Abstract

The concept of clean technology was applied in the traditional process of using Eucalyptus globulus bark as fuel in the pulp and paper industry. The bark was investigated for its potential as a source of antioxidants by the solid–liquid extraction process before being used as fuel source. An experiment was set up to determine its antioxidant capacity and heating value. Volatile components of the extracts were also identified and analyzed by gas chromatography–mass spectrometry. The experimental results suggested that ethanol extraction solution at a ratio of 1:20 yielded the highest content of phenolic compounds (674.19 mg of gallic acid/l) and antioxidant capacity (30.53 ± 1.76 mg/l). We also examined and compared the fuel properties of extracted and unextracted bark, and it was found that the fuel properties of extracted and unextracted bark showed no significant difference. These findings suggested that the bark can be put to a better use by extracting the compounds before being ultimately used as fuel source in the traditional process. This might lead to an alternative process for the pulp and paper industry in which the standard process is maintained to obtain the desired products, with the additional extraction process to obtain high-value compounds.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Eucalyptus has been widely used for industrial purposes, especially in the paper industry. In the paper industry, only the eucalyptus wood tissue is utilized, with the leftovers, mainly barks in large quantity. In Thailand, the amount of bark produced in the pulp and paper industry is more than 4 million tons per year. The suitable eucalyptus variety for pulp and paper production in Thailand has been studied by Senjuntichai’s work (2014). Eucalyptus bark is usually fed into a gasifier and converted to CO for further use as clean energy in a biomass power plant (Gonzalez et al. 2011; Guerra et al. 2016), or used as a fertilizer (Yadav et al. 2002). Direct use of the bark in the boiler generally reduces the boiler efficiency, resulting from tar deposit on the heating surface of the boiler. Laaksometsä et al. (2009) have reported an increase in boiler efficiency by lignin extraction, thus reducing environmental pollution. It is a well-known fact that Eucalyptus bark contains large quantity of bioactive compounds (Piwowarska and González-Alvarez 2012) such as triterpenic (TT) acid and their acetyl derivatives (betulinic acid, betulonic, oleanolic and ursolic) (de Melo et al. 2012; Domingues et al. 2010, 2011a, b), ellagic acid rhamnosides (Kim et al. 2001) and tannin (Pinto et al. 2013). Some of these compounds have antioxidant properties which can replace synthetic additives such as butylated hydroxytoluene (BHT), butylated hydroxyanisole (BHA), propylgallate and tert-butylhydroquinone (TBHQ). Even though these synthetic compounds possess highly effective antioxidant properties, they also carry carcinogenic effect (Baydar et al. 2007; Iyer et al. 2015). For example, BHA and BHT have been suspected of causing some health problems, such as liver swelling and influence on liver enzyme activities (Siddhuraju and Becker 2003). These concerns lead to the growing interest in the study of secondary plant metabolites. Most of the previous studies (Almeida et al. 2016; Hossain et al. 2010) have focused on antioxidants from natural sources, especially from medicinal plants, in order to obtain environmentally friendly and low-cost antioxidants that can be used as antioxidants in food and pharmaceutical products (de Melo et al. 2012; Mirabella et al. 2014). Furthermore, they could be used as a component in cosmetics for anti-aging, anti-wrinkle and whitening activities.

In order to obtain the antioxidants, a proper extraction process is required. Among the available extraction processes, the solvent extraction is mostly used to extract bioactive compounds. The important factors in this process are the type of solvents, extraction time and temperature (Dai and Mumper 2010). The efficiency of the extraction process mostly depends on the extraction technique. It has been reported that traditional techniques such as a one-stage, maceration or Soxhlet, extraction provide a high extraction yield. However, these techniques usually require long extraction time and a large quantity of solvent (Aspé and Fernández 2011). Many researchers have developed alternative techniques to improve the efficiency and reduce the environmental impact of the extraction process, for example, combination of mechanic partitioning (Maroušek, 2014a), steam explosion (Maroušek 2013a, b), enzymatic hydrolysis (Maroušek et al. 2015), pressure shockwaves (Maroušek et al. 2013; Maroušek 2014b), microwave-assisted extraction (MAE) or ultrasound-assisted extraction (UAE) (Liazid et al. 2010; Oniszczuk and Podgórski 2015). The MAE technique is based on the absorption of microwave energy from water contained in the plant matrix. During the process, the internal heating will promote the cell disruption to facilitate the liberation of compounds into the solvent (Wang and Weller 2006). Among the extraction techniques, one-stage extraction is one of the most commonly used techniques, because of its high efficiency, relatively inexpensive equipment and simple operational process (Li et al. 2006).

Therefore, in this work, the one-stage technique was selected for antioxidant extraction due to its simplicity and high production yield. The aim of this research is to find the optimal condition for extraction of the total phenolic compounds from Eucalyptus globulus bark using ethanol, methanol and dichloromethane as extractants. The extraction system was improved by continuous mixing during the extraction period. The Folin–Ciocalteu colorimetric method was used to measure the total phenolic compounds. DPPH radical scavenging capacity assay and ferric reducing antioxidant power (FRAP) method were used to determine the antioxidant activity of the extract. Furthermore, thermal degradation and heating value of the bark before and after extraction were carried out to compare the fuel properties. GC-MS analyses were performed to identify the volatile compounds. The rationale of this work lies in the fact that a solid–liquid extraction process may be used in order to realize more benefits than the simple gasification of the bark. Through the extraction process, useful chemicals may be obtained for further use with little sacrifice of the heating value of the bark. The proposed conceptual process of this technology will be later discussed in detail.

Materials and methods

Chemical and reagent

Methanol (MeOH), ethanol (EtOH), dichloromethane (DCM), Folin–Ciocalteu reagent, sodium carbonate anhydrous (Na2CO3), gallic acid, 2,2-diphenyl-1-picrylhydrazyl (DPPH) and butylated hydroxytoluene (BHT) were purchased from Sigma (Singapore) in analytical reagents grade.

Extraction and concentration

Preparation of the Eucalyptus globulus bark extract

Eucalyptus globulus bark was obtained from Phoenix Pulp & Paper Public Company Limited (PPPC), Thailand. The bark was cleaned and air-dried at 50 °C for 12 h. After that, the bark was crushed in a ball mill (in house building with 3 m3 (0.15 m of diameters and 0.17 m of height) of mill size and 10 mm balls) before passing through a 1–3 mm sieve. The proximate analysis of bark is given in table S.1 (Supplementary materials).

Extraction and concentration

The conventional solid–liquid extraction was performed by soaking the ground eucalyptus bark with various solvents including methanol (MeOH), ethanol (EtOH) and dichloromethane (DCM). The total volume of extraction was 100 ml with various ratios of solid and liquid at 1:10, 1:15 and 1:20 g (solid)/ml (solvent). The extraction was performed under a shaking speed of 200 rpm at 30 °C for 6 h. After the extraction was completed, all solid phase was removed. The liquid phase was retained and evaporated by using a rotary vacuum R-205 (Buchi, Switzerland) at 40 °C, vacuum pressure of 300 mbar with the rotating speed of 90 rpm. The extract was weighed and expressed in a unit of milligram per gram dry bark (mg/g DW). The extract was reconstituted in methanol for further analysis. All experiments were conducted in 3 replicates.

Determination of antioxidant activity

DPPH radical scavenging activity

The antioxidant activity of each extract was analyzed using free radicals from 2,2-diphenyl-1-picrylhydrazyl (DPPH) method (Blois 1958) with some modification. The principle of the assay is based on the color change of the DPPH solution from purple to yellow, as the radical is quenched by the antioxidants. When a solution of DPPH is mixed with a substance that can donate hydrogen, the reduced form of DPPH is obtained, and the solution which is initially violet turns yellow. This change in color was monitored by visible spectroscopy at 517 nm (UV-1201 spectrometer, Shimadzu, Japan). Briefly, 1 ml of a sample solution with different concentrations (10–100 mg/l for methanol and ethanol and 500–5000 mg/l for dichloromethane) of each extraction solvent and solid–liquid ratio was mixed with 4 ml of a DPPH solution (0.051 mmol l−1) in methanol (ethanol or dichloromethane depending on each extraction solvent). The reaction mixtures were kept in the dark for 30 min at room temperature. The absorbance of the DPPH solution in the absence of the bark extract under analysis was also measured as a control. Butylated hydroxytoluene (BHT) was used as reference compound (Brand-Williams et al. 1995). All experiments were conducted in 3 replicates. The DPPH radical scavenging activity was calculated by the following equation:

where Abscontrol is the absorbance of the control, and Abssample is the absorbance of the DPPH in each sample at 517 nm. DPPH scavenger activity is defined by the IC50 values. The IC50 (mg/l) values are determined from the equation reported in Supplementary information (Fig. S2–S4).

Ferric reducing antioxidant power (FRAP) assay

This method was modified from Benzie and Strain (1996). The FRAP reagent was prepared from the mixture of 10 mM 2,4,6-tripyridyl-s-triazine (TPTZ) solution in 40 mM HCl, 20 mM FeCl3·6H2O solution and 0.3 M acetate buffer (pH 3.6) in a proportion of 1:1:10 (v/v). The FRAP reagent was freshly prepared and heated to a temperature of 37 °C. The absorbance of each sample was measured at 600 nm using an UV–Vis spectrophotometer (UV-1201 spectrometer, Shimadzu, Japan). The FRAP values of each sample were determined using the standard curve prepared from 50 to 1000 μM FeSO4·7H2O.

Determination of total phenolic compounds

The total phenolic compounds of extract were analyzed by Folin–Ciocalteu colorimetric method (Slinkard and Singleton 1977) with gallic acid as positive control; 125 µl of extract in methanol was mixed with 500 µl of distilled water before addition of 125 µl of Folin–Ciocalteu reagent. The reaction was continued for 6 min, after addition of 1.25 ml of 7 % w/v sodium carbonate. Finally, the sample volume was adjusted to 3 ml with distilled water and placed in the dark room for 90 min. The absorbance of each sample was observed at 760 nm by UV–Vis spectrophotometer (UV-1201 spectrometer, Shimadzu, Japan) and expressed as milligrams of gallic acid equivalent per grams dry bark (mg GAE/g DW).

Thermogravimetric analyses (TGA)

Thermogravimetric analyzer (TGA 50) was used for investigating thermal degradation of both raw bark and extracted bark. All samples were milled and ground to less than 1 mm before testing; 10 mg of each sample was loaded into an alumina crucible and heated at a programmed temperature. The sample was held at 25 °C for 30 min. The temperature was then increased at a heating rate of 10 °C min−1 up to 700 °C and held for 10 min. The weight losses were recorded and analyzed.

The heating value of Eucalyptus globulus bark

The calorific value of raw bark and extracted bark was determined by Gallenkamp Auto Bomb™ adiabatic calorimeter (Gallenkamp, UK), following the method outline in ASTM E711 (ASTM International, 1987).

Gas chromatography (GC) and mass spectroscopy (MS) analysis

The extract identification and quantification of low molecular weight compounds were carried out by GC-MS analysis using an Agilent 6890 N (Agilent, Singapore) model connected to MS Agilent 5973 inert mass selective detector (Agilent, Singapore). The sample preparation was as follows: 20 mg of extract was dissolved in 250 μl of ethanol and passed through 0.45 μm filter membrane to clean the sample. DB-5 ms capillary column (Agilent 122-5532, Singapore) of 30 m long, with a 0.25 mm internal diameter and 0.25 µm film thicknesses, was used. Helium at a flow rate of 1 ml/min was used as a carrier gas. One microliter of this sample was injected into the column. The injection temperature was at 250 °C with a split rate of 10.0 ml/min. The column temperature was programmed at 80 °C for 2 min, then 10 °C/min increment up to 200 °C. Finally, a heating rate of 5 °C/min was performed up to 280 °C and held for 15 min. The identification of any low molecular weight aromatic compounds as TMS derivatives produced from the experiments was completed by comparing their mass spectra with those in the Agilent ChemStation Database.

Results and discussion

Influence of type of solvents on E. globulus bark extraction

Three types of solvents were used to compare the effect of solvents on extraction. The extraction process follows that of the conventional extraction technique with shaking at 50 °C for 6 h, while high temperature was used to shorten the extraction time. As shown in Fig. 1, the weight of the extract obtained from methanol was approximately two times higher than those from other solvents in similar condition. This suggests that methanol provided the highest extraction efficiency in the test condition.

Amount of extract from extraction of 10 g of eucalyptus bark in dichloromethane (DCM), ethanol (EtOH) and methanol (MeOH) under a shaking speed of 200 rpm at 30 °C for 6 h. t test of two sample assuming unequal variance is performed; asterisk statistical analysis of different solvents with the same ratio

The effect of solvent quantity on extraction yield was examined by varying the bark and solvents at the ratios of 1:10, 1:15 and 1:20 (gram bark/ml solvent). For comparison among the same solvent but different ratios, dichloromethane and methanol at a ratio of 1:20 were found to be the most effective for extraction, while no difference was observed for ethanol. This may be due to the unsaturation of the extract dissolved in those organic solvents. The result suggested that methanol is the most effective solvent for this extraction condition, especially at the ratio of 1:20 which is due to higher polarity of methanol compared with that of other solvents. The statistical analysis confirmed that the methanol provides significantly higher extraction yield (at p value <0.05) compared to ethanol and dichloromethane. In addition, the extract yields from ethanol and dichloromethane showed no difference. Moreover, the extraction yields were similar to the previous studies of eucalyptus bark extraction (2.48 % extraction yield for ethanol and 2.70 % extraction yield for methanol) (Vázquez et al. 2008).

Total phenolic content of extracts

In the present work, the total phenolic content in each sample was investigated. As shown in Fig. 2, the sample extracts using ethanol and methanol at a ratio of 1:20 provide the best condition for the total phenolic content. This result correlates with the extraction yield in the previous experiment. The maximum total phenolic contents obtained at the ratio of 1:20 were 3.18 ± 0.03, 3.13 ± 0.03 and 0.64 ± 0.06 mg GAE/g DW for ethanol, methanol and dichloromethane extracts, respectively. This suggests that methanol and ethanol provide a better yield of phenolic compound than dichloromethane in the experimental condition. The statistical analysis confirms the significant difference of the phenolic content of DCM extract when compared with other solvents at the similar ratio (with p value <0.05). High polarity of methanol and ethanol is one of the important parameters to enhance the extraction efficiency, and in this case, to obtain polar phenolic compounds. The polarity of methanol, ethanol and DCM are 0.762, 0.654 and 0.269, respectively (Reichardt and Welton 2010). The highest total phenolic content obtained in this work is lower than that from other plant sources, including eucalyptus leaves (62.10 ± 2.49 mg GAE/g DW), black tea (24.9 ± 0.2 mg GAE/g DW) and purple potato peels (4.74 ± 0.07 mg GAE/g DW), as given in Table 1. The methanol extraction used in this study gave a higher yield (3.13 ± 0.03 mg GAE/g DW, with methanol) than that of Santos et al. (0.819 mg GAE/g DW, with methanol/water) (Santos et al. 2011). This possibly suggests that the continuous mixing and polarity of solvent could enhance the extraction yield. The polarity of solvent affects the total phenolic contents of the extract, for example, flavonoid glycosides and more polar aglycones can be extracted by alcohols or alcohol–water mixtures, while less polar flavonoids (isoflavones, flavanones, methylated flavones and flavonols) usually can be extracted by chloroform, dichloromethane, diethyl ether or ethyl acetate (Stankovic et al. 2011). Therefore, apart from the high amount of total phenolic content acquired, choice of solvents suitable for specific groups of phenolic compounds has to be considered. It is also need to be considered that even though ethanol does not show the best extraction yield (based on previous section), ethanol gives the comparable phenolic content to the methanol extracts. Ethanol could be used as a better alternative for downstream processing, especially in the medical industry due to its lower cytotoxicity compared with methanol.

Antioxidant activity test

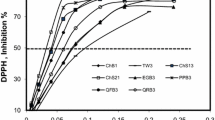

Antioxidant activity of sample extracted using DPPH test

The antioxidant activity was determined by the ability of molecules to provide hydrogen atoms to reduce the free radical DPPH. This causes the formation of the DPPH-H, non-radical form that can be detected under the spectrophotometer at 517 nm. The antioxidant activity obtained in this work was expressed in terms of the amount of extract required for decreasing 50 % of DPPH concentration (IC50). Thus, butylated hydroxytoluene (BHT), a synthetic phenolic molecule, was used as a reference compound to evaluate the antioxidant activity of tested samples. Table 2 shows IC50 of the samples extracted with different solvents at various ratios with BHT as standard anti-oxidant. The antioxidant activities show a similar trend to the total phenolic content as mentioned in Sect. 3.2. The antioxidant activities were the lowest (5113.98 ± 347.16 mg/l) in the sample extracted by DCM at 1:10 ratio, while the sample extracted by ethanol at 1:20 ratio provided the highest activity (30.53 ± 1.76 mg/l). It is clear that the extracts by ethanol and methanol have similar antioxidant properties. It has been reported by Ham et al. (2015) that an aqueous ethanol is effective in extracting phenolic compounds and provides the highest DPPH radical scavenging activity. All extracts in the present work show lower antioxidant activities than those of BHT compound (IC50 = 15.1 mg/l). However, the antioxidant activity of E. globulus bark extracts in this study is comparable to Syrian and Egyptian coriander, a natural source of polyphenol compound, with their IC50 values being 36 ± 3.22, and 32 ± 2.8 mg/l, respectively (Msaada et al. 2013).

Antioxidant activity of E. globulus bark extract using ferric reducing antioxidant power (FRAP) assay

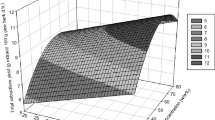

Total antioxidant of E. globules bark extract was analyzed by FRAP, with Trolox as a reference compound. As shown in Fig. 3, the result correlated with the DPPH experiment, the antioxidant activity of the sample extracted by methanol is statistically higher than the sample extracted by ethanol (p value <0.05), and 100 times higher than that by DCM (data not shown). The highest antioxidant power was found in the sample extracted from 1:10 methanol (630 ± 15.76 of µM Fe2SO4). It is comparable to the standard reagent, Trolox at a concentration of 50 mg/ml (678.5 of µM Fe2SO4). It should be mentioned here that the work of Henderson et al. (2015) with manuka honey reported the FRAP value of 677 ± 78 of µM Fe2SO4 with UMF of 15 which is in a similar range to our work.

Thermogravimetric analysis (TGA) value of E. globules barks before and after extraction

Thermogravimetric curves of E. globulus bark before and after extraction are presented in Fig. 4. The decomposition of both untreated and treated bark is quite similar and can be divided into three stages. The first stage (region 1 in Fig. 4) is related to moisture loss, which was around 15 % weight loss at 0–140 °C (da Silva et al. 2009). The second stage is the degradation of tars and volatile organics which occurred at 140 and 520 °C, and the decomposition was observed at 70 % weight loss of untreated bark and 75 % weight loss of bark after extraction. The last stage, the degradation of ash contents in both untreated and treated bark occurred at a temperature higher than 520 °C. The percentage weight loss of both untreated and treated bark show some difference at high temperatures (at 400–700 °C). In addition, the residual weight of the untreated bark is slightly higher than that of the treated bark. This might correlate to the amount of phenolic contents and other compounds which were eliminated in the extraction process.

Heating value of E. globulus bark after extraction

The quality of fuel can be determined by the amount of heat generated from a unit mass of fuel (in kJ/kg). The calorific value is considered as an important parameter for comparing one fuel with another. As listed in Table 3, the mean calorific values of untreated and treated bark were 7754 and 7449.74 kJ/kg, respectively. A smaller calorific value in the treated bark might result from the loss of some compounds during the extraction process. This similarity in the calorific values suggests that the treated bark can still be used as a fuel with little loss of heating value.

Identification of the extracts by GC-MS

Gas chromatography–mass spectroscopy (GC-MS) was used to identify the volatile compounds in the extracts by ethanol at the ratio of 1:20, which gave the highest yield. The result is given in Table 4 with nine identified compounds including 2,4-bis-(1,1-dimethylethyl)-phenol, 2,2′-[(1-methyl-1,2-ethanediyl)bis(nitrile-methylidyne)]bis-phenol, (S)-2-iodo-1-methoxy-(1-methoxyethyl)benzene, 1-methyl-3,3-ethylenedioxy-1,2,3-trihydro-2-oxo-1-benzazole, lidocaine, methyl n-nitro cinnamate, silicic acid, γ-sitosterol and β-amyrin. In a study by Domingues et al. (2011a, b), the dichloromethane extracted samples from other eucalyptus species contained highly valued compound of triterpenoids such as β-sitosterol and β-amyrin. β-Sitosterol has been studied for its anti-tumor and thermal-induced protein denaturation inhibitory activities (Rauf et al. 2015). γ-Sitosterol can be considered for developing into a potent anti-diabetic drug (Balamurugan et al. 2012), and β-amyrin (C30H50O), the derivative of triterpenes, showed anti-anxiety and anti-depressive actions through α1 receptor blockade (Jeon et al. 2015). Lidocaine, a class Ib anti-arrhythmic agent and local anesthetic agent, has emerged within the pediatric literature as an anti-epileptic drug (AED) in neonatal status epilepticus (SE) (Zeiler et al. 2015). It is worth mentioning here that the present study successfully extracted three compounds, namely γ-sitosterol, β-amyrin and lidocaine, which have medicinal applications.

Proposed conceptual process for clean technology

Figure 5 shows the conventional process and a proposed process of eucalyptus bark. As discussed in Sect. 3.5, the heating value of the bark after the solid–liquid extraction process hardly changes. The conventional process in using eucalyptus bark (Fig. 5a) to produce syngas for electricity generation is shown in Fig. 5a. The syngas was not the only product from this process. CO2 and tar were obtained as by-products (Baloch et al. 2016). The presence of tar in the gas results in tar deposit on the heating surface of the boiler which reduces its efficiency. Thus, the extracted bark may be decreased the tar deposit effect because some hydrocarbon in bark might be eliminated. In the proposed conceptual process as illustrated in Fig. 5b, phenolic and fine chemical extraction of eucalyptus bark is obtained. The obtained chemical fines could be further used to produce high-value fine chemicals (as mentioned in Sect. 3.6). The products from extraction process will be separated by vacuum evaporation. The solvent can also be extracted and recycled in the extraction process. It can be seen that the proposed conceptual process not only produce extracted bark but also products which can be upgraded to products with high commercial values. Furthermore, the proposed conceptual process could be considered as an alternative clean technology for increasing the value of eucalyptus bark and reducing environmental pollution.

Conclusions

Ethanol and methanol, with the ratio of bark to solvent of 1:20, was found to give the best condition for extraction of E. globulus bark, with slight difference in total phenolic content and antioxidant activity. The methanol extraction provides the greatest amount of extracts among the three tested solvents. Ethanol, despite yielding comparatively lower amounts of extract, provides better antioxidant activity than that of methanol. TGA of untreated bark and treated bark had some difference at high temperatures (at 400–700 °C). The heating value results showed no significant difference between the untreated E. globulus bark (ca. 7803 kJ/kg) and the extracted barks (ca. 7570 kJ/kg). The GC-MS results revealed that useful compounds with potential medicinal application can be derived from the bark before it is ultimately used as a source of energy. More importantly, it has been demonstrated that the proposed conceptual process is feasible with greater commercial and environmental benefits. However, further study is needed before the actual benefits can be realized.

References

Albishi T, John JA, Al-Khalifa AS, Shahidi F (2013) Phenolic content and antioxidant activities of selected potato varieties and their processing by-products. J Funct Foods 5(2):590–600

Almeida MLB, de Souza Freitas WE, de Morais PLD, Sarmento JDA, Alves RE (2016) Bioactive compounds and antioxidant potential fruit of Ximenia americana L. Food Chem 192:1078–1082

Aspé E, Fernández K (2011) The effect of different extraction techniques on extraction yield, total phenolic, and anti-radical capacity of extracts from Pinus radiata bark. Ind Crops Prod 34(1):838–844

ASTM International (1987) ASTM E711 standard test method for gross calorific value of refuse-derived fuel by the Bomb Calorimeter

Balamurugan R, Stalin A, Ignacimuthu S (2012) Molecular docking of γ-sitosterol with some targets related to diabetes. Eur J Med Chem 47:38–43

Baloch HA, Yang T, Li R, Nizamuddin S, Kai X, Bhutto AW (2016) Parametric study of co-gasification of ternary blends of rice straw, polyethylene and polyvinylchloride. Clean Technol Environ Policy 18:1031–1042

Baydar NG, Özkan G, Yaşar S (2007) Evaluation of the antiradical and antioxidant potential of grape extracts. Food Control 18(9):1131–1136

Benzie IF, Strain J (1996) The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: the FRAP assay. Anal Biochem 239(1):70–76

Blois MS (1958) Antioxidant determinations by the use of a stable free radical. Nature 181(4617):1199–1200

Brand-Williams W, Cuvelier ME, Berset C (1995) Use of a free radical method to evaluate antioxidant activity. LWT Food Sci Technol 28(1):25–30

da Silva DA, Feitosa JP, Paula HC, de Paula RC (2009) Synthesis and characterization of cashew gum/acrylic acid nanoparticles. Mater Sci Eng, C 29(2):437–441

Dai J, Mumper RJ (2010) Plant phenolics: extraction, analysis and their antioxidant and anticancer properties. Molecules 15(10):7313–7352

de Melo MM, Oliveira EL, Silvestre AJ, Silva CM (2012) Supercritical fluid extraction of triterpenic acids from Eucalyptus globulus bark. J Supercrit Fluids 70:137–145

Domingues RMA, Sousa GDA, Freire CSR, Silvestre AJD, Neto CP (2010) Eucalyptus globulus biomass residues from pulping industry as a source of high value triterpenic compounds. Ind Crops Prod 31(1):65–70

Domingues R, Sousa G, Silva C, Freire C, Silvestre A, Neto CP (2011a) High value triterpenic compounds from the outer barks of several Eucalyptus species cultivated in Brazil and in Portugal. Ind Crops Prod 33(1):158–164

Domingues RMA, Patinha DJS, Sousa GDA, Villaverde JJ, Silva CM, Freire CSR, Silvestre AJD, Neto CP (2011b) Eucalyptus biomass residues from agro-forest and pulping industries as sources of high-value triterpenic compounds. Cellul Chem Technol 45(7–8):475–481

Gonzalez R, Treasure T, Phillips R, Jameel H, Saloni D, Abt R, Wright J (2011) Converting Eucalyptus biomass into ethanol: financial and sensitivity analysis in a co-current dilute acid process. Part II. Biomass Bioenergy 35(2):767–772

Guerra SPS, Oguri G, Spinelli R (2016) Harvesting eucalyptus energy plantations in Brazil with a modified New Holland forage harvester. Biomass Bioenergy 86:21–27

Ham J-S, Kim H-Y, Lim S-T (2015) Antioxidant and deodorizing activities of phenolic components in chestnut inner shell extracts. Ind Crops Prod 73:99–105

Henderson T, Nigam PS, Owusu-Apenten RK (2015) A universally calibrated microplate ferric reducing antioxidant power (FRAP) assay for foods and applications to Manuka honey. Food Chem 174:119–123

Hossain MB, Rai DK, Brunton NP, Martin-Diana AB, Barry-Ryan C (2010) Characterization of phenolic composition in lamiaceae spices by LC-ESI-MS/MS. J Agric Food Chem 58(19):10576–10581

Iyer KA, Zhang L, Torkelson JM (2015) Direct use of natural antioxidant-rich agro-wastes as thermal stabilizer for polymer: processing and recycling. ACS Sustain Chem Eng 4(3):881–889. doi:10.1021/acssuschemeng.5b00945

Jeon SJ, Park HJ, Gao Q, Lee HE, Park SJ, Hong E, Jang DS, Shin CY, Cheong JH, Ryu JH (2015) Positive effects of β-amyrin on pentobarbital-induced sleep in mice via GABAergic neurotransmitter system. Behav Brain Res 291:232–236

Kim JP, Lee IK, Yun BS, Chung SH, Shim GS, Koshino H, Yoo ID (2001) Ellagic acid rhamnosides from the stem bark of Eucalyptus globulus. Phytochemistry 57(4):587–591

Laaksometsä C, Axelsson E, Berntsson T, Lundström A (2009) Energy savings combined with lignin extraction for production increase: case study at a eucalyptus mill in Portugal. Clean Technol Environ Policy 11(1):77–82

Li BB, Smith B, Hossain MM (2006) Extraction of phenolics from citrus peels: I. Solvent extraction method. Sep Purif Technol 48(2):182–188

Liazid A, Schwarz M, Varela RM, Palma M, Guillén DA, Brigui J, Macías FA, Barroso CG (2010) Evaluation of various extraction techniques for obtaining bioactive extracts from pine seeds. Food Bioprod Process 88(2):247–252

Maroušek J (2013a) Removal of hardly fermentable ballast from the maize silage to accelerate biogas production. Ind Crops Prod 44:253–257

Maroušek J (2013b) Study on commercial scale steam explosion of winter Brassica napus STRAW. Int J Green Energy 10(9):944–951

Maroušek J (2014a) Biotechnological partition of the grass silage to streamline its complex energy utilization. Int J Green Energy 11(9):962–968

Maroušek J (2014b) Novel technique to enhance the disintegration effect of the pressure waves on oilseeds. Ind Crops Prod 53:1–5

Maroušek J, Itoh S, Higa O, Kondo Y, Ueno M, Suwa R, Komiya Y, Tominaga J, Kawamitsu Y (2013) Pressure shockwaves to enhance oil extraction from Jatropha Curcas L. Biotechnol Biotechnol Equip 27(2):3654–3658

Maroušek J, Hašková S, Maroušková A, Myšková K, Vaníčková R, Váchal J, Vochozka M, Zeman R, Žák J (2015) Financial and biotechnological assessment of new oil extraction technology. Energy Sources Part A Recovery Utilization Environ Eff 37(16):1723–1728

Mirabella N, Castellani V, Sala S (2014) Current options for the valorization of food manufacturing waste: a review. J Clean Prod 65:28–41

Msaada K, Jemia MB, Salem N, Bachrouch O, Sriti J, Tammar S, Bettaieb I, Jabri I, Kefi S, Limam F (2013). Antioxidant activity of methanolic extracts from three coriander (Coriandrum sativum L.) fruit varieties. Arabian J Chem. Corrected proof—Available online 23 December 2013 (in press)

Oniszczuk A, Podgórski R (2015) Influence of different extraction methods on the quantification of selected flavonoids and phenolic acids from Tilia cordata inflorescence. Ind Crops Prod 76:509–514

Pereira V, Dias C, Vasconcelos MC, Rosa E, Saavedra MJ (2014) Antibacterial activity and synergistic effects between Eucalyptus globulus leaf residues (essential oils and extracts) and antibiotics against several isolates of respiratory tract infections (Pseudomonas aeruginosa). Ind Crops Prod 52:1–7

Pichayadecha A, Senjuntichai A (2014) Grouping eucalyptus species in kraft pulp process for cost reduction. KKU Eng J 41(2):437–448

Pinto PCR, Sousa G, Crispim F, Silvestre AJD, Neto CP (2013) Eucalyptus globulus bark as source of tannin extracts for application in leather industry. ACS Sustain Chem Eng 1(8):950–955

Piwowarska N, González-Alvarez J (2012) Extraction of antioxidants from forestry biomass: kinetics and optimization of extraction conditions. Biomass Bioenergy 43:42–51

Rauf A, Uddin G, Khan H, Raza M, Zafar M, Tokuda H (2015) Anti-tumour-promoting and thermal-induced protein denaturation inhibitory activities of β-sitosterol and lupeol isolated from Diospyros lotus L. Nat Prod Res:1–3 (ahead-of-print)

Reichardt C, Welton T (2010) Empirical parameters of solvent polarity. Solvents and solvent effects in organic chemistry. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, pp 425–508

Santos SA, Freire CS, Domingues MRM, Silvestre AJ, Neto CP (2011) Characterization of phenolic components in polar extracts of Eucalyptus globulus Labill. bark by high-performance liquid chromatography–mass spectrometry. J Agric Food Chem 59(17):9386–9393

Siddhuraju P, Becker K (2003) Antioxidant properties of various solvent extracts of total phenolic constituents from three different agroclimatic origins of drumstick tree (Moringa oleifera Lam.) leaves. J Agric Food Chem 51(8):2144–2155

Slinkard K, Singleton VL (1977) Total phenol analysis: automation and comparison with manual methods. Am J Enol Vitic 28(1):49–55

Stanković M, Niciforovic N, Topuzović M, Solujić S (2011) Total phenolic content, flavonoid concentrations and antioxidant activity, of the whole plant and plant parts extracts from Teucrium montanum L. var. montanum, f. supinum (L.) Reichenb. Biotechnol Biotechnol Equip 25:2222–2227

Tukun AB, Shaheen N, Banu CP, Mohiduzzaman M, Islam S, Begum M (2014) Antioxidant capacity and total phenolic contents in hydrophilic extracts of selected Bangladeshi medicinal plants. Asian Pac J Trop Med 7:S568–S573

Vázquez G, Fontenla E, Santos J, Freire M, González-Álvarez J, Antorrena G (2008) Antioxidant activity and phenolic content of chestnut (Castanea sativa) shell and eucalyptus (Eucalyptus globulus) bark extracts. Ind Crops Prod 28(3):279–285

Wang L, Weller CL (2006) Recent advances in extraction of nutraceuticals from plants. Trends Food Sci Technol 17(6):300–312

Yadav KR, Sharma RK, Kothari RM (2002) Bioconversion of eucalyptus bark waste into soil conditioner. Bioresour Technol 81(2):163–165

Zeiler FA, Zeiler KJ, Kazina CJ, Teitelbaum J, Gillman LM, West M (2015) Lidocaine for status epilepticus in adults. Seizure 31:41–48

Zhu F, Sakulnak R, Wang S (2016) Effect of black tea on antioxidant, textural, and sensory properties of Chinese steamed bread. Food Chem 194:1217–1223

Acknowledgments

This study was partially supported by Farm Engineering and Automatic Control Technology Research group (FEAT group), Applied Engineering for Important Crops of the North East Research group (AENE group) Khon Khaen University and Phoenix Pulp & Paper Public Company Limited (PPPC), Thailand.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jutakridsada, P., Iamamornphanth, W., Patikarnmonthon, N. et al. Usage of Eucalyptus globulus bark as a raw material for natural antioxidant and fuel source. Clean Techn Environ Policy 19, 907–915 (2017). https://doi.org/10.1007/s10098-016-1276-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-016-1276-y