Abstract

The purpose of this study is to evaluate the energy balance of organic olive production in Aydın-Karpuzlu Region in Turkey in 2015. In order to evaluate the energy input-output of organic olive, data has been provided by Aydın-Karpuzlu Organic Olive Producers Association. The agricultural input energies and output energies used in organic olive production have been calculated to evaluation the energy inputs and energy output. According to the research findings, the energy inputs in organic olive production have been calculated respectively as 19,426.95 MJ ha−1 (50.31%) diesel fuel energy, 12,960 MJ ha−1 (33.56%) machinery energy, polyethylene trap energy 3520 MJ ha−1 (9.12%), 2116.80 MJ ha−1 (5.48%) human labour energy, 276.48 MJ ha−1 (0.72%) electricity energy, 231.60 MJ ha−1 (0.60%) organic chemical energy and 81.87 MJ ha−1 (0.21%) transportation energy. Total input energy has been calculated as 38,613.70 MJ ha−1. Total output energy have been calculated as 104,888.78 MJ ha−1. The energy output/input ratio, specific energy, energy productivity and net energy calculations have been calculated respectively as 2.72, 4.34 MJ kg−1, 0.23 kg MJ−1 and 66,275.08 MJ ha−1 in organic olive production.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Olive (Olea europaea L.) is a member of Oleacea family, Olea cultivar and its homeland is Upper Mesopotamia, covering South-eastern Anatolian Region too and South Asia Minor (Heywood 1978). Olive can be consumed directly or it can be used to produce oil. Olive oil is natural fruit oil produced through physical methods only and contains unique antioxidant matters (phenolic compounds, tocopherol and other aromatic matters), high levels of monounsaturated fatty acid (oleic acid) and high oxidative stability (Öztürk et al. 2009). Olive is a Mediterranean plant and it can be grown regardless of the soil quality, as long as there suitable climate conditions available. In Turkey, 62% of the production is in the Aegean Region, 16% in Marmara Region, 14% in Mediterranean Region, 7.8% in South-eastern Anatolian Region and 0.2% is in Black Sea Region. 49% of the production of olive for oil is in Aegean Region, 26.6% is in Mediterranean Region, 12.3% is in South-eastern Anatolian Region and 12.1% is in Marmara Region (TÜİK 2016).

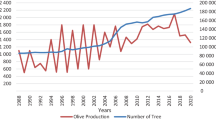

Organic olive is mostly produced in Mediterranean countries. The significant olive producing countries are Spain, Italy, Greece, Tunisia, Turkey, Morocco and Syria (Özkaya et al. 2015). In all Mediterranean countries, the total area for olive cultivation is 7,379,090 ha and there is organic olive production in 4.91% (362,210 ha) of this area. Among the Mediterranean countries, the highest organic olive production is in Tunisia by 80,016 ha, followed by Syria, 5000 ha and Turkey by 3776 ha (Santucci 2007; Olgun et al. 2008). Of the organic products produced in Aydın province in the Aegean Region, about 92% consists of fruits, 6% is field plants, 1.5% is vegetables while 0.5% is plants collected from the nature. Among the fruits, olive (168,167 da), fig (96,787 da) and chestnut (12,010 da) have the highest ratios, while cotton (7491 da) is the leading field product. About 25% of Turkey’s organic olive production is in Aydın (Anonymous 2014).

An application has been made to Aydın Provincial Directorate of Food Agriculture and Livestock on 22 April 2013, requesting to establish Karpuzlu Organic Olive Producers Association and following an approval of the application on 17 May 2013, the association has been founded. Since then, the association has started to gather the producers registered at Organic Farming under its roof and simplified the membership process. The number of producers has reached 1070 as of 31 December 2012. Producers have been receiving support funding. In 2013, 664 producers received 806,000 TL for 23,280 decare land, In 2014, 821 producers received 2,275,000 TL for 32,500 decare land and in 2015, 1053 producers received 2,940,000 TL for 42,000 decare land. Not satisfied by merely certifying the products, the association has launched plans to make use of the products of the producers, aiming to establish olive press, processing and packaging integrated facilities (Anonymous 2016a).

Organic farming both utilizes and maintains ecosystem services. Ecosystem services, such as biological control, pollination, soil formation, nutrient cycling in agriculture are staminal for the sustainable supply of food. It is therefore more sustainable than is conventional agriculture which degrades some ecosystem services (Sandhu et al. 2010; Bilalis et al. 2013). Organic farming, through its ecological approach, upgrades biodiversity and maintains the integrity of the ecosystem. Research into organic farming practices has shown that organic systems can support biodiversity conservation through increasing the number and variety of wild species found on farms and supporting high levels of agrobiodiversity (Grandi 2008; Bilalis et al. 2013). The current situation of worldwide concern over the emission of greenhouse gases and its effect on the climate, demands an evaluation, from the perspective of energy usage efficiency and more specifically of non-renewable energy sources, of tendencies for change in the management of agricultural systems which have arisen in recent years (Guzman and Alonso, 2008; Mirzaee et al. 2011).

Efficient usage of energy is one of the primary requirements of sustainable agriculture. Energy usage in agriculture has been increasing in response to increasing population, restricted supply of arable land and a desire for higher standards of living. Continuous demand in increasing food production resulted in intensive usage of chemical fertilizers, pesticides, agricultural machinery and other natural resources. Intensive usage of energy causes problems threatening public health and environment. Efficient usage of energy in agriculture will minimize environmental problems, prevent destruction of natural resources, and promote sustainable agriculture as an economical production system. The development of energy usage efficiency agricultural systems with a low input of energy compared to the output of products should therefore help to decline the emissions of greenhouse gasses in agricultural production (Dalgaard et al. 2001; Kızılaslan 2009).

Several researches have been performed on energy input-output analysis of agricultural products. For example, researches have been done on energy input-output analyses of organic olive (Guzman and Alonso 2008), organic and conventionel black carrot (Çelik et al. 2010), organic apricot (Gündoğmuş 2006), organic grape (Baran et al. 2017a), organic mulberry (Gokdogan et al. 2017), walnut (Baran et al. 2017b) cherry (Kizilaslan 2009), sweet cherry (Demircan et al. 2006), apple (Asakereh et al. 2010), citrus (Özkan et al. 2004a), pomegranate (Çanakçı 2010), grape (Koçtürk and Engindeniz 2009), peach (Göktolga et al. 2006), kiwifruit (Mohammadi et al. 2010), apricot (Gezer et al. 2003), lemon (Bilgili 2012), organic maize and organic potato (Pimentel 1993), organic lentil (Mirzaee et al. 2011), sugar beet (Baran and Gökdoğan 2016), wheat (Marakoğlu and Çarman 2010), corn (Öztürk et al. 2006), corn silage (Barut et al. 2011), garlic (Samavatean et al. 2011), soybean (Mandal et al. 2002), stake-tomato (Esengün et al. 2007), cotton (Baran 2016), beef cattle (Demircan and Köknaroğlu 2007), broiler (Atılgan and Köknaroğlu 2006), lamb (Köknaroglu et al. 2007) etc. Although many experimental works have been done on energy input-output analysis in agriculture, there is no study on the energy input-output analysis of organic olive production in Turkey. In this study, it is aimed to evaluate the energy input-output analysis of organic olive production.

Materials and Method

The surface features of Aydın-Karpuzlu Region are being shaped by the Karpuzlu Stream from Beşparmak Mountains and Gökbel mountain, Karpuzlu Plain fed by this stream and many creeks joining this stream and the mountains surrounding this plain (Uyguç 1998). Karpuzlu Region is 55 km away from Central Aydın. The region is surrounded by mountains all sides (Anoymous 2016b). In order to evaluate the energy input-output of organic olive (2015 production season) data has been provided by Aydın-Karpuzlu Organic Olive Producers Association. Total energy input in unit area (ha) constitutes each total of input energy. Human labour energy, machinery energy, diesel fuel energy, electricty energy, organic chemical energy, polyethylene trap energy and transportation energy have been calculated as inputs. Organic olive has been calculated as output. In Table 1, the agricultural production inputs, energy equivalents of input and output have been taken as energy values. Energy usage efficiency calculations have been made to determine the productivity levels of organic olive production.

The units shown in Table 1 have been used to find out the input values in organic olive production. Input amounts have been calculated and then these input data have been multiplied by the energy equivalent coefficient. When determining the energy equivalent coefficients, previous energy analysis sources have been used. By adding energy equivalents of all inputs in MJ unit, the total energy equivalent has been evaluationed. In order to evaluation the energy input-output in organic olive production, “Energy usage efficiency, energy productivity, specific energy and net energy have been calculated by using the following formulates (Mandal et al. 2002; Mohammadi et al. 2008, 2010)”.

Results and Discussion

The amount of organic olive produced per hectare during the 2015 production season has been calculated as an average of 8888.88 kg. For the 2015 organic olive production season, the energy balance of organic olive production related to this study has been given in Table 2. It can be seen from these tables that the first, second and third highest energy inputs in organic olive production have diesel fuel energy by 50.31%, machinery energy by 33.56% and polyethylene trap energy by 9.12%, respectively. If the average values are investigated by referring to Table 2, it can be seen that the highest energy inputs in organic olive production are diesel fuel energy by 19,426.95 MJ ha−1 (50.31%), machinery energy by 12,960 MJ ha−1 (33.56%), polyethylene trap energy by 3520 MJ ha−1 (9.12%), human labour energy by 2116.80 MJ ha−1 (5.48%), electricity energy by 276.48 MJ ha−1 (0.72%), organic chemical energy by 231.60 MJ ha−1 (0.60%) and transportation energy by 81.87 MJ ha−1 (0.21%), respectively.

Human labour time input has been calculated 1080 h ha−1. Machinery time input has been calculated 200 h ha−1 and diesel fuel amount has been calculated 345 l ha−1. Human labour energy and diesel fuel energy have been used for tractor and farm operations. The amount of electricity used for organic olive yield harvesting has 76.80 kWh ha−1. Accumulator machine powered by electricity has been used for harvesting in organic olive yield. Polyethylene trap has been used for olive fly for (one unit for one tree). Organic chemical has been used 3 kg ha−1 in organic olive production. Organic olive yield has been produced as 8888.88 kg ha−1.

In this study, diesel fuel energy has the biggest share by 19,426.95 MJ ha−1 (50.31%). Similarly, in previous studies, Gündoğmuş (2006) has found in organic apricot study that the diesel fuel energy has the biggest share by 6199.73 MJ ha−1 (44.99%), Azizi and Heidari (2013) have found in wheat study that the diesel fuel energy has the biggest share by 3399.32 MJ ha−1 (43.21%), Çelik et al. (2010) have found in organic black carrot study that the diesel fuel energy has the biggest share by 13,311.68 MJ ha−1 (35.26%), Mohammadi and Omid (2010) have found in cucumber study that the diesel fuel energy has the biggest share by 62,426.96 MJ ha−1 (41.94%), Özkan et al. (2007) have found in open-field grape study that the diesel fuel energy has the biggest share by 7545.50 MJ ha−1 (31.92%), Pishgar-Komleh et al. (2011) have found in rice study that the diesel fuel energy has the biggest share by 18,072.93 MJ ha−1 (45.95%), Esengün et al. (2007) have found in stake-tomato study that the diesel fuel energy has the biggest share by 40,757.18 MJ ha−1 (42.04%) etc.

Energy usage efficiency calculations in organic olive production have been given in Table 3. According to Table 3, organic olive yield, energy input, energy output, energy usage efficiency, specific energy, energy productivity and net energy in organic olive production have been calculated as 8888.88 kg ha−1, 38,613.70 MJ ha−1, 104,888.78 MJ ha−1, 2.72, 4.34 MJ kg−1, 0.23 kg MJ−1 and 66,275.08 MJ ha−1, respectively. In previous studies, in the studies conducted to determine energy usage efficiency in organic maize, organic potato, organic apricot, organic black carrot, organic lentil, organic soybean, organic spring barley, organic pea, banana, apple production, the energy usage efficiency value has been determined as; 5.90, 1.08 (Pimentel 1993), 2.22 (Gündoğmuş 2006), 1.90 (Çelik et al. 2010), 2.12 (Mirzaee et al. 2011), 3.80 (Pimentel et al. 2005; Arthurson and Jäderlund 2011), 10.9, 12.8 (Klimekova and Lehocka 2007; Arthurson and Jäderlund 2011), 1.90 (Akçaöz 2011), 2.26 (Yılmaz et al. 2010), respectively.

In this study, energy balance of organic olive production has been determined. Organic olive production is a profitable production in terms of energy usage efficiency (2.72). In this study, diesel fuel energy has the highest input. Guzman and Alonso (2008) have reported that, “The usage of biofuel could increase the energy usage efficiency of agricultural systems in general, although it would involve more extensive land use, which would need to be taken into consideration (Fredriksson et al. 2006)”. Some of the benefits desired to be obtained through energy input/output analysis are summarized as: being able to evaluation whether energy has been used effectively or not. Once this is determined, then energy wastage will be avoided, as use of excessive energy will be avoided, which in turn, will lower the negative effects caused by environmental exposure of excessive energy, fuel, etc. (Göktolga et al. 2006). Demircan et al. (2006) reported that, “proper tractor selection and management of machinery to decrease direct use of diesel fuel (Işık and Sabancı 1991) have needed to save non-renewable energy sources without impairing the yield or profitability, in order to improve the energy usage efficiency of sweet cherry production”. For decrease of inputs (machinery and diesel fuel) of organic olive production, these notices may apply for organic olive production.

References

Acaroğlu M (2004) Miscanthus X Giganteus’un orta Anadolu-Konya şartlarında yetiştirilmesi ve enerji bilançosunun belirlenmesi. II. Ulusal Ege Enerji Sempozyumu ve Sergisi, Dumlupınar Üniversitesi, Kütahya, pp 358–362 (in Turkish)

Akçaöz H (2011) Analysis of energy use for banana production: a case study from Turkey. Afr J Agric Res 6(25):5618–5624

Anonymous (2014) Aydın organik ve iyi tarim yol haritasi raporu. T.C. Güney Ege Kalkınma Ajansı, Türkiye

Anonymous (2016a) Aydın-Karpuzlu Organic Olive Producers Association. Karpuzlu-Aydın, Turkey

Anonymous (2016b) Türkiye Cumhuriyeti Karpuzlu Kaymakamlığı. http://www.karpuzlu.gov.tr/default_B0.aspx?content=367. Accessed 17 Sept 2016

Arthurson V, Jäderlund L (2011) Utilization of natural farm resources for promoting high energy efficiency in low-input organic farming. Energies 4:804–817

Asakereh A, Shiekhdavoodi MJ, Almassi M, Sami M (2010) Effects of mechanization on energy requirements for apple production in Esfahan province, Iran. Afr J Agric Res 5(12):1424–1429

Atılgan A, Köknaroğlu H (2006) Cultural energy analysis on broilers reared in different capaticty poultry houses. Ital J Anim Sci 5:393–400

Azizi A, Heidari S (2013) A comparative study on energy balance and economical indices in irrigated and dry land barley production systems. Int J Environ Sci Technol (Tehran) 10:1019–1028

Baran MF (2016) Energy efficiency analysis of cotton production in Turkey: a case study for Adıyaman province. Am J Agric Environ Sci 16(2):229–233

Baran MF, Gökdoğan O (2016) Determination of energy of sugar beet production in Turkey: a case study of Kırklareli Province. Energy Effic 9(2):487–494

Baran MF, Lüle F, Gökdoğan O (2017a) Energy input-output analysis of organic grape production: a case study from Adiyaman Province. Erwerbs-Obstbau. doi:10.1007/s10341-017-0322-1

Baran MF, Gökdoğan O, Oğuz H I (2017b) Determining the energy usage efficiency of walnut (Juglans regia L.) cultivation in Turkey. Erwerbs-Obstbau 59:77–82. doi:10.1007/s10341-016-0301-y

Barut ZB, Ertekin C, Karaağaç HA (2011) Tillage effects on energy use for corn silage in Mediterranean Coastal of Turkey. Energy 36:5466–5475

Bilalis D, Kamariari P‑E, Karkanis A, Efthimiadou A, Zorpas A, Kakabouki I (2013) Energy inputs, output and productivity in organic and conventional maize and tomato production, under Mediterranean Conditions. Not Bot Horti Agrobot 41(1):190–194

Bilgili ME (2012) Limon üretiminde enerji kullanım etkinliğinin belirlenmesi; Adana ili örneği. Tarım Makinaları Bilimi Dergisi 8(2):199–203 (in Turkish)

Çanakçı M (2010) Energy use pattern and economic analyses of pomegranate cultivation in Turkey. Afr J Agric Res 5(7):491–499

Çelik Y, Peker K, Oğuz C (2010) Comparative analysis of energy efficiency in organic and conventional gardening systems: A case study of black carrot (Daucus carota L.) production in Turkey. Philipp Agric Sci 93(2):224–231

Dalgaard T, Halberg N, Porter JR (2001) A model for fossil energy use in Danish agriculture used to compare organic and conventional farming. Agric Ecosyst Environ 87(1):51–65

Demircan V, Ekinci K, Keener HM, Akbolat D, Ekinci C (2006) Energy and economic analysis of sweet cherry production in Turkey: A case study from Isparta province. Energy Convers Manag 47:1761–1769

Demircan V, Köknaroğlu H (2007) Effect of farm size on sustainability of beef cattle production. J Sustain Agric 31(1):75–87

Esengün K, Gündüz O, Erdal G, Erdal H (2007) An economic analysis and energy use in stake-tomato production in Tokat province of Turkey. Renew Energy 32:1873–1881

Fredriksson H, Baky A, Bernesson S, Nordberg A, Noren O, Hansson PA (2006) Use of on-farm produced biofuels on organic farms-evaluation of energy balances and environmental loads for three possible fuels. Agric Syst 89:184–203

Gezer I, Acaroğlu M, Hacıseferoğulları H (2003) Use of energy and labor in apricot agriculture in Turkey. Biomass Bioenergy 24:215–219

Gokdogan O, Oguz HI, Baran MF (2017) Energy input-output analysis in organic mulberry (Morus spp.) production in Turkey: a case study Adiyaman-Tut Region. Erwerbs-Obstbau. doi:10.1007/s10341-017-0333-y

Göktolga ZG, Gözener B, Karkacıer O (2006) Şeftali üretiminde enerji kullanımı: Tokat ili örneği. Gaziosmanpaşa Üniversitesi Ziraat Fakültesi Dergisi 23(2):39–44 (in Turkish)

Grandi C (2008) Organic agriculture enhances agrobiodiversity. Biodiversity 9:33–35

Green MB (1987) Energy in pesticide manufacture, distribution and use. In: Helsel ZR (ed) Energy in plant nutrition and pest control. Energy in World Agriculture, vol 2. Elsevier, Amsterdam, pp 165–177

Guzman GI, Alonso AM (2008) A comparison of energy use in conventional and organic olive oil production in Spain. Agric Syst 98:167–176

Gündoğmuş E (2006) Energy use on organic farming: a comparative analysis on organic versus conventional apricot production on small holdings in Turkey. Energy Convers Manag 47:3351–3359

Heywood VH (1978) Flowering plants of the World. Oxford University Press, Oxford London Melbourne

Işık A, Sabancı A (1991) A research on determining basic management data and developing optimum selection models of farm machinery and power for the mechanization planning in the irrigated farming of the Çukurova region. Turk J Agric For 15:899–920

Karaağaç MA, Aykanat S, Çakır B, Eren O, Turgut MM, Barut ZB, Öztürk HH (2011) Energy balance of wheat and maize crops production in Hacıali undertaking. 11th International Congress on Mechanization and Energy in Agriculture Congress, Istanbul, 21–23 September 2011, pp 388–391

Kızılaslan H (2009) Input-output energy analysis of cherries production in Tokat province of Turkey. Appl Energy 86:1354–1358

Klimekova M, Lehocka Z (2007) Comparison of organic and conventional farming system in term of energy efficiency. http://orgprints.org/view/projects/wissenschaftstagung-2007.html. Accessed 9 Mar 2011

Koçtürk OM, Engindeniz S (2009) Energy and cost analysis of sultana grape growing: a case study of Manisa, west Turkey. Afi J Agric Res 4(10):938–943

Köknaroğlu H, Ali A, Ekinci K, Morrical DG, Hoffman MP (2007) Cultural energy analysis of lamb production in the feedlot or on pasture and in the feedlot. J Sustain Agric 30(4):95–108

Mani I, Kumar P, Panwar JS, Kant K (2007) Variation in energy consumption in production of wheat-maize with varying altitudes in hill regions of Himachal Prades, India. Energy 32:2336–2339

Mandal KG, Saha KP, Ghosh PK, Hati KM, Bandyopadhyay KK (2002) Bioenergy and economic analysis of soybean based crop production systems in central India. Biomass Bioenergy 23:337–345

Marakoğlu T, Çarman K (2010) Energy balance of direct seeding applications used in wheat production in middle Anatolia. Afr J Agric Res 5(10):988–992

Mirzaee E, Omid M, Asakereh A, Safaieenejad M, Dalvand MJ (2011) 11th Energy efficiency in organic lentil production in Lorestan Province of Iran. International Congress on Mechanization and Energy in Agriculture Congress, Istanbul, 21–23 September 2011, pp 383–387

Mohammadi A, Tabatabaeefar A, Shahin S, Rafiee S, Keyhani A (2008) Energy use and economical analysis of potato production in Iran a case study: Ardabil province. Energy Convers Manag 49:3566–3570

Mohammadi A, Omid M (2010) Economical analysis and relation between energy inputs and yield of greenhouse cucumber production in Iran. Appl Energy 87:191–196

Mohammadi A, Rafiee S, Mohtasebi SS, Rafiee H (2010) Energy inputs-yield relationship and cost analysis of kiwifruit production in Iran. Renew Energy 35:1071–1075

Olgun A, Artukoğlu MM, Adanacıoğlu H (2008) Konvansiyonel zeytin üreticilerinin organik zeytin üretimine geçme konusundaki eğilimleri üzerine bir araştırma. Ege Üniversitesi Ziraat Fakültesi Dergisi 45(2):95–101 (in Turkish)

Özkan B, Akcaoz H, Karadeniz F (2004a) Energy requirement and economic analysis of citrus production in Turkey. Energy Convers Manag 45:1821–1830

Özkan B, Kürklü A, Akçaöz H (2004b) An input-output energy analysis in greenhouse vegetable production: a case study for Antalya region of Turkey. Biomass Bioenergy 26:89–95

Özkan B, Akçaöz H, Fert C (2004c) Energy input-output analysis in Turkish agriculture. Renew Energy 29:39–51

Özkan B, Fert C, Karadeniz CF (2007) Energy and cost analysis for greenhouse and open-field grape production. Energy 32:1500–1504

Özkaya MT, Tunalıoğlu R, Özkaya FD, Ulaş M (2015) Zeytin üretiminde değişimler ve yeni arayışlar, TMMOB Ziraat Mühendisleri Odası. Ziraat Mühendisliği VIII. Teknik Kongresi, Ankara, 12–16 Ocak 2015, pp 630–644

Öztürk HH, Ekinci K, Barut ZB (2006) Energy analysis of the tillage systems in second crop corn production. J Sustain Agric 28(3):25–37

Öztürk F, Yalçın M, Dıraman H (2009) Türkiye Zeytinyağı ekonomisine genel bir bakış. Gıda Teknolojileri Elektronik Dergisi 4(2):35–51 (in Turkish)

Pimentel D (1992) Energy inputs in production agriculture. In: Fluck RC (ed) Energy in farm production energy in world agriculture, vol 6. Elsevier, Amsterdam, pp 13–29

Pimentel D (1993) Economics and energetics of organic and conventional farming. J Agric Environ Ethics 6(1):53–60

Pimentel D, Hepperly P, Hanson J, Seidel R, Douds D (2005) Environmental, energetic, and economic comparisons of organic and conventional farming systems. Bioscience 55:573–582

Pishgar-Komleh SH, Sefeedpari P, Rafiee S (2011) Energy and economic analysis of rice production under different farm levels in Gulian province of Iran. Energy 36:5824–5831

Samavatean N, Rafiee S, Mobli H, Mohammadi A (2011) An analysis of energy use and relation between energy inputs and yield, costs and income of garlic production in Iran. Renew Energy 36:1808–1813

Santucci FM (2007) Organic olive oil. DSEEA UniPG, Washington DC

Sandhu HS, Wratten SD, Cullen R (2010) Organic agriculture and ecosystem services. Environ Sci Policy 13:1–7

Singh JM (2002) On garden energy use pattern in different cropping systems in Haryana, India. International Institute of Management University of Flensburg, Germany (Sustainable Energy Systems and Management. Master of Science)

TÜİK (2016) Türkiye İstatistik Kurumu Bitkisel Üretim İstatistikleri 2013 Verileri. http://tuikapp.tuik.gov.tr/bitkiselapp/bitkisel.zul. Accessed 17 Sept 2016

Uyguç A (1998) Dünden bugüne Karpuzlu. Aydın Güneş Matbaası, Türkiye (in Turkish)

Yılmaz I, Özalp A, Aydoğmuş F (2010) Antalya ili bodur elma üretiminde enerji kullanım etkinliğinin belirlenmesi: Elmalı ilçesi örneği. Akdeniz Üniversitesi Ziraat Fakültesi Dergisi 23(2):93–97 (in Turkish)

Acknowledgements

We thanks to Aydın-Karpuzlu Organic Olive Producers Association for help in study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

O. Gökdoğan and O. Erdoğan declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Gökdoğan, O., Erdoğan, O. Evaluation of Energy Balance in Organic Olive (Olea Europaea L.) Production in Turkey. Erwerbs-Obstbau 60, 47–52 (2018). https://doi.org/10.1007/s10341-017-0338-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10341-017-0338-6