Abstract

Managing value chain of perishable food items or pharmaceutical drugs is known as cold chain management. In India, approximately 30% fruits and vegetables get wasted due to lack of effective cold chain management. Logistic providers play a crucial role in making cold chains more effective. Based on literature review, ten criteria are selected for the third party logistics (3PL) selection process. Some of these criteria are transportation and warehousing cost, logistic infrastructure and warehousing facilities, customer service and reliability, network management, etc. This study illustrates a hybrid approach for selection of 3 PL for cold chain management under fuzzy environment. A hybrid model of Fuzzy AHP and Fuzzy TOPSIS is proposed in this paper for the selection of an appropriate 3PL in order to outsource logistics activities of perishable products. Fuzzy AHP is used to rank different criteria for 3PL selection, then Fuzzy TOPSIS is used to select the best 3 PL based on performance. The results imply that logistic providers should focus on practices such as automation of processes and innovation in cold chain processes to become more competitive.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

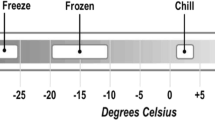

Managing value chain of products like food items, medicines, fruits, chemical products is a big challenge for organizations in the present volatile market. Most of such value chains are not able to sustain their performance due to huge losses and extra cost occurring at different stages (Manoj et al. 2008; Brandenburg and Rebs 2015). Singh et al. (2016) have observed that geographical dispersion of customers and their unpredictable demands as well as the varying shelf life of products has increased complexity in cold chain management. In developing countries such as India, approximately 30% fruits and vegetables get wasted due to lack of cold chain infrastructure available. Managing such kind of perishable products is known as Cold chain management (CCM). CCM can be defined as the process of planning, implementing and controlling the flow and storage of perishable goods, related services and information in order to enhance customer value and to ensure low costs (Bogataj et al. 2005; Fearne et al. 2006). Limited shelf life of perishable products asserts the need of special equipment and facilities for storage, sales, and distribution of these products under varying temperatures and humidity in order to preserve their usage and quality for a longer period of time (Shabani et al. 2012). A cold chain protects a wide variety of food, pharmaceutical, and chemical products from degradation, improper exposure to temperature, humidity, light or particular contaminants to keep them frozen, chilled and fresh. According to Bogataj et al. (2005), any deviation in time-distance or temperature in the chain, could hamper the net present value of the products. Cold chain management plays a significant part in modern global food commodities business (Jol et al. 2007). The primary objective of Cold chain management is the achievement of desired levels of service and quality at minimum cost through necessary planning and coordination of all involved activities (Christopher 2011).

According to James and James (2010); Akdemir (2008) and Kuo and Chen (2010), cold chain logistics can be broadly divided into three processes: cold processing (primary chilling and secondary cooling), cold storage (storage of perishable products under controlled temperatures) and cold transportation and distribution (sorting, distribution and transportation of perishable products in restricted timeframe). According to Gao Xuling et al. (2006), three main features of a CCL system are: (i) a large amount of investment for construction of complex systems. (ii) Timeliness required for higher co-operation of various organization sectors. (iii) Sufficient control of operation costs. Since, it has become increasingly difficult for organizations to perform these intricate logistics operations effectively with their core competencies of manufacturing; they tend to outsource their logistics operations to 3PL (Large et al. 2011).

A 3PL is an independent firm which provides logistics services under a contract to a primary manufacturer, vendor, or user of a product or services (Aguezzoul 2008). According to Göl and Çatay (2007), 3PL service providers contribute to achieving greater flexibility, operational efficiency, improved customer service levels, and a better focus on their core business. Five major 3PL functions are transportation, warehousing, inventory management, order processing & information system and packaging (Delfmann et al. 2002). Many 3PL companies are present in the market, which has resulted in a cut-throat competition. As a result, selection of appropriate 3PL from the available lot is of strategic importance for any organization as it enhances their competitive advantage and at the same time, it ensures the long-term relationship between the two firms (Perçin 2009; Bhatnagar et al. 1999; Troyer and Cooper 1995). 3PL selection is of primary importance in the cold supply chain due to the specific needs of customer preferences.

The cold chain industry in India is mainly unorganized sector. This sector lacks in terms of modern supply chain practices as well as it is not well researched in Indian scenario. This study has tried to address issues related to slection of 3 PL by using Fuzzy Analytical Hierarchy Process (FAHP) and Fuzzy Technique for Order Preference by Similarity to Ideal Solution (FTOPSIS). Paper has been organized as follows: Sect. 2 deals with literature review, Sect. 3 lays out the proposed selection methodology of Fuzzy AHP and Fuzzy TOPSIS, Sect. 4 deals with the case illustration of the proposed methodology and Sect. 5 presents the results and conclusion of the research work.

2 Literature review: cold chain management

Cold chain management can be defined as a process of planning, implementing and coordination of efficient and effective flow and storage of perishable goods and related services in order to satisfy customer’s requirements (Vorst and Van der 2000). All these activities should be properly scheduled for on time delivery of services (Manoj et al. 2008), Cold chain processes, particularly include sorting, distributing and transporting cold chilled frozen and fresh products (Kuo and Chen 2010). All food products have a temperature range under which they have to be kept for maintaining the food quality and food safety (Ovca and Jevšnik 2008). An increase in temperature may cause food poisoning or have a significant influence on Salmonellosis, Campylobacteriosis, Vibriosis, which are associated with diarrheal disease (Tirado et al. 2010). According to Coulomb (2008), the cold chain is necessary for health, avoiding diseases and deaths. Globalization has led to an increasing number of companies exporting food products. The increase in exports of food products due to globalization has put pressure for an effective logistics management system.

Due to the globalization of markets and competitive pressures, organizations are facing increasing demands to deliver customer-adapted products all over the world quickly and on time (Sohail and Al-Abdali 2005). Singh and Sharma (2015) have observed that supply chains doing better in terms of cost and responsiveness can sustain their performance. Involvement of logistics providers in a supply chain can reduce cost and delivery time (UNCTAD 2006). Cold chain logistics (CCL) may be considered as a logistics system involving refrigeration and temperature controlled compartments. Refrigeration is considerable in maintaining safety and quality of perishable products (James and James 2010). CCL involves transportation and storage of products like vegetables, fruits, meat, pharmaceuticals, etc. at various temperatures and under the strict timelines in order to ensure their satisfactory performance and quality (Guo et al. 2007). According to Shabani et al. (2012), cold chain logistic has emerged because of the limited shelf life of some products, which requires special equipment and facilities for sales, storage and distribution.

According to Christopher (2011), effective logistics management ensures that the requirement from customers is satisfied from the whole systems’ point of view, by employing methods like good material flow coordination, information flows and expanding of the marketplace. Logistics operations involve planning, implementation and controlling the flow of goods, services, and related information. Appropriate cold chain logistic operations can yield various benefits such as keeping the products at an appropriate temperature, improving the efficiency of the whole supply chain and saving cost when implementing cold chain work. According to Montanari’s (2008), data tracking and temperature monitoring are two significant components of the cold chain management system and further added that the implementation of monitoring in real time is of prime importance.

On the other hand, various challenges in the cold chain logistics system have been mentioned in the literature, particularly in the fields of innovative technologies, packaging, sustainability and customer satisfaction. As mentioned by Manzini and Accorsi (2012), innovative technologies mean specific techniques for inspecting the quality of food products, especially in raw materials. This is particularly done through RFID technology. It sufficiently reduces the number of recalls, which in turn saves cost for the company (Li and Chandra 2007). The unreliability in RFID implementation is a big challenge, especially in reading range and reading accuracy (Kumar et al. 2009). An innovative and good packaging would provide complete information for products, making it easier and simpler to register the goods, making it suitable for logistics operations like material handling, warehousing storage systems and shipments. Thus, it will save time and enhance the efficiency of logistics. Hamprecht et al. (2005) have observed two major challenges in supply sustainability. First, the manufacturing process should be refined and extended regularly in order to ensure a sustainable quality of the product. Secondly, the environment and society performance should be controlled and should be integrated into the work. Christopher (2011) has observed that increasing customers’ expectation has become a significant challenge for an organization because of increasing service-sensitive markets.

According to Perego et al. (2011), improvements in logistics are key factors in providing good customer service in terms of delivery, punctuality, timeliness, accuracy, and maintaining a sustainable performance. Because a company’s sustainable performance comes from the delivery process as from the product itself, logistics has been upgraded from its traditional backroom function to a strategic boardroom function. A typical cold chain infrastructure generally consists of pre-cooling facilities, cold storages, refrigerated carriers, packaging, warehouse, traceability, retailer, and consumers, under the aegis of information management systems (Montanari 2008).

In developing countries, apart from high wastage of perishable items such as fruits and vegetables, logistic cost is also very high. For example, in context to India, logistic cost is around 14% of GDP as compared to 8% in developed countries. The major causes behind this is an unorganized cold chain sector and poor infrastructure. Therefore present study will try to suggest an approach for selection of 3 PL on the basis of the comprehensive performance framework.

2.1 Selection of 3PL

Nowadays, organizations are trying to give more focus on their core competencies. According to Diabat et al. (2013), third-party logistics (3PL) is a single professional service provider, who will manage the logistics functions of a company, including inventory management, warehouse operations, physical distribution of goods, shipment consolidation, information systems, product returns, etc. A 3PL provider is an external company hired to perform some or all of the logistics activities that have traditionally been performed within an organization (Perçin 2009). A 3PL provider is usually associated with the offering of multiple, bundled services, rather than just isolated transport or warehousing functions (Leahy et al. 1995). Cho et al. (2008) have observed that the use of 3PL will increase a firm’s logistics capability and enhance its performance by leveraging the third-party’s expertise.

3PL selection is a complex multi-criteria decision-making problem as it involves various criteria depending upon the requirements and specifications of the outsourcing firm (Aguezzoul 2008). Partners’ culture, past experience, size, partners’ technical know-how, financial assets, managerial experience and access to markets are also important criteria for a compatible partner selection. Holistic logistics operations include activities such as purchasing and supply, materials handling, materials management, production planning and control, transport, storage, distribution, project management, installation and servicing, re-use and recycling and strategic management. Evaluating 3PLs based on their abilities to conduct the above mentioned logistic activities effectively and efficiently helps companies to increase the value of their goods which strengthens the customers‘ satisfaction. According to Bowersox and Closs (1996), the logistic activities must be measured in terms of availability, operational performance, and flexibility. Miller et al. (2013) have also developed a decision-support-system (DSS) to improve the firm’s ability to effectively utilize its storage capacity and meet customer shipping requirements across a widely dispersed network.

The study conducted by McGinnis et al. (1995) and Menon et al. (1998) in the USA concluded that both the firm’s competitiveness strategy and external environmental affect the selection criteria for 3PL. They also listed eight important criteria for 3PL selection which are on-time shipment and deliveries, superior error rates, financial stability, creative management, ability to deliver as promised, the availability of top management, responsiveness to unforeseen occurrences and meet performance and quality requirements before price discussions occur. These findings were further bolstered by Sangam (2004), who concluded that the 3PL selection criteria should include general information about product lines, price, shipping volumes, financial stability, growth forecast, IT systems used, quality standards, the value added services, and the capacity and compliance. Rijswijk and Frewer (2008) have observed that that traceability is very important not only for food safety but also for food quality. To counter the traceability problem, Montanari (2008) has found the need for reliable IT infrastructure of the cold chain. The web platform, even allows a company to overcome traditional logistics problems (Gunasekaran and Ngai 2003).

Spencer et al. (1994) used on-time service delivery, service quality, communication, reliability, service speed and flexibility criteria for 3PL Selection. McGinnis et al. (1995) and Menon et al. (1998) employed on-time shipment and deliveries, superior error rates, financial stability, creative management, the ability to deliver as promised, the availability of top management, responsiveness to unforeseen occurrences and meeting of performance and quality requirements as criteria for evaluating 3PL firms. Dapiran et al. (1996) and Bhatnagar et al. (1999) have found service quality, workforce capability, and cost as the most important criteria for a 3PL selection. Efendigil et al. (2008) used 12 performance indicators for 3PL selection which are: on time delivery rate, confirmed fill rate, service quality level, unit operation cost, capacity usage ratio, total order cycle time, system flexibility index, integration level index, increment in market share, research and development ratio, environmental expenditures and customer satisfaction index. Moberg and Speh (2004) found four most important criteria for 3PL selection i.e. responsiveness to service requirements, quality of management, the track record of ethical importance and ability to provide value-added services. Wolf and Seuring (2010) while studying the environmental impacts as criteria for 3PL selection reported that, although a 3PL shows an increasing interest in environmental issues, outsourcing decisions are essentially made on traditional performance indicators such as price, quality, and on-time delivery.

The share of organized retailing in the USA is around 80%, Europe—70%, Brazil—40% and China—20% (PWC 2007). In developing countries, the status of organized retailing is not very good. One of the reasons for this may be unorganized logistic providers. It is observed that around 35–40% of the total production of fresh fruits and vegetables is wasted in India, which is about the total production of the Great Britain. The primary reason for this waste may be a lack of adequate storage, transportation, cold chain facilities and other infrastructure supports. Therefore, organizations need to manage their logistics in a systematic manner. Consideration of criteria and their importance totally depend on the needs and prevailing economic conditions of the buyer firm. Therefore, clear and realistic objectives and expectations of a 3PL arrangement will allow a company to establish its selection criteria and select the 3PL, which will meet and provide the best service to the buyer firm (Sangam 2004). Based on literature review, the criteria selected for a 3PL selection process in this study are transportation and warehousing cost, logistic infrastructure and warehousing facilities, customer service and reliability, network management, material handling capabilities, quality control and inspection, automation of processes, innovation and effectiveness of cold chain processes, IT applications for tracking and tracing and flexibility of processes. These are summarized in Table 1.

3 Methodological background

Hybrid approach consisting of Fuzzy AHP and Fuzzy TOPSIS is applied for 3PL selection in cold chain management in the present study. Fuzzy AHP is employed to determine the relative weights of the criteria while Fuzzy TOPSIS is used to ascertain the final rankings of 3PL alternatives. Theory and mathematics of this model are based on studies done by Sun (2010) and Torfi et al. (2010). Govindan and Murugesan (2011) used Fuzzy Extent analysis for 3PL selection. Kumar and Singh (2012) have also used Fuzzy AHP and TOPSIS approach for 3PL selection in global supply chains. Singh and Sharma (2015) have used fuzzy AHP and extent analysis for evaluating most competitive supply chains. In this research paper, a hybrid approach of FAHP and FTOPSIS is employed for 3PL selection for cold chain management. FAHP is used to find the relative weights of the shortlisted criteria and FTOPSIS is employed to determine final rankings of the alternatives. Işıklar and Büyüközkan (2006) used AHP-TOPSIS hybrid to evaluate mobile phone alternatives. Gumus (2009) used this approach to evaluate hazardous waste transportation firms. Dağdeviren et al. (2009) employed AHP-TOPSIS under fuzzy decision-making environment for the purpose of weapon selection. Therefore Fuzzy AHP and Fuzzy TOPSIS approach had been very useful and realistic under fuzzy and uncertain conditions.

AHP is a Multi-Criteria Decision-Making tool, which is used extensively for modeling the unstructured problems in different areas such as politics, economics, social and management sciences (Buyukozkan et al. 2007). Pure AHP has some shortcomings. AHP is used in crisp-information, decision applications where the pairwise comparison is made by using a ratio scale. The unreliability associated with the mapping of one’s perception or judgments to a number are not taken into account (Büyüközkan et al. 2004). AHP works only with exact and ordinary data, whereas humans, because of their good ability for qualitative data processing make decisions in fuzzy environments (Torfi et al. 2009). Many studies used AHP integrated with fuzzy logic to solve different problems. Cakir and Canbolat (2008) used fuzzy AHP for an inventory classification system. Büyüközkan et al. (2004) used it to select the most appropriate software development strategy whereas Tolga et al. (2005) used it in the operating system selection problem. Pan (2008) used the application of fuzzy AHP for selection of suitable bridge construction method. Multiplicative priority rating methods for the AHP have been used by Stam and Duarte (2003). The level of faulty behavior risk has been evaluated by Dagdeviren and Yuksel (2008), based on the AHP methodology. Chen et al. (2008) used it to determine the weighting of subjective/perceptive judgment for criterion which was used to derive the fuzzy synthetic utility values of alternatives.

TOPSIS is a multi-criteria technique, which has been widely accepted because of its sound logic, the simultaneous condition of the ideal and anti-ideal solutions and easily programmable computation procedure (Kim et al. 1997). In TOPSIS, the rank of alternatives is calculated by finding its distance from the positive ideal solution and negative ideal solution, the alternative which has the shortest distance from the positive ideal solution and the longest distance from the negative ideal solution is the best. In TOPSIS the decision maker faces the difficulty of assigning precise performance rating to alternatives for the attributes under consideration. The crisp data used in TOPSIS are inadequate in the real life world, so linguistics assessment must be used instead of crisp values (Chu 2002). In the past 20 years, various methods have developed which integrates TOPSIS with fuzzy logic, which can be used for solving group decision-making problems. Chen (2000) has shown the usage of extensions of TOPSIS for group decision making in fuzzy environment. Feng and Wang (2000) used TOPSIS for evaluating the performance of different airlines. Chen et al. (2008) used interval-valued fuzzy TOPSIS method for experimental analysis.

3.1 Fuzzy set theory

Let U be the universe of discourse, \(\hbox {U}=\left\{ {\mu _1 ,\mu _2 ,\mu _3\ldots \mu _n } \right\} \). According to Zadeh (1965), a fuzzy set à of U is a set of ordered pairs \(\left\{ {\left( {\mu _1 ,f_{\tilde{A}} (\mu _1 )} \right) ,\left( {\mu _2 ,f_{\tilde{A}} (\mu _2 )} \right) ,\ldots \left( {\mu _n ,f_{\tilde{A}} (\mu _n )} \right) } \right\} \),where \(f_{\tilde{A}} ,f_{\tilde{A}} :U\rightarrow [0,1]\), is the membership function of à and \(f_{\tilde{A}} (\mu _i )\) indicates the grade of membership of \(\mu _i\) in Ã. Among various membership functions, the triangular fuzzy number is the most prominently applied in engineering applications. According to Dubois and Prade (1980), this fuzzy number is characterized by triangular distribution functions with the linear and symmetric sides, which is parameterized by a triple (m, n, p). In this methodology, t (m, n, p) is denoted as triangular fuzzy number Ã, with \(m\le n\le p\), where m and p stand for the lower and upper values for the support of à respectively and n stands for moderated value. Its membership function can be defined as:

The graph of the membership function of the triangular fuzzy number is shown in Fig. 1.

The algebraic operations on triangular numbers (Dubois and Prade 1980; Kaufmann and Gupta 1991) say \(\tilde{A}\) and \(\tilde{B}\) parameterized by triplet \((m_1 ,n_1 ,p_1 )\) and \((m_2 ,n_{2,} p_2)\) respectively are stated below:

The distance between \(\tilde{A}\) and \(\tilde{B}\) can be calculated using the vertex method as in the following equation:

3.2 Determination of linguistic variables

Linguistic Variables take values defined in the set of subjective linguistic terms. Linguistic terms are words or sentences in common language with the scale of fuzzy numbers associated with them to quantify their value. In this paper, fuzzy numbers defined by Gumus (2009) are employed along with their respective linguistic variables as shown in Table 2 and graphically represented in Fig. 2.

3.3 Fuzzy AHP

Analytical Hierarchy Process (AHP) is a multi-criteria decision-making tool in which a complex problem is broken down into multiple hierarchy levels representing multiple sub-problems. Each level consists of various attributes and criteria relative to each sub-problem. In this hybrid model, AHP is employed in a fuzzy environment to determine the relative weights of relevant criteria shortlisted for 3PL selection in the cold supply chain.

The process of carrying out Fuzzy AHP process is explained in the following steps.

Step 1 Construct a \(\hbox {n}\times \hbox {n}\) pairwise comparison matrix of criteria in terms linguistic variables and then substitute the linguistic variables with their corresponding fuzzy scales, as shown in the following matrix Ã.

where

The pairwise comparison is based on the Saaty’s research work on AHP (Saaty 1990).

Step 2 Geometric mean of each row of à now using the geometric mean technique and then fuzzy relative weight matrix is deduced by Hsieh et al. (2004).

where \(\tilde{\hbox {a}}_{\mathrm{in}}\) is a fuzzy comparison value of the criterion i to criterion n, thus, \(\tilde{\hbox {r}}_\mathrm{i}\) is geometric mean of fuzzy comparison value of the criterion i to each criterion, \(\tilde{\hbox {w}}_{\mathrm{i}}\) is the fuzzy weight of the \(\hbox {i}{\mathrm{th}}\) criterion, can be indicated by TFN.

Thus, we get a n x 1 relative weight matrix w. Each element of this matrix consists of a triangular fuzzy number, \(\tilde{\hbox {w}}_\mathrm{i} =( {\hbox {mw}_\mathrm{i} ,\hbox {nw}_\mathrm{i} ,\hbox {pw}_\mathrm{i} })\).

3.4 Fuzzy TOPSIS

TOPSIS evaluates alternatives about each criterion on the basis of their distance from the positive ideal solution (most favorable value about that criteria) and negative ideal solution (least favorable value about that criteria). An index is defined called similarity to the positive ideal solution and remoteness to the negative ideal solution about a criterion. The shorter the distance to the positive ideal solution about a criterion and longer the distance to the negative ideal solution about that criterion, more strong is the alternative about that criterion. Considering the difficulty of the decision maker to assign precise performance rating for an alternative about a particular criterion, fuzzy numbers are used instead of precise numbers to extend TOPSIS to fuzzy decision-making environment. Fuzzy TOPSIS is further extended to group decision making by amalgamating the evaluations of multiple decision makers (Kumar and Singh 2012). The process of carrying out fuzzy TOPSIS is explained in the following steps.

Step 1 Devise a fuzzy performance matrix \(\tilde{\hbox {D}}\) consisting of the evaluations of each alternative about each criterion under consideration. Appropriate linguistic variables must be chosen for this purpose. The linguistic variables are converted into the quantitative scales as shown in Table 3 and graphically represented by Fig. 3.

where \(\hbox {i} =1,2,{\ldots },\hbox {m}; \hbox {j}=1,2,{\ldots },\hbox {n}\) and \(\tilde{\hbox {x}}_{\mathrm{ij}}\) is the performance rating of alternative \(\hbox {A}_{\mathrm{i}}\) with respect to criterion \(\hbox {C}_{\mathrm{j}}\) evaluated by \(\hbox {k}{\mathrm{th}}\) expert. \(\tilde{\hbox {x}}_{\mathrm{ij}}\) is a triangular fuzzy number of the form (\(\hbox {m}^{\mathrm{k}}_{\mathrm{ij}}, \hbox {n}^{\mathrm{k}}_{\mathrm{ij}}, \hbox {p}^{\mathrm{k}}_{\mathrm{ij}})\).

Step 2 Normalize the fuzzy decision matrix to get matrix \(\tilde{\hbox {R}}\) where

Step 3 Weighted fuzzy normalized decision matrix \(\tilde{\hbox {V}}\) is calculated as shown:

Step 4 Determine the fuzzy positive ideal solution (FPIS) and fuzzy negative ideal solution (FNIS): We know that elements in the weighted fuzzy normalized matrix \(\tilde{\hbox {V}}\) are triangular fuzzy numbers and their ranges belong to the interval [0, 1]. Then, we can define the FPIS as \(\tilde{\hbox {v}}_\mathrm{j}^{{*}}=(1,1,1)\) and FNIS as \(\tilde{\hbox {v}}_\mathrm{j} ^{-}=(0,0,0); \; \hbox {j}=1,2,\ldots ,\hbox {n}\).

Step 5 Calculate the distance of each alternative from positive ideal solution (FPIS) and from negative ideal solution (FNIS) about each criterion using Eq. (3). Subsequently, we get two m \(\times \) n matrices. Now, employing the area compensation method in each matrix we get two m \(\times \) 1 matrix.

Step 6 Calculate closeness coefficient (\(\hbox {CC}_{\mathrm{i}})\) which is defined as closeness to the ideal solution by the following formula.

Thus, we will eventually get a \(\hbox {m}\times 1\) matrix with final performance scores of each alternative about all the criteria considered. Greater the score of the alternative, better the alternative.

4 Case illustration

To illustrate Fuzzy AHP-Fuzzy TOPSIS hybrid approach suggested in this paper, a case study from food sector has been taken.

4.1 Profile of case company

Firm XYZ Ltd (Name Changed) is a health food manufacturing company situated on the outskirts of National Capital Region (NCR) of New Delhi, India. The company runs three product lines-two for health food powders (used as nutritional additives to milk) and one for ghee (Milk Fat). These products are packaged in various pack sizes of polythene bags, corrugated paper boxes, cartons and tin containers. The company has a total capital outlay of approximately INR 50 million and commands around 10–12% of the health food market in India.

Milk is the major raw material for products manufactured by the company. Milk suppliers include 8 contractors, 200 progressive dairy farmers, 12 distant direct suppliers and various village collection centers (VCCs), collecting milk from around 25,000 milk producers. All of these are spread across various small towns and villages within 50 km distance from the Plant. Milk is a perishable food product with a limited shelf life. Its collection, inspection, and transportation is a cumbersome process involving a complex delivery network. The company is also particular about the quality of ingredients goings into its final products and banks on the reliability and consistency in raw material quality and delivery. Moreover, the raw material transportation cost is borne by the company. Hence, in order to ensure timely and efficient procurement, inspection and transportation of milk and to effectively manage this complex procurement network, Company XYZ Ltd has decided to outsource its milk procurement activities to a Third Party Logistics (3PL) Service provider.

4.2 Data collection and analysis of results

The management of the company has set-up a team of four members to select a compatible and reliable 3PL company with whom the company can enjoy a long-term business partnership. These experts were working in the area of cold chains in the food industry for past 10 years. Based on the literature, database available and the experience of a team of experts, ten criteria are shortlisted for the selection of a compatible 3PL (Table 1). The team of experts then determined the relative importance of the shortlisted criteria using concepts of linguistic variables and Fuzzy AHP as discussed in Sects. 3.1 and 3.2. These 3PLs (A1, A2, A3) were rated using linguistic variables as depicted in Table 3. The pairwise comparison matrix for all selected criteria as devised by the four experts based on Eq. 4 is as given in Table 4.

By using Fuzzy AHP Eqs. (5) and (6), fuzzy relative weight matrix for all criteria are obtained as shown below:

After opening the tenders for logistics companies, it was found that three 3PL companies, specializing in cold chain logistics have applied before the deadline. These three companies were named as \(\hbox {A}_{1},\hbox {A}_{2,}\) and \(\hbox {A}_{3}\). Then each individual member of the team evaluated each of the 3PL companies on the basis of the ten shortlisted criteria. Four experts were selected to evaluate 3PL firms based on their expertise. All experts were having more than ten years experience in the area of cold supply chains. Criteria were selected based on literature review and as per the requirements of company XYZ Ltd in order to select a compatible 3PL and to ensure a long-term healthy relationship between the two firms.

Using Eqs. (7) and (8) in Sect. 3, we get a fuzzy performance matrix as shown in Table 5 for all the Decision Makers (DMs) j = 1, 2, 3, 4.

An average rating of all the 3PLs are computed giving equal importance to all the decion makers fuzzy decision matrix is prepared which is shown in Table 6.

The elements of fuzzy decision matrix are normalized to bring them on the same quantitative scale from 0 to 1 using the Eqs. (9) and (10) and a fuzzy normalized matrix is prepared as shown in Table 7.

In the Table 7, the normalized elements are multiplied by the corresponding weights of criteria and a weighted matrix is prepared using Eqs. (11) and (12). The weighted fuzzy normalized matrix is shown in Table 8.

Using Eqs. (13) and (14) respectively, the distances of the alternatives, i.e. 3PLs from the positive ideal solution (1, 1, 1) and negative ideal solution (0, 0, 0) are calculated as given below:

Now, closeness coefficient based on closeness to ideal solution is calculated using Eq. (15) of Sect. 3 as shown below:

In TOPSIS analysis, \(\hbox {CC}_{\mathrm{i}}\) is defined as the closeness of the alternative to the positive ideal solution. Thus, greater the value of \(\hbox {CC}_{\mathrm{i}}\) for an alternative better is its rank. In the present case, based on the above analysis, \(\hbox {A}_{3}\) has got the highest CC of 0.100906 and it outperforms the other two alternatives in terms of selected criteria. As a result, \(\hbox {A}_{3}\) is the major candidate to win the contract for milk procurement and logistics operations of company XYZ Ltd. \(\hbox {A}_{3}\) is followed by \(\hbox {A}_{2}\) and \(\hbox {A}_{1}\). Reason behind top ranking of A3 may be, its strength on automation of processes, innovation in cold chain processes, IT applications for tracking and tracing, flexibility of processes. As market requirements are changing very fast in terms of lead time reduction, transparency, Govt. policies such as GST implementation, demonetisation, digital India and make in India, logistic providers need to be proactive in terms of these changes.

Conspicuous from the \(\hbox {CC}_{\mathrm{i}}\) values of all the three 3PL firms in contention, the respective scores are very close to each other indicating the sensitive nature of cold chain logistics providers. It also reflects that 3PL market is highly competitive, therefore each company operates with very close tolerances in their services. This is primarily done in order to provide high-quality services to the clients at the lowest possible cost, thus giving a competitive edge over its competitors. Therefore, under such a highly competitive environment, Fuzzy AHP- Fuzzy TOPSIS proves to be a credible and reliable methodology to find the best 3PL.

5 Conclusion

Selection of 3PL is based on multiple criteria. In this study ten criteria, i.e. transportation and warehousing cost, logistic infrastructure and warehousing facilities, customer service and reliability, network management, material handling capabilities, quality control and inspection, automation of processes, innovation and effectiveness of cold chain processes, IT applications for tracking and tracing and flexibility of processes are considered for selection of third-party logistics service providers (3PL) for a cold chain. In cold chain, 3PLs have to work under highly uncertain and fuzzy condition. Therefore a hybrid approach of Fuzzy AHP and Fuzzy TOPSIS has been illustrated with the help of a case study of the Indian food industry. Fuzzy AHP is used to determine the relative weights of the different criteria shortlisted for 3PL selection in the cold chain. After determining the weights of the selected criteria, fuzzy TOPSIS is used to rank the available alternatives for selecting the best 3PL under fuzzy decision-making environment. This methodology incorporates the fuzziness associated with real life decisions, thus increasing the reliability and credibility of the process.

Managerial implications, limitations and future scope In this study, logistic provider \(\hbox {A}_{3}\) is found most suitable 3 PL. On the basis of analysis done in the study, it is observed that the major reasons behind the top ranking of \(\hbox {A}_{3}\) is its emphasis on automation of processes, innovation in cold chain processes, IT applications for tracking and tracing and flexibility of processes. Therefore, the findings imply that 3PL should focus on continuous process improvement in cold chain by application of advanced technologies and other innovative means to meet dynamic and complex market requirements. As criteria and their relative ranking may vary from sector to sector, findings may not be generalized. For generalizing the findings, empirical study may be carried out as a future scope. Although the end results may differ, but the same methodology can be also applied in other sectors such as FMCG, automotive, service sectors such as banking and hotel industry for 3PL selection. In future, criteria may be selected related to sustainability measures such as use of renewable energy sources, use of recyclable and reusable packaging material and changing service quality measures. To further validate the robustness of the framework proposed, sensitivity analysis may be also carried out.

References

Agrawal, S., Singh, R. K., & Murtaza, Q. (2016). Outsourcing decisions in reverse logistics: Sustainable balanced scorecard and graph theoretic approach. Resources, Conservation and Recycling, 108, 41–53.

Aguezzoul, A. (2008). A preliminary analysis on third-party logistics selection. In 7th International Meeting for Research in Logistics AVIGNON (pp. 24–26).

Akdemir, S. (2008). Designing of cold stores and choosing of cooling system elements. Journal of Applied Science, 8(5), 788–794.

Bhatnagar, R., Sohal, A. S., & Millen, R. (1999). Third party logistics services: A Singapore perspective. International Journal of Physical Distribution and Logistics Management, 29(9), 569–587.

Bogataj, M., Bogataj, L., & Vodopivec, R. (2005). Stability of perishable goods in cold logistics chains. International Journal of Production Economics, 93–94(8), 345–35.

Bolumole, Y. (2001). The supply chain role of third-party logistics providers. International Journal of Logistics Management, 12(2), 87–102.

Bowersox, D. J., & Closs, D. J. (1996). Logistical management: The integrated supply chain process. New York: McGraw-Hill Companies.

Brandenburg, M., & Rebs, T. (2015). Sustainable supply chain management: A modeling perspective. Annals of Operations Research, 229(1), 213–252.

Büyüközkan, G., Kahraman, & Ruan, D. (2004). A fuzzy multi-criteria decision approach for software development strategy selection. International Journal of General Systems, 33(2–3), 259–280.

Buyukozkan, G., Ruan, D., & Feyzioglu, O. (2007). Evaluating e-Learning web site quality in a fuzzy environment. International Journal of Intelligent Systems, 22(5), 567–586.

Cakir, O., & Canbolat, M. S. (2008). A web-based decision support system for multi-criteria inventory classification using fuzzy AHP methodology. Expert Systems with Applications, 35(3), 1367–1378.

Chan, F. T. S., & Chan, H. K. (2004). Development of the supplier selection model—a case study in the advanced technology industry. Journal of Engineering Manufacture, 218, 1807–1823.

Chen, C.-T. (2000). Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Sets & Systems, 114(1), 1–9.

Chen, M.-F., Tzeng, G.-H., & Ding, C.-G. (2008). Combining fuzzy AHP with MDS in identifying the preference similarity of alternatives. Applied Soft Computing, 8(1), 110–117.

Cho, J. J.-K., Ozment, J., & Sink, H. (2008). Logistics capability, logistics outsourcing and firm performance in an E-commerce market. International Journal of Physical Distribution & Logistics Management, 38(5), 336–359.

Chow, H. K. H., Choy, K. L., Lee, W. B., & Chan, F. T. S. (2005). Design of a knowledge based logistics strategy system. Expert Systems with Applications, 29(2), 272–290.

Choy, K. L., Chow, H. K. H., Tan, K. H., Chan, C. K., Mok, E. C. M., & Wang, Q. (2008). Leveraging the supply chain flexibility of third party logistics-hybrid knowledge based system approach. Expert Systems with Applications, 35(4), 1998–2016.

Choy, K. L., Lee, C. L., So, S. C. K., Lau, H., Kwonk, S. K., & Leung, D. (2007). Managing uncertainty in logistics service supply chain. International Journal of Risk Assessment and Management, 7(1), 19–43.

Christopher, M. (2011). Logistic & supply chain management (4th ed.). Cambridge: Pearson Education Limited.

Chu, T. C. (2002). Facility location selection using fuzzy TOPSIS under group decisions. International Journal of Uncertainty, Fuzziness & Knowledge-Based Systems, 10(6), 687–701.

Coulomb, D. (2008). Refrigeration and cold chain serving the global food industry and creating a better future: Two key IIR challenges for improved health and environment. Trend in Food Science & Technology, 19(8), 413–417.

Dagdeviren, M., & Yuksel, I. (2008). Developing a fuzzy analytic hierarchy process (AHP) model for behavior-based safety management. Information Sciences, 178(6), 1717–1733.

Dapiran, P., Lieb, R., Millen, R., & Sohal, A. (1996). Third party logistics services usage by large Australian firms. International Journal of Physical Distribution and Logistics Management, 26(10), 36–45.

Delfmann, W., Albers, S., & Gehring, M. (2002). The impact of electronic commerce on logistics service providers. International Journal of Physical Distribution & Logistics Management, 32(3), 203–222.

Diabat, A., Khreishah, A., Kannan, A., Panikar, V., & Gunasekaran, A. (2013). Benchmarking the interactions among barriers in third-party logistics implementation. Benchmarking: An International Journal, 20(6), 805–824.

Dubois, D., & Prade, H. (1980). Fuzzy sets and systems: Theory and applications. New York: Academic Press.

Efendigil, T., Önüt, S., & Kongar, E. (2008). A holistic approach for selecting a third-party reverse logistics provider in the presence of vagueness. Computers & Industrial Engineering, 54(2), 269–287.

Feng, C. M., & Wang, R. T. (2000). Performance evaluation for airlines including the consideration of financial ratios. Journal of Air Transport Management, 6, 133–142.

Flint, D. J., Larsson, E., Gammelgaard, B., & Mentzer, J. T. (2005). Logistics innovation: A customer value-oriented social process. Journal of Business Logistics, 26(1), 113–147.

Fu, P., & Yin, H. (2012). Logistics enterprise evaluation model based on fuzzy clustering analysis. Physics Procedia, 24(C), 1583–1587.

Göl, H., & Çatay, B. (2007). Third party logistics provider selection: Insights from Turkish automobile company. Supply Chain Management: An International Journal, 12(6), 379–384.

Govindan, K., & Murugesan, P. (2011). Selection of third-party reverse logistics provider using fuzzy extent analysis. Benchmarking: An International Journal, 18(1), 149–167.

Gumus, A.-T. (2009). Evaluation of hazardous waste transportation firms by using a two step fuzzy-AHP and TOPSIS methodology. Expert Systems with Applications, 36(2), 4067–4074.

Gunasekaran, A., & Ngai, E. W. T. (2003). The successful management of a small logistics company. International Journal of Physical Distribution & Logistics Management, 33(9), 825–842.

Gunasekaran, A., & Ngai, E. W. T. (2004). Information systems in supply chain integration and management. European Journal of Operational Research, 159(2), 269–295.

Guo, L., Ma, Y., Sun, D., & Wang, P. (2007). Effects of controlled freezing-point storage at \(0^\circ \)C on quality of green bean as compared with cold and room-temperature storages. Journal of Food Engineering, 86(1), 25–29.

Gupta, R., Sachdeva, A., & Bhardwaj, A., (2010). Selection of 3PL service provider using integrated fuzzy delphi and fuzzy TOPSIS. In Proceedings World Congress on Engineering and Computer Science, 20–22 October, San Francisco.

Hamprecht, F., Corsten, D., Noll, M., & Meier, E. (2005). Controlling the sustainability of food supply chains. Supply Chain Management: An International Journal, 10(1), 7–10.

Ho, W., He, T., Lee, C. K. M., & Emrouznejad, A. (2012). Strategic logistic outsourcing: An integrated QFD and fuzzy AHP approach. Expert Systems with Applications, 39(12), 10841–10850.

Hsieh, T.-Y., Lu, S.-T., & Tzeng, G.-H. (2004). Fuzzy MCDM approach for planning and design tenders selection in public office buildings. International Journal of Project Management, 22(7), 573–584.

Işiklar, G., Alptekin, E., & Büyüközkan, G. (2007). Application of a hybrid intelligent decision support model in logistic outsourcing. Computer and Operations Research, 34(12), 3701–3714.

James, S. J., & James, C. (2010). The food cold-chain and climate change. Food Research International, 43(7), 1944–1956.

Jharkharia, S., & Shankar, R. (2007). Selection of logistics service provider: An analytic network process (ANP) approach. Omega, 35(3), 2744–2789.

Jol, S., Kassianenko, A., Wszol, K., & Oggel, J. (2007). The cold chain, one link in Canada’s food safety initiatives. Food Control, 18(6), 713–715.

Kaufmann, A., & Gupta, M. M. (1991). Introduction to fuzzy arithmetic: Theory and applications. Van Nostrand Reinhold Co.

Kim, G., Park, C. S., & Yoon, K. P. (1997). Identifying investment opportunities for advanced manufacturing systems with comparative-integrated performance measurement. International Journal of Production Economics, 50(1), 23–33.

Kumar, M., Vrat, P., & Shankar, R. (2006). A multi objective 3PL allocation problem for fish distribution. International Journal of Physical Distribution and Logistics Management, 36(9), 702–715.

Kumar, P., & Singh, R. K. (2012). A fuzzy AHP and TOPSIS methodology to evaluate global 3PL. Journal of Modelling in Management, 7(3), 287–303.

Kumar, R., Reintz, H. W., Simunovic, J., Sandeep, K. P., & Franzon, P. D. (2009). Overview of RFID technology and its applications in the food industry. Journal of Food Science, 74(8), 101–106.

Kuo, J. C., & Chen, M. C. (2010). Developing an advanced multi-temperature joint distribution system for the food cold chain. Food Control, 21(4), 559–566.

Large, R. O., Kramer, N., & Hartmann, R. K. (2011). Customer-specific adaptation by providers and their perception of 3PL-relationship success. International Journal of Physical Distribution & Logistics Management, 41(9), 822–838.

Leahy, S. E., Murphy, P. R., & Poist, R. F. (1995). Determinants of successful logistical relationships: A third party provider perspective. Transportation Journal, 35(2), 5–13.

Li, X., & Chandra, C. (2007). Efficient knowledge integration to support a complex supply network management. International Journal of Manufacture Technology Management, 10(1), 1–18.

Manoj, U. V., Gupta, J. N. D., Gupta, S. K., & Sriskandarajah, C. (2008). Supply chain scheduling: Just-in-time environment. Annals of Operations Research, 161(1), 53–86.

Manzini, R., & Accorsi, R. (2012). The new conceptual framework for food supply chain assessment. Journal of Food Engineering, 115, 251–263.

McGinnis, M., Kochunny, C., & Ackerman, K. (1995). Third party logistics choice. International Journal of Logistics Management, 6(2), 93–102.

Melnyk, A. S., Davis, E. W., Spekman, R. E., & Sandor, J. (2010). Outcome-driven supply chains. MIT Sloan Management Review, 51(2), 33–38.

Menon, M., McGinnis, M., & Ackerman, K. (1998). Selection criteria for providers of third-party logistics services: An exploratory study. Journal of Business Logistics, 19(1), 121–137.

Miller, T., Peters, E., Gupta, V., & Bode, O. (2013). A logistics deployment decision support system at Pfizer. Annals of Operations Research, 203(1), 81–99.

Min, S., Roath, A. S., Daugherty, P. J., Genchev, S. E., Haozhe, C., Arndt, A. D., et al. (2005). Supply chain collaboration: What’s happening? The International Journal of Logistics Management, 16(2), 237–256.

Moberg, C. R., & Speh, T. W. (2004). Third-party warehousing selection: A comparison of national and regional firms. American Journal of Business, 19(2), 71–76.

Montanari, R. (2008). Cold chain tracking: A managerial perspective. Trends in Food Science & Technology, 19, 425–431.

Ovca, A., & Jevšnik, M. (2008). Maintaining a cold chain from purchase to the home and at home: Consumer opinions. Food Control, 20(2), 167–172.

Pan, N.-F. (2008). Fuzzy AHP approach for selecting the suitable bridge construction method. Automation in Construction, 17(8), 958–965.

Perçin, S. (2009). Evaluation of third-party logistics (3PL) providers by using a two-phase AHP and TOPSIS methodology. Benchmarking: An International Journal, 16(5), 588–604.

Perego, A., Perotti, S., & Mangiaracina, R. (2011). ICT for logistics and freight transportation: A literature review and research agenda. International Journal of Physical Distribution & Logistics Management, 41(5), 457–483.

Porter, E. M., & Kramer, R. M. (2006). Strategy and society: The link between competitive advantage and corporate social responsibility. Harvard Business Review, 84(12), 78–92.

PWC. (2007). Farm to retail—overview of India’s retail sector. In Indo-US Economic Summit (pp. 12–26). www.pwc.com/extweb/pwcpublications.nsf/docid/50e7c984c1feebe5ca25739f0023b7e7/$file/buidingstongpartnership.pdf.

Qureshi, M. N., Kumar, D., & Kumar, P. (2008). An integrated model to identify and classify the key criteria and their role in the assessment of 3PL service providers. Asia Pacific Journal of Marketing and Logistics, 20(2), 227–249.

Rijswijk, W. V., & Frewer, L. J. (2008). Consumer perceptions of food quality and safety and their relation to traceability. British Food Journal, 110(10), 1034–46.

Sangam, V. K. (2004). Global logistics outsourcing trends: Challenges in managing 3PL relationship. Palmerston: Massey University.

Singh, A. K., Subramanian, N., Pawar, K. S., & Bai, R. (2016). Cold chain configuration design: Location-allocation decision-making using coordination, value deterioration, and big data approximation. Annals of Operations Research. doi:10.1007/s10479-016-2332-z.

Saaty, T. L. (1990). How to make a decision: The analytic hierarchy process. European Journal of Operational Research, 48(1), 9–26.

Shabani, A., Saen, R. F., & Torabipour, S. M. R. (2012). A new benchmarking approach in cold chain. Applied Mathematical Modelling, 36(1), 212–224.

Singh, R. K., & Sharma, M. K. (2015). Selecting competitive supply chain using fuzzy AHP and extent analysis. Journal of Industrial and Production Engineering. doi:10.1080/21681015.2014.999723 (In press).

Singh, R. K., & Sharma, M. K. (2014). Prioritizing the alternatives for flexibility in supply chains. Production Planning and Control, 25(2), 176–192.

Singh, R. K. (2011). Analyzing the interaction of factors for success of total quality management in SMEs. Asian Journal on Quality, 12(1), 6–19.

Singh, R. K., Garg, S. K., & Deshmukh, S. G. (2008). Implementation of information technology: Evidences from Indian SMEs. International Journal of Enterprise Network Management, 2(3), 248–267.

Singh, R. K., Kumar, R., & Shankar, R. (2012). Supply chain management in SMEs: A case study. International Journal of Manufacturing Research, 7(2), 165–180.

Soh, H. (2010). A decision model for evaluating third party logistics provider using fuzzy analytic hierarchy process. African Journal of Business Management, 4(3), 339–349.

Sohail, M. S., & Al-Abdali, O. S. (2005). The usage of third party logistics in Saudi Arabia: Current position and future prospects. International Journal of Physical Distribution & Logistics Management, 35(9), 637–653.

Spencer, M. S., Rogers, D. S., & Daugherty, P. J. (1994). JIT systems and external logistics suppliers. International Journal of Operations and Production Management, 14(6), 60–74.

Stam, A., & Duarte, A. P. S. (2003). On multiplicative priority ratings method for the AHP. European Journal of Operational Research, 145, 92–108.

Sun, C. C. (2010). Performance evaluation model by integrating fuzzy AHP and fuzzy TOPSIS methods. Expert Systems with Applications, 37, 7745–7754.

Thakkar, J., Deshmukh, S. G., Gupta, A. D., & Shankar, R. (2005). Selection of third party logistics (3PL): A hybrid approach using interpretive structural modeling (ISM) and analytic network process (ANP). Supply Chain Forum: An International Journal, 6(1), 32–46.

Tirado, M. C., Clarke, R., Jaykus, L. A., McQuatters-Gollop, A., & Frank, J. M. (2010). Climate change and food safety: A review. Food Research International, 43(7), 1745–1765.

Tolga, E., Demircan, M. L., & Kahraman, C. (2005). Operating system selection using fuzzy replacement analysis and analytic hierarchy process. International Journal of Production Economics, 97(1), 89–117.

Torfi, F. A., Farahani, R. Z., & Rezapour, S. (2009). Fuzzy AHP to determine the relative weights of evaluation criteria and Fuzzy TOPSIS to rank the alternatives. Applied Soft Computing, 10(2), 520–528.

Torfi, F., Farahani, R. Z., & Rezapour, S. (2010). Fuzzy AHP to determine the relative weights of evaluation criteria and Fuzzy TOPSIS to rank the alternatives. Applied Soft Computing, 10(2), 520–528.

Troyer, C., & Cooper, R. (1995). Smart moves in supply chain integration. Transportation and Distribution, 36(9), 55–62.

UNCTAD. (2006). Report of the Expert Meeting on ICT Solutions to Facilitate Trade at Border Crossings and Ports, United Nations Conference on Trade and Development, Geneva.

Vaidyanathan, G. (2005). A framework for evaluating third party logistics. Communications of ACM, 48(1), 89–94.

Vorst, J. G., & Van der, A. G. (2000). Effective food supply chains generating, modeling and evaluating supply chain scenarios. Dutch: Wageningen University.

Wolf, C., & Seuring, S. (2010). Environmental impacts as buying criteria for third party logistical services. International Journal of Physical Distribution & Logistics Management, 40(1/2), 84–102.

Yan, G. E. (2009). Evaluation on competitiveness of TPL enterprises based on AHP and genetic algorithm. In Proceedings of the 2nd IEEE International Conference on Computer Science and Information Technology.

Ying, W., & Dayong, S. (2005). Multi-agent framework for third party logistics in E-commerce. Expert Systems with Applications, 29, 431–436.

Zadeh, L. A. (1965). Fuzzy sets. Information and Control, 8(3), 338–356.

Zang, J. (2009). The research of 3PLs provider selection based on rough set and PSO. In Proceeding of the IITA International Conference on Services Science, Management and Engineering.

Zhou, G., Min, H., Xu, C., & Cao, Z. (2008). Evaluating the comparative efficiency of Chinese third party logistics provider using data envelopment analysis. International Journal of Physical Distribution and Logistics Management, 34(4), 262–279.

Zokaee, S., Jabbarzadeh, A, Fahimnia, B, Sadjadi, S. J. (2014). Robust supply chain network design: an optimization model with real world application. In Annals of Operations Research, November (pp. 1–30).

Acknowledgements

Authors would like to express their sincere thanks to the Chief Editor of the journal and unanimous reviewers for valuable comments and suggestions to enhance quality and content of the paper. Authors also acknowledge the support of Mr. Ankit Bansal and Mr. Sidhant Issar, UG students in doing this research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, R.K., Gunasekaran, A. & Kumar, P. Third party logistics (3PL) selection for cold chain management: a fuzzy AHP and fuzzy TOPSIS approach. Ann Oper Res 267, 531–553 (2018). https://doi.org/10.1007/s10479-017-2591-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-017-2591-3