Abstract

Selenium (Se) has caused several ecological disasters due to its toxicity and bioaccumulation along trophic networks. Industrial activities that process fossil fuels and mineral ores, such as electricity generation, metal extraction and oil refining, produce wastewaters containing selenium. Currently, these wastewaters are insufficiently treated before being discharged into the environment. Several environmental biotechnological processes are used to convert soluble selenium oxyanions, selenite and selenate, to solid elemental selenium, Se(0), because elemental selenium is less toxic. Applying a post-treatment solid–liquid separation step to these biological processes removes and separates Se(0) from the treated effluent. Here, we review the sources of selenium-rich waste streams, and we propose several techniques for the removal and reuse of selenium. The major points are as follows: (1) Biogenic Se(0) has colloidal properties that can be offset by the addition of coagulants, either by dissolving multivalent salts or by electrogenerating the coagulant in situ; (2) recovered biogenic Se(0) is a secondary raw material and (3) biogenic Se(0) can be used for niche applications such as fertilizers and adsorbent for metals. The biological treatment of industrial wastewater containing selenium can be linked with resource recovery as a sound and economic approach to alleviate the demand for this critical element.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Selenium (Se) is a chalcogen element with complex biogeochemistry (Fernandez-Martinez and Charlet 2009). Se oxyanions, selenite (Se[IV], SeO3 2−) and selenate (Se[VI], SeO4 2−), have been documented to exhibit toxicity toward various aquatic groups (Simmons and Wallschlaeger 2005). During the mid-1970s, chronic Se poisoning occurred as a result of Se oxyanions leached from ash deposited in the vicinity of Lake Belews (North Carolina) by a coal-fired power plant. The impact was devastating for the resident fish populations: 19 out of 20 species were eliminated (Lemly 2002). Another major event occurred in the 1980s when agricultural drain water enriched in Se severely affected the migratory bird populations in Kesterson Reservoir, California (Ohlendorf 1989).

Among its valence numbers, elemental selenium, Se(0), has long been considered as the least toxic due to its solid state and low bioavailability (Chapman et al. 2010). Se(0) has nevertheless been shown to be bioavailable to filter feeders and fish (Li et al. 2008; Luoma et al. 1992; Schlekat et al. 2000). Extensive research on the impact of colloidal Se(0) on filter-feeding mollusks and the trophic networks has been conducted in San Francisco Bay area (Presser and Luoma 2006; Purkerson et al. 2003; Schlekat et al. 2000; USEPA 2010). Furthermore, micro- and nanosize Se(0) particles have increased reactivity caused by their high surface–volume ratio, leading to concerns about the short-term toxicity of Se(0) nanoparticles (SeNP) (Zhang et al. 2005). Moreover, Se(0) is reoxidized to SeO3 2− and SeO4 2− when Se(0) reaches an environment with an elevated redox potential, e.g., surface waters compared to anaerobic bioreactors or sediments (Zhang et al. 2004).

Biogenic Se(0): metabolism

Se(0) can be produced by chemical (i.e., chemogenic) or biological (i.e., biogenic) synthesis (see Glossary). Even if pure cultures have been shown to withstand high concentrations of toxic Se oxyanions (Hunter and Manter 2011; Staicu et al. 2015b), mixed microbial cultures, e.g., those present in anaerobic granular sludge, are used in full-scale bioreactors that treat large volumes of selenium-laden wastewaters (Opara et al. 2014; Pickett et al. 2008). Mixed cultures are preferred over pure cultures as wastewaters are not sterile, and thus have a contamination potential by microorganisms present in the wastewater. Besides, mixed cultures often grow in flocs, biofilm or granular sludges, which have an increased capacity to withstand toxicants (Schmidt and Ahring 1996; van Hullebusch et al. 2003).

To date, only a limited number of bacteria (Kuroda et al. 2011a; Lortie et al. 1992; Tomei et al. 1992, 1995) were shown to reduce SeO4 2− to Se(0) (Fig. 1a), whereas the reduction of SeO3 2− appears to be a more common feature of many phylogenetically diverse bacterial species (Sura-de Jong et al. 2015). Certain fungal species can also reduce SeO3 (Espinosa-Ortiz et al. 2015). The end product of Se oxyanions reduction can be Se(0) (Fig. 1b). Sometimes, the complete reduction to Se2− occurs, but this most reduced Se species is rapidly reoxidized to Se(0) under oxic conditions (Kagami et al. 2013).

a Biological reduction of Se oxyanions to Se(0) and b Biogenic Se(0) produced by anaerobic granular sludge (Staicu et al. 2015c)

The reduction of selenate is mediated by SerA reductase in Thauera selenatis (Krafft et al. 2000; Schröder et al. 1997) and by SrdA reductase in Bacillus selenatarsenatis (Kuroda et al. 2011b). A distinct selenate reductase, YnfE, was reported in Citrobacter freundii (Theisen and Yee 2014). However, the exact biochemical mechanism of selenite reduction is still unclear. A vast amount of data suggest the presence of a common metabolic pathway used by bacteria for the reduction of other compounds (nitrate, nitrite and sulfate) as well (Fig. 1a). In the β-proteobacterium T. selenatis, a nitrite (NO2 −) reductase has been reported to be involved in selenite reduction (DeMoll-Decker and Macy 1993). In Clostridium pasteurianum, an inducible sulfite (SO3 2−) reductase has been reported to reduce selenite pointing toward another putatively shared metabolic pathway (Harrison et al. 1980; Harrison et al. 1984).

Also, thiols have also been proposed to play a role in Se(0) formation. When amended with selenite, cultures of Escherichia coli (Bebien et al. 2002) and Rhodospirillum rubrum (Kessi and Hanselmann 2004) showed overexpressed glutathione reductase activity, indicative of a detoxification process. Staicu et al. 2015b (unpublished results) reported a subspecies of Pseudomonas moraviensis able to withstand high levels of SeO3 2− (up to 120 mM) and SeO4 2− (over 150 mM). The strain was isolated from the roots of the Se hyperaccumulator plant Stanleya pinnata growing on seleniferous soils in Colorado (USA). In addition, the strain can aerobically reduce 10 mM of SeO3 2− below the detection limit within 48 h, to red Se(0) as the end product. Because of its fast Se metabolism, the new isolate holds promise for the development of a more efficient aerobic treatment system of selenite-laden wastewaters.

Selenium-laden wastewater

Even if selenium is a trace element in the earth’s crust, it can be enriched in certain rocks and soils. As it can substitute for sulfur in biolites and minerals, Se is often found associated with fossil fuels and sulfide minerals, e.g., pyrite and chalcopyrite (Fernandez-Martinez and Charlet 2009). Fossil fuels (e.g., crude oil and coal) can contain high levels of Se: High-sulfur coals have been reported to contain up to 43 mg Kg−1 Se (Yudovich and Ketris 2006) and crude oil can also be highly enriched in Se with concentrations in the range 5−22 mg L−1 (Lemly 2004).

Human activities such as fossil fuel burning, non-metal smelting industry and agriculture practiced on Se-rich soils have resulted in the introduction of important quantities of selenium in the environment, thus modifying its natural cycle (Chapman et al. 2010). Wen and Carignan (2007) connected the increasing Se anthropogenic emissions to the onset of the Industrial Revolution (eighteenth century). A positive correlation between the high coal combustion activity observed in 1940 and 1970, and the Se accumulation in archived herbage and soil samples from the Rothamsted Experimental Station (UK) has been documented (Haygarth 1994). Considering the future trends in energy production based on fossil fuel combustion, it is expected that Se will increase its presence and toxicity in the environment (IEA 2014).

By burning or processing Se-containing raw materials, wastewaters contaminated with high concentrations of this element are generated. Major sources of wastewaters containing selenium oxyanions are those of the oil refining industry, coal combustion and metal processing (Lemly 2004; USEPA 2010). Se-laden wastewaters can be treated by a number of physical–chemical and biological treatment technologies (NAMC 2010). Biological treatment processes using bioreactors produce different concentration levels of colloidal Se(0) as a function of the initial Se content and the Se conversion rate (NAMC 2010). Several reactor types are currently employed on a full-scale configuration, notably fluidized bed reactors and the Advanced Biological Metals Removal (ABMet®) system. ABMet® employs anaerobic bacteria fixed to a granular activated carbon bed or a biomatrix (Pickett et al. 2008).

Se(0): separation

Biogenic Se(0) has been shown to exhibit colloidal properties, making it stable in suspension and difficult to sediment by gravitational settling (Buchs et al. 2013; Staicu et al. 2015c). The colloidal stability of biogenic Se(0) particles (Fig. 2) is related to the coating biopolymer layer that imparts an overall negative charge preventing the particles from aggregation (Buchs et al. 2013; Dobias et al. 2011). The chemogenic Se(0) undergoes allotropic transition shortly after synthesis unless not stabilized with a capping agent, e.g., protein and polyvinylpyrrolidone (Gates et al. 2002). This implies that the stability of chemogenic Se(0) is not intrinsic, but can be modified by adding stabilizing agents such as organic polymers (Jain et al. 2015b). Removal of colloidal Se(0) from a bioreactor effluent is necessary to reduce its environmental load and the potential negative impact of Se(0) exerted on aquatic ecosystems (See section “Introduction”). Several approaches have been investigated for the removal of colloidal Se(0), such as chemical dosing (Staicu et al. 2015c) and electrocoagulation (Staicu et al. 2015a).

Chemical dosing (coagulation–flocculation)

Coagulation–flocculation relies on the destabilization and settling of colloids and suspended particles that cannot sediment by gravity within practical time frames. When coagulants are added to water, the metal ions (e.g., Al3+ and Fe3+) hydrolyze spontaneously and form a series of metastable metal hydrolysis products that alter the physical state of the suspended particles. The coagulants act by repressing the charge of the colloids and by forming large aggregates of Al(OH)3/Fe(OH)3 which ultimately leads to particle sedimentation (Gregory and Duan 2001). Staicu et al. (2015c) investigated the effect of aluminum sulfate and ferric chloride on the solid–liquid separation of highly turbid (850 NTU) colloidal Se(0) solutions produced by anaerobic granular sludge under anaerobic conditions. Aluminum sulfate achieved the highest turbidity removal efficiency (92 %) at a dose of 10−3 M, whereas ferric chloride achieved a maximum turbidity removal efficiency of only 43 %. Charge repression appeared to play a minor role in particle neutralization.

Electrocoagulation

In electrocoagulation, an electrical current is applied between two electrodes (including a sacrificial anode) immersed in wastewater (Fig. 3a). Applying current across the electrodes creates an electrical field and causes the dissolution of the sacrificial anode to form a coagulant and the electrolysis of water. The coagulants are thus electrogenerated in situ and in a continuous manner during the coagulation–sedimentation process. Another advantage of using an electrochemical approach for the treatment of wastewaters stems from the electrical field that exerts an electrophoretic action on the charged particles, inducing their migration toward the oppositely charged electrode.

a Electrocoagulation setup and treatment effectiveness using Al sacrificial electrodes. Notes: M = metal (e.g., Al and Fe), b colloidal biogenic Se(0) produced by P. moraviensis stanleyae and c colloidal Se(0) treated by electrocoagulation with aluminum electrodes (Staicu et al. 2015a)

Staicu et al. (2015a) reported the removal of colloidal Se(0) produced aerobically by P. moraviensis stanleyae by electrocoagulation (Fig. 3b). Iron and aluminum sacrificial anodes were employed under galvanostatic (i.e., constant current) conditions. The best Se(0) turbidity removal efficiency (97 %) was achieved using iron electrodes at 200 mA. Aluminum electrodes removed 96 % of the colloidal Se(0) at a slightly higher current intensity (300 mA). Due to the less compact nature of the Al flocs (Fig. 3c), the Se–Al sediment was three times more voluminous than the Se–Fe sediment. The toxicity characteristic leaching procedure test showed that the Fe–Se sediment released Se below the regulatory level (1 mg L−1), whereas the Se concentration leached from the Al–Se sediment exceeded the limit by about 20 times. This entails that the Se–Fe sediment might be landfilled, although recovery of Se is a more preferred alternative.

Recovery and reuse

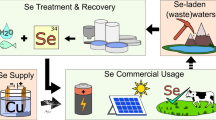

Figure 4 presents a possible scheme of recovering and reusing Se oxyanions present in wastewaters. Biological treatment is a promising alternative that can reduce the load of Se that reaches the environment. In contrast to sulfur (S), Se can be converted from its oxidized forms directly to the Se(0) and, thus, Se removal can be achieved in a single reactor unit. The direct reduction of sulfur oxyanions to S(0) occurs in nature only in minor quantities. Therefore, high-rate sulfur removal from wastewater needs to be achieved by a two-step process: first the complete reduction to sulfide (S2−) and the subsequent oxidation to elemental sulfur (Muyzer and Stams 2008). Furthermore, to avoid the complete reoxidation back to sulfate, the S2− oxidation must proceed under strict micro-aerophilic conditions that are difficult to control (Janssen et al. 2001). If recycling is adopted, biogenic Se(0) particles, formed as a by-product of the biological treatment of selenium-laden wastewater, can link bioremediation with the generation of new materials. Several potential applications of the removed biogenic Se(0) are given below.

Fertilizer

The recovered biogenic Se(0) can be applied on soils that are low in bioavailable Se. Various regions of the world suffer from low Se (e.g., Finland, China and Ireland), and in some countries (e.g., Finland), national programs have been successfully implemented to overcome this deficit (Alfthan et al. 2014). A slower degradation and, therefore, a longer lifetime in the soil can be an argument in favor of using Se(0) instead of fertilizers containing selenate. Staicu et al. (2015a) have reported the precipitation of biogenic Se(0) with iron hydroxides using an electrocoagulation strategy. The Fe–Se sediment generated at the end of the treatment was shown to have a strong binding capacity, and Se was slowly released from the iron matrix. However, a detailed study is needed to investigate the behavior of Se(0) or Fe–Se sediment in agricultural soils. Other limitations, such as social acceptance and the potential contamination of Se(0) with toxic metals co-present in wastewaters, should also be addressed.

Semiconductors

Having photoconductive properties (i.e., decreased electrical resistance with increased illumination) as well as photovoltaic properties (i.e., the direct conversion of light into electricity), metal selenides are routinely exploited in a variety of industrial applications including solar and photo cells, exposure meters and xerography (Johnson et al. 1999). The use of Se(0) as a starting material for the production of the II–VI semiconductors ZnSe and CdSe could be an alternative process for the production of metal selenides. ZnSe nanoparticles were generated when selenite was reduced sequentially to Se(0) and then to selenide under anaerobic conditions by Veillonella atypica in the presence of ZnCl2 (Pearce et al. 2008). The formation of metal selenides through a disproportionation reaction between Se(0) and Ag+ and Hg2+ has also been proposed (Nuttall 1987).

Adsorbent for toxic metals

Another potential application for biogenic Se(0) is its use as adsorbent in the treatment of wastewaters and waste gases containing heavy metals (Jain et al. 2015a). Because biogenic Se(0) is covered by a biopolymer layer with an overall negative charge (Jain et al. 2015b), it will bind positively charged ions from the bulk solution. Several studies were focused on the interaction of Se(0) with mercury (Hg2+) (Fellowes et al. 2011; Jiang et al. 2012; Johnson et al. 2008) and zinc (Zn2+) (Jain et al. 2015a). Se(0) was shown to form HgSe on the surface of Se(0) particles (Johnson et al. 2008). The retention of Hg in a solid phase is desirable from an ecotoxicological standpoint as the formation of toxic methyl mercury and volatile liquid Hg(0) is thus prevented. The Se(0) particles were shown to be around 20 times more efficient than commonly used adsorbents such as nanosilver (188 vs 8.5 mg g−1) and around 70 times than sulfur-impregnated activated carbon nanotubes (188 vs 2.6 mg g−1) (Johnson et al. 2008). It is interesting to note that the other nanoparticles tested (Cu, Ni and Zn), even if their size was in the nano-range domain, exhibited a limited adsorption capacity for Hg, pointing toward the influence induced by the biopolymer layer (Johnson et al. 2008).

The Zn2+ (added as ZnCl2) adsorption capacity of biogenic Se(0) produced anaerobically by anaerobic granular sludge of onto was recently quantified (Jain et al. 2015a). The maximum adsorption capacity amounted to 60 mg Zn g−1 biogenic Se(0). The effect of competing cations showed that the Zn2+ ion adsorption onto Se(0) was impacted by the presence of Ca2+ and Fe2+, whereas the presence of Na+ and Mg2+ had only a marginal impact. This is particularly relevant when treating industrial wastewaters, which usually have a complex matrix. As a comparison, zero valent iron (ZVI) has a much higher Zn adsorption capacity, 393 mg Zn g−1 ZVI (Yan et al. 2010). In order to gain more acceptance, the removal of soluble metals using Se(0) should be further investigated, particularly, with respect to the absorbance capacity of biogenic elemental Se and the stability of the metal Se(0) matrices.

Perspectives

Considering the depletion of raw materials at an accelerated pace, the change of perception relative to the waste-resource dichotomy is an important pillar of sustainable development (Macaskie et al. 2010). Instead of discharging Se-laden wastewaters into the environment, Se can be converted into Se(0) through a bioremediation approach and recovered for further use. As there is limited incentive for such a strategy to become popular, legislation should be the major driving factor. Similarly to the removal of sulfur from flue gas streams under the pressure of the Clean Air Acts, selenium can become an element of great concern and increased interest. The biological treatment of Se wastewaters is likely to gain popularity in the coming years and so the amount of biogenic Se(0) produced and reused.

References

Alfthan G, Eurola M, Ekholm P, Venäläinen ER, Root T, Korkalainen K, Hartikainen H, Salminen P, Hietaniemi V, Aspila P, Aro A (2014) Effects of nationwide addition of selenium to fertilizers on foods and animal and human health in Finland: from deficiency to optimal selenium status of the population. J Trace Elem Med Biol. doi:10.1016/jjtemb201404009

Bebien M, Lagniel G, Garin J, Touati D, Vermeglio A, Labarre J (2002) Involvement of superoxide dismutases in the response of Escherichia coli to selenium oxides. J Bacteriol 184:1556–1564

Buchs B, Evangelou MWH, Winkel LHE, Lenz M (2013) Colloidal properties of nanoparticular biogenic selenium govern environmental fate and bioremediation effectiveness. Environ Sci Technol 47:2401–2407

Chapman PM, Adams WJ, Brooks M, Delos CG, Luoma SN, Maher WA, Ohlendorf HM, Presser TS, Shaw P (2010) Ecological assessment of selenium in the aquatic environments. SETAC Press, Pensacola

DeMoll-Decker H, Macy JM (1993) The periplasmic nitrite reductase of Thauera selenatis may catalyze the reduction of selenite to elemental selenium. Arch Microbiol 160:241–247

Dobias J, Suvorova EI, Bernier-Latmani R (2011) Role of proteins in controlling selenium nanoparticle size. Nanotechnology 22:195605

Espinosa-Ortiz EJ, Gonzalez-Gil G, Saikaly PE, van Hullebusch ED, Lens PNL (2015) Effects of selenium oxyanions on the white-rot fungus Phanerochaete chrysosporium. Appl Environ Microb. doi:10.1007/s00253-014-6127-3

Fellowes JW, Pattrick RA, Green DI, Dent A, Lloyd JR, Pearce CI (2011) Use of biogenic and abiotic elemental selenium nanospheres to sequester elemental mercury released from mercury contaminated museum specimens. J Hazard Mater 189:660–669

Fernandez-Martinez A, Charlet L (2009) Selenium environmental cycling and bioavailability: a structural chemist point of view. Rev Environ Sci Biotechnol 8:81–110

Gates B, Mayers B, Cattle B, Xia Y (2002) Synthesis and characterization of uniform nanowires of trigonal selenium. Adv Funct Mater 12:219–227

Gregory J, Duan J (2001) Hydrolyzing metal salts as coagulants. Pure Appl Chem 73:2017–2026

Harrison GI, Laishley EJ, Krouse HR (1980) Stable isotope fractionation by Clostridium pasteurianum. 3. Effect of SeO3 on the physiology and associated sulfur isotope fractionation during SO3 and SO4 reductions. Can J Microbiol 26:952–958

Harrison GI, Curle C, Laishley EJ (1984) Purification and characterization of an inducible dissimilatory type sulfite reductase from Clostridium pasteurianum. Arch Microbiol 138:72–78

Haygarth PM (1994) Global importance and global cycling of selenium. In: Frankenberger WT, Benson S (eds) Selenium in the environment. Marcel-Dekker, New York, pp 1–28

Hunter WJ, Manter DK (2011) Pseudomonas seleniipraecipitatus sp nov: a selenite reducing γ-Proteobacteria isolated from soil. Curr Microbiol 62:565–569

International Energy Agency (IEA). http://www.iea.org/topics/coal/(2014). Accessed 25 Oct 2014

Jain R, Jordan N, Schild D, van Hullebusch ED, Weiss S, Franzen C, Farges F, Lens PNL (2015a) Adsorption of zinc by biogenic elemental selenium nanoparticles. Chem Eng J 260:855–863

Jain R, Jordan N, Weiss S, Foerstendorf H, Heim K, Kacker R, Hübner R, Kramer H, van Hullebusch ED, Farges F, Lens PNL (2015b) Extracellular polymeric substances (EPS) govern the surface charge of biogenic elemental selenium nanoparticles. Environ Sci Technol. doi:10.1021/es5043063

Janssen AJH, Ruitenberg R, Buisman CJ (2001) Industrial applications of new sulphur biotechnology. Water Sci Technol 44:85–90

Jiang S, Ho CT, Lee JH, Duong HV, Han S, Hur HG (2012) Mercury capture into biogenic amorphous selenium nanospheres produced by mercury resistant Shewanella putrefaciens 200. Chemosphere 87:621–624

Johnson JA, Saboungi ML, Thiyagarajan P, Csencsits R, Meisel D (1999) Selenium nanoparticles: a small-angle neutron scattering study. J Phys Chem B 103:59–63

Johnson NC, Manchester S, Sarin L, Gao Y, Kulaots I, Hurt RH (2008) Mercury vapor release from broken compact fluorescent lamps and in situ capture by new nanomaterial sorbents. Environ Sci Technol 42:5772–5778

Kagami T, Narita T, Kuroda M, Notaguchi E, Yamashita M, Sei K, Soda S, Ike M (2013) Effective selenium volatilization under aerobic conditions and recovery from the aqueous phase by Pseudomonas stutzeri NT-I. Water Res 47:1361–1368

Kessi J, Hanselmann KW (2004) Similarities between the abiotic reduction of selenite with glutathione and the dissimilatory reaction mediated by Rhodospirillum rubrum and Escherichia coli. J Biol Chem 279:50662–50669

Krafft T, Bowen A, Theis F, Macy JM (2000) Cloning and sequencing of the genes encoding the periplasmic-cytochrome B-containing selenate reductase of Thauera selenatis. DNA Seq 10:365–377

Kuroda M, Notaguchi E, Sato A, Yoshioka M, Hasegawa A, Kagami T, Narita T, Yamashita M, Sei K, Soda S, Ike M (2011a) Characterization of Pseudomonas stutzeri NT-I capable of removing soluble selenium from the aqueous phase under aerobic conditions. J Biosci Bioeng 112:259–264

Kuroda M, Yamashita M, Miwa E, Imao K, Fujimoto N, Ono H, Nagano K, Sei K, Ike M (2011b) Molecular cloning and characterization of the srdBCA operon encoding the respiratory selenate reductase complex from the selenate-reducing bacterium Bacillus selenatarsenatis SF-1. J Bacteriol 193:2141–2148

Lemly AD (2002) Symptoms and implications of selenium toxicity in fish: the Belews Lake case example. Aquat Toxicol 57:39–49

Lemly AD (2004) Aquatic selenium pollution is a global environmental safety issue. Ecotoxicol Environ Saf 59:44–56

Li H, Zhang J, Wang T, Luo W, Zhou Q, Jiang G (2008) Elemental selenium particles at nano-size (Nano-Se) are more toxic to Medaka (Oryzias latipes) as a consequence of hyper-accumulation of selenium: a comparison with sodium selenite. Aquat Toxicol 8:251–256

Lortie L, Gould WD, Rajan S, McCready RGL, Cheng KJ (1992) Reduction of selenate and selenite to elemental selenium by a Pseudomonas stutzeri isolate. Appl Environ Microbiol 58:4042–4044

Luoma SN, Johns C, Fisher NS, Steinberg NA, Oremland RS, Reinfelder JR (1992) Determination of selenium bioavailability to a bivalve from particulate and solute pathways. Environ Sci Technol 26:485–491

Macaskie LE, Mikheenko IP, Yong P, Deplanche K, Murray AJ, Paterson-Beedle M, Coker VS, Pearce CI, Cutting R, Pattrick RAD, Vaughan D, van der Laan G, Lloyd JR (2010) Today’s wastes tomorrow’s materials for environmental protection. Hydrometallurgy 104:483–487

Muyzer G, Stams AJM (2008) The ecology and biotechnology of sulphate-reducing bacteria. Nat Rev Microbiol 6:441–454

North American Metal Council (NAMC) (2010) Review of available technologies for removal of selenium from water. http://www.namcorg/docs/00062756.pdf

Nuttall KL (1987) A model for metal selenide formation under biological conditions. Med Hypotheses 2:217–221

Ohlendorf HM (1989) Bioaccumulation and effects of selenium in wildlife. In: Jacobs LM (ed) Selenium in agriculture and the environment. Soil Science Society of America and American Society of Agronomy, Madison Wisconsin series number 23, pp 133–177. doi:10.2136/sssaspecpub23.c8

Opara A, Peoples MJ, Adams JD, Martin AS (2014) Electro-biochemical reactor (EBR) technology for selenium removal from British Columbia’s coal-mining wastewaters http://www.inotecus/uploads/5/1/2/8/5128573/selenium_removal_coal_mine_water_inotec-sme2014pdf

Pearce CI, Coker VS, Charnock JM, Pattrick RA, Mosselmans JF, Law N, Beveridge TJ, Lloyd JR (2008) Microbial manufacture of chalcogenide-based nanoparticles via the reduction of selenite using Veillonella atypica: an in situ EXAFS study. Nanotechnology 19:1–13

Pickett T, Sonstegard J, Bonkoski B (2008) Using biology to treat selenium. Power Eng 110:140–145

Presser TS, Luoma SN (2006) Forecasting selenium discharges to the San Francisco Bay-Delta estuary: ecological effects of a proposed San Luis drain extension US geological survey professional paper 1646

Purkerson DG, Doblin MA, Bollens SM, Luoma SN, Cutter GA (2003) Selenium in San Francisco Bay zooplankton: potential effects of hydrodynamics and food web interactions. Estuaries 26:956–969

Schlekat CE, Dowdle PR, Lee BG, Luoma SN, Oremland RS (2000) Bioavailability of particle-associated selenium on the bivalve Potamocorbila amuresis. Environ Sci Technol 34:4504–4510

Schmidt JE, Ahring BK (1996) Granular sludge formation in upflow anaerobic sludge blanket (UASB) reactors. Biotechnol Bioeng 49:229–246

Schröder I, Rech S, Krafft T, Macy JM (1997) Purification and characterization of the selenate reductase from Thauera selenatis. J Biol Chem 272:23765–23768

Simmons DB, Wallschlaeger D (2005) A critical review of the biogeochemistry and ecotoxicology of selenium in lotic and lentic environments. Environ Toxicol Chem 24:1331–1343

Staicu LC, van Hullebusch ED, Lens PNL, Pilon-Smits EAH, Oturan MA (2015a) Electrocoagulation of colloidal biogenic selenium. Environ Sci Poll Res. doi:10.1007/s11356-014-3592-2

Staicu LC, Ackerson CJ, Cornelis P, Ye L, Berendsen RL, Hunter WJ, Noblitt SD, Henry CS, Cappa JJ, Montenieri RL, Wong AO, Musilova L, Sura-de Jong M, van Hullebusch ED, Lens PNL, Pilon-Smits EAH (2015b) Pseudomonas moraviensis subsp. stanleyae: a bacterial endophyte capable of efficient selenite reduction to elemental selenium under aerobic conditions. J Appl Microb (in revision)

Staicu LC, van Hullebusch ED, Oturan MA, Ackerson CJ, Lens PNL (2015c) Removal of colloidal biogenic selenium from wastewater. Chemosphere. doi:10.1016/j.chemosphere.2014.12.018

Sura-de Jong M, Reynolds J, Richterova K, Musilova L, Staicu LC, Hrochova I, Cappa JJ, van der Lelie D, Frantik T, Sakmaryova I, Strejcek M, Cochran A, Lovecka P, Pilon-Smits EAH (2015) Selenium hyperaccumulators harbor a diverse endophytic bacterial community characterized by extreme selenium tolerance and growth promoting properties. Front Plant Sci (in revision)

Theisen J, Yee N (2014) The molecular basis for selenate reduction in Citrobacter freundii. Geomicrobiol J 31:875–883

Tomei FA, Barton LL, Lemanski CL, Zocco TG (1992) Reduction of selenate and selenite to elemental selenium by Wolinella succinogenes. Can J Microbiol 38:1328–1333

Tomei FA, Barton LL, Lemanski CL, Zocco TG, Fink NH, Sillerud LO (1995) Transformation of selenate and selenite to elemental selenium by Desulfovibrio desulfuricans. J Ind Microbiol 14:329–336

USEPA (2010) North San Francisco Bay selenium characterization study plan (2010–2012). http://www2.epagov/sites/production/files/documents/epa-r09-ow-2010-0976-0023-1pdf

van Hullebusch ED, Zandvoort MH, Lens PNL (2003) Metal immobilisation by biofilms: mechanisms and analytical tools. Rev Environ Sci Biotechnol 2:9–33

Wen H, Carignan J (2007) Reviews on atmospheric selenium: emissions speciation and fate. Atmos Environ 41:7151–7165

Yan W, Herzing AA, Kiely CJ, Zhang WX (2010) Nanoscale zero-valent iron (nZVI): aspects of the core-shell structure and reactions with inorganic species in water. J Contam Hydrol 118:96–104

Yudovich YE, Ketris MP (2006) Selenium in coal: a review. Int J Coal Geol 67:112–126

Zhang Y, Zahir ZA, Frankenberger WT Jr (2004) Fate of colloidal-particulate elemental selenium in aquatic systems. J Environ Qual 33:559–564

Zhang ES, Wang HL, Yan XX, Zhang LD (2005) Comparison of short-term toxicity between nano-Se and selenite in mice. Life Sci 76:1099–1109

Acknowledgments

We are grateful our collaborators Prof. Mehmet Oturan (Université Paris-Est, France) and Prof. Elizabeth Pilon-Smits (Colorado State University, USA) for useful discussions during the preparation of this manuscript. The authors would like to thank the European Commission for providing financial support through the Erasmus Mundus Joint Doctorate Programme ETeCoS3 (Environmental Technologies for Contaminated Solids, Soils and Sediments) under the grant agreement FPA n°2010-0009.

Author information

Authors and Affiliations

Corresponding author

Glossary

- Anaerobic granular sludge

-

Biomass in granular form produced by the auto-immobilization of mixed microbial populations and employed for the treatment of wastewater in up flow anaerobic granular sludge reactors

- Biogenic

-

Resulting from the action of a living organism; in the current context, Se nanoparticles produced by the metabolic activity of microorganisms.

- Chalcogen

-

Chemical element in group 16 of the periodic table; i.e., Oxygen (O), Sulfur (S), Selenium (Se), Tellurium (Te) and Polonium (Po). These elements are strongly associated with metal-bearing minerals.

- Chemogenic

-

Resulting from chemical action; in the current context, Se nanoparticles produced through the reduction of Se oxyanions using a chemical reducing agent.

- Colloidal system

-

System containing fine particles dispersed within a continuous medium that cannot be settled easily by gravitation.

Rights and permissions

About this article

Cite this article

Staicu, L.C., van Hullebusch, E.D. & Lens, P.N.L. Production, recovery and reuse of biogenic elemental selenium. Environ Chem Lett 13, 89–96 (2015). https://doi.org/10.1007/s10311-015-0492-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10311-015-0492-8