Abstract

Microbial oils have been analyzed as alternatives to petroleum. However, just a handful of microbes have been successfully adapted to produce chemicals that can compete with their petroleum counterparts. One of the reasons behind the low success rate is the overall economic inefficiency of valorizing a single product. This study presents a lab-scale analysis of two yeast species that simultaneously produce multiple high-value bioproducts: intracellular triacylglycerols (TG) and extracellular polyol esters of fatty acids (PEFA), two lipid classes with immediate applications in the biofuels and surfactant industries. At harvest, the yeast strain Rhodotorula aff. paludigena UCDFST 81-84 secreted 20.9 ± 0.2 g L−1 PEFA and produced 8.8 ± 1.0 g L−1 TG, while the yeast strain Rhodotorula babjevae UCDFST 04-877 secreted 11.2 ± 1.6 g L−1 PEFA and 18.5 ± 1.7 g L−1 TG. The overall glucose conversion was 0.24 and 0.22 g(total lipid) g −1(glucose) , respectively. The results present a stable and scalable microbial growth platform yielding multiple co-products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Decades of intense research behind microbial production of triacylglycerols (TG) as precursors for biodiesel have not yet been translated into an industrially successful technology due to unfavorable economics associated with valorizing a single, low-value commodity product. Research in this field continues because the benefits associated with the microbial production of fuels and other chemicals have the potential for faster turnover rates, independent of environmental factors such as seasons, temperatures and rain cycles, environmentally friendly processes and sustainable production processes [13, 33]. In cases with high price points such as pharmaceuticals, microbial biorefinery approaches have replaced traditional production methods such as extraction of active compounds from plant materials [23, 44].

Strategies currently being utilized to improve microbial production efficiencies include reducing input costs by utilization of cheaper or more diverse feedstocks, by increasing productivity through higher density cultures, faster production rates, fewer unwanted byproducts, and simplified product purification. An alternative approach is development of microbial technologies for production of multiple co-products from either a single microbe or consortia of microbes [14]. This approach has recently been studied using the polymorphic fungus Aureobasidium pullulans due to its capacity to simultaneously synthesize and secrete an antimicrobial polyol lipid biosurfactant called liamocin and two exopolysaccharides called pullulan and poly-(β-l-malic acid) [21, 22]. Selection of appropriate microbial strains is a crucial step in this approach.

The goal of the present study was to demonstrate the validity of this approach by identifying and quantifying two co-products with commercial value. The model used two basidiomycetous yeasts that simultaneously accumulate high levels of intracellular triacylglycerols (TG) [10], and also secrete glycolipids. Previous research identified several oleaginous yeasts in the order Sporidiobolales that are capable of synthesizing and secreting glycolipids called polyol esters of fatty acids (PEFA), a novel type of glycolipid biosurfactant produced by a few yeast species in the taxonomic order Sporidiobolales [7, 11]. PEFA consist of a polyol head group (either d-arabitol or d-mannitol), bound through the carboxyl end of an acetylated (R)-3-hydroxy fatty acid (see Fig. 1) [7]. The acetylated (R)-3-hydroxy fatty acids are saturated, primarily C16:0 or C18:0. Each yeast species, and to some extent strains within a species, produces a slightly different mixture of 8–12 PEFA molecules, which differ in length of the acetylated (R)-3-hydroxy fatty acid, whether they contain d-arabitol or d-mannitol, and the number of acetylations in the polyol head group (typically 3–5) [7, 11].

Glycolipids are amphipathic, thus have distinct surfactant properties and have been commercialized [12, 42, 43]. Two glycolipid biosurfactants which are available commercially are sophorolipids [42] and rhamnolipids [2], sourced from the yeast Starmerella bombicola and bacteria Pseudomonas [8], respectively. These species do not produce sufficient TG to be co-valorized with the surfactant [10].

Two yeast strains were selected that produced high quantities of both PEFA and TG [7, 11]: Rhodotorula babjevae UCDFST 04-877 and R. aff. paludigena UCDFST 81-84. Of the 26 strains belonging to nine species that have been shown to produce PEFA [7, 11, 27, 40], these two yeasts produce high quantities of both PEFA and TG [10, 11] and also two different mixtures of PEFA chemical structures [11]. R. babjevae utilizes several carbon substrates, tolerates inhibitors and achieves high cellular growth [32, 34]. R. aff. paludigena UCDFST 81-84 produced the highest amounts of PEFA among a panel of 65 strains tested [11]. These two yeasts were cultivated in bioreactors, and production of TG and PEFA were quantified to evaluate this multi-co-product biorefinery model.

Materials and methods

Chemicals and yeast

Glucose (cat. No. S25295B, Fisher Science Education PA, USA) and yeast extract (cat. No. 211929, Becton, Dickinson and Company, Sparks, MD, USA) were of technical grade. All other chemicals were of analytical grade, including Nile red (9-diethylamino-5-benzo[α]phenoxazinone) obtained from Acros Organics (cat. No. 7385-67-3, NJ, USA), d 7-glucose was obtained from Sigma–Aldrich. LC–MS-grade solvents, mobile-phase modifiers, and other reagents were obtained from Fisher Scientific, Hampton, NH, USA. Oleaginous yeast Rhodotorula babjevae (synonym: Rhodosporidium babjevae) UCDFST 04-877 (referred to as R. babjevae throughout the rest of the manuscript) [32, 34] was isolated from an olive fly at the University of California Davis, and is currently available at the Phaff Yeast Culture Collection, University of California Davis (http://phaffcollection.ucdavis.edu/). The yeast Rhodotorula aff. paludigena (synonym: Rhodosporidium aff. paludigenum) UCDFST 81-84 (referred to as R. aff. paludigena throughout the rest of the manuscript) [11] was isolated from decaying cactus [37, 38]. The taxonomic abbreviation “aff.” (affinis) signifies that it is an undescribed species, whose closest relative is R. paludigena.

Molecular identification

The species identification of yeast strains R. aff. paludigena and R. babjevae were confirmed as previously described [11].

Yeast growth and culture conditions in benchtop bioreactors

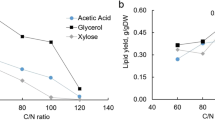

Rhodotorula aff. paludigena and R. babjevae were revived from cryopreserved stocks by plating on potato dextrose agar (cat. No. 213400, DifcoTM, Sparks, MD, USA). Yeasts grown 3–4 days at room temperature were used for preparation of the inoculants for the bioreactors. Three bioreactor runs with increasing glucose concentration were performed for each yeast. The first two had batch dosings of 50 and 100 g L−1 glucose, respectively, while the third one had 100 g L−1 glucose dosed before inoculation and 50 g L−1 glucose dosed at 48 h (referred to as 150 g L−1 glucose throughout the present work). Medium A [39], a medium with high C:N ratio known to induce lipid accumulation in oleaginous yeasts [10, 31, 39], was used. Three C:N molar ratios were used: 68.2:1, 134:1 and 201:1 corresponding to 50, 100 and 150 g L−1 glucose, respectively. Medium A contains 0.5 g L−1 NH4Cl, 1.5 g L−1 yeast extract, 7.0 g L−1 KH2PO4, 5 g L−1 Na2HPO4.2H2O, 1.5 g L−1 MgSO4·7H2O, 0.1 g L−1 CaCl2, 0.08 g L−1 FeCl3·6H2O, 10.0 mg L−1 ZnSO4·7H2O, 0.1 mg L−1 MnSO4·H2O, 0.1 mg L−1 CuSO4, and 0.1 mg L−1 Co(NO3)2. The glucose concentration was adjusted from the standard Medium A composition to either 50, 100 or 150 g L−1. Inocula were prepared by suspending a loopful of cells (≈20 µL) in 5 mL deionized sterile water (DSW) at room temperature. In total, 500 µL of this inoculum was inoculated into 50 mL bioreaction tubes (part number 229475, Celltreat Scientific Products, Shirley, MA, USA) containing 9.5 mL of Medium A with 50 g L−1 glucose, and incubated for 24 h at room temperature (24 °C) and 200 rpm in a rotary shaker incubator (Series 25, New Brunswick Scientific Co., Edison, NJ, USA).

To prepare the seed culture, a set of 500-mL baffled Erlenmeyer flasks containing 95 mL medium A with 50 g L−1 glucose were inoculated with 5% inoculum (5 mL) taken from the bioreaction tube, to reach a culture-to-volume ratio of 1:5. Shake flasks were sealed with foam stoppers (cat. No. L800-D, Identi-Plugs®, Jaece Industrie, Inc., NY, USA) to provide sufficient aeration. The cultures were incubated at 200 rpm in a rotary shaker incubator (Series 25, New Brunswick Scientific Co., Edison, NJ, USA) at room temperature. The seed culture was inoculated to a 7-L bioreactor (BioFlo 3000, New Brunswick, Edison, NJ USA) containing 4 L of Medium A with one of three glucose concentrations mentioned above. Cultures were incubated for 7 days at 27 °C, 2 L min−1 air and agitation looped to the dissolved oxygen sensor to maintain a minimum of 40% dissolved oxygen during the entire fermentation. The starting pH of the media was 6.5 in all cases and no pH adjustment was made during the fermentation as it caused a decrease in PEFA production (results not shown). Temperature was kept constant at 27 °C. No antifoam was added during the course of fermentation.

Recovery of cells, secreted PEFA and intracellular lipid (containing TG) in bioreactors

Fifty milliliter samples were collected from the bioreactors at multiple time points to monitor cell growth, glucose consumption, PEFA and intracellular lipid production. The overall sample processing workflow is described in Fig. 2. Samples were vortexed briefly to homogenize the culture and divided into two pairs of 10-mL aliquots. The first pair (duplicates) was extracted twice with 40 mL of ethyl acetate as described [11], the solvent was removed using a vacuum speed concentrator (miVac Duo®, Genevac Inc., Stone Ridge, NY, USA), and the dry weight of the ethyl acetate extract residue was recorded and then stored at −80 °C for PEFA characterization, as described in section “Analysis and characterization of PEFA and TG”.

Cells from the second pair of 10-mL cultures were harvested in tared 15 mL conical tubes (cat. No. 339650 Thermo ScientificTM NuncTM, Waltham, MA, USA) via centrifugation at 3220×g for 10 min at room temperature to remove the spent media, followed by two more water washing steps [10]. Aliquots of spent media after the first centrifugation were saved and stored at −80 °C for glucose determination. The cell pellet was frozen overnight at −80 °C and freeze-dried at −46 °C, 0.133 mbar (Freez-one® 4.5 L Freeze Dry System Model 7750020, Labconco®, Kansas City, MO, USA). The dry cells were weighed and the values for the ethyl acetate extract residue above were subtracted to determine the dry cell weight (DCW) in terms of g(recovered dry cells) L −1(culture) .

Intracellular lipids were processed as previously described [10]. Twenty milligrams ±1 mg of dry cells was lysed via 5 consecutive bead beating cycles (30 s each) in 2.0-mL screw cap tubes (cat. No. 89004-310 VWR Radnor, PA, USA) containing 1.5 mL Folch reagent, 0.5 mm zirconia beads and two 3.5-mm glass beads in an MP Bio Fast Prep-24 homogenizer (MP Biomedicals, OH, USA). The process was repeated four times, adding 1.5 mL of fresh Folch reagent each time. 1.2 mL of a 0.9% w/v NaCl solution was added to the solvent fractions containing the TG for improved phase separation. Three milliliters of chloroform phase was extracted and dried in tared amber glass vials (cat. No. 500-322, Sun Sri, Rockwood, TN, USA) in the vacuum concentrator as described above, and the resulting Folch reagent extract residue was weighed and used to calculate total lipid as a percent of DCW. The Folch reagent extract residues were stored at −80 °C, and used later for TG characterization, as described in section “Analysis and characterization of PEFA and TG”.

The Folch reagent extract residue contained primarily TG with some co-extracted PEFA; the ethyl acetate extract residue contained primarily PEFA with traces of TG, as shown in Fig. 2. Total PEFA and TG yields were calculated as described below.

Determination of glucose in spent media

Ten microliters of centrifuged spent media was added to 990 µL acetonitrile/water (80:20, v/v) mixture containing 250 µg mL−1 d7-glucose (internal standard). After brief vortexing and centrifugation (12,000 rpm, 2 min, at room temperature), a 100 µL aliquot was transferred to a glass vial and submitted to hydrophilic interaction chromatography–mass spectrometry (HILIC–MS) analysis. Standard solutions of glucose (in the range 1–1500 µg mL−1) each with d 7-glucose (250 µg mL−1) were used for quantification. The system consisted of an Agilent 1290 Infinity LC system (Agilent Technologies, Santa Clara, CA) with a pump (G4220A), a column oven (G1316C), an autosampler (G4226A), and an Agilent 6550 iFunnel QTOFMS. Diluted samples were separated on an Acquity UPLC BEH Amide column (150 × 2.1 mm; 1.7 µm) coupled to an Acquity UPLC BEH Amide VanGuard pre-column (5 × 2.1 mm; 1.7 µm) (Waters). The column was maintained at 45 °C at a flow-rate of 0.4 mL min−1. The mobile phases consisted of (A) water with 10 mM ammonium formate and 0.125% formic acid and (B) 95:5 (v/v) acetonitrile/water with 10 mM ammonium formate and 0.125% formic acid. The separation was conducted under the following gradient: 0 min 100% (B); 0–2 min 100% (B); 2–7.7 min 70% (B); 7.7–9.5 min 40% (B); 9.5–10.25 min 30% (B); 10.25–12.75 min 100% (B); 12.75–17.75 min 100% (B). A sample volume of 3 µL was used for the injection. Sample temperature was maintained at 4 °C. The QTOF instrument was operated in electrospray ionization in negative mode with following parameters: mass range: m/z 50–1700; capillary voltage: −3 kV; nozzle voltage: −1 kV; gas temperature: 200 °C; drying gas (nitrogen): 14 L min−1; nebulizer gas (nitrogen): 35 psi; sheath gas temperature: 350 °C; sheath gas flow (nitrogen): 11 L min−1; acquisition rate: 2 spectra s−1. The instrument was tuned using an Agilent tune mix (mass resolving power ~20,000 full width at half maximum, FWHM). A reference solution (m/z 119.0360, m/z 966.0007) was used to correct small mass drifts during the acquisition. MassHunter Qualitative (B.05.00) and Quantitative (B.05.01) Analysis (Agilent) software programs were used for the data processing.

Sample preparation for PEFA analysis

The ethyl acetate extract residues were diluted with methanol to a final concentration of 10 µg mL−1 [7], sonicated for 30 s and vortexed for 5 s prior to injection.

Sample preparation for intracellular TG analysis

The Folch reagent extract residues were suspended in 1 mL of a chloroform/methanol (1:1, v/v) mixture followed by ultrasonication/vortexing, and methanol dilution to obtain a final concentration of around 20 µg lipid per mL, as previously reported [10].

Analysis and characterization of PEFA and TG

Analysis of native PEFA and TG molecules employing reversed-phase liquid chromatography-electrospray ionization in positive mode ESI(+) with a quadrupole/time-of-flight mass spectrometer (RPLC-ESI(+)–QTOFMS) was used in all time point samples to characterize the PEFA and TG profiles in time across the different fermentation experiments. The LC–QTOFMS system, its tuning, and data processing software were the same as for “Determination of glucose in spent media”. For separation an Acquity UPLC CSH C18 Van Guard precolumn (5 × 2.1 mm; 1.7 µm, Waters) coupled to an Acquity UPLC CSH C18 column (100 × 2.1 mm; 1.7 µm, Waters) was used. The column was maintained at 65 °C at a flow-rate of 0.6 mL min−1. The mobile phases consisted of (A) acetonitrile/water (60:40, v/v) with 10 mM ammonium formate and 0.1% formic acid and (B) isopropanol/acetonitrile (90:10, v/v) with 10 mM ammonium formate and 0.1% formic acid. The separation was conducted under the following gradient: 0 min 15% (B); 0–2 min 30% (B); 2–2.5 min 48% (B); 2.5–11 min 82% (B); 11–11.5 min 99% (B); 11.5–12 min 99% (B); 12–12.1 min 15% (B), 12.1–15 min 15% (B). For injection, a sample volume of 1 µL was used for PEFA analysis and 3 µL for TG analysis. Sample temperature was maintained at 4 °C. The QTOF instrument was operated in ESI(+) with the following parameters: MS1 mass range: m/z 50–1700; MS/MS mass range: m/z 50–1700; collision energy: 20 eV; capillary voltage: +3 kV; nozzle voltage: +1 kV; gas temperature: 200 °C; drying gas (nitrogen): 14 L min−1; nebulizer gas (nitrogen): 35 psi; sheath gas temperature: 350 °C; sheath gas flow (nitrogen): 11 L min−1; acquisition rate MS1: 10 spectra s−1; acquisition rate MS/MS: 13 spectra s−1; total cycle time: 0.508 s; number of precursor ions per cycle: 4; mass range for selection of precursor ions: m/z 500–1200. A reference solution (m/z 121.0509, m/z 922.0098) was used to correct small mass drifts during the acquisition. For the identification of the structural fragments and structural assembly of PEFA the software Mass Frontier 7.0 was used. For full structural and stereochemical confirmation of PEFA structures, the reader is referred to the work reported by Cajka et al. [7]. TG were identified based on their unique MS/MS fragmentation patterns using LipidBlast software [15]. PEFA purity within the ethyl acetate extract residue was determined as a relative percentage of the total ion chromatogram (TIC) by dividing the different PEFA molecules (peak heights) over the sum of TIC (sum of peak heights of all PEFA and TG species). In a similar fashion, TG purity within the Folch reagent extract residue was also determined as a relative percentage of the TIC peaks corresponding to the different TG molecules divided by the sum of TIC (sum of peak heights of all PEFA and TG species). PEFA and TG yields were calculated by summing PEFA or TG quantities in both the Folch extract residue and the ethyl acetate extract residue.

Microscopic visualization of PEFA and TG

A drop from yeast culture was placed on a slide, and a drop of a fresh Nile red solution (5 µg mL−1 in acetone) was added [31]. Visualization was performed under bright-field mode and under fluorescence (530/25 nm excitation and 590/35 nm emission) [31], at 40× and 100× magnification during early timepoints, and as secretion increased with time, then 10× magnification was used to view PEFA droplet formation, using a Carl Zeiss Axio Imager.A1 fluorescence microscope (Göttingen, Germany).

Results

Yeast species identification

The species identification was confirmed as described [11]. The GenBank accession numbers are KU609487 and KU609429 for R. babjevae ITS and partial 26S sequences, and KU609496 and KU609438 for R. aff. paludigena ITS and partial 26S regions, respectively [11].

Growth of R. babjevae and R. aff. paludigena in benchtop bioreactors

Both strains produced PEFA and TG simultaneously under all growth conditions tested (Fig. 3; Table 1). DCW values for R. babjevae at stationary phase (>80 h) increased significantly between 50 and 100 g L−1 glucose from 17 ± 1 to 30 ± 1 g L−1 (p < 0.01), but the increase between 100 and 150 g L−1 glucose was not significant at stationary phase (p = 0.71). The same pattern was observed for R. aff. paludigena, with a 14 ± 3 g L−1 increase from 50 to 100 g L−1 glucose (p < 0.01) and a slight, non-significant increase of from 100 g L−1 to 150 g L−1 glucose (p = 0.64) during stationary phase.

Fermentation profiles for R. babjevae, (a–c) and R. aff. paludigena (d–f) including DCW, intracellular lipid production, extracellular PEFA production and glucose consumption, all expressed as g L−1. Both strains were incubated in 7-L bioreactors using 4 L of medium A, with 50 g L−1 glucose (a, d), 100 g L−1 glucose (b, e) and an initial 100 g L−1 supplemented at 48 h with an additional 50 g L−1 for a total of 150 g L−1 glucose (c, f), for 7 days, at 27 °C with the agitation looped to the dissolved oxygen and maintained at a minimum of 40%

Glucose was consumed completely under batch conditions of 50 and 100 g L−1 glucose for both strains, but not under fed batch conditions with 150 g L−1 glucose, suggesting that the additional 50 g L−1 glucose at 48 h was not used by either strain for sustained growth. R. babjevae achieved higher DCW values compared to R. aff. paludigena in all conditions (see Table 1) and both reached stationary phase at approximately the same time (between 50 and 100 h). R. babjevae produced higher amounts of intracellular lipids compared to R. aff. paludigena (see Table 1). Specifically, at stationary phase R. babjevae produced 260, 73 and 61% more intracellular lipid than R. aff. paludigena at 50, 100 and 150 g L−1 glucose. However, R. aff. paludigena secreted 70, 170 and 51% more PEFA than R. babjevae with increasing glucose doses at stationary phase. When grown with 50 g L−1 glucose, R. babjevae reached 9.5 ± 0.8 g L−1 intracellular lipid by 75 h, while R. aff. paludigena from that point until the end of the fermentation reached 2.6 ± 0.5 g L−1, resulting in a significant 6.9 g L−1 difference (p < 0.01). The intracellular lipid yield of R. babjevae when grown in 100 g L−1 glucose reached 11.3 g L−1 (± 1.0 g L−1) as early as 89 h, while R. aff. paludigena achieved 7.4 ± 0.4 g L−1 (p < 0.01). The pH for yeasts grown in 50, 100, and 150 g L−1 glucose decreased slightly during the course of the fermentation from an initial value of 6.5 to final values of 6.3, 6.2 and 6.2 for R. babjevae, and 6.2, 6.1 and 6.0 for R. aff. paludigena, respectively.

Microscopic visualization

When stained with Nile red, PEFA fluoresced profusely, facilitating differentiation of cells vs. PEFA particles (see Fig. 4). PEFA were detected as early as 17 h in the case of R. aff. paludigena and 29 h for R. babjevae as water-insoluble droplets that readily absorbed the dye, and displayed strong fluorescence, in some cases even masking the less intense fluorescence associated with intracellular lipid droplets (Fig. 4). Some droplets were considerably larger than the cells themselves. As fermentation progressed, the droplets became more numerous, and coalesced into globules with amorphous shapes around 113 h for both strains. The PEFA droplets of R. aff. paludigena became visible to the naked eye at 89 h, displaying a yellowish viscous appearance, while those of R. babjevae became visible at 113 h, displaying an orange/brown viscous appearance. PEFA droplets coalesced and sank to the bottom of the sample tube within a few minutes without centrifugation.

Analysis and characterization of PEFA and TG

Both the Folch reagent extract residue and the ethyl acetate extract residue (Fig. 2) were subjected to the same analytical method. PEFA eluted between 2.05 and 3.69 min, and TG eluted between 9.10 and 12.00 min. Only trace amounts of TG were detected in the ethyl acetate extract residues, resulting in PEFA purities of no less than 97% for both yeasts across the different growth conditions during stationary phase. R. babjevae UCDFST 04-877 and R. aff. paludigena UCDFST 81-84 produced a mixture of 13 slightly different PEFA molecules. Each molecule was identified. Figure 5 shows that the PEFA profile varied over time, across the three growth conditions, and between the two yeasts. The detailed structural characterization of each of the 11 most abundant PEFA produced by R. babjevae has been previously reported [7]. The same procedure was also followed to identify the key structural features of PEFA produced by R. aff. paludigena, identifying similar molecules but in different abundances. The PEFA structures present in the mixtures secreted by each yeast were identified, and are listed in Table 2. For the purpose of tracking the changes of PEFA profiles during the course of fermentation, analysis of native molecules was conducted via RPLC-ESI(+)–QTOFMS (Fig. 5), as well as MS/MS fragmentation patterns (Fig. 6). PEFA profiles varied between the strains, and had less variation for R. aff. paludigena within treatments compared to R. babjevae. For instance, PEFA 8 and 13 were the most abundant molecules produced by R. babjevae across the experimental conditions and sampling times (see Fig. 5a–c), followed by similar amounts of PEFA 6 and 10 at 50 g L−1 glucose, and varying amounts of these and other PEFA at 100 and 150 g L−1 glucose. In contrast, R. aff. paludigena had a more conserved profile across the different conditions, with PEFA 5 and 8 accounting for more than 75% of total PEFA across all the experimental conditions. The fragmentation patterns for these two molecules are shown in Fig. 6.

Predicted fragment structures of the two most abundant PEFA secreted by R. aff. paludigena based on MS/MS spectra acquired in ESI(+): (1) PEFA 5: acetylated 3-hydroxy hexadecanoate (C16:0) esterified to D-arabitol with 3 acetylations (C29H50O11), (2) PEFA 8: acetylated 3-hydroxy hexadecanoate (C16:0) fatty acid esterified to D-arabitol with 4 acetylations (C31H52O12) (for detailed structure elucidation of PEFA see Ref. [7])

In terms of fatty acyl chain length at stationary phase, R. babjevae produced mixtures of PEFA across the different conditions with a slight tendency towards more C16:0 (48–58%) than C18:0 (40–50%) fatty acyl chain lengths, whereas R. aff. paludigena secreted PEFA mixtures tending to contain even more C16:0 (77–82%). Both strains secreted trace amounts of PEFA containing C12:0 or C20:0, and low amounts (0.5–2.5%) of PEFA bearing C14:0 fatty acyl moieties. Both strains secreted PEFA with saturated acyl moieties across all timepoints and experimental conditions. No unsaturated acyl moieties were detected.

As per the type of polyol head group present in PEFA during stationary phase, R. babjevae synthesized 29–37% of PEFA containing D-mannitol and 63–71% containing D-arabitol, while R. aff. paludigena PEFA comprised D-arabitol (>96%). It is also noteworthy that during stationary phase, the most abundant two PEFA molecules produced by R. babjevae, PEFA 8 and PEFA 13 were fully acetylated, while the most abundant PEFA in R. aff. paludigena, PEFA 5, had one free hydroxyl group, followed by the fully acetylated PEFA 8. However, R. babjevae secreted 2.5–13.5% of PEFA containing two or more free hydroxyl groups, while R. aff. paludigena only secreted 0.5–3.5%.

Both strains produced a wider range of TG molecules compared to PEFA (Online Resource 1). However, many of them were synthesized in either small or trace amounts. In both cases 17 different TG were detected in varying levels, as listed in Table 3. The TG profiles for both strains showed more variation depending on the growth condition employed. The fatty acyl moieties comprising the TG mixtures for both strains had predominantly 16 or 18 carbons. Small amounts of 24 carbons were also detected, more prominent in R. aff. paludigena (see Fig. 7 and Table 3). All the TG identified for both strains listed in Table 3 have at least one unsaturated fatty acyl moiety. This is in sharp contrast with the PEFA profiles obtained for both yeasts, in which all fatty acyl moieties were saturated. The most common unsaturated TG fatty acid in both strains in all conditions was C18:1, present in one or even two fatty acyl chains of the most abundant TG. Furthermore, both strains produced some TG in which at least one fatty acyl chain has two or three double bonds, though in lower amounts.

Rhodotorula babjevae produced considerably higher amounts of each TG compared to R. aff. paludigena. TG 52:2, corresponding to TG 16:0_18:1_18:1 (see Table 3), was the most abundant TG in all growth conditions for R. babjevae, followed by varying amounts of TG 50:1, TG 52:3 and TG 54:3. Some of the TG identified in the study were isomers that failed to be separated chromatographically, having the same m/z and retention time and mixed MS/MS spectra (see Online Resource 2). The first isomer in Table 3 is more abundant than the second one, based on intensity of MS/MS fragments.

Both total and individual TG amounts in R. aff. paludigena were lower than in R. babjevae across growth conditions and timepoints. Varying amounts of PEFA co-extracted in the Folch reagent extract residues after RPLC–QTOFMS analysis, because the cell pellet was resting in the PEFA layer. TG 52:3 and TG 52:2 were the two most abundant TG produced when the yeast was fed 50 g L−1 glucose, but as glucose concentration increased, the TG profiles changed, and TG 50:1 and TG 50:2 became the most abundant, with an overlap of TG 52:2 at 100 g L−1 glucose. R. aff. paludigena generated TG with C16 and C18 fatty acyl moieties in comparable amounts across the different growth conditions, while R. babjevae produced more TG with C18 fatty acyl moieties, especially at 100 and 150 g L−1 glucose (see Fig. 7).

Discussion

PEFA yields obtained in the present work are the highest yields reported by any basidiomycetous yeast. In 1964, Tulloch and coworkers reported yields as high as 2 g L−1 in aerated 3-L bioreactors using Rhodotorula glutinis and R. graminis [40], which are close relatives of R. babjevae. In recent years, there have been numerous taxonomic revisions of yeast. Recent molecular discrimination of species in the Rhodotorula glutinis sensu stricto group revealed that many yeast strains previously identified as R. glutinis or R. graminis were actually R. babjevae [18]. One strain utilized in early studies of yeast PEFA [27, 40], strain CBS 4648, was identified as Rhodotorula glutinis at the time, but is now named Rhodosporidium azoricum in the online CBS strain catalog (http://cbs.knaw.nl). The other original strains cited by Tulloch et al. are not available to determine whether they would be identified as R. babjevae under current taxonomy.

Yields for R. babjevae have been reported previously as high as 8.6 g L−1 [7] and for R. aff. paludigena as high as 12.7 g L−1 in shake flask studies [11], when grown in 100 and 50 g L−1 glucose, respectively, corresponding to glucose to product conversions of 0.086 and 0.25 g(PEFA) g −1(glucose) , respectively. The present work reports product conversions as the slopes that result after plotting g L−1 PEFA, TG and total lipid (TG plus PEFA) against the glucose consumed (see Table 1 and Online Resource 3), thus taking into account the product conversion across time. The total amount of lipid produced was roughly equivalent for both strains, but varied differently with increasing glucose doses. The values for total lipid conversion fell from 0.29 to 0.22 g(total lipid) g −1(glucose) with increasing glucose doses for R. babjevae (see Online Resource 3a-c). In contrast, total product conversion values for R. aff. paludigena seemed less sensitive to increasing glucose concentrations, shifting from 0.27 to 0.24 g(total lipid) g −1(glucose) with increased glucose doses (see Online Resource 3 d-f). In both cases, the decrease in total product conversion could have been due to substrate inhibition. The values for R. babjevae PEFA conversion were 0.08, 0.11 and 0.09 g(PEFA) g −1(glucose) with increased glucose doses, showing small variation. However, values for R. babjevae TG conversion decreased sharply with increased glucose doses: 0.21, 0.14 and 0.13 g(TG) g −1(glucose) . In the case of R. aff. paludigena, values for PEFA conversion decreased from 50 to 100 g L−1 glucose, but remained similar from 100 to 150 g L−1 glucose at 0.22, 0.16 and 0.16 g(PEFA) g −1(glucose) , respectively. TG conversions in contrast increased slightly, from 0.05 to 0.08 g(TG) g −1(glucose) . The PEFA conversion values (Table 1) were between 80% and 400% higher than those reported by Tulloch [40]. Optimization of the glucose concentrations, C:N ratios and feeding rates is the subject of future work. However, C:N ratios were in the range suitable for high lipid accumulation by oleaginous yeasts [33].

Productivities, expressed in mg(product) g −1(glucose) h−1 were also calculated and plotted against time (see Table 1 and Online Resource 4). For both yeasts, productivities peaked as soon as the yeasts left exponential phase and synthesis of PEFA began (between 24 and 48 h), and then fell at different rates. Total peak productivities for R. babjevae decreased with increased glucose concentrations, while those for R. aff. paludigena seemed more stable with increased glucose concentration (see Online Resource 4). At 50 g L−1 glucose, total peak productivity for R. babjevae was almost twice that of R. aff. paludigena. However, as glucose doses increased, the differences decreased. The decline in total productivity in time for R. aff. paludigena at different glucose concentrations was also less pronounced than that of R. babjevae, arguably due to less substrate inhibition in the case of R. aff paludigena. These observations could have industrial implications since high sugar loadings are normally used to obtain higher product yields. Thus, R. aff. paludigena could perform better in such settings given the above observations.

Rhodotorula aff. paludigena produced more of the secreted PEFA compared to R. babjevae, reaching PEFA/TG production ratios as high as 3.15, 1.9 and 2.05 g(PEFA) g −1(TG) at stationary phase when cultured in 50, 100 and 150 g L−1 glucose, respectively. Conversely, R. babjevae produced 0.45, 0.70 and 0.57 g (PEFA) g −1(TG) at stationary phase, when cultured in 50, 100 and 150 g L−1 glucose, respectively. The differences in chemical structures of PEFA produced by these two yeast species may explain the observed differences in tendency to phase separate from the culture mentioned above, and also suggest that they may have different surfactant activities. Further work is needed to elaborate on these properties.

The contrast between the high abundance of unsaturation within the TG and the lack of unsaturation in the (R)-3-hydroxyacyl moieties for both yeasts could imply differences in the biosynthetic pathways. It has been reported that some basidiomycetous fungi contain genes encoding polyketide synthases [19], which could synthesize hydroxylated fatty acids. However, it has been recently shown that yeasts from the Pucciniomycotina subphylum are devoid of polyketide synthase genes [19]. Furthermore, in Starmerella bombicola, an ascomycetous yeast capable of producing sophorolipids, the fatty acid which is supplied as nutrient in the media is taken up by the yeast and hydroxylated by an enzyme located at the endoplasmic reticulum membrane [41]. Similar findings have been reported for the biosynthesis of cellobiose lipids and mannosylerythritol lipids, other yeast glycolipid biosurfactants [26]. In addition, fatty acid desaturation occurs at the level of the endoplasmic reticulum membrane, and not in the fatty acid synthase [25, 29], and the transacylase enzymes required for esterification of fatty acids with glycerol to form TG via the Kennedy pathway are located at the endoplasmic reticulum membrane as well [9]. Fatty acid elongation beyond 18 carbons has also been reported to occur at the level of the endoplasmic reticulum. Regardless of whether the fatty acids produced in R. babjevae and R. aff. paludigena are converted to TG or PEFA, they undergo at least one biosynthetic step at the endoplasmic reticulum. This step could be desaturation, elongation or esterification in the case of TG synthesis [9], or fatty acid hydroxylation at the endoplasmic reticulum membrane. The latter would be consistent with the observation of small amounts of C24 chains present in the TG profiles of both yeasts in the present study, but more markedly in R. aff. paludigena. Ongoing research is describing in detail the biosynthetic pathways and their corresponding interactions within these yeasts.

Liamocins are another type of polyol lipids that are synthesized by Aureobasidium species within the ascomycetous phylum of fungi [24]. In 2011, Manitchotpisit et al. reported that liamocins produced by Aureobasidium pullulans strains also fluoresced when visualized under the microscope at ×40 magnification using reflective light with a green fluorescent protein (GFP) filter [20]. However, the materials secreted by these yeasts differ structurally from the PEFA identified in the present work, and were not produced in concomitance with significant quantities of any other lipid. In one study conducted by Kurosawa et al. [17], C10 dihydroxyl esters of d-mannitol and d-arabitol with unknown levels of acetylation were the main compounds identified to be produced by Aureobasidium sp. strains A-2 and A-21 M [17]. In another study conducted by Manitchotpisit et al. [20], ten strains of Aureobasidium pullulans produced an oil that fluoresced in yields of up to 6 g L−1 when grown in media containing 50 g L−1 sucrose [20]. MALDI-TOFMS analysis in positive ion mode of the oils revealed [M+Na]+ ions in a mass range m/z 750–1010, differing in mass range from the ions reported in the present study. The authors published a follow up study identifying the structures as liamocins [24], which are different structurally from the compounds identified in the present study. Liamocins consist of a single polyol head group linked via an ester bond to polyester tails composed of three or four 3,5-dihydroxydecanoic ester groups, some of which can be also 3-O-acetylated. These structures differ from PEFA in several ways: PEFA lack the 5-hydroxylation, and the acyl chains are longer than those of liamocins. The polyol head group of liamocins is also non-acetylated, while the PEFA polyol headgroups have various degrees of acetylation. However, like the yeasts described in this study that produce both PEFA and TG, the Aureobasidium species produce multiple coproducts that can be valorized, namely liamocins and two exopolysaccharides called pullulan (a food additive) and poly(β-l-malic acid) [21, 22].

The biological purposes and environmental implications of microbial lipid accumulation have been discussed in the literature. It has been suggested that algae accumulate large quantities of intracellular neutral TG as a survival tactic to endure periods of carbon stress [36]. This would also be a selective advantage for yeast [25, 33]. TG are a compact form of storage of energy and carbon. The biological purpose of glycolipids is not as clear. Among the subset of surfactants unique to microorganisms, several hypotheses have been postulated to explain the biological and environmental role of these molecules. Some researchers propose a role as extracellular carbon storage [42]. Some studies have identified antimicrobial activities in some biosurfactants such as sophorolipids and bacterial rhamnolipids, implying a competitive advantage [30, 35]. Another theory suggests that the amphiphilic nature of biosurfactants solubilize the waxy cuticles of leaves, permitting access to nutrients [6, 28]. Coupled together, the simultaneous production of an intracellular high energy molecule and an extracellular molecule displaying surfactant properties provides a competitive advantage for the yeast to adapt in an environment where access to nutrients, especially carbon, is variable. R. babjevae has been isolated from plant surfaces, air and soil. The only known strain of R. aff. paludigena (UCDFST 81-84) was isolated from decaying cactus. Plant surfaces have high nutrient fluctuations, and are typically spaces where microbial communities compete for survival.

For industrial-scale technologies, the simultaneous production of two lipid-based fractions from a single culture represents an appealing biorefinery model. The secreted PEFA are renewable, sustainable alternatives to petroleum-based surfactants. In practice, microbial biosurfactants that are currently on the market (e.g., sophorolipids) display a unique combination of market attractiveness and high demand growth, with values of US $10–30 per kg, depending on the type, the market and the application [1]. In addition, the TG from these yeasts are particularly suitable for biodiesel production, since the most abundant unsaturated fatty acid was C18:1, followed by varying amounts of saturated fatty acyl chains with 16 and 18 carbon length [10, 33]. These mixtures are preferred for biodiesel production because they contain low levels of unsaturated fatty acids which lower cloud point values without becoming too vulnerable to oxidation [16].

The yeasts used in the present study are known to utilize multiple carbon sources and tolerate several inhibitors present in biomass hydrolysates [34], and produce carotenoids [18], making them favorable strains for biotechnological applications. Several techno-economic studies have explored the conditions under which biosurfactants are profitable [3]. Ashby et al. [3] analyzed two scenarios for commercial production of sophorolipids, providing the yeast Starmerella bombicola with either glucose syrup and commercial grade oleic acid or glucose syrup and crude high oleic sunflower oil. The hydrophobic substrate was the most expensive, costing up to 27.2 and 37.6% of the total annual operating cost, respectively [3]. The present work provides two substantial advantages over the Starmerella system for production of sophorolipids. First, it demonstrates that R. babjevae and R. aff. paludigena can produce PEFA in commercially relevant yields without supplementation of a costly hydrophobic substrate such as oleic acid or vegetable oil [3]. Second, it results in the production of at least two products that could help leverage the economics of the process. Starmerella bombicola, being a low oil content and unpigmented yeast species, does not produce commercially significant quantities of TG or carotenoids. Further, our study clearly showed a disparity in the ratio of TG to PEFA production between R. babjevae and R. aff. paludigena. This variation could serve as a useful tool in systems biology to tailor yeast that can produce desired product combinations depending on particular market needs.

The yeast R. aff. paludigena has provided a clear proof of principle. This species secreted more PEFA than R. babjevae under all experimental conditions used. A secreted product simplifies downstream processing. Although these are two closely related yeast species, their phenotypic differences points towards the value that genetic diversity of yeast is used to design systems according to outcome values, whether as oils or for biodiesel production, surfactants, or a variety of biological outputs. Furthermore, R. aff. paludigena had less PEFA profile variation under the three growth conditions used in this study, i.e., less batch to batch variation. This is a desirable feature of an ingredient in formulated products, especially a biosurfactant. These competitive advantages place R. aff. paludigena as an ideal candidate for further research and commercialization. The strain of this species held in the Phaff Yeast Culture Collection at the University of California Davis is the only known strain of this species, collected by Herman Phaff in 1981 from cactus in the Bahamas. This work emphasizes the importance of preserving microbes for future research, and of supporting public culture collections [4, 5].

References

(2014) Microbial biosurfactants market: global industry analysis, size, share, growth, trends and forecast 2014 - 2020. Transparency Market Research, pp 1–74

Abdel-Mawgoud AM, Lépine F, Déziel E (2010) Rhamnolipids: diversity of structures, microbial origins and roles. Appl Microbiol Biotechnol 86:1323–1336

Ashby RD, McAloon AJ, Solaiman DK, Yee WC, Reed M (2013) A process model for approximating the production costs of the fermentative synthesis of sophorolipids. J Surfactants Deterg 16:683–691

Boundy-Mills KL (2012) Yeast culture collections of the world: meeting the needs of industrial researchers. J Ind Microbiol Biotechnol 39:673–680

Boundy-Mills KL, Glantsching E, Roberts IN, Yurkov A, Casaregola S, Daniel HM, Groenewald M, Turchetti B (2016) Yeast culture collections in the twenty-first century: new opportunities and challenges. Yeast 33:243–260

Bunster L, Fokkema NJ, Schippers B (1989) Effect of surface-active Pseudomonas spp. on leaf wettability. Appl Environ Microbiol 55:1340–1345

Cajka T, Garay LA, Sitepu IR, Boundy-Mills KL, Fiehn O (2016) Multiplatform mass spectrometry-based approach identifies extracellular glycolipids of the yeast Rhodotorula babjevae UCDFST 04-877. J Nat Prod 79:2580–2589

Das P, Mukherjee S, Sen R (2008) Genetic regulations of the biosynthesis of microbial surfactants: an overview. Biotechnol Genet Eng Rev 25:165–186

Garay LA, Boundy-Mills K, German J (2014) Accumulation of high value lipids in single cell microorganisms: a mechanistic approach and future perspectives. J Agric Food Chem 62:2709–2727

Garay LA, Sitepu IR, Cajka T, Chandra I, Shi S, Lin T, German JB, Fiehn O, Boundy-Mills KL (2016) Eighteen new oleaginous yeast species. J Ind Microbiol Biotechnol 43:887–900

Garay LA, Sitepu IR, Cajka T, Fiehn O, Cathcart E, Fry RW, Kanti A, Nugroho AJ, Faulina SA, Silaban S et al (2017) Discovery of synthesis and secretion of polyol esters of fatty acids by four basidiomycetous yeast species in the order Sporidiobolales. J Ind Microbiol Biotechnol. doi:10.1007/s10295-017-1919-y

Inès M, Dhouha G (2016) Glycolipid biosurfactants; main properties and potential applications in agriculture and food industry. J Sci Food Agric 96:4310–4320

Kamm B, Kamm M (2004) Principles of biorefineries. Appl Microbiol Biotechnol 64:137–145

Kamm B, Kamm M (2007) Biorefineries-multi product procesess. White Biotechnology. Springer, Berlin Heidelberg, pp 175–204

Kind T, Liu K-H, Lee DY, DeFelice B, Meissen JK, Fiehn O (2013) LipidBlast in silico tandem mass spectrometry database for lipid identification. Nat Methods 10:755–758

Knothe G (2005) Dependence of biodiesel fuel properties on the structure of fatty acid alkyl esters. Fuel Process Technol 86:1059–1070

Kurosawa T, Sakai K, Nakahara T, Oshima Y, Tabuchi T (1994) Extracellular accumulation of the polyol lipids, 3, 5-dihydroxydecanoyl and 5-hydroxy-2-decenoyl esters of arabitol and mannitol, by Aureobasidium sp. Biosci Biotechnol Biochem 58:2057–2060

Kurtzman C, Fell J, Boekhout T (2011) The yeasts: a taxonomic study, 5th edn. Elsevier, Amsterdam

Lackner G, Misiek M, Braesel J, Hoffmeister D (2012) Genome mining reveals the evolutionary origin and biosynthetic potential of basidiomycete polyketide synthases. Fungal Genet Biol 49:996–1003

Manitchotpisit P, Price NP, Leathers TD, Punnapayak H (2011) Heavy oils produced by Aureobasidium pullulans. Biotechnol Lett 33:1151–1157

Manitchotpisit P, Skory CD, Peterson SW, Price NP, Vermillion KE, Leathers TD (2012) Poly(β-l-malic acid) production by diverse phylogenetic clades of Aureobasidium pullulans. J Ind Microbiol Biotechnol 39:125–132

Manitchotpisit P, Watanapoksin R, Price NP, Bischoff KM, Tayeh M, Teeraworawit S, Kriwong S, Leathers TD (2014) Aureobasidium pullulans as a source of liamocins (heavy oils) with anticancer activity. World J Microbiol Biotechnol 30:2199–2204

Paddon CJ, Keasling JD (2014) Semi-synthetic artemisinin: a model for the use of synthetic biology in pharmaceutical development. Nat Rev Microbiol 12:355–367

Price NP, Manitchotpisit P, Vermillion KE, Bowman MJ, Leathers TD (2013) Structural characterization of novel extracellular liamocins (mannitol oils) produced by Aureobasidium pullulans strain NRRL 50380. Carbohydr Res 370:24–32

Ratledge C, Wynn JP (2002) The biochemistry and molecular biology of lipid accumulation in oleaginous microorganisms. Adv Appl Microbiol 51:1–52

Roelants SL, De Maeseneire SL, Ciesielska K, Van Bogaert IN, Soetaert W (2014) Biosurfactant gene clusters in eukaryotes: regulation and biotechnological potential. Appl Microbiol Biotechnol 98:3449–3461

Ruinen J, Deinema MH (1964) Composition and properties of the extracellular lipids of yeast species from the phyllosphere. Antonie Van Leeuwenhoek 30:377–384

Schreiber L, Krimm U, Knoll D, Sayed M, Auling G, Kroppenstedt RM (2005) Plant–microbe interactions: identification of epiphytic bacteria and their ability to alter leaf surface permeability. New Phytol 166:589–594

Schweizer M (2004) Lipids and membranes. The metabolism and molecular physiology of Saccharomyces cerevisiae. CRC Press, London, pp 140–223

Shah V, Badia D, Ratsep P (2007) Sophorolipids having enhanced antibacterial activity. Antimicrob Agents Chemother 51:397–400

Sitepu I, Ignatia L, Franz A, Wong D, Faulina S, Tsui M, Kanti A, Boundy-Mills K (2012) An improved high-throughput Nile red fluorescence assay for estimating intracellular lipids in a variety of yeast species. J Microbiol Methods 91:321–328

Sitepu IR, Sestric R, Ignaita L, Levin D, German JB, Gillies LA, Almada LA, Boundy-Mills KL (2013) Manipulation of culture conditions alters lipid content and fatty acid profiles of a wide variety of known and new oleaginous yeasts species. Bioresour Technol 144:360–369

Sitepu I, Garay LA, Sestric R, Levin D, Block DE, German JB, Boundy-Mills KL (2014) Oleaginous yeasts for biodiesel: current and future trends in biology and production. J Biotechnol Adv 32:1336–1360

Sitepu I, Selby T, Zhu S, Lin T, Boundy-Mills K (2014) Carbon source utilization and inhibitor tolerance of 45 oleaginous yeast species. J Ind Microbiol Biotechnol 41:1061–1070

Sleiman JN, Kohlhoff SA, Roblin PM, Wallner S, Gross R, Hammerschlag MR, Zenilman ME, Bluth MH (2009) Sophorolipids as antibacterial agents. Ann Clin Lab Sci 39:60–63

Solovchenko A (2012) Physiological role of neutral lipid accumulation in eukaryotic microalgae under stresses. Russ J Plant Physiol 59:167–176

Starmer WT, Lachance M, Phaff HJ, Heed WB (1990) The biogeography of yeasts associated with decaying cactus tissue in North America, the Caribbean, and northern Venezuela. Evolutionary Biology (USA)

Starmer WT, Phaff HJ (1983) Analysis of the community structure of yeasts associated with the decaying stems of cactus. II. Opuntia species. Microb Ecol 9:247–259

Suutari M, Priha P, Laakso S (1993) Temperature shifts in regulation of lipids accumulated by Lipomyces starkeyi. J Am Oil Chem Soc 70:891–894

Tulloch A, Spencer J (1964) Extracellular glycolipids of Rhodotorula species: the isolation and synthesis of 3-d-hydroxypalmitic and 3-d-hydroxystearic acids. Can J Chemistry 42:830–835

Van Bogaert IN, Demey M, Develter D, Soetaert W, Vandamme EJ (2009) Importance of the cytochrome P450 monooxygenase CYP52 family for the sophorolipid-producing yeast Candida bombicola. FEMS Yeast Res 9:87–94

Van Bogaert IN, Saerens K, De Muynck C, Develter D, Soetaert W, Vandamme EJ (2007) Microbial production and application of sophorolipids. Appl Microbiol Biotechnol 76:23–34

Van Bogaert IN, Zhang J, Soetaert W (2011) Microbial synthesis of sophorolipids. Process Biochem 46:821–833

Walsh G (2005) Therapeutic insulins and their large-scale manufacture. Appl Microbiol Biotechnol 67:151–159

Acknowledgements

This work was supported by the National Mexican Council of Science and Technology (CONACYT), The University of California Davis Science Translation and Innovation Research (STAIR) program, the National Institute of Health (Grant NIH HL113452, NIH DK097154 and NIH S10-RR031630). The authors gratefully acknowledge the technical assistance of Enrique Fernandez, Ting Lin and Sylviana Tjahyono. All authors have agreed to submit this manuscript to The Journal of Industrial Microbiology and Biotechnology.

Funding Information

This work, including the efforts of L.A. Garay was funded by the National Mexican Council of Science and Technology (CONACYT) Fellowship [291795]. This work, including the efforts of O. Fiehn and T. Cajka was funded by the National Institutes of Health grants NIH HL113452 and NIH DK097154, as well as the NIH instrument funding NIH S10-RR031630. This work, including the efforts of I.R. Sitepu and K.L. Boundy Mills was funded by an award from the University of California Davis Science Translation and Innovation Research (STAIR) program.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Garay, L.A., Sitepu, I.R., Cajka, T. et al. Simultaneous production of intracellular triacylglycerols and extracellular polyol esters of fatty acids by Rhodotorula babjevae and Rhodotorula aff. paludigena . J Ind Microbiol Biotechnol 44, 1397–1413 (2017). https://doi.org/10.1007/s10295-017-1964-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-017-1964-6