Abstract

In the present study, glutaraldehyde (GLA) activated gelatin hydrogel was used as a solid support to encapsulate the manganese peroxidase (MnP; E.C. 1.11.1.13) produced by Ganoderma lucidum IBL-05 under pre-optimized growth environment. Through gelatin-assisted immobilization, a maximal of 83.2 ± 2.91 % immobilization yield was achieved at optimum conditions of gelatin; 20.0 % (w/v), GLA 0.25 % (v/v) after 2 h activation time using 0.6 mg/mL of enzyme concentration. In contrast to aqueous form, the insolubilized MnP presented its maximum activity at pH 6.0 and 60 °C. Inevitably, enzyme immobilization significantly (P < 0.05) increased the thermal stability profile of in-house isolated MnP. At 60 °C, maximum activity of free MnP decreased to 14.2 ± 1.4 %, whereas immobilized MnP retained 70.18 ± 3.2 % of its original activity after 120 min. To explore the industrial applicability of MnP, the immobilized MnP was tested for apple and orange fruit juice clarification features in a packed bed reactor system. The immobilized MnP showed commendable results in the de-bittering’s of investigated fruit juices, decreasing 42.7 % of the original apple juice color and 36.3 of its turbidity. Whereas, the color and turbidity reduction characteristics of orange juice were 51.5 and 43.6 %, respectively. After six consecutive cycles, the immobilized-MnP was able to retain more than 60.0 % of its initial activity. Collectively, catalytic, thermo-stability and clarity amelioration features of the gel-entrapped MnP suggest a high potential of enzymatic treatment for biotechnological exploitability.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Polyphenols in fruit juices are a natural source of antioxidants and are associated with enormous health benefits [1]. Nevertheless, these phenolic constituents can interact with proteins, leading to an increase in turbidity, color intensification, fragrance, and flavor alteration, and formation of haze or sediments during storage, markedly affecting product shelf-life and consumer interest [2–4]. The scientific community, as well as industrialists commonly, use clarification processes through physicochemical adsorbents or filtration technology to stabilize fruit juices and to minimize the impact of above-mentioned phenomena on beverages. The processed juices through conventional technologies not always remain stable, and tend to produce obvious haze and browning during the processing cycle. This is mainly because of the reactive phenolic compounds that cannot be efficiently eliminated by these techniques [5, 6].

In recent years, extensive research efforts have been devoted to find out some effective and economical route for selective removal of these compounds. Being less-expensive, more efficient and environmental acceptability, enzymes are continuously gearing the importance as a green catalyst in this concern. Oxidoreductases from various microbial sources have been demonstrated to perform outstandingly; particularly fungal laccases and peroxidases have displayed a great prospect for clarification purposes [2, 6–10]. Previously, several authors have documented the use of MnPs as stabilizing agents, due to their capability to catalyze the oxidation of phenolic compounds present in juices [2, 7]. Besides, this enzyme has considerable biotechnological potential in plant biomass delignification, bioremediation, bio-pulping, bio-bleaching, oxidation of organic pollutants, textile, animal feed, cosmetics, detergent manufacturing, and biosensors and biofuel cell development [11–16]. Notwithstanding all the above-mentioned advantages, application of enzymes at the industrial level is often restrained by lack of catalytic efficiencies and marginal operational stabilities. Immobilizing a biocatalyst can be considered a straightforward way to overcome these obstacles [17–19]. Additionally, insolubilized enzymes are essentially resistive to environmental disquiets like pH, temperature and are amenable to a wide variety of process formats [19, 20].

A diversity of new carrier-supports and technologies such as mutation, chemical engineering modification, gel entrapment and surface binding have been developed to encapsulate ligninolytic enzymes [21]. Gel entrapment is of utmost importance because of cheapness, gentle preparation conditions, non-toxicity, and good performances [22, 23]. In the present study, an indigenous MnP isolated from Ganoderma lucidum IBL-05 was encapsulated in gelatin by entrapment and the conditions for immobilization and characterization of the free and immobilized enzyme were investigated. Stability and reusability characteristics of immobilized MnPs were also assessed in contrast with the equivalent soluble counterpart. The solid-optimized biocatalyst was subsequently exploited in the clarification of fruit juices.

2 Materials and Methods

2.1 Chemicals/Reagents

Veratryl alcohol, ammonium sulfate, Sephadex G-100, and glutaraldehyde were obtained from Sigma-Aldrich (USA). All other chemicals/reagents used, in this study, were of analytical laboratory grade and mainly obtained from Sigma-Aldrich (USA) and Scharlau (Spain).

2.2 Solid State Fermentation for MnP Production

The MnP was produced via solid state fermentation of rice straw by G. lucidum IBL-05. The fermentation was carried out in triplicate shake flasks (250 mL), each containing 5.0 g rice straw in the controlled environment of 30 ± 0.5 °C under an agitation speed of 150 rpm. After stipulated time, the enzyme from fermented mesh was extracted by centrifugation (Eppendorf 5415 C, Germany) at 4000×g for 10 min, and resulting clear supernatant was assessed for MnP activity. 100 mL sterile production medium (pH 4.5) containing 2.0 % glucose and 0.2 % yeast extract was inoculated with a loop-full culture of G. lucidum IBL-05 and incubated at 30 °C (150 rpm) for 5–7 days. After getting satisfactory spores counting (1 × 106–1 × 108 spores/mL), this medium was served as inoculum medium for enzyme production [11]. Inoculum medium comprised: glucose (10.0 g/L); ammonium tartrate (0.2 g/L), KH2PO4 (0.21 g/L), MgSO4 7 H2O (0.05 g/L), CaCl2 (0.01 g/L), thiamine (0.001 g/L), 10-mL of Tween 80 (10 %), 10 mL veratryl alcohol (100 mM) and 10 mL trace mineral solution (S). The S contained CuSO4, (0.08 g/L); NaMoO4, (0.05 g/L), MnSO4·H20, (0.07 g/L), ZnSO4·7H2O (0.043 g/L) and FeSO4, (0.05 g/L).

2.3 Purification and Immobilization of MnP

The MnP purification was carried out by adopting four-step purification protocol involving ammonium sulfate fractionation, dialysis, diethylaminoethyl (DEAE) cellulose ion exchange and Sephadex G-100 gel permeation chromatography in a manner elaborated earlier [24]. The purified MnP fraction was immobilized in gelatin gel matrix according to the procedure reported earlier [23]. Briefly, various gelatin concentrations (10–25 % w/v) were prepared in water at 50 °C. 1 mL of the MnP was thoroughly mixed to the gelatin solution and resulting suspension was casted on the pre-assembled glass plate and allowed to cool at room temperature followed by 2.0 h at 4 °C. Upon hardening, the gelatin immobilizate was cut into small gel cubes which were then added into 0.25 % glutaraldehyde (GLA) solution. After occasional shaking for 2 h, immobilizate pieces were washed several times with distilled water and finally with 50 mM Na-malonate buffer. The immobilizate pieces were assessed for enzyme activity and stored in the same buffer at 4 °C for further application.

2.4 MnP Activity Assay

The Spectrophotometric procedure based on the transformation of Mn2+ to Mn3+ was adopted to analyze the catalytic activity of MnP by measuring absorbance at 270 nm (Ɛ270 = 11,590 M−1 cm−1) [25]. The reactive mixture contained 1.7 mL of Na-malonate buffer (50 mM, pH 4.5), 50 μL of MnSO4 (400 mM), 200 μL of enzyme and 50 μL of H2O2 (16 mM). One unit (IU) of MnP catalytic activity was defined as “the quantity of enzyme which results in 10.0 % of OD270 nm increase per minute under the given assay conditions”.

2.5 Determination of Total Proteins

Total proteins were quantified from standard curve standardized with bovine serum albumin as a calibration standard. 10 µL of MnP was mixed with 1.0 mL of the Bradford reagent and allowed to incubate at 37 °C for 15 min [26]. After agitation, the optical density was recorded on a double beam UV/Vis spectrophotometer (Shimadzu UV-2700) at 595 nm.

2.6 Characterization of Free and Immobilized MnPs

Influence of pH on the catalytic activities of free MnP and immobilized MnP were studied by altering the pH of assay solutions from 3.0 to 10 using different buffers. The samples were incubated in different pHs buffer solution prior to carrying out enzyme-substrate assay procedure.

The temperature profile of free MnP and immobilized MnP was examined as follows: both MnPs forms were incubated in each temperature ranging from 25 to 65 °C (5 °C interval) for 1 h before measuring their catalytic activities using a standard assay protocol as mentioned above.

In order to analyze thermal inactivation profile, free and immobilized MnPs were heated at 60 °C in Na-malonate buffer (50 mM, pH 4.5) for the designated time period (up to 240 min) and residual enzyme catalytic activities were monitored as discussed before.

For all experiments, the concentration of enzyme and assay substrate (MnSO4) was kept fixed to investigate the effect of pH, temperature and thermal inactivation of MnP. To ensure the reproducibility, all the characterization studies were repeated at least three times and data reported are mean of the three independent experiments. The activities were denoted as percent of relative activity with reference to highest activity which was considered as 100 %.

2.7 Fruit juice Clarification and Reusability Efficiency

Apples and oranges were procured from a local fruit market of Shanghai-China, rinsed in distilled water and triturated. The extracted pulps were filtered through three layers of gauze, and resulting mixtures were briefly shaken followed by centrifugation at 4000×g for 30 min at 4 °C. A treatment reactor system based on the packed bed of gelatin-matrix entrapped-MnP was used for the clarification purposes of both fruit pulps (Fig. 1). 100 mL of both centrifuged juices were eluted through a column incorporating 5.0 g of immobilized MnP derivative as a green biocatalyst. Continuous juices flow though the column was sustained by means of a peristaltic pump (Amersham Pharmacia Biotech.) with a flow rate of 1.0 mL/min for 60 min. Samples were collected from the outlet stream before and after treatment for the physicochemical analyses such as color, turbidity [27], total phenols [28] and antioxidant activity [29]. After reaching maximum juices clarification, packed bed reactor system (PBRS) was washed with a continuous flow of Na-malonate buffer (50 mM, pH 4.5) for 30 min. After careful washing, the treatment process was repeated for six cycles at regular intervals under the same conditions. After every cycle, the samples were collected from the outlet stream and analyzed as mentioned above.

2.8 Statistical Analysis

All the data reported in this study was trialed using three replicates under the same working environment. A statistical-based software package i.e. SPSS Statics 21 was used to evaluate any of the statistical differences.

3 Results and Discussion

3.1 Enzyme Purification

Solid state fermentation of agricultural waste rice straw was carried out by an indigenous white-rot fungal strain G. lucidum IBL-05 using previously optimized conditions. Maximum recovery of MnP activity (679.13 ± 3.4 U/mL) was achieved in the culture filtrate after 5 days under a sterile inert environment. The cell-free crude MnP produced was purified through a series of purification steps including ammonium sulfate fractionation, dialysis, and two chromatographic (ion exchange and gel filtration chromatography) techniques. Enzymatic and specific activities of crude and purified MnPs are summarized in Table 1. After final purification, the enzyme was 7.59-folds purified with percent recovery and specific activity of 27.12 and 962.10 U/mg, respectively.

3.2 Immobilization of MnP on Gelatin Gel

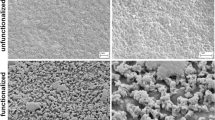

The quest for simple and cost-effective matrices or strategies for encapsulating enzymes is conceived as one of the important advances in biotechnology [16, 23, 30]. A purified MnP fraction from G. lucidum was incorporated inside gelatin matrix with an expectation that the micro-environment provided by the gel might be suitable for an enzyme to retain its biologically active conformation, and thus enzymatic activity. Varying concentrations of gelatin solution [ranging from 10 to 20 % (w/v)] were attempted to achieve the most suitable concentration for maximum enzyme immobilization yield (IY). Results shown in Fig. 2 evidenced that gelatin gel at a concentration of 20 % appraised the preeminent entrapped MnP activity. Beyond this optimal point, IY was reduced plausibly because of less tightly cross-linked feeble gelatin gel which leads to greater pore size in the gel resulting in increased percolation of the enzyme. Similarly, the diminished IY at elevated gelatin concentration (beyond 20 %) may be the result of steric hindrance [30].

Subsequently, MnP coupled gelatin gel was treated with different concentrations of organic hardener glutaraldehyde (GLA) solution (ranging from 0.05 to 2.5 %) for different activation time (ranging from 1.0 to 3.0 h) to gain immobilized MnP with desired mechanical rigidity (Table 2). Gel entrapment using GLA as a crosslinking agent has emerged a very simple, robust and gentle immobilization approach applicative to a wide variety of industrially relevant enzymes [23]. Results revealed that gelatin gel cross-linked with 0.25 % GLA concentration for a contact time of 2 h contributed good mechanical stability as well as IY. Excess GLA concentration caused steric hindrance, and as a consequence, IY is decreased. GLA generates aldehyde groups on the surface of immobilization matrix which forms Schiff base with an amino group of protein, and support the conjugation of enzyme molecule with a matrix. It not only acts as cross-linking agent but also reinforces the gel as well [31]. The appropriate concentration of MnP that gives the maximum activity of immobilizate was found to be 0.6 mg/mL representing that utmost numbers of MnP molecules were incorporated into the gelatin surface at this concentration [30, 31].

3.3 Responses of Free and Immobilized MnPs on Various Physicochemical Changes

3.3.1 Effect of pH on MnP Activity

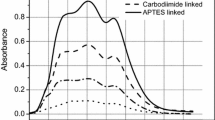

The influence of pH and temperature on catalytic activity is of immense importance in evaluating the most favorable working conditions for enzyme functioning. Therefore, relative activities of soluble and gelatin-encapsulated MnPs were investigated at varying pHs (ranging from 3.0 to 10.0) and reaction temperatures (ranging from 25.0 to 65.0 °C) to profile their comparative performance, and results thus, obtained are displayed in Fig. 3. Free and immobilized MnP presented optimum activity at pH 5.0 and 6.0, respectively. The optimum pH of the enzyme was displaced by 1.0 pH unit toward the alkaline region (high pH) in the case of gelatin-encapsulated MnP. This alkaline shift could be due to secondary interactions (i.e., ionic, polar or hydrogen interactions) between the protein and polymeric network [16], or due to increased hydrogen ion (H+) concentration in the enzyme interior micro-environment necessitating a more basic medium for optimum activity [24]. Relatively lower catalytic activities were noted at acidic and basic pH values presumably due to protonation of different amino groups (NH2) that play a significant role in the stability of MnP enzyme [15, 32, 33].

In contrast to free form, the immobilized MnP-derivative proved to be actively stable at wider pH ranges. At pH 3.0 and 10.0, immobilized enzyme displayed greater catalytic activity than that of free counterpart essentially signifying the role of carrier support in retaining catalytically active conformation of the biocatalyst. The type of enzymatic reaction, as well as the degree of interaction of the enzyme with supporting network, determines the extent of an enzyme by changing its conformation [33–35]. Previously, optimum pH of the gelatin encapsulated tyrosinase was shifted toward the alkaline region than that of native enzyme [22]. In a variation to this, free as well as gelatin entrapped invertase demonstrated optimum catalytic activity at the similar pH, being around pH 5.0. Nevertheless, carrier-supported enzyme showed higher relative activity at pH values above 6.0 as compared to corresponding free enzyme [23].

3.3.2 Effect of Temperature on MnP Activity

The temperature profile, as illustrated in Fig. 4, revealed that MnP in free-state exhibited optimum catalytic activity at 35 °C; whereas, this temperature optimum was observed to be shifted to the elevated temperature in the case of enzyme conjugation on gelatin matrix, and immobilized state showed maximum activity at 60 °C. The lower vulnerability of the carrier-coupled enzyme towards temperature-dependent conformational changes might be rationalized for the considerable improved thermal stability following immobilization [33, 36]. There are certain reports in the literature where similar shifts in temperature optima have been observed for immobilized MnP using different carrier-supports i.e., Asgher et al. [24] reported that sol-gel entrapped MnP fraction showed the highest activity at 70 °C as compared to the comparable free enzyme. Gelatin insolubilized invertase displayed optimum activity at 70 °C, while soluble enzyme lost all of its activity at the same temperature [23]. In another study, the maximum activities of alginate and gelatin entrapped enzymes were achieved at 35 and 40 °C, accordingly [22], as compared to the free counterpart (20 °C).

3.3.3 Heat Inactivation Kinetics at 60 °C

The thermal inactivation studies of MnP in the free and immobilized state were carried out at 60 °C up to 240 min without assay substrate, and results are illustrated in Fig. 5. A pronounced enhancement in a tolerance capacity against thermal denaturation was recorded in case of an immobilized form of MnP than that of non-immobilized free form. Immobilized MnP preserved 70.18 ± 3.2 % of its original activity after incubation at 60 °C for 120 min whereas only 14.2 ± 1.4 % activity was noted in the case of free MnP at the same time period. After 240 min, the free MnP almost lost all of its original activity; however immobilized MnP maintained 42.15 ± 1.9 % activity. This improved thermally-stable attribute of MnP succeeding gelatin immobilization could be valuable in terms of potential applications [16]. The restricted conformational flexibility of enzyme in immobilized state might be the possible explanation for significant augmentation of thermal transition of an enzyme [37]. Similar reports have been documented earlier in literature where enzymes displayed marked thermal and durable stability features when they were immobilized in gelatin matrix [22, 38].

3.4 Fruit Juice Clarification Study and Reusability Efficiency

The fruit juices treatment efficiency of immobilized MnP was evaluated choosing apple and orange juices and results before and after enzymatic treatment are displayed in Fig. 6. It was observed that immobilized MnP treatment caused 42.7 and 36.3 % of the color and turbidity removal of apple juice, respectively. Whereas the color and turbidity reduction of orange juice was noted to be 51.5 and 43.6 %, respectively by the concerted action of MnP-gelatin biocatalyst, making immobilized MnP derivative to be a good candidate for industrial relevancy. Since the elimination of phenols in a gentle manner was the objective of enzymatic treatment, encapsulated MnP derivative displayed the remarkable application potential, as the mild MnP catalyzed oxidation reaction decreased the antioxidant capacity of the apple juice by 38.3 %; whereas in case of orange juice MnP-gelatin biocatalyst removed up to 66.7 % of the phenolic compounds that ultimately leading to 41.6 % reduction in antioxidant capacity. Control experiments using gelatin solid support without incorporated enzyme showed no phenolics removal, signifying that phenol reduction was predominantly attributed to the intensive catalytic action of MnP enzyme.

Clarified juices are natural pulpless juices without any cloudy appearances [7, 39]. In an earlier study, de Souza Bezerra et al. [40] reported that green coconut fiber (GCF) encapsulated laccase reduced the turbidity (61.0 %) and color (29.0 %) of the apple juice in a very gentle oxidation mode. Similarly, Manavalan et al. [10] treated the pomegranate, lemon and apple juice by G. lucidum-derived MnP and recorded the significant reduction of phenolic contents up to 89, 85 and 78 %, respectively. Berry pomegranate juice-treated by formulated ligninolytic enzymes was observed to be clearer as compared to free enzymes [7].

The phenolic compounds present in the raw fruit juices are responsible for the formation of a cloudy appearance of juices during storage [7]. Ligninolytic enzymes (manganese peroxidase, lignin peroxidase, and laccase) can catalyze the oxidation of juice phenols to highly reactive o-quinones compounds, which undergo spontaneous polymerization to generate insoluble higher molecular weight compounds. These compounds could easily be separated by centrifugation, while lighter oligomers may remain in the supernatant resulting brownish and turbid, as characterized by high OD values at 420 and 650 nm, accordingly [2, 6, 7, 40]. Moreover, the immobilized MnP derivative exhibited more than 60 and 63 % of its original activity for the oxidation of phenolic compounds in apple and orange juice, respectively, after six consecutive cycles of reusability (Fig. 7). It is concluded that immobilization support prevented the MnP enzyme from inactivation as well as boosted its catalytic efficacy and stability to efficiently clarify the tested juices. Therefore, it can replace the conventional ultrafiltration process and can be employed in food manufacturing industries for clarification of juices in order to make the process more economical and sustainable.

4 Conclusions

In light of current findings, gelatin hydrogel is considered an excellent supporting matrix for the immobilization of fungal MnP. It endowed the encapsulated enzyme with significant improvements in certain desired catalytic traits such as thermal stability, reusability, and resistance to environmental perturbations (extreme pH and temperature) that are imperative for economizing enzyme bioprocessing. Moreover, MnP-gelatin derivative exhibited encouraging results for clarifying fruit juices and showed a promising capability to oxidize phenolic compounds in several successive batches. The study suggests the potential applications of immobilized MnP for industrial food and beverage applications.

References

Agcam E, Akyıldız A, Akdemir Evrendilek G (2014) Food Chem 143:354–361

Neifar M, Ellouze-Ghorbel RAOUDHA, Kamoun A, Baklouti S, Mokni A, Jaouani A, Ellouze-Chaabouni SEMIA (2011) J Food Process Eng 34(4):1199–1219

Ozdal T, Capanoglu E, Altay F (2013) Food Res Int 51(2):954–970

Pezzella C, Guarino L, Piscitelli A (2015) Cell Mol Life Sci 72:923–940

Friedman M (1996) J Agric Food Chem 44(3):631–653

Lettera V, Pezzella C, Cicatiello P, Piscitelli A, Giacobelli VG, Galano E, Sannia G (2016) Food Chem 196:1272–1278

Gassara-Chatti F, Brar SK, Ajila CM, Verma M, Tyagi RD, Valero JR (2013) Food Chem 137(1):18–24

Zhou XW, Cong WR, Su KQ, Zhang YM (2013) Crit Rev Microbiol 39(4):416–426

Manavalan T, Manavalan A, Thangavelu KP, Heese K (2013) Biochem Eng J 70:106–114

Manavalan T, Manavalan V, Thangavelu KP, Kutzner A, Heese K (2015) J Food Biochem 39(6):754–764

Yasmeen Q, Asgher M, Sheikh MA, Nawaz H (2013) Bioresources 8(1):944–968

DiCosimo R, McAuliffe J, Poulose AJ, Bohlmann G (2013) Chem Soc Rev 42(15):6437–6474

Mukhopadhyay A, Dasgupta AK, Chakrabarti K (2015) Bioresour Technol 179:573–584

Asgher M, Wahab A, Bilal M, Iqbal HMN (2016) Biocatal Agric Biotechnol 6:195–201

Bilal M, Asgher M (2016) J Mol Catal B 128:82–93

Bilal M, Iqbal M, Hu H, Zhang X (2016) Biochem Eng J 109:153–161

Hanefeld U, Gardossi L, Magner E (2009) Chem Soc Rev 38(2):453–468

Secundo F (2013) Chem Soc Rev 42(15):6250–6261

Asgher M, Shahid M, Kamal S, Iqbal HMN (2014) J Mol Catal B 101:56–66

Shin M, Nguyen T, Ramsay J (2002) Appl Microbiol Biotechnol 60(1–2):218–223

Hernandez K, Fernandez-Lafuente R (2011) Enzyme Microb Technol 48(2):107–122

Munjal N, Sawhney SK (2002) Enzyme Microb Technol 30(5):613–619

Vujčić Z, Miloradović Z, Milovanović A, Božić N (2011) Food Chem 126(1):236–240

Asgher M, Aslam B, Iqbal HMN (2013) Chin J Catal 34(9):1756–1761

Iqbal HMN, Asgher M, Bhatti HN (2011) Bioresources 6(2):1273–1287

Bradford MM (1976) Anal Biochem 72(1–2):248–254

Oszmianski J, Lee CY (1990) J Agric Food Chem 38(10):1892–1895

Swain T, Hillis WE (1959) J Sci Food Agric 10(1):63–68

Brand-Williams W, Cuvelier ME, Berset CLWT (1995) LWT–Food Sci Technol 28(1):25–30

Jaiswal N, Prakash O, Talat M, Hasan SH, Pandey RK (2012) J Genet Eng Biotechnol 10(1):161–167

Srivastava PK, Anand A (2014) Int J Biol Macromol 64:150–154

Bauduin P, Nohmie F, Touraud D, Neueder R, Kunz W, Ninham BW (2006) J Mol Liq 123(1):14–19

Singh V, Rakshit K, Rathee S, Angmo S, Kaushal S, Garg P, Singhal N (2016) Bioresour Technol 214:528–533

Ansari SA, Husain Q (2012) Biotechnol Adv 30(3):512–523

Sohrabi N, Rasouli N, Torkzadeh M (2014) Chem Eng J 240:426–433

Lu R, Miyakoshi T (2012) Enzyme Res 12:8

Kutcherlapati SR, Yeole N, Jana T (2016) J Coll Interface Sci 463:164–172

Akgöl S, Kacar Y, Denizli A, Arıca MY (2001) Food Chem 74(3):281–288

Abdullah AL, Sulaiman NM, Aroua MK, Noor MMM (2007) J Food Eng 81(1):65–71

de Souza Bezerra, Bassan JC, de Oliveira Santos VT, Ferraz A, Monti R (2015) Process Biochem 50(3):417–423

Acknowledgments

The financial support provided by the Higher Education Commission (HEC), Islamabad, Pakistan is thankfully acknowledged. The authors are also grateful to the State Key Laboratory of Microbial Metabolism, and School of Life Sciences and Biotechnology, Shanghai Jiao Tong University, Shanghai 200240, China for providing technical and analytical help.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Bilal, M., Asgher, M., Iqbal, H.M.N. et al. Gelatin-Immobilized Manganese Peroxidase with Novel Catalytic Characteristics and Its Industrial Exploitation for Fruit Juice Clarification Purposes. Catal Lett 146, 2221–2228 (2016). https://doi.org/10.1007/s10562-016-1848-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-016-1848-9