Abstract

The aim of this study was to evaluate the degree of conversion (DC), Vickers microhardness (VHN), main components and surface properties of a microhybrid and two bulk-fill composite resins polymerized with second and third generation light emitting diodes (LED). Sixty cylindrical specimens of Filtek™ Bulk-Fill, everX Posterior (bulk technique) and Filtek Z250 (incremental technique) were prepared in plexiglass molds (5 mm in diameter and 4 mm in thickness) and cured with second-generation LED (Woodpecker LED.B) and third-generation LED (Valo) resulting in six groups (n = 10). DC was determined using Fourier transform infrared spectroscopy (FT-IR), and VHN with Vickers microhardness tester. The main components were identified by means of energy-dispersive X-ray spectroscopy (EDX) microanalysis; whereas filler particles and surface properties were analyzed by scanning electron microscopy (SEM). VHN and DC data were analyzed using two-way ANOVA, followed by t-test with Bonferroni correction for pairwise comparison (p < 0.05). When DC and VHN values were evaluated, after polymerization with second and third generation LED, there was a statistical difference in bulk-fill composites, while there was no statistical difference in microhybrid composite. While, the highest DC and VHN values were obtained after polymerization of Filtek Z250 with Valo, the lowest DC and VHN values were obtained with Filtek Bulk-Fill with Woodpecker LED.B. The degree of conversion and microhardness are affected by the structure of the composite resin and LEDs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Resin-based composites (RBCs) are widely used in dentistry, such as filling material for the anterior and posterior region, endodontic post and core material, and bonding material for indirect restorations [1, 2]. RBCs contain a polymeric matrix, a silane coupling agent, and filler particles, as well as minor additional components such as initiators, coloring pigments, and stabilizers, and are polymerized in a variety of ways. Many factors affect the photopolymerization of light-cured RBCs, such as the type of light-curing unit (LCU), illumination parameters (light exposure time and density), photoinitiator system, monomers, and fillers [3, 4].

Along with developments in RBCs, there have also been developments in LCU used for polymerization. Light emitting diode (LED) LCUs have replaced quartz-tungsten-halogen (QTH) today. Second Generation LED, which offers uniform and homogeneous polymerization and better polymerization with extra strong light intensity, and third generation LED, which is also efficient for photoinitiators other than camphorquinone due to their wide wavelengths, have been introduced. While, it was thought that approximately 40 s of exposure to curing light would be required for complete polymerization, LCUs have been developed that require only 5 s of exposure as a result of recent developments [5]. The manufacturers have focused on increasing the curing efficiency of RBCs through changes in duration, irradiation intensity, and curing mode, maintaining the claim that adequate polymerization can be achieved at short exposure times (5 s or less) at high irradiance [6].

The incremental technique, which is based on the oblique or horizontal placement of conventional 2 mm composite layers, is advantageous in terms of reducing polymerization shrinkage, although it has disadvantages such as time consumption, contamination, and risk of gaps between layers [7]. In order to eliminate the disadvantages of the incremental technique, bulk fill composites placed in layers of 4 mm or more have been developed. There are different fillers (for example, prepolymer particles and fiberglass rods), photosensitive materials, and more reactive photoinitiators to increase the depth of polymerization in bulk fill composites. In addition, the inorganic filler ratio is generally lower than conventional RBCs, but the larger size of the fillers is also effective in increasing the depth of polymerization [5, 8].

In addition, nowadays, short treatment time is very important for clinicians and patients. For this reason, bulk fill composites are gaining popularity in terms of use. The fact that third generation LED provides polymerization with high light intensity in a short time is also effective in saving time. However, the frequency of use of second generation LED for photopolymerization and microhybrid composites as composite resins in dentistry cannot be ignored.

In dimethacrylate-based resins, photopolymerization is triggered by free radicals produced by irradiation of a photosensitive initiator. Under the action of the initiation system, the crosslinking reaction begins, and the C=C double bonds are converted into C–C single bonds to form a polymer. The percentage of polymerizable double bonds converted to single bonds is indicated by the degree of conversion (DC) [9]. The major clinical problems for light-cured RBCs are the DC and polymerization qualities. It has been stated that DC is directly related to the physical and mechanical properties of RBCs, such as hardness, strength, color changes, solubility, and biocompatibility [6, 10]. DC is affected by factors such as organic matrix chemistry, filler type, dispersion, photoinitiators used, light intensity, exposure time and mode, and light tip size [11]. The DC of RBCs generally varies between 43 and 75%, depending on the content, light intensity, and exposure time [12].

Fourier transform infrared spectroscopy (FT-IR) is widely used as a reliable method to study DC by detecting C=C double bonds before and after polymerization of the RBCs. Many studies have used scanning electron microscopy (SEM) and FT-IR to evaluate the surface properties and DC of composites [12,13,14,15].

Microhardness is a mechanical property that should always be considered when comparing restorative materials, especially in areas subject to high chewing forces. In addition, microhardness is a useful method for determining the degree of polymerization for RBCs [16].

This study aims to evaluate the effect of the use of second and third generation LED on the DC and microhardness of two bulk-fill and a microhybrid composites, as well as to evaluate the surface properties and components of fillers with SEM and energy dispersive X-ray spectroscopy (EDX).

Materials and methods

In this study, two bulk-fill RBC; Filtek Bulk Fill (3 M ESPE, USA) (FBF group) and everX Posterior (GC Corporation, Tokyo, Japan) (EXP group) and a microhybrid composite Filtek Z250 (3 M ESPE, USA) (Z250 group) and 2 LED-units; Woodpecker LED.B (Guilin Woodpecker Medical Instrument Co, Guilin, China) and Valo (Ultradent Products Inc., South Jordan, USA) LCU were used (Table 1). For microhardness and FTIR analysis, 60 cylindrical specimens (n = 10) were prepared from each material using 5 mm diameter × 4 mm thick plexiglass molds and 18 cylindrical samples (n = 3) for SEM analysis. EXP and FBF were placed in bulk (4 mm), and for the Z250, two consecutive horizontal increments of 2 mm each were placed using a plastic instrument according to the manufacturer’s instructions. Thirty of the samples were filled in a plexiglass mold placed on a celluloid strip and on a glass slide, and light cured for 20 s using the second generation LED curing light (LED.B) with soft-start mode, and the other thirty of the samples using the third generation LED curing light (Valo) for 12 s with high power mode [17]. Then, the samples were immersed in distilled water solution in plastic bottles and stored in an incubator at 37 °C for 24 h. DC was determined using FT-IR, and microhardness was tested using a Vickers microhardness (VHN) tester. The schematic diagram of the study is shown in Fig. 1.

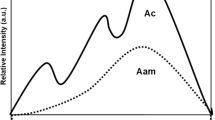

Determination of the DC

A Fourier transform-infrared spectroscope (NicoletTMiSTM5, USA) operating at 400–4000 cm−1 was used to measure DC. FT-IR spectra of both cured and uncured samples were analyzed using an accessory for diffuse absorption. Measurements were recorded as absorbance values. The number of double carbon bonds converted to single bonds provides the DC% of the RBCs. The percentage of non-reactive carbon–carbon double bonds (C=C%) was determined from the ratio of the absorbance density of aliphatic C=C (peak at 1637 cm−1) to aromatic C–C (peak at 1608 cm−1). DC was determined according to the following equation [2].

Microhardness test

For the microhardness values of the RBCs, a load of 300 g was applied through the Vickers indentation for 15 s with a digital microhardness tester (Shimadzu HMV-M3, Kyoto, Japan). Measurements were made from different regions of the top surfaces of each sample, and the average of the five measurements was calculated.

SEM and EDX analysis

SEM photographs were taken from randomly selected samples from each group. Samples were plated with gold (Quorum Q150R ES, Quorum Technologies, UK) and evaluated by SEM (Zeiss EVO MA10, Zeiss, Germany). The entire surface of the sample was scanned, and the most representative areas showing structural surface changes were photographed from 20 µm areas at 500x magnification and 2 µm areas at 5kx magnification with an accelerating voltage of 10 kV. To evaluate the chemical composition and surface structure, randomly selected samples from each group were examined with an EDX (EDX, Inca, Oxford Inst.) system for surface elemental analysis.

Statistical analysis

The data obtained from the present study were evaluated with the SPSS 22.0 (Statistical Package for Social Science Version: 22) program. For evaluation of the data, Kolmogorov-Smirnow and the paired sample t test were used. VHN and DC data were analyzed using two-way ANOVA, followed by t-test with Bonferroni correction for pairwise comparison. p-values equal to or less than 0.05 were considered statistically significant.

Results

Degree of conversion

Among all groups, the highest DC% was observed in the Z250, which was cured with Valo, while the lowest DC% was observed in the FBF, which was cured with Woodpecker LED.B. In addition, there was a statistically significant difference in terms of DC% in both EXP and FBF cured with Valo and Woodpecker LED.B (p < 0.05), while there was no significant difference in the Z250 (p > 0.05).

The mean DC% results obtained for the composites are also shown in Table 2 and Fig. 2. FT-IR plots for uncured and cured composites with different LEDs are shown in Fig. 3.

Microhardness

The highest VHN value among all groups was observed in the Z250, which was cured with Valo. The lowest VHN value was observed in the FBF cured with Woodpecker LED.B. In addition, for both EXP and FBF, there was a statistically significant difference between the samples cured with all second and third generation LED, while there was no significant difference in the Z250 (p > 0.05).

The mean microhardness value (VHN) in all groups is shown in Table 2 and Fig. 2.

SEM and EDX analysis

SEM-EDX, the composition of fillers was recorded for each group by weight of each element (wt%). Barium, aluminum, and silica were observed to be common elements in all RBCs. The shapes and sizes of the filler particles were different among the RBCs. The filler particles in EXP were basically fiberglass consisting of silicon, barium, sodium and aluminum. SEM-EDX analysis revealed that the bulk-fill composite FBF contained aluminum, silicon, zirconium, barium and fluoride consisting only of spherical irregular particles. Z250 contains fillers with a more regular and spherical morphology compared to FBF. SEM-EDX analysis revealed that the microhybrid Z250 contains spherical, regular and dense fillers of aluminum, silicon, zirconium, barium and fluoride (Fig. 4).

Discussion

In RBCs, the polymerization process depends on many factors and various properties such as mechanical properties, color stability, biocompatibility, polymerization shrinkage and stress, degradation, solubility, and water absorption are directly affected by the DC achieved during polymerization [18, 19]. The DC and microhardness are considered important physical properties of composite resins and play an important role in the comparison and characterization of restoration materials [16].

Microhardness is widely used to evaluate the depth of polymerization and thus the efficiency of polymerization devices and is significantly affected by increased crosslinking by polymerization reactions [20, 21]. Vickers hardness assessment is widely used to study resin composite polymerization due to the relationship between a composite’s microhardness and DC [22].

Since, the photoirradiation tip of the LCU is focused directly on the surface, the surface provides an optimum microhardness measurement. For this reason, the upper surface of the samples was chosen to measure the microhardness in this study. In our study, there was no significant difference in DC or microhardness of Z250 cured with Woodpecker LED.B and Valo, while higher microhardness values were obtained in the Z250 compared to the other two bulk-fill composite groups. Melo et al. [23], in their study evaluating the mechanical properties of bulk-fill and conventional composites, obtained higher VHN values in the Z250 compared to the FBF, similar to the results of this study. Gezawi et al. [24] reported that Filtek Z250 composites showed higher VHN values than bulk-fill composites in their study, in which they evaluated the microhardness of composites. In the study of Saati et al. [25], in which they evaluated the surface properties of the composites, the Z250 showed a higher VHN value than the other bulk-fill and conventional composites. These findings may be due to the higher filler volume and weight in the Z250 composite group compared to the other resin composites tested. Therefore, it can be said that the Z250 composite group with higher filler content has better mechanical properties than bulk-fill composites, including microhardness, regardless of the type of LCU. In addition, the Z250 may have shown a high VHN value due to the fillers consisting of quartz and ceramic particles [26].

When we compared two bulk-fill composites in our study, EXP showed a higher VHN value than FBF after polymerization with both LCUs. Fronza et al. [8], in their study evaluating the mechanical properties of bulk-fill composites, showed that the EXP had a higher VHN value than the FBF. In addition, Flury et al. [27] stated that low viscosity bulk-fill composites (SDR, Filtek Bulk Fill and Venus) showed significantly lower microhardness values compared to other RBCs tested. Although EXP has a lower filler volume, its higher VHN may be due to its higher light transmittance. In addition, the heterogeneous nature of bulk-fill composites causes light to scatter at the resin-filler interface. More irregularity in the shape of the filler and an increase in the filler content can also cause a decrease in light transmission [28]. In line with this information, a high filler volume of FBF may cause a decrease in light transmittance, which may be another reason for lower VHN [29].

FT-IR has been frequently used in the literature to analyze DC as it is an efficient and frequently used technique, provides a better understanding of the materials expected to optimize the polymerization process, and directly detects spatial couplings such as C–C and C=C vibrations [12, 30]. In this study, the DC of the tested composites was also measured by FT-IR spectroscopy.

There are many factors that affect photopolymerization and, thus, the DC. When these are examined: internal factors are the photoinitiator system, organic matrix (monomer type, amount) and fillers (filler size/type, amount and volume) and external factors are curing time/mode, position of light curing tip, irradiance, light spectrum [19, 31]. It is known that irradiance has a great effect on the polymerization of the material. However, the energy dose is considered the most important factor in determining the DC [32]. For this reason, LCU with two different light intensities were used in this study.

DC can be affected by material composition (matrix and filler) and translucency. The high filler particle content (volume) in the RBC also explains the reduced translucency of the material and, hence, the low DC [33, 34]. At the same time, fillers can cause a scattering effect. Because the increased filler volume of the material may cause the light intensity to decrease as it moves through the material. In our study, the DC value may have been found to be lower than EXP due to the high filler particle content (53% by volume) in the FBF and the decrease in its translucency. Increasing the irradiation time to achieve light penetration in deeper layers can increase the conversion using a higher energy density to achieve the minimum DC required for a larger thickness [35]. In this study, a significantly higher DC was obtained with the Valo with higher energy density in all composite groups.

According to some studies, DC is affected by organic content because properties such as reactivity and monomer mobility are related to the formation of polymeric chains. Radical sites move faster on the chain structure through the reactions of UDMA monomers, which are amino groups responsible for specific chain transfer reactions. This results in increased conversion and monomer polymerization, thus achieving high reactivity and conversion rates with the use of UDMA monomers [10, 36]. In our study, the presence of UDMA monomer also supports the fact that the Z250 restorative material with the highest filler volume has a higher DC than the two bulk-fill composites. Moldovan et al. [37] evaluated the DC and mechanical properties of three experimental and two commercial composite materials and found that the group with the highest filler content had the least unreacted bonds, while the composite resin without UDMA monomer showed the lowest DC. However, although FBF contains UDMA monomer, its low DC from EXP can be explained by the larger filler volume.

Factors such as polymeric matrix refractive index, monomer type, filler type, and size can affect the light transmittance of RBCs. In addition, it was concluded that as the sample volume decreases, less light attenuation (low attenuation coefficient) may be possible due to the reduction of incoming light blocking [28, 38]. It is thought that increasing the irradiation time will also increase the DC [39]. As shown in previous studies [40, 41] the mechanical properties of light-cured composites can also affect the DC of the composite material by irregular distribution of light energy due to its attenuation along depth. In our study, each layer polymerized in Z250 is 2 mm, and according to bulk-fill composite groups, the irradiation time in both light devices is two times the total at Z250. For these reasons, DC of Z250 may have been found higher than other RBCs. Additionally, when bulk-filled composites were evaluated, higher DC values may have been obtained in the EXP group than in the FBF group, as the glass fibers randomly placed in the EXP may have contributed to the transmission of light. When considered in terms of microhardness, the longer path of light in bulk-fill composites may have caused the microhardness values to be lower compared to the Z250 group.

Silve et al. [42] 1., 2. and third generation LED, they obtained the highest DC with the third generation LED in their study, where they evaluated the DC of conventional composites. Aguiar et al. [43] in their study evaluating the DCs of resin composites polymerized with different LCUs, there was no statistically significant difference, but they achieved a higher DC with the third generation LED than with the second generation. Bragança et al. [44], in their study, evaluated the DC and microhardness of two resin cements as a result of polymerization with different LCU and exposure times, they obtained data that LCU did not have a significant effect on DC and microhardness, but low light output reduced the values. Similar to these results, in this study, the highest DC in all composite groups was obtained with the third generation LED.

Conclusion

In all composite groups used in this study, an acceptable DC was obtained after polymerization with both LCU. In line with the limitations of our study, we think that DC has not a greater effect on VHN and a high correlation with the filler fraction content of VHN and translucency. DC alone does not provide a complete characterization of the polymer network structure because polymers with similar DC may show different crosslinking densities due to differences in affected chain-to-chain interactions. As a result, not only the light devices but also the properties of the resin (e.g., translucency, amount, type, and size of filler) affect the material polymerization and thus, the DC and microhardness.

References

Ferracane JL (2011) Resin composite—state of the art. Dent Mater 27:29–38

Yılmaz AP, Doğu KB, Manav ÖA, Tarçın B, Şenol AA, Tüter BE et al (2022) Assessment of micro-hardness, degree of conversion, and flexural strength for single-shade universal resin composites. Polymers 14:4987

Daugherty MM, Lien W, Mansell MR, Risk DL, Savett DA, Vandewalle KS (2018) Effect of high-intensity curing lights on the polymerization of bulk-fill composites. Dent Mater 34:1531–1541

Li Z, Zou X, Shi F, Liu R, Yagci Y (2019) Highly efficient dandelion-like near-infrared light photoinitiator for free radical and thiol-ene photopolymerizations. Nat Commun 10:3560

Garoushi S, Vallittu P, Shinya A, Lassila L (2016) Influence of increment thickness on light transmission, degree of conversion and micro hardness of bulk fill composites. Odontology 104:291–297

Lohbauer U, Rahiotis C, Krämer N, Petschelt A, Eliades G (2005) The effect of different light-curing units on fatigue behavior and degree of conversion of a resin composite. Dent Mater 21:608–615

Karadas M, Hatipoglu O, Havva ER, Turumtay EA (2018) Influence of different light-curing units on monomer elution from bulk fill composites. J Adhes Sci Technol 32:2631–2646

Fronza BM, Rueggeberg FA, Braga RR, Mogilevych B, Soares LES, Martin AA et al (2015) Monomer conversion, microhardness, internal marginal adaptation, and shrinkage stress of bulk-fill resin composites. Dent Mater 31:1542–1551

Yoshida K, Greener E (1993) Effects of two amine reducing agents on the degree of conversion and physical properties of an unfilled light-cured resin. Dent Mater 9:246–251

Alshali RZ, Silikas N, Satterthwaite JD (2013) Degree of conversion of bulk-fill compared to conventional resin-composites at two time intervals. Dent Mater 29:e213–e217

Abed Y, Sabry H, Alrobeigy N (2015) Degree of conversion and surface hardness of bulk-fill composite versus incremental-fill composite. Tanta Dent J 12:71–80

Moraes LGP, Rocha RSF, Menegazzo LM, Araújo EBd, Yukimito K, Moraes JCS (2008) Infrared spectroscopy: a tool for determination of the degree of conversion in dental composites. J Appl Oral Sci 16:145–149

Prasanna N, Reddy YP, Kavitha S, Narayanan LL (2007) Degree of conversion and residual stress of preheated and room-temperature composites. Indian J Dent Res 18:173

Bonon AJ, Weck M, Bonfante EA, Coelho PG (2016) Physicochemical characterization of three fiber-reinforced epoxide-based composites for dental applications. Mater Sci Eng C 69:905–913

Wu D, Zhao Z, Zhang Q, Qi HJ, Fang D (2019) Mechanics of shape distortion of DLP 3D printed structures during UV post-curing. Soft Matter J 15:6151–6159

Gokce K, Ersoy M, Ozel E, Sabuncu H (2013) Effect of different light curing systems on surface hardness of composite resins. Balkan J Stomatol 17:75–78

Gonulol N, Ozer S, Tunc ES (2016) Effect of a third-generation LED LCU on microhardness of tooth-colored restorative materials. Int J Paediatr Dent 26:376–382

Wang WJ, Grymak A, Waddell JN, Choi JJE (2021) The effect of light curing intensity on bulk-fill composite resins: heat generation and chemomechanical properties. Biomater Investig Dent 8:137–151

Sarosi C, Moldovan M, Soanca A, Roman A, Gherman T, Trifoi A et al (2021) Effects of monomer composition of urethane methacrylate based resins on the C=C degree of conversion, residual monomer content and mechanical properties. Polymers 13:4415

Yaman BC, Efes BG, Dörter C, Gömeç Y, Erdilek D, Büyükgökçesu S (2011) The effects of halogen and light-emitting diode light curing on the depth of cure and surface microhardness of composite resins. J Conserv Dent 14:136

Andrzejewska E (2001) Photopolymerization kinetics of multifunctional monomers. Prog Polymer Sci 26:605–665

Ferracane JL (1985) Correlation between hardness and degree of conversion during the setting reaction of unfilled dental restorative resins. Dent Mater 1:11–14

Melo RA, Bispo AdSL, Barbosa GA, Galvão MR, de Assunção IV, Souza ROdA et al (2019) Morphochemical characterization, microhardness, water sorption, and solubility of regular viscosity bulk fill and traditional composite resins. Microsc Res Tech 82:1500–1506

El Gezawi M, Kaisarly D, Al-Saleh H, ArRejaie A, Al-Harbi F, Kunzelmann K (2016) Degradation potential of bulk versus incrementally applied and indirect composites: color, microhardness, and surface deterioration. Oper Dent 41:e195–e208

Saati K, Khansari S, Mahdisiar F, Valizadeh S (2022) Evaluation of microhardness of two bulk-fill composite resins compared to a conventional composite resin on surface and in different depths. J Dent 23:58

Ilie N, Hickel R (2009) Investigations on mechanical behaviour of dental composites. Clin Oral Investig 13:427–438

Flury S, Hayoz S, Peutzfeldt A, Hüsler J, Lussi A (2012) Depth of cure of resin composites: Is the ISO 4049 method suitable for bulk fill materials? Dent Mater 28:521–528

Arikawa H, Kanie T, Fujii K, Takahashi H, Ban S (2007) Effect of filler properties in composite resins on light transmittance characteristics and color. Dent Mater J 26:38–44

Chung KH, Greener E (1990) Correlation between degree of conversion, filler concentration and mechanical properties of posterior composite resins. J Oral Rehabil 17:487–494

Peutzfeldt A, Asmussen E (2005) Resin composite properties and energy density of light cure. J Dent Res 84:659–662

Costa V, Pereira JM (eds) (2010) Multi-level grid strategies for ray tracing-improving render time performance for row displacement compressed grids. In: International conference on computer graphics theory and applications, Scitepress

Franco EB, Santos PAd, Mondelli RFL (2007) The effect of different light-curing units on tensile strength and microhardness of a composite resin. J Appl Oral Sci 15:470–474

Frauscher KE, Ilie N (2012) Depth of cure and mechanical properties of nano-hybrid resin-based composites with novel and conventional matrix formulation. Clin Oral Investig 16:1425–1434

Bucuta S, Ilie N (2014) Light transmittance and micro-mechanical properties of bulk fill versus conventional resin based composites. Clin Oral Investig 18:1991–2000

Ilie N, Stark K (2014) Curing behaviour of high-viscosity bulk-fill composites. J Dent 42:977–985

Sideridou I, Tserki V, Papanastasiou G (2002) Effect of chemical structure on degree of conversion in light-cured dimethacrylate-based dental resins. Biomaterials 23:1819–1829

Moldovan M, Balazsi R, Soanca A, Roman A, Sarosi C, Prodan D et al (2019) Evaluation of the degree of conversion, residual monomers and mechanical properties of some light-cured dental resin composites. Materials 12:2109

Fujita K, Ikemi T, Nishiyama N (2011) Effects of particle size of silica filler on polymerization conversion in a light-curing resin composite. Dent Mater 27:1079–1085

Stansbury JW (2012) Dimethacrylate network formation and polymer property evolution as determined by the selection of monomers and curing conditions. Dent Mater 28:13–22

Cho E, Sadr A, Inai N, Tagami J (2011) Evaluation of resin composite polymerization by three dimensional micro-CT imaging and nanoindentation. Dent Mater 27:1070–1078

Hayashi J, Tagami J, Chan D, Sadr A (2020) New bulk-fill composite system with high irradiance light polymerization: integrity and degree of conversion. Dent Mater 36:1615–1623

Silva EH, Albuquerque RC, Lanza LD, Vieira GC, Peixoto RT, Alvim HH et al (2011) Influence of different light sources on the conversion of composite resins. Indian J Dent Res 22:790

Aguiar FHB, Georgetto MH, Soares GP, Catelan A, Dos Santos PH, Ambrosano GMB et al (2011) Effect of different light-curing modes on degree of conversion, staining susceptibility and stain’s retention using different beverages in a nanofilled composite resin. J Esthet Restor Dent 23:106–114

Bragança GF, Vianna AS, Neves FD, Price RB, Soares CJ (2020) Effect of exposure time and moving the curing light on the degree of conversion and Knoop microhardness of light-cured resin cements. Dent Mater 36:e340–e351

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors deny any conflicts of interest related to this study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bilge, K., İpek, İ. Effects of different LED light curing units on the degree of conversion and microhardness of different composites: FT-IR and SEM-EDX analysis. Polym. Bull. (2024). https://doi.org/10.1007/s00289-024-05362-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00289-024-05362-2