basic synthetic polypyrrole (PPy) and functionalized multi-walled carbon nanotubes (MWCNT) urease deposited immobilized electrode of stainless steel used for the revealing of heavy metal ions in water. PPy and MWCNT nanocomposites were electrochemically synthesized to 0.1 M aqueous acid dodecylbenzene solution in stainless steel. The processing of nanocomposite films required an additional weight percent of functional MWCNT compared to pyrrole. The film deposited on the electrode was used to immobilize urease. Immobilization was achieved by crosslinking 2 mg/mL of urease with 0.1% of glutaraldehyde at 7.0 pH of phosphate buffer (0.1 M). CV, FTIR, and SEM have been used to characterize synthesized nanocomposites. Following standardization, urease biosensors have been used to detect heavy metal ions with varying concentrations. The detection limits for Cd and Pb were located in the 1–10 mM band.

Saeedfar et al. [102] have developed a new way to quickly modify fullerene to build a potentiometric biosensor for subsequent enzyme attachments. Fullerene urease was restrained on the adapted nanomaterial. Bioconjugate of the modified fullerene restrained urease (C60-urease) has been revealed to catalyze urea. These were then placed on a screen-printed electrode with a non-plasticized, ionophoric hydrogen membrane, poly(n-butylate)(PnBA) membrane. This pH-selective membrane could be used as a possible urea biosensor with C60 urease deposition on the PnBA membrane. To change the fullerene and to immobilize urease, different parameters have been investigated. The optimum pH and phosphate buffer concentrations for the urea biosensor are 7.0 and 0.5 mM, respectively. The biosensor sensitivity is similar to the theoretical value at 59.67 ± 0.91 mV/decade. There was no apparent intervention of urea biosensors with typical cations. By using the bio-conjugate fullerene-urease and the well-adhered acrylic membrane, the urease enzyme was not released and the urea biosensor stability was therefore improved up to 140 days. The ureases were immobilized on nanoporous alumina membranes constructed using a two-step anodizing technique. A novel piezoelectric urea sensor with a separate porous alumina/urease electrode was constructed [103]. The urease immobilization phase has been refined and the efficacy of the urea biosensor has been assessed. High-level urea regulation, shorter reaction time, larger linear range, lower recognition limit, and strong long-term stock reliability were presented. The clinical urea biosensor study firmed the viability of urea identification in urine trials.

5 Applications of Urease-Based Biocatalytic Platforms

5.1 Dialysis

The portable artificial kidney device for patients with end-stage renal disease has been significantly advanced over the last decade. WAK is most important for the proper operation of the Uremic solution removal and water regeneration method. Realigned urease on the silk fibroin filter indicated better dialysis results [39]. Dialysis is a classic therapy for chronic kidney disease. For a long time, cumbersome, inefficient, and time-consuming solutions have been pursued. The dialysis can almost be replaced by a compact device consisting of ultrafiltration series hemoperfusion. The only step to complete this solution is the method of urea removal. The prospect of mixing MIC, urease, and zirconium phosphate with urea extract was tested in vitro. The use of ammonium adsorbent ion has been studied. Urease converts urea to zirconium-adsorbed ammonium ions. This mixture is the most successful in the intestinal tract. In general, zirconium phosphate's ability to remove enough urea to eliminate dialysis is not sufficient in patients lacking renal function [104,105,106].

5.2 Anticancer Agent and Hypertension Treatment

Cancer is one of the world's leading deaths, accounting for 7.6 million (13% of all deaths) in 2008. In the USA, for example, the chance of cancer growing for a lifetime is ~ 44% for men and ~ 38% for women. Alcohol and tobacco abuse, infection, radiation, obesity, and physical activity have been identified as a cause of cancer [107]. While "cancer" is a heterogeneous group of diseases, abnormal cells that develop beyond their natural boundaries are a characteristic and unifying feature. In 2000 Hanahan and Weinberg suggested that the underlying concept of this malignant transformation was six characteristics of cancer. As tumor development is a multi-step process, normal cells gradually develop into the neoplastic stage and develop specific capabilities to make them tumorigenic [108].

DOS47 is a jack bean enzyme known as urease. Urease activity contributes to the development of metabolites: ammonia and hydroxide ions by triggering urea catabolism in the interstitial medium around cancer cells. Metabolic products of urease activity are predicted to stress cancer cells by direct toxicity and alkaline induction. Ammonia is toxic to cancer cells and the local pH of the nearby medium increases urea catabolism. Improved alkalization could mitigate the destructive effects of acidic microenvironments on weakly basic drugs and increase their consumption [109].

The breakdown of urea in ammonia is catalyzed by jack bean urease, which increases the environment’s pH. Researchers have studied the anti-tumor influence of urease in vitro and in vivo on human lungs and breast cancer cells, either by the enzyme itself or by other chemical therapeutic agents that depend on these two properties. Initially, urease specifically performed cytotoxicity in tumor cells A549 and MDA-MB-231 with 0.22 and 0.45 U/ml LC50 through toxic ammonia production. Cytotoxic effects can be effectively inhibited by the reversible urease inhibitor of acetohydroxamic acid. Dose > or = 2 mM was observed with maximum safety. Models for nude xenograft mice have also been shown to suppress in vivo tumor development with A549 and MCF-7 intratumor urease injections (1–10 U/dose). Second, urease has developed indirect antitumor effects by increasing pH in combination with weak-base anticancer drugs [110].

The plant source of urease is Cucumis melo, and the diuretic activity of Cucumis melo can be seen in herbal medicines. These diuretic medicines are used to relieve blood pressure and improve urine and sodium excretion in the urine [111].

5.3 Nitrogen Metabolism and Urea Hydrolysis

Urease is essential for efficient nitrogen assimilation. Substrate (urease substrate) flows large amounts of nitrogen from the plant, which can only be recycled through ureases. This rebound will have a significant impact on rich protein crops. The germination of protein-deficient seed appears to play an important role. Arginine and ureids are derived from the urease substratum urea. Arginine is the richest depository of nitrogen in seed protein amino acids (Fig. 5) [112]. On the other hand, Ureides are essential nitrogen factors for the turnover of nucleic acid but are mainly transported in soya beans and other tropical vegetables with fixed nitrogen. Without urease, plants accumulate massive, unusable urea in both maternal and embryonic tissue. Further, urea accumulates as a dead-end to the metabolism of nitrogen when urease-negative seeds are germinated. Many seed ureases like Sumner's jack bean urease will play a part in chemical defenses [113, 114]. The nitrogen metabolism of ruminants, such as livestock, sheep, and other animals containing a forestomach, also plays a significant role. Types of Staphylococcus, Lactobacillus, and Klebsiella aerogenes responsible for urease activity in rumen sheep have been identified. The rumen is recycled with a considerable amount of animal urea, which contains ammonia as the primary source of nitrogen for most ruminal bacteria [115].

Metabolic links of urease in soybean (Glycine max). Reprinted from de Souza et al. [112] with permission from Springer nature

Urease catalyzes urea hydrolysis to carbon dioxide and ammonia. The treatment of ammonia raises the local pH of the samples. Samples are kept in a gel containing urea and a pH indicator. A color shift occurs as bacteria break down the urea. In contrast to histology, the use of rapid urease, which may be due to lower mucosal bacterial pressure in pediatrics, is slightly less susceptible [116]. The mechanism of immobilized urease has very different kinetic activity than soluble urease since it varies from the pH of the pore fluid near the enzyme’s active sites. The effect is a change from a dialyzed solution of 6.6 (soluble urease) to 7.6 and a pH of 8.0 in a 20 mM phosphate buffer to an optimum pH. The reactor template is particularly useful for calculating the kinetic parameters of the immobilized enzyme and for the design of urea removal columns [117].

5.4 Germination Of Nitrogen-limited Seeds

Urease has been shown to recycle urea-bound nitrogen in urea that is collected during early planting. The urease transcription levels in Arabidopsis thaliana increased dramatically from 2 to 4 days after germination and were maintained at maximum levels up to a minimum of 8 DAG. After germination, urease-specific activity decreased but continued to grow by approximately 75% of the seed activity in seedlings 2 DAG. The Urea values showed a modest increase of 1 DAG, which was therefore approximately parallel, to a final level of around 9 DAG. Urea levels were increased 2-to-fourfold during seedling production during inhibition by phenyl phosphorodiamidate [118]. About the time of the urea pool arginine pools (0–8 DAG) have been modified. The arginase production was tenfold between 0 and 6 DAG, consistent with the assumption that arginine is a significant source of urea. Allopurinol, an inhibitor of xanthine dehydrogenase, showed no outcome on urea levels up to 3 DAG but lowered urea injections between 5 and 8 DAG by 30–40%, indicating that purine degradation contributed well, if any, to germination. Inhibitor of urea. The relationship between urease inactivation of phenyl phosphorodiamidate and inhibition of germination, NH4NO2, or superseded amino acid was found in aged Arabidopsis plants. Activities of urease lead to a reversible injection of nitrogen by germination as urease pioneer and urea rise in- young seedlings and urease inactivation [119].

5.5 Vaccines and Enzyme-linked Immunosorbent Assay

Previous studies have shown that the first crystallized enzyme was jack bean urease, which could be used as an antigen54 that stimulates a powerful immunoglobulin response. The plant enzyme has also been studied- to understand the mechanism of defense against H. Pylori that causes gastritis ulceration and potentially gastric cancer based on catalytic activity inhibition [115]. Urease immunization can protect mice from Helicobacter pylori’s challenge, although the findings differ based on individual vaccinations, stress, and assessment methods. In comparison to the mouse, the rhesus monkeys also have H. Pylori, and therefore, a higher estimate of human efficacy will be provided. The objective of the research work was to investigate the efficacy of H. Pylori urease as a vaccine in rhesus monkeys free of specified pathogens (H. pylori). Monkeys were bred and reported free of H. pylori. Orogastric (n = 4) or intramuscular (n = 5) urease has been vaccinated against pylori. Two control monkeys were sham-vaccinated. The results of the vaccine were evaluated using quantitative gastric tissue cultures, histological methods, and serum immunoglobulin G (IgG) and salivary IgA tests in both monkeys. The use of the H. pylori strain has been tested. Despite the humoral immune response, both monkeys were infected following the helicobacter pylori challenge and there were no variations in colonization concentration. Therefore, immunization with urease would not fully defend against the challenge of H. pylori. Efficient Helicobacter pylori vaccine needs separate or possibly additional antigens and changes in host immune response stimulation [120]

For culture confirmation, 270 N isolates from Neisseria gonorrhoeae, 56 diverse Neisseria spp. isolates and 29 Moraxella isolates were evaluated with a new immunosorbent urease-based assay using novel monoclonal antibodies. The result was particular (100.00%) and sensitive (97.83%). For either Neisseria or Moraxella isolates examined. No cross-reactions were found. Serovar isolate IA-4, a serovar rarely seen in North America, obtained 50% (3 of 6) of false-negative findings [121].

5.6 Wine Industry

The presence of ethyl carbamate (a carcinogen) in wine consisting of ethanol and urea (if present) in wine is currently of great concern during wine storage. As a precautionary measure, these vintages preserved with the production of dead cells comprising acid urease eliminate urea from the wine, a possible source of ethyl carbamate [122, 123]. Increased urea levels in wine will come from the yeast activity and then become urethane due to a chemical reaction (ethyl carbamate). Other pioneers for ethyl carbamate, such as arginine-dependent citrulline and carbamyl phosphate, may be produced by lactic acid bacteria during malolactic fermentation. Fermented wines might comprise excessive quantities of urethane, especially at higher temperatures [124]. Adequate safeguards must also be taken to avert the manufacture of urethane. This includes the collection and reduction of arginine levels in grapes of appropriate starter crops for malolactic fermentation. Urease was introduced as a new wine therapy enzyme by the EU in 1997 and suitable for rare circumstances. The enzyme separates urea from ammonia and carbon dioxide to prevent the production of urethane. Lactobacillus fermentum commercial urease is successful in red wines with a concentration of 50 mg/L and white wines with a concentration of 25 mg/L. (Claus and Moysov, 2018).

5.7 Biosensors

In recent decades, enzyme-based biosensing tools have been widely developed. They have proved to be ground-breaking tools for qualitative and quantitative studies of various target substrates in a wide range of applications [125]. Various benefits provided by enzyme-based biosensors, such as high sensitivity and accuracy, compact, cost-effective, and miniature functionality, and point-of-care diagnostic tests, make them increasingly desirable for clinical studies, food-protection regulation, or intent-testing monitoring [126]. Sheppard et al. [127] have developed an experimental model for envisaging a conductimetric urea biosensor’s reaction. The biosensor in the discussion is formed by a flat interdigital electrode range, which immobilizes the enzyme urease to the surface. Enzymatic hydrolysis of urea produces ion products such as NH4+ and HCO3, raising the solution's electrode-proximal conductivity. The model integrates a diffusive transport analysis and an enzyme urea hydrolysis near the biosensor exterior with an electrical field model for interelectrode impedance computing. The model was validated by immobilizing urease in the interdigital space of interdigitalized, microfabricated electrodes through urea biosensors’ development. Reactions in urea solutions produced in deionized water were analyzed at concentrations between 10 μM and 5 mM. The model predictions are consistent with experimental results For the whole spectrum of concentrations based on rational assumptions for the parameters.

5.8 Blood Purification

As a public health disease, chronic kidney disease has attracted a lot of concern and is mainly caused by uremic contaminant accumulation in the bloodstream. Urea is a type of high-solubility representative toxin that cannot be removed easily; currently, no effective absorbers have been found in the physical adsorption to extract urea. Immobilized urease effectively eliminates urea [11, 90]. Urease is present as a toxic factor in various disease-causing bacteria. It is necessary for the establishment of the host organism and the preservation of bacterial tissue cells. Urease shows a harmful influence on human cells due to its enzymatic activity. The existence of ureolytic activity is a significant indicator of many bacterial infections. It an immunogenic enzyme believed to exist in human serum antibodies. The presence of antibodies such as rheumatoid arthritis, atherosclerosis, or urinary tract infections has been associated with the development of many long-term diseases. Patterns comparable to human proteins could arise with bacterial ureases. This mechanism, recognized as molecular imitation, contributes to the generation of autoantibodies involved in the degradation of host molecules. Detection in bacterial proteins of antibody-binding motives is a composite operation. Organic chemistry methods, such as artificial peptide libraries, are helpful in both epitome mapping and serological studies [128].

6 Conclusions and Future Prospects

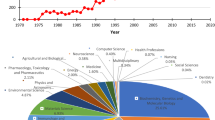

Enzyme immobilization technology is one of the most innovative developments in industrial biotechnology. Since the industrial application of the first immobilized enzymes in the 1960s, the exponential growth of enzyme immobilization methods and immobilization materials and chemical products has taken place. Designs of immobilized enzymes that adapt to different specific applications have today abandoned the traditional approach to trial and error and have gradually moved towards an optimum design, characterized by the use of enzyme immobilization technology to improve process monitoring and not just to reuse expensive ones. In a way, genetic modification complements the technology of enzyme immobilization. Urea is one of the uremic toxins that threaten human well-being. Sustainable urease with strong support reveals good hemocompatibility and high performance in urea removal. Urease is covalently grafted to robust supports. Low protein adsorption, lower coagulation times, low hemolytic association, and suppressed complement system activation and interaction were associated with immobilized urease. Even the immobilized urease exhibited remarkable urea removal capability. The accessible robust immobilized enzyme is becoming increasingly apparent from the early stage of process production, which will undoubtedly allow an early insight into process development. However, the inability to provide instructions on assessing the immobilization process and the expected efficacy of the immobilized enzyme for some applications seriously impedes a reasonable approach to designing such solid immobilized enzymes.

References

Datta S, Christena LR, Rajaram YRS (2013) Enzyme immobilization: an overview on techniques and support materials. 3 Biotech 3(1):1–9

Liang S, Wu XL, Xiong J, Zong MH, Lou WY (2020) Metal-organic frameworks as novel matrices for efficient enzyme immobilization: an update review. Coord Chem Rev 406:213149