Abstract

Objective

To investigate the inhibiting effect of formic acid on acetone/butanol/ethanol (ABE) fermentation and explain the mechanism of the alleviation in the inhibiting effect under CaCO3 supplementation condition.

Results

From the medium containing 50 g sugars l−1 and 0.5 g formic acid l−1, only 0.75 g ABE l−1 was produced when pH was adjusted by KOH and fermentation ended prematurely before the transformation from acidogenesis to solventogenesis. In contrast, 11.4 g ABE l−1 was produced when pH was adjusted by 4 g CaCO3 l−1. The beneficial effect can be ascribed to the buffering capacity of CaCO3. Comparative analysis results showed that the undissociated formic acid concentration and acid production coupled with ATP and NADH was affected by the pH buffering capacity of CaCO3. Four millimole undissociated formic acid was the threshold at which the transformation to solventogenesis occurred.

Conclusion

The inhibiting effect of formic acid on ABE fermentation can be alleviated by CaCO3 supplementation due to its buffering capacity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Butanol is an important chemical feedstock and, more importantly, a superior fuel to gasoline with a potential to substitute for it (Jang et al. 2012). With the ongoing crisis of fossil fuels and our increasing concentrations of climate changes, fermentative butanol production from renewable substrates has attracted increasing attention. Substrate cost is the most important factor influencing the price of butanol production by fermentation (Qureshi et al. 2007). Lignocellulosic biomass is the most abundant renewable material and has potential as a substrate for butanol fermentation (Ezeji et al. 2007b).

The major components of lignocellulosic biomass are cellulose, hemicellulose, and lignin. Minor components are organic extractives and inorganic minerals. However, clostridia, the main producers of butanol, do not utilize lignocellulosic biomass directly as a carbon source (Ezeji et al. 2007b). For this reason, lignocellulosic biomass must be hydrolyzed to fermentable sugars either by acid hydrolysis or enzymatic hydrolysis (Hendriks and Zeeman 2009). Compared with enzymatic hydrolysis, acid hydrolysis process produces monosaccharides without a pre-treatment step with a higher conversion of polysaccharides but can form fermentation inhibitors by further reactions of monosaccharides. The fermentation inhibitors produced during the acid hydrolysis process include aliphatic acids (primarily formic acid, acetic acid and levulinic acid) and furan aldehydes [furfural and 5-hydroxymethylfurfural (HMF)] (Jönsson et al. 2013).

Furfural and HMF are formed by dehydration of pentose and hexose sugars, respectively (Jönsson et al. 2013). Ezeji et al. (2007a) reported that furfural and HMF (3 g l−1) are not inhibitory to ABE fermentation by Clostridium beijerinckii BA 101. The formation of the aliphatic acids contained in the lignocellulose hydrolysates is different. Acetic acid is mainly formed by the hydrolysis of acetyl groups of hemicellulose, while formic acid is a degradation product of furfural and HMF and levulinic acid comes from the degradation of HMF (Jönsson et al. 2013). Compared with acetic acid and levulinic acid, formic acid is more deleterious to butanol production because it triggers the so-called acid crash i.e., the state when acetone/butanol/ethanol (ABE) fermentation ends prematurely before the transformation from acidogenesis to solventogenesis takes place (Wang et al. 2011). The aliphatic acids inhibit fermentation by either uncoupling metabolism or accumulating intracellularly in its anionic form (Baral et al. 2014). The two mechanisms are both based on the following principle: (i) Dissociated weak acids cannot diffuse across the plasma membrane, and their inhibition is due to the influx of undissociated acid into the cytosol. (ii) Dissociation of the weak acid occurs in the cytosol due to the neutral intracellular pH, thus resulting in the decrease of cytosolic pH (Palmqvist and Hahn-Hägerdal 2000b). The concentration of undissociated acids depends on the pH, and therefore the pH is a crucial variable during fermentation from the medium containing the weak acids inhibitors.

Formic acid can be removed by upstream manipulations, such as anion exchange or distillation, but it is not cost-effective compared with CaCO3 supplementation or pH control during fermentation process because formic acid showed severe inhibition effect at a very low concentration. Anion exchange will cause a considerable loss of sugars while removing inhibitors (Palmqvist and Hahn-Hägerdal 2000a). Removal of the low concentration of formic acid in the hydrolysate by distillation will lead to a high energy cost. In the present study, the inhibition of formic acid on ABE fermentation under different pH adjustment methods was investigated, and the mechanism of the alleviation in the inhibiting effect under CaCO3 supplementation condition is explained.

Materials and methods

Microorganism and seed culture

Clostridium acetobutylicum CH02 obtained from C. acetobutylicum ATCC 824 by long-term adaptation was used in this research for ABE fermentation. The seed culture conditions have been described in detail in our previous work (Qi et al. 2015).

Media preparation and batch fermentations

The glucose/xylose mixture was used as the carbon source for ABE fermentation, and the semi-synthetic media for batch ABE fermentation composed of (per l medium): glucose 25 g, xylose 25 g and wheat bran 11 g (Qi et al. 2015). In order to evaluate the influence of formic acid on ABE fermentation process, 0.5 g formic acid l−1 was added to the media. The initial pH of the media with formic acid addition was adjusted to 6.5 with the following two methods: (i) by adding 4 g CaCO3 l−1 and small amount of CaO or (ii) by adding 6 M KOH. The initial pH of the media without formic acid addition was adjusted to 6.5 with 10 mM H2SO4.

In order to find out the threshold molar concentration of undissociated formic acid at which the phase transition from acidogenesis to solventogenesis occur, 32 groups of batch fermentations were conducted. The medium composed of (per l medium): glucose 25 g, xylose 25 g, wheat bran 11 g and different concentrations of formic acid and CaCO3. Formic acid was added to the medium at 0.25, 0.5, 0.75, 1, 2, 3, 4 or 5 g l−1. CaCO3 supplementation was at 1, 2, 4 or 8 g l−1. The initial pH of the medium was adjusted to 6.5 by a small amount of CaO. All media were sterilized at 115 °C for 20 min.

All batch fermentations were performed in 250 ml serum bottles in triplicates with working volume of 200 ml and the results were averaged. The inoculation levels for all batch experiments were controlled at 5 % (v/v), and the bottles were incubated statically at 37 °C for 104 h. Two ml samples were taken regularly for analysis.

Analytical methods

Solvents (acetone, butanol and ethanol) were analyzed by GC equipped with a hydrogen flame ionization detector (FID) and a capillary column (DB-FFAP column, 30 m × 0.25 mm ID × 0.25 µm). The initial temperature, final temperature, and heating rate in the oven were 60, 210, and 20 °C min−1, respectively. The injector and FID were both operated at 250 °C. Helium was used as the carrier gas at 1 ml min−1. Air and hydrogen flow rates were controlled at 400 and 30 ml min−1, respectively. Sugars (glucose and xylose) and acids (formate, acetate and butyrate) were analyzed by HPLC equipped with a refractive index (RI) detector and an ultraviolet detector. The components in the fermentation broth were separated with an Aminex HPX-87H column (300 × 7.8 mm, Bio-Rad) at 55 °C with 5 mM H2SO4 as the mobile phase, at 0.5 ml min−1. Sugars were quantified by the RI detector, while acids were quantified at 210 nm. Undissociated acids concentrations were calculated using the Henderson-Hasselbalch-buffer equation:

where [HA] and [A− + HA] are the undissociated acid and total acid concentrations, and the total acid concentration [A− + HA] is determined by HPLC. PKa is the negative decadic logarithm of the acid dissociation constant.

The pKa for formic acid, acetic acid and butyric acid under the experimental condition are 3.76, 4.77 and 4.81, respectively.

Results and discussion

ABE fermentation without formic acid addition

To investigate the influence of formic acid on ABE fermentation from the mixture of glucose and xylose, batch ABE fermentation from the medium without formic acid addition was conducted firstly, and the results were illustrated in Fig. 1.

As can be seen, the consumption of glucose and xylose was not simultaneous and the utilization of xylose was severely inhibited by glucose, which was due to the carbon catabolite repression (CCR) as previously reported by Ren et al. (2010). Acetone/butanol/ethanol fermentation by C. acetobutylicum is typically characterized by acidogenesis and solventogenesis (Jones and Woods 1986). As illustrated in Fig. 1a, b, acidogenesis was predominant in the first 32 h, and acetate and butyrate accumulated quickly. The transformation from acidogenesis to solventogenesis occurred at about 32 h, and acetate and butyrate were clearly re-assimilated and ABE was produced rapidly thereafter. The time-course of the pH value was in accordance with the transformation from acidogenesis to solventogenesis. 11.1 g butanol l−1 and 18.1 g ABE l−1 were achieved with a fermentation time of 104 h, with butanol and ABE yields of 0.24 and 0.39 g g−1, respectively.

The inhibiting effect of weak acids on ABE fermentation is caused by an influx of undissociated acids into the cytosol and dissociation at neutral internal pH. The dissociation of acids inside the cell uncouples the proton motive force, which increases the energy requirements to maintain the neutral internal pH (Jones and Woods 1986). In addition, the uptake of acids also decreases the availability of coenzyme A and phosphate pools which decreases the flux of glucose through glycolysis (Gottwald and Gottschalk 1985). The acid crash phenomenon is associated with the concentrations of undissociated acetic acid and butyric acid in the fermentation broth (Maddox et al. 2000) whose concentrations are depicted in Fig. 1c. The maximum concentration of undissociated acids (acetic acid plus butyric acid, 25.3 mM) was at 32 h which was lower than the threshold of 57–60 mM for an acid crash to occur (Maddox et al. 2000).

Comparative analysis of ABE fermentation processes from the medium containing 0.5 g formic acid l−1 with different pH adjustment methods

Different fermentation results were obtained from the medium containing formic acid with different pH adjustment methods (KOH or CaCO3), and the fermentation profiles were compared in Fig. 2. The stoichiometric chemical reactions between the pH adjustment regent, formic acid and the fermentation products are shown in Table 1. The fermentation process with KOH adjustment showed typical profiles of acid crash, which was characterized by premature cessation of fermentation process in acidogenesis (Maddox et al. 2000). Only 0.46 g butanol l−1 and 0.75 g ABE l−1 were produced from 7.97 g sugars l−1, with butanol and ABE yield of 0.06 and 0.09 g g−1, respectively. The total ABE production decreased dramatically to 4 % compared to the control group due to the failed transformation from acidogenesis to solventogenesis. Acetate and butyrate accumulated in the first 32 h, and maintained at this level thereafter. The re-assimilation of acetate and butyrate was not observed, which was in accordance with the time-profile of pH. In contrast, the time-profiles of sugars consumption and solvents production with CaCO3 adjustment were similar to those of the control group, which showed a typical biphasic process (Jones and Woods 1986). 8 g butanol l−1 and 11.4 g ABE l−1 were produced from 37.48 g sugars l−1, with respective yields of 0.21 and 0.3 g g−1. The total ABE production decreased to 63 % compared to the control group. As shown in Fig. 2b2, butyrate accumulated in acidogenesis and re-assimilated in the solventogenesis. Acetate increased during the whole fermentation which was different from the time-profile of acetate in the control group. Moreover, a relative high pH was maintained during the whole fermentation due to the buffering capacity of CaCO3 as shown in Table 1.

Aliphatic acids inhibit fermentation by either uncoupling metabolism or accumulating intracellularly in an anionic form (Baral et al. 2014). Influx of weak acids in the undissociated state is the prerequisite for uncoupling metabolism or being accumulated intracellularly in the anionic form. To investigate mechanism of acid crash caused by formic acid addition, undissociated formic acid, acetic acid and butyric acid were calculated and the results are illustrated in Fig. 2c1, c2. The maximum concentrations of undissociated acetic acid plus butyric acid (25.6 mM for KOH adjustment and 42 mM for CaCO3 adjustment) in the two groups were both lower than the threshold for acid crash (Maddox et al. 2000). Undissociated formic acid increased quickly to 4.7 mM in the first 32 h and then maintained in this level in Fig. 2c-1. In contrast, the maximum undissociated formic acid concentration in Fig. 2c-2 was only 0.8 mM at 32 h. Formic acid cannot be metabolized by C. acetobutylicum due to its lack of formic acid dehydrogenase (Calusinska et al. 2010) and therefore the undissociated formic acid concentration is the function of the medium pH (Eq. 1). Compared with KOH adjustment method, the pH of the medium containing 4 g CaCO3 l−1 was maintained in a relative high level due to its buffering capacity. Without doubt, the lower undissociated formic acid concentration in the medium containing CaCO3 showed alleviative inhibiting effect on ABE fermentation. This is one reason for the successful transformation from acidogenesis to solventogenesis. Total ABE production by C. acetobutylicum decreased to 77 % on addition of 0.4 g formic acid l−1 (Cho et al. 2012) which was probably due to the buffering capacity of phosphate and ammonium acetate in P2 medium.

Acid production and re-assimilation from the medium containing formic acid was different from that of control group. Acetate and butyrate re-assimilation was observed in control group as shown in Fig. 1b, and no re-assimilation of acetate and butyrate was observed when the medium containing formic acid was adjusted by KOH (Fig. 2b-1). Interestingly, only butyrate re-assimilation was observed when the medium containing formic acid was adjusted by CaCO3, and more acetate was accumulated during the whole fermentation process (Fig. 2b-2). On one hand, a high pH value provided by CaCO3 is favorable for acids accumulation during ABE fermentation process (Jones and Woods 1986). On the other hand, the balance of NADH and ATP can be maintained by regulating the production of acids. The theoretical balance of ATP and NADH in ABE fermentation from glucose by C. acetobutylicum is summarized in Table 2 (Desai et al. 1999). Obviously, more ATP can be produced when more acetate accumulates in the medium. As a result, the uncoupling effect of the undissociated acids can be alleviated by the over-production of acetate. Moreover, acetate production is also associated with NADH balance, and 2 mol NADH can be generated when 1 mol glucose was metabolized to 2 mol acetate. The oxidoreduction potential (ORP) of the medium containing formic acid will increase dramatically after acidogenesis (Wang et al. 2011). The intracellular ORP is reflected by the internal reducing equivalents (NADH/NAD+), and can be regulated by the over-production of NADH (Liu et al. 2013). The over-production ATP and NADH coupled with acetate was probably another reason for the successful transformation from acidogenesis to solventogenesis.

The relationship between undissociated formic acid and transformation from acidogenesis to solventogenesis

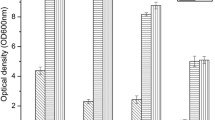

To find the threshold molar concentration of undissociated formic acid at which the transformation from acidogenesis to solventogenesis occurred, 32 groups of batch fermentations containing different concentrations of formic acid with different buffering capacities were conducted. The pH was measured every 12 h during the fermentation process and the lowest pH value was recorded. The maximum undissociated formic acid concentrations were calculated based on the lowest pH value and total formate concentration. The successful transformation from acidogenesis to solventogenesis was defined as the total solvents titer higher than 1 g ABE l−1. As can be seen from Fig. 3, undissociated formic acid at 4 mM was found to be the threshold at which the transformation occurred. In other words, successful transformation can be achieved by keeping the lowest pH higher than the critical pH (pHc) when the medium contained known concentration of formic acid. The pHc can be calculated as the following equation.

The threshold concentration of undissociated formic acid is meaningful for ABE fermentation from lignocellulosic hydrolysates, which will provide a guide for fermentation process regulation (such as pH control) from the medium containing formic acid inhibitor.

Conclusions

Formic acid severely inhibits ABE fermentations but the effect can be alleviated by CaCO3 supplementation. The beneficial effect is ascribed to the buffering capacity of CaCO3. On the one hand, high pH condition provided by CaCO3 decreases the concentration of undissociated formic acid. On the other hand, acid production coupled with the NADH and ATP balances can be regulated by CaCO3. Four millimole undissociated formic acid was the threshold at which the transformation from acidogenesis to solventogenesis occurred. This provides useful information for regulation of the fermentation process (such as pH control) from the medium containing formic acid inhibitor.

References

Baral NR, Li J, Jha AK (2014) Perspective and prospective of pretreatment of corn straw for butanol production. Appl Biochem Biotechnol 172:840–853

Calusinska M, Happe T, Joris B, Wilmotte A (2010) The surprising diversity of clostridial hydrogenases: a comparative genomic perspective. Microbiology 156:1575–1588

Cho DH, Shin S-J, Kim YH (2012) Effects of acetic and formic acid on ABE production by Clostridium acetobutylicum and Clostridium beijerinckii. Biotechnol Bioprocess Eng 17:270–275

Desai RP, Nielsen LK, Papoutsakis ET (1999) Stoichiometric modeling of Clostridium acetobutylicum fermentations with non-linear constraints. J Biotechnol 71:191–205

Ezeji T, Qureshi N, Blaschek HP (2007a) Butanol production from agricultural residues: impact of degradation products on Clostridium beijerinckii growth and butanol fermentation. Biotechnol Bioeng 97:1460–1469

Ezeji TC, Qureshi N, Blaschek HP (2007b) Bioproduction of butanol from biomass: from genes to bioreactors. Curr Opin Biotechnol 18:220–227

Gottwald M, Gottschalk G (1985) The internal pH of Clostridium acetobutylicum and its effect on the shift from acid to solvent formation. Arch Microbiol 143:42–46

Hendriks A, Zeeman G (2009) Pretreatments to enhance the digestibility of lignocellulosic biomass. Bioresour Technol 100:10–18

Jang Y-S, Malaviya A, Cho C, Lee J, Lee SY (2012) Butanol production from renewable biomass by clostridia. Bioresour Technol 123:653–663

Jones DT, Woods DR (1986) Acetone–butanol fermentation revisited. Microbiol Rev 50:484

Jönsson LJ, Alriksson B, Nilvebrant N-O (2013) Bioconversion of lignocellulose: inhibitors and detoxification. Biotechnol Biofuels 6:1

Liu C-G, Xue C, Lin Y-H, Bai F-W (2013) Redox potential control and applications in microaerobic and anaerobic fermentations. Biotechnol Adv 31:257–265

Maddox I, Steiner E, Hirsch S, Wessner S, Gutierrez N, Gapes J, Schuster K (2000) The cause of “acid crash” and “acidogenic fermentations” during the batch acetone–butanol–ethanol (ABE) fermentation process. J Mol Microb Biotechnol 2:95–100

Palmqvist E, Hahn-Hägerdal B (2000a) Fermentation of lignocellulosic hydrolysates. I: Inhibition and detoxification. Bioresour Technol 74:17–24

Palmqvist E, Hahn-Hägerdal B (2000b) Fermentation of lignocellulosic hydrolysates. II: Inhibitors and mechanisms of inhibition. Bioresour Technol 74:25–33

Qi G-X, Xiong L, Huang C, Chen X-F, Lin X-Q, Chen X-D (2015) Solvents production from a mixture of glucose and xylose by mixed fermentation of Clostridium acetobutylicum and Saccharomyces cerevisiae. Appl Biochem Biotechnol 177:996–1002

Qureshi N, Saha BC, Cotta MA (2007) Butanol production from wheat straw hydrolysate using Clostridium beijerinckii. Biotechnol Bioprocess Eng 30:419–427

Ren C, Gu Y, Hu S, Wu Y, Wang P, Yang Y, Yang C, Yang S, Jiang W (2010) Identification and inactivation of pleiotropic regulator CcpA to eliminate glucose repression of xylose utilization in Clostridium acetobutylicum. Metab Eng 12:446–454

Wang S, Zhang Y, Dong H, Mao S, Zhu Y, Wang R, Luan G, Li Y (2011) Formic acid triggers the “acid crash” of acetone/butanol/ethanol fermentation by Clostridium acetobutylicum. Appl Environ Microb 77:1674–1680

Acknowledgments

This work was supported by National Natural Science Foundation of China (51378486, 51508547, 21606229, 31600475), the Science and Technology Project of Huaian (HAS2015035), Natural Science Foundation of Guangdong Province, China (2016A030310124), the Science and Technology Planning Project of Guangdong Province, China (2016A010104009, 2016A010105016), Youth Innovation Promotion Association CAS (2015290).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qi, G., Xiong, L., Lin, X. et al. CaCO3 supplementation alleviates the inhibition of formic acid on acetone/butanol/ethanol fermentation by Clostridium acetobutylicum . Biotechnol Lett 39, 97–104 (2017). https://doi.org/10.1007/s10529-016-2231-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-016-2231-z