Abstract

This in vitro study aimed to evaluate shear bond strength (SBS) between CAD/CAM blocks with different compositions and orthodontic metal brackets, following various surface treatments and bonding procedure. Specimens were prepared from Vita Enamic, CeraSmart, Tetric CAD and Vita Mark II CAD/CAM blocks and were subjected to thermocycling for 5000 cycles. Then, the specimens were allocated into 6 groups according to the surface treatment (n = 12): control (no surface treatment); hydrofluoric acid etching (HF); air-borne particle abrasion with aluminium-oxide; tribochemical silica coating; bur abrasion; and Monobond Etch and Prime application (MEP). The surface morphology of the CAD/CAM blocks was characterized using scanning electron microscope. Then, specimens were silanized and brackets were bonded with adhesive resin. After thermocycling, the SBS test was performed until failure, and failure types were noted according to the adhesive remnant index (ARI). Data were analysed using two-way ANOVA and Tukey tests to perform pairwise analyses. The significance level was taken as α = 0.05. Both the CAD/CAM block type and the surface treatment significantly influenced SBS. Control groups of all CAD/CAM blocks demonstrated significantly the lowest SBS values. The highest SBS values were observed for Vita Mark II specimens treated with HF among all groups. Control groups showed exclusively ARI score 5, whereas surface treated groups had lower and similar scores. All groups, except the control, had reliable SBS values (above 6 MPa). Therefore, clinicians can use MEP, novel self-etching single-component ceramic primer, safely besides other surface treatments while bonding orthodontic brackets.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The recent advancements in orthodontic treatment and increase in patients’ awareness result in more adults consulting with orthodontists for treatment day by day [1]. According to a survey that American Association of Orthodontists conducted in 2018, adults comprise almost 33% of orthodontic patients and their number increased by 14.8% since 2016 [2]. In adult population, associated with aging, there is an increase in number of extensive direct and indirect restorations with predisposing orthodontic factors [3]. The presence of increased restorations necessitates adhering the orthodontic brackets onto existing restorations rather than the tooth surface. Adhesive systems are known to provide superior bond strength to enamel, yet bond strength to restorative materials always remains a question mark.

Recently, usage of computer-aided design and manufacturing (CAD/CAM) systems in dentistry for metal-free indirect restorations has become widespread because of the advantages it has, such as timesaving, minimizing human mistakes, precision and accuracy [4]. As a result of increase in CAD/CAM utility, manufacturers are focused on developing optimum material. Firstly, CAD/CAM blocks of feldspar ceramic, which is highly aesthetic and has high strength after cementation, has been introduced. However, it has some disadvantages, including difficulty of occlusal adjustment, necessity of firing for adequate strength, wearing the antagonist tooth and chipping [5, 6]. Therefore, the polymer-based CAD/CAM bioceramic blocks which overcome the problems related to dental ceramics are produced. Besides this, they are more flexible than dental ceramics; they can be easily fabricated with improved marginal quality and can be easily repaired [7, 8]. Polymer-based CAD/CAM bioceramic blocks can be classified into two main categories, based on their microstructure: (1) resin with dispersed fillers and (2) polymer-infiltrated ceramic networks (PICNs) [9]. The first category includes composite blocks containing predominantly organic phase consisting of methacrylate monomers with dispersed filler particles such as silica, zirconium and barium glass. The second category includes PICN materials which are composed of predominantly inorganic phase (feldspar ceramic) with polymer infiltration [9].

The durability of bond strength between restorative materials and orthodontic brackets has gained importance since the orthodontic bracket failures extend the treatment period significantly which is approximately 0.6 months for each failed bracket, and failures cause additional cost and even more importantly affects the patient comfort negatively [10]. Therefore, it is crucial to maintain adequate bond strength between bracket and restorative material throughout the treatment process. To ensure enough bond strength, different surface treatments, such as hydrofluoric acid, air-borne particle abrasion with aluminium-oxide, tribochemical silica coating, grinding with diamond bur and silanization, are applied. It is widely known that different materials require different surface treatment [11]. As ceramic component in a material increase, hydrofluoric acid is preferred to dissolve the ceramic component and to make a porous surface to enhance bonding. On the other hand, with the increase in organic component, more complex treatments like air-borne particle abrasion with aluminium-oxide or tribochemical silica coating might be required [12]. However, hydrofluoric acid and tribochemical silica coating have potentially hazardous effects on gingiva [13] and lungs [14] respectively, so the use of rubber dam is mandatory. In addition, grinding with diamond bur or air-borne particle abrasion with aluminium-oxide may cause heat production, chipping, cracking and residual stresses that may cause flaws reducing bond strength [15]. To overcome these disadvantages, a novel self-etching ceramic primer, Monobond Etch and Prime (MEP) (Ivoclar Vivadent AG, Schaan, Liechtenstein), is produced. It is a one bottle product that claims application with ease and elimination of the hazardous effects related with previously mentioned treatment protocols. It is composed mainly of ammonium polyfluoride, which counts for mild etching, and the trimethoxypropyl methacrylate which provides silanization [16]. Although there are few studies published about MEP’s performance on bonding between orthodontic brackets and restorative materials such as feldspathic ceramic, zirconia, lithium disilicate or leucite-reinforced glass ceramics [17,18,19], to the best of the authors’ knowledge, MEP’s bonding performance between orthodontic metal brackets and polymer-based CAD/CAM bioceramic blocks remains unclarified. Considering that the bond strength of brackets to the CAD/CAM block is directly related to the material content and orthodontists cannot be sure which tooth-coloured restorative material they are facing with under clinical conditions, there is a need to determine an appropriate surface treatment for all tooth-coloured restorative materials. Therefore, this study aimed to evaluate the effect of different surface treatments on the shear bond strength of orthodontic metal brackets bonded to CAD/CAM feldspathic ceramic block and various polymer-based CAD/CAM bioceramic blocks. The null hypothesis was that shear bond strength would not be affected by CAD/CAM block material and by surface treatments.

Materials and methods

Four different types of CAD/CAM blocks, namely Vita Enamic (VE) (Vita Zahnfabrik H. Rauter, Bad Sackingen, Germany), CeraSmart (CS) (GC Corp., Tokyo, Japan), Tetric CAD (TET) (Ivoclar Vivadent AG, Schaan, Liechtenstein) and Vitablocks Mark II (VM) (Vita Zahnfabrik H. Rauter, Bad Sackingen, Germany) were used in this in vitro study. The brands, manufacturers, batch numbers and chemical compositions of the tested blocks are presented in Table 1.

Specimen preparations

The sample size was calculated as 12 per group with G* Power software (version 3.1; University of Dusseldorf, Germany), with an effect size (d) of 1.65, α of 0.05 and 1 − β (power) of 0.80, according to previously published study [20]. A total number of seventy-two specimens with 2-mm thickness of each CAD/CAM blocks were prepared using a low-speed cutting device (PRESI, Mecatome T180, France). Thicknesses of the slices were confirmed with a digital caliper (Digimatic, Mitutoyo Co., Tokyo, Japan). CAD/CAM block specimens were embedded in a self-cured acrylic resin (IMICRYL, Konya, Turkey) with the surfaces to be polished exposed, and they were ground finished using water-cooled 600-, 800- and 1200-grit silicon carbide paper respectively. All specimens were ultrasonically cleaned and subjected to an artificial aging protocol; 5000 × thermal cycles between 5 and 55 °C with a dwelling time of 30 s in distilled water [21, 22]. Following the aging protocol, specimens were randomly assigned into 6 groups according to the surface treatment (n = 12):

-

Group control: No surface treatment was applied on the specimens.

-

Group HF: Hydrofluoric acid etching (9% Porcelain Etch; Ultradent, South Jordan, UT, USA) was performed on the specimen surfaces using the manufacturer’s brush tip, which ensures controlled flow from the tip and support even coating, and it was left on the specimen for 60 s.

-

Group AL: Specimens were exposed to air-borne particle abrasion with aluminium-oxide particles using a chairside sandblaster (Airsonic® mini sandblaster; Hager Werken, Duisburg, Germany) from 10 mm above the specimen surface, at 2 bar pressure for 10 s.

-

Group TSC: Tribochemical silica coating, with alumina coated by silica particles (CoJet sand; 30 μm, 3 M ESPE, Seefeld, Germany), was performed using the same sandblaster from 10 mm above, at 2-bar pressure for 10 s.

-

Group BUR: The specimens were grounded with 600-grit silicon carbide paper as it mimics an extra-fine diamond bur for 8 s [23, 24].

-

Group MEP: Specimen surfaces were etched and silanized by Monobond Etch and Prime, according to the manufacturer’s instructions. MEP was applied with microbrush and rubbed for 20 s. MEP was left on the sample surfaces for the next 40 s, and then, samples were thoroughly washed off and air-dried for 10 s.

Orthodontic bracket bonding procedures

All groups, except MEP, was rinsed with distilled water for 30 s, and air-dried immediately after surface treatments to clean the residues. Then, a silane-coupling agent (Bis-Silane; Bisco, Inc. Schaumburg, IL, USA) was brushed as a thin coat on each specimen except MEP group and left on the specimens for 30 s and air-dried as recommended by the manufacturer. Orthodontic brackets for lower central incisors (Mini Master Metal Bracket; American Orthodontics, WI, USA) were bonded to the center of prepared specimens using a light cure adhesive paste (Transbond XT; 3 M Unitek, Monrovia, CA, USA) During the bonding procedures, a constant finger pressure was applied on the brackets to obtain a uniform adhesive thickness. Excess adhesive paste was gently discarded using a dental explorer, and the placement of the brackets was checked with digital caliper. Then, adhesive paste was light-cured with an LED curing device (Valo Grand, 1000 mW/cm2; Ultradent, South Jordan, UT, USA) for 40 s from a constant distance of 1 mm. Light curing was performed from two directions to achieve adequate polymerization. Polymerized specimens were kept in distilled water at 37 °C for 24 h. All specimens were prepared by one operator (RTO) for standardization purpose. Prior to shear bond strength (SBS) testing, specimens were further subjected to same artificial aging protocol to simulate clinical conditions.

Shear bond strength testing

The shear bond strength test was conducted using a SBS testing machine (MOD Dental, Esetron Smart Robotechnologies, Ankara, Turkey) at a crosshead speed of 0.5 mm/min. A gradually increasing force was applied to the adhesive interface between bracket base and specimen surface. The load at debonding was noted, and the SBS data was recorded in MPa by dividing the load at failure (N) to the surface area of the metal bracket base (9.34 mm2). After debonding, the failure types were examined with a stereomicroscope at magnification of 30 × and were classified according to the adhesive remnant index (ARI) as follows: (1) all the adhesive paste remained; (2) ˃ 90% remained; (3) 10–90% remained; (4) ˂ 10% remained; and (5) none remained on the CAD/CAM block surface.

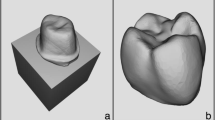

Scanning electron microscopy

After surface treatments, the surface morphology of two specimens from each CAD/CAM block (in total, 12 specimens) was observed under scanning electron microscopy (SEM). The specimens were sputter-coated with gold (Polaron SC7620; ThermoVG Scientific, West Sussex, England), and were examined at 10-kV operating voltage, under the SEM (Apreo S; Thermo Fisher Scientific, USA) with 1000 × and 5000 × magnifications.

Statistical analysis

The mean and standard deviations were calculated. The data were analysed using the Kolmogorov–Smirnov and Shapiro–Wilk tests to ensure a normal distribution. Two-way ANOVA test was performed to specify the effects of CAD/CAM block types and surface treatments on SBS value, and to analyse the interaction of these two factors. Tukey HSD test was used to perform pairwise analyses. SPSS software (SPSS Version 20; IBM, Chicago, IL, USA) was used to accomplish statistical analyses, and p < 0.05 was accounted as statistically significant.

Results

The two-way ANOVA revealed that both the CAD/CAM block type and the surface treatment remarkably influenced the SBS values. Additionally, a significant interaction was found between these two factors (p < 0.001) (Table 2).

The SBS values between CAD/CAM blocks and orthodontic metal brackets, after different surface treatments, are shown on Table 3. Control groups of all CAD/CAM blocks presented significantly lower SBS values compared to the surface-treated groups. There was no significant difference between the CAD/CAM blocks among the control group in terms of SBS values. According to the pairwise analysis, SBS values obtained for Vita Mark II were significantly higher than the other CAD/CAM blocks, except the control and TSC-treated groups. Vita Enamic specimens exhibited significantly higher SBS values compared to Tetric CAD and CeraSmart specimens in the HF- and MEP-treated groups. On the other hand, SBS values obtained for Tetric CAD were significantly higher than the other CAD/CAM blocks treated with AL. Furthermore, Vita Enamic and CeraSmart specimens demonstrated significantly greater SBS values, following TSC treatment, than Vita Mark II and Tetric CAD did. Regarding the surface treatment, SBS values obtained for Vita Mark II were significantly enhanced mostly by HF, followed by MEP, Bur, AL and TSC respectively. TSC, HF and MEP treatments significantly increased the SBS values that Vita Enamic has presented, compared to Bur and AL treatments. The SBS values obtained for CeraSmart were significantly improved by TSC, compared to the other surface treatments.

Concerning the ARI score, the incidence of score 1 was the highest in CeraSmart specimens treated with TSC (100%) followed by AL (90%) and Vita Enamic specimens treated with TSC (90%). Control groups showed exclusively score 5 ARI score regardless of the CAD/CAM block type. Rest of the groups had similar frequencies of failure types, below score 5, yet Vita Mark II treated with TSC had also score 5 (20%) (Table 4).

Figures 1, 2, 3 and 4 present the SEM micrographs of CAD/CAM blocks after the surface treatments. The control group and BUR specimens presented smoother and more homogeneous surfaces. When HF was applied on Vita Enamic and Vita Mark II specimens, dissolution of the glassy phase was observed producing deep pores in which adhesive resin can penetrate. On the other hand, Tetric CAD and CeraSmart specimens treated with HF presented smaller and shallower pores like woodpecker holes. Vita Enamic specimens treated with AL presented bounded porosities with crevices, and Vita Mark II presented more of a sharp-edged microgeometry. CeraSmart and Tetric CAD specimens treated with AL presented irregularities with depression and elevation areas. Vita Enamic and CeraSmart treated with TSC presented a microporous structure, with smaller laminations compared to Vita Enamic and CeraSmart specimens treated with AL. MEP-treated Vita Enamic, Tetric CAD and CeraSmart specimen surfaces seem similar to the control group with slightly more irregularities and micropores whereas MEP-treated Vita Mark II specimen showed a shallow etching pattern with more prominent irregularities.

SEM micrographs of Vita Enamic exposed to different surface treatments, at 1000 × and 5000 × magnifications. Black arrows on HF-treated sample image with 5000 × magnification indicate deep pores, arrows on AL and TSC-treated sample image show crevices and arrows on MEP-treated sample image resemble the micropores

SEM micrographs of Vita Mark II exposed to different surface treatments, at 1000 × and 5000 × magnifications. Black arrows on HF-treated sample image indicate dissolution of the glassy phase with deep pores, arrows on AL-treated sample image indicate sharp-edged microgeometry and arrows on MEP treated sample image resemble the shallow etching pattern with prominent irregularities

Discussion

This study was undertaken to evaluate the effect of different surface treatments on the SBS between different CAD/CAM blocks and orthodontic metal brackets bonded with adhesive resin. According to the results of this study, since both the block type and the surface treatment significantly influenced SBS, null hypothesis is rejected. Moreover, a significant interaction is found between block type and surface treatment. Several studies have also revealed that the SBS was significantly affected by the CAD/CAM block (p < 0.05) and by the surface treatments [20, 25, 26]. In previous studies, it is also reported that surface treatments promoted an increase in SBS values when compared with the control group (p < 0.001) which is parallel with the results of the present study [20, 27]. SBS enhancement by surface treatments could be explained by the higher surface roughness which promotes the impregnation of bonding agents [28].

Silane is a multifunctional molecule with the siloxane group which hydrolyses and the methacrylate group that polymerizes with resin-based materials and forms covalent bonds with the glassy phase in dental ceramics [29]. It is reported that silane application clearly advances the SBS value [30], increases the wettability of the surfaces with bonding agents, and provides a chemical bond between dental ceramics and resin composites [31]. However, a more recent study reported that silane application alone is not effective in bonding orthodontic brackets to polymer-infiltrated ceramic network or resin nanoceramic materials, which coincides with the findings of this study [32].

One of the surface treatments used in this study is HF, as its use along with silane is highly recommended for treating glassy ceramics [30]. HF increases the surface roughness by creating an irregular etching pattern and a deeper glassy phase dissolution resulting in increased micromechanical retention and promotes SBS values [33]. In the findings of the present study, SEM micrographs of both Vita Mark II and Vita Enamic exhibited similar etching pattern since both consists of feldspar ceramics as glassy phase that is dissolved by HF application. Previously, it was reported that highest SBS was obtained by etching the ceramic surface with 9.6% HF and applying silane or a bonding agent, supporting the present study in which SBS values obtained for Vita Mark II were significantly enhanced mostly by HF [30]. Additionally, it is also reported that HF combined with silane is considered the gold-standard surface treatment protocol for glassy ceramics [12, 27]. In case of resin with dispersed filler subcategory of polymer-based CAD/CAM bioceramic blocks (Tetric CAD and CeraSmart), it is also found that HF significantly increased the SBS values. In a study, it is revealed that HF promotes surface energy and wettability of bonding materials by etching the glassy particles, and creating microporosities on the resin matrix, which is probably the reason of increase in SBS values of polymer-based CAD/CAM bioceramic blocks [20]. However, SBS values for Tetric CAD and CeraSmart were lower than Vita Enamic which might be because Vita Enamic’s inorganic filler ratio (86% by weight) is higher than Tetric CAD’s and CeraSmart’s inorganic filler ratio (71% by weight) resulting in HF dissolving more glassy particles and making Vita Enamic more porous than Tetric CAD and CeraSmart, thereby increasing micromechanical retention. Despite the efficiency of HF in promoting SBS values, intraoral administration of HF may cause harmful effects on the surrounding tissue and may require safety measures [13].

Air-borne particle abrasion could be an alternative surface treatment for mechanical roughening, considering the potential harmful effects of HF [30]. Blasting with aluminium-oxide particles with high pressure causes microretentive surfaces [32], supportingly SEM micrographs of AL-treated Tetric CAD and CeraSmart surfaces demonstrated irregularities with depression and elevation areas which probably increased the surface area and resulted in increased microretention. In a study evaluating the bond strength of orthodontic brackets to a resin composite CAD/CAM block which is similar to Tetric CAD, SBS values were found to be the highest for AL, HF and MEP treatments respectively, in line with the present study [20]. Tribochemical silica coating is another air-borne particle abrasion technique that is able to create ultrafine mechanical retention by abrasion and by chemicophysical bonding using silane-coupling agent [34]. In this study, SEM micrographs of surfaces treated with TSC displayed microporous structure that increases micromechanical retention. Correspondingly, it is found that TSC provided the highest SBS values for Vita Enamic and CeraSmart blocks, and it also enhanced SBS values significantly for Tetric CAD. As a possible explanation, it can be interpreted that the methoxy groups of silane bonds chemically with both the silica and the methacrylate components of these blocks cause an improvement in SBS values [35]. A previous study reported that Vita Enamic specimens treated with TSC presented significantly higher SBS values compared to HF and BUR-treated specimens, which is supporting the results of the present study [26]. Although Vita Mark II block has demonstrated the highest SBS values when compared to the other CAD/CAM blocks in HF, MEP and BUR treatments, TSC-treated Vita Mark II specimens exhibited SBS values (6.7 MPa) on the edge of clinically acceptable threshold which is 6–8 MPa [17, 36]. Peumans et al. [12] stated that the significant differences in SBS values observed on different CAD/CAM blocks is probably due to their chemical compositions which affect the material properties and their response to different surface treatments. From this point of view, low SBS values of Vita Mark II specimens treated with TSC could be related to the chemical composition of Vita Mark II which consists of glassy ceramic, but not any resin polymer component. In addition, although Vita Enamic, CeraSmart and Tetric CAD blocks are classified as polymer-based CAD/CAM bioceramic blocks, they differ in terms of manufacturing methods, organic matrix type and inorganic filler types and ratios, which are probably the reasons of the significant differences in our study [20].

Surface treatment with a diamond bur is a practical method for roughening, which creates deep grooves and streaks forming macroretentive and microretentive areas without the need of any additional armamentarium [37]. SEM micrographs with 5000 × magnification of the present study exhibited irregular surfaces with small porosities that might have contributed to retention. Although AL, BUR and TSC treatments provided the highest SBS values for Tetric CAD, the SBS values demonstrated on other blocks with BUR treatment were also clinically acceptable. However, surface treatment with a diamond bur has some possible disadvantages which are chipping by aggressive impingements, loss of ceramic material, heat generation and residual stresses which initiate strength-reducing flaws jeopardizing the bond strength [15].

Due to the disadvantages of these surface treatments, MEP, a self-etching ceramic primer, combining the etching and silanization in a single step is introduced to simplify the treatment protocol for dental ceramics [16]. Studies have shown promising results of MEP on ceramic materials, creating a less-aggressive etching pattern in comparison with HF, and producing comparable bond strength with separate application of HF and silanization [16, 20]. SEM micrographs of Vita Mark II surfaces treated with MEP demonstrated a shallow etching pattern, which is consistent with the previous studies. In a study, investigating the bond strength of orthodontic brackets to various CAD/CAM blocks, it was suggested that MEP treatment is a valid alternative for most of the blocks (Cerec Blocs, IPS Empress CAD, Vita Suprinity, inCoris TZI and Vita Enamic) regarding the bracket bonding [19]. It is also reported in a recent study that MEP could be an alternative for TSC and HF, while bonding stainless steel brackets to leucite-reinforced feldspathic ceramic [17]. Another study revealed that MEP demonstrated clinically acceptable results for SBS between orthodontic metal brackets and zirconia ceramic blocks [18]. Contrary, it was reported that weaker acidic character of MEP results in lower SBS value compared to separate etching and silanization [31]. Similar results were found in the present study; however, the SBS values observed for MEP, for all polymer-based CAD/CAM bioceramic blocks and feldspathic ceramic block, were adequate for bracket bonding as they were above 6 MPa, which is the lower limit of clinically acceptable SBS value for bracket bonding.

Adhesive failure is extremely affected by the bond strength between the restorative material and the adhesive resin, and the bond strength between the bracket and the adhesive resin, and the mechanical characteristics of the adhesive resin [38]. The ARI scores showed that most of the surface-treated specimens exhibited adhesive failures between the bracket and adhesive resin, yet there was also cohesive failure through the adhesive resin in some groups. This finding supported that the bond strength between the adhesive resin and surface-treated CAD/CAM blocks was higher than the bond strength between the adhesive resin and orthodontic bracket which may have resulted in more adhesive resin remnants to clean after debonding to prevent discoloration and plaque accumulation [36].

Through this study, we observed that MEP could be an alternative surface treatment to increase bonding performance between orthodontic metal brackets and polymer-based CAD/CAM bioceramic blocks. Due to the disadvantages of other surface treatments, mentioned above, MEP can be a safer and practical option as it does not require additional equipment for protection and as it is not affected significantly by saliva contamination unlike the silane applications that needs to be performed with other surface treatments [17, 39]. Considering the results of the previous studies and the current study, showing promising results of MEP on different restorative materials such as feldspathic ceramic, zirconia, lithium disilicate or leucite reinforced glass ceramics, composite resin and polymer-based CAD/CAM bioceramic blocks [16,17,18,19,20], MEP might be an appropriate surface treatment for all tooth-coloured restorative materials that orthodontists cannot be sure of their content.

There are several limitations to this study. First, in vitro studies do not reflect the intra-oral conditions exactly, in terms of thermal alterations, pH changes, saliva contamination, etc. which can affect SBS [36]. Nevertheless, to simulate the effects of thermally induced stresses within the adhesive interface, specimens were subjected to thermocycling before and after the bracket bonding procedure. As Alavi et al. reported in their study, International Standard Organization recommends 500 cycles at 5–50 °C for thermocycling protocol, but 500 cycles of thermocycling are equivalent to less than 2 months of simulation of intra-oral conditions [21]. Since the duration of orthodontic treatments ranges between 18 and 30 months, simulation of two months was not enough [21]. Therefore, in this study, all specimens were subjected to thermocycling for 5000 cycles to simulate the intra-oral conditions more closely, as applied also in other studies [21, 22]. Second, the natural tooth surface has an anatomical morphology, yet CAD/CAM samples tested through this study were flat, as stated in ISO standards. Third, the ceramic restorations in the oral cavity are mostly glazed, but we did not glaze the specimens because this study did not evaluate SBS value between the metal bracket and the glaze; it evaluated SBS value between the metal bracket and the CAD/CAM block. In addition, some studies also reported that a thin superficial part of glazed layer should be removed completely or partially for the orthodontic bonding process to enhance the SBS values [19, 29]. Fourth, instead of diamond bur, sandpaper was used in this study to imitate bur effect [23, 24], which might have affected the SBS values and the SEM images. Further in vitro and clinical studies, overcoming these limitations, should be performed to confirm the results of the present study. Moreover, the present study evaluated only the SBS, but tensile and torquing forces should also be investigated. Future studies can test surface profilometry, surface energy of CAD/CAM blocks after different surface treatments and internal defects in CAD/CAM blocks after debonding.

Conclusion

According to the findings of the present study, it can be asserted that surface treatments have a significant effect on ensuring sufficient durability. In the present study, the mean SBS values of orthodontic brackets bonded to all the CAD/CAM blocks after different surface treatments were within the acceptable range (6–8 MPa). Therefore, clinicians should apply surface treatment while placing metal brackets on CAD/CAM blocks. Moreover, MEP, the novel self-etching single-component ceramic primer, could be a safer alternative for this purpose, to use on polymer-based CAD/CAM bioceramic blocks, with adequate adhesion.

Data availability

The data presented in this study are available on request from the corresponding author.

References

Mcmorrow, S.M., Millett, D.T.: Adult orthodontics in the Republic of Ireland: specialist orthodontists’ opinions. J Orthod 44(4), 277–286 (2017). https://doi.org/10.1080/14653125.2017.1403144

American Association of Orthodontists.: Economics of orthodontics survey results highlight specialty trends. https://www1.aaoinfo.org/economics-of-orthodontics-survey-results-highlight-recent-specialty-trends/ (2019). Accessed 10 January 2022

Christensen, L., Luther, F.: Adults seeking orthodontic treatment: expectations, periodontal and TMD issues. Br Dent J 218(3), 111–117 (2015). https://doi.org/10.1038/sj.bdj.2015.46

Davidowitz, G., Kotick, P.G.: The use of CAD / CAM in dentistry. Dent Clin of N Am 55(3), 559–570 (2011). https://doi.org/10.1016/j.cden.2011.02.011

Giordano, R.: Materials for chairside CAD/CAM-produced restorations. J Am Dent Assoc 137(9), 14S-21S (2006). https://doi.org/10.14219/jada.archive.2006.0397

Ruse, N.D., Sadoun, M.J.: Resin-composite blocks for dental CAD/CAM applications. J Dent Res 93(12), 1232–1234 (2014). https://doi.org/10.1177/0022034514553976

Awada, A., Nathanson, D.: Mechanical properties of resin-ceramic CAD/CAM restorative materials. J Prosthet Dent 114(4), 587–593 (2015). https://doi.org/10.1016/j.prosdent.2015.04.016

Coldea, A., Swain, M.V., Thiel, N.: Mechanical properties of polymer-infiltrated-ceramic-network materials. Dent Mater 29(4), 419–426 (2013). https://doi.org/10.1016/j.dental.2013.01.002

Mainjot, A.K., Dupont, N.M., Oudkerk, J.C., Dewael, T.Y., Sadoun, M.J.: From artisanal to CAD-CAM blocks: state of the art of indirect composites. J of Dent Res 95(5), 487–495 (2016). https://doi.org/10.1177/0022034516634286

Stasinopoulos, D., Papageorgiou, S.N., Kirsch, F.: Failure patterns of different bracket systems and their influence on treatment duration: a retrospective cohort study. The Angle Orthod 88(3), 338–347 (2018). https://doi.org/10.2319/081817-559.1

Alzainal, A.H., Majud, A.S., Al-Ani, A.M., Mageet, A. O.: Orthodontic bonding: review of the literature. Inter J Dent 1–10(2020), 8874909 (2020). https://doi.org/10.1155/2020/8874909

Peumans, M., Valjakova, E.B., De Munck, J., Mishevska, C.B., Van,: Meerbeek, B: Bonding effectiveness of luting composites to different CAD/CAM materials. J Adhes Dent 18(4), 289–302 (2016). https://doi.org/10.3290/j.jad.a36155

Anusavice, K.J., Shen, C., Rawls, H.R.: Phillips’ Science of Dental Materials. Elsevier, Missouri (2014)

Schmalz, G., Arenholt-Bindslev, D.: Biocompatibility of dental materials. Springer, Berlin (2009)

Albakry, M., Guazzato, M., Vincent, M.: Effect of sandblasting, grinding, polishing, and glazing on the flexural strength of two pressable all-ceramic dental materials. J Dent 32(2), 91–99 (2004). https://doi.org/10.1016/j.jdent.2003.08.006

Colombo, L., Murillo-Gómez, F., De Goes, M.F.: Bond strength of CAD/CAM restorative materials treated with different surface etching protocols. J Adhes Dent 21(4), 307–317 (2019). https://doi.org/10.3290/j.jad.a42931

Recen, D., Yıldırım, B., Othman, E., Çömlekoğlu, M.E., Aras, I.: Bond strength of metal brackets to feldspathic ceramic treated with different surface conditioning methods: an in vitro study. Eur Oral Res 55(1), 1–7 (2021). https://doi.org/10.26650/eor.20210004

Franz, A., Raabe, M., Lilaj, B., Dauti, R., Moritz, A., Müßig, D., Cvikl, B.: Effect of two different primers on the shear bond strength of metallic brackets to zirconia ceramic. BMC Oral Health 28(19), 51 (2019). https://doi.org/10.1186/s12903-019-0740-6

González-Serrano, C., Phark, J.H., Fuentes, M.V., Albaladejo, A., Sánchez-Monescillo, A., Duarte, S., Ceballos, L.: Effect of a single-component ceramic conditioner on shear bond strength of precoated brackets to different CAD/CAM materials. Clin Oral Investig 25(4), 1953–1965 (2021). https://doi.org/10.1007/s00784-020-03504-0

de Almeida, R.M., Hass, V., Sasaki, D.Y., Berger, S.B., Fernandes, T.M., Tonetto, M.R.: The impact of different surface treatments on the shear bond strength of orthodontic metal brackets applied to different CAD/CAM composites. J Clin Exp Dent 13(6), 608–613 (2021). https://doi.org/10.4317/jced.58137

Alavi, S., Shirani, F., Zarei, Z., Raji, S.: Effect of different surface treatment with panaviaV5 on shear bond strength of metal brackets to silver amalgam. Dent Res J 18(9), 1–7 (2021). https://doi.org/10.4103/1735-3327.310038

Asiry, M.A., AlShahrani, I., Alaqeel, S.M., Durgesh, B.H., Ramakrishnaiah, R.: Effect of two-step and one-step surface conditioning of glass ceramic on adhesion strength of orthodontic bracket and effect of thermo-cycling on adhesion strength. J Mech Behav Biomed Mater 84, 22–27 (2018). https://doi.org/10.1016/j.jmbbm.2018.04.021

Kim, J.W., Covel, N.S., Guess, P.C., Rekow, E.D., Zhang, Y.: Concerns of hydrothermal degradation in CAD/CAM zirconia. J Dent Res 89(1), 91–95 (2010). https://doi.org/10.1177/0022034509354193

Wiegand, A., Stucki, L., Hoffmann, R., Attin, T., Stawarczyk, B.: Repairability of CAD/CAM high-density PMMA- and composite-based polymers. Clin Oral Investig 19(8), 2007–2013 (2015). https://doi.org/10.1007/s00784-015-1411-x

Şişmanoğlu, S., Gürcan, A.T., Yildirim-Bilmez, Z., Turunç-Oğuzman, R., Gümüştaş, B.: Effect of surface treatments and universal adhesive application on the microshear bond strength of CAD/CAM materials. J Adv Prosthodont 12(1), 22–32 (2020). https://doi.org/10.4047/jap.2020.12.1.22

Elsaka, S.E.: Influence of surface treatments on bond strength of metal and ceramic brackets to a novel CAD/CAM hybrid ceramic material. Odontology 104(1), 68–76 (2016). https://doi.org/10.1007/s10266-014-0188-8

Gilbert, S., Keul, C., Roos, M., Edelhoff, D., Stawarczyk, B.: Bonding between CAD/CAM resin and resin composite cements dependent on bonding agents: three different in vitro test methods. Clin Oral Investig 20(2), 227–236 (2016). https://doi.org/10.1007/s00784-015-1494-4

Matinlinna, J.P., Lung, C.Y.K., Tsoi, J.K.H.: Silane adhesion mechanism in dental applications and surface treatments: a review. Dent Mater 34(1), 13–28 (2018). https://doi.org/10.1016/j.dental.2017.09.002

Grewal Bach, G.K., Torrealbab, Y., Lagravère, M.O.: Orthodontic bonding to porcelain: a systematic review. Angle Orthod 84(3), 555–560 (2014). https://doi.org/10.2319/083013-636.1

El-Damanhoury, H.M., Gaintantzopoulou, M.D.: Self-etching ceramic primer versus hydrofluoric acid etching: etching efficacy and bonding performance. J Prosthodont Res 62(1), 75–83 (2018). https://doi.org/10.1016/j.jpor.2017.06.002

Özarslan, M.M., Üstün, Ö., Buyukkaplan, U.S., Barutcigil, Ç., Türker, N., Barutcigil, K.: Assessment the bond strength of ceramic brackets to CAD/CAM nanoceramic composite and interpenetrating network composite after different surface treatments. BioMed Res Int (2018). https://doi.org/10.1155/2018/1871598

Tian, T., Tsoi, J.K.H., Matinlinna, J.P., Burrow, M.F.: Aspects of bonding between resin luting cements and glass ceramic materials. Dent Mater 30(7), e147-162 (2014). https://doi.org/10.1016/j.dental.2014.01.017

Şişmanoğlu, S., Turunç-Oğuzman, R.: Microshear bond strength of contemporary self-adhesive resin cements to CAD/CAM restorative materials: effect of surface treatment and aging. J Adhes Sci and Technol 34(22), 2484–2498 (2020). https://doi.org/10.1080/01694243.2020.1763543

Nergiz, I., Schmage, P., Herrmann, W., Özcan, M.: Effect of alloy type and surface conditioning on roughness and bond strength of metal brackets. Am J Orthod Dentofac Orthop 125(1), 42–50 (2004). https://doi.org/10.1016/S0889-5406(03)00507-9

Özcan, M., Vallittu, P.K.: Effect of surface conditioning methods on the bond strength of luting cement to ceramics. Dent Mater 19(8), 725–731 (2003). https://doi.org/10.1016/S0109-5641(03)00019-8

Yüzbaşıoğlu, E., Sayar-Torun, G., Özcan, M.: Adhesion of orthodontic brackets to indirect laboratory-processed resin composite as a function of surface conditioning methods and artificial aging. J Adhes Sci Technol 30(23), 2565–2572 (2016). https://doi.org/10.1080/01694243.2016.1186327

Bayram, M., Yeşilyurt, C., Kuşgöz, A., Ülker, M., Nur, M.: Shear bond strength of orthodontic brackets to aged resin composite surfaces: effect of surface conditioning. Eur J Orthod 33(2), 174–179 (2011). https://doi.org/10.1093/ejo/cjq048

Iijima, M., Ito, S., Muguruma, T., Saito, T., Mizoguchi, I.: Bracket bond strength comparison between new unfilled experimental self-etching primer adhesive and conventional filled adhesives. Angle Orthod 80(6), 1095–1099 (2010). https://doi.org/10.2319/012010-43.1

Lyann, S.K., Takagaki, T., Nikaido, T., Wada, T., Uo, M., Ikeda, M., Sadr, A., Tagami, J.: Efficacy of Various Surface Treatments on the Bonding Performance of Saliva-contaminated Lithium-Disilicate Ceramics. J Adhes Dent. 21(1), 51–58 (2019). https://doi.org/10.3290/j.jad.a41918.

Funding

CAD/CAM blocks of this study were funded by the Altınbaş University Coordination of Scientific Research and Projects (grant number PB2019-DIS-3).

Author information

Authors and Affiliations

Contributions

Rana Turunç Oğuzman: conceptualization; methodology; data acquisition; investigation; writing original draft and editing; and funding acquisition. Soner Şişmanoğlu: conceptualization; supervision; validation; statistical analysis; and writing—review and editing. All authors have read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Turunç-Oğuzman, R., Şişmanoğlu, S. Effect of surface treatments on shear bond strength between CAD/CAM bioceramic and resin blocks and orthodontic metal brackets bonded to each other. J Aust Ceram Soc 59, 187–196 (2023). https://doi.org/10.1007/s41779-022-00825-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-022-00825-z