Abstract

In this work, extracts from various lignocellulosic wastes were analyzed with the aim of applying them to prevent colour ultraviolet degradation of dyed veneers used for board coating. Chestnut fruit (Castanea sativa) shell and bur, barks from Pinus pinaster, Eucalyptus globulus, Quercus frainetto and Quercus robur and wood from Tilia cordata were extracted using water or aqueous solutions of sodium sulphite and/or sodium hydroxide. The extracts were analyzed for their antioxidant activity (using the ferric reducing antioxidant power, the free radical DPPH and the free radical ABTS essays), totals phenols content, molecular weight distribution and phenolic composition. Except for chestnut bur and steam peeled chestnut shell whose water extract was the best, the best antioxidant properties were obtained for the 2 % sodium sulphite extracts. Extracts from pine bark and steam peeled chestnut shell, with the highest total phenols content and antioxidant activity, not only showed the best properties as bioprotectors but also high extraction yields. These extracts also presented the higher average molecular weights. Extract antioxidant properties were related to the presence of various phenolic compounds identified by reverse phase high-performance liquid chromatography electrospray ionization time-of-flight mass spectrometry: flavan-3-ols, flavonols, flavonol glycosides, dihydroflavonols and phenolic acids.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

All wood materials are susceptible to photodegradation by ultraviolet (UV) light when exposed to solar radiation and can undergo surface degradation, colour changes and mechanical breakdown. The mechanisms of wood degradation have been investigated, and lignin has been recognised to be the key structure as, of the main wood components, cellulose, hemicelluloses and lignin, only lignin absorbs relatively strongly in the UV/visible region (George et al. 2005).

Different alternatives have been proposed to protect wood against photodegradation (George et al. 2005) including wood finishing with coatings which act as UV/visible light screeners, treatment of the wood surface with additives, such as radical trapping additives or UV absorbers, or the chemical modification of wood by acetylation, esterification (Evans et al. 2002; Jebrane et al. 2009) or by treatment with different chemicals such as chromic acid that has been recognized to be highly effective in photostabilizing wood (Evans 2009). However, chromic acid is highly toxic, and the aim is to look for non-toxic and environmentally friendly alternatives for preventing wood photodegradation.

Chang et al. (2010a, b) investigated if antioxidant phenolic compounds could protect wood against photodegradation, and when comparing extracted and non-extracted woods they found that wood extractives play an essential role in wood photodegradation, and surface deteriorated less when the extractives existed. Using ESR spectroscopy it was demonstrated that wood radicals induced by UV light were inhibited by Acacia confusa heartwood extracts and consequently wood photodegradation was retarded (Chang et al. 2014). Diouf et al. (2006) found that wood species with low antioxidant capacity happened to be less colour durable, whereas those with high antioxidant capacity were more light resistant. Additionally, color stability was conferred to non durable woods if impregnated with extracts of durable species.

Wood preservatives based on flavonoid and hydrolysable tannins have been developed. They are based on the complexing capacity for a metal with the vicinal hydroxyl groups on the B-ring of flavonoids and the ring of hydrolysable tannins (Bruce and Palfreyman 1998). Thus, tannins have been used as wood preservatives offering protection against light and against biological attack by insects, fungi and bacteria (Laks et al. 1988; Thevenon et al. 2009; Tondi et al. 2012). However, the main drawback for the use of tannins as wood preservatives has been their high leachability that determines their use for outdoor applications (Tondi et al. 2013a, b). In order to overcome this, various advanced formulations have been developed based on the cross-linking and hardening of condensed polyflavonoid tannins by hexamine and enriched with small amounts of boron, also known for its biocide activity (Thevenon et al. 2009; Tondi et al. 2012). The behaviour of wood impregnated with these formulations was studied. Dimensional stability, resistance to leaching and resistance to biological agents were investigated (Tondi et al. 2012, 2013a; Schnabel et al. 2014).

In this work, the antioxidant activity of the phenolic extracts of various lignocellulosic wastes was analysed with the aim of applying them for the prevention of colour degradation by UV light of dyed wood veneers used for board coating. Chestnut shell and bur (from the Castanea sativa species), waste products from the food industry, and barks from Pinus pinaster, Eucalyptus globulus, Quercus frainetto and Quercus robur and Tilia cordata wood, waste products from the wood industry, were extracted using different extracting agents. The extracts were analysed for their phenols content and antioxidant activity, and their phenolic composition was determined.

2 Materials and methods

2.1 Materials

Chestnut bur (from the Castanea sativa species, ChB) was collected in a chestnut plantation in Santiago de Compostela (Galicia, NW Spain). Chestnut shell (from the Castanea sativa species) was supplied by the food factory Marron Glacé S.A. (Ourense, Spain); the shell called ChS1 was collected from a dry chestnut peeling process and that called ChS2 from a peeling stage where chestnuts were peeled using steam and washed with hot water. Eucalyptus globulus bark (EGB) was supplied by Grupo Empresarial ENCE S.A. (Pontevedra, Spain). Pinus pinaster bark (PPB), Quercus frainetto bark (QFB), Quercus robur bark (QRB) and Tilia cordata wood (TW) were supplied by ASERPAL S.A. (Curtis, A Coruña, Spain). All the materials were air-dried till equilibrium moisture content, ground and the fraction of particle size between 0.1 and 2 mm was selected for the extraction experiments.

2.2 Extraction and concentration

The extraction experiments were carried out in a 2 L Pyrex glass reactor with mechanical stirring and temperature control. The material and water were mixed at room temperature, heated and, once the selected temperature had been attained (90 °C), except for the water extraction, the alkali (sodium hydroxide and/or sodium sulphite) was added and contact time begun to run. The solid/liquid ratio was fixed at 1/10 (w/w) for all the experiments. After 1 h, the suspension was vacuum filtered; the solid residue was washed with water and the extract together with the first water washings were concentrated by spray-drying. The solid was dried at room temperature in order to calculate the extraction yield as the weight loss percentage of the starting raw material. The extraction experiments are summarized in Table 1.

2.3 Total phenols content

Extract total phenols content was determined by the Folin-Ciocalteu method (Singleton and Rossi 1965): to 0.5 ml of an aqueous solution of the extract, 2.5 ml of Folin-Ciocalteu reactive, previously diluted with water (1:10, v/v), and 2 ml of a 75 g/l Na2CO3 aqueous solution were added. The mixture was kept 5 min at 50 °C and, after cooling, the absorbance at 760 nm was measured. The phenols content was expressed as g gallic acid equivalent (GAE)/100 g extract (on dried basis). The analyses were carried out in triplicate and the results averaged.

2.4 Antioxidant activity

2.4.1 Ferric reducing antioxidant power (FRAP)

The FRAP assay was done according to Szöllösi and Szöllösi-Varga (2002) as follows: 0.1 ml of an aqueous solution of the extracts were transferred to a test tube and 3.0 ml of freshly prepared FRAP reagent (25 ml of acetate buffer, 300 mmol/l, pH 3.6; 2.5 ml of 10 mmol TPTZ (2,4,6-tripyridyl-1,3,5-triazine) in 40 mmol/l HCl; 2.5 ml of 20 mmol/l FeCl3·6H2O) were added. The absorbance was recorded after 5 min at 593 nm. The relative activities of samples were expressed as nmol ascorbic acid equivalent (AAE) per mg extract (on dried basis). The analyses were carried out in triplicate and the results averaged.

2.4.2 DPPH radical-scavenging activity

The radical-scavenging activity (RSA) of the extracts was monitored using the stable free radical DPPH following a modification of the method described by Barreira et al. (2008). Aqueous solutions of the different extracts (8–240 μg/ml) were prepared. The extract solution (0.3 ml) was mixed with 2.7 ml of a freshly prepared DPPH (1,1-diphenyl-2-picrylhydrazyl) solution (6.10–5 M in 80 % methanol). The mixture was shaken vigorously and left to stand for 20 min in the dark at room temperature. Then the absorbance was read at 517 nm. It was determined as % RSA = 100 (A0 − As)/A0, where As is the absorbance of the extract solution and A0 is the absorbance of a control solution prepared without extracts. The EC50 value, or extract concentration necessary to achieve a 50 % radical DPPH inhibition, was obtained by plotting the % RSA as a function of sample concentration. The Trolox equivalent of the extracts (TRE) was defined as the amount of Trolox (mmol) giving the same antioxidant capacity as one gram of extract. TRE was calculated from the plots obtained for % RSA as a function of sample concentration for both Trolox and the extract, which were linear in the range tested (r2 > 0.99 in all cases).

2.4.3 ABTS radical-scavenging activity

The radical scavenging capacity was determined according to the ABTS method of Re et al. (1999). ABTS (2,2′-Azinobis-3-ethylbenzothiazoline-6-sulfonic acid) radical cation (ABTS•+) was produced by reacting an ABTS solution (7 mM) with potassium persulfate (2.45 mM) for 16 h in the dark at room temperature. The ABTS•+ solution was diluted with water to an absorbance of 0.70 at 734 nm. Aqueous solutions of the extracts in the concentration range 20–960 μg/ml were prepared. The extract solution (25 μl) was mixed with the ABTS•+ solution (2.5 ml) and after 6 min in the dark at room temperature the absorbance was read at 734 nm. The % RSA of the extract solutions, the extracts TRE and the EC50 values were calculated as indicated in the DPPH method.

2.5 UV spectroscopy

Extracts were redissolved in water and the UV spectra of the solutions were measured in Hach Lange DR5000 equipment using water as reference.

2.6 Reverse phase high-performance liquid chromatography electrospray ionization time-of-flight (RP-HPLC-ESI-TOF) mass spectrometry

A selection of the extracts was evaluated using an Agilent Technologies 1100 HPLC and a Bruker Microtof ESI-TOF instrument. Phenolic compounds were separated using a Zorbax Eclipse XDB-C18 5 μm (4.6 × 150 mm) column and a binary gradient of 2 % acetic acid for mobile phase A and 0.5 % acetic acid in water/acetonitrile (1:1, v/v) for mobile phase B at a flow rate of 1 ml/min and a postcolumn split of 1/0.2 ml/min. The linear gradient was from 10 to 55 % B from 0 to 50 min, from 55 to 100 % B from 50 to 60 min and from 100 to 10 % B from 60 to 65 min. The mass spectrometry analysis was performed in negative ion mode. The samples were dissolved in water to a concentration in the range 100–200 ppm.

2.7 Average molecular weights by gel permeation chromatography (GPC)

Average-molecular-weights of the extracts were determined. GPC analyses were performed with an Agilent Technologies 1100 chromatograph (Germany) equipped with a diode array detector. The column used was a HP-PL gel 5 μm Mixed-D protected with a PL gel 5 μm guard column. Tetrahydrofuran (THF) was used as eluent and the conditions used were: flow rate, 1 ml/min; column temperature, 30 °C; injection volume, 20 μl; detection at 270 with a bandwidth of 15 nm. The calibration curve was obtained with polystyrene standards. The spray-dried extracts were acetylated previous to GPC analysis. Samples (20 mg) were acetylated with pyridine-acetic anhydride (4 ml, 1:1 v/v) overnight at room temperature. The mixture was poured into distilled water (40 ml) and the precipitate obtained was recovered by vacuum filtration through a 20 μm nylon filter. The acetylated extracts were dissolved in THF (2–5 mg/ml) and analysed by GPC.

2.8 Statistical analysis

For each material, the existence of significant differences among the results for total phenols content and FRAP antioxidant activity of the extracts depending on the extraction agent used was analysed. One-way analysis of variance (ANOVA) was used followed by the Tukey’s HSD or Dunnett T3 test, depending on whether equal variances could be assumed or not. All statistical tests were performed at a 5 % significance level using the IBM SPSS Statistics 20 software.

3 Results and discussion

Plant materials contain various phenolics compounds (e.g., phenolic acids, anthocyanins, tannins, etc.) in variable amounts. Moreover, phenolics may be associated with other components such as carbohydrates and proteins that can be extracted together with them. Therefore, the extraction process must be designed for each phenolics source, and many factors can contribute to the extraction efficiency, such as the type of the solvent, pH, temperature, solid/liquid ratio, etc. The extraction of antioxidant phenolic compounds from plant materials is habitually carried out with organic solvents, alone or combined, and the extraction efficiency for a particular phenolics group depends on solvent polarity (Dai and Mumper 2010). This alternative has previously been studied (Fernández-Agulló et al. 2014). However, in this work plant materials from various species were extracted with water or aqueous alkaline solutions, which is the extraction method habitually used for tannin extraction (Pizzi 1994). Depending on the extraction agent used (water or aqueous solutions of sodium hydroxide, sodium sulphite or both) changes in the extraction yield and process selectivity for phenolics are expected.

The experimental results for extraction yield, extract total phenols content and extract antioxidant activity evaluated according to the FRAP, DPPH and ABTS essays are shown in Table 1.

Extraction yield varied between 2.07 % for the lime wood extracted with an aqueous solution of 2 % sodium sulphite (TW3), and 38.42 % for the steam peeled chestnut shell extracted with an aqueous solution of 1 % sodium hydroxide and 1 % sodium sulphite (ChS24). In general, the yield increased in the order TW < EGB < QRB < QFB < PPB < ChB < ChS1 < ChS2. Except for lime wood, the lowest extraction yields were obtained for the water extractions and the highest for the extractions carried out with an aqueous solution of 1 % sodium hydroxide and 1 % sodium sulphite. Significantly lower extraction yields (2–14.7 %) were obtained for wood and bark extracted with methanol/water 70:30 (v/v) (Diouf et al. 2006), and it is noteworthy that the lowest value corresponded to pine bark. Although a high extraction yield is important in terms of process economic viability, it must be accompanied by extracts with high values of those properties related to prevent wood photodegradation, as is the case for extract antioxidant activity which was evaluated by different methods.

The highest values of the extract antioxidant activity were achieved for Pinus pinaster bark (PPB) or steam peeled chestnut shell (ChS2) extracts depending on the essay used and the lowest values for Eucalyptus globulus bark (EGB) or Tilia cordata wood (TW) extracts. The FRAP antioxidant activity decreased in the order ChS21 > PPB3 > QRB3 > ChS12 > QFB1 > TW3 > ChB1 > EGB3 and, for each material, it was statistically dependent on the extraction agent used (the highest value attained for each material is indicated); the DPPH radical scavenging activity decreased in the order: PPB1 > ChS21 > ChS13 > QFB3 > QRB3 > ChB4 > EGB3 > TW1 and the ABTS radical scavenging activity in the order ChS21 > PPB1 > QFB1 > ChS14 > QRB2 > ChB4 > EGB3 > TW3. With respect to the influence of extraction conditions, in general, for most of the materials the water and the 2 % sodium sulphite extracts showed the highest antioxidant activities.

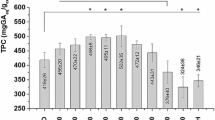

For all materials studied, total phenols content was significantly dependent on the extraction agent (see Table 1). The total phenols contents of Pinus pinaster bark extracts, from 67.06 to 73.81 %, were significantly higher than those of the rest of materials which decreased in the order PPB4 > ChS21 > QRB3 > QFB1 > ChS13 > ChB1 > EGB3 > TW3. The highest value corresponded to the extraction of pine bark with 1 % sodium hydroxide and 1 % sodium sulphite (PPB4) although not significantly different from that of the 2 % sodium sulphite extract (PPB3). Pine bark extracts obtained with methanol/water showed notably lower total phenols content (Diouf et al. 2006).

Extracts from pine bark and steam peeled chestnut shell, with the highest total phenols content and antioxidant activity, not only showed the best properties as bioprotectors but also high extraction yields, especially for pine bark. In the case of chestnut shell, the water extract showed the best properties (ChS21). For pine bark, the 2 % sodium sulphite extract (PPB3) was the best, although PPB4 extract, obtained using 1 % sodium hydroxide and 1 % sodium sulphite, showed very similar properties and a slightly higher extraction yield. With respect to the other materials, except for chestnut bur whose water extract was the best, the best antioxidant properties were obtained for the 2 % sodium sulphite extract.

Figure 1 shows the inhibition percentage of the DPPH radical for the selected extract of each material as a function of extract concentration which allowed calculating the EC50 values, which decreased in the same order in which the TRE increased for the DPPH essay. The EC50 values obtained for the different extracts were compared with those obtained for the antioxidant compound used as reference, Trolox, with values of EC50 of 0.04 mg/mL for the DPPH essay and 0.30 mg/mL for the ABTS essay. As shown in Table 1, lower EC50 values were obtained for all ChS2 extracts and for most of the PPB extracts for both essays, which confirms the selection of ChS21 and PPB3 extracts as the ones with the best antioxidant properties.

Inhibition percentage for the DPPH radical as a function of extract concentration for the selected extract of each material [ChB1: chestnut bur; ChS13: dry peeled chestnut shell; ChS21: steam peeled chestnut shell; EGB3: Eucalyptus globulus bark; PPB3: Pinus pinaster bark; QFB3: Quercus frainetto bark; QRB3: Quercus robur bark; TW3: Tilia cordata wood (1, water extracts; 3, 2 % Na2SO3 extracts)]

It should be noted that the results obtained for the antioxidant activity of pine bark extracts are contrary to those of industrial and methanol/water pine bark extracts that showed a poor antioxidant activity (Diouf et al. 2006).

Of the main wood constituents, cellulose, hemicellulose and lignin, only lignin is a good UV absorber and is the key structure in wood photodegradation. However, some wood extractives may play a role as antioxidants and as radical quenchers (George et al. 2005). Chang et al. (2014) demonstrated that A. confusa heartwood extract can absorb UV light, inhibiting the formation of wood radicals induced by UV light and consequently retarding wood photodegradation. To test the capacity of the extracts obtained to absorb UV light, the UV spectra of a selection of extracts were obtained and are shown in Fig. 2. Pinus pinaster bark, chestnut shell and Tilia cordata wood extracts exhibited a single peak with maximum absorbance in the range 273–278 nm characteristic of proanthocyanidins. However, chestnut bur, Eucalyptus globulus bark and Quercus frainetto bark extracts did not show a clear maximum but a broad band that could be explained by the presence of hydrolysable tannins that have an additional absorption maximum at 365 nm (Cadahía et al. 1997). The capacity of some of the extracts prepared in this work for preventing wood colour photodegradation was demonstrated subjecting dyed veneers treated with the extracts to essays of accelerated exposure to UV light (Galiñanes et al. 2015).

UV spectra of selected extracts [ChB2: chestnut bur; ChS13: dry peeled chestnut shell; ChS21: steam peeled chestnut shell; EGB3: Eucalyptus globulus bark; PPB3: Pinus pinaster bark; QFB3: Quercus frainetto bark; TW3: Tilia cordata wood (1, water extracts; 2, 1 % NaOH extracts, 3, 2 % Na2SO3 extracts)]

Linear relationships were found between the different methods used for evaluating extract antioxidant activity, as shown in Fig. 3 for the ABTS and FRAP essays (r2 = 0.8678), which allows to make indirect estimations of the different essays (Thaipong et al. 2006). Additionally, significant linear relationships between antioxidant capacity and total phenolic content were found, indicating that phenolic compounds are the major contributors to the antioxidant properties of the extracts analyzed. As an example, Fig. 4 shows the linear relationship encountered for total phenols content and DPPH antioxidant activity (r2 = 0.7876) which was practically independent of the type of material. Diouf et al. (2006) also found linear relationships between phenols content and antioxidant activity, however, they were dependent on extract composition, i.e. comprising condensed or hydrolysable tannins.

Relationship between total phenols content and DPPH radical scavenging activity (ChB: chestnut bur; ChS1: dry peeled chestnut shell; ChS2: steam peeled chestnut shell; EGB: Eucalyptus globulus bark; PPB: Pinus pinaster bark; QFB: Quercus frainetto bark; QRB: Quercus robur bark; TW: Tilia cordata wood)

Number and weight average molecular weights (Mn and Mw, respectively, Table 1) and molecular weight distribution (MWD) of the extracts were analyzed. Comparing the Mn and Mw values for the different materials studied, the higher values corresponded to Pinus pinaster bark and steam peeled chestnut shell extracts, which also presented the best antioxidant properties. In particular, the water extract of steam peeled chestnut shell (ChS21) had not only the highest average molecular weights but also the highest values of the antioxidant activity, which could be related to the polyphenolic composition of this extract. With respect to molecular weight distribution, Fig. 5 shows the extract selected for each material. Most of them (ChS21, PPB3, QFB3, QRB3, and TW3 extracts) presented unimodal distribution with the position of the peak located towards the low molecular weight region and with some resolution of low molecular components. On the contrary, EGB3, ChB1 and ChS13 extracts show a bimodal distribution with both peaks located in the lower molecular weight region.

Molecular weight distribution of the selected extract of each material [ChB1: chestnut bur; ChS13: dry peeled chestnut shell; ChS21: steam peeled chestnut shell; EGB3: Eucalyptus globulus bark; PPB3: Pinus pinaster bark; QFB3: Quercus frainetto bark; QRB3: Quercus robur bark; TW3: Tilia cordata wood (1, water extracts; 3, 2 % Na2SO3 extracts)]

RP-HPLC-ESI-TOF mass spectrometry was used to identify the phenolic compounds with potential antioxidant activity present in the optimum extract selected for each of the materials analysed. Some of the compounds were identified based on their retention times and comparison with the standard compounds and others by their molecular weight. A summary of the identified compounds, various flavonoids and phenolic acids, is presented in Table 2. Chestnut bur and eucalyptus bark extracts contained the phenolic acids, gallic acid and ellagic acid, both base units of hydrolysable tannins, and in the case of bur extracts also the flavonol myricetin. On the contrary, pine bark and lime wood extracts contained precursors of condensed tannins, the flavan-3-ols (+)-catechin and/or (−)-epigallocatechin, together with a flavonol, kaempferol, and in the former the flavonoid dihydroquercetin. The other extracts contained precursors of both hydrolysable and condensed tannins together with flavonols and flavonol glycosides.

4 Conclusion

Extracts obtained from various lignocellulosic wastes, chestnut fruit (Castanea sativa) shell and bur, barks from Pinus pinaster, Eucalyptus globulus, Quercus frainetto and Quercus robur and wood from Tilia cordata have demonstrated to have antioxidant properties, which convert them into potential preservatives of wood color photodegradation. Among them, aqueous extracts of steam peeled chestnut shell and 2 % sodium sulphite extracts of pine bark were selected due to their higher antioxidant activity, total phenols content and extraction yield. Various kinds of phenolic compounds, precursors of hydrolysable and condensed tannins, phenolic acids and flavan-3-ols, respectively, and other flavonoids have been identified and related to extract antioxidant properties.

References

Barreira JCM, Ferreira ICFR, Oliveira MBPP, Pereira JA (2008) Antioxidant activities of the extracts from chestnut flower, leaf, skins and fruit. Food Chem 107:1106–1113

Bruce A, Palfreyman JW (eds) (1998) Forest Product Biotechnology. Taylor and Francis, London

Cadahía E, Conde E, Fernández de Simón B, García-Vallejo MC (1997) Tannin composition of Eucalyptus camaldulensis, E.globulus and E. rudis. Part II. Bark. Holzforschung 51:125–129

Chang TC, Chang HT, Wu CL, Lin HY, Chang ST (2010a) Influences of extractives on the photodegradation of wood. Polym Degrad Stab 95:516–521

Chang TC, Chang HT, Wu CL, Lin HY, Chang ST (2010b) Stabilizing effect of extractives on the photo-oxidation of Acacia confusa wood. Polym Degrad Stab 95:1518–1522

Chang TC, Lin HY, Wang SY, Chang ST (2014) Study on inhibition mechanisms of light-induced wood radicals by Acacia confusa heartwood extracts. Polym Degrad Stab 105:42–47

Dai J, Mumper RJ (2010) Plant phenolics: extraction, analysis and their antioxidant and anticancer properties. Molecules 15:7313–7352

Diouf PN, Merlin A, Perrin D (2006) Antioxidant properties of wood extracts and colour stability of woods. Ann For Sci 63:525–534

Evans PD (2009) Review of the weathering and photostability of modified wood. Wood Mat Sci Eng 4(1 and 2):2–13

Evans PD, Owen NL, Schmid S, Webster RD (2002) Weathering and photostability of benzoylated wood. Polym Degrad Stab 76:291–303

Fernández-Agulló A, Freire MS, Antorrena G, Pereira JA, González-Álvarez J (2014) Effect of the extraction technique and operational conditions on the recovery of bioactive compounds from chestnut (Castanea sativa) bur and shell. Sep Sci Technol 49:267–277

Galiñanes C, Freire MS, González-Álvarez J (2015) UV protection effects of phenolic extracts from chestnut fruit and forest industries residues. Eur J Wood Prod. doi:10.1007/s00107-015-0937-6

George B, Suttie E, Merlin A, Deglise X (2005) Photodegradation and photostabilisation of wood-the state of the art. Polym Degrad Stab 88:268–274

Jebrane M, Sebe G, Cullis I, Evans PD (2009) Photostabilisation of wood using aromatic vinyl esters. Polym Degrad Stab 94:151–157

Laks PE, McKaig PA, Hemingway RW (1988) Flavonoid biocides: wood preservatives based on condensed tannins. Holzforschung 42:299–306

Pizzi A (1994) Advanced wood adhesives technology. Marcel Dekker Inc., New York

Re R, Pellegrini N, Proteggente A, Pannala A, Yang M, Rice-Evans C (1999) Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic Biol Med 26:1231–1237

Schnabel T, Musso M, Tondi G (2014) Univariate and multivariate analysis of tannin-impregnated wood species by using vibrational spectroscopy. Appl Spectrosc 68:488–494

Singleton VL, Rossi JA (1965) Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am J Enol Vitic 16:144–158

Szöllösi R, Szöllösi-Varga I (2002) Total antioxidant power in some species of Labiatae (Adaptation of FRAP method). Acta Biol Sxegediensis 46:125–127

Thaipong K, Boonprakob U, Crosby K, Cisneros-Zevallos L, Byrne DK (2006) Comparison of ABTS, DPPH, FRAP, and ORAC assays for estimating antioxidant activity from guava fruit extracts. J Food Compos Anal 19:669–675

Thevenon MF, Tondi G, Pizzi A (2009) High performance tannin resin-boron wood preservatives for outdoor end-uses. Eur J Wood Prod 67:89–93

Tondi G, Palanti S, Wieland S, Thevenon MF, Petutschnigg A, Schnabel T (2012) Durability of tannin- boron-treated timber. BioResources 7:5138–5151

Tondi G, Schnabel T, Wieland S, Petutschnigg (2013a) Surface properties of tannin treated wood during natural and artificial weathering. Int Wood Prod J 4:150–157

Tondi G, Thevenon MF, Mies B, Standfest G, Petutschnigg A, Wieland S (2013b) Impregnation of Scots pine and beech with tannin solutions: effect of viscosity and wood anatomy in wood infiltration. Wood Sci Technol 47:615–626

Acknowledgments

This work was financially supported by the Xunta de Galicia (Project 09DPI106) under a contract with the company ASERPAL S.A.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Galiñanes, C., Freire, M.S. & González-Álvarez, J. Antioxidant activity of phenolic extracts from chestnut fruit and forest industries residues. Eur. J. Wood Prod. 73, 651–659 (2015). https://doi.org/10.1007/s00107-015-0936-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-015-0936-7