Abstract

This article presents a comprehensive study on the geotechnical behavior of problematic expansive subgrade stabilized by guar gum (GG) biopolymer. In this regard, many geotechnical tests were conducted (such as consistency limits, Proctor compaction, unconfined compressive strength (UCS), California bearing ratio (CBR), and resilient modulus tests) on expansive soil treated with varying GG contents (i.e., from 0 to 5%) and aging periods (0–60 days). The results show that GG treatment increases soil consistency and optimum moisture content, whereas the maximum dry density decreases. The stress–strain behavior, UCS values, and CBR tend to increase with the increase in GG content and aging period, highlighting that GG induced better load-carrying capacity against the imposed loading while retaining the ductile behavior. At 60 days of aging the UCS value at 1.5% GG was found to be increased by 342%, elastic modulus by 309%, energy absorption capacity by 250%, and soaked CBR by 176%, transforming the soil into a better-quality subgrade for pavement construction. The stabilization mechanism showed that the inclusion of GG results in the formation of hydrogels which induce a covering effect, that not only clogs the pore spaces but also binds the soil particles in the soil matrix upon hardening, thus reducing the swelling potential and greatly enhance the soil’s strength parameters. Besides, the GG biopolymer exhibits resistance to degradation and exhibits slight improvement considering the long-term aging effects of up to 365 days. Overall, the GG treatment provides a green sustainable approach to mitigate the adverse expansive subgrade problems.

Graphic Abstract

Graphical abstract of expansive clay strengthening using guar gum biopolymer treatment

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Several strategies to improve the geotechnical properties of soils have emerged throughout time such as compaction, incorporation of natural and synthetic materials (Ali et al. 2020; Hamza et al. 2022a, b), dewatering, or incorporation of chemical and physical techniques (Khan et al. 2017; Ijaz et al. 2020a, b). The selection of the optimum approach is influenced by several factors such as the soil type, the nature of the project, the cost, the material accessibility, and other considerations. Among different available techniques, ground-improvement strategies by employing different chemical admixtures have gained considerable attention considering the economical perspective (Aziz et al. 2015; Ijaz et al. 2022a,b). Besides, the applications of such stabilizing techniques have their concerns on the soil environment. For instance, ground improvement using traditional stabilizers such as lime or cement results in the creation of a high pH environment that could induce significant detrimental effects on fauna and flora. Moreover, such stabilizers induce a brittle mode of failure which is least desirable in engineering practice. In addition, the manufacture of such cementing admixtures has a significantly high environmental impact in terms of carbon footprints (Chang et al. 2016; Salman et al. 2021). Thus, there is a need for a sustainable alternative soil stabilization approach that is both effective and efficient from an economical and environmental perspective. In this regard, the incorporation of polymers from biological origin has gained significant attention owing to its attributes and significantly less environmental impact.

Biopolymers are naturally available polymeric molecules extracted from nature. Biopolymers are biodegradable, harmless, and exhibit tensile-strengthening behavior. Owing to their minimal environmental impact, non-toxic nature, and absence of secondary contamination, biopolymers are acknowledged as an effective alternative to traditional stabilizers (Hamza et al. 2022c). The identity of biopolymers is determined by the glucose and polymerization molecular composition (Chang et al. 2016). The three main types of biopolymers are polynucleotides, polypeptides, and polysaccharides, while polysaccharides are more popular among them due to their abundant availability in nature. Different biopolymers like xanthan gum (XG), chitosan, alginate, guar gum (GG), polyhydroxy butyrate, beta-glucan, polyglutamic acid, gellan gum, etc., have been used in various geotechnical applications, for example, biopolymer grouts, contamination barriers, biological encapsulation, compressive coatings, mining tailings stabilization, etc. (Chang et al. 2016). Despite several applications, the use of biopolymers as a ground stabilizer to stabilize different problematic soils is still limited and requires comprehensive studies to pave the way for field implication.

Studies reported that biopolymers have inherent properties such as resistance to shear degradation, high viscosity, pseudo-plasticity, and stability across a broader range of pH and temperature that make them potential candidates as ground stabilizers. For instance, biopolymers such as beta-1,3/1,6 glucan and XG reported significant amelioration in resilience to soil erosion (Chang and Cho 2014; Reddy et al. 2018). Also, XG was found to improve the shear strength and compressibility parameters of kaolinite clay and bentonite owing to the formation of the hydrogels that filled the pore spaces (Latifi et al. 2017). Moreover, biopolymers treatment has also been reported to stabilize surficial soils by increasing effective cohesion, which improves stability against shallow slope failures (Puppala and Pedarla 2017). Other studies reported that XG and GG were found to be quite effective in stabilizing mine tailings by enhancing moisture retention, minimizing dust, and improving surface strength beyond the water-soaking threshold, whereas due to the higher viscosity GG than XG, GG is more effective in improving the undrained shear strength of mine tailing (Chen et al. 2013). Considering the effectiveness of GG, this study is mainly focused on GG as a problematic soil stabilizer (i.e., expansive soil).

GG is a preferred biopolymer for thickening and binding in food preparation. It generates extremely strong chemical bonds, enabling colloidal thixotropic dispersion, and is highly viscous. As a result, strong cohesive gels can be formed (El-Daw GEA 1994). It is composed of a 1:2 ratio of water-soluble D-galactose and D-mannose polysaccharides. Galactomannan is a non-ionic neutral polysaccharide (Mahmoud 2000). However, GG application in the field of geotechnical engineering is either from a different dimension with limited focus as a ground stabilizer, especially in treating problematic expansive soils. For instance, GG is quite effective in treating soil slurry that can be used to reinforce trench excavation walls and prevent dam constructions from collapsing their sides (Puppala and Pedarla 2017). Also, Sujatha and Saisree (2019) reported that GG is quite effective in the treatment of non-expansive clays and reported improvement in consolidation and strength parameters. Similarly, Sujatha and Saisree (2019) reported that GG induces significant improvement in the treatment of silty clays considering the compressive strength and deformation characteristics. It is pertinent to mention here that most studies on GG have been reported on different types of soils i.e., sand, silt, silty clays, etc., whereas very few studies focused on expansive fat clays. Such expansive clays are comprised of montmorillonite clay minerals that exhibit volumetric change behavior upon slight variation in moisture content and reported billion of dollars of damages to the engineering structure all over the world (Hamza et al. 2022d). Given the potential attributes and scarcity of literature on GG as a ground stabilizer, especially for expansive soil subgrades, demands comprehensive studies. Such studies are deemed necessary to provide a better understanding of the extent of amelioration observed in the GG-based soil treatment from different geological conditions. Table 1 shows recent findings on the use of biopolymers to improve soil engineering characteristics.

Considering the above discussion, this research comprehensively investigates the efficacy of GG to improve the engineering properties of problematic expansive soil subgrade by utilizing its gelling and bonding properties. In this regard, the expansive soil has been treated with different percentages of GG, and its effect on key geotechnical properties i.e., consistency limits, compaction characteristics, unconfined compressive strength, CBR, resilient modulus (MR), and long-term degradation behavior was evaluated. This study will provide promising applications of GG as a sustainable and green option for expansive soil sub-grade improvement.

Material procurement and characterization

Materials

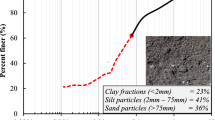

The soil used in this research was collected from 2 to 3.5 m below the ground level from Dera Ghazi Khan, Punjab, Pakistan (Fig. 1). Figure 2 presents the gradation curve that shows that the soil comprised 68% clay, 24% silt, and 8% sand contents. Table 2 shows the physical properties of expansive soil procured from the field. The soil exhibits a high liquid limit (LL) of 54.1% has a plasticity index (PI) of 31.7% and is classified as high plastic clay (CH) according to the Unified Soil Classification System (USCS). X-ray diffractogram (XRD) shows the presence of clay minerals i.e., montmorillonite and illite majorly responsible for the swell-shrinkage behavior, whereas other non-clay minerals are quartz (Q), and albite are shown in Fig. 3.

Guar gum (GG) biopolymer, also known as Cyamopsis tetragonolobus, is a natural biopolymer derived from the endosperm polysaccharide of the guar seed, which belongs to the Leguminosae family and is classified as a seed gum. GG is naturally hydro-colloidal and non-ionic (Mudgil et al. 2014). GG exhibits good stability over the wide range of pH from 4 to 10.5 (Gupta et al. 2009) and has good water solubility as compared to other biopolymers (Ayeldeen et al. 2016). It is comprised of polymers D-galactose and D-mannose in a 1:2 ratio (Chudzikowski 1971). GG when fully hydrated, generates viscous, colloidal dispersions that are thixotropic (El-Daw GEA 1994). GG contains borate ions, which function as cross-linking agents, resulting in the formation of thick and cohesive gels. The GG biopolymer used in this study is procured from Acros Organics, Pakistan. The extraction procedure of GG powder and its molecular structure are presented in Fig. 4, wWhereas Table 3 presents the physio-chemical properties of the GG used in this study.

Scanning Electron Microscopy (SEM) and Energy-Dispersive X-ray Analysis (EDX) analyses of untreated soil and GG powder are presented in Fig. 5. The SEM micrographs of untreated soil showed inter and intra assemblage pore spaces as shown in Fig. 5a. The micrographs exhibit grain-to-grain contact along with some connectors, whereas Fig. 5b shows the SEM micrograph of pure GG exhibiting continuous surface with fiber matrices. The EDX of untreated soil shows the abundant presence of oxygen (O), silicon (Si), and aluminum (Al) elements, while the carbon (C) and oxygen (O) elements are present in great amounts in EDX of pure GG. The elemental composition analysis of the studied materials presented in Fig. 6 also validates the attached EDX graphs.

Specimen preparation and testing program

To perform different laboratory experiments dry mixing technique was adopted in this study. As wet mixing might lead to poor workability and mixing issues if the water content exceeds the solubility point. Therefore, the GG biopolymer was mixed with untreated soil at 0, 0.5, 1, 1.5, 2, and 5% as per the dry weight of the soil. For water equilibration purposes, the prepared mixtures were placed in sealed plastic bags for 24 h (Ijaz et al. 2022c). The untreated and treated soil samples were then subjected to soil consistency, compaction, UCS, CBR, MR, and chemical and microstructural tests. The brief procedure and standard adopted to perform these tests are described as under:

Soil consistency

The soil consistency test was performed as per ASTM D4318-17e1. To determine the liquid limit (LL), a brass cup is raised to a certain height and then let fall into a firm rubber base using a manually turned cam. The metal cup is filled with a piece of the soil sample, which is then separated using a grooving tool. The LL is the moisture level at which the groove closes for 1/2 inch after 25 drops of the cup. And, the plastic limit is measured by physically rolling out a tiny ball of damp plastic soil into a 1/8-inch thread after continuously remolding it. The thread begins to fall apart before being completely rolled out at the moisture content known as the plastic limit. The associated moisture content at LL and PL was determined using the oven-dried method.

Compaction test

Proctor compaction tests were performed on untreated and GG-treated soil following ASTM standards (ASTM D698-12, ASTM D1557-12e1), to determine the maximum dry density (MDD) and optimum moisture content (OMC) for each soil sample. This test consists of compacting soil specimens at a given water content in a 4-inch-diameter mold with different compaction energy (standard and modified). Firstly, the soil was air-dried and then separated into 4 to 6 samples, then the water content of each sample was adjusted by adding water increments of 3 to 5 percent. The soil was then homogenously mixed with the desired percentage of GG and water. The prepared soil samples were then closed in polyethylene bags in the laboratory for 24 h at room temperature (27 ± 2 °C) for water equilibration. The soil was then placed and compacted in the compaction mold in three layers subjected to 25 blows on each layer using standard and modified compaction energy. In the end, the water content and dry density of the untreated and treated soil with different percentages of GG were determined.

Unconfined compressive strength

Unconfined compression tests were performed according to ASTM D2166M-16. The untreated and treated soil samples for the UCS test were prepared in a cylindrical mold 76 mm in height and 38 mm in diameter. The soil samples were compacted at their respective MDDs and OMCs, and the prepared mixtures were then naturally air-dried for the requisite age duration (0–60 days). After the required aging time, the specimen was placed on the base plate of the digital strain-controlled compression machine to obtain the stress–strain behavior of soil samples at a loading rate of 0.8 mm/min.

California bearing ratio (CBR)

CBR test was conducted on Digital Tinius Olsen CBR Test Machine based on ASTM D1883-16. In the CBR testing, all soil specimens were compacted into a CBR mold having dimensions (inner diameter of 152.4 mm, height of 177.8 mm) by using a modified compaction effort. A surcharge weight of 4.54 kg was placed on the top of the compacted soil specimen in the CBR mold to simulate the pavement and base course confining loads. In the case of the soaked CBR test, the mold with surcharge weights was fully immersed in water for 4 days of the soaking period, so that water can completely infiltrate into the soil specimen. Swelling gage was also attached during the soaking period to mark the swelling behavior of untreated and treated soil during inundation. CBR test was performed on all soil mixtures with a constant loading rate of 1.27 mm/min.

Scanning electron microscope and energy dispersive X-ray analysis (EDX) test

Nova NanoSEM 450 field-emission scanning electron microscope (FE-SEM) was used commonly for examining the microscopic structure of soil fabric in detail. In this study, SEM tests were conducted on soil-GG mixtures to examine the formation of hydrogels inside the soil pore spaces along with Energy-Dispersive X-ray Analysis (EDX) analyses to determine the elemental composition in samples. For this to be done, the prepared specimens were first subjected to a drying process for each test. Then, each dried soil specimen was positioned on an aluminum stub covered with two-sided carbon tape and coated by gold (Au) sputtering for 110 s at 25 milliamperes under a high vacuum, until it was fully covered and ready for SEM analysis. Energy-Dispersive X-Ray Analysis (EDX) technique is used that incorporates X-rays to determine the elemental composition of materials. EDX analysis produces spectra with peaks matching the elements that make up the real composition of the material being observed.

BET-specific surface area test

The N2-BET technique, developed by (Brunauer et al. 1938), is used for estimating the surface area of untreated and treated soil. The BET (Brunauer, Emmett, and Teller) theory is used to evaluate the specific surface area in terms of (m2/g) based on gas adsorption data.

The test specifications, specimen details, and their associated standards of various macro and micro tests are summarized in Table 4.

Results and discussion

Soil consistency limits of GG-treated soil

Soil consistency limit tests were carried out on soil samples mixed with GG in varying proportions between 0 and 5% to check its effect on the liquid limit (LL) and plasticity index (PI). Overall, an increasing trend was observed with the incorporation of GG. Figure 7 shows that at 5% GG, LL, and PI values increased by 33% and 29%, respectively. Similar increasing trends in LL and PI with biopolymer addition have also been reported in the literature (Sujatha and Saisree 2019). Meanwhile, the plastic limit also shows an increase of 38% with an increase in GG concentration from 0 to 5%, because the threads of the monomeric molecules make the soil stiffer. The increase in consistency limits is mainly due to the hydrophilic nature of GG which initially tends to hydrate. As GG is anionic and comprised of different hydroxyl ions (OH−). Thus, in soil-GG amalgam the hydrogen atom acts as a link between the two electronegative atoms, resulting in the development of a hydrogen bond. The oxygen atoms on silicate surfaces and edge hydroxyls can form hydrogen bonds with organic matter's hydroxyl, carboxyl, and amino groups. As a result of absorbing more water, the soil-GG amalgam developed a hydrogen bonding network, resulting in higher LL and PL values.

Viscosity parameters of GG-treated soil

Figure 8 shows the fluctuation in viscosity (µ) of untreated and treated soil with varying GG content percentages. The determination of viscosity was determined with the help of a procedure developed by Shimizu et al. (2018), and the results show that the pore fluid viscosity gets increased from 45 to 2567 cps (gel-form) with increased GG contents from 0.5 to 5%, respectively. This increase in viscosity with GG addition leads to the change in the plastic behavior as already shown in Fig. 7, and the hydrophilic nature of biopolymer also contributes to this plasticity change in treated soil (Nugent et al. 2009).

Compaction characteristics of GG-treated soil

The effect of GG addition on the maximum dry densities (MDD) and optimum moisture content (OMC) of untreated soil was investigated by conducting standard and modified proctor tests. For comparison purposes, the compaction curves of untreated soil and GG-treated soil are presented in Fig. 9a, and the respective linear regression models are given in Fig. 9b. Overall, due to relatively high compaction energy, the values of MDDs are greater and OMCs are lesser in modified proctor (MP) tests than that of the standard proctor (SP) tests along with relatively steep shapes of the compaction curves in modified proctor tests. With the increase in GG contents from 0 to 5%, a decrease of 11.5% and 15.7% in MDD has been observed for MP and SP tests, respectively. Likewise, a corresponding increase in OMC values in the case of MP and SP tests was found to be by 50.3% and 28.3%, respectively. The soil particles tend to separate in a highly viscous solution that coats the particles causing a reduction in the dry unit weight at higher percentages of GG addition, whereas the OMC increased with the increase in GG dosage owing to the hydrophilic nature of GG (Vydehi and Moghal 2022).

Unconfined compressive strength (UCS) tests on GG-treated soil

UCS tests were performed on untreated and treated soil with different GG contents considering the aging periods of 1, 4, 7, 14, 28, and 60 days to assess the effects of GG on stress–strain behavior, UCS value, elastic modulus (E50), and energy absorption capacity (Ev) of the soil. The untreated and treated soil samples with GG were prepared at their respective MDDs and OMCs using standard compaction effort. In general, the GG addition has a positive effect in improving the unconfined compressive strength of the soil. Figure 10 shows the stress–strain relationships for GG-treated soil samples at different aging periods. The aging period exhibits a noticeable effect on the increase in compressive strength in the case of GG-treated soil. The UCS value of untreated soil was found to be 99.5 kPa at 3.4% failure strain. With GG treatment, the peak axial stress tends to increase, for instance at 1.5% GG content the peak axial stress was found to be 154 kPa exhibiting failure at a larger strain of 4.5% at 1 day of curing. Further, with an increased aging period the peak axial stress value tends to increase, and this trend was observed in all treated soil samples. Meanwhile, despite increase in axial peak stresses with the aging period, it was also observed that the failure strain tends to be smaller compared to the failure strain during the initial aging period. For instance, at 60 days of curing the treated soil with 1.5%, GG content exhibited the peak axial stress of 468 kPa at the axial strain of 3.9%. This shows that even at the higher aging period the failure strain of treated soil is quite comparable with untreated soil intact the ductile behavior. Such ductile behavior is always desirable in engineering practice unlike the traditional admixtures (such as lime or cement) which exhibit significant brittle behavior. Figure 11 presents the different stages of UCS sample preparation for the different aging periods and test execution.

Stages of sample preparation for UCS testing a soil mixed with powdered GG biopolymer, b hand mixing of the soil-GG mixture, c prepared soil sample coming out of UCS mold, d prepared samples at different GG contents, e sample placed in UCS machine, and f appearance of shear planes in the soil after testing

Meanwhile, it is also important to note the engineering behavior of soil treated with 1.5% GG changed from medium-quality subgrade to hard quality, as its UCS value (441 kPa) is greater than the minimum value of 360 kPa for a hard-quality subgrade (Das and Sobhan 2013). The quantitative effects of GG content and aging period on UCS and elastic modulus (E50) of the soil have been illustrated in Fig. 12a and b. Both the UCS and E50 increased with the addition of GG and prolonged aging. The optimum dosage of GG is found to be 1.5% for all aging periods. The increase in UCS values can be attributed to the formation of hydrogels in the pores of soil fabric, which hardened with time and make the soil fabric stiffer with prolonged aging (Sujatha and Saisree 2019). Several investigators (Biju and Arnepalli 2020; Anandha Kumar and Sujatha 2021b; Bozyigit et al. 2021) have also reported similar results on the enhancement of UCS of GG-treated for various kinds of soils from different geological origins.

Similar to UCS values, the E50 is also increasing with the increase in both GG content and the aging time. The elastic modulus of the treated sample at 1-day aging is 6 MPa which increased to 24 MPa when aged for 60 days. According to Young’s modulus criteria for hard soils (E50 ≥ 20 MPa) proposed by Obrzud (2010), the consistency of soil treated with 1.5% GG alters from soft to hard. The correlations of increase in UCS and E50 values of GG-treated soils with aging along with their interrelationships have been presented in Fig. 12c. Linear and power regression analyses between E50 and UCS of GG-treated soil are presented in Eqs. 1 and 2. About 97% of the data points of these models fall within \(\frac{{E}_{50}}{UCS}=65\,\,\mathrm{to}\,\,45\).

Meanwhle, energy absorption capacity (Ev) also shows increasing trends with increased GG content and aging time. Ev of 1.5% GG-soil mix increased from 16.2 to 25.2 kJ/m3 when subjected to an aging period from 1 to 60 days. Linear and exponential correlations have been developed and presented in detail in Fig. 13.

Based on the UCS test results, regression analysis was performed to develop prediction models for the respective increase in UCS, E50, and Ev of treated soil at aging periods shown in Fig. 14. In this model, 92% of data points fall within the 90% upper-lower prediction ranges, so it is an acceptably good prediction model. The list of important regression models developed is summarized in Table 5.

Long-term durability assessment

In essence, the GG biopolymer is organic, so its efficacy considering long-term aging considering the degradation factor is crucial. In this regard, a long-term effect on strength was carried out considering the aging period of 60, 100, and 365 days as presented in Fig. 15. The results show that the stability of stabilized soil did not degrade with time but improved slightly. The UCS and E50 appeared to increase slightly; this rise may also be ascribed to possible long-term variations of hardening/aging. Chang et al. (2015) also observed similar trends of long-term durability. The respective SEM micrographs are also presented to further clarify the transformation of the treated soil matrix with the aging process, as shown in Fig. 16.

Effects of GG on california bearing ratio (CBR)

Figure 17a presents the efficacy of GG inclusion to stabilize expansive soil subgrade. A significant improvement in CBR values can be observed with the addition of GG along with prolonged aging. With 1.5% GG contents as an optimum dosage and 7 days of aging, a respective increase in unsoaked and soaked CBR values by 2.7 and 2.1 times has been observed as compared to the natural soil. This effect further intensified with a 3.8 and 2.7 times increase in unsoaked and soaked CBR values, respectively at 28 days of aging. These results are in line with the findings of other investigators (Biju and Arnepalli 2020; Anandha Kumar and Sujatha 2021b). Unsoaked CBR values are much greater than the soaked values since an additional resistance is offered by the surface frictional forces to the plunger penetration which diminishes in a soaked condition (Petersen et al. 2003). Hence, according to the general specifications of the National Highway Authority (NHA), Pakistan (NHA 1998), the soils treated with 1.5% GG fulfills the minimum requirements of 8% CBR. Resilient modulus (MR) plays a significant role in the design of flexible pavements subjecting to a rapidly applied imposed load (Wang and Baaj 2021). The MR can be measured in the laboratory by performing the cyclic triaxial shear test as described in the AASHTO standard (T307-99 2000). The MR value of treated soil with 1.5 percent GG ranges from 57 to 99 MPa, which is expected to offer adequate support to the applied load (Schaefer et al. 2008). The increase in CBR and MR value considering the aging period is attributed to the hydrogel formation which tends to adhere to the soil particles resulting in the formation of bigger soil particles and hydrogel tends to become stiffer considering the long-term aging effect which ultimately provides better load and better resistance against the imposed load.

Meanwhile, the swelling potential of the expansive subgrade is also measured with the help of a soaked CBR test. From the test results, the soil classification shifts from high expansion to low expansion group after the GG treatment. The swell potential of untreated soil was 7.5%, but it considerably reduced to 1.1% with the addition of 1.5% GG at an aging period of 28 days, as in Fig. 17b. The obtained value of 1.1% swell for treated soil is well below the permissible limit (≤ 2%) (Day 2006). All the stages of sample preparation for CBR testing are presented in Fig. 18.

Stages of sample preparation for CBR testing a hand-mixing of soil and guar gum powder, b sample pouring in CBR mold for compaction, c layer-by-layer compaction of soil-GG mix in CBR mold by modified Proctor hammer, d trimming and leveling of the mix by spatula, e prepared mold placed in the machine for CBR testing, f tested CBR sample, and g dial gages placed on top of mold soaked in water for swell measurement after 4 days

Soil-GG interaction mechanism

The strength improvement at different GG content and aging periods imply that the biopolymer has not decomposed and continues to reinforce the soil matrix via aggregation, hydrogen bonding, and the formation of cross-link elements. Figure 19 presents the SEM micrographs explaining the interaction mechanism of GG-treated soil samples along with EDX analysis at an aging period of 28 days. It is evident from the micrograph illustration that with the increase in GG content, the soil exhibits more coating with biopolymer gel. For instance, at 0.5% GG content the SEM micrographs exhibit some biopolymer gel coating along with some inter and intra-assemblage pore spaces (Fig. 19a), whereas with an increase in GG content, the biopolymer molecules were able to fill the voids between the individual soil grains i.e., at 1.5% content and above, resulting in enhanced strength with dense flocculation, (Fig. 19b–e). The development of hydrogels and cross-link elements in the soil’s microstructure is responsible for the enhanced shear and bearing strengths. The attached EDX profiling also corroborates the presence of such hydrogels in the soil-GG mix.

It has been found that soil-biopolymer specimens subjected to natural air-dried aging conditions are dehydrated more swiftly and result in the formation of hardened biopolymer gel (Wang et al. 2015). This dried biopolymer gel created a thin layer that strongly linked the individual soil grains. After 28 aging days, the soil particles were tightly bound together to form a dense flocculated structure, and the pore spaces were filled by the new hydrogel formations. The visible surface of the clay particles appears to have significantly transformed at this point of the aging process. The detailed mechanism of soil-GG and water interaction and its schematic illustration are presented in Figs. 20 and 21.

Mechanism of soil-GG and water interaction (modified from Latifi et al. (2016))

BET surface area analysis

Figure 22 depicts the results of BET testing on untreated and GG-stabilized soil with prolonged aging for up to 60 days. The increase in the aging period resulted in a substantial reduction in the BET surface area of the stabilized soil samples. The enhanced aggregation of soil particles results in the formation of larger soil aggregates held together by the hydro-gelling, which in addition fills the voids and resultantly a decrease in the total surface area was observed which further verifies the SEM micrographs presented in Fig. 15. The results showed that GG-stabilized soil samples show a substantial drop in BET surface area ranging from 38 of untreated soil to 20 m2/g (28 days aging of 1.5% GG-treated soil), whereas further a slight decremental trend was observed from 20 to 15 m2/g of 1.5% GG-treated soil with the enhanced aging period (60 days aging). The considerable decrement in the surface area proposed that the GG treatment reduced the outside surface area by filling the pore spaces in stabilized soil with a hydro-gelling effect (Latifi et al. 2015). The observed behavior is in line with SEM micrographs results, associated with the physical interaction of GG with soil resulting in the formation of hydrogel which cements the soil particles, fill the voids, and results in the formation of a dense-flocculated structure.

Fourier-transform infrared spectroscopy (FTIR) of soil

Figure 23 displays that there is a backward shift of the absorption band from 3422 of untreated soil to 3414 cm−1 at 1.5% GG-treated soil, and a respective slight forward shift from 1640 to 1649 cm−1. The reinforced soil is also comprised of all other absorption bands. The FTIR data show that there is a difference in the observed spectra before and after stabilization with GG treatment. This is due to the development of new molecular links between the soil and biopolymer, which results in increased UCS and CBR strength (Smitha et al. 2021). A similar trend was also observed by Smitha et al. (2021) on using a similar gel-type agar biopolymer.

Field implications of guar gum biopolymer in geotechnical engineering

Based on its potential attributes, the GG treatment of problematic expansive soils can be employed in different geotechnical-related field applications especially considering the ground improvement. Different important areas could be the possible field of interest for the implication of GG such as the stabilization of expansive soil embankments, expansive soil subgrade improvement, expansive soil slope stability, retaining wall backfill stabilized material, swell potential reducer, erosion control, etc. Besides, as a green non-traditional stabilizer, GG can also be employed for the improvement of various other types of soils (Reddy et al. 2018; Biju and Arnepalli 2020; Onah et al. 2022). Various advantages can be linked to the GG-treated soil such as high resistance to biodegradation, availability, and ecological benefits. GG is very cost-competitive when compared to other traditional admixtures, unlike different chemical stabilization procedures, the construction operation of GG-reinforced soil is unaffected by climate conditions (Kumar and Sujatha 2021). Hence, eco-friendly GG biopolymer may lead to the more prevalent usage of GG-reinforced soil and more economical construction in the geotechnical engineering field.

Conclusions

This study comprehensively examined the efficacy of GG for the treatment of problematic expansive soil. A large number of geotechnical tests were conducted to evaluate the soil consistency, compaction, and CBR behavior considering its long-term behavior. Besides, a detailed study was carried out to understand the underlying stabilization mechanism considering the specialized tests i.e., SEM, EDX, BET, and FTIR. Based on the test outcomes the following conclusions can be drawn from this study:

-

i.

The GG inclusion in expansive soil results in an increase in Atterberg’s limits (LL and PL) owing to the high absorption of water molecules by biopolymer monomers.

-

ii.

GG treatment induces a reduction in MDD with an increase in OMC for both standard and modified compaction effort, owing to the low specific gravity and high absorption capacity of GG biopolymer whereas the modified compaction test results in high MDD associated with the implication of the higher compaction energy compared to the standard compaction effort.

-

iii.

GG treatment induces significant improvement in the UCS values along with the aging period. At 1.5% GG-addition the UCS value significantly improved (i.e., 441 kPa) and E50 (24 MPa) at the aging period of 60 days, transforming the soft quality into the hard quality subgrade. The improved mechanical behavior is attributed to the development and stiffening of the hydrogels due to GG addition which led to the crosslinking of soil grains and provides better resistance to the imposed loading. Further, GG was found to be stable against degradation considering the long-term effect and exhibit further slight improvement at the aging period of 365 days.

-

iv.

The subgrade strength in terms of CBR value was found to be significantly improved with GG inclusion exhibiting an increase of 284% for unsoaked and 176% for soaked CBR of natural soil at 28 aging days. Thus, the stabilized soil fulfills the minimum requirements of 8% CBR as per the design specifications of the National Highway Authority of Pakistan. Besides, the MR value of the treated soil with 1.5% GG ranges from 57 to 99 MPa, which ultimately provides adequate support to the applied external load.

-

v.

SEM micrographs coupled with EDAX profiling corroborated the formation of hydrogels and crosslinking elements in the soil matrix, which fills the voids and reduces the specific surface area along with the curing period. Such behavior is mainly responsible for the enhancement of the UCS and CBR behavior of the stabilized soil. Moreover, the FTIR data showed a difference in the observed spectra before and after GG treatment highlighting the development of new molecular links between the soil and GG biopolymer.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

ASTM D422–63e2 (2007), Standard test method for particle-size analysis of soils, ASTM international, West Conshohocken, PA, www.astm.org

ASTM D2487–17 (2017), Standard practice for classification of soils for engineering purposes (unified soil classification system), ASTM international, West Conshohocken, PA, www.astm.org

ASTM D4318–17e1 (2017), Standard test methods for liquid limit, plastic limit, and plasticity index of soils, ASTM international, West Conshohocken, PA, www.astm.org

ASTM D698–12 (2021), Standard test methods for laboratory compaction characteristics of soil using standard effort (12,400 ft-lbf/ft3 (600 kN-m/m3)), ASTM international, West Conshohocken, PA, www.astm.org

ASTM D1557–12e1 (2012), Standard test methods for laboratory compaction characteristics of soil using modified effort (56,000 ft-lbf/ft3 (2,700 kN-m/m3)), ASTM international, West Conshohocken, PA, www.astm.org

ASTM D2166M-16 (2016), Standard test method for unconfined compressive strength of cohesive soil, ASTM international, West Conshohocken, PA, www.astm.org

Ali M, Aziz M, Hamza M, Madni MF (2020) Engineering properties of expansive soil treated with polypropylene fibers. Geomech Eng 22:227–236. https://doi.org/10.12989/gae.2020.22.3.227

Anandha Kumar S, Sujatha ER (2021a) Assessing the potential of xanthan gum to modify in-situ soil as baseliners for landfills. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-021-03721-4

Anandha Kumar S, Sujatha ER (2021b) Compaction and permeability characteristics of biopolymer-treated soil. In: Lecture notes in civil engineering. pp 107–117

Ayeldeen M, Negm A, El-Sawwaf M, Kitazume M (2017) Enhancing mechanical behaviors of collapsible soil using two biopolymers. J Rock Mech Geotech Eng 9:329–339. https://doi.org/10.1016/j.jrmge.2016.11.007

Ayeldeen MK, Negm AM, El Sawwaf MA (2016) Evaluating the physical characteristics of biopolymer/soil mixtures. Arab J Geosci 9:371

Aziz M, Saleem M, Irfan M (2015) Engineering behavior of expansive soils treated with rice husk ash. Geomech Eng 8:173–186. https://doi.org/10.12989/gae.2015.8.2.173

Biju MS, Arnepalli DN (2020) Effect of biopolymers on permeability of sand-bentonite mixtures. J Rock Mech Geotech Eng 12:1093–1102. https://doi.org/10.1016/j.jrmge.2020.02.004

Bozyigit I, Javadi A, Altun S (2021) Strength properties of xanthan gum and guar gum treated kaolin at different water contents. J Rock Mech Geotech Eng 13:1160–1172. https://doi.org/10.1016/j.jrmge.2021.06.007

Brunauer S, Emmett PH, Teller E (1938) Adsorption of gases in multimolecular layers. J Am Chem Soc 60:309–319. https://doi.org/10.1021/ja01269a023

Chang I, Cho G-C (2019) Shear strength behavior and parameters of microbial gellan gum-treated soils: from sand to clay. Acta Geotech 14:361–375

Chang I, Cho GC (2014) Geotechnical behavior of a beta-1,3/1,6-glucan biopolymer-treated residual soil. Geomech Eng 7:633–647

Chang I, Im J, Cho G-C (2016) Geotechnical engineering behaviors of gellan gum biopolymer treated sand. Can Geotech J 53:1658–1670

Chang I, Im J, Prasidhi AK, Cho GC (2015) Effects of xanthan gum biopolymer on soil strengthening. Constr Build Mater 74:65–72. https://doi.org/10.1016/j.conbuildmat.2014.10.026

Chen R, Zhang L, Budhu M (2013) Biopolymer stabilization of mine tailings. J Geotech Geoenviron Eng 139:1802–1807. https://doi.org/10.1061/(asce)gt.1943-5606.0000902

Chudzikowski RJ (1971) Guar gum and its applications. J Soc Cosmet Chem 22:43

Das (2013) Principles of geotechnical engineering. Cengage learning

Day RW (2006) Foundation engineering handbook: design and construction with the 2006 international building code. McGraw-Hill

El-Daw GEA (1994) A study of guar seed anf guar gum properties (Cyamopsis tetragonolabous). University of Khartoum, Faculty of Agriculture

Gupta SC, Hooda KS, Mathur NK, Gupta S (2009) Tailoring of guar gum for desert sand stabilization. Indian J Chem Technol 16:507–512

Hamza M, Aziz M, Xiang W et al (2022a) Strengthening of high plastic clays by geotextile reinforcement. Arab J Geosci 15:805. https://doi.org/10.1007/s12517-022-09972-w

Hamza M, Ijaz N, Fang C, Ijaz Z (2022b) Stabilization of problematic expansive clays using polypropylene fiber reinforcement. Jordan J Civ Eng 16:531–539

Hamza M, Nie Z, Aziz M et al (2022c) Strengthening potential of xanthan gum biopolymer in stabilizing weak subgrade soil. Clean Technol Environ Policy. https://doi.org/10.1007/s10098-022-02347-5

Hamza M, Nie Z, Aziz M et al (2022d) Geotechnical properties of problematic expansive subgrade stabilized with xanthan gum biopolymer. Road Mater Pavement Des. https://doi.org/10.1080/14680629.2022.2092027

Ijaz N, Dai F, Meng L et al (2020a) Integrating lignosulphonate and hydrated lime for the amelioration of expansive soil: a sustainable waste solution. J Clean Prod 254:119985. https://doi.org/10.1016/j.jclepro.2020.119985

Ijaz N, Dai F, Rehman Z, ur, (2020b) Paper and wood industry waste as a sustainable solution for environmental vulnerabilities of expansive soil: a novel approach. J Environ Manage 262:110285. https://doi.org/10.1016/j.jenvman.2020.110285

Ijaz N, Ye W, Rehman Z, ur et al (2022) New binary paper/wood industry waste blend for solidification/stabilisation of problematic soil subgrade: macro-micro study. Road Mater Pavement Des. https://doi.org/10.1080/14680629.2022.2064905

Khan MI, Irfan M, Aziz M, Khan AH (2017) Geotechnical characteristics of effluent contaminated cohesive soils. J Environ Eng Landsc Manag 25:75–82. https://doi.org/10.3846/16486897.2016.1210155

Kumar SA, Sujatha ER (2021) Experimental investigation on the shear strength and deformation behaviour of xanthan gum and guar gum treated clayey sand. Geomech Eng 26:101–115

Latifi N, Horpibulsuk S, Meehan CL et al (2017) Improvement of problematic soils with biopolymer—an environmentally friendly soil stabilizer. J Mater Civ Eng 29:04016204. https://doi.org/10.1061/(asce)mt.1943-5533.0001706

Latifi N, Horpibulsuk S, Meehan CL et al (2016) Xanthan gum biopolymer: an eco-friendly additive for stabilization of tropical organic peat. Environ Earth Sci. https://doi.org/10.1007/s12665-016-5643-0

Latifi N, Marto A, Eisazadeh A (2015) Analysis of strength development in non-traditional liquid additive-stabilized laterite soil from macro-and micro-structural considerations. Environ Earth Sci 73:1133–1141. https://doi.org/10.1007/s12665-014-3468-2

Mahmoud NM (2000) Physico-chemical study on guar gum

Mudgil D, Barak S, Khatkar BS (2014) Guar gum: processing, properties and food applications—a review. J Food Sci Technol 51:409–418. https://doi.org/10.1007/s13197-011-0522-x

Muguda S, Booth SJ, Hughes PN et al (2017) Mechanical properties of biopolymer-stabilised soil-based construction materials. Géotech Lett 7:309–314. https://doi.org/10.1680/jgele.17.00081

Nugent RA, Zhang G, Gambrell RP (2009) Effect of exopolymers on the liquid limit of clays and its engineering implications. Transp Res Rec 2101:34–43

Obrzud RF, Truty A (2018) The hardening soil model—a practical guidebook. Zace Serv Ltd Softw Eng 05:205

Onah HN, Nwonu DC, Ikeagwuani CC (2022) Feasibility of lime and biopolymer treatment for soft clay improvement: a comparative and complementary approach. Arab J Geosci 15:337. https://doi.org/10.1007/s12517-022-09552-y

Petersen D, Link R, Pandian N, Krishna K (2003) The pozzolanic effect of fly ash on the california bearing ratio behavior of black cotton soil. J Test Eval 31:11586

Puppala AJ, Pedarla A (2017) Innovative ground improvement techniques for expansive soils. Innov Infrastruct Solut 2:1–15. https://doi.org/10.1007/s41062-017-0079-2

Reddy NG, Rao BH, Reddy KR (2018) Biopolymer amendment for mitigating dispersive characteristics of red mud waste. Geotech Lett 8:201–207. https://doi.org/10.1680/JGELE.18.00033

Schaefer VR, White DJ, Ceylan H, Stevens LJ (2008) Design guide for improved quality of roadway subgrades and subbases. Iowa Highw Res Board 7:8–72

Shimizu Y, Tanabe T, Yoshida H et al (2018) Viscosity measurement of xanthan–poly(vinyl alcohol) mixture and its effect on the mechanical properties of the hydrogel for 3D modeling. Sci Rep 8:16538. https://doi.org/10.1038/s41598-018-34986-4

Smitha S, Rangaswamy K, Keerthi DS (2021) Triaxial test behaviour of silty sands treated with agar biopolymer. Int J Geotech Eng 15:484–495. https://doi.org/10.1080/19386362.2019.1679441

Soldo A, Miletić M, Auad ML (2020) Biopolymers as a sustainable solution for the enhancement of soil mechanical properties. Sci Rep 10:1–13. https://doi.org/10.1038/s41598-019-57135-x

Specifications G (1998) National highway authority (NHA), NHA Headquarters, 27-Mauve Area. G-9/1, Islamabad, Pakistan

Subramani AK, Ramani SE, Selvasembian R (2021) Understanding the microstructure, mineralogical and adsorption characteristics of guar gum blended soil as a liner material. Environ Monit Assess 193:855. https://doi.org/10.1007/s10661-021-09644-4

Sujatha ER, Saisree S (2019) Geotechnical behaviour of guar gum-treated soil. Soils Found 59:2155–2166. https://doi.org/10.1016/j.sandf.2019.11.012

T307–99 A (2000) Standard method of test for resilient modulus of subgrade soils and untreated base/subbase materials

Vydehi KV, Moghal AAB (2022) Effect of biopolymeric stabilization on the strength and compressibility characteristics of cohesive soil. J Mater Civ Eng 34:4021428. https://doi.org/10.1061/(ASCE)MT.1943-5533.0004068

Wang H, Wang Z, Blight RJ, Sheehy EC (2015) Derivation of pay adjustment for in-place air void of asphalt pavement from life-cycle cost analysis. Road Mater Pavement Des 16:505–517. https://doi.org/10.1080/14680629.2015.1020848

Wang L, Weng Z, Liu Q et al (2021) Improving the mechanical properties of red clay using xanthan gum biopolymer. Int J Polym Sci 2021:1–16. https://doi.org/10.1155/2021/1535772

Wang S-L, Baaj H (2021) Treatment of weak subgrade materials with cement and hydraulic road binder (HRB). Road Mater Pavement Des 22:1756–1779. https://doi.org/10.1080/14680629.2020.1712224

Acknowledgements

The authors gratefully acknowledge the laboratory and technical support provided by the Geotechnical Engineering Laboratory at the School of Civil Engineering, Central South University, Changsha, China, College of Civil Engineering, Tongji University, and the University of Lahore, Lahore, Pakistan.

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

MH: Conceptualization, Validation, Formal analysis, Investigation, Writing—Original Draft, Review, and editing. ZN: Supervision, Project, Administration, Review, and editing. MA: Visualization, Formal analysis, Review, and editing. NI: Conceptualization, Validation, Formal analysis, Investigation, Writing—Original Draft, Review, and editing. CF: Visualization, Formal analysis, Review, and editing. MUG: Methodology, Software, Validation, Review, and editing. ZI: Conceptualization, Investigation, Writing—Original Draft, Review, and editing. SN: Methodology, Investigation, Visualization, Review, and editing. MS: Visualization, Formal analysis, Review, and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hamza, M., Nie, Z., Aziz, M. et al. Geotechnical properties of problematic expansive subgrade stabilized with guar gum biopolymer. Clean Techn Environ Policy 25, 1699–1719 (2023). https://doi.org/10.1007/s10098-023-02466-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-023-02466-7