Abstract

In today’s world, industries are facing massive pressure to integrate sustainability issues for efficient and successful supply chain management (SCM). Hence, worldwide it has become critically important to make economic operational balance satisfying environment protection norms and social welfare perspectives. Consequently, the industries are investigating their SCM structures in association with a third party logistics (3PL) service provider adopting the triple bottom line framework for improving the overall supply chain performance. Therefore, selection of the right 3PL provider for the sustainable alliance is supremely important for broader perspective of greater business value. Thus, the main objective of this research work is the selection of most appropriate 3PL provider for a food manufacturing company (FMC) after systematic evaluation of six different feasible logistic providers serving over a decade in India. Selection of optimal alternative 3PL provider is very complex and challenging because of the qualitative description of service provider performances and the inherent uncertainty due to subjectivity. The concept of interval-valued fuzzy-rough number (IVFRN) offers perfect treatment of such uncertainty. In this paper, we develop a multi criteria decision making (MCDM) model combining the factor relationship (FARE) and multi-attributive border approximation area comparison (MABAC) models based on IVFRN. The proposed model is tested and validated on a case study where the optimal selection of 3PL providers is performed for an Indian FMC. Based on the results obtained in sensitivity analysis, it was shown that the proposed IVFRN based FARE-MABAC model produces stable/consistent solutions. Through the research presented in this paper, it is shown that the new hybrid MCDM method is a useful and reliable tool for rational decision-making.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In today’s competitive world, the manufacturing industries are re-investigating their SCM structures in association with sustainable collaboration with external partners for improving the overall supply chain performance in a broader perspective of greater business value. The notions of successful supply chain practices demand the optimal management exchanging the physical and information flows among all participants in the supply chain where managers (decision makers) aim to reduce costs as well as rise profits all over the supply chain (Wang et al. 2017; Singh et al. 2018; Govindan et al. 2017). Therefore, after maintaining the TBL liabilities, selection of the suitable 3PL provider for sustainable alliance is absolutely important for improving business performance, reducing carbon tax, and contributing towards society.

However, the US Environmental Protection Agency reported nearly 26% of all greenhouse emissions in 2014 caused by transport and logistics actions. But, the tactical involvement of logistics service providers are proved to be immensely important to minimize CO\(_2\) emissions while sustaining the economic growth pace of an organization. Almost 60% of the Fortune 500 enterprises in USA have at least one 3PL provider and the marketplace for logistics companies is growing day by day (Lieb and Bentz 2004). In 2011, most of CO\(_2\) in the world were emitted from China, the USA, India, Russia, Japan, Canada, and the European Union. Emissions are caused by several reasons like fossil fuel burning, cement production, and petro-gas blazing (USEPA 2014). Thus, a manufacturing enterprise should collaborate with at least one suitable logistics provider company who implements consistent sustainable development norms for handling the global warming concerns while outsourcing their logistics operations.

For finding an appropriate logistics provider, one has to evaluate the eligible candidates against multiple tangible and intangible criteria for outsourcing their logistics operations (Kannan et al. 2017; Tzeng and Huang 2012; Wang et al. 2016; Milosavljevic et al. 2018). Aguezzoul (2014) presented a systematic literature review on criteria and methods of 3PL provider selection problem. There he classified 3PL provider evaluation methods into five different groups, namely: multi criteria decision making (MCDM) techniques, statistical approaches, artificial intelligence, mathematical programming, and hybrid methods. But, MCDM tools are most widely used for 3PL provider selection. This is because these tools can solve easily and successfully the evaluation problems that are complex, ill–structured, and possess multiple conflicting objectives/criteria. Now, the manager of the company seeks answers to the subsequent research questions: (1) How to select the sustainability indicators for evaluating 3PL providers? (2) How to set priorities of these indicators after considering their mutual influences? (3) Which should be the optimal choice for a sustainable collaboration partner for logistics services?

Encapsulating the above characteristics and motives, this paper attempts to design a systematic and comprehensive evaluation framework for a bakery FMC which wants to make an optimal choice of sustainable 3PL provider. The projected framework includes a hybrid model for assessing the feasible alternative logistics providers considering sustainability objectives. The goal of this paper is to offer a knowledge based expert system/research framework to find out the best 3PL provider for sustainable outsourcing considering several conflicting objectives (e.g., benefit, cost). The main features of this paper are: (1) Simultaneous consideration of the economic, environmental, and social objectives while selecting the best 3PL provider in an FMC; (2) The decision makers (DMs) have the flexibility to entrench their importance depending upon their past work experience and expertise in logistics management in terms of weights; (3) In the 3PL provider assessment procedure, the decision makers (DMs) are allowed to use linguistic ratings which are inherently uncertain in nature; (4) The projected framework is aimed to find the most suitable 3PL provider based on their sustainable practices while making a trade–off among the triple bottom line (socio–economic–environmental) objectives/criteria in a food supply chain management.

In order to achieve the above aspirations, the integrated research framework implemented in this paper is as follows:

-

Three major dimensions—economic, environmental, and social objectives and corresponding to these dimensions relevant criteria are assessed by a group of experts/decision makers in the relevant field to obtain the hierarchical weights in terms of their importance in sustainable 3PL services. The relative criteria weights and inter-relations among them is analysed and obtained using interval valued fuzzy rough numbers (IVFRNs) based factors relationship (FARE) method.

-

Next, the modified IVFRN based multi-attributive border approximation area comparison (MABAC) method is developed to evaluate and select the most suitable 3PL provider for the case company in this study.

The rest of the paper is structured as follows: an all-inclusive literature survey of research background and decision making tools in logistic outsourcing management in supply chain management(SCM) is outlined in Sect. 2. The proposed integrated research framework using IVFRNs is presented in Sect. 3 while Sect. 4 discusses a numerical case illustration of the proposed model in a supply chain of an FMC. Section 5 deals with result discussions, comparison, and sensitivity analysis. In Sect. 6, conclusions, limitations, and future directions are presented.

2 Research background

This section presents a literature survey including the needs of logistics outsourcing management, major objectives/dimensions for 3PL provider evaluation, and the methodologies used so far in the relevant area. The research gap has been highlighted in sustainable 3PL provider selection and measuring routine metrics based on each objective while designing a sustainable SCM.

2.1 Third party logistics service provider selection

In business, outsourcing is an agreement in which one company contracts out a part of their existing internal activity to another company (McCarthy and Anagnostou 2004). It involves the contracting out of a business process (e.g. payroll processing, claims processing) and operational, and/or non-core functions (e.g. manufacturing, facility management) to another party to enhance the overall performance level (Wu et al. 2005). The concept “outsourcing” came from the American Glossary “outside resourcing” and it dates back to at least 1981. Logistics outsourcing is one of the prime accomplishments of a company. Now a days, a logistics service provider outsources concurrently with several companies at the same time and hence gets the benefits of economic balance, and that benefit can tip the firm to reduce its cost. Although, Yang et al. (2007) discussed that cost reduction is rarely the main objective of outsourcing in decision making problems. In contrast, prospects to upgrade services, improving performance, boosting information safety, and advancing flexibility are critical success factors (CSFs) of the firm. In the survey article of Abdur Razzaque and Chen Sheng (1998), it was noticed that several CSFs are the main motives of a firm to select an outsourcing collaborator. They include the benefits of competitive opportunity, advancement of efficiency, enlargement of overall business proportions, and improvement of information technology competences. Contemporary researchers emphasis on various modules of third party logistics (3PL) outsourcing: (1) the risks and benefits of 3PL outsourcing (Hsiao et al. 2010), and (2) the evaluation of 3PL providers and selecting them for sustainable collaboration (Aguezzoul 2014). The current research work is focused on the second module which deals with the evaluation and selection of 3PL providers considering the sustainability perspectives in the decision making procedure.

There are five steps of logistics outsourcing management—identification of its necessity, finalization of feasible 3PL providers/alternatives, fixation the major dimensions and criteria for outsourcing partner selection, implementation and execution of the partnership (Wan et al. 2015). Furthermore, 3PL adoption is essentially important to extended life span and returns in the product cycle, which greatly supports the reduction of environmental hazards and resolves the problems due to lack of resources (Gonzalez-Torre et al. 2010). More importantly in developing counties it was asserted that the bureaucrats have been promoting and making sustainable development guidelines necessary to implement 3PL set-ups in SCM (de Sousa Jabbour et al. 2014). Such instructions can initiate private and public partnership through share responsibility to achieve the sustainable business progress. Many researchers (Pamucar et al. 2019; Yayla et al. 2015; Wu and Barnes 2016; Prakash and Barua 2016a, b; Sharma and Kumar 2015; Tavana et al. 2016; Wan et al. 2015; Senthil et al. 2014; Roy et al. 2018) have studied optimal selection of third-party logistics service provider according to different perspectives. Only a few (Govindan et al. 2017; Mavi et al. 2017) researchers have dealt with the TBL (social, economic and environmental) goals simultaneously. But, both of these papers avoided the interacting influences and impacts among these goals and criteria for selecting suitable 3PL provider for a company. However, according to the systems theory and real conditions, all the things around us are inter-related, and it is hardly possible to ignore this fundamental law of nature (Ginevičius 2011).

2.2 Methodologies used in 3PL provider selection

Since this paper deals with sustainable logistics outsourcing provider evaluation and selection, several solution approaches can be used in this particular problem and produce satisfactory solutions towards tactical decision making. Different optimization tools and approaches have been applied and suggested by several researchers and practitioners in this field. A comprehensive and immediate overlook of the methods and applications domains of 3PL service management can be found in Table 1. Many scholars have employed several strategies of 3PL provider selection frameworks for decision analysis in the relevant discipline. Despite the use of many single decision making methods to investigate the 3PL provider selection problem, it has been observed hybrid approaches are trending in recent years (Debnath et al. 2017; Aguezzoul 2014). However, it is previously mentioned that MCDM tools are most frequently used for 3PL provider selection since they can solve successfully the evaluation problems that are complex, ill-structured, and possess multiple conflicting objectives/criteria.

2.3 Dimensions and criteria for 3PL provider selection

The substantial objectives (dimension) and criteria (sub-dimension) for 3PL provider selection with sustainable perspectives for a FMC have been acknowledged in a complete wide-ranging literature survey and inputs from experts. In total, 22 evaluation criteria of main three objectives (economic, environmental, and social) of sustainability were identified through a detailed literature search. Finally, 15 criteria (Refer to Table 2) for 3PL provider valuation were authorized with the help of expert’s approval and characterized into three main dimensions of sustainable SCM.

2.4 Research gap and highlights

Apparently the above discussion shows a literature gap to consider the TBL framework for evaluating 3PL providers by incorporating the mutual influence and inter-dependencies among these criteria and dimensions. Many authors used analytic hierarchy process (AHP) method to measure the criteria weights in MCDM problems. But, for simplicity, AHP model assumes criteria are independent (i.e., no correlation between criteria). This leads to ignore the fact that fundamental law of nature and the systems theory which says all the things around us are inter-related in real conditions. This is a serious limitation of AHP method. Hence, researchers developed ANP (analytic network process) as a generalization of AHP. Also, the computational requirement of ANP is tremendous even for a small problem. Thus, the above discussion shows the fact that criteria weights for 3PL provider evaluation problems are generally calculated utilizing AHP or ANP models which adopt pairwise comparison matrices from experts’ opinion. Determination of the criteria weights considering their inter-dependencies is one of the vital pivotal stages in the 3PL provider evaluation process. However, experts fail to opine on the relative criteria weights accurately if the number of criteria is too large.

On the other hand, 3PL provider evaluation is made based the service qualities which are recorded linguistically, i.e., expressed in some natural language as opposed to precise numerical measurements. Table 1 shows that type-1 fuzzy sets theory and interval valued fuzzy sets are widely used to tackle this kind of uncertainty in 3PL provider evaluation and selection problems. In spite of the successful implementation of fuzzy approaches, many authors (Kang et al. 2016; Qazi et al. 2016; Bozanic et al. 2018) cited the disadvantage of them to define the borders of the sets and the footprint of uncertainty. For more practical approaches, one can consult with learning approach based on the examples. Usually, referential activities are well known to the DM, and he is able to order them and express in this way his preferences. Simply, he shows us how he does his job. The rough set theory (RST) which was suggested by (Pawlak 1991) and extended by (Greco et al. 1997, 2001) as Dominance-Based Rough Set Approach (DRSA) allow us to solve multi criteria choice and ranking problems. After that rough approximation of preference relation by multi attribute dominance for deterministic, stochastic and fuzzy decision problems was suggested by (Zaras 2004). This approach does not require knowledge of weights or thresholds to give the solution of the problems considered by the authors. It makes possible to find the reduced subsets of the criteria which give the same order of alternatives as the original set of criteria. However, algorithms based on RST/DRSA can address only a part of the problem, say, criteria weighting. MCDM problems need tools that not only can it be used in the determination of criteria weights, but also can it be adopted in the alternative ranking (Zhu et al. 2015).

To overcome the limitations of fuzzy as well as rough approaches, Pamučar et al. (2018) proposed interval valued fuzzy-rough number (IVFRN) which offers the advantages of fuzzy and rough numbers simultaneously. Traditional fuzzy set theory as well as probability theory define the degree of uncertainty based on assumptions whereas IVFRN measures the uncertainty by means of approximation. Thus, the IVFRN based approaches use solely the internal knowledge, i.e., operative data, and there is no need to rely on prior data. In other words, one can implement IVFRN in decision making problems without additional parameters (e.g. robust membership function, data distribution, etc.) and decision can be made directly from the structure of the given data.

Interval valued fuzzy-rough number \(\bar{{\bar{Z}}}\) (Pamučar et al. 2018)

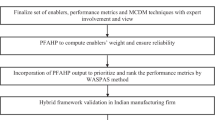

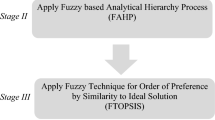

Hence, it is apparent that many researchers have applied several MCDM techniques for assessing, moderating and selecting 3PL provider, but most of them are either very complex or require large number computations. Some seek additional help of linear programming to insert in the proposed models to produce effective results, which leads to suffer from time complexity. Further, for such MCDM problems with large number of criteria and smaller number of alternatives, these approaches may sometimes give poor results under uncertainty and vagueness. To overcome such difficulties, this research work aims to develop a novel methodology based on IVFRN including factor relationship (FARE) and multi–attributive border approximation area comparison (MABAC) methods (Refer to Fig. 1). The anticipated framework (IVFRN based FARE-MABAC model) will allow decision makers to incorporate inter-relationships and dependencies among criteria while calculating the criteria weights under subjective and vague data. It also reduces experts’ assessment tasks allowing a large number of decision makers to take part in the evaluation process. Finally, improved IVFRN-MABAC model evaluates the feasible 3PL provider alternatives and helps to decide and justify the best alternative for the case company (Fig. 2).

3 Preliminaries

In this section, we briefly discuss about the basic definitions related to this research work.

3.1 Interval valued fuzzy-rough numbers (IVFRNs)

We will define fuzzy set \({\tilde{Z}}\) as a set of ordered pairs \({\tilde{Z}}=\lbrace (x, \mu _{Z}(x)))| x\in Z, 0\le \mu _{Z}(x)\le 1\rbrace \) which is described by means of a triangular membership function. Then, we can represent fuzzy number \({\tilde{Z}}\) as \({\tilde{Z}}=(l, t, r)\), where l and r respectively represent the left and right limits of the interval of fuzzy number \({\tilde{Z}}\), and t represents the modal value.

We assume that universe \({\mathscr {U}}\) contains all the objects and let E be an arbitrary object from \({\mathscr {U}}\). We assume there is a set of k classes which represent the preferences of the DM, \({\mathscr {G}}^{*}=\lbrace {\tilde{Z}}_{1}, {\tilde{Z}}_{2}, \ldots , {\tilde{Z}}_{k}\rbrace \) with the condition that they belong to a series which satisfies the condition \({\tilde{Z}}_{1} \prec {\tilde{Z}}_{2} \prec \cdots \prec {\tilde{Z}}_{k}\). All objects are defined in the universe and connected with the preferences of the DM. Each element \({\tilde{Z}}_{s} (1\le s\le k)\) represents a fuzzy number that is defined as \({\tilde{Z}}_{s}=(l_s, t_s, r_s)\). Since element \({\tilde{Z}}_{s}\) from the class of objects \({\mathscr {G}}^{*}\) is represented as fuzzy number \({\tilde{Z}}_{s}=(l_s, t_s, r_s)\) for each value \(l_s, t_s\) and \(r_s\) we obtain one class of objects that is represented in the interval \({\mathscr {I}}(l_s)=[{\mathscr {I}}(l_s^{L}), {\mathscr {I}}(l_s^{U})]\), \({\mathscr {I}}(t_s)=[{\mathscr {I}}(t_s^{L}), {\mathscr {I}}(t_s^{U})]\) and \({\mathscr {I}}(r_s)=[{\mathscr {I}}(r_s^{L}), {\mathscr {I}}(r_s^{U})]\) where the condition is fulfilled that \({\mathscr {I}}(\eta _s^{L})\le {\mathscr {I}}(\eta _s^{U})\) for \(\eta =l, t, r\) and \(1\le s\le k\) as well as the condition \({\mathscr {I}}(l_s),{\mathscr {I}}(t_s), {\mathscr {I}}(r_s)\in {\mathscr {G}}^{*}\). Then \({\mathscr {I}}(\eta _s^{L})\) and \({\mathscr {I}}(\eta _s^{U})\) for \(\eta =l, t, r\) respectively represent the lower and upper border of the intervals of the sth class of objects. If both limits of the classes of objects (upper and lower limits) respectively are compared so that \({\mathscr {I}}(\eta _{1}^{L})< {\mathscr {I}}(\eta _{2}^{L})< \cdots < {\mathscr {I}}(\eta _{f}^{L})\); \({\mathscr {I}}(\eta _{1}^{U})< {\mathscr {I}}(\eta _{2}^{U})< \cdots < {\mathscr {I}}(\eta _{h}^{U}) (\eta =l, t, r; 1\le f, h \le k)\), then for any of the classes of objects \({\mathscr {I}}(\eta _{s}^{L}), {\mathscr {I}}(\eta _{s}^{U})\in {\mathscr {G}}^{*} (\eta =l, t, r; 1\le s \le k)\) we can define the lower approximation \({\mathscr {I}}(\eta _{s}^{L})\) using the following equations:

And the upper approximation of \({\mathscr {I}}(\eta _{s}^{U})\) using the following equations

Both classes of objects (object classes \({\mathscr {I}}(\eta _{s}^{L})\) and \({\mathscr {I}}(\eta _{s}^{U})\) (; \(1\le s \le k\)) are defined by their lower limits \({\underline{Lim}}({\mathscr {I}}(\eta _{s}^{L}))\); \(\eta =l, t, r\), and upper limits \({\overline{Lim}}({\mathscr {I}}(\eta _{s}^{U}))\); \(\eta =l, t, r\). The lower limits are defined by the following equations

where \(M_{L(l)}\), \(M_{L(t)}\) and \(M_{L(r)}\) respectively represent the number of objects included in the lower approximation of the classes of objects \({\mathscr {I}}(l_{s}^{L}))\), \({\mathscr {I}}(t_{s}^{L}))\) and \({\mathscr {I}}(r_{s}^{L}))\).

The upper limits \({\overline{Lim}}({\mathscr {I}}(\eta _{s}^{U}))\); \(\eta =l, t, r\) are defined by Eqs. (10)–(12)

where \(M_{U(l)}\), \(M_{U(t)}\) and \(M_{U(r)}\) respectively represent the number of objects included in the upper approximation of the classes of objects \({\mathscr {I}}(l_{s}^{U}))\), \({\mathscr {I}}(t_{s}^{U}))\) and \({\mathscr {I}}(r_{s}^{U}))\).

Both limits of the objects (lower limit and upper limit) \({\underline{Lim}}({\mathscr {I}}(\eta _{s}^{L}))\) and \({\overline{Lim}}({\mathscr {I}}(\eta _{s}^{U}))\); \(\eta =l, t, r\) should satisfy the condition that

Thus, an interval valued fuzzy-rough number, \(\bar{{\bar{Z}}}\), is defined and denoted in the following form:

where \(\eta _{s}^{L}={\underline{Lim}}({\mathscr {I}}(\eta _{s}^{L}))\) and \(\eta _{s}^{U}={\underline{Lim}}({\mathscr {I}}(\eta _{s}^{U}))\); (\(\eta =l, t, r; 1\le s\le k\)). For more details regarding IVFRNs please see Pamučar et al. (2018).

4 Multi-criteria model based on IVFRN

IVFRN based approach used in this paper combines fuzzy and rough approach by taking into account the benefits of both concepts. In the IVFRN approach, the borders are determined from border approximation areas and the uncertainty that governs them. At the same time, using the benefits of both the (fuzzy and rough) in IVFRN approaches eliminates the defects of traditional fuzzy sets and interval-valued fuzzy sets. The boundaries are determined on the basis of the boundary approximate region and the uncertainty present within (Pamučar et al. 2017). Whereas in the traditional fuzzy theory and probability theory, the degree of indeterminacy is defined by the assumption in the IVFR approach and determined on the basis of the approximation which is the basic concept of the IVFRN. In other words, in the application of the IVFRN, instead of various additional/external parameters, only the structure of the given data is used. While IVFRN adopts the advantage of both the fuzzy sets and rough sets collectively, IRNs is limited to rough sets only. Thus, IVFRNs offers more flexibility to the decision makers express their opinions in terms of linguistic variables.

The IVFRN based approach has been successfully used in modeling MCDM problems where determination of criteria weights and evaluation of alternatives are main two phases. This paper adopts IVFRN approach to determine the criteria weights and inter-influences among them via modified FARE model. The FARE model (Ginevičius 2011; Chatterjee et al. 2017) is among the more recent than AHP, ANP, ISM (interpretative structural modelling), DEMATEL (Decision making trial and evaluation laboratory) methods. The main benefits of the FARE model are as follows: (1) AHP method (Saaty and Vargas 2012) ignores the inter-relationships between the criteria. But, the systems theory and the real situations show that all things in nature are inter-related and everything is based on these relationships (Ginevičius 2011). Therefore, this fact cannot be ignored if we want to describe the research objects more accurately; (2) the FARE model allows to incorporate the potential impact of each dimension and criterion on the main goal of research work; (3) FARE model uses the direction and strength of inter-relationship between the criteria and analytically determines the criteria weights with more accuracy.

After applying the FARE model, in the second phase of the MCDM model for evaluating the alternatives is an original modification of the improved MABAC method based on IVFRN (Pamučar et al. 2018). The next section gives a detailed algorithm for the application of the IVFRN-FARE and improved IVFRN-MABAC method.

4.1 FARE method using IVFRN

Ginevičius (2011) proposed FARE model for calculating criteria weights in MCDM framework. In this work, the FARE model is modified with IVFRN for making decisions under subjectivity and uncertainty. The step-wise description of IVFRN-FARE model for computing the criteria weights as well as incorporating the inter-relationships between the criteria are described as follows:

-

Step 1:

Determination of potential impact of the attributes

Initially, the potential impact of each criterion according to eth expert is found out using TFNs:

$$\begin{aligned} {\tilde{P}}_j^e={\tilde{S}}_j^e (n-1); ~~~e=1, 2, \ldots , k \end{aligned}$$(15)Table 3 Scale of quantitative evaluation of interrelationship between the system’s attributes where n being the number of criteria, \({\tilde{P}}_e\) is the potential of the system’s criteria impact, \({\tilde{S}}_e\) is the maximum TFN value of the evaluation scale used, as given in Table 3, and k is number of experts involved in the decision making process. Applying Eqs. (1)–(14) discussed in the Sect. 3, one can easily find the aggregated potential impact of each criterion in terms of IVFRNs as follows:

$$\begin{aligned} \bar{{\bar{P}}}_j=\bar{{\bar{S}}}_j (n-1); \end{aligned}$$(16) -

Step 2:

Ranking criteria and assessment of their inter-relationship

Criteria are now ranked based on their importance and relationship among the criteria is assessed using Table 4. Any criterion with a lower rank has less significant impact on other criteria having higher ranks and consequently it ought to transmit a larger part of its potential impact to others.

-

Step 3:

Determination of impact of the attributes on the main attribute

Table 4 Measurement scale for pair wise comparison The impact of the criterion \(\bar{{\bar{a}}}\) on the main criterion is computed and then, this impact is transformed as follows:

$$\begin{aligned} \bar{{\bar{a}}}_{1j}=\bar{{\bar{a}}}-\bar{{\bar{a}}}_{1j} \end{aligned}$$(17)where, \(\bar{{\bar{a}}}_{j}\) is the impact of jth criterion on the first main criterion and \(\bar{{\bar{a}}}_{j}\) is the part of jth attribute’s potential impact transmitted to the main criterion.

-

Step 4:

Determination of total impact

The total impact and consistency of any criterion is calculated using Eq. (18). The subset considered is reliable, consistent and steady if the total impact of its criteria with a positive sign is equal to the total impact with a negative sign, i.e. their sum is always equal to zero.

$$\begin{aligned} \bar{{\bar{P}}}_{j}=\sum _{j=1}^{n} \bar{{\bar{a}}}_{ij}; ~~~j\ne i \end{aligned}$$(18)The total impact can also be estimated using Eq. (19). The total impact or dependence of a criterion exemplifies its dominance over other. Therefore, the most significant criterion in the matrix presented should be the first criterion with maximum total dominance.

$$\begin{aligned} \bar{{\bar{P}}}_{j}=\bar{{\bar{P}}}_1 -n\bar{{\bar{a}}}_{1j}; ~~~j\ne i \end{aligned}$$(19)where \(\bar{{\bar{P}}}_j\) is the total impact (dependence) of the jth criterion and n is the total number of criteria.

-

Step 5:

Computation of attribute weights:

Lastly, the criteria weights are derived using following equations:

$$\begin{aligned} \bar{{\bar{w}}}_j=\frac{\bar{{\bar{P}}}_{j}^{f}}{\bar{{\bar{P}}}_{S}}= \frac{\bar{{\bar{P}}}_{1}-n\bar{{\bar{a}}}_{1j}+\bar{{\bar{S}}}(n-1)}{n\bar{{\bar{S}}}(n-1)} \end{aligned}$$(20)where \(\bar{{\bar{P}}}_{S}\) is the total potential of a set of criteria, calculated using Eq. (20) and \(\bar{{\bar{P}}}_{j}^{f}\) is the actual total impact of the jth criterion of the system, calculated using Eq. (21):

$$\begin{aligned} \bar{{\bar{P}}}_{S}= & {} n\bar{{\bar{P}}}_{S}=n\bar{{\bar{S}}}(n-1) \end{aligned}$$(21)$$\begin{aligned} \bar{{\bar{P}}}_{j}^{f}= & {} P_1-n\bar{{\bar{a}}}_{ij}+ \bar{{\bar{S}}}(n-1)=\bar{{\bar{P}}}_{j}+\bar{{\bar{P}}} \end{aligned}$$(22)where \(\bar{{\bar{P}}}_{j}\) is the total impact produced by the jth criterion of the system signifying its total dependence on the other criteria and \(\bar{{\bar{P}}}\) is the potential impact of the criteria.

4.2 The improved MABAC method using IVFRN

The MABAC method is a more recent MCDM method compared to TOPSIS (Technique for Order of Preference by Similarity to Ideal Solution), VIKOR (VIseKriterijumska Optimizacija I Kompromisno Resenje), and COPRAS (Complex Proportional Assessment of alternatives) models. The next section presents the algorithm for the improved IVFRN-MABAC method.

-

Step 1:

Establish the primary assessment matrix (X).

As the first step the evaluation of m alternatives is carried out according to n criteria. Evaluation of the alternatives is carried out based on a predefined fuzzy scale (Refer to Table 5) represented with triangular fuzzy numbers \({\tilde{x}}=(x^l, x^t, x^r)\). Based on the response matrices \(X_e=[{\tilde{x}}^e_{ij}]_{m\times n} (1\le e\le k)\), we obtain three matrices of aggregated sequences of the experts \(X^{*l}, X^{*t}\) and \(X^{*r}\).

$$\begin{aligned} X^{*l}= & {} \begin{pmatrix} x_{11}^{1l}, x_{11}^{2l}, \ldots , x_{11}^{kl} \quad x_{12}^{1l}, x_{12}^{2l}, \ldots , x_{12}^{kl} \quad \cdots \quad x_{1n}^{1l}, x_{1n}^{2l}, \ldots , x_{1n}^{kl}\\ x_{21}^{1l}, x_{21}^{2l}, \ldots , x_{21}^{kl} \quad x_{22}^{1l}, x_{22}^{2l}, \ldots , x_{22}^{kl} \quad \cdots \quad x_{2n}^{1l}, x_{2n}^{2l}, \ldots , x_{2n}^{kl}\\ \cdots \qquad \qquad \qquad \cdots \qquad \qquad \qquad \cdots \qquad \qquad \qquad \cdots \\ x_{m1}^{1l}, x_{m1}^{2l}, \ldots , x_{m1}^{kl} \quad x_{m2}^{1l}, x_{m2}^{2l}, \ldots , x_{m2}^{kl} \quad \cdots \quad x_{mn}^{1l}, x_{m2}^{2l}, \ldots , x_{mn}^{kl} \end{pmatrix} \nonumber \\\end{aligned}$$(23)$$\begin{aligned} X^{*t}= & {} \begin{pmatrix} x_{11}^{1t}, x_{11}^{2t}, \ldots , x_{11}^{kt} \quad x_{12}^{1t}, x_{12}^{2t}, \ldots , x_{12}^{kt} \quad \cdots \quad x_{1n}^{1t}, x_{1n}^{2t}, \ldots , x_{1n}^{kt}\\ x_{21}^{1t}, x_{21}^{2t}, \ldots , x_{21}^{kt} \quad x_{22}^{1t}, x_{22}^{2t}, \ldots , x_{22}^{kt} \quad \cdots \quad x_{2n}^{1t}, x_{2n}^{2t}, \ldots , x_{2n}^{kt}\\ \cdots \qquad \qquad \qquad \cdots \qquad \qquad \qquad \cdots \qquad \qquad \qquad \cdots \\ x_{m1}^{1t}, x_{m1}^{2t}, \ldots , x_{m1}^{kt} \quad x_{m2}^{1t}, x_{m2}^{2t}, \ldots , x_{m2}^{kt} \quad \cdots \quad x_{mn}^{1t}, x_{m2}^{2t}, \ldots , x_{mn}^{kt} \end{pmatrix} \nonumber \\\end{aligned}$$(24)$$\begin{aligned} X^{*r}= & {} \begin{pmatrix} x_{11}^{1r}, x_{11}^{2r}, \ldots , x_{11}^{kr} \quad x_{12}^{1r}, x_{12}^{2r}, \ldots , x_{12}^{kr} \quad \cdots \quad x_{1n}^{1r}, x_{1n}^{2r}, \ldots , x_{1n}^{kr}\\ x_{21}^{1r}, x_{21}^{2r}, \ldots , x_{21}^{kr} \quad x_{22}^{1r}, x_{22}^{2r}, \ldots , x_{22}^{kr} \quad \cdots \quad x_{2n}^{1r}, x_{2n}^{2r}, \ldots , x_{2n}^{kr}\\ \cdots \qquad \qquad \qquad \cdots \qquad \qquad \qquad \cdots \qquad \qquad \qquad \cdots \\ x_{m1}^{1r}, x_{m1}^{2r}, \ldots , x_{m1}^{kr} \quad x_{m2}^{1r}, x_{m2}^{2r}, \ldots , x_{m2}^{kr} \quad \cdots \quad x_{mn}^{1r}, x_{m2}^{2r}, \ldots , x_{mn}^{kr} \end{pmatrix}\nonumber \\ \end{aligned}$$(25)where \(x_{ij}^l = \lbrace x_{ij}^{1l}, x_{ij}^{2l}, \ldots , x_{ij}^{kl}\rbrace \), \(x_{ij}^t = \lbrace x_{ij}^{1t}, x_{ij}^{2t}, \ldots , x_{ij}^{kt}\rbrace \) and \(x_{ij}^r = \lbrace x_{ij}^{1r}, x_{ij}^{2r}, \ldots , x_{ij}^{kr}\rbrace \) represent sequences of triangular fuzzy number \({\tilde{x}}_{ij}\) by means of which the relative significance of criterion i is described in relation to alternative j. Using Eqs. (1)–(14) each sequence \(x_{ij}^{el}, x_{ij}^{et}\) and \(x_{ij}^{er}\) is transformed into rough sequence \(RN(x_{ij}^{el}), RN(x_{ij}^{et})\) and \(RN(x_{ij}^{er})\). Thus we obtain matrices \(X^{1l}, X^{2l}, \ldots , X^{kl}; X^{1t}, X^{2t}, \ldots , X^{kt}; X^{1r}, X^{2r}, \ldots , X^{kr}\) for each rough sequence \(RN(x_{ij}^{el}), RN(x_{ij}^{et})\) and \(RN(x_{ij}^{er})\) respectively. Thus for each group of rough matrices we obtain rough sequences

$$\begin{aligned} RN(x_{ij}^l)= & {} \Big \{ \left[ {\underline{Lim}}(x_{ij}^{1l}), {\overline{Lim}}(x_{ij}^{1l})\right] , \left[ {\underline{Lim}}(x_{ij}^{2l}), {\overline{Lim}}(x_{ij}^{2l})\right] , \ldots , \\&\times \left[ {\underline{Lim}}(x_{ij}^{kl}), {\overline{Lim}}(x_{ij}^{kl})\right] \Big \} \\ RN(x_{ij}^t)= & {} \Big \{ \left[ {\underline{Lim}}(x_{ij}^{1t}), {\overline{Lim}}(x_{ij}^{1t})\right] , \left[ {\underline{Lim}}(x_{ij}^{2t}), {\overline{Lim}}(x_{ij}^{2t})\right] , \ldots , \\&\times \left[ {\underline{Lim}}(x_{ij}^{kt}), {\overline{Lim}}(x_{ij}^{kt})\right] \Big \} \\ RN(x_{ij}^r)= & {} \Big \{ \left[ {\underline{Lim}}(x_{ij}^{1r}), {\overline{Lim}}(x_{ij}^{1r})\right] , \left[ {\underline{Lim}}(x_{ij}^{2r}), {\overline{Lim}}(x_{ij}^{2r})\right] , \ldots , \\&\times \left[ {\underline{Lim}}(x_{ij}^{kr}), {\overline{Lim}}(x_{ij}^{kr})\right] \Big \} \end{aligned}$$Using Eqs. (26)–(28) we obtain averaged rough sequences

$$\begin{aligned} RN({\bar{x}}_{ij}^l)= & {} RN\left( x_{ij}^{1l}, x_{ij}^{2l}, \ldots , x_{ij}^{kl}\right) = {\left\{ \begin{array}{ll} x_{ij}^{lL}=\frac{1}{k}\sum \limits _{e=1}^{k} {\underline{Lim}}(x_{ij}^{el}) \\ x_{ij}^{lU}=\frac{1}{k}\sum \limits _{e=1}^{k} {\overline{Lim}}(x_{ij}^{el}) \end{array}\right. } \end{aligned}$$(26)$$\begin{aligned} RN({\bar{x}}_{ij}^t)= & {} RN\left( x_{ij}^{1t}, x_{ij}^{2t}, \ldots , x_{ij}^{kt}\right) = {\left\{ \begin{array}{ll} x_{ij}^{tL}=\frac{1}{k}\sum \limits _{e=1}^{k} {\underline{Lim}}(x_{ij}^{et})\\ x_{ij}^{tU}=\frac{1}{k}\sum \limits _{e=1}^{k} {\overline{Lim}}(x_{ij}^{et}) \end{array}\right. } \end{aligned}$$(27)$$\begin{aligned} RN({\bar{x}}_{ij}^r)= & {} RN\left( x_{ij}^{1r}, x_{ij}^{2r}, \ldots , x_{ij}^{kr}\right) = {\left\{ \begin{array}{ll} x_{ij}^{rL}=\frac{1}{k}\sum \limits _{e=1}^{k} {\underline{Lim}}(x_{ij}^{er})\\ x_{ij}^{rU}=\frac{1}{k}\sum \limits _{e=1}^{k} {\overline{Lim}}(x_{ij}^{er}) \end{array}\right. } \end{aligned}$$(28)where \(RN({\bar{x}}_{ij}^l), RN({\bar{x}}_{ij}^t)\) and \(RN({\bar{x}}_{ij}^r)\) represent rough sequences of the interval valued fuzzy-rough number \(\bar{{\bar{x}}}_{ij}=\left[ RN({\bar{x}}_{ij}^l), RN({\bar{x}}_{ij}^t), RN({\bar{x}}_{ij}^r)\right] =\left[ \left( x_{ij}^{lL}, x_{ij}^{lU}\right) , \left( x_{ij}^{tL}, x_{ij}^{tU}\right) , \left( x_{ij}^{rL}, x_{ij}^{rU}\right) \right] \).

Thus we obtain the interval valued fuzzy-rough vectors \(A_i=\left( \bar{{\bar{x}}}_{i1}, \bar{{\bar{x}}}_{i2}, \ldots , \bar{{\bar{x}}}_{in}\right) \) represents the performance of the ith alternative against the jth criterion(\(i=1, 2, \ldots , m; j=1, 2, \ldots , n\)).

$$\begin{aligned} X=\begin{pmatrix} \bar{{\bar{x}}}_{11} &{} \bar{{\bar{x}}}_{12} &{} \cdots &{} \bar{{\bar{x}}}_{1n}\\ \bar{{\bar{x}}}_{21} &{} \bar{{\bar{x}}}_{22} &{} \cdots &{} \bar{{\bar{x}}}_{2n}\\ \cdots &{} \cdots &{} \cdots &{} \cdots \\ \bar{{\bar{x}}}_{m1} &{} \bar{{\bar{x}}}_{m2} &{} \cdots &{} \bar{{\bar{x}}}_{mn} \end{pmatrix} \end{aligned}$$(29)where m is the cardinality of the set of alternatives, n is the cardinality of criteria set.

-

Step 2:

Normalize the primary decision matrix (X) using Eqs. (30)–(32). The normalized decision matrix (Y) is shown in Eq. (42). This step makes the elements of X commensurable.

$$\begin{aligned} Y=\begin{pmatrix} \bar{{\bar{y}}}_{11} &{} \bar{{\bar{y}}}_{12} &{} \cdots &{} \bar{{\bar{y}}}_{1n}\\ \bar{{\bar{y}}}_{21} &{} \bar{{\bar{y}}}_{22} &{} \cdots &{} \bar{{\bar{y}}}_{2n}\\ \cdots &{} \cdots &{} \cdots &{} \cdots \\ \bar{{\bar{y}}}_{m1} &{} \bar{{\bar{y}}}_{m2} &{} \cdots &{} \bar{{\bar{y}}}_{mn} \end{pmatrix} \end{aligned}$$(30)Elements \(\bar{{\bar{y}}}_{ij}\) of the normalized matrix (Y) are calculated according to Eqs. (31) and (32): (a) For benefit type criteria

$$\begin{aligned} \bar{{\bar{y}}}_{ij}= & {} \left\{ \left[ \left( \frac{x_{ij}^{lL} -x_{j-}^{L}}{x_{j+}^{U}-x_{j-}^{L}}, \frac{x_{ij}^{lU} -x_{j-}^{L}}{x_{j+}^{U}-x_{j-}^{L}} \right) , \left( \frac{x_{ij}^{tL} -x_{j-}^{L}}{x_{j+}^{U}-x_{j-}^{L}}, \frac{x_{ij}^{tU} -x_{j-}^{L}}{x_{j+}^{U}-x_{j-}^{L}} \right) ,\right. \right. \nonumber \\&\left. \left. \times \left( \frac{x_{ij}^{rL} -x_{j-}^{L}}{x_{j+}^{U}-x_{j-}^{L}}, \frac{x_{ij}^{rU} -x_{j-}^{L}}{x_{j+}^{U}-x_{j-}^{L}} \right) \right] \right\} \end{aligned}$$(31)(b) For cost type criteria

$$\begin{aligned} \bar{{\bar{y}}}_{ij}= & {} \left\{ \left[ \left( \frac{x_{ij}^{rU} -x_{j+}^{U}}{x_{j-}^{L}-x_{j+}^{U}}, \frac{x_{ij}^{rL} -x_{j+}^{U}}{x_{j-}^{L}-x_{j+}^{U}} \right) , \left( \frac{x_{ij}^{tU} -x_{j+}^{U}}{x_{j-}^{L}-x_{j+}^{U}}, \frac{x_{ij}^{tL} -x_{j+}^{U}}{x_{j-}^{L}-x_{j+}^{U}} \right) ,\right. \right. \nonumber \\&\left. \left. \times \left( \frac{x_{ij}^{lU} -x_{j+}^{U}}{x_{j-}^{L}-x_{j+}^{U}}, \frac{x_{ij}^{lL} -x_{j+}^{U}}{x_{j-}^{L}-x_{j+}^{U}} \right) \right] \right\} \end{aligned}$$(32)where \(x_{j+}^{U}\) and \(x_{j-}^{L}\) are defined as \(x_{j+}^{U}=\max \limits _{1\le i\le m}\Big \{ x_{ij}^{rU}\Big \}\) and \(x_{j-}^{L}=\min \limits _{1\le i\le m}\Big \{ x_{ij}^{lL}\Big \}\)

-

Step 3:

Calculate the weighted decision matrix \(V=\left[ \bar{{\bar{v}}}_{ij}\right] _{m\times n}\) from Y. The components of V can be computed according to Eq. (33) as follows.

$$\begin{aligned} \bar{{\bar{v}}}_{ij}=\bar{{\bar{w}}}_{j}\times \left( \bar{{\bar{y}}}_{ij} +1\right) \end{aligned}$$(33)and the weighted IVFRN based decision matrix becomes

$$\begin{aligned} V=\begin{pmatrix} \bar{{\bar{v}}}_{11} &{} \bar{{\bar{v}}}_{12} &{} \cdots &{} \bar{{\bar{v}}}_{1n}\\ \bar{{\bar{v}}}_{21} &{} \bar{{\bar{v}}}_{22} &{} \cdots &{} \bar{{\bar{v}}}_{2n}\\ \cdots &{} \cdots &{} \cdots &{} \cdots \\ \bar{{\bar{v}}}_{m1} &{} \bar{{\bar{v}}}_{m2} &{} \cdots &{} \bar{{\bar{v}}}_{mn} \end{pmatrix} \end{aligned}$$(34)where \(\bar{{\bar{y}}}_{ij}\) symbolize components of Y, \(\bar{{\bar{w}}}_{j}\) represents the weight coefficients of the criteria.

-

Step 4:

Determining the border approximation area matrix (G).

The border approximation area matrix (BAA) is determined according to Eq. (35)

$$\begin{aligned} {\left\{ \begin{array}{ll} \bar{{\bar{g}}}_{j}=\left[ (g_{j}^{lL}, g_{j}^{lU}), (g_{j}^{tL}, g_{j}^{tU}), (g_{j}^{rL}, g_{j}^{rU})\right] =\left( \prod \limits _{i=1}^{m}\bar{{\bar{v}}}_{ij}\right) ^{1/m}\\ \text {where}\\ (g_{j}^{lL}, g_{j}^{lU})=\left( \left\{ \prod \limits _{i=1}^{m}\bar{{\bar{v}}}_{ij}^{lL}\right\} ^{1/m}, \left\{ \prod \limits _{i=1}^{m}\bar{{\bar{v}}}_{ij}^{lU}\right\} ^{1/m} \right) ;\\ (g_{j}^{tL}, g_{j}^{tU})=\left( \left\{ \prod \limits _{i=1}^{m}\bar{{\bar{v}}}_{ij}^{tL}\right\} ^{1/m}, \left\{ \prod \limits _{i=1}^{m}\bar{{\bar{v}}}_{ij}^{tU}\right\} ^{1/m} \right) ;\\ (g_{j}^{rL}, g_{j}^{rU})=\left( \left\{ \prod \limits _{i=1}^{m}\bar{{\bar{v}}}_{ij}^{rL}\right\} ^{1/m}, \left\{ \prod \limits _{i=1}^{m}\bar{{\bar{v}}}_{ij}^{rU}\right\} ^{1/m} \right) \end{array}\right. } \end{aligned}$$(35)where \(\bar{{\bar{v}}}_{ij}\) represent elements of weighted matrix (V), M represents the total number of alternatives.

After calculating the values of \(\bar{{\bar{g}}}_{j}\)the border approximation area matrix G in Eq. (36) is formed, format \(1\times n\) (n represents the total number of criteria by which alternatives are selected).

$$\begin{aligned} G=\left[ \bar{{\bar{g}}}_{1}, \bar{{\bar{g}}}_{2}, \ldots , \bar{{\bar{g}}}_{n}\right] _{1\times n} \end{aligned}$$(36) -

Step 5:

Calculating the elements of the matrix for the distance of the alternatives from the border approximation area (Q).

The distance of the alternatives from the BAA is determined as the difference between the elements from weighted matrix (V) and the values of the border approximation area (G)

$$\begin{aligned} Q=\begin{pmatrix} \bar{{\bar{v}}}_{11}-\bar{{\bar{g}}}_{1} &{} \bar{{\bar{v}}}_{12}-\bar{{\bar{g}}}_{2} &{} \cdots &{} \bar{{\bar{v}}}_{1n}-\bar{{\bar{g}}}_{n}\\ \bar{{\bar{v}}}_{21}-\bar{{\bar{g}}}_{1} &{} \bar{{\bar{v}}}_{22}-\bar{{\bar{g}}}_{2} &{} \cdots &{} \bar{{\bar{v}}}_{2n}-\bar{{\bar{g}}}_{n}\\ \cdots &{} \cdots &{} \cdots &{} \cdots \\ \bar{{\bar{v}}}_{m1}-\bar{{\bar{g}}}_{1} &{} \bar{{\bar{v}}}_{m2}-\bar{{\bar{g}}}_{2} &{} \cdots &{} \bar{{\bar{v}}}_{mn}-\bar{{\bar{g}}}_{n} \end{pmatrix} =\begin{pmatrix} \bar{{\bar{q}}}_{11} &{} \bar{{\bar{q}}}_{12} &{} \cdots &{} \bar{{\bar{q}}}_{1n}\\ \bar{{\bar{q}}}_{21} &{} \bar{{\bar{q}}}_{22} &{} \cdots &{} \bar{{\bar{q}}}_{2n}\\ \cdots &{} \cdots &{} \cdots &{} \cdots \\ \bar{{\bar{q}}}_{m1} &{} \bar{{\bar{q}}}_{m2} &{} \cdots &{} \bar{{\bar{q}}}_{mn} \end{pmatrix} \end{aligned}$$(37)where \(\bar{{\bar{g}}}_{j}\) represents the BAA for criterion \(C_j, \bar{{\bar{v}}}_{ij}\) represents the elements of weighted decision matrix (V). Further, n represents the number of criteria, m represents the number of alternatives.

The values of the criteria functions for the alternatives are obtained as the sum of the distance of the alternatives from the border approximation areas \(\bar{{\bar{q}}}_{ij}\). By summing the elements of the matrix (37) by rows we obtain the final values of the criteria functions of the alternatives

$$\begin{aligned}&S(A_i)=\sum \limits _{j=1}^{n} \bar{{\bar{q}}}_{ij}\nonumber \\&\quad =\left[ \left( \sum \limits _{j=1}^{n} q_{ij}^{lL}, \sum \limits _{j=1}^{n} q_{ij}^{lU}\right) , \left( \sum \limits _{j=1}^{n} q_{ij}^{tL}, \sum \limits _{j=1}^{n} q_{ij}^{tU}\right) , \left( \sum \limits _{j=1}^{n} q_{ij}^{rL}, \sum \limits _{j=1}^{n} q_{ij}^{rU}\right) \right] \end{aligned}$$(38)where n represents the number of criteria, m represents the number of alternatives. The alternatives are ranked based on the value obtained for \(S(A_i)\). The highest possible value of \(S(A_i)\) is desirable. The alternatives are compared using Eq. (38).

-

Step 6:

Defining the dominance index \(\left( A_{D, 1-i} \right) \) of the best-ranked alternative and final rank of alternatives.

The dominance index of the best-ranked alternative defines its advantage in relation to the other alternatives, and determined here by applying Eq. (39).

$$\begin{aligned} A_{D, 1-i}=\bigg \vert \frac{\vert Q_i \vert + \vert Q_1 \vert }{\vert Q_m \vert } \bigg \vert ~~~ i=1, 2, \ldots , m. \end{aligned}$$(39)where \(Q_1\) denotes the criterion function of the best-ranked alternative, \(Q_m\) denotes the criterion function of the last ranked alternative, \(Q_i\) denotes the criterion function of the alternative which is compared to the best-ranked alternative, and m denotes the number of alternatives. More details ranking order using dominance index can be found in Chatterjee et al. (2018).

5 Case illustration

To illuminate IVFRN-FARE-MABAC approach recommended in this paper, a real case study of food SCM has been discussed.

5.1 Outline of case enterprise

Well-founded ABC Bakery Ltd (Name Altered) is a bakery food manufacturing enterprise located on the outer edge of Durgapur–Asansol division of Burdwan district in West Bengal, India. The enterprise is in full service of bakery products specializing in wedding, anniversary, and birthday cakes, for over forty years. This food stuff is parceled in several carton volumes of plastic baggage, grooved paper containers, packets, and tin vessels. The enterprise has over-all capital overheads of roughly INR 40 Lakhs and control about 20–25% of the bakery food bazaar in West Bengal.

The FMC uses fresh ingredients/raw materials like real butter, low-fat fresh cream, and milk, flour, sugar, Swiss, and Belgian Chocolates as primary raw materials for bakery products. Raw material suppliers consist of 10 free-lancers, 300 enlightened dairy farmers, 12 distinct sub-divisions, and five wholesale merchants. They collect milk from thousands of milk producers and flour, sugar, and chocolates from the wholesale merchants. The raw material collection centers are distributed across numerous small cities and villages within 100 km distance from the Plant. Since perishable food product (milk) has a limited life span and other raw materials are nonperishable, so their proper collection, inspection, and transportation is a burdensome procedure including a complex transport system. The case company utilizes merely the premium and newest materials in its foodstuffs, with the persistence of quality control at every phase of manufacturing, packing, and on time distribution. It is also concrete about the reliability and consistency in raw material quality. However, transportation costs of raw materials are endured by the company. It is necessary to make procurement of all types of raw materials timely and efficiently followed inspection and transportation of them. Hence, ABC Bakery Ltd has decided to outsource its raw material procurement activities to a 3PL provider for managing this complex transport network efficiently and successfully.

5.2 Data collection and implementation of IVFRN-FARE-MABAC method

The FMC has formed a board of four decision makers (DMs)/experts to identify a well-organized and dependable 3PL provider with whom the FMC can have an active collaboration in the long-run of business partnership. All DMs/experts have more than 15 years of work experience in the area of food SCM. From the literature survey, a data set of 25 essential criteria are sorted with the help of these experienced DMs and finally, 15 criteria are accounted for the case FMC which aims to satisfy the main three dimensions/objectives (economic, environmental, and social) of sustainability while selecting a suitable 3PL provider (Refer to Table 2). The board of experts then assessed the relative importance (see Table 4) and inter-relationship impacts (see Table 3) of the enlisted criteria in the decision making process using the concepts of linguistic variables and the corresponding TFNs. On calling the tenders for logistics providers, the case FMC found six 3PL provider companies as feasible collaborator having specialized in food SCM. These six companies were named as A1, A2, A3, A4, A5, and A6. Next, the feasible alternatives 3PL provider 1 (A1), 3PL provider 2 (A2), 3PL provider 3 (A3), 3PL provider 4 (A4), 3PL provider 5 (A5), 3PL provider 6 (A6)) are evaluated based on their service performances using TFNs as depicted in Table 5.

To show the utilization of IVFRN approach for manipulating the uncertainty in data, we first explain one simple numerical illustration. Assume that the Table 6 represents the four DMs’ pairwise comparison of potential impact (\(Z_{SO}^{EN}=\lbrace {\tilde{3}}, {\tilde{4}}, {\tilde{5}}, {\tilde{5}}\rbrace \)) between the social (SO) and environmental (EN) dimensions. According to the Eqs. (1)–(14), the upper and lower approximation of the IVFRNs can be very simply determined. Note that SO dimension is compared with EN by four DMs who were invited to evaluate the potential impacts between the criteria and dimensions and they use triangular fuzzy numbers (TFN) for this evaluation problem. Now, a TFN can be represented as \({\tilde{P}}=(l, t, r)\) with t being the modal value of membership function, whereas l and r represent the left and right boundaries of the TFN, respectively. Table 6 reveals the fact that the DMs do not possess the same opinions while evaluating the potential impact between SO and EN factors. Following the procedure of IVFRN rating calculation discussed by Pamučar et al. (2018), we compute the relative potential impact \(Z_{SO}^{EN}\). A comparison of experts’ opinions can be represented by crisp, fuzzy, and IVFRN, as shown in Table 7.

5.3 Implementation of IVFRN-FARE model

In this section, we discuss the systematic procedure to calculate the criteria weights according to the proposed IVFRN-FARE method (refer to Sect. 4.1).

Firstly, we collect the pairwise comparison matrices (Tables 8, 9, 10 and 11) of main three criteria (EC, EN and SO) and among their sub-criteria. Next, the collected experts, data are aggregated using IVFRN method described in Eqs. (1)–(14). The aggregated pairwise comparison matrix of main three dimension is presented in Table 12. On contrast, Table 13 represents the aggregated pairwise comparison matrices of sub-criteria within each main dimension.

In order to calculate the criteria weight, we first have to find the total impact (\(\bar{{\bar{P}}}_j\)) of each criterion on the system according to Eq. (18). The initial total impacts (dependence) of evaluation dimensions ({EC, EN, SO}) and criteria ({EC1, EC2, \(\ldots \), EC5; EN1, EN2, \(\ldots \), EN5; SO1, SO2, \(\ldots \), SO5}) are presented in Table 14. Next, the actual total impact of each dimension and criterion are calculated through Eq. (22) and are presented in Table 15. Finally, using the Eqs. (20)–(22) we compute the local weights of each dimension and criterion. After calculating the local weights, the global weights of the evaluation criteria are calculated as follows. Global weight of a criterion= weight of its dimension x local weight of the criterion within its dimension. The local and global weights are shown in Table 16.

Now, in Table 16, the local priority orders indicate that “Cost of services” (EC1) is the most important economic criterion, while “Resource consumption” (EN1) is most preferred environmental concern in 3PL provider evaluation and selection for the case FMC. Moreover, Table 16 shows the local and global priorities of all the evaluation criteria in this case study. Based on the experts’ decisions, it is interesting to note that among these 15 criteria “Health and safety practices” (SO1) is ranked as the most important valuation criterion for 3PL provider selection problem. These weights are subsequently used for MABAC-based analysis.

5.4 Implementation of improved MABAC model with IVFRNs

For evaluating 3PL providers and selecting the best 3PL provider for the case FMC are accomplished with improved IVFRN-MABAC method (see from Sect. 4.2). Table 17 contains the performance evaluation data of six logistics providers which are evaluated by experts using the fuzzy variables described in Table 5. We follow the step-by-step calculation mechanism is discussed in Sect. 4.2 and phase 3 in Fig. 1.

Step 1: Firstly, the IVFRN-MABAC method includes the aggregation of the DM’s individual judgments via IVFRN arithmetic operations (Pamučar et al. 2018). In this method, the individual decision matrices are aggregated according to Eqs. (23)–(28) and finally Eq. (29) shows the average decision matrix containing IVFRNs. Let us discuss the calculation procedure briefly. Consider the evaluation of 3PL provider 1 (we call it, A1) against criteria EC1 (Cost of services). Four experts have assessed the performance of A1 with respect to EC1 and the \(\lbrace VG, G, G, VG\rbrace \). The linguistic variables are transformed into their corresponding triangular fuzzy numbers (TFNs) as \(\lbrace (3.5, 4, 4.5), (2.5, 3, 3.5), (2.5, 3, 3.5), (3.5, 4, 4.5)\rbrace \). Thus, from Eqs. (23)–(25), we divide the relative performance of A1 with respect to EC1 into three components: \(x_{11}^l=\lbrace 3.5,2.5,2.5,3.5\rbrace ; x_{11}^t=\lbrace 4,3,3,4\rbrace ; x_{11}^r=\lbrace 4.5,3.5,3.5,4.5\rbrace \). Then, the rough sequences are computed as follows:

Next, using IVFRN method as described by Eqs. (26)–(28) we get the aggregated IVFRN based performance, \(\bar{{\bar{x}}}_{11}=[(2.75,3.25), (3.25,3.75), (3.75,4.25)]\). The rest matrix entries of Eq. (29) are computed in the similar manner. Table 18 represents the aggregated IVFRN based decision matrix.

Step 2: The data in the IVFRN based decision matrix obtained in the previous step are normalized according to Eqs. (30)–(32) and make them commensurable. In order to calculate of the normalized performances, we first determine

and

Thus, we have

i.e.

Similarly, we compute normalize the rest data and get the normalized decision matrix (see Table 19)

Step 3: The weighted normalized decision matrix is computed according to Eqs. (33)–(34). In this step, the criteria weights obtained by using IVFRN-FARE model are multiplied with the normalized performances of the 3PL providers. Table 20 represents the weighted normalized performances of 3PL providers.

Step 4: According to Eq. (35), we compute the border approximation area (BAA) vector which is used as criteria reference points to obtain optimal solution (see Table 21). According to Eq. (35),

\(g_1^{lL}=\left( \prod \limits _{j=1}^6 \bar{{\bar{v}}}_{i1}^{lL}\right) ^{1/6}=\left( 0.032*0.035*0.027*0.025*0.03*0.032\right) ^{1/6}=0.03\)

\(g_1^{lU}=\left( \prod \limits _{j=1}^6 \bar{{\bar{v}}}_{i1}^{lU}\right) ^{1/6}=\left( 0.074*0.078*0.063*0.06*0.067*0.074 \right) ^{1/6}=0.069\)

\(g_1^{tL}=0.083\), \(g_1^{tU}=0.18\), \(g_1^{rL}=0.083\), and \(g_1^{rU}=0.18\).

Hence, \(\bar{{\bar{g}}}_1=[(0.03, 0.069), (0.083, 0.18), (0.218, 0.45)]\). In the same way, BAA of all criteria are calculated and presented in Table 21.

Step 5–6: The distances (closeness and remoteness) of the alternative logistic providers from the BAA is computed according to Eq. (37). The distance matrix (Q) is formed by the subtraction of the elements of the BAA matrix (G) from each element in the weighted matrix (V). Now, we obtain the values of criteria functions by taking the sum of each row of distance matrix (Q). According to Eq. (38), let us compute the initial value of the criterion function, \(S(A_1)\).

In a similar manner, we compute the initial value of the criterion function of other alternatives too. Alternative with highest criteria function value will get top rank. Based on the initial value of the criterion functions alternative 3PL providers are initially ranked (see Table 22).

Step 7: It is necessary for an alternative to have the biggest possible value of the criteria function, and therefore the primarily top-ranked 3PL provider is the one with the largest criteria function value (\(S_i\)). Here, A3 has been top ranked initially. In order to define the final rank of the alternative logistics providers, one must find the dominance index (Chatterjee et al. 2018) of the top-ranked 3PL provider in relation to other logistics providers. In our problem, the dominance threshold (DT) is calculated as \((6-1)/36=0.139\). Using Eq. (39) represent the formula to compute the dominance index of each alternatives. Second last column (i.e., \(A_{D, 1-i}\)) of Table 22 shows the DI of each alternatives. Now, we observe that the DI of A3(3PL provider 3) in relation to A6 (which was initially the second-ranked alternative) is smaller than the DT (0.139). So, we accomplish that 3PL provider 3 does not have sufficient gain in relation to 3PL provider 6, and thus 3PL provider 6 will be assigned the corrected rank “\(1^*\)”. Similar conclusions can be drawn for all other alternative candidates.

The reasons behind top ranking of 3PL provider 6 (A6) may be its low cost of services, delivery reliability, on automation of processes, environmental protection policies, carbon tax savings, health and safety practices, modern technical flexibility, etc. But, the logistic providers need to be proactive and live up to the changes in 3PL provider evaluation characteristics. Since these attributes can be altered due to market volatility caused by several factors like reducing lead time, improving transparency, Govt. law and policies, goods and service tax implementation, demonetization, digitalization.

6 Discussion of results

The result discussion section consists of a sensitivity analysis of the proposed IVFRN-FARE-MABAC model through fifteen scenarios and a comparative analysis of the results received from different MCDM methods.

6.1 The sensitivity analysis of the IVFRN-FARE-MABAC model

Roy (1988) recommended the application of imposing the idea of robustness in the obtained solutions as well as the conclusions. Robustness is the property of being strong and healthy in constitution. In the same line robustness can be defined as “the ability of a system to resist change without adapting its initial stable configuration”. Similarly, a decision is known as robust if it is true for all (or almost all) of the situations. Hites (2002) presented one more concept where a robust decision means a good solution and at the same time it should not be too risky. In this study, we perform a sensitivity analysis to investigate the effect of altering the criteria weights derived from experts’ judgments on the selection procedure of 3PL providers. This analysis consists of 15 different scenarios (S1 to S15). First scenario (S1) reveals that the weight of “Cost of services (EC1)” is raised by 55%, and all other criteria weights are reduced by 45%. In S2, the weight of “Reputation and market position (EC2)” is raised by 55%, while the weights of all other criteria are reduced by 45%. Similar arguments can be made for rest of the scenarios. The detail ranking orders of 15 situations are listed in Table 23 and shown in Fig. 3.

The initially best-ranked alternative is A3, as shown in Table 22. The ranking results in Table 23 indicate that alternative A3 and A6 are the best ranked, with good advantage, for the weight sets S1–S10 and S12–S15. Only in S11 the first ranked alternative is A5, but A6 is the second ranked. In fourteen out of fifteen scenarios, A3 or A6 are the first ranked alternatives.

In S1, S3, S4, S6, S7 and S8, the first ranked alternatives (A3 and A6) has no advantage to be a single solution since the dominance index \(A_{D,3-j}\) of the best-ranked alternative (A3) in relation to A6 is smaller than \(I_D=0.139\). We cannot say that the alternative A3 has enough advantage over A6 and therefore a rank “\(1^{*}\)” is assigned to A6. These results are confirming the ranks shown in Table 22. Also in other scenarios, the first ranked alternative is either A3 or A6.

In S2, S9, S13 and S14, alternative A3 is the first ranked and have enough domination over the second ranked alternative. This shows us that alternative A3 is better than other alternatives for some criteria like EC2, EC3, SO3 and SO4. In S12 alternative A6 is the first ranked and have enough domination over the second ranked alternative and we can conclude that A6 is better for SO2 than other alternatives.

Fluctuation of the weight priorities of criteria set under different situations caused those variations in the ranking order of six logistics providers. However, we witness no drastic change in the alternative ranking order in such circumstances. Spearman’s correlation coefficients (SCCs) are calculated for every scenario and presented in Table 24. A significantly high correlation of the ranks is noted in all scenarios except in S11. Such high correlation between the ranks indicates the trustworthiness of the final rank obtained by our proposed model.

6.2 A comparative analysis of the alternative ranking methods

In order to make ultimate decisions under with conflicting criteria/objectives, DMs requires a set of compromised (Pareto) solutions from which then can find optimal solution. The groundwork for compromised solution was established by Zeleny (1982). A compromised solution is a feasible solution, which is the nearest to the ideal one, and a compromise stands for a settlement accepted by joint concerns. The VIKOR method was presented as one appropriate MCDM tool for attaining the compromised solution (Opricovic 1998). On the other hand, the MABAC method fixes a solution after assessing the shortest distance from the ideal solution and the farthest distance from the negative-ideal solution (Pamučar and Ćirović, 2015). The COPRAS and CODAS methods define the ideal and anti-ideal alternative and measure the observed alternative in relation to the defined extreme points.

Since the MABAC model (like COPRAS, CODAS and VIKOR models) is based on an aggregating function representing closeness to the ideal solution, the results is shown through the application of these four models and their extensions using IVFRN, fuzzy and rough numbers. The comparative rankings obtained by MABAC, COPRAS, CODAS and VIKOR methods are showed in Table 25. The results indicate that the alternatives \(\{A3, A6\}\) are good solutions. Alternatives A3 and A6 are top ranked by all proposed models in Table 25. The alternatives ranked highest by IVFRN, fuzzy and rough MABAC approach are A3 and A6, of which alternative A3 is closer to the ideal according to the IVFRN MABAC and A6 is closer to the ideal according to the F-MABAC and R-MABAC approach. But, in all three approaches (IVFRN MABAC, F-MABAC and R-MABAC), neither A3 nor A6 have a sufficient advantage to be first ranked alternative. The ranking results by CODAS, COPRAS and VIKOR are similar to ranking order according to MABAC. The initially best-ranked alternative is A3 in all approaches except F-CODAS and R-VIKOR where A6 is first ranked. It may be concluded that two alternatives \(\{A3, A6\}\) are recognized as most appropriate solutions.

This result stands merely for the specified set of alternatives. Including (or excluding) an alternative might disturb the original ranking order produced by MABAC, CODAS, COPRAS and VIKOR and bring fresh ranking orders. One may avoid such phenomena if he/she fixes the best and the worst values. But, in that case is assumed the DM can describe a fixed ideal solution. This study does not consider the trade-off involved by normalization in obtaining the aggregating function in IVFRN MABAC method and this topic remains for further research.

Finally, the stability of the IVFRN–MABAC ranking result is checked by comparing them with the results obtained by using presented MCDM methods and their rough, fuzzy and IVFRN extensions. Once again the Spearman’s correlation coefficient (SCC) has been used to find the relations between the rankings obtained by using the proposed approach and other methods. The results are presented on Fig. 4.

For establishing the linkage among the outcomes attained using twelve dissimilar methods, the concept of SCC is again utilized here (see Table 25). From this comparative analysis and the corresponding SCC values, we plot Fig. 4 which depicts the high correlation among these methods. Such high correlation signifies the ability of the proposed IVFRN-FARE-MABAC model to effectively exploit the uncertainties that occur in group decision making.

7 Managerial implications

This study is aimed to assist DMs (managing director of the FMC) to carefully choose the most suitable 3PL provider for FMC which abides the environmental criteria and traditional criteria. The enhanced MCDM approach, an alternative solution to traditional ones, enables managers to select appropriate 3PL provider(s) and is successful in reducing the disparities in the green practices of several enterprises.

This study offers a careful investigation of 3 main dimensions and 15 sub-criteria for evaluating the 3PL providers and the managing director of the FMC can understand the whole process with added benefits. The first advantage of this research is the inclusive literature survey of evaluating dimensions and criteria. Secondly, a new flexible method that can tackle complex problems like setting criteria weights, performance evaluation of 3PL providers, and final selection of the alternative most likely to achieve the desired outcome with the best effect on the organization. This flexible technique deliberates sensitivity analyses at numerous stages and thus the manager can find more robust and appropriate solutions.

From the outcomes of this research work, managers can find a great difference in analytical strength if he/she compares our proposed method to the other traditional methods for a given problem. In spite of the existence conflicting opinions and lack of quantitative data the present study empowers the DMs to evaluate the alternate solutions and make fruitful decisions. This particular research is adequate to assist company managers dealing a larger amount of uncertainties and vagueness in 3PL provider selection procedure. In practical applications, the proposed model helps to obtain credible outcomes even if the decisive action has to be taken under uncertain circumstances due to insufficient and imprecise data. Thus, the model basically assists managers to cope up with their own subjective dilemmas while selecting criteria weights and logistics providers.

8 Conclusion

Evaluating and selecting 3PL provider for an organization is an MCDM problem. In this study, fifteen criteria are sorted from the main three dimensions of sustainability perspectives – economic, environmental, and social factors. These include cost of services, reputation and market position, technological expertise, geographical location, resource consumption, compliance with International Organization for Standardization (ISO), green distribution strategies and efficient transportation network, environmental protection policies, emission, effluents and waste generation, health and safety practices, staff training, equity labour sources, local community influence, and compliance with International Labour Organization (ILO) code are considered for optimal selection of 3PL provider for a FMC. In food SCM, the managers of FMC have to make decisions under high uncertainty and several quantitative and qualitative data. Therefore, IVFRN approach is adopted here since it has advantages of both the fuzzy sets theory and rough sets theory which are two best tools to manipulate uncertain data. With this consideration, this paper initially modified the FARE model with IVFRNs and then an improved version of IVFRN-MABAC method is defined by incorporating dominance index of alternatives. Finally, a hybrid evaluation framework named as IVFRN-FARE-MABAC is proposed for selecting the optimal 3PL provider for the case FMC. First, the IVFRN-FARE model is used to determine the relative local and global weights of the main dimensions and criteria accounted for 3PL provider selection in the FMC. Once the weights of valuation criteria are calculated, improved IVFRN-MABAC method is used to evaluate and select the feasible alternatives based on their ranking under hybrid uncertain environment, i.e., IVFRN set-up. The proposed framework incorporates both the fuzziness and roughness linked with real life decisions, thus improves the trustworthiness and reliability of the process.

This study tells that logistic providers A3 (3PL provider 3) and A6 (3PL provider 6) are found to be closer to the ideal solution. Initial rank shows A3 is the optimal choice whereas on plugging dominance index in evaluation process A6 outranks A3. Furthermore, sensitivity analysis shows robustness in the solution and the case FMC can select either A3 or A6 as a collaboration partner for its logistics services under sustainability perspectives. Result analysis shows the major reasons behind the top ranking of A3 and A6 is its prominence on its low cost of services, delivery reliability, on automation of processes, environmental protection policies, carbon tax savings, health and safety practices, modern technical flexibility, etc. These imply that 3PL provider must concentrate on improving its processes continuously in food SCM by incorporating advanced technologies and other inventive resources to meet volatile and complicated market demands. The outcomes of this study may not be generalized since the objectives/dimension and criteria and their relative priorities might change from company to company. To generalize these findings, one may carry out empirical study as a future research. Despite the possible different final results the projected research framework can be also implemented in several other firms from automotive services, IT service sectors, banking and hotel industry for 3PL provider selection.

The advantages of IVFRN-FARE-MABAC model over presented MCDM methods derives from the edges of FARE and MABAC models, which are its integral elements: (1) The simple concept and application of a familiar approach based on relative judgments of the criteria, that allows decision-makers to easily determine the weight coefficients of the criteria through their comparative comparisons; (2) Stable mathematical apparatus that allows easy adaptation to different decision problems depending on the hierarchical structure of the problem itself; (3) Also, unlike the fuzzy MCDM models (Fuzzy MABAC, Fuzzy CODAS, Fuzzy VIKOR, Fuzzy COPRAS) presented in this analysis, whose application needs to include the partial membership function having no sharp boundary of the sets, the IVFRN-FARE-MABAC method utilizes border area sets to express uncertainty. While fuzzy MCDM approaches aimed to tackle the degree of uncertainty on assumptions, IVFRN-FARE-MABAC method exhibits uncertainty on an approximation, which is the basic concept of rough sets. Finally, unlike the fuzzy and rough MCDM models, the IVFRN-FARE-MABAC model needs merely the internal information, which is nothing but the operational data and is exempted from depending on the prerequisite assumption. This is how the notion of an efficient MCDM method must utilize internal numerical information and tackle the inherent subjective uncertainty that occurs in the DMs’ preferences. Hence, the projected IVFRN-FARE-MABAC model can successfully tackle uncertainties in the assessment procedure of attributes, and further objectively replicate the DMs’ perceptions.

The IVFRN-FARE-MABAC method permits the actual treatment of qualitative data, subjectivity in experts’ opinions, and helps to make decisions in the presence of partial information or very little amount of data. Thus, DMs find it easier to convey their decisions while considering vagueness and insufficient information on specific phenomena. Although on the other hand, the IVFRN-FARE-MABAC model is based on a complex mathematical tool and, as such, its application in practice can cause an aversion to the manager. Therefore, the limitations of the model come from its hybrid components.

References

Abdur Razzaque, M., & Chen Sheng, C. (1998). Outsourcing of logistics functions: A literature survey. International Journal of Physical Distribution & Logistics Management, 28(2), 89–107.

Aguezzoul, A. (2014). Third-party logistics selection problem: A literature review on criteria and methods. Omega, 49, 69–78.

Bozanic, D., Tešić, D., & Milićević, J. (2018). A hybrid fuzzy AHP-MABAC model: Application in the Serbian Army—The selection of the location for deep wading as a technique of crossing the river by tanks. Decision Making: Applications in Management and Engineering, 1(1), 143–164.

Chatterjee, P., Mondal, S., Boral, S., Banerjee, A., & Chakraborty, S. (2017). A novel hybrid method for non-traditional machining process selection using factor relationship and multi-attribute border approximation method. Facta Universitatis, Series: Mechanical Engineering, 15(3), 439–456.

Chatterjee, K., Pamucar, D., & Zavadskas, E. K. (2018). Evaluating the performance of suppliers based on using the R’AMATEL-MAIRCA method for green supply chain implementation in electronics industry. Journal of Cleaner Production, 184, 101–129.

de Sousa Jabbour, A. B. L., Jabbour, C. J. C., Latan, H., Teixeira, A. A., & de Oliveira, J. H. C. (2014). Quality management, environmental management maturity, green supply chain practices and green performance of Brazilian companies with ISO 14001 certification: Direct and indirect effects. Transportation Research Part E: Logistics and Transportation Review, 67, 39–51.

Debnath, A., Roy, J., Kar, S., Zavadskas, E. K., & Antucheviciene, J. (2017). A hybrid MCDM approach for strategic project portfolio selection of agro by-products. Sustainability, 9(8), 1302.

Ecer, F. (2017). Third-party logistics (3PLs) provider selection via fuzzy AHP and EDAS integrated model. Technological and Economic Development of Economy, 24, 615–634.

Ginevičius, R. (2011). A new determining method for the criteria weights in multicriteria evaluation. International Journal of Information Technology & Decision Making, 10(06), 1067–1095.

Gonzalez-Torre, P., Alvarez, M., Sarkis, J., & AdensoDiaz, B. (2010). Barriers to the implementation of environmentally oriented reverse logistics: Evidence from the automotive industry sector. British Journal of Management, 21(4), 889–904.

Govindan, K., Agarwal, V., Darbari, J. D., & Jha, P. C. (2017a). An integrated decision making model for the selection of sustainable forward and reverse logistic providers. Annals of Operations Research, 273, 607–650.

Greco, S., Matarazzo, B., & Słowiński, R. (1997). Dominance-based rough set approach to interactive multiobjective optimization. In J. Branke, K. Deb, K. Miettinen, & R. Słowiński (Eds.), Multiobjective optimization: Interactive and evolutionary approaches. State-of-the-art surveys. LNCS (Vol. 5252, Chap. 5, pp. 121–155). Berlin: Springer.

Greco, S., Matarazzo, B., & Slowinski, R. (2001). Rough sets theory for multicriteria decision analysis. European Journal of Operational Research, 129(1), 1–47.

Haldar, A., Haldar, A., Qamaruddin, U., Qamaruddin, U., Raut, R., Raut, R., et al. (2017). 3PL evaluation and selection using integrated analytical modeling. Journal of Modelling in Management, 12(2), 224–242.

Hites, R. (2002). The aggregation of preferences method for solving combinatorial problems with uncertainty. In Proceedings of the 56th meeting of the European Working Group “multiple criteria decision aiding”.

Hsiao, H., Kemp, R. G. M., Van der Vorst, J. G. A. J., & Omta, S. O. (2010). A classification of logistic outsourcing levels and their impact on service performance: Evidence from the food processing industry. International Journal of Production Economics, 124(1), 75–86.

Jung, H. (2017). Evaluation of third party logistics providers considering social sustainability. Sustainability, 9(5), 777.

Kang, R., Zhang, T., Tang, H., & Zhao, W. (2016). Adaptive region boosting method with biased entropy for path planning in changing environment. CAAI Transactions on Intelligence Technology, 1(2), 179–188.

Kannan, D., Garg, K., Jha, P. C., & Diabat, A. (2017b). Integrating disassembly line balancing in the planning of a reverse logistics network from the perspective of a third party provider. Annals of Operations Research, 253(1), 353–376.

Keshavarz Ghorabaee, M., Amiri, M., Kazimieras Zavadskas, E., & Antuchevičenė, J. (2017). Assessment of third-party logistics providers using a CRITIC-WASPAS approach with interval type-2 fuzzy sets. Transport, 32(1), 66–78.

Lieb, R. C., & Bentz, B. A. (2004). The use of third-party logistics services by large American manufacturers: The 2003 survey. Transportation Journal, 43, 24–33.

Li, F., Li, L., Jin, C., Wang, R., Wang, H., & Yang, L. (2012). A 3PL supplier selection model based on fuzzy sets. Computers & Operations Research, 39(8), 1879–1884.

Liu, H. T., & Wang, W. K. (2009). An integrated fuzzy approach for provider evaluation and selection in third-party logistics. Expert Systems with Applications, 36(3), 4387–4398.

Mavi, R. K., Goh, M., & Zarbakhshnia, N. (2017). Sustainable third-party reverse logistic provider selection with fuzzy SWARA and fuzzy MOORA in plastic industry. The International Journal of Advanced Manufacturing Technology, 91, 2401–2418.

McCarthy, I., & Anagnostou, A. (2004). The impact of outsourcing on the transaction costs and boundaries of manufacturing. International Journal of Production Economics, 88(1), 61–71.

Milosavljevic, M. S., Bursać, M. & Tričković, G. (2018). The selection of the railroad container terminal in Serbia based on multi criteria decision making methods. Decision Making: Applications in Management and Engineering. https://doi.org/10.31181/dmame1802001m.

Oliveira Neto, G. C. D., Oliveira, J. C. D., & Librantz, A. F. H. (2017). Selection of Logistic Service Providers for the transportation of refrigerated goods. Production Planning & Control, 28, 813–828.

Opricovic, S. (1998). Multicriteria optimization of civil engineering systems. Faculty of Civil Engineering, Belgrade, 2(1), 5–21.

Pamucar, D., Chatterjee, K., & Zavadskas, E. K. (2019). Assessment of third-party logistics provider using multi-criteria decision-making approach based on interval rough numbers. Computers & Industrial Engineering, 127, 383–407.

Pamučar, D., & Ćirović, G. (2015). The selection of transport and handling resources in logistics centres using Multi-Attributive Border Approximation area Comparison (MABAC). Expert Systems with Applications, 42, 3016–3028.

Pamučar, D., Mihajlović, M., Obradović, R., & Atanasković, P. (2017). Novel approach to group multi-criteria decision making based on interval rough numbers: Hybrid DEMATEL-ANP-MAIRCA model. Expert Systems with Applications, 88, 58–80.

Pamučar, D., Petrović, I., & Ćirović, G. (2018). Modification of the best-worst and MABAC methods: A novel approach based on interval-valued fuzzy-rough numbers. Expert Systems with Applications, 91, 89–106.