Abstract

This work reports simple, efficient, selective protocol for the oxidation of sulfide compounds. Various sulfides were selectively and completely converted into their corresponding sulfoxides and sulfones using H2O2 as an oxidant in presence of catalytic amount of caprylic acid. The reaction proceeds at room temperature to give sulfoxide and by increasing the reaction temperature to 50 °C, this system provides selective formation of sulfone with high conversion and excellent yields. Green, convenient, easy work-up, chemoselectivity, broad substrate scope and regeneration of catalyst are the important highlights of this protocol.

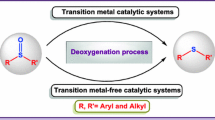

Graphical Abstract

Using H2O2 as an oxidant in presence of catalytic amount of caprylic acid various sulfides were selectively and completely converted into their corresponding sulfoxides and sulfones.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Oxidation of sulfide is the most important synthetic aspects for various industries such as pharmaceuticals, chemicals and petrochemicals [1–4]. Now-a-days the chemical research is directed towards developing green processes. Innovation in a synthetic route becomes inefficient without a green approach. Oxidation of sulfide gives formation of sulfoxide or sulfone compounds with the help of oxidant. The main problem encountered during this type of oxidation is chemoselectivity and due to this the reaction results in the mixture of sulfoxide and sulfone. Therefore, selective oxidation of sulfide still remains one of the most stimulating tasks for researchers. High atom economy is also an essential contribution to the overall process efficiency. Numerous reagents and oxidative procedures are available for this transformation [5–11]. Use of oxidants such as hydrogen peroxide with various transition metal catalysts under homogenous and heterogeneous conditions for this transformation is reported [12–17]. Oxidation also worked well in supercritical carbon dioxide as an environmentally benign reaction medium [18, 19]. Previous reports also suggested that this type of oxidation of sulfides is carried out with the use of acid–oxidant system [20–24], deep eutectic solvent–oxidant system [25], tetrazole amides-H2O2 system [26], zirconium tetrachloride [27] and silica supported sodium periodate [28], etc. However, by acknowledging the all reported work in this field, still hazardous metal contamination or preparation and use of metal catalysts, solvents, oxidants, long reaction time, high temperature, toxic waste generation, tedious workup, formation of side products etc. significantly lower their appeal. Therefore, development of new oxidation systems to overcome these drawbacks is necessary.

The use of green oxidant, i.e. hydrogen peroxide which is cheap, attractive, readily available and eco-friendly with water as a byproduct. The oxidative power of H2O2 is highlighted in several publications [29–31]. As per the principles of green chemistry, the process should be ‘green’ which implies that green techniques/chemicals should be used in order to make reaction conditions eco-friendly. The inorganic acids such as HCl, H2SO4 are not eco-friendly and thus use of such acids should be avoided which causes pollution in environment. Medium chain fatty acids (MCFAS) have more advantages as compaired to other acids such as non-toxic in nature, easy to handle and reusable. Caprylic acid is one of the medium chain fatty acid (MCFA) which is cheap and easily available. It is obtained from butter and other animal fats. It is issued as an algaecide, bactericide, and fungicide in nurseries, greenhouses, garden centers, and interiorscapes on ornamentals, dairy equipment, food processing equipment, breweries, wineries, and beverage processing plants in the manufacture of perfumes and flavors. In this context, with the aim to improve the efficiency and eco-friendly conditions of catalytic processes, we have developed new oxidation system, i.e. H2O2 with caprylic acid as a part of our research work on oxidation of organic compounds [32]. Herein, we report selective oxidation of sulfide to sulfoxide and sulfone with hydrogen peroxide in presence of catalytic amount of caprylic acid (Scheme 1).

The present protocol is found to be effective with acetonitrile (MeCN) as a solvent. Higher selectivity was achieved in the oxidation of sulfides to sulfoxides and sulfones. By increasing the reaction temperature to 50 °C for oxidation of sulfides to sulfones provides excellent conversion and maximum yield. Use of dichloromethane (CH2Cl2) gives product separation easily. Moreover, the sodium caprylate obtained after the workup is also used in foods as abinder, emulsifier in cosmetics etc. To best of our knowledge, this is the first oil/MCFA based oxidation system which offers high selectivity, purity, good to excellent yields, metal free approach, regeneration of catalyst, easy reaction condition with workup process which avoid expensive catalyst and harsh reaction condition.

2 Experimental

2.1 Materials and Methods

All chemicals were purchased from Sigma Aldrich, S.D Fine Chemical, commercial suppliers and used without further purifications. The MCFAS were procured from Loba Chemie Pvt Ltd. The reaction was monitored by TLC and GC analysis and performed on PerkinElmer Clarus 480. GC equipped with flame ionized detector with capillary column (Elite-1701, 30 m × 0.32 × 0.25). The product mass conformed by GC–MS–QP 2010 instrument (Rtx-17, 30 m_25 mm ID, film thickness 0.25 µm, column flow: 2 mL min-1, 80–240 °C at 10 °C/min rise). The products were purified by column chromatography using (60–120 mesh) silica gel with n-hexane and ethyl acetate as solvent. The pure product 1H NMR spectroscopic data was recorded on a Varian Mercury plus-300 spectrometer using CDCl3 as a solvent and TMS as internal standard. Melting or boiling points of the products were determined on a Galaxy scientific melting/boiling point apparatus.

2.2 General Procedure for Oxidation of Sulfide to Sulfoxide and Sulfone Compounds (Table 3)

An oven-dried Schlenk flask was allowed to cool to room temperature and charged sequentially with sulfide (1.0 mmol), MeCN (3.0 mL) and caprylic acid (10/20 mol%). The reaction was then activated by slow addition of 30% H2O2 (1.2/2.4 equiv.) and stirred at room temperature for the required time as given in Table 3. The progress of reaction was monitored by GC. After completion of the reaction, the reaction was quenched by adding aqueous solution of 10% Na2SO3 to the reaction mixture. Then the product was extracted with CH2Cl2 (30 mL) and then washed with distilled water (10 mL). The organic extract was dried over Na2SO4 and the solvent was removed under reduced pressure. The resultant product was purified by column chromatography using silica gel (60–120 mesh) with n-hexane and ethyl acetate as solvent to get the pure product. The structure of the product was confirmed by GC–MS, M.P./B.P. and 1H NMR spectroscopic techniques.

2.3 General Procedure for Oxidation of Sulfide to Sulfone Compounds (Table 4)

An oven-dried Schlenk flask was allowed to cool to room temperature and charged sequentially with sulfide (1.0 mmol), MeCN (3.0 mL) and caprylic acid (20 mol%). The reaction was then activated by the addition of 30% H2O2 (2.4 equiv.) and stirred at 50 °C for the required time as given in Table 4. The progress of reaction was monitored by GC. After completion of the reaction, the reaction was quenched by adding aqueous solution of 10% Na2SO3 to the reaction mixture. Then the product was extracted with CH2Cl2 (30 mL) and then washed with distilled water (10 mL). The organic extract dried over Na2SO4 and the solvent removed under reduced pressure. The resultant product was purified (if necessary) by column chromatography using silica gel (60–120 mesh) with n-hexane and ethyl acetate as solvent to get the pure product. The structure of the product was confirmed by GC–MS, M.P./B.P. and 1H NMR spectroscopic techniques.

3 Results and Discussion

Initially, for optimization purpose diphenyl sulfide 1a (DPS) was selected as a substrate and oxidation of this substrate was studied as a model reaction (Table 1) with acetonitrile (MeCN) and caprylic acid. Oxidant plays a key role in this reaction. The effect of the oxidant on DPS was studied by varying the amount of 30% H2O2 from 0.8 to 2.4 equiv. (Table 1, entry1–7). H2O2 turned out to be the best oxidant as it gave 100% conversion of the products (Table 1, entry 3–7) at room temperature. It was observed that 1.2 equiv. of H2O2 gives 97% of diphenyl sulfoxide 2a in 30 min (Table 1, entry 3) and 2.4 equiv. of oxidant gives 100% conversion of 1a to diphenyl sulfone 3a in 90 min (Table 1, entry 7). However, during conversion of 1a–3a, time required for complete conversion was higher as compaired to that of 1a–2a. So we decided to increase the temperature to 50 °C which provided excellent yield and also helped to reduce the time during the sulfide to sulfone conversion (Table 1, entry 8). When the oxidation of diphenyl sulfide was carried out using different amounts of H2O2 such as 0.8 and 1.0 equiv. of oxidant, the reaction did not go to completion (Table 1, entry 1–2). However, absence of caprylic acid in model reaction showed incomplete conversion of product even after 24 h (Table 1, entry 9). It is also clear that the selectivity with respect to 3a also increases as the caprylic acid amount increased from 10 to 20 mol% (Table 1, entry 4–8).

In further investigation, we carried out the model reaction in different solvents such as toluene, dichloromethane (DCM), methanol, hexane, chloroform (CHCl3), acetone, ethyl acetate (EtOAc) but found less conversion and mixture of 2a and 3a (Table 1, entry 10–16). The oxidation was investigated with various oxidants such as tert-butyl hydrogen peroxide (TBHP), oxone, peracetic acid and m-CPBA but found less conversion of 1a–2a (Table 1, entry 17–20).

In order to establish the catalytic activity of caprylic acid, we performed the model reaction with other MCFAS and LCFAS to investigate effect of medium chain fatty acid (MCFA) and long chain fatty acid (LCFA) on the oxidation of 1a–2a (Table 2, entry 1–6). We found that higher conversion was obtained only with caprylic acid while others failed to give high conversion of 1a–2a. This proves that caprylic acid is the most suitable catalyst for the oxidation of sulfides.

It was observed that higher conversion and selectivity for oxidation of sulfide to sulfoxide or sulfone is solubility dependent and excellent under homogenous conditions. Acetonitrile helps the reaction to proceed in homogeneous phase which provides proper mixing of substrate with caprylic acid and oxidant. Acetonitrile also plays an important role in this oxidation as the nitrogen atom of –CN stabilizes the partial positive charge on the sulfur atom in the transition state [23, 33]. Sulfoxide formation is an intermediate step during the oxidation of sulfide to sulfone. Since sulfoxide is less nucleophilic in nature, formation of sulfone takes longer time as compared to that of sulfoxide. We increased the amount of oxidant and caprylic acid along with increasing temperature to 50 °C. This helped to give selective and complete conversion of sulfide to sulfone without formation of sulfoxide.

In order to generalize the scope of the reaction, a series of structurally diverse sulfides were subjected to oxidation under optimized reaction conditions, and the results are presented in Table 3. Oxidation of alkyl, aryl–alkyl, diaryl sufides etc. produced excellent yields of corresponding sulfoxides or sulfones depending upon the reaction condition (Table 3, entry 1–8). The sulfoxide and sulfone formation occurred in specified time in Table 3. DPS 1a was easily and selectively oxidized to 2a and 3a with excellent yields (Table 3, entry 1). Similarly, methyl phenyl sulfide 1b also oxidized to 2b and 3b selectively (Table 3, entry 2). The influence of electron donating or withdrawing group on substrate was not significant in this protocol. The substrates bearing electron donating and withdrawing groups were smoothly oxidized to the corresponding sulfoxide and sulfone selectively (Table 3, entry 3, 4). Dibenzyl sulfide 1e and tetrahydrothiophene 1f also oxidized selectively with good yields (Table 3, entry 5, 6). Aliphatic sulfides such as dimethyl sulfide 1g and dibutyl sulfide 1h were easily oxidized (Table 3, entry 7, 8).

The oxidation of sulfide to sulfone at 50 °C is achieved with high yields and selectivity and the results are presented in Table 4. A clean synthetic method was developed, in which sulfones were redily precipitated as the pure product with high yields (Table 4, entry 1–10). The sulfone formation occurred in specified time as given in Table 4. The product analysis study showed that sulfone was the only product formed under present reaction conditions. It is also clear that aromatic or aliphatic sulfides are chemoselectively oxidized to sulfones (Table 4, entry 1–10). Also no effect on sulfone formation was observed due to electron donating or withdrawing group present on sulfides (Table 4, entry 3–7). This indicates that both the protocols, one in which without heating sulfoxide is formed selectively at room temperature and the other in which sulfone is formed by heating the reaction mass at 50 °C provide excellent yields and purity. This shows that both the protocols are very selective and easily controllable.

The regeneration of a catalyst was carried out and then the activity was tested. The oxidation of diphenyl sulfide 1a to diphenyl sulfone 3a was carried out by using the catalyst. After completion of the reaction, the reaction was quenched by adding aqueous solution of 10% Na2SO3 to the reaction mixture. Then the product was extracted with CH2Cl2 (30 mL) and then washed with distilled water (10 mL). The aqueous layer obtained from this method was again acidified with 0.1 N HCl till the pH became acidic. Then aqueos layer was extracted with CH2Cl2 (25 mL). This extract was dried over Na2SO4 and the solvent was removed under reduced pressure. The resultant caprylic acid was reused in next cycle. The results of the recycling experiments with the yields of corresponding sulfone was still higher after three cycles and then slightly decreases Fig. 1. For the loss of catalyst in each reusability experiment, the diphenyl sulfide 1a added should be decreased proportionally in each cycle.

4 Conclusions

In summary, we have developed a simple, highly efficient and environmentally benign methodology for the oxidation of sulfide compounds by using new oxidation system (H2O2-caprylic acid). This MCFA based oxidation is a metal and additive free protocol for the oxidation of sulfide compounds. Here, these two protocols have a good substrate scope with excellent yields as well as high selectivity. The transformation worked well with the liquid and solid sulfides with homogeneous reaction mixture. Due to its green, convenient and easy work up procedures with regeneration of catalyst, we believe that new oxidation system surpasses previously reported systems. These developed protocols promise broad applications in organic synthesis. Importantly, significant yield and quality is achieved which is the noticeable achievement of this protocols. Other applications of this new oxidation system in organic reactions are under way in our laboratory.

References

Frenanez I, Khiar N (2003) Chem Rev 103:3651

Munoza M, Romanellia G, Bottob IL, Cabelloa CI, Lamonierc C (2010) Appl Catal B 100:254

Ghaemi A, Rayati S, Zakavi S, Safari N (2009) Appl Catal A 353:154

Spencer CM, Faulds D (2000) Drugs 103:321

Romanowski G (2013) J Mol Catal A Chem 368:137

Mba M, Prins LJ, Zonta C, Cametti M, Valkonen A, Rissanen K, licini G (2010) Dalton Trans 39:7384

Khurana JM, Nand B (2010) Can J Chem 88:906

Alcon MJ, Corma A, Iglesias M, Sanchez F (2002) J Mol Catal A Chem 178:253

Das R, Chakarborty D (2010) Tetrahedron Lett 51:6255

Mandal M, Chakarborty D (2015) RSC Adv 5:12111

Chen TH, Yuan ZB, Carver A, Zhang R (2014) Appl Catal A 478:275

Bagherzadeh M, Latifi R, Tahsini L, Amini M (2008) Catal Commun 10:196

Matteucci M, Bhalay G, Bradley M (2003) Org Lett 5:235

Gao J, Guo H, Liu S, Wang M (2007) Tetrahedron Lett 48:8453

Raju BR, Sarkar S, Reddy U C, Saikia AK (2009) J Mol Catal A Chem 308:169

Jayaseeli AMI, Rajagopal S (2009) J Mol Catal A Chem 309:103

Gunaratne HQN, McKervey MA, Feutren S, Finlay J, Boyd J (1998) Tetrahedron Lett 39:5655

Mello R, Olmos A, Aragonés AA, Rodríguez AD, Núñez MEG, Asensio G (2010) Eur J Org Chem 32:6200

Karmee SK, Greiner L, Kraynov A, Muller TE, Niemeijer B, Leitner W (2010) Chem Commun 46:6705

Rostami A, Akradi J (2010) Tetrahedron Lett 51:3501

Jafarpour M, Ghahramaninezhad M, Rezaeifard A (2014) New J Chem 38:2917

Golchoubian H, Hosseinpoor F (2007) Molecules 12:304

Gayakwad EM, Patil VV, Shankarling GS (2016) New J Chem 40:223:24.

Tumula VR, Bondwal S, Bisht P, Pendem C, Kumar J (2012) React Kinet Mech Cat 107:449

Dai DY, Wang L, Chen Q, He MY (2014) J Chem Res 38:183

Secci F, Arca M, Frongia A, Piras PP (2014) New J Chem 38:3622

Bahrami K (2006) Tetrahedron Lett 47:2009

Varma RS, Saini RK, Meshram HM (1997) Tetrahedron Lett 38:6525

Rostami A, Tahmasbi B, Abedi F, Shokri Z (2013) J Mol Catal A Chem 378:200

Islam SM, Roy AS, Mondal P, Tuhina K, Mobarak M, Mondal J (2012) Tetrahedron Lett 53:127

Jereb M (2012) Green Chem 14:3047

Wagh RB, Gund SH, Nagarkar JM (2016) J Chem Sci 128:1321

Malkov AV, Derrien N, Barlog M, Kocovsky P (2014) Chem Eur J 20:4542

Acknowledgements

The author (RBW) is greatly thankful to the UGC (University Grant Commission, India) for providing the junior research fellowship (JRF).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wagh, R.B., Nagarkar, J.M. A Simple Metal Free Oxidation of Sulfide Compounds. Catal Lett 147, 181–187 (2017). https://doi.org/10.1007/s10562-016-1932-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-016-1932-1