Abstract

Sand reinforced with hydraulic binder (cement) has played an important role in recent decades. However, the natural properties of soil have deteriorated due to pollution resulting from excessive use of cement. Today, the use of biopolymers as a soil improvement method has become very popular. However, since biopolymers are organic and degradable, their long-term effects are not fully understood.

This study investigates the effectiveness of using xanthan gum as a binding agent to improve the shear strength and volume change behavior of Chlef sandy soil. Samples were prepared with varying xanthan gum percentages (XG = 0.25%, 0.5%, and 1%) and curing times (7, 14, and 30 days) at a medium relative density (Dr = 50%). The samples were subjected to normal stresses of 50 kPa, 100 kPa, and 200 kPa.

Results showed significant improvement in the shear strength, cohesive intercept, and friction angle of the treated sand. The study highlights the potential of using xanthan gum as a microbiological binding agent and provides insights for the long-term effectiveness of sand reinforcement.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Due to increasing demands for environmentally friendly and sustainable applications in soil improvement procedures, biological remediation materials such as biopolymers have become more widespread (Bağrıaçık and Mahmutluoğlu 2021). In addition to increasing shear strength, biopolymers have also been employed to improve the hydraulic behavior of soils by filling the voids in a soil medium and adsorbing water, thus causing expansion of the soil. While chemical admixtures like lime, cement, bituminous materials, fly ash, calcium, and carbide have normally been used for construction purposes (Kumar and Sujatha 2021; Sujatha et al. 2020), they leave a permanent and irreversible mark on the environment. Ecological concerns and the need for sustainable development demand an environment-friendly stabilization technique. Biopolymers like chitosan, sodium alginate, beta-glucan, and xanthan show great potential for replacing traditional admixtures as soil additives (Sujatha et al. 2020).

The main purpose of soil treatment and improvement (i.e., engineered soil) is to enhance the engineering characteristics (Stabilization of Soil Using Flyash 2016). Two primary methods have consisted of mechanical and chemical treatments. Mechanical improvements were obtained by reinforcing the strength of the soil through physical processes such as compaction (Ehrlich et al. 2012; Reinforcement 2019; Hejazi et al. 2012; Kumar 2020), drainage (Mujahid et al. 2020; Yang et al. 2018; Correia et al. 2021; Kerry Rowe and Lunzhu Li 1999), external loading (Hamza et al. 2011; Lo et al. 2020; Lynch et al. 2019; Deng et al. 2019), consolidation (Pradhan et al. 2011; Moghaddas Tafreshi et al. 2021), and the use of geosynthetics (Benziane et al. 2019; Denine et al. 2016; Barrett 1967; Symposium on polymer grid reinforcement in civil engineering 1984; Eith and Koerner 1992). Similarly, chemical treatments involved hydration or pozzolanic reactions inside the soil to create artificial binding.

Portland cement has been the primary soil treatment technique due to its high strength and durability, workability, and hydraulicity, as well as low cost. However, despite the cement’s benefits and its numerous applications, overdependence and overuse have given rise to environmental concerns. It has been reported that CO2 emissions related to the usage of cement in geotechnical applications (e.g., mixing, grouting, soil stabilization) amounted to approximately 2% of the total global CO2 emissions (Chen et al. 2018; Plank 2005). Furthermore, the presence of cement inside the soil quickly raises the pH up to 12–13, due to the release of alkaline hydroxide (OH-) ions as a byproduct of hydration (Taylor 1997). This increase in pH has detrimental effects on biological organisms (Hansen 2002). Additionally, as the hydration reaction of cement is irreversible, it is difficult to return soil–cement mixtures to their original state. To address these problems, the geotechnical industry began introducing chemically synthesized polymers as soil conditioners, including polyacrylamide (PAM) (Narjary et al. 2012), anionic polyacrylamide (PAM) (Malik and Letey 1991; Laird 1997), acrylics, lignosulfonates, and phenolasts, especially for sandy soils. However, chemically synthesized polymers and solutions have raised concerns about toxicity and water pollution problems (Karol 2003).

To help counteract these problems, the geotechnical industry began actively investigating biological approaches as an alternative to traditional soil treatment and improvement techniques (Estabragh et al. 2014), including microbe injection and by-product precipitation. In particular, the introduction of microbial-induced polymers or biopolymers as a new type of construction binder, especially for soil treatment and improvement.

In the current investigation, direct shear box tests were carried out to evaluate the effectiveness of microbiological techniques in improving the shear properties of soil using xanthan gum as an eco-friendly biopolymer cement obtained from microbial sources. Results were presented and discussed on the effect of xanthan gum content, curing time, and normal stress on the shear strength of reinforced soil. We can say that the effect of the previous parameters on the efficacy of xanthan gum treatment is more effective on the earth's surface layers.

This paper is structured as follows: in Sect. 2, we provide a detailed description of the methodology used in the laboratory testing of the biocemented Chlef sandy soil. Section 3 presents the results and discussion of the laboratory testing, including the maximum shear strength, cohesion intercept, and internal friction angle of the treated sand. In Sect. 4, we have a validation and in Sect. 5, we provide conclusions.

We emphasize that our use of xanthan gum as a biopolymer for soil stabilization and investigation of the long-term effectiveness of biocemented sandy soil are unique contributions to the field of geotechnical engineering.

2 Materials and Methods

2.1 Materials

2.1.1 Soil

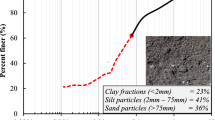

The soil used for this study was collected from the riverbanks of Chlef in northern Algeria (see Fig. 1). Durville and Meneroud (1982) reported that the soil in this region liquefied during an earthquake in October 1980. The soil was classified as poorly graded sand (SP), and its grain size distribution curve is shown in Fig. 2 according to ASTM D-422. The engineering properties of Chlef sand are presented in Table 1.

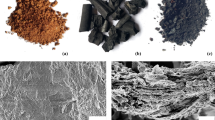

2.1.2 Biopolymer Additive

Xanthan gum, a polysaccharide that is made by the Xanthomonas campestris bacterium, is generally used as a viscosity thickener due to its hydrocolloid rheology (Barrére et al. 1986). Xanthan gum has gained great interest in geotechnical engineering due to the variety in strength it adds to soil (Hong et al. 2019; Bouazza et al. 2009; Nugent et al. 2009; Chang et al. 2015). The simplified chemical structure of xanthan gum (C35H49O29) is a linear linked b-D glucose backbone with a trisaccharide side chain attached to each glucose. The trisaccharide side chain and the backbone are in alignment, providing stability and conformity throughout the structure by the formation of hydrogen bonds (Latifi et al. 2016). The xanthan gum was obtained from Eurl Pro Lysa company Algiers.

2.2 Test Procedures

Thirty-six direct shear box tests were conducted in this study on untreated and treated sand with different Xanthan gum contents of 0, 0.25, 0.5 and 1% by dry soil mass (see Research Methodology in Fig. 3). The tests were conducted on sand samples subjected to three normal stresses of 50, 100 and 200 kPa and prepared at an initial relative density of 50% representing medium dense state. It was crucial to maintain consistency between the specimens prepared for testing. Therefore, great care was taken to have reasonable repeatability during the preparation of the specimens to be tested. All the tests were conducted at the Laboratory of Materials Science and Environment (LMSE) at University Hassiba Benbouali of Chlef in Algeria. Xanthan gum treatment tests were conducted using a standard laboratory Shear strength apparatus with a box specimen of 60 × 60 mm (see Fig. 3a). The thickness of all samples was 25 mm. Each test was repeated multiple times to ensure the results reliability. All the parameters considered in the testing program are listed in Table 2.

3 Results and Discussion

3.1 Effect of Xanthan Gum Content on the Shear Strength

Figure 4 shows the evolution of maximum shear strength τmax (kPa) as function of normal stress Ϭn (kPa) of untreated and treated soil samples with Xanthan gum with different gum contents by dry sand mass XG (%) for different curing periods T (Days) at a medium dense state (Dr = 50%). It can be noted from the figure that the resistance of sand characterized by the shear stress increased significantly with the addition of xanthan gum. This effect was presumably a result of the formation of thicker biopolymer films due to the higher xanthan gum content (Lee et al. 2019). Additionally, curing time had an important consequence on the maximum shear strength of the sand-biopolymer mixture. The maximum values of shear strength for samples treated with xanthan gum at a normal stress of 100 kPa at 7 days of curing were 300.42, 347.44 and 392 kPa compared to 367.78, 405.11 and 454.17 kPa for treated samples at 30 days of curing for xanthan gum contents of 0.25%, 0.5%, and 1%, respectively. This increase in strength was due to the electrically charged nature of clay particles present in the soil. Direct interaction between fine particles and xanthan gum occurred and increased the attractive forces leading in a growth of cementitious products with time that welded the soil particles together (Latifi et al. 2016). Similar results were found by Cabalar et al. (Cabalar et al. 2017) on xanthan gum treated sand samples.

3.2 Influence of Xanthan Gum on Soil Volumetric Behaviour

The vertical displacement as a function of horizontal displacement of untreated and treated sand specimens are illustrated in Fig. 5 for different xanthan gum contents of XG = 0; 0.25; 0.5 and 1% and curing periods of 7, 14 and 30 days. The introduction of xanthan gum affected the soil volumetric behaviour since treated sand specimens showed a more pronounced dilation (i.e., expansion) compared with untreated specimens. This dilative behavior was amplified with an increase in xanthan gum content. In addition, it was noted that an increase of curing period had a similar effect to that of xanthan gum content on the dilation of biopolymer treated sandy soil. Samples cured for longer periods of time showed a noticeable accentuation in the soil dilatancy. It can be argued that this amplification of behavior was mainly due to the formation of a condensed biofilm that became thicker as the xanthan gum content increased, resulting in a more brittle and dilative behaviour. These results agree with (Chang et al. 2020).

3.3 Effect of Xanthan Gum on the Strength Properties

Figure 6 provides a visual representation of the evolution of maximum shear strength for samples of untreated and treated sand with xanthan gum, which were prepared to achieve a medium dense state. The data presented in the figure demonstrates that the maximum shear strength of the samples increased with increasing xanthan gum content, curing period, and normal stress. This suggests that the addition of xanthan gum to the sand has a positive impact on its strength, which is an important finding that could have practical applications in various industries. Furthermore, the fact that these results are in agreement with the findings of a previously reported study (Missoum Benziane et al. 2022) adds weight to the reliability and validity of the current study. This further strengthens the scientific understanding of the topic and suggests that the findings presented in this paper are consistent with other studies in the field. Overall, the results presented in Fig. 6 provide valuable insights into the potential benefits of treating sand with xanthan gum and could inform future research and development efforts in this area.

The Mohr–Coulomb circle associated with the various tests relating to untreated and treated sand results in the following Eq. 1:

where: α is the slope of the line (friction angle) and β is the intercept expressing the cohesion of the studied sand.

The values of two parameters, cohesion and angle of internal friction, calculated from the intrinsic equations, were plotted in Fig. 7 as a function of xanthan gum content and curing period. Figure 7a shows a remarkable increase in the cohesion values of xanthan gum-sand mixtures since biopolymer-induced soil strengthening was mainly attributed to the improvement of inter-particle cohesion (Latifi et al. 2016); (Ayeldeen et al. 2017; Lee et al. 2017). The cohesion of xanthan gum-treated sand specimens increased proportionally with an increase in gum percentage in the specimen. For a cure period of 7 days, samples prepared at 0.25% gum content had a cohesion value of 260.47 kPa, compared to 295.4 kPa for a content of 0.5% and up to 333.04 kPa for a content of 1%. It was noticeable from the results that the addition of xanthan gum changed the characteristics of the mixture to make it behave as cohesive soil. The same observation can be made regarding the effect of curing time. It can be noted that an increase in curing period drastically increased the cohesion values of the sand-biopolymer mixture. Cohesion values for a fixed gum content of 0.5% by dry sand mass and cured for 7 days were found to be 248.23 kPa, compared to 295.4 kPa for a curing period of 14 days and up to 351.55 kPa for a curing period of 30 days.

However, the addition of Xanthan gum to sand did not seem to greatly affect the internal friction angle (Fig. 7b). we can say that the effect of the biopolymer on the grain surfaces decreases slightly the microscale roughness, thereby reducing the asperity interlocking of sand grains, which led to only a slight reduction in the friction angle (Lee et al. 2019).

3.4 Effect of Xanthan Gum on the Strength Ratio

The strength ratio (Sr) was calculated for each treated sample to assess the effect of reinforcement at different Xanthan gum contents and different curing periods. According to Latha and Murthy (2007) the strength stress ratio is defined by the following relationship, Eq. 2:

where, \({\tau }_{\mathrm{max}}\) is the maximum shear strength of treated sand and \({\tau }_{u}\) is the maximum shear strength of untreated sand.

Figure 8 shows the variation of the strength ratio for treated sand with Xanthan gums under different normal stresses (Ϭn = 50, 100, 200 kPa). It was observed that the shear strength ratio increased with an increase in Xanthan gum content and decreased with an increase in normal stress.

The results indicated that the strength ratio increased with increasing Xanthan gum content where specimens reinforced with 1% gum exhibited more strength than untreated sand or samples with a lower gum percentage (i.e., 0.25% and 0.5%).

In the case of curing period, it was observed that the maximal strength ratio values were recorded at the longest curing periods (Fig. 8). It can be deduced that the longer the curing period the higher the shear strength ratio as shown in Figs. 8a to 8c where it was observed that specimens reinforced after 30 days of curing exhibited greater strength than those with shorter periods (i.e., 7 and 14 days).

All reinforced specimens presented a strength ratio superior to or equal to 1, where the greater Sr values were those samples prepared with 1% gum content for a curing period of 30 days (Sr = 9.87). However, it can be noticed in Figs. 8a to 8c, that there was a decrease in strength ratios with increasing normal stress. For example, the strength ratios of treated samples with 0.5% gum at 14 days curing period were 7.35, 4.67 and 2.49 for normal stresses of 50, 100 and 200 kPa, respectively. From the results, it seemed that the normal stress contribution in the soil strength enhancement diminished the contribution of the reinforcing agent. Similar findings were reported by numerous researchers active in the field of soil reinforcement (Benziane et al. 2019, 2021; Denine et al. 2016).

Nonetheless, the study concluded that the use of xanthan gum as a bio-treatment can improve the shear strength of soils at shallow depths. (Lee et al. 2019) (Missoum Benziane et al. 2022).

3.5 Effect of Xanthan Gum on Soil Stiffness

The brittleness index was used in this study to investigate the influence of biopolymer treatment on the stiffness of soils. Brittleness index values were calculated using Eq. 3:

where, BI is the brittleness index, τmax and τres are the peak and residual shear strengths respectively.

Figure 9 shows the changes in the brittleness index of biocemented Chlef sand at different xanthan gum contents and different curing periods. The results indicated that the brittleness index of bio-cemented sand samples increased with the increase of curing period due to the growth and thickening of cementitious products with time that weld the soil particles together consecutively increasing the soils stiffness.

4 Validation

To validate the results obtained in this study on the shear behavior of biocemented Chlef sandy soil, several steps were taken to ensure the accuracy and reliability of the data.

First, the samples were prepared and tested according to standard protocols and procedures. The testing equipment was calibrated before each test, and the tests were performed by trained technicians to ensure consistency and repeatability.

To check the accuracy of the test results, we conducted multiple tests on each sample under different conditions. For example, we tested the samples at different normal stresses and biocement concentrations.

In addition, we validated the results by comparing them to those obtained from previous studies on the shear behavior of sandy soil. We used data from established studies to verify that the results obtained in this study were consistent with the trends observed in previous research. Few studies have been conducted to investigate the effect of xanthan gum content on the strength properties of the sand. In this section, a comparative study will be conducted to compare the results of this research with those presented in the literature. It has been noted that the results of the present study are in good agreement with those found by Misoum Benziane et al. (Missoum Benziane et al. 2022) and Berkane et al.2022 (Berkane et al. 2022), which adds further support to the potential use of xanthan gum as a reinforcement material for sand.

Figure 10 provides a visual representation of the evolution of maximum shear strength for samples of treated sand with xanthan gum, which were prepared to achieve a medium dense state. The data presented in the figure demonstrates that the maximum shear strength of the samples increased with increasing xanthan gum content and normal stress.

Overall, the validation steps taken in this study demonstrate the accuracy and reliability of the data presented in this paper. The results are consistent with the expected behavior of biocemented Chlef sandy soil, and the statistical analyses support the conclusions drawn from the data.

5 Conclusions

In this study, laboratory tests were conducted on untreated and xanthan gum-treated Chlef sand at different curing periods and xanthan gum contents to investigate their influence on the shearing behavior of Chlef sandy soil. Based on the findings of this study, the following conclusions can be drawn:

Firstly, the maximum shear strength of Chlef natural sand treated with xanthan gum increased significantly with an increase in xanthan gum content, curing period, and normal stress. However, the reinforcing effect of biopolymer treatment was found to be less effective with an increase in normal stress. The cohesion intercept was considerably increased by biopolymer treatment, but no significant impact was observed on the internal friction angle.

Secondly, the treated sand showed a more dilative behavior with increasing xanthan gum content due to the formation of thicker biofilms. The bio-cementation process of treated mixtures led to a decrease in the composite's ductility. Moreover, the brittleness of xanthan gum-treated sand samples increased at longer curing periods.

Overall, these findings provide valuable insights into the long-term effectiveness of sand reinforced with hydraulic binder cement. However, there are certain limitations to this study, such as the fact that it was conducted on a specific type of sand in a laboratory setting. Therefore, further investigations are required to verify the findings of this study and to explore the potential of xanthan gum treatment in enhancing the mechanical properties of other types of soils.

In conclusion, this study has contributed to the understanding of the behavior of xanthan gum-treated sandy soil and has provided a foundation for future research in the fields of biology and geotechnical engineering. The findings of this study could potentially lead to the development of new techniques for improving the strength and stability of soils, thereby benefiting various industries that rely on soil stability, such as construction and agriculture.

Data Availability

Not applicable.

References

Ayeldeen, M., Negm, A., El-Sawwaf, M., Kitazume, M.: Enhancing mechanical behaviors of collapsible soil using two biopolymers. J Rock Mech Geotech Eng 9(2), 329–339 (2017). https://doi.org/10.1016/j.jrmge.2016.11.007

Bağrıaçık, B., Mahmutluoğlu, B.: Model experiments on coarse-grained soils treated with xanthan gum biopolymer. Arab. J. Geosci. 14(16), 1–10 (2021). https://doi.org/10.1007/s12517-021-08134-8

Barrére, G.C., Barber, C.E., Daniels, M.J.: Molecular cloning of genes involved in the production of the extracellular polysaccharide xanthan by Xanthomonas campestris pv campestris. International Journal of Biological Macromolecules 8(6), 372–374 (1986). https://doi.org/10.1016/0141-8130(86)90058-9

Barrett, R. J. (1967). Use of Plastic Filters in Coastal Structures. Coastal Engineering 1966. https://doi.org/10.1061/9780872620087.062

Benziane, M.M., Della, N., Denine, S., Sert, S., Nouri, S.: Effect of randomly distributed polypropylene fiber reinforcement on the shear behavior of sandy soil. Studia Geotechnica Et Mechanica 41(3), 151–159 (2019). https://doi.org/10.2478/sgem-2019-0014

Benziane, M. M., Della, N., Sert, S., Denine, S., Nouri, S., Bol, E., & Elroul, A. B. (2021). Shear behaviour of sandy soil from Chlef river reinforced with different types of fibres. Marine Georesources & Geotechnology, 1–11. https://doi.org/10.1080/1064119x.2021.1984619.

Berkane, H.A., Della, N., Benziane, M.M., et al.: Laboratory investigation on the effect of a combination of xanthan gum and clay on the behavior of sandy soil. Innov. Infrastruct. Solut. 7, 269 (2022). https://doi.org/10.1007/s41062-022-00867-z

Bouazza, A., Gates, W.P., Ranjith, P.G.: Hydraulic conductivity of biopolymer-treated silty sand. Géotechnique 59(1), 71–72 (2009). https://doi.org/10.1680/geot.2007.00137

Cabalar, A.F., Wiszniewski, M., Skutnik, Z.: Effects of Xanthan Gum Biopolymer on the Permeability, Odometer, Unconfined Compressive and Triaxial Shear Behavior of a Sand. Soil Mech. Found. Eng. 54(5), 356–361 (2017). https://doi.org/10.1007/s11204-017-9481-1

Chang, I., Im, J., Prasidhi, A.K., Cho, G.-C.: Effects of Xanthan gum biopolymer on soil strengthening. Constr. Build. Mater. 74, 65–72 (2015). https://doi.org/10.1016/j.conbuildmat.2014.10.026

Chang, I., Lee, M., Tran, A.T.P., Lee, S., Kwon, Y.-M., Im, J., Cho, G.-C.: Review on biopolymer-based soil treatment (BPST) technology in geotechnical engineering practices. Transp Geotech 24, 100385 (2020). https://doi.org/10.1016/j.trgeo.2020.100385

Chen, T., Hong, L., Shi, C.: Forecasting Chinese cement production: An improved grey forecasting model. Resour. Policy 57, 78–85 (2018). https://doi.org/10.1016/j.resourpol.2018.02.003

Correia, N.S., Rocha, S.A., Lodi, P.C., McCartney, J.S.: Shear strength behavior of clayey soil reinforced with polypropylene fibers under drained and undrained conditions. Geotext. Geomembr. 49(5), 1419–1426 (2021). https://doi.org/10.1016/j.geotexmem.2021.05.005

Deng, J.H., Lee, J.W., Lo, W.: Closed-form solutions for one-dimensional consolidation in saturated soils under different waveforms of time-varying external loading. J. Hydrol. 573, 395–405 (2019). https://doi.org/10.1016/j.jhydrol.2019.03.087

Denine, S., Della, N., Dlawar, M.R., Sadok, F., Canou, J., Dupla, J.-C.: Effect of Geotextile Reinforcement on Shear Strength of Sandy Soil: Laboratory Study. Studia Geotechnica Et Mechanica 38(4), 3–13 (2016). https://doi.org/10.1515/sgem-2016-0026

Ehrlich, M., Mirmoradi, S.H., Saramago, R.P.: Evaluation of the effect of compaction on the behavior of geosynthetic-reinforced soil walls. Geotext. Geomembr. 34, 108–115 (2012). https://doi.org/10.1016/j.geotexmem.2012.05.005

Eith, A. W., & Koerner, R. M. (1992). Field Evaluation of Geonet Flow Rate (Transmissivity) under Increasing Load. Geosynthetics in Filtration, Drainage and Erosion Control, 153–165. https://doi.org/10.1016/b978-1-85166-796-3.50015-3

Estabragh, A.R., Rafatjo, H., Javadi, A.A.: Treatment of an expansive soil by mechanical and chemical techniques. Geosynth. Int. 21(3), 233–243 (2014). https://doi.org/10.1680/gein.14.00011

Geosynthetics Reinforcement. (2019). Geosynthetic Reinforced Soil (GRS) Walls, 181–229. https://doi.org/10.1002/9781119375876.ch4

Hamza, M.A., Al-Adawi, S.S., Al-Hinai, K.A.: Effect of combined soil water and external load on soil compaction. Soil Research 49(2), 135 (2011). https://doi.org/10.1071/sr09144

Hansen, P.: Effect of high pH on the growth and survival of marine phytoplankton: implications for species succession. Aquat. Microb. Ecol. 28, 279–288 (2002). https://doi.org/10.3354/ame028279

Hejazi, S.M., Sheikhzadeh, M., Abtahi, S.M., Zadhoush, A.: A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 30, 100–116 (2012). https://doi.org/10.1016/j.conbuildmat.2011.11.045

Hong, E., Jeong, M.S., Lee, K.S.: Optimization of nonisothermal selective plugging with a thermally active biopolymer. J. Petrol. Sci. Eng. 173, 434–446 (2019). https://doi.org/10.1016/j.petrol.2018.10.041

Karol, R.H.: Chem. Grouting Soil Stabilization. (2003). https://doi.org/10.4324/9780429213830

Kerry Rowe, R., Lunzhu Li, A.: Reinforced embankments over soft foundations under undrained and partially drained conditions. Geotext. Geomembr. 17(3), 129–146 (1999). https://doi.org/10.1016/s0266-1144(98)00035-1

Kumar, S.A., Sujatha, E.R.: Experimental investigation on the shear strength and deformation behaviour of xanthan gum and guar gum treated clayey sand. Geomechanics and Engineering 26(2), 101–115 (2021). https://doi.org/10.12989/GAE.2021.26.2.101

Laird, D.A.: BONDING BETWEEN POLYACRYLAMIDE AND CLAY MINERAL SURFACES. Soil Sci. 162(11), 826–832 (1997). https://doi.org/10.1097/00010694-199711000-00006

Latha, G.M., Murthy, V.S.: Effects of reinforcement form on the behavior of geosynthetic reinforced sand. Geotext. Geomembr. 25(1), 23–32 (2007). https://doi.org/10.1016/j.geotexmem.2006.09.002

Latifi, N., Horpibulsuk, S., Meehan, C. L., Majid, M. Z. A., & Rashid, A. S. A. (2016). Xanthan gum biopolymer: an eco-friendly additive for stabilization of tropical organic peat. Environmental Earth Sciences, 75(9). https://doi.org/10.1007/s12665-016-5643-0

Lee, S., Chang, I., Chung, M.-K., Kim, Y., Kee, J.: Geotechnical shear behavior of Xanthan Gum biopolymer treated sand from direct shear testing. Geomech Eng 12(5), 831–847 (2017). https://doi.org/10.12989/gae.2017.12.5.831

Lee, S., Chung, M., Park, H.M., Song, K.-I., Chang, I.: Xanthan Gum Biopolymer as Soil-Stabilization Binder for Road Construction Using Local Soil in Sri Lanka. J. Mater. Civ. Eng. 31(11), 06019012 (2019). https://doi.org/10.1061/(asce)mt.1943-5533.0002909

Lo, W., Borja, R.I., Deng, J.H., Lee, J.W.: Analytical solution of soil deformation and fluid pressure change for a two-layer system with an upper unsaturated soil and a lower saturated soil under external loading. J. Hydrol. 588, 124997 (2020). https://doi.org/10.1016/j.jhydrol.2020.124997

Lynch, K., Sivakumar, V., Tripathy, S., Hughes, D.: Development of a laboratory technique for obtaining soil water retention curves under external loading in conjunction with high-capacity tensiometers. Géotechnique 69(4), 320–328 (2019). https://doi.org/10.1680/jgeot.17.p.176

Malik, M., Letey, J.: Adsorption of Polyacrylamide and Polysaccharide Polymers on Soil Materials. Soil Sci. Soc. Am. J. 55(2), 380 (1991). https://doi.org/10.2136/sssaj1991.03615995005500020014x

Missoum Benziane, M., Della, N., Bedr, S., Flitti, A., Kaddour Djebbar, M., & Baizid, M. (2022). Mechanical behavior of bio-cemented silty sand. Arabian Journal of Geosciences, 15(7). https://doi.org/10.1007/s12517-022-09776-y

Moghaddas Tafreshi, S.N., Parvizi Omran, M., Rahimi, M., Dawson, A.: Experimental investigation of the behavior of soil reinforced with waste plastic bottles under cyclic loads. Transp. Geotechnics. 26, 100455 (2021). https://doi.org/10.1016/j.trgeo.2020.100455

Mujahid, M., Lashari, A.A., Zardari, N.H., Mahar, R.B.: Ground improvement techniques for cohesionless soil using geosynthetics: A review. Journal of King Saud University-Engineering Sciences 32(2), 192–201 (2020). https://doi.org/10.1016/j.jksues.2018.10.007

Narjary, B., Aggarwal, P., Singh, A., Chakraborty, D., Singh, R.: Water availability in different soils in relation to hydrogel application. Geoderma 187–188, 94–101 (2012). https://doi.org/10.1016/j.geoderma.2012.03.002

Nugent, R.A., Zhang, G., Gambrell, R.P.: Effect of Exopolymers on the Liquid Limit of Clays and Its Engineering Implications. Transportation Research Record: Journal of the Transportation Research Board 2101(1), 34–43 (2009). https://doi.org/10.3141/2101-05

Plank, J. (2005). Applications of Biopolymers in Construction Engineering. Biopolymers Onlinehttps://doi.org/10.1002/3527600035.bpola002

Pradhan, P.K., Kar, R.K., Naik, A.: Effect of Random Inclusion of Polypropylene Fibers on Strength Characteristics of Cohesive Soil. Geotech. Geol. Eng. 30(1), 15–25 (2011). https://doi.org/10.1007/s10706-011-9445-6

Rajnish Kumar. (2020). Compaction Characteristics of BC Soil Reinforced with Untreated and Treated Coir Fibers. International Journal of Engineering Research And, V9(06). https://doi.org/10.17577/ijertv9is060678

Stabilization of Soil Using Flyash: Lime & Cement. International Journal of Science and Research 5(6), 527–529 (2016). https://doi.org/10.21275/v5i6.nov164333

Sujatha, E.R., Atchaya, S., Sivasaran, A., Keerdthe, R.S.: Enhancing the geotechnical properties of soil using xanthan gum—an eco-friendly alternative to traditional stabilizers. Bull. Eng. Geol. Env. 80(2), 1157–1167 (2020). https://doi.org/10.1007/s10064-020-02010-7

Symposium on polymer grid reinforcement in civil engineering: International Journal of Cement Composites and Lightweight Concrete. Symposiun. Polym. Grid. Reinforcement. Civil Eng. 6(2), 123 (1984). https://doi.org/10.1016/0262-5075(84)90041-1

Taylor, H. F. W. (1997). Cement chemistryhttps://doi.org/10.1680/cc.25929

Yang, K.H., Thuo, J.N., Huynh, V.D.A., Nguyen, T.S., Portelinha, F.H.M.: Numerical evaluation of reinforced slopes with various backfill-reinforcement-drainage systems subject to rainfall infiltration. Comput. Geotech. 96, 25–39 (2018). https://doi.org/10.1016/j.compgeo.2017.10.012

Acknowledgements

All tests were carried out in the Laboratory of Material Sciences & Environment at Hassiba Benbouali of Chlef, Algeria. The writers acknowledge the technicians who contributed to this experimental program.

Funding

This work was supported by the the Directorate General for Scientific Research and Technological Development, (DGRSDT), Algeria.

Author information

Authors and Affiliations

Contributions

A.B.E., N.D., M.M.B., S.B., S.D., S.S. and E.B. contributed equally to this work. A.B.E., M.M.B., S.B., S.D., S.S. and E.B. wrote the whole manuscript. A.B.E., S.D. and M.M.B. drew all the figures and tables. N.D., M.M.B., S.B., S.S. and E.B. reviewed and edited the paper. A.B.E., N.D., M.M.B., S.B., S.D., S.S. and E.B. conceptualized the work. All authors read and approved the final paper.

Corresponding author

Ethics declarations

Ethics Approval

Not applicable.

Consent for Publication

Not applicable.

Competing Interests

No potential conflict of interest was reported by the author(s).

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Elroul, A.B., Della, N., Benziane, M.M. et al. A Laboratory Study on Shear Behavior of Biocemented Chlef Sandy Soil. Transp. Infrastruct. Geotech. 11, 726–741 (2024). https://doi.org/10.1007/s40515-023-00303-4

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40515-023-00303-4