Abstract

The scientific community is becoming increasingly interested in the production of activated carbon (AC) using pyrolyzed biomass wastes as potential sustainable precursors. Both chemical and physical methods may have a significant impact on the chemical and physical properties of AC, making it suitable for a variety of applications such as water pollution treatment, CO2 capture, dye, and heavy metal (HM) removal, and energy storage. The properties of AC are significantly influenced by feedstock composition, pyrolysis conditions, and carbon activation parameters. In comparison to traditional AC, activated biochar appears to be a new potentially cost-effective, and environmentally friendly carbon material with a wide range of applications. Walnut is a well-known member of the Juglandaceae family. Walnut Shell (WS) is extremely tough and degrades very slowly, and the multiple synthesis procedures employ the shell to prepare AC. In this review article, a detailed list of products and different applications of AC from the WS is provided. The cited results explain the optimal conditions for an adsorption process, which include pH, adsorbent dosage, temperature, agitation speed, contact time, efficiency, adsorption capacity, fitting model, kinetics, and thermodynamics. In addition, it also describes the removal of a few organic compounds, and energy storage applications using parameters such as BET, different electrolytes, and specific capacitance.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

At present, the world’s resources, energy crisis, and environmental problems have become increasingly prominent. In most developed and developing countries, global environmental contamination from various hazardous wastes [1] with particular emphasis on industrial [2], medical, household, and agricultural wastes, and heavy metals (HMs) [3] are reused as an ingredient in an industrial process to make a useful product. For this reason, many researchers have focused on the major challenge to collect, recycle, treat, and dispose of waste materials [4]. Carbon is one of the most abundant elements on Earth. All living things on earth contain carbon, especially plants are almost half carbon. Traditionally, coal, lignite, and wood were often used as raw materials for carbon. The preparation of activated carbon (AC) from these materials not only increases production costs but also wastes non-renewable resources [5]. Besides, the fast growth of global demand and consumer awareness certainly requires sustainable alternatives and utilizing agricultural wastage including rice husk, walnut shell (WS), coconut shell, palm shell, pecan shell, bamboos, wheat stalk, poplar wood, cashew nutshell, etc [6]. . These biomass products can be used to prepare AC with high specific surface area (SSA), low pore size, high porous structure, and good electrical conductivity for excellent electrochemical performances [7]. Owing to the global demand for environmental awareness, research on the development of composites prepared using various waste materials is being vigorously pursued [8].

The development of alternative clean and sustainable energy solutions has benefited greatly from the use of carbon materials [9,10,11]. Carbon-based materials, such as AC, carbon nanotubes (CNTs), graphene, carbon quantum dots (CQDs), carbon dots (CDs), etc., typically have exceptional physicochemical, adsorption, and electrical properties. Excellent chemical, mechanical, thermal, and electrical capabilities are particularly found in carbon-based materials with various nanostructures [12]. Pore diameters in conventional ACs fluctuate widely, mostly from 2 to 2000 Å. Although they have a huge surface area (approximately 1000 m2/g), the shape and size of the molecules limit their ability to selectively adsorb substances [13]. Energy storage is notably increased by tunable porosity, sufficient active sites, strong electrical conductivity, and high thermal/electrochemical stability [14]. In general, AC can be prepared from the vast majority of carbonaceous materials. Therefore, the more suitable material to prepare the AC should contain higher carbon content, volatility, and less ash [15]. There have been many studies about biomass waste materials which led to the main objective of carbon material. AC and biochar are frequently employed to clean up the environment, for example, in water treatment to remove pesticides and enhance taste and odor. It also can remove numerous drugs, including antibiotics, by adsorption which is frequently followed by biodegradation on the AC surface biofilm [16, 17]. Furthermore, crop residues, food processing waste, and manures, such as sewage sludge and biosolids, are treated with biochar [18]. Biochar obtained from various plant sources promotes the phytoremediation capacity of plants grown in HMs polluted soils. Plant-based biochar is a promising and sustainable approach for soil remediation [19]. In this aspect, WS is considered as one of the waste materials. Chemically modified and unmodified WSs have been prepared and studied for different applications. In earlier publications, both modified and unmodified WS sources have been discussed. However, no study has been done in detail about the use of biochar and AC produced from WS to date. Therefore, in this short review, we summarize the (i) properties and composition of WS, (ii) synthesis of AC from WS, (iii) removal of dye molecules and HMs through the adsorption process, and (iv) supercapacitor application, followed by future perspectives.

2 Properties and composition of WS

Of the overall biomass, lignocellulosic substances make up about 70%. The Juglandaceae family, which includes walnuts (juglans regia), is widely cultivated in Iran, China, the United States, and Eastern Europe [20]. Lignin, cellulose, hemicellulose, and tannins are the primary components of WSs and can be isolated and used to produce additional chemicals and materials that are very comparable to those found in wood biomass [21].

Around 2,000,000 and 890,000 Tons of walnuts (in the shell form) and kernels are produced worldwide each year, respectively [22, 23]. WS is an abrasive that is hard, chemically inert, non-toxic, and biodegradable. Soft metals, fiberglass, wood, plastics, and stone can all be cleaned and polished using a WS abrasive. When used to tumble and polish metal components, jewelry, ink pens, and gun casings, it is an effective soft abrasive [24]. The WS is also mainly focused on utilizing in the filtration application to separate crude oil from water, which is characterized in different ways to produce the desirable product [25]. Furthermore, WS contains phenolic compounds that produce different beneficial health effects such as anticarcinogenic, antimutagenic, and cardioprotective activities which have been attributed to their antioxidant activity [26, 27]. Owing to this aspect, most of the researchers focus on the natural antioxidant activities of biomass from WS. As a result, the processing of walnuts produces a lot of waste, which can be an important source of energy [28]. A variety of walnut components, including kernels and fruits, are employed in solar cells, batteries, supercapacitors, textile, dyeing, and biological applications [29].

Compared to cellulosic materials, WSs include more hydrophobic materials (lignin) and less hydrophilic ones (hemicellulose and cellulose) [30]. Around 50.3% of the chemical composition is lignin, followed by 22.4% hemicellulose, 23.9% cellulose, and 3.4% ash [31]. The main benefits of lignocellulosic WSs over other organic materials are their widespread availability and renewable nature. Na (554 mg/kg), K (5202 mg/kg), Ca (9081 mg/kg), Mg (1283 mg/kg), P (691 mg/kg), S (791 mg/kg), Fe (3095 mg/kg), Cu (6.2 mg/kg), Zn (18 mg/kg), Mn (111 mg/kg), B (29.7 mg/kg), and Mo (9.9 mg/kg) are the minerals identified in WS [32]. High lignin content makes a material more brittle, whereas cellulose makes a material less brittle (Table 1) [33]. Moreover, the presence of several polar hydroxyl groups in cellulose and hemicellulose might spark interactions between the filler and polymeric matrix. WSs have several benefits provided with sufficient reactive functional groups, a high carbon content, and compatibility with a variety of industrial chemicals making them a potential candidate for use as a reinforcing material in polymer composites. They also have good stability and mechanical properties due to the presence of aromatic rings. The use of WSs as inexpensive materials in various industries has been well-documented [34].

The chemical composition of lignocellulosic compounds mainly involves cellulose, hemicellulose, and lignin, which contain two or more –OH groups per molecule [35]. This results in an “energy content” that is comparable to coal along with increased moisture resistance. The combustion of WSs generates carbon as solid waste that can find some applications in wastewater treatment, adsorption, supercapacitors, batteries, etc [28]. .

3 Synthesis of carbon from WS

Biomass materials of the waste WS are the best raw material to prepare the carbon precursor due to their large scale, low cost, sustainability, and eco-friendliness. Waste WS has been successfully well developed to prepare carbon materials by two basic methods, namely, carbonization and activation process. Biochar is generated through carbonization, which is carried out at a high temperature in an inert atmosphere through pyrolysis and/or gasification [36]. At this point, the volatile stuff was removed from the carbonaceous substance using thermal degradation to prepare the carbon content [37]. Significant parameters are the temperature, heating rate, gas (N2) flow rate, and residence time. Due to the limited adsorption capacity of the obtained biochar, an activation step is necessary to increase pore volume, pore diameter, and surface area [38]. The disordered carbon was initially removed during the activation process, exposing the lignin to the activating chemicals and creating the microporous structure [39]. Chemical or physical activation procedures can even be used to achieve the activation process. Chemicals including phosphoric acid (H3PO4), zinc chloride (ZnCl2), sulfuric acid (H2SO4), potassium hydroxide (KOH), citric acid (C6H8O7), iron (III) chloride (FeCl3), potassium carbonate (K2CO3), boric acid (H3BO3), nitric acid (HNO3), and sodium hydroxide (NaOH) can all be used to perform chemical activation (CA). In physical activation (PA), it is subject to partial and controlled gasification at the predetermined condition of high temperature and gas flow rates such as steam, CO2, air, or a mixture of others [40]. The polarity and hydrophobicity of the surface’s chemical characteristics are altered during the PA process [41]. Even though the PA process does not include the use of chemicals and is less expensive than other activation methods, the CA process is where the majority of the reactions take place.

3.1 Chemical activation (CA) method

This method explores several strategies for producing sustainable energy as well as various techniques for generating carbon materials. Generating carbon materials out of waste biomass, a different type of carbonaceous source that is frequently used as a starting material. These biomass waste materials are used as starting materials by many researchers and employed in different applications. X. Qiu et al. clearly explain the preparation of porous carbon materials through KOH activation of carbonized WS (Fig. 1a) [42]. The obtained porous carbon material was activated at 600 °C which exhibits an SSA of 736.2 m2/g. This high-specific surface area material shows excellent microwave absorption performance. Few other researchers have also performed KOH activation and successfully increased the surface area and pore size volume (Fig. 1d-f) [43,44,45]. A general mechanism for KOH activation is shown in the following equations (Eqs. 1–5) which implies that there is no specific reaction [46]. However, upon using HNO3, ZnCl2, and con. H2SO4 the surface area and pore volume increase, when compared to the high-surface-area KOH activation procedure.

WS biomass was transformed into activated porous carbon through carbonization and activation with HNO3 treatment (Fig. 1b). This derived AC from WSs exhibited better electrochemical performance with a high specific capacitance of 137 F/g− 1 at 1 A/g− 1 [47]. Straightaway, the AC derived from WSs has been an effective absorber when used for environmentally friendly remediation of Alachlor-contaminated soils (Fig. 1c) [48]. A fast hydrothermal technique was used to create the porous carbon material from WSs and subsequently activated with K2CO3 (Fig. 1e). This porous carbon-derived material showed good electrode characteristics in a symmetric all-solid-state supercapacitor [49]. In another approach, using ZnCl2 proved effective in producing WSs-based nanoporous carbon (Fig. 2a). Due to their inadequate dielectric loss capacity, WS calcined at 600 °C directly demonstrated poor microwave absorption performance. Fascinatingly, the SSA, dielectric loss capacities, and microwave absorption performances of the samples were considerably increased when the WSs were activated by ZnCl2 (Fig. 2b) [50]. Both the DFT technique and the matched isotherms of low-temperature N2 adsorption demonstrate the activated materials’ significant mesoporosity and substantial micropore volume. Furthermore, it has been shown that the activation procedure yields samples with metal impregnation of surface reactive AC (Fig. 2e) [51].

Successfully developed pyrolusite-templated catalyst functioned as a powerful persulfate (PS) activator for the synthesis of pyrolusite–template mesoporous catalyst (PMC) (Fig. 2c). It provides a sustainable and affordable way to utilize WS waste resources to the fullest possible extent and can be very beneficial for the structural design and property adjustment of carbonaceous material to obtain a catalyst with excellent properties for the efficient removal of organic pollutants in real wastewater [52]. Zhang et al. recently developed a unique hybrid nanomaterial by carbonization, followed by the generation of AC through CA (Fig. 2d) [53]. The AC and Ni-MOF/SPANI are successfully combined and the resulting WS@Ni-MOF/SPANI/AC composition was used for supercapacitor electrochemical performance. In another method, two different types of bio-carbons were generated as a lightweight, porous, affordable, and environmentally acceptable supporting matrix up on carbonizing and chemically activating WSs (Fig. 2f). The carbon generated from WS and activated WSC (SC) was assessed as novel shape stabilizers and thermal conductivity enhancers for methyl palmitate (MP), which was chosen as the preferred phase change material (PCM) for thermal regulating applications in buildings [54]. The CA process led to the activation of several compounds like KOH, ZnCl2, HNO3, K2CO3, and H2SO4. Due to their high SSA and superior porosity, they have good adsorption capabilities and make ideal energy storage materials. From the above synthesis, The ZnCl2 activated achieved an excellent adsorption mechanism application, and other supercapacitor applications received a high specific capacitance.

3.2 Physical activation (PA) method

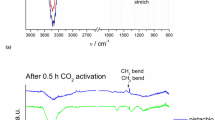

The raw materials are initially carbonized at high temperatures in this process. A physical or thermal activation employing a single gas or mixture of gases, such as steam, air, or CO2, with predetermined settings of temperatures between 1100 and 1250 K [55] and gas flow rate [40] is known as partial gasification of biomass. In the PA process, initially, disorganized materials are removed which subsequently increases the pore volume and elementary crystallites. Then it becomes exposed to the activation for further development of porosity with increasing surface area [55]. The PA by using steam (heating rate 40 °C/min) takes place after the carbonization process step (Fig. 3a). However, this method is eco-friendly, inexpensive to get a good yield of AC, and doesn’t require any chemicals [56]. Zheng et al. successfully prepared AC by thermal activation (TA) under an N2 atmosphere and found the SSA of AC as 410.84 m2/g, and pore volume as 0.61 cm3/g (Fig. 3c) [57]. The fine powder was recovered and used as a precursor for producing AC after being crushed, powdered, and sieved (200 m in size).

Very recently, when a precursor is physically activated at high temperatures, water vapor is used as an adsorbent for monoethanolamine (MEA) was reported. The use of AC generated from waste WS improves the absorption efficiency of the MEA solution [56]. A plethora of research is being done on improved porous carbon-based materials, especially for the utilization and capture of CO2. This study used distinct KOH activation methods on melamine-modified WS to create renewable, microporous granular N2-doped carbons at a comparatively low pyrolysis temperature (650 °C) (Fig. 3d) which shows that nanoporous N2-doped carbon has considerable promise for capturing CO2 [58]. A chemical cutting technique was used to synthesize water-dispersible Carbon Quantum Dots (CQDs) from the pre-oxidation of sustainable bio-precursors. The effectiveness of the WS-based CQDs as bioimaging agents for intracellular transport was confirmed by the Raman mapping approach (Fig. 3e). In terms of bioimaging and illness diagnosis, these CQDs exhibit promise [59]. The chemical reaction of the PA process is illustrated by the following equations (Eqs. 6–8) [60]. The PA technique typically results in a high yield and uses no chemicals when used in various applications. The produced synthesis contains PA mostly using the application of water vapor adsorption and capturing carbon dioxide.

3.3 Pyrolysis process

Compared to the pyrolysis approach, the synthesis of AC via CA and PA is considerably more prevalent. Both CA and PA give a high yield and less environmental pollution [62]. The preparation of biomass-based AC was proposed by using pyrolysis liquids as activators, which enables the entire process of AC preparation. This method allows for the production of AC from biomass throughout the entire process. Although the pyrolysis of liquid bio-oil has the highest AC yield, its low adsorption efficiency and underdeveloped pore structure make it challenging to utilize as a porous adsorption material. Other components of the pyrolysis process primarily become trapped in the pores of the carbon and produce a low adsorbent. For this reason, the activation process (CA and PA) must be performed to generate these pores and be used as an adsorbent.

Using the pyrolysis method, biomass was heated to 500–900 °C to produce gas, liquids, and char. There are many options for the products, for example, pyrolysis liquids can be refined into chemicals, biodiesel, pitch, etc. Due to the complicated compositions, surplus water content, high oxygen content, and strong acidity, the refinery process could be challenging [63]. Figure 4 shows reported methods of pyrolysis and preparation of biochar, carbon, bio-oil, etc. reported the preparation of WS biochar by pyrolysis process, and these were modified by ZnCl2, KOH, H2SO4, and H3PO4 (Fig. 4a) [64]. The modified biochar of the WS showed a good adsorption mechanism in the following order: ZnCl2 > KOH > H3PO4 > H2SO4. From this order, it is confirmed that ZnCl2 has a good adsorption property but a low SSA compared to KOH. The different reagents of modified biochar have different SSAs and pore volumes as ZnCl2, KOH, H2SO4, and H3PO4 with 534.40, 712.07, 114.38, 117.64 m2/g, and 0.3086, 0.4082, 0.0495 and 0.0926 cm3/g, respectively. Figure 4b-d shows a few pyrolysis and activation processes [65,66,67] Further, pyrolyzed at different temperatures (300 ℃, 450 ℃, 600 ℃) for 2 h and followed by other activation of β-cyclo-dextrin-chitosan. Using this modification and preparing biochar improved the physicochemical properties, SSA, porosity, and thermal stability and provided an uptake of 206 mg/g [68].

Utilizing the limited oxygen pyrolysis method, WS biochar was generated (Fig. 4a). To modify this biochar, ZnCl2, KOH, H2SO4, and H3PO4 were employed. Using methylene blue (MB) as a pigment model, the study of the liquid-phase adsorption performance revealed that modified biochar made from biomasses had a mesoporous structure. Although KOH treatment produced the largest modified biochar SSA, the alkaline modification was more conducive to the creation of pores in biomass-modified biochar materials [64]. The hard carbon was generated using WS at high-temperature (1000 °C) pyrolysis in an inert atmosphere, which results in a large interplanar and a low surface area (Fig. 4b). This functions well in Na-ion battery-based energy storage devices [65]. After being gently pyrolyzed, WS biochar was loaded with numerous La(OH)3 nanorods utilizing the parallel flow co-precipitating technique. It maintained outstanding phosphate adsorption characteristics while achieving high La use efficiency (Fig. 4c). Furthermore, it is reported that La-loaded biochar after phosphorus adsorption by burned to recycle La or by spreading it on the soil as fertilizer to increase future crop yields [66]. A variety of ACs, including N2-doped AC produced from WSs (N/WSAC), was developed for catalytic fast pyrolysis (CFP) of WS to create alkylphenols (Fig. 4d). Due to the electron-transfer or charge-transfer interactions, the N2 functional groups in N/WSAC provided the catalytic active sites to support the depolymerization of lignin and produce monomeric phenolics. It also catalyzed the demethoxylation and deoxygenation reactions of the primary phenolics to produce alkylphenols [67]. Temperatures between 300 and 1000 ℃ were used throughout the pyrolysis process. In this process, various products, including carbon, biochar, bio-oil, and modified biochar, are usually obtained.

3.4 Comparision of CA and PA processes

CA and PA are the two main ways used to activate the carbonized material. The raw material is activated in the PA process following the carbonization of the porous structure that has formed both inside and outside of the carbon material. Typically, activation is carried out in anaerobic conditions at temperatures between 800 and 1000 °C to reduce carbon loss. Using an inert gas as a protective heat source, chemical agents are introduced to the raw materials in the CA process before being heated. The carbonization and activation steps advance simultaneously in this preparation procedure. Among these processes are taking advantage of CA compared to PA processes, lower treatment temperature, shorter treatment times, as well as products with high BET surface area and well-developed pore structure [69]. Eco-friendly and simple to recover by simply dissolving the salts in water and recycling them back into the process, is one of the CA reagents [70]. In the CA method has been obtained the SSA of 736.2 m2/g and PA method contains 410.84 m2/g. During the preparation of AC, PA, CA, and pyrolysis are very common processes. The CA approach, which is more popular, offers a higher AC yield than the PA method at a more suitable temperature. It also produces less environmental pollution. Steam or CO2 are used as activating agents in PA. The CO2 activation produces microporous carbons, whereas steam activation produces meso and macroporous carbons. The activation is affected by variables such as activation temperature and time. The variable activation time and temperature caused a considerable change in the textural features and CO2 capture capacity of the produced ACs. Prolonged activation time resulted in pore damage, reducing the surface area, and pore volume.

4 Applications of WS

For the two types of adsorption processes, chemical and physical adsorption, specific surface chemistry is necessary. Physical adsorption uses a very weak van der Waals force in place of the chemical force that is said to be present in chemical adsorption between the adsorbent and the adsorbate. Adsorption is regulated by environmental physical and chemical factors, such as temperature, pH, and redox conditions, like every other chemical reaction [71]. In the surface process for adsorption, the adsorbent’s surface plays a significant role. The best adsorbents of porous materials with a higher surface area per unit volume are therefore preferred (for example, AC and clay) [72]. Due to its high level of porosity and large surface area, AC is the most popular adsorbent for the removal of dyes, HMs, and organic waste. The carbonization of biomass and subsequent activation contribute to the formation of AC [73]. Because of its substantial Brunauer-Emmett-Teller (BET) SSA, well-developed pore structure, and consistent physical-chemical characteristics, AC is an efficient and cost-effective material to remove water vapor from the gas stream [5].

4.1 Removal of dye molecules, HMs, and organic compounds by adsorption method

Several million tons of dyes are produced and widely used in various industries, such as dyestuffs, textiles, paper, printing, plastics, leather, food, pharmaceutical, petrochemical, and cosmetics [74]. Dyes are typically classified into three types, specifically, cationic, anionic, and nonionic dyes (water-insoluble) based on the charge of the chromophore group dissolved in the aqueous solution [75]. Some dyes are more harmful and some are insoluble in water. Untreated dyes that are disposed of in the hydrosphere will contaminate the water. As the concentration of dyes in water increases, the biological activity of amphibians decreases atmospheric oxygen levels and blocks sunlight from reaching plants and animals. Furthermore, the waste liquids can create serious problems such as allergies, dermatitis, skin irritations, malignancies, mutations in humans, and deterioration of water quality (odor and color), thereby revealing toxicity [76]. Dye removal with the use of agricultural wastes and forestry residues has recently attracted considerable attention due to the abundance and low price of these by-products [77]. Excitingly, WS is used for the removal of different dyes such as reactive brilliant red K-2BP (RBR K-2BP) [78], C. I. Acid Red 97 (AR97) [79], Maxilon Red (MR GRL) [80], Crystal Violet (CV) [81], MB [82], and Rhodamine B [83]. In addition, hazardous metals such as Mercury (Hg2+), Copper (Cu2+), Cadmium (Cd2+), Cesium (Cs1+), Chromium (Cr3+/6+), Iron (Fe2+), Nickel (Ni2+), Lead (Pb2+), Zinc (Zn2+), Manganese (Mn2+), etc. are also contaminating the aquatic environment. Industrial and mining wastewaters are the major sources of these metals’ pollution. The presence of these HMs affects both humans and animals due to their high toxicity, non-biodegradability, and carcinogenic nature [84]. This problem can be resolved by the removal of HMs through several conventional methods such as chemical precipitation, ion exchange, and adsorption by AC.

The method of adsorption has been widely used due to its low cost and high efficiency. The sorption process by using bio-sorbent is based on the use of organic sorbents, for example, agricultural residues, and microbial and algal biomass [85]. The functional groups including carboxyl, hydroxyl, sulfhydryl, and amide present on the surface of biomaterials are responsible for the sorption of metal ions from wastewater [86]. In adsorption studies, most of them show the removal of a single HM from the aqueous solution and are carried out by parameters and mechanisms of kinetic, isotherm, and thermodynamics. In this section, we summarize the removal of various dye molecules, and HMs by using WS through adsorption processes.

4.1.1 Removal of various dye molecules

Natural dyes produced from shells, flowers, roots, insects, and even insects have been used by humans to color clothing, animal hides, and food. However, the majority of the utilization of natural colors has been replaced by inexpensive and mass-produced synthetic dyes [87]. When it comes to the various organic compounds discharged into industrial effluents, dyes, and pigments are by far the most prevalent and harmful water pollutants. Dyes are manmade chemical compounds with a specified color that can chemically bond to the substrate (such as fiber, paper, or fur) to impart a beautiful color [78]. More than 10,000 dyes are now used in the textile, paper, cosmetic, and food industries, producing a considerable volume of dye effluent [88]. Even at low concentrations, several of these effluents are extremely dangerous and can cause cancer and mutagenesis in both humans and aquatic life [83]. The most common and efficient method for removing color is adsorption, where AC is usually employed as an adsorbent because of its substantial surface area and high adsorption capacity. An alternative to the adsorption technique, which uses limited organic resources like coal or wood, is to employ biomass waste from WS to prepare AC [89].

To remove dyes like CR, MB, CV, RR2, and others, processing biomass waste (from WS) to generate AC is one possibility. WSAC was prepared with ZnCl2 to study MB and CR dye removal. The adsorption of MB and CR dyes on WSAC was measured at different (i) temperatures (298–318 K), (ii) pHs, (iii) amounts of adsorbent, (iv) rate, and (v) contact time. The adsorption capacity for all the dye molecules was analyzed. Noteworthy to mention that there is a decrease in the adsorption parameter when the temperature is increased during these degradation/adsorption processes. WSAC adsorbs CR and MB with an adsorption capacity of 442.56 mg/g over a pH range of 7 at a reported stirring speed of 300 rpm (Fig. 5) [70]. In a different approach, MB was adsorbed at pH 7 at a stirring speed of 270 rpm, and an AC dosage of 0.75 g/L. The AC showed an adsorption capacity of 315 mg/g and 99% efficiency. The isotherm of this heterogeneous surface adsorption was determined by the Redlich-Peterson model [90]. Appealingly, AC was spontaneously prepared through WS, and its RR2 adsorption aptitude was investigated in an aqueous solution. Different adsorption doses (0.5–2.0 g) of AC were applied and the Langmuir adsorption isotherm at 25 °C was analyzed [91].

X-ray mapping of sulfur on the surfaces WSAC after the adsorption of (a) MB, and (b) CR [75]

4.1.2 Purging of HMs

Nowadays, the increasing concentration of HMs causes the most serious environmental threat due to their toxic nature. HMs are described as metallic elements, with high specific density (5.0 g/cm3) than that of water, and are non-biodegradable [92]. Pb2+, Cd2+, Hg2+, As3+, etc. are examples of HMs [93]. HMs can be found in wastewater from industry [94] and overcome by the adsorption, ion exchange process, etc. The maximum adsorption capacity of HMs using WS following this order are Cd (76.9 mg/g) > Fe (62.6 mg/g) > Cu (38.8 mg/g) > Zn (33.3 mg/g) > Ni (29.4 mg/g) > Mn (28.6 mg/g) and these are confirmed by SEM micrographs [95].

Hg2+ is one of the most harmful HM in the environment. As a key component of both organic and inorganic mercury, Hg2+ can interact with the cysteine in human proteins to form CH3Hg and cause substantial bioaccumulation in food chains [96]. Human carcinogenesis, renal dysfunction, lung damage, and a variety of syndromes can occur when the dosage of Hg2+ is increased [97]. On the other hand, Hg2+ has been used for the treatment of syphilis, calomel (Hg2Cl2) has been used as a diuretic, and mercury amalgam is still used to fill teeth cavities [93]. As per the World Health Organization (WHO) report, the maximum permissible Hg2+ concentration in wastewater and drinkable water is 5.0 and 1.0 g/L, respectively [98]. Compared with other methods, adsorption methods for removing Hg2+ ions from wastewater provide several advantages. Wide pH range, low cost, strong metal binding capabilities, and simple operating conditions are some of its most advantageous features, which may afford high removal efficiency [99]. M. Zabihi et al. utilized powder-activated carbon (PAC) derived from the WS for the removal of Hg2+ in an aqueous solution [100]. This adsorption process is well fitted by pseudo-second-order kinetic and Langmuir isotherm models with an adsorption capacity of 151.5 and 100.9 mg/g, respectively, at 29 °C, pH 5, and an adsorbate dosage of 0.05 g/L. Asl et al. also carried out the removal of Hg2+ using carbonaceous adsorbents derived from Iranian WSs which was prepared by the CA method using ZnCl2 as an activating reagent [101]. It was determined that the adsorption mechanism follows both Langmuir and Freundlich isotherms as well as pseudo-second-order kinetics. The suitable preparation condition resulted in microporous AC with a density of 0.45 g/cm3, BET surface area of 780 m2/g, and adsorbate dosage of 9.7–10.7 g/L at pH 5. The monolayer sorption capacity of this superior adsorbent was determined to be 151.5 mg/g at 29 °C.

The production of chlorophyll, photosynthesis, respiratory electron transport chains, oxidative stress defense, and the metabolism of proteins, carbohydrates, and cell walls all depend on naturally occurring Cu2+ in plants [102]. Cu2+ pollution of plant and human ecosystems is rising. Cu2+ in drinking water is only allowed up to 0.05 mg/L [103]. It causes mental difficulties, heart issues, sleeplessness, autism, stuttering, and other issues over this level [104, 105]. Mining, the burning of fossil fuels and waste, residential wastewater, landfills, the manufacture of phosphate fertilizer, the manufacturing of wood, volcanoes, wind-blown dust, sea spray, forest fires, and decaying vegetation are the main sources of Cu2+ [106]. Owing to this, various techniques have been used to extract Cu2+ from wastewater. After being chemically altered to insert or inhibit its surface functional groups, WS-based AC was successfully used by Xie et al. [107]. The contribution of various functional groups on AC to the adsorption of Cu2+ was assessed, and the findings from the adsorption equilibrium fit the Langmuir isotherm well. The Oxidised Activated Carbon (OAC) has a maximum Cu2+ capacity of 89.29 mg/g. Furthermore, it was discovered that the kinetic data at 20 ± 1 °C followed the pseudo-second-order model.

Though Ni2+ is occurring in a very low quantity in the environment, it is an essential element for some animal species. The nutrients with Ni2+ must be consumed daily in amounts of approximately 170 g by humans [108]. The main sources of Ni2+ include dust from volcanic emissions and the weathering of rocks and soils [109]. Inorganic fertilizers, particularly, phosphate fertilizers have variable levels of Ni2+ depending on their resources [110]. The deficiency of Ni2+ seriously affects human health such as allergies, cardiovascular and kidney diseases, lung fibrosis, and lung and nasal cancer [111, 112]. Georgieva et al. studied disposing of industrial wastewater, the removal of Ni2+ by adsorption, the mechanism of isotherm, and kinetic and thermodynamic reactions of the adsorption process [113]. Thus, the removal of Ni2+ using bio-char of WS-biochar adsorbent (WSBA) shows a good fit with the Toth isotherm model, kinetics following pseudo-second-order, and thermodynamic reaction is spontaneous or exothermic (Fig. 6b). Further, adsorbate dosage, temperature, and adsorption capacity are found as 6.53 g/L, 288 to 303 K, and 13.25 mg/g, respectively.

The earth’s crust contains the element Cr3+, which can exist in oxidation states (also known as valence states) ranging from Cr3+ to Cr6+ [92, 114]. Cr6+ differs from Cr3+ in terms of its characteristics. Cr3+ is less hazardous than Cr6+ because it is insoluble, mostly present in organic stuff, and stationary in ambient settings. Since Cr6+ is more soluble, mobile, and poisonous than Cr3+, it has more detrimental effects on both people and animals [115]. The WHO recommends ranges of 0.03–0.13 µg/kg and 20–30 µg/l of Cr3+ as acceptable daily doses per kilogram of body weight and normal blood concentration, respectively [116]. Even Cr6+ is harmful to people if consumed in big dosages and at high concentrations. Both humans and animals may pass away from exposure to hexavalent Cr6+, which is a powerful, exceedingly deadly carcinogen [117]. Yet, the use of Cr6+ in numerous industrial processes including textile dyeing, electroplating, leather processing, steel manufacturing, and the tanning industry leads to the release of effluents that contain chromium. In the end, this causes a significant rise in chromium content in the environment [118]. Nethaji et al. [119] prepared the AC by different impregnation with NaOH ratios of 1:1, 1:3, and 1:5. The different ratios of AC and NaOH showed different adsorptive properties. Among the three ratios, 1:5 has good chromium adsorption capacity with the fitting mechanism of D–R isotherm, pseudo-second-order, and thermodynamic adsorption process was an endothermic reaction.

Owing to a lack of biodegradation and the potential of HMs like Pb2+, there is a risk concomitant with their presence in the water [120]. Pb2+ has the worst effects on human health. But, Pb2+ is used in industries like the preparation of batteries, paints, and other products. Domestic uses include cooking and adulteration [121]. The removal of Pb2+ from surface water through adsorption using traditional coagulation techniques is a promising and economical method. Pb2+ from aqueous solutions has been recovered or removed using a variety of biomass materials and WS as adsorbents [122]. Yi et al. investigated the equilibrium and kinetics of Pb2+ adsorption onto Chinese WS-AC (CWSAC) [123]. The adsorption isotherm was defined by the Langmuir equation over the initial Pb(II) concentration range. The maximum Pb2+ adsorption capacity calculated from the Langmuir model was 81.96 mg/g.

Cd2+ has an atomic number of 48 and a specific density of 8 g/cm3, is listed in the periodic table’s 12th group, and has an electronegativity of 1.69 [124]. Even though Cd2+ is incredibly rare in the earth’s crust, numerous human activities such as mining and smelting, application of sewage sludge and compost, and the use of fertilizers, pesticides, and insecticides, have led to elevated Cd2+ soil concentrations [125]. Cd2+ is highly mobile in the soil-plant system, which makes it simple for plants to absorb [126]. Cd2+ is poisonous and can build up over time in the environment and living things [127]. Research on the negative consequences of ambient Cd2+ contamination on health, particularly its adverse effects on bone and kidneys, is plentiful [128]. The carbon material produced from WS adsorbed Cd2+ in 0.1 g of adsorbent dosage, at a pH range of 6–10, with 50.9% efficiency was reported [129].

4.1.3 Elimination of organic compounds

Organic water contamination from substances like polycyclic aromatic hydrocarbons is a significant global problem [130]. The primary anthropogenic sources of polycyclic aromatic hydrocarbons (PAHs) in the environment are combustion, waste incineration, and filtration, petroleum and petrochemicals, automobile exhaust, and the manufacture of coke, asphalt, coal tar, and carbon black [131]. PAHs can enter natural water bodies through atmospheric fallout, urban runoff, municipal sewage, industrial runoff, and oil spills or spills [132]. Several methods such as chlorination, oxidation, ultrasonic irradiation, adsorption, etc. have been proposed to remove PAHs from wastewater. Among these methods, adsorption is widely used due to its high removal efficiency of organic compounds in wastewater [133]. The adsorption process is intended to remove organic matter such as naphthalene and phenanthrene by using AC and modifying the parameters. The adsorption parameters were set as pH 3, 10 mg/l adsorbent dosages, and 170 rpm stirring speed, with adsorption capacities of 93.62, and 145.62 mg. This adsorption process follows Freundlich’s isothermal and pseudo-second-order kinetics [134]. All the experimental parameters utilized during these aforementioned dyes, HMs, and organic matter adsorption by WS-based carbon materials are summarized in Tables 2 and 3.

4.2 Supercapacitor application

Due to the world economy’s rapid expansion, there is a large rise in the usage of fossil fuels, which results in two key related problems. The rapid depletion or exhaustion of the world’s fossil fuel reserves is the first problem. The second concern is related to environmental issues, such as general air and water pollution and rising greenhouse gas emissions [135]. Electric double-layer capacitors (EDLCs), also known as supercapacitors (SCs), or rapid surface redox reactions (named pseudocapacitors) are two ways that supercapacitors (SCs), also referred to as ultracapacitors, store energy. They have a substantially higher capacitance than regular physical capacitors as electrochemical energy storage devices [136]. Supercapacitors have a substantially higher power/energy density and charge/discharge rate than other batteries. This supercapacitor is divided into three types, namely, EDLC, pseudocapacitor, and hybrid supercapacitor. Each type of supercapacitor uses different materials, for example, EDLC uses carbon materials, a pseudocapacitor uses metal oxide (MO), and polymers and a hybrid supercapacitor uses both EDLC and pseudocapacitor materials [137]. Using carbon materials, an EDLC contains a high surface area, good specific capacitance, and long-life cycling stability [138].

The MOs are getting very good specific capacitance and low stability in cycling. However, ruthenium oxide (Ru2O) is the best material for supercapacitors because of its high specific capacitance and long-life cycling stability, but it is very expensive and toxic. Notably, carbon from low-cost materials is non-toxic, provides good specific capacitance, and has long-life cycling stability. In addition, the carbon that is produced from biomass generates energy that is sustainable and clean. Biomass waste products have attracted tremendous attention as carbon sources due to their abundance, sustainability, and low cost. For example, bean dregs, dead leaves, waste coffee beans, banana peels, and pomelo peels have all been used to prepare carbon materials with good electrochemical performances in supercapacitors. The biomass-derived carbon materials fabricated to polymer like sulfonated polyaniline (SPANI), increase specific capacitance, and well retention performance reported [53]. They showed good novelty in hybrid nano-materials presenting carbonized materials from WS and nickel metal-organic framework (MOF) in SPANI. The asymmetric method was utilized for the fabrication of material, WS@Ni-MOF/SPANI, which exhibits 14 times higher specific capacitance than biochar and high cycle stability (retention rate of 90.4% after 20,000 cycles) (Fig. 7). In addition, the assembled asymmetrical supercapacitor (ASC) shows a high energy density of 34.79 Wh kg− 1 at a power density of 824 W kg− 1. It can be concluded that utilizing these biomass waste products in this way not only reduces environmental waste but also provides new energy storage materials [45]. The parameters such as surface area, current density, specific capacitance, and retention of different biomass carbon derived from WS are listed in Table 4.

Asymmetric supercapacitor model of WS@Ni-MOF/SPANI [53]

Xu et al. prepared a porous carbon material by hydrothermal method and conducted symmetric all-solid-state electrode system studies using polyvinyl alcohol (PVA)/KOH gel electrolyte [45]. This system shows a specific capacitance of 255 F/g at a current density of 0.5 A/g and 96% retention in the 3000 cycles shown. In another method, a porous carbon was prepared by the CA method using KOH [139]. In this system, chemical activation of porous carbon has shown a good specific capacitance of 186.68 F/g at 0.5 A/g in a 6.0 M KOH electrolyte solution. Moreover, this porous carbon showed cycling stability of 20,000 at a current density of 2.0 A/g and retention of 100%. Notably, bio-char carbon prepared from the WS (ACWS) with a high SSA (3577 m2/g) showed a specific capacitance of 330 F/g at 0.1 A/g current density and retention of 81% in a 6.0 M KOH electrolyte [136].

In another typical approach, upon doping the metal in carbon materials, high specific capacitance (462 F/g) was achieved at a current density of 1 A/g in the 6.0 M KOH electrolyte [140]. Excitingly, this system comprises a high surface area (BET is 2635 m2/g) and good retention of cycling stability (94.2% at 5000 cycles). Agricultural WS biowaste served as a precursor for the KOH activation process used to create AC-based compounds. At a current density of 0.5 A/g in 6.0 M KOH, the AC successfully achieved a specific surface area of 1016.4 m2/g and a specific capacitance of 169.2 F/g [141]. At various activation temperatures, it was proposed that biowaste (Wn) could easily be converted into porous AC (Wn AC). Wn-600, Wn-700, and Wn-800 are further terms for the AC from WSs used to make the supercapacitor electrode materials. In the range of temperatures 600–800 ºC, Wn-800 had the highest specific capacitance, measuring 595 F/g at 1.0 A/g in 1.0 M KOH electrolyte [142].

A commercial AC was prepared from WS by using an ultrasound-assisted extraction method and applied to pseudocapacitance and asymmetric supercapacitor application. The prepared AC-WS contains a hierarchical structure, specific area, and highly porous structure. The structure expands the active site of particles and obtains a specific capacitance of 248 F/g at a current density of 0.5 A/g. It also improved the cyclic stability up to 75% in 3000 cycles [143]. Rohit Yadav et al. prepared AC-W from WS biomass with optimal activation temperature at 700 ℃ by the CA method. The fabricated electrode was employed in a symmetric supercapacitor and obtained the high specific capacitance of 50 F/g at 1 A/g [144]. The synthesized nanoporous carbon from WS modified with NiO was prepared by the thermal activation method. This nanocomposite forms a uniform size and develops a porous structure in carbon material with 2200 m2/g surface area. The modified AC/NiO electrode obtained the specific capacitance of 205 F/g at 500 mA/g in the basic medium of 6 M KOH [145]. A hierarchically porous structural carbon material was prepared by facile method by pyrolyzing C10H14N2Na2O8/KOH (dual-porogen) and walnut peel biomass as a carbon source with HCl. Based on this synthesis, the hierarchically porous carbon materials with a regulated structure with an appropriate pore volume, broadened pore-size distribution, ultrahigh specific surface area, as well as the effective remarkable capacitor performances obtained. The highest specific capacitance for a porous carbon material achieved was 557.9 F/g (at 1 A/g) and 291.0 F/g (at 30 A/g) in 1 M H2SO4 [146]. Mukhtar et al. prepared the graphene-like porous carbon (GLC) from WS by carbonization and thermochemical activation process, which contains a high specific surface area of 2800 m2/g and a specific capacitance value of 263 F/g at 1 A/g in 6 M KOH. The surface area has efficient adsorption of ions, which has a positive effect on the capacity for electrochemical applications including catalysts, fuel cells, sorbents, and sensors [147].

The surface area mainly focused on the porous structure and porosity within the carbon material. Porosity refers to the presence of void spaces in the material and enhances the electrochemical performances. The most advantages of high surface area are (i) an increase in the electrode-electrolyte interface (the presence of the porous structure provides more active sites for the electrolyte to come into contact with the electrode and enhance charge storage) [148], (ii) improved ion diffusion (the porous structure help to easy diffusion of ions within the electrode material, these improve the capacitance and charge/discharge) [149], (iii) enhanced accessibility (the interconnected porous provide a pathway for electrolyte penetration, leading to improve the utilization of the electrode material) [150]. Therefore, enhancing the porosity and porous structure in supercapacitor electrode materials is a crucial aspect of optimizing their performance. It significantly influences the surface area, electrode-electrolyte interface, ion diffusion, and overall efficiency of the supercapacitor, making it an area of active research and development in energy storage technologies [151]. Interestingly, Table 4 implies that when nitrogen or metal are doped into low-cost porous carbon material derived from bio-mass, the specific capacitance, surface area, and retention of cycling stability increase.

5 Conclusion and future perspectives

Based on the results in this review article, we propose that AC is a possible option and has remarkable qualities for use in adsorption and energy storage applications [152]. The adsorption process carried out with exact adsorbent dosage, appropriate contact time, and specific pH showed a very good adsorption capacity and followed an interesting mechanism. Even though the pH is neutral, AC has worthy dye adsorption capacity when it is activated by a suitable chemical. For example, using H3PO4 (Low SSA), ZnCl2, FeCl3 (dehydration agent), and KOH, NaOH (High SSA) increases porous structure and pore volume [153]. When CA is done purposefully to increase the surface functional group, adsorption is carried out at low pH, and with less contact time, a decent adsorptive capacity is achieved. Appealingly, the presence of ultra-small micropores with a low surface area showed outstanding performance in energy storage and adsorption applications. In addition, upon doping with different metals, the AC materials displayed excellent energy storage capacity. In conflict, whatever AC possesses excellent characteristics, studies based on its intrinsic properties are lacking due to its hydrophobic nature [154].

The green synthesis of AC is a good innovative solution for exhaustive environmental remediation and energy storage applications. Various studies have been carried out by different research groups regarding the production of biomass-derived carbon. A few expansions are proposed for the development of resource utilization. Developing biomass of carbon composition with improved surface area and pore volume by activation process, showing a very good performance in adsorption and energy storage applications. During the activation by chemicals, harmful gases may be released and will affect the environment [155]. The pore characteristics (specific surface area, pore volume, micropore volume, and mesopore volume) of the prepared walnut-based AC [156,157,158,159,160,161] are summarized in Table 5.

The relationship between the surface functional groups of ACs and their removal capacity of various contaminants is significant to describe. Adsorption is based on two processes, i.e. chemisorption, and physisorption. Chemisorption is directly induced by the number of active sites in the surface functional group of AC. Physisorption is related to weak van der Waals interaction between the target contaminant and the adsorbent. These adsorbents do not undergo any chemical changes. The removal process depends heavily on electrostatic interactions between cationic dyes, HMs, organic compounds, and the functional groups on the surface of the AC. For example, as a cationic dye, MB naturally induces an electrostatic attraction between a positively charged object and a negatively charged surface [162]. On the other hand, in phenanthrene molecule π-π bonding occurs between the C = C double bond or benzene rings of adsorbent and the functional groups on the surface of the AC [163].

In addition, general mechanisms explain the interaction between the functional groups of AC and the chromium species (hexavalent and trivalent chromium) during the adsorption process. There are four mechanisms have been proposed. Mechanism I is related to the anion adsorption on the basic functional group. In mechanism II it acts as an electron donor in the functional group of AC. The third mechanism is established into three steps in surface interaction, (a) Cr (VI) is adsorbed on basic sites by anion adsorption; however, (b) it may be reduced to Cr (III) by an adjacent electron donor, and then (c) Cr (III) is released to the solution by electrostatic repulsion. Finally, the fourth mechanism involves the cation exchange on the acid sites; this is a coupled reduction adsorption mechanism [164]. To conclude, electrostatic interaction, π-π and π-π electron-donor-acceptor interaction, surface precipitation, and ligand exchanges/ion exchanges are all important mechanisms for adsorption onto AC surface functional groups.

To conclude, consequently, taking special care and attention are required to minimize environmental pollution. To our knowledge, all the methods used for the synthesis of AC involve chemicals, which prove deleterious to the environment. To date, there are no methods available to prepare without adding chemicals. Therefore, in our study, we are exploring the possibility of non-chemical-based preparation of the materials. Further systematic and in-depth research is required to explain effectually the possible approaches for preparing biomass-derived carbon and its applications. Currently, in our laboratory, (i) synthesis of CQDs in different sizes for biological applications, and (ii) modification of the AC with appropriate metal salts to make corresponding nanocomposites for photocatalytic and energy storage applications are underway.

Data availability

Not applicable.

References

Rajczykowski, K., Loska, K.: Stimulation of heavy metal adsorption process by using a strong magnetic field. Water. Air Soil. Pollu. 229, 20 (2018). https://doi.org/10.1007/s11270-017-3672-2

Timotius, E., Kristen, U., Wacana, K., Sukmarani, G.: Industrial Waste Treatment Management: A Review Industrial Waste Treatment Management : A review. J. Sci. Appl. Eng. 4, 01–08 (2022). https://doi.org/10.31328/jsae.v4i1.2400

Qasem, N.A.A., Mohammed, R.H., Lawal, D.U.: Removal of Heavy Metal ions from Wastewater: A Comprehensive and critical review. Clean. Water. 4, 36 (2021). https://doi.org/10.1038/s41545-021-00127-0

Danish, M., Ahmad, T.: A review on utilization of Wood Biomass as a sustainable precursor for activated carbon production and application. Renew. Sustain. Energy Rev. 87, 1–21 (2018). https://doi.org/10.1016/j.rser.2018.02.003

Zhao, H., Yu, Q., Li, M., Sun, S.: Preparation and Water Vapor Adsorption of Green Walnut-Shell activated Carbon by CO2 physical activation. Adsorpt. Sci. Technol. 38, 60–76 (2020). https://doi.org/10.1177/0263617419900849

Gao, X., Wu, L., Wan, W., Xu, Q., Li, Z.: Preparation of activated carbons from Walnut Shell by fast activation with H3PO4: Influence of fluidization of particles. Int. J. Chem. React. Eng. 16, 1–10 (2018). https://doi.org/10.1515/ijcre-2017-0074

Jiang, D., Mingming, L., Yong, W.: Biomass-derived Carbon: Synthesis and application on Energy Storage and Conversion. Green. Chem. 18, 4824–4854 (2016). https://doi.org/10.1039/C6GC01172A

Ogah, A.O., Afiukwa, J.N., Nduji, A.A.: Characterization and comparison of Rheological properties of Agro Fiber filled high-density polyethylene bio-composites. Open. J. Polym. Chem. 4, 12–19 (2014). https://doi.org/10.4236/ojpchem.2014.41002

Tan, X.F., Liu, S.B., Liu, Y.G., Gu, Y., Zeng, G.M., Hu, X.J., Wang, X., Liu, S.H., Jiang, L.H.: Biochar as potential sustainable precursors for activated Carbon production: Multiple applications in Environmental Protection and Energy Storage. Bioresour Technol. 227, 359–372 (2017). https://doi.org/10.1016/j.biortech.2016.12.083

Devi, M.S., Thangadurai, T.D., Manjubaashini, N., Nataraj, D.: Walnut shell biomass waste derived excitation-dependent CQDs for toxic insecticide sensing and protein denaturation inhibition–An ecofriendly and sustainable approach. Diam. Relat. Mater. 136(110021) (2023). https://doi.org/10.1016/j.diamond.2023.110021

Adaikalapandi, S., Thangadurai, T.D., Manjubaashini, N., Nataraj, D., Babu, T.S., Kumar, S.M.: Bamboo stem biomass waste-derived excitation-dependent carbon dots for nanomolar detection of fungicide dodine in real samples and their pH-sensitive bacterial interaction studies. Diam. Relat. Mater. 141(110692) (2024). https://doi.org/10.1016/j.diamond.2023.110692

Lee, H., Kim, B.J., Kim, S.J., Park, Y.K., Jung, S.C.: Enhanced Electrochemical performance of Carbon Nanotube with Nitrogen and Iron using Liquid Phase plasma process for Supercapacitor Applications. Int. J. Mol. Sci. 19, 3830 (2018). https://doi.org/10.3390/ijms19123830

Hu, Z., Vansant, E.F.: Synthesis and characterization of a controlled-micropore-size carbonaceous adsorbent produced from Walnut Shell. Microporous Mater. 3, 603–612 (1995). https://doi.org/10.1016/0927-6513(94)00067-6

Liu, C.F., Liu, Y.C., Yi, T.Y., Hu, C.C.: Carbon materials for high-voltage supercapacitors. Carbon. 145, 529–548 (2019). https://doi.org/10.1016/j.carbon.2018.12.009

Shraddha, R.S., Singh, A.P.: Adsorption of Heavy metals from Waste Waters using Waste Biomass. Int. J. Eng. Res. Tech. 6, 2278–0181 (2017)

Carvalho, I.T., Santos, L.: Antibiotics in the aquatic environments: A review of the European scenario. Environ. Int. 94, 736–757 (2016). https://doi.org/10.1016/J.ENVINT.2016.06.025

Flores-Cano, J.V., Sánchez-Polo, M., Messoud, J., Velo-Gala, I., Ocampo-Pérez, R., Rivera- Utrilla, J.: Overall adsorption rate of metronidazole, dimetridazole, and diatrizoate on activated carbons prepared from coffee residues and almond shells. J. Environ. Manag. 169, 116–125 (2016). https://doi.org/10.1016/j.jenvman.2015.12.001

Nita, C., Zhang, B., Dentzer, J., Ghimbeu, C.M.: Hard Carbon Derived from Coconut shells, Walnut shells, and Corn Silk Biomass Waste Exhibiting High Capacity for Na-Ion batteries. J. Energy Chem. 58, 207–218 (2021). https://doi.org/10.1016/j.jechem.2020.08.065

Mathiyazhagan, N., Ying, M.: Influences of Biochar on Bioremediation/Phytoremediation potential of metal-contaminated soils. Front. Microbiol. 13, 929730 (2022). https://doi.org/10.3389/fmicb.2022.929730

Zheng, D., Zhang, Y., Guo, Y., Yue, J.: Isolation and characterization of Nanocellulose with a novel shape from Walnut (Juglans regia L.) Shell Agricultural Waste. Polymers. 11, 1130 (2019). https://doi.org/10.3390/polym11071130

Jahanban-Esfahlan, A., Amarowicz, R.: Walnut (Juglans Regia) Shell Pyroligneous Acid: Chemical constituents and functional applications. RSC Adv. 8, 22376–22391 (2018). https://doi.org/10.1039/c8ra03684e

Sun, K., Jiang, J.C.: Preparation and characterization of activated Carbon from Rubber-seed Shell by Physical activation with Steam. Biomass Bioenergy. 34, 539–544 (2010)

Okada, K., Yamamoto, N., Kameshima, Y.: Adsorption Properties of Activated Carbon from Waste Newspaper prepared by Chemical and physical activation. J. Colloid Interf Sci. 262, 194–199 (2003)

Srinivasan, A., Viraraghavan, T.: Removal of oil by Walnut Shell Media. Bioresour Tech. 99, 8217–8220 (2008). https://doi.org/10.1016/j.biortech.2008.03.072

Srinivasan, A., Viraraghavan, T.: Removal of oil by walnut shell media. Bioresource Technol. 99, 8217–8220 (2008). https://doi.org/10.1016/j.biortech.2008.03.072

Balasundram, N., Sundram, K., Samman, S.: Phenolic compounds in plants and agri-industrial by-products: Antioxidant activity, occurrence, and potential uses. Food Chem. 99, 191–203 (2006). https://doi.org/10.1016/j.foodchem.2005.07.042

Stampar, F., Solar, A., Hudina, M., Veberic, R., Colaric, M.: Traditional walnut liqueur–cocktail of phenolics. Food Chem. 95, 627–631 (2006). https://doi.org/10.1016/j.foodchem.2005.01.035

Miladinović, M.R., Zdujić, M.V., Veljović, D.N., Krstić, J.B., Banković-Ilić, I.B., Veljković, V.B., Stamenković, O.S.: Valorization of Walnut Shell Ash as a Catalyst for Biodiesel Production. Renew. Energy. 147, 1033–1043 (2020). https://doi.org/10.1016/j.renene.2019.09.056

Paul, B.T., Clement, G.Y., Anita, K.P., Dwayne, J.: Sutton Heavy Metal Toxicity and the Environment. Mol. Clin. Environ. Toxicol. 101, 133–164 (2012). https://doi.org/10.1007%2F978-3-7643-8340-4_6

Vassilev, S.V., Baxter, D., Andersen, L.K., Vassileva, C.G., Morgan, T.J.: An overview of the organic and inorganic phase composition of biomass, Fuel, vol. 94, no.1–33, (2012). https://doi.org/10.1016/j.fuel.2011.09.030

Mohan, S., Panneerselvam, K.: An investigation on Antibacterial Filler Property of Silver Nanoparticles Generated from Walnut Shell Powder by Insitu process. Mater. Today Proc. 39, 368–372 (2020). https://doi.org/10.1016/j.matpr.2020.07.516

Sowinska-Baranowska, A., Maciejewska, M., Duda, P.: The potential application of Starch and Walnut shells as Biofillers for Natural Rubber (NR) composites. Int. J. Mol. Sci. 23, 7968 (2022). https://doi.org/10.3390/ijms23147968

Queirós, C.S.G.P., Cardoso, S., Lourenço, A., Ferreira, J., Miranda, I., Lourenço, M.J.V., Pereira, H.: Characterization of Walnut, Almond, and Pine nut shells regarding Chemical composition and extract composition. Biomass Convers. Biorefinery. 10, 175–188 (2020). https://doi.org/10.1007/s13399-019-00424-2

Członka, S., Strąkowska, A., Kairytė, A.: Effect of Walnut shells and Silanized Walnut shells on the Mechanical and Thermal properties of rigid polyurethane foams. Polym. Test. 87, 106534 (2020). https://doi.org/10.1016/j.polymertesting.2020.106534

Członka, S., Strakowska, A., Kairyte, A.: Application of Walnut shells-Derived Biopolyol in the synthesis of rigid polyurethane foams. Mater. (Basel). 13, 1–21 (2020). https://doi.org/10.3390/ma13122687

Odetoye, T.E., Abu Bakar, M.S., Titiloye, J.O.: Pyrolysis and Characterization of Jatropha Curcas Shell and seed Coat. Niger J. Technol. Dev. 16, 71 (2019). https://doi.org/10.4314/njtd.v16i2.4

Radenahmad, N., Azad, A.T., Saghir, M., Taweekun, J., Bakar, M.S.A., Reza, M.S., Azad, A.K.: A review on Biomass Derived Syngas for SOFC Based Combined Heat and Power Application. Renew. Sustain. Energy Rev. 119, 109560 (2020). https://doi.org/10.1016/j.rser.2019.109560

Yang, X., Wan, Y., Zheng, Y., He, F., Yu, Z., Huang, J., Wang, H., Ok, Y.S., Jiang, Y., Gao, B.: Surface Functional groups of Carbon-based adsorbents and their roles in the removal of Heavy metals from Aqueous solutions: A critical review. Chem. Eng. J. 366, 608–621 (2019). https://doi.org/10.1016/j.cej.2019.02.119

Reza, M.S., Yun, C.S., Afroze, S., Radenahmad, N., Bakar, M.S.A., Saidur, R., Taweekun, J., Azad, A.K.: Preparation of activated Carbon from Biomass and its’ applications in Water and Gas Purification, a review. Arab. J. Basic. Appl. Sci. 27, 208–238 (2020). https://doi.org/10.1080/25765299.2020.1766799

Albatrni, H., Qiblawey, H., Al-marri, M.J.: Walnut Shell Based adsorbents: A review study on Preparation, mechanism, and application. J. Water Process. Eng. 45, 102527 (2022). https://doi.org/10.1016/j.jwpe.2021.102527

Gupta, M., Savla, N., Pandit, C., Pandit, S., Kumar, P., Pant, M.: Science of the total Environment Use of Biomass-Derived Biochar in Wastewater Treatment and Power Production: A promising solution for a sustainable environment. Sci. Total Environ. 825, 153892 (2022). https://doi.org/10.1016/j.scitotenv.2022.153892

Qiu, X., Wang, L., Zhu, H., Guan, Y., Zhang, Q.: Lightweight and efficient microwave absorbing materials based on Walnut Shell-Derived Nano-Porous Carbon. Nanoscale. 9, 7408–7418 (2017). https://doi.org/10.1039/c7nr02628e

Song, X., Li, K., Ning, P., Wang, C., Sun, X., Tang, L., Ruan, H., Han, S.: Surface characterization studies of Walnut-Shell Biochar catalysts for simultaneously removing of Organic Sulfur from Yellow Phosphorus tail gas. Appl. Surf. Sci. 425, 130–140 (2017). https://doi.org/10.1016/j.apsusc.2017.06.328

Xu, X., Gao, J., Tian, Q., Zhai, X., Liu, Y.: Walnut Shell Derived Porous Carbon for a symmetric all-solid-state Supercapacitor. Appl. Surf. Sci. 411, 170–176 (2017). https://doi.org/10.1016/j.apsusc.2017.03.124

Shao, Q., Li, Y., Wang, Q., Niu, T., Li, S., Shen, W.: Preparation of Copper Doped Walnut Shell-based Biochar for efficiently removal of Organic dyes from Aqueous solutions. J. Mol. Liq. 336, 116314 (2021). https://doi.org/10.1016/j.molliq.2021.116314

Zhao, H., Cheng, Y., Liu, W., Yang, L., Zhang, B.: Biomass-Derived Porous Carbon-based nanostructures for microwave absorption. Nano-Micro Lett. 11, 1–17 (2019). https://doi.org/10.1007/s40820-019-0255-3

Wang, W., Qi, J., Sui, Y., He, Y., Meng, Q., Wei, F., Jin, Y.: An asymmetric Supercapacitor based on activated porous Carbon Derived from Walnut shells and NiCo2O4 nanoneedle arrays electrodes. J. Nanosci. Nanotechnol. 18, 5600–5608 (2018). https://doi.org/10.1166/jnn.2018.15410

Ahmad, K.S.: Sorption and Juglans Regia-Derived activated Carbon-mediated removal of Aniline-based Herbicide Alachlor from Contaminated soils. Environ. Earth Sci. 77, 437 (2018). https://doi.org/10.1007/s12665-018-7633-x

Wang, L., Zhou, P., Guo, Y., Zhang, J., Qiu, X., Guan, Y., Yu, M., Zhu, H., Zhang, Q.: The effect of ZnCl2 activation on microwave absorbing performance in Walnut Shell-Derived Nano-Porous Carbon. RSC Adv. 9, 9718–9728 (2019). https://doi.org/10.1039/c8ra09932d

Fu, H.H., Chen, L., Gao, H., Yu, X., Hou, J., Wang, G., Yu, F., Li, H., Fan, C., Shi, Y.L., Guo, X.: Walnut Shell-Derived Hierarchical Porous Carbon with High performances for Electrocatalytic Hydrogen Evolution and Symmetry Supercapacitors. Int. J. Hydrogen Energy. 45, 443–451 (2020). https://doi.org/10.1016/j.ijhydene.2019.10.159

Feng, W., Faraj, Y., Yan, Y., An, Y., Xie, R., Lai, B.: Novel pyrolusite-templated Biochar as an outstanding Catalyst for Persulfate activation: Structural Design, Synergistic Effect, and mechanism. Ind. Eng. Chem. Res. 61, 1885–1896 (2022). https://doi.org/10.1021/acs.iecr.1c04459

Mansurov, Z.A., Lodewyckx, P., Velasco, L.F., Azat, S., Kerimkulova, A.R.: Modified sorbents based on Walnut Shell for Sorption of toxic gases. Mater. Today Proc. 49, 2521–2526 (2021). https://doi.org/10.1016/j.matpr.2020.12.948

Zhang, J., Guo, H., Yang, F., Wang, M., Zhang, H., Zhang, T., Sun, L.: Colloids and surfaces a: Physicochemical and Engineering Aspects Walnut Shell-Derived Porous Carbon Integrated with Ni-MOF / SPANI composites for High-Performance Supercapacitor. Colloids Surf. Physicochem Eng. Asp. 630, 127584 (2021). https://doi.org/10.1016/j.colsurfa.2021.127584

Hekimoğlu, G., Sarı, A., Kar, T., Keleş, S., Kaygusuz, K., Tyagi, V.V., Sharma, R.K., Al-Ahmed, A., Al-Sulaiman, F.A., Saleh, T.A.: Walnut Shell Derived Bio-Carbon/Methyl Palmitate as Novel Composite Phase Change Material with enhanced Thermal Energy Storage properties. J. Energy Storage. 35, 102288 (2021). https://doi.org/10.1016/j.est.2021.102288

Rodríguez-Reinoso, F., Molina-Sabio, M.: Activated carbons from Lignocellulosic materials by Chemical and/or physical activation: An overview. Carbon. 30, 1111–1118 (1992). https://doi.org/10.1016/0008-6223(92)90143-K

Ghasemi, M., Ghoreyshi, A.A., Younesi, H., Khoshhal, S.K.: Synthesis of a high characteristics activated Carbon from Walnut Shell for the removal of cr(VI) and Fe(II) from aqueous solution: Single and binary Solutes Adsorption. Ira J. Chem. Eng. 12, 28–51 (2015)

Zheng, X., Lin, H., Tao, Y., Zhang, H.: Selective adsorption of Phenanthrene dissolved in tween 80 solution using activated Carbon Derived from Walnut shells. Chemosphere. 208, 951–959 (2018). https://doi.org/10.1016/j.chemosphere.2018.06.025

Shao, X., Zhang, Y., Miao, X., Wang, W., Liu, Z., Liu, Q., Zhang, T., Ji, J., Ji, X.: Renewable N-Doped Microporous carbons from Walnut shells for CO2 capture and Conversion. Sustain. Energy Fuels. 5, 4701–4709 (2021). https://doi.org/10.1039/d1se01000j

Cheng, C., Shi, Y., Li, M., Xing, M., Wu, Q.: Carbon Quantum Dots from Carbonized Walnut shells: Structural evolution, fluorescence characteristics, and Intracellular Bioimaging. Mater. Sci. Eng. C. 79, 473–480 (2017). https://doi.org/10.1016/j.msec.2017.05.094

Hu, W., Xiang, R., Lin, J., Cheng, Y., Lu, C.: Lignocellulosic biomass-derived Carbon electrodes for flexible supercapacitors: An overview. Materials. 14, 4571 (2021). https://doi.org/10.3390/ma14164571

Khoshraftar, Z., Ghaemi, A.: Presence of activated Carbon particles from Waste Walnut Shell as a Biosorbent in Monoethanolamine (MEA) solution to Enhance Carbon Dioxide absorption. Heliyon. 8(89) (2022). https://doi.org/10.1016/j.heliyon.2021.e08689

Cristian, I.C., Shiba, P.A., Nidia, C.G., Neal, D.E., Bryan, E.B.: Activated carbons derived from high-temperature pyrolysis of Lignocellulosic Biomass. Carbon. 4, 51 (2018). https://doi.org/10.3390/c4030051

Feng, P., Li, J., Wang, H., Xu, Z.: Biomass-based activated Carbon and activators: Preparation of activated Carbon from Corncob by Chemical activation with Biomass Pyrolysis liquids. ACS Omega. 5, 24064–24072 (2020). https://doi.org/10.1021/acsomega.0c03494

Liu, C., Wang, W., Wu, R., Liu, Y., Lin, X., Kan, H., Zheng, Y.: Preparation of Acid- and Alkali-Modified Biochar for removal of Methylene Blue Pigment. ACS Omega. 5, 30906–30922 (2020). https://doi.org/10.1021/acsomega.0c03688

Wahid, M., Gawli, Y., Puthusseri, D., Kumar, A., Shelke, M.V., Ogale, S.: Nutty Carbon: Morphology replicating hard Carbon from Walnut Shell for na Ion Battery Anode. ACS Omega. 2, 3601–3609 (2017). https://doi.org/10.1021/acsomega.7b00633

Luo, Y., Xie, K., Feng, Y., He, Q., Zhang, K., Shen, S.: Synthesis of a La(OH)3 Nanorod / Walnut Shell Biochar Composite for Reclaiming Phosphate from Aqueous solutions. Colloids Surf. A. 610, 125736 (2021). https://doi.org/10.1016/j.colsurfa.2020.125736

Ma, S., Li, H., Zhang, G., Iqbal, T., Li, K., Lu, Q.: Catalytic Fast Pyrolysis of Walnut Shell for Alkylphenols Production with Nitrogen-Doped activated Carbon Catalyst. Front. Environ. Sci. Eng. 15, 25 (2021). https://doi.org/10.1007/s11783-020-1317-y

Don, B., Angelin, R., Baskaran, S., Natarajan, R., Senthil, K.: Remediation of emerging metal pollutants using environment-friendly biochar- review on applications and mechanism. Chemosphere. 290, 133384 (2022). https://doi.org/10.1016/j.chemosphere.2021.133384

Ceyhan, A.A., Ömer, C., Saka, A., Yalçın, A.: A novel thermal process for activated Carbon Production from the Vetch Biomass with Air at Low temperature by two-stage Procedure. J. Anal. Appl. Pyrol. 104, 170–175 (2013)

Xu, J., Chen, L., Qu, H., Jiao, Y., Xie, J., Xing, G.: Preparation and characterization of activated Carbon from Reedy Grass leaves by Chemical activation with H3PO4. Appl. Surf. Sci. 320, 674–680 (2014)

Alaor, V.F., Raíssa, X.K., Luana, V.T., André, R.A., Gabriela, S.R.: Preparation and Characterization of Activated Carbon Obtained from Water Treatment Plant Sludge for removal of Cationic Dye from Wastewater. Processes. 8, 1549 (2020). https://doi.org/10.3390/pr8121549

El-Dairi, M., House, R.J., Rao, S.N., Artioli, Y., However, K., Duro, R., Souto, C., Gómez-Amoza, J.L., Martínez-Pacheco, R., Concheiro, A., Pharmaceutics-i, P., Phenomena, I., Erkey, C., Savjani, K.T., Gajjar, A.K., Savjani, J.K., Series, A.C.S.S., Shinoda, K., Wiley, J., Son, S.: Introduction, Alliances Re/envisioning Indig. Relationships, vol. 25, pp. 11–28, (2014)

Qiu, Y., Zheng, Z., Zhou, Z., Sheng, G.D.: Effectiveness and mechanisms of Dye Adsorption on a straw-based Biochar. Bioresour Technol. 100, 5348–5351 (2009). https://doi.org/10.1016/j.biortech.2009.05.054

Li, S., Zeng, Z., Xue, W.: Kinetic and Equilibrium Study of the removal of reactive dye using modified Walnut Shell. Water Sci. Technol. 80, 874–883 (2019). https://doi.org/10.2166/wst.2019.324

Li, Z., Hanafy, H., Zhang, L., Sellaoui, L., Schadeck Netto, M., Oliveira, M.L.S., Seliem, M.K., Luiz Dotto, G., Bonilla-Petriciolet, A., Li, Q.: Adsorption of Congo Red and Methylene Blue dyes on an Ashitaba Waste and a Walnut Shell-based activated Carbon from Aqueous solutions: Experiments, characterization and physical interpretations. Chem. Eng. J. 388, 124263 (2020). https://doi.org/10.1016/j.cej.2020.124263

Al-Tohamy, R., Ali, S.S., Li, F., Okasha, K.M., Mahmoud, Y.A.G., Elsamahy, T., Jiao, H., Fu, Y., Sun, J.: A critical review on the treatment of Dye-Containing Wastewater: Ecotoxicological and Health Concerns of Textile Dyes and possible remediation approaches for Environmental Safety. Ecotoxicol. Environ. Saf. 231, 113160 (2022). https://doi.org/10.1016/j.ecoenv.2021.113160

Tadele, A.A., Fekadu, M.B.: Biomass-based adsorbents for removal of dyes from Wastewater: A review. Front. Environ. Sci. 9, 764958 (2021). https://doi.org/10.3389/fenvs.2021.764958

Cao, J.S., Lin, J.X., Fang, F., Zhang, M.T., Hu, Z.R.: A new absorbent by modifying walnut shell for the removal of anionic dye: Kinetic and thermodynamic studies. Bioresource Technol. 163, 199–205 (2014). https://doi.org/10.1016/j.biortech.2014.04.046

Ghazi Mokri, H.S., Modirshahla, N., Behnajady, M.A., Vahid, B.: Adsorption of C.I. Acid Red 97 dye from aqueous solution onto walnut shell: kinetics, thermodynamics parameters, isotherms, Int. J. Environ. Sci. Tech, vol. 12, pp. 1401–1408, https://doi.org/10.1007/s13762-014-0725-6. (2015)

Fatih, D.: Effective removal of Maxilon Red GRL from Aqueous solutions by Walnut Shell: Nonlinear kinetic and equilibrium models. Environ. Progress Sustainable Energy. 33, 396–401 (2014). https://doi.org/10.1002/ep.11797

Motahare, A., Ghadamali, B., Mansour, A.C., Nasser, G.: Removal of Brilliant Green and Crystal violet from Mono- and bi-component aqueous solutions using NaOH-modified Walnut Shell. Anal. Bioanal Chem. Res. 5, 95–114 (2018). https://doi.org/10.22036/ABCR.2018.106139.1172

Juan, Y., Keqiang, Q.: Preparation of activated carbons from walnut shells via vacuum chemical activation and their application for methylene blue removal. Chem. Eng. J. 165, 209–217 (2010). https://doi.org/10.1016/j.cej.2010.09.019

Jasmin, S., Rasul, M., Attaul, H., Younas, K.: Removal of rhodamine B from aqueous solutions and wastewater by walnut shells: Kinetics, equilibrium and thermodynamics studies. Front. Chem. Sci. Eng. 7, 428–436 (2013). https://doi.org/10.1007/s11705-013-1358-x

Mataji, M., Khoshandam, B.: Benzene adsorption on activated Carbon from Walnut Shell. Chem. Eng. Comm. 201, 1294–1313 (2014). https://doi.org/10.1080/00986445.2013.808996

Idalina, D., José Ferreira, P., Luísa, P., Cruz-Lopes, P., Bruno, E.: Liquefaction and chemical composition of walnut shells. Open. Agric. 7, 249–256 (2022). https://doi.org/10.1515/opag-2022-0072

Feizi, M., Jalali, M.: Removal of heavy metals from aqueous solutions using sunflower, Potato, Canola and Walnut Shell Residues. J. Taiwan. Inst. Eng. 54, 125–136 (2015). https://doi.org/10.1016/j.jtice.2015.03.027

Tchounwou, P.B., Yedjou, C.G., Patlolla, A.K., Sutton, D.: Experientia Supplementum. J. Mol. Clin. Environ. Toxicol. vol. 3, 101 (2012). https://doi.org/10.1007/978-3-7643-8340-4

Järup, L.: Hazards of Heavy Metal Contamination. Br. Med. Bull. 68, 167–182 (2003). https://doi.org/10.1093/bmb/ldg032

Muhammad, K.D., Muhammad, R.R.K., Linda, B.L.L.: Water remediation using low-cost adsorbent walnut shell for removal of malachite green: Equilibrium, kinetics, thermodynamic and regeneration studies. J. Environ. Chem. Eng. 2, 1434–1444 (2014). https://doi.org/10.1016/j.jece.2014.07.008

Yang, J., Qiu, K.: Preparation of activated carbons from Walnut shells via Vacuum Chemical activation and their application for Methylene Blue removal. Chem. Eng. J. 165, 209–217 (2010). https://doi.org/10.1016/j.cej.2010.09.019

Almasi, A., Mousavi, S.A., Hesari, A., Janjani, H.: Walnut Shell as a natural adsorbent for the removal of reactive red 2 form aqueous solution. Chem. Eng. J. 165, 551–556 (2016). https://doi.org/10.1016/j.cej.2010.09.019

Shenmaishang, L., Zuoxiang, Z., Weilan, X.: Kinetic and equilibrium study of the removal of reactive dye using modified walnut shell. Water Sci. Tech. 80, 874–883 (2019). https://doi.org/10.2166/wst.2019.324

Baccar, R., Bouzid, J., Feki, M., Montiel, A.: Preparation of activated carbon from Tunisian olive-waste cakes and its application for adsorption of heavy metal ions. J. Hazard. Mater. 162, 1522–1529 (2009). https://doi.org/10.1016/j.jhazmat.2008.06.041

Türkmen, D., Bakhshpour, M., Akgönüllü, S., Aşır, S., Denizli, A.: Heavy metal ions removal from Wastewater using cryogels: A review. Front. Sustain. 3, 1–17 (2022). https://doi.org/10.3389/frsus.2022.765592

Ioannis, A., Ioannis, P., Ahmad, H.B., Dimitrios, A.G., Artis, R., Muhammad, U., Leticia, B.E., Yaoyu, Z., Juan, C.C., Avelino, N., Éder, C.L.: Agricultural biomass/waste as adsorbents for toxic metal decontamination of aqueous solutions. J. Mole Liquids. 295, 111684 (2019). https://doi.org/10.1016/j.molliq.2019.111684

Xia, M., Chen, Z., Li, Y., Li, C., Ahmad, N.M., Cheema, W.A., Zhu, S.: Removal of hg(II) in Aqueous solutions through Physical and Chemical Adsorption principles. RSC Adv. 9, 20941–20953 (2019). https://doi.org/10.1039/c9ra01924c

Zhang, X., Hao, Y., Wang, X., Chen, Z., Li, C.: Competitive adsorption of Cadmium(II) and Mercury(II) ions from aqueous solutions by activated Carbon from Xanthoceras Sorbifolia Bunge Hull. J. Chem. 2016, 1–10 (2016). https://doi.org/10.1155/2016/4326351

Li, R., Wu, H., Ding, J., Fu, W., Gan, L., Li, Y.: Mercury Pollution in vegetables, grains and soils from Areas surrounding coal-fired power plants. Sci. Rep. 7, 1–9 (2017). https://doi.org/10.1038/srep46545

Al-Ghouti, M.A., Da’ana, D., Abu-Dieyeh, M., Khraisheh, M.: Adsorptive removal of Mercury from Water by adsorbents derived from date pits. Sci. Rep. 9, 1–15 (2019). https://doi.org/10.1038/s41598-019-51594-y

Zabihi, M., Haghighi Asl, A., Ahmadpour, A.: Studies on Adsorption of Mercury from Aqueous solution on activated carbons prepared from Walnut Shell. J. Hazard. Mater. 174, 251–256 (2010). https://doi.org/10.1016/j.jhazmat.2009.09.044

Zabihi, M., Ahmadpour, A., Haghighi Asl, A.: Removal of Mercury from Water by Carbonaceous sorbents Derived from Walnut Shell. J. Hazard. Mater. 167, 230–236 (2009). https://doi.org/10.1016/j.jhazmat.2008.12.108

Rehman, M., Liu, L., Wang, Q., Saleem, M.H., Bashir, S., Ullah, S., Peng, D.: Copper Environmental Toxicology, recent advances, and Future Outlook: A review. Environ. Sci. Pollut Res. 26, 18003–18016 (2019). https://doi.org/10.1007/s11356-019-05073-6

Subramaniyam, V., Thangadurai, T.D., Lee, Y.I.: Zirconium Based Metal-Organic Framework for the adsorption of Cu (II) ions in Real Water samples. Clean. Eng. Techno. 9, 100526 (2022). https://doi.org/10.1016/j.clet.2022.100526

Arora, R.: Adsorption of Heavy Metals-a review. Mater. Today Proc. 18, 4745–4750 (2019). https://doi.org/10.1016/j.matpr.2019.07.462