Abstract

This study was conducted in an organic fig farm in the 2017 production season in Adıyaman, Tut, at the Southeast Anatolia in Turkey. According to the findings, the energy inputs of organic fig production were calculated respectively as 2217.57 MJ ha−1 (38.07%) human labour energy, 2025 MJ ha−1 (34.76%) farmyard manure energy, 858.73 MJ ha−1 (14.74%) diesel fuel energy, 545.29 MJ ha−1 (9.36%) machinery energy, 79.72 MJ ha−1 (1.37%) electricity energy, 49.56 MJ ha−1 (0.85%) transportation energy and 49.30 MJ ha−1 (0.85%) irrigation water energy. The energy yield of organic fig was calculated as 12,900 MJ ha−1. The energy output-input ratio, specific energy, energy productivity, and net energy calculations were calculated as 2.21, 1.08 MJ kg−1, 0.92 kg MJ−1, and 7074.83 MJ ha−1, respectively. Total input energy consumption in organic fig production was classified as 55.02% direct, 44.98% indirect, 73.67% renewable, and 26.33% non-renewable. Total GHG emission was calculated as 1109.02 kgCO2‑eqha−1. The most significant portion was human labor (71.41%). The second most significant value was farmyard manure usage (17.65%), and others were as follows: diesel fuel consumption (3.80%), machinery usage (3.49%), electricity consumption (2.38%), water consumption of irrigation (1.20%) and transportation (0.07%). Additionally, GHG ratio value was calculated as 0.21 kgCO2‑eqkg−1 in organic fig.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Fig has a remarkable nutritional value due to being a rich deposit of carbohydrates. Figs contain essential amino acids as they are rich in vitamins and minerals A, B1, B2 and C (Sadhu 1990; Javanmard and Mahmoudi 2008). The fig tree (Ficus carica L.) is a unique ficus variety that is widespread in tropical and subtropical regions with edible fruits. Fig production is either located around the Mediterranean Sea or in the countries with a regional mediterranean climate like California (USA), Australia, or South America. Turkey is in the first place in the world in terms of fig production and exportation (Çobanoğlu 2010). The fresh fig production of Turkey is 305,450 tons in the 2016/2017 season while total production of the world is 1,050,459 tons (Anonymous 2018).

Current agricultural production heavily depends on non-renewable fossil fuels—consumption of fossil energy results in indirect emissions of CO2 and other burnout gases. Also, there are other negative impacts on the environment like pollution, climate change, and high input prices. Searching for agricultural production methods with a higher energy productivity is a popular topic today as it was 20 years ago (Pimentel et al. 1973; Refsgaard et al. 1998). According to the Brundtland Commission, the total consumption of energy has to be dropped by 50% before 2035 (Refsgaard et al. 1998). Fossil resources are limited and hazardous to the environment. This leads researchers to evaluate the energy efficiency of different crops in different regions (Houshyar et al. 2015; Eren et al. 2019).

Energy usage in agricultural production is becoming more and more each day due to the intensity of modern practices, chemical inputs, pesticides, machinery, and electricity to ensure rapidly growing population’s demands are met. However, more intense energy usage has caused some significant human health and environment problems such as greenhouse gas emissions. Proper and efficient usage of input has a crucial role in sustainable agricultural production (Yılmaz et al. 2005). A greenhouse gas (GHG) is a gas in the atmosphere that absorbs and spreads radiation within the thermal infrared range. The greenhouse gas (GHG) emissions of agriculture come from several sources such as machinery, diesel fuel, chemical fertilizers, biocides, and electricity. So, the rise in energy inputs can cause a rise in the greenhouse (GHG) emissions in agricultural action (Nabavi-Pelesaraei et al. 2016).

Different studies were done as energy balance of horticulture products. For example, studies were defined on the energy balance of fig (Çobanoğlu 2010), organic farming (Gündoğmuş and Bayramoğlu 2006), organic apricot (Gündoğmuş 2013), organic olive (Kaltsas et al. 2007), organic black carrot (Celik et al. 2010), organic grape (Baran et al. 2017a), organic mulberry (Gökdoğan et al. 2017), apricot (Gezer et al. 2003), lemon (Özkan et al. 2004a), avocado (Astier et al. 2014), almond (Beigi et al. 2016), pear (Aydın et al. 2017), peach & cherry (Aydın and Aktürk 2018) etc. Several studies on greenhouse gas emissions were had on horticulture crops such as olive (Rajaeifar et al. 2014), nectarine (Qasami-Kordkheili and Nabavi-Pelesaraei 2014), peach (Nikkhah et al. 2017), pomegranate (Özalp et al. 2018), apple (Taghavifar and Mardani 2015), watermelon (Nabavi-Pelesaraei et al. 2016), grape (Mardani and Taghavifar 2016), strawberry (Khoshnevisan et al. 2013) and different fruits (Eren et al. 2019). Although many experimental studies were defined on energy balance on agriculture, there was no study on the energy balance and greenhouse gas emissions (GHG) of organic fig production in Turkey. In this study, it has been aimed to define the energy balance and greenhouse gas emissions (GHG) of organic fig.

Materials and Method

Description of the Study Area

Southern part of the Adıyaman province has hot and dry during summer months and rainy and cold during winter months. Center of Adıyaman is located at 37° 45′ north latitude and 38° 16′ eastern longitude. Adıyaman’s altitude from sea level is 672 m. The daily difference is between the highest, and the lowest temperature is about 10 °C (Anonymous 2016a). The general soil structure of Adıyaman is clayed-loamy (¾) (Anonymous 2016b). The study area is a 2-hectare organic fig farm, located at Adıyaman-Tut region. The data obtained for this study contains 2017 production season. This study was carried out as a randomized complete block design with three replicates (3 recurrences). Human labor energy, machinery energy, diesel fuel energy, farmyard manure energy, irrigation water energy, electricity energy, and transportation energy were calculated as inputs. Organic fig yield was calculated as the output. Images of organic figs were given in Fig. 1.

The units shown in Tables 1 and 2 are the inputs of organic fig production. Previous energy balance and greenhouse gas emissions (GHG) studies were evaluated when defining the energy equivalent and greenhouse gas emissions (GHG) coefficients.

Energy balance values and related calculations are presented in Table 3. Energy balance indicators in organic fig production were shown in Table 4. Total fuel consumption of each parcel was calculated as l ha−1. Full tank method was used to measure the amount of fuel used (Göktürk 1999; El Saleh 2000; Sonmete 2006). Labor yield of area (ha h−1) was calculated by the total time in the trial area (Sonmete 2006; Güzel 1986; Özcan 1986). Chronometers were used to measure the time spent during agricultural operations (Sonmete 2006). In order to define the energy balance in organic fig production, Mohammadi et al. (2010) reported that energy use efficiency, energy productivity, specific energy, and net energy were calculated by using the following formulates (Mohammadi et al. 2008; Mandal et al. 2002):

Koçtürk and Engindeniz (2009) reported that the input energy is also classified into direct and indirect, and renewable and non-renewable forms. The indirect energy consists of pesticide and fertilizer, while direct energy includes human and animal labor, diesel, and electricity used during the production process. Non-renewable energy includes petrol, diesel, electricity, chemicals, fertilizers, machinery, while renewable energy consists of human and animal labor (Mandal et al. 2002; Singh et al. 2003). Energy inputs of organic fig production, in the form of direct and indirect, as well as renewable and non-renewable energy were given in Table 5.

Greenhouse gas (GHG) emissions of inputs in organic fig production were shown in Table 6. The greenhouse emissions (GHG) (kgCO2‑eqha−1) united with the inputs to growing 1 ha of organic fig were calculated as following, adapted by (Hughes et al. 2011):

∑ Where R(i) is the application rate of input, I (unitinputha−1), and EF (i) is the GHG emission coefficient of input i (kgCO2‑equnitinput−1). Table 2 is the GHG emissions coefficients of agricultural inputs. However, an index is determined to evaluate the amount of emitted kg CO2‑eq per kg yield as following adapted Houshyar et al. (2015) and Khoshnevisan et al. (2014). Where IGHG is GHG ratio, and Y is the yield as kg per ha.

Results and Discussion

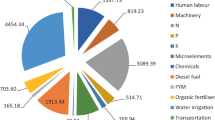

As a result of this study, fig produced per hectare in the 2017 season was 5375 kg. As shown in Table 3, energy inputs in organic fig production were as follows: 2217.57 MJ ha−1 (38.07%) human labour energy, 2025 MJ ha−1 (34.76%) farmyard manure energy, 858.73 MJ ha−1 (14.74%) diesel fuel energy, 545.29 MJ ha−1 (9.36%) machinery energy, 79.72 MJ ha−1 (1.37%) electricity energy, 49.56 MJ ha−1 (0.85%) transportation energy and 49.30 MJ ha−1 (0.85%) irrigation water energy. Production output organic fig yield was calculated as 12,900 MJ ha−1. Human labor input was calculated as 1131.42 h ha−1. Human labor energy and diesel fuel energy were used for tractor and farm operations. Farm operations were tillage, fertilizer application, pruning-collecting, hoeing, harvesting classification, or similar. As organic fertilizer, farmyard manure was performed 6750 kg ha−1, and farmyard manure was the second input. Organic fig yield was produced as 5375 kg ha−1.

Organic fig yield, energy input, energy output, energy output-input ratio, specific energy, energy productivity and net energy in organic fig production were calculated as 5375 kg ha−1, 5825.17 MJ ha−1, 12,900 MJ ha−1, 2.21, 1.08 MJ kg−1, 0.92 kg MJ−1 and 7074.83 MJ ha−1, respectively (Table 4). Similarly, in previous studies related to organic agricultural production, Baran et al. (2017b) calculated the energy output-input ratio as 0.25 in organic strawberry, Celik et al. (2010) calculated the energy output-input ratio as 1.90 in organic black carrot, Gündoğmuş (2006) calculated the energy output-input ratio as 2.22 in organic apricot.

The distribution of inputs used for the production of organic fig, in accordance with direct, indirect, renewable, and non-renewable energy groups were given in Table 5. The consumed total energy input in organic fig production can be classified as 55.02% direct, 44.98% indirect, 73.67% renewable, and 26.33% non-renewable. Similarly, organic black carrot (Celik et al. 2010), organic apricot (Gündoğmuş 2006) and organic strawberry (Baran et al. 2017b) yielded results where the ratio of direct energy was higher than the ratio of indirect energy. In this study, the ratio of renewable energy (73.67%) was higher than the ratio of non-renewable (26.33%) energy because usage of farmyard manure was used instead of chemical fertilizers.

The results of greenhouse gas (GHG) emissions of organic fig production are tabulated in Table 6. The total GHG emissions were calculated as 1109.02 kgCO2‑eqha−1. The results of the study showed that the share of human labor in total GHG emissions was the highest (791.99 kgCO2‑eqha−1), farmyard manure (195.75 kgCO2‑eqha−1) and machinery (38.72 kgCO2‑eqha−1) held the second and third. GHG ratio (per kg) was determined as 0.21. In a similar study, Taghavifar and Mardani (2015) calculated the total GHG emissions of apple production as 1200 kgCO2‑eqha−1, Özalp et al. (2018) calculated the total GHG emissions of pomegranate production as 1730 kgCO2‑eqha−1 and Mardani and Taghavifar (2016) calculated the total GHG emissions of grape production as 860 kgCO2‑eqha−1.

Conclusion

In this study, the energy balance of organic fig production was defined. According to the results, organic fig production is a profitable activity (2.21) in terms of energy balance in 2017 production season. Organic fig production consumed a total of 5825.17 MJ ha−1 energy; the highest share is human labor energy (38.07%). The energy input of farmyard manure comes second (34.76%) and diesel fuel energy third (14.74%) in total inputs. Organic fig yield, energy input, energy output, energy output-input ratio, specific energy, energy productivity and net energy in organic fig production were calculated as 5375 kg ha−1, 5825.17 MJ ha−1, 12,900 MJ ha−1, 2.21, 1.08 MJ kg−1, 0.92 kg MJ−1 and 7074.83 MJ ha−1, respectively. The consumed total energy input in organic fig production was classified as 55.02% direct, 44.98% indirect, 73.67% renewable, and 26.33% non-renewable. The total greenhouse gas (GHG) emissions were determined as 1109.02 kgCO2‑eqha−1 and 0.21 of GHG ratio (per kg). The results of the study showed that the share of human labor in total GHG emissions was the highest (791.99 kgCO2‑eqha−1), farmyard manure (195.75 kgCO2‑eqha−1) and diesel fuel (42.09 kgCO2‑eqha−1) held the second and third. Energy balance and GHG emissions were increased because the usage of farmyard manure was used instead of chemical fertilizers. Celen (2016) reported that “reducing the usage of nitrogen by lowering erosion, leakage, and evaporation, using more bio-nitrogen, using farmyard manure and other bio-fuels, implementing waste and left-over management in harvest residues and having minimum soil processing are compulsory”.

References

Acaroğlu M (2004) Cultivation of Miscanthus X Giganteus in middle Anatolian-Konya conditions and determination of energy balance. In: II. National Aegean Energy Symposium and Exhibition Dumlupınar University, Kütahya-Turkey, pp 358–362 (in Turkish)

Anonymous (2016a) Turkey Republic, Adıyaman Governorship. http://www.adiyaman.gov.tr/iklim. Accessed 1 May 2016

Anonymous (2016b) Turkey Republic, Ministry of Culture and Tourism, Defence of natural resources general principalship. http://www.korumakurullari.gov.tr/TR,89638/adiyaman.html. Accessed 1 May 2016

Anonymous (2018) Turkey Republic, Ministry of Customs and Trade, Cooperative Directory, 2017 Yılı KuruIncirRaporu. http://koop.gtb.gov.tr/data/5ad0695fddee7dd8b423eb22/2017%20Kuru%20incir%20raporu.pdf. Accessed 13 April 2018

Astier M, Merlin-Uribe Y, Villamil-Echeverri L, Garciarreal A, Gavito ME, Masera OR (2014) Energy balance and greenhouse gas emissions in organic and conventional avocado orchards in Mexico. Ecol Indic 43(2014):281–287

Aydın B, Aktürk D (2018) Energy use efficiency and economic analysis of peach and cherry production regarding good agricultural practices in Turkey: A case study in Çanakkale province. Energy 158(1):967–974

Aydın B, Aktürk D, Özkan E, Hurma H, Kiracı MA (2017) Armut üretiminde karşılaştırmalı enerji kullanım etkinliği ve ekonomik analiz: Trakya Bölgesi örneği. Türk Tarım-Gıda Bilim Ve Teknoloji Dergisi 5(9):1072–1079 (in Turkish)

Baran MF, Lüle F, Gökdoğan O (2017a) Energy input-output analysis of organic grape production: a case study from Adıyaman Province. Erwerbs-Obstbau 59(4):275–279

Baran MF, Oğuz HI, Gökdoğan O (2017b) Determination of energy input-output analysis in organic strawberry production. Fresenius Environ Bull 26(3):1842–1846

Beigi M, Torki-Harchegani M, Ghanbarian D (2016) Energy use efficiency and economical analysis of almond production: a case study in Chaharmahal-Va-Bakhtiari province, Iran. Energy Effic 9:745–754

Celen I (2016) Tarımsal uygulamalarda enerji kullanımı üzerine bir değerlendirme. Electron J Vocat Coll 6(3):18–29 (in Turkish)

Celik Y, Peker K, Oğuz C (2010) Comparative analysis of energy efficiency in organic and conventional gardening systems: A case study of black carrot (Daucus carota L.) production in Turkey. Philipp Agric Scientist 93(2):224–231

Clark S, Khoshnevisan B, Sefeedpari P (2016) Energy efficiency and greenhouse gas emissions during the transition to organic and reduced-input practices: Student farm case study. Ecol Eng 88:186–194

Çobanoğlu F (2010) Analysis of energy use for fig production in Turkey. J Food Agric Environ 8(3&4):842–847

Demircan V, Ekinci K, Keener HM, Akbolat D, Ekinci C (2006) Energy and economic analysis of sweet cherry production in Turkey: A case study from Isparta province. Energy Convers Manag 47:1761–1769

El Saleh Y (2000) Syria and Turkey lentil and chickpea harvest mechanization research on the identification of opportunities. Ph.D. Thesis (Unpublished), Cukurova University, Institute of Science and Technology, Adana, Turkey (in Turkish)

Eren Ö, Baran MF, Gökdoğan O (2019) Determination of greenhouse gas emissions (GHG) in the production of different fruits in Turkey. Fresenius Environ Bull 28(1):464–472

Ertekin C, Canakci M, Kulcu R, Yaldiz O (2010) Energy use in legume cultivation in Turkey. In: XVIIth world congress of the international commission of agricultural and biosystems engineering (CIGR) Québec, Canada, 13–17 June, pp 1–9

Gezer I, Acaroğlu M, Hacıseferoğulları H (2003) Use of energy and labor in apricot agriculture in Turkey. Biomass Bioenergy 24:215–219

Gökdoğan O, Oğuz HI, Baran MF (2017) Energy input-output analysis in organic mulberry (Morus spp.) production in Turkey: a case study Adiyaman-Tut Region. Erwerbs-Obstbau 59(4):325–330

Göktürk B (1999) A study on the determination of some properties of dry onion for harvesting, development of the excavator knife type harvesting machine, and comparison with other harvesting methods. Ph.D. Thesis, Trakya University, Institute of Science and Technology, Tekirdağ, Turkey (in Turkish)

Gündoğmuş E (2006) Energy use on organic farming: A comparative analysis of organic versus conventional apricot production on smallholdings in Turkey. Energy Convers Manag 47:3351–3359

Gündoğmuş E (2013) Energy use patterns and econometric models of quince production. Actual Probl Econ 5(143):236–246

Gündoğmuş E, Bayramoğlu Z (2006) Energy input use on organic farming: a comprative analysis on organic versus conventional farm in Turkey. J Agron 5(1):16–22

Güzel E (1986) A study on the mechanization of the dismantling and blending of peanuts in Çukurova region and the determination of the properties of the plant for mechanization. Agricultural equipment association professional publications, vol 47. Ankara, Turkey (in Turkish)

Houshyar E, Dalgaard T, Tarazgar MH, Jorgensen U (2015) Energy input for tomato production what the economy says, and what is good for the environment. J Clean Prod 89:99–109

Houshyar E, Mahmoodi-Eshkaftaki M, Azadi H (2017) Impacts of technological change on energy use efficiency and GHG mitigation of pomegranate: Application of dynamic data envelopment analysis models. J Clean Prod 162:1180–1191

Hughes DJ, West JS, Atkins SD, Gladders P, Jeger MJ, Fitt BD (2011) Effects of disease control by fungicides on greenhouse gas emissions by UK arable crop production. Pest Manag 67:1082–1092

Javanmard M, Mahmoudi H (2008) A SWOT analysis of organic dried fig production in Iran. Environ Sci 6(1):101–110

Kaltsas AM, Mamolos AP, Tsatsarelis CA, Nanos GD, Kalburtji KL (2007) Energy budget in organic and conventional olive groves. Agric Ecosyst Environ 122(2007):243–251

Karaağaç MA, Aykanat S, Çakır B, Eren O, Turgut MM, Barut ZB, Öztürk HH (2011) Energy balance of wheat and maize crops production in Hacıali undertaking. In: 11th international congress on mechanization and energy in agriculture congress Istanbul-Turkey, 21–23 September, pp 388–391

Khoshnevisan B, Rafiee S, Mousazadeh H (2013) Environmental impact assessment of the open field and greenhouse strawberry production. Eur J Agron 50:29–37

Khoshnevisan B, Shariati HM, Rafiee S, Mousazadeh H (2014) Comparison of energy consumption and GHG emissions of open field and greenhouse strawberry production. Renew Sustain Energy Rev 29:316–324

Koçtürk OM, Engindeniz S (2009) Energy and cost analysis of sultana grape growing: a case study of Manisa, West Turkey. African J Agric Resour 4(10):938–943

Kızılaslan H (2009) Input-output energy analysis of cherries production in Tokat province of Turkey. Appl Energy 86:1354–1358

Lal R (2004) Carbon emission from farm operations. Environ Int 30:981–990

Mandal KG, Saha KP, Ghosh PK, Hati KM, Bandyopadhyay KK (2002) Bioenergy and economic analysis of soybean-based crop production systems in central India. Biomass Bioenergy 23:337–345

Mani I, Kumar P, Panwar JS, Kant K (2007) Variation in energy consumption in the production of wheat-maize with varying altitudes in hill regions of Himachal Prades, India. Energy 32:2336–2339

Mardani A, Taghavifar H (2016) An overview on energy inputs and environmental emissions of grape production in West Azerbaijan of Iran. Renew Sustain Energy Rev 54:918–924

Meisterling K, Samaras C, Schweizer V (2009) Decisions to reduce greenhouse gases from agriculture and product transport: LCA case study of organic and conventional wheat. J Clean Prod 17:222–230

Mohammadi A, Rafiee S, Mohtasebi SS, Rafiee H (2010) Energy inputs-yield relationship and cost analysis of kiwifruit production in Iran. Renew Energy 35:1071–1075

Mohammadi A, Tabatabaeefar A, Shahin S, Rafiee S, Keyhani A (2008) Energy use and economical analysis of potato production in Iran a case study: Ardabil province. Energy Convers Manag 49:3566–3570

Mrini M (1999) Le cout energetique de l’irrigation des cultures sucrieres au Gharb. Institut Agronomique et Veterinaire Hassan II, Rabat (2eme rapport d’atat d’avancement, Ecole Doctorale)

Mrini M, Senhaji F, Pimentel D (2002) Energy analysis of sugar beet production under traditional and intensive farming systems and impacts on sustainable agriculture in Morocco. J Sustain Agric 20(4):5–28

Nabavi-Pelesaraei A, Abdi R, Rafiee S (2016) Neural network modeling of energy use and greenhouse gas emissions of watermelon production systems. J Saudi Soc Agric Sci 15(1):38–47

Nguyen TLT, Hermansen JE (2012) System expansion for handling co-products in LCA of sugar cane bio-energy systems: GHG consequences of using molasses for ethanol production. Appl Energy 89:254–261

Nikkhah A, Royan M, Khojastehpour M, Bacenetti J (2017) Environmental impacts modeling of Iranian peach production. Renew Sustain Energy Rev 75:677–682

Özalp A, Yılmaz S, Ertekin C, Yılmaz I (2018) Energy analysis and emissions of greenhouse gases of pomegranate production in Antalya province of Turkey. Erwerbs-Obstbau 60(4):321–329

Özcan MT (1986) Comparison of lentil harvesting and blending methods in terms of work efficiency, quality, energy consumption and cost, and research on the development of an appropriate harvesting machine. Turkey agricultural equipment corporation press, vol Release No. 46. Ankara

Özkan B, Akçaöz H, Karadeniz F (2004a) Energy requirement and economic analysis of citrus production in Turkey. Energy Convers Manag 45:1821–1830

Özkan B, Kürklü A, Akçaöz H (2004b) An input-output energy analysis in greenhouse vegetable production: A case study for the Antalya region of Turkey. Biomass Bioenergy 26:89–95

Pimentel D, Hurd LE, Bellotti AC, Forster MJ, Oka IN, Sholes OD, Whitman RJ (1973) Food production and the energy crisis. Science 182:443–449

Pishgar-Komleh SH, Ghahderijani M, Sefeedpari P (2012) Energy consumption and CO2 emissions analysis of potato production based on different farm size levels in Iran. J Clean Prod 33:183–191

Qasami-Kordkheili P, Nabavi-Pelesaraei A (2014) Optimization of energy required and potential of greenhouse gas emissions reductions for nectarine production using data envelopment analysis approach. Int J Energy Environ 5(2):207–218

Rajaeifar MA, Akram A, Ghobadian B, Rafiee S, Heidari MD (2014) Energy-economic life cycle assessment (LCA) and greenhouse gas emissions analysis of olive oil production in Iran. Energy 66:139–149

Refsgaard K, Halberg N, Kristensen ES (1998) Energy utilization in crop and dairy production in organic and conventional livestock production systems. Agric Syst 57(4):599–630

Sadhu MK (1990) Fig. In: Kose TK, Mitra SK (eds) Fruits: tropical and subtropical. Naya Prokash, Calcutta

Singh JM (2002) On farm energy use pattern in different cropping systems in Haryana, India. Master of Science, International Institute of the Management University of Flensburg, Flensburg

Singh H, Mishra D, Nahar NM, Ranjan M (2003) Energy use pattern in production agriculture of a typical village in Arid Zone India (Part II). Energy Convers Manag 44:1053–1067

Sonmete MH (2006) Harvest-threshing mechanization and development possibilities of beans. Ph.D. Thesis (Unpublished), Selcuk University Institute of Science and Technology, Konya, Turkey (in Turkish)

Strapatsa AV, Nanos GD, Tsatsarelis CA (2006) Energy flow for integrated apple production in Greece. Agric Ecosyst Environ 116:176–180

Taghavifar H, Mardani A (2015) Prognostication of energy consumption and greenhouse gas (GHG) emissions analysis of apple production in West Azarbayjan of Iran using Artificial Neural Network. J Clean Prod 87:159–167

Yaldız O, Öztürk HH, Zeren Y, Basçetinçelik A (1993) Energy usage in the production of field crops in Turkey. In: 5th international congress on mechanization and energy in agriculture Kuşadası-Turkey, 11–14 October, pp 527–536 (in Turkish)

Yılmaz I, Akçaöz H, Özkan B (2005) An analysis of energy use and input costs for cotton production in Turkey. Renew Energy 30(2005):145–155

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

H.I. Oğuz, M.F. Baran, O. Gökdoğan, Ö. Eren and M. Solak declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Oğuz, H.I., Baran, M.F., Gökdoğan, O. et al. Energy Balance and Greenhouse Gas (GHG) Emissions of Organic Fig (Ficus carica L.) Production in Turkey. Erwerbs-Obstbau 64, 61–67 (2022). https://doi.org/10.1007/s10341-021-00617-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10341-021-00617-y