Abstract

Estimation of rock mass deformation modulus is the subject of many studies in rock engineering research work. Although numerous predictive models have been developed for the estimation of the deformation modulus, they cannot be generalized for other sites because of inadequate accuracy. Furthermore, it is very valuable that the predictive models involve some accessible input parameters. The rock mass rating (RMR) is a well-known geomechanical parameter, which is usually determined to describe the quality of rock mass in rock engineering projects. In this study, five parameter ratings of the RMR classification system are used to predict the deformation modulus of rock mass in the abutment of the Gotvand earth dam. Statistical analysis and an artificial neural network are employed to present two new predictive models. Finally, probabilistic analysis is used to predict the rock mass deformation modulus, which overcomes the low accuracy caused by the inherent uncertainty in prediction. The results indicated that the parameter ratings used in the RMR classification system can predict the rock mass deformation modulus with a satisfactory correlation. However, the parameters don’t have the same influence on the rock mass deformability with the joint condition and the groundwater as the major and minor influencing parameters, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The deformation modulus of rock masses is one of the most critical parameters used in the design stage of engineering structures such as dams, tunnels and slopes. By definition, the deformation modulus is the rock mass tendency to be deformed permanently and non-permanently. Thus, the deformation modulus has an inverse relationship with the deformation level of the rock mass. Although there are some in situ tests to determine the rock mass deformation modulus, many researches (Bieniawski 1978; Serafim and Pereira 1983; Nicholson and Bieniawski 1990; Mitri et al. 1994. Palmstrom and Singh 2001; Barton 2002 Kayabasi et al. 2003; Gokceoglu et al. 2003; Zhang and Einstein 2004; Sonmez et al. 2004, 2006) have been performed to present an indirect method for estimation of rock mass deformability. This is due to the limitations of the in situ tests, e.g., the test procedures are usually difficult, expensive and time consuming.

In previous studies, many empirical equations have been suggested using parameters, which describe the quality of the rock mass, such as rock mass rating (RMR), tunnelling quality index (Q), rock quality designation (RQD), geological strength index (GSI), etc. In other words, at least one of the rock mass classification indices may be used in the empirical equations (Sonmez et al. 2006). This is because the joints and their particular properties, such as weathering, infilling material, roughness and aperture have considerable effect on the deformation of a rock mass. The RMR as one of the preferred classification systems has been used in many research works to describe rock mass quality.

Bieniawski (1978) suggested the first empirical equation for estimation of deformation modulus which considers only RMR as an input parameter. However, Bieniawski’s model has a fundamental limitation and applies to rock masses with RMR < 50. For RMR > 50, Serafim and Pereira (1983) proposed another empirical equation. Nicholson and Bieniawski (1990) and Mitri et al. (1994) then used the RMR value and presented a ratio of rock mass modulus to the intact modulus which is varied from 0 to 1. Finally, Sonmez et al. (2006) suggested an empirical equation, which considers RMR and the elastic modulus of intact rock using worldwide data. Table 1 lists some of the empirical equations which are based on the RMR system for estimation of rock mass deformation modulus.

The proposed equations in previous studies cannot be generalized to obtain a realistic result on the estimation of rock mass deformation modulus for other sites. In this study, prediction of the rock mass deformation modulus with RMR parameters and their ratings is evaluated in the abutment of the Gotvand earth dam. Statistical analysis and an Artificial Neural Network (ANA) were used to propose two new predictive models with a more practical performance than previous models. Furthermore, a probabilistic approach is applied to determine the impact of geomechanical characteristics of rock mass on the rock mass deformation modulus.

Case study on Gotvand earth dam abutments

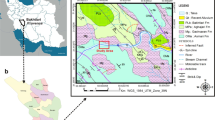

The Gotvand Olia hydroelectric power plant project is located at 48°, 56′ and 10″ of east and 32°, 16′ and 8″ of north. It is situated 380 km of the Karun river mouth and is distanced 10 km to north-east of Gotvand city in Khuzestan province, Iran (Fig. 1). Bakhtiary and Aghajari are two predominant formations in the bed rock and abutments of the Gotvand dam. Conglomerate, cherty lime-stone and interbedded mudstones and sandstone are found in the Bakhtiary formation; and the Aghajari formation contains of gray and greenish gray sandstones, interbeded clay-stone, siltstone and brow reddish marlstone. The Gotvand Dam is an earthen dam and will have an installed generating capability of 2,000 MW which is divided into two 1,000 MW phases. It is estimated to be complete in 2015 and is going to become one of Iran’s largest power stations (IWPCO 2005).

In-situ test

For this study, data were gathered from some in situ tests conducted at the Gotvand earth dam. Two types of in situ tests (plate bearing test and dilatometer test) have been performed to measure the modulus of rock mass at various locations of the site.

Eight plate bearing tests have been planned in the exploration galleries and deviation tunnels on the sandy siltstone, and conglomerate. The tests have been performed in the large scale (plate diameter is 1 meter) with five loading–unloading cycles. The maximum pressure applied in the two last cycles was 6 MPa. Five tests were performed horizontally and three tests vertically.

Forty four dilatometer tests have been carried out using flexible packers inside some boreholes excavated in siltstone, sandstone, conglomerate, mudstone, faulted rock mass and the shear zone. Dilatometer tests have been done in four cycles of loading–unloading upon 6 MPa pressure in the three dimensions (IWPCO 2005).

Site investigation

For description of the rock mass quality and gathering of information about the studied abutments, a site investigation has been carried out. Generally, the quality of rock mass in the site is variable. The average value of RMR is presented in Table 2 in different formations and rock masses.

The RMR values vary in the range of 30–76. Thus, the rock masses are situated in the poor, fair and good rock classes, based on Bieniawski’s geomechanics classification (Bieniawski 1989). Figure 2 depicts distribution of RMR values in the abutments of the Gotvand site.

Correlation of rock mass deformation modulus and RMR value

Rock mass classification can provide a global insight about the project site and its geomechanical characteristics even if detailed information is not available during the feasibility and preliminary design stages of a project. The deformation modulus is site specific and depends strongly on the quality of rock mass. The RMR system as one of the preferred classification systems has been utilized in numerous rock engineering projects for different applications. For example, estimation of effective porosity and hydraulic conductivity of rock masses (Liu et al. 1999), modification of rock mass failure criteria (González Nicieza et al. 2006), and prediction of TBM performance (Khademi Hamidi et al. 2010), are some of derivative application of the RMR system in rock engineering projects.

Figure 3 depicts variation of the rock mass deformability versus the RMR values of the Gotvand dam abutments, where the data is approximated by exponential and linear correlation trends depicted through Fig. 3a, b, respectively. Although the results reveal that there is a significant correlation between the rock deformation modulus and RMR, the correlation coefficient, R-square, achieved for exponential trend is 0.64 and for that of the linear trend is 0.67 which are not sufficiently adequate for estimation of rock mass deformability.

Statistical analysis

In-situ tests determine the value of rock mass deformability in various locations of the site. The site investigation quantifies the rating of classification parameters applied in Bieniawski’s classification (Bieniawski 1989). Table 3 presents a quantitative description of the site's geomechanical condition, namely, the value of rock mass deformability and the classification parameter ratings.

In other words, the values given in Table 3, except for the rock mass deformability, are the allocated ratings for the RMR classification parameters. Mean, standard deviation, Minimum, First quartile (Q1), median or second quartile, Third quartile (Q3), and maximum value of parameters and parameter ratings are presented in Table 3. The Q1 and Q3 represent the values that 25 and 75 % of the data are less than or equal to them, respectively.

Multiple linear regressions

Multiple linear regression (MLR) is a multivariate statistical technique used to examine the linear correlations between two or more independent variables and a single dependent variable. The deformation modulus of rock and the rating of the classification parameters were considered as dependent and independent variables, respectively. The regression analysis was performed using MINITAB 15 statistical software and the detailed results are summarized in Table 4.

The coefficient of independent variables along with its standard error is shown in Table 4. Based on this coefficient, a linear equation for prediction of dependent variable (E rm) is presented;

According to Eq. 1, rock mass deformability is estimated as R 2 = 0.84 % (Fig. 4). Furthermore, the T statistic and the P value of the correlation between dependent and independent variables are given in Table 4. The P value, which varies from 0 to 1, determines the appropriateness of rejecting the null hypothesis in a hypothesis test. The probability of a mistake in rejecting the null hypothesis is decreased with smaller P values.

The correlations between R 1 and R 5 with E rm are not considerably appropriate. Hence, it is implied that the allocated ratings to the two parameters (R 1 and R 5) are not balanced for estimation of the rock mass deformation modulus. Although UCS has a strong influence on deformability of intact rocks, rock mass deformability is substantially affected by the deformation modulus of rock joints and discontinuities that is significantly less than the intact rock modulus.

Regression analysis presents a new equation with combinations of parameter ratings used in the RMR system with an R square of 0.84 % while the exponential and linear trends estimate a rock deformation modulus with 0.64 and 0.67 % r-squares, respectively (see Fig. 3a, b). Thus, the proposed equation using linear regression is more accurate than the RMR based equation (Fig. 3a, b). This is because the five parameter ratings used in the RMR system do not have a similar influence on the deformation modulus. In other words, the weights of each parameter in the proposed statistical model are not the same value. However, each parameter should be properly weighted to precisely predict the output. One of the best-known methods for weighting adjustment is the artificial neural network (ANN). Numerous studies have been conducted to predict rock properties using ANNs (Meulenkamp and Grima 1999; Kim et al. 2001; Singh et al. 2001, 2007; Gokceoglu et al. 2004; Monjezi el al. 2010). Although the values of the allocated weights are not visible in ANN, the resulting models provide the adjustment of the weights by a training process in order to minimize the error between the desired target and the estimated output. In the next section, an ANN model is presented for prediction of rock mass deformability based on the five rating parameters of the RMR system (Fig. 4).

Artificial neural networks (ANNs)

Artificial neural networks (ANNs) simulate human brain performance by training data for applications where formal analysis is difficult or impossible. The network could be defined using combinations of simple elements known as neurons. Neurons in ANNs are a computational model inspired in biological neurons so as to perform certain computations. The main inspiration of ANNs is to adjust the values of the connection or weights between the neurons (Fig. 5). As shown in Fig. 5, weights are continuously modified and adjusted by a training process to minimize the error between the desired target and the estimated output.

Multi-layer feed forward network

A wide range of problems are solved through the application of ANNs. The Multi-Layer Feed Forward Network (MLFF) is one of the frequently used networks proposed by Rumelhart (1986) and is used here as the neural network. The MLFFs are organized in layers including input, output and hidden layers. The number of neurons in input and output layers is equal to the size of input and output data arrays, respectively.

In this section, the purpose is to estimate the rock mass deformability using five parameters including allocated ratings to the UCS, RQD, joint spacing, joint condition and groundwater. The input and target values are first mapped into the interval [−1, 1] and, after the training process; the outputs are inversely mapped to the real values. The mapping formula is defined as,

where y is the mapped value of x and x max, and x min are the maximum and minimum values of x, respectively.

Figure 6 depicts the structure of the model used in this study. Two hidden layers with 11 neurons in the first layer and three neurons in the second are adopted in the MLFF model. Furthermore, sigmoidal transfer functions are implemented in hidden layer neurons. Table 5 lists the specifications of the developed network.

Among 52 available data, 32 random data are selected to train the network. In addition, ten data are separately selected for each of the validation and test operations. Performance of the training data set is measured in terms of the mean squared error (MSE) and rapidly decreases as the network is trained (Fig. 7). After 100,000 epochs of training, the network performance will be satisfactory based on the MSE of the validation data. Figure 8 depicts the correlation between the simulated and real rock mass deformation modulus for the training and test data sets. As shown in Fig. 8b, there is a fair correlation between the output and target values for the test data set (0.95 %).

A comparison of the regression analysis results with those of the neural network shows that the developed model using neural network predicts the rock mass deformation modulus more accurately. Therefore, it can be concluded that the considered parameters in the RMR classification provide a capable system for prediction of rock mass deformability, though the parameters don’t have the same influence on the result. Nevertheless, the neural network is stronger than the statistical analysis in adjusting the weight of the parameters, and; thus, the correlation between the neural network output and the target values is highly satisfactory.

One of the most important disadvantages of neural networks is that the model obtained with the neural network is not understandable and does not use a parametric approach, unlike the statistical methods. Therefore, the effect of each input parameter on the value of the output cannot be considered.

On the other hand, uncertainty and variability of rock properties are inevitable due to some features including (a) measurement errors, (b) data inconsistency and non-homogeneity and (c) data handling (Malkawi et al. 2000). Furthermore, in the geotechnical design, interpretation of geological characteristics is sometimes inevitable and is based on personal judgment, previous knowledge and experience of the experts related to the scenarios (Polson and Curtis 2010), while in a deterministic analysis; it is assumed that all input parameters are exactly known. Therefore, a deterministic approach, which results only in a unique value, does not present a sufficient accuracy for calculation of rock properties. On the contrary, probability analysis gives both the range of values that the variable can take and the relative frequency of each value within the range (Evans et al. 1993). Thus, the problem can be solved using probability analysis in this study case.

Probabilistic sensitivity analysis

Probabilistic analysis provides a reasonable tool to quantify the variability and uncertainty of predictions. In particular, the probabilistic approach to rock mass classifications makes it possible to consider uncertainty and variability in rating allocation.

The Monte Carlo Simulation (MCS) is one of the most preferred approaches for probabilistic analysis, which is based on the generation of multiple trials to determine the expected values of a random variable (Rubinstein and Kroese 2007). Then input(s) and output(s) of the probabilistic analysis are denoted by distribution functions. It is worth mentioning that the input distribution functions are obtained based on the variation of parameters whereas the output distribution is calculated by MCS. Figure 9 depicts the Probability Density Function (PDF) of input parameters based on their variation on the abutments of the Gotvand dam.

Sensitivity analysis can provide a comprehensive insight to help engineers gain knowledge of complex model behaviors and make informed decisions regarding where to spend engineering effort. In an uncertain design, probabilistic sensitivity analysis is performed to quantify the impact of uncertainties in random variables on the uncertainty in model outputs (Nejati et al. 2012). In other words, probabilistic sensitivity analysis is used to rank the significance of input parameters.

The output of probabilistic analysis is calculated using MCS on the basis of Eq. 1. In MCS randomness is introduced into simulation models via independent distributed random variables. Figure 10a shows the distribution of deformation modulus in the abutment of the Gotvand earth dam. Furthermore, probabilistic sensitivity analysis is performed to quantify the impact of uncertainties in random variables on the uncertainty in model outputs. Figure 10b depicts the impact of input parameters on the deformation modulus of rock mass using a Tornado diagram.

As shown in Fig. 10a, the value of the deformation modulus is in the range of 1.38–6.07 GPa with a probability of 90 %. In other words, the value of rock mass deformation modulus is less than 6.07 GPa or more than 1.38 with 95 % probability.

Furthermore, Fig. 10b indicates that all parameter ratings used in the RMR system have a direct and different, influence on the value of the rock mass deformation. Joint condition has the most, and groundwater has the least, effect on the deformation of rock mass.

Deformation modulus of rock masses is made up of two components: one due to deformation of the intact rock; the other due to the deformability of the joints and discontinuities (Hudson and Harrison 1997). Whereas deformation modulus of rock joints is considerably less than the intact rock deformation modulus, the predominant factor on rock mass deformability is rock joint condition.

Conclusion

In this study, parameter ratings of the RMR classification system were used to predict rock mass deformation modulus of Gotvand earth dam. The parameter ratings were discussed and investigated and it was shown that they can precisely describe the quality of rock mass, especially rock mass deformability, though all these parameters may have different influences on the rock mass deformability. In other words, the value of rating for the RMR parameters is not allocated accurately; and it may be modified.

Rock mass rating (RMR), which is a combination of five parameter ratings, affects the rock deformation modulus with a rather satisfactory correlation. Exponential and linear trend lines were presented which showed a correlation coefficient of 0.64 and 0.67 %, respectively. These coefficients are obtained with the assumption that the RMR parameter ratings have identical influence on the rock mass deformability.

The equation obtained by multiple linear regressions predicts rock mass deformability with a correlation coefficient of 0.84 %, which is more appropriate than the latter correlations.

The artificial neural network (ANN) is a useful means to enhance the prediction efficiency and is also used in this study. In this case, a multi-layer feed forward network (MLFF) with five inputs is developed and used for prediction of rock mass deformability. The optimum ANN architecture is found to be five neurons in the input layer, one neuron in the output layer and two hidden layers with 11 and three neurons, respectively.

The correlation between the neural network output and target values is 0.95 % which is highly satisfactory compared to statistical analysis.

On the basis of probabilistic analysis, the value of deformation modulus is in the range of 1.38–6.07 GPa with 90 % probability; specifically it is more than 1.38 GPa with 95 % probability; and a probability of 5 % can be expected for a modulus of more than 6.07 GPa.

Probabilistic sensitivity analysis indicates that all parameter ratings used in RMR system have a direct and different influence on the value of the rock mass deformation. Joint condition has the most and groundwater has the least effect on the deformation of rock mass.

References

Barton N (2002) Some new Q value correlations to assist in site characterisation and tunnel design. Int J Rock Mech Min Sci 39:185–216

Bieniawski ZT (1978) Determining rock mass deformability: experience from case histories. Int J Rock Mech Min Sci Geomech Abstr 15:237–247

Bieniawski ZT (1989) Engineering rock mass classifications. Wiley, New York

Evans E, Hastings N, Peacock B (1993) Statistical distributions, 2nd edn. Wiley, New York, p 170

Gokceoglu C, Sonmez H, Kayabasi A (2003) Predicting the deformation moduli of rock masses. Int J Rock Mech Min Sci 40:701–710

Gokceoglu C, Yesilnacar E, Sonmez H, Kayabasi A (2004) A neuro-fuzzy model for modulus of deformation of jointed rock masses. Comput Geotech 31:375–383

González Nicieza C, Álvarez Fernández MI, Menéndez Díaz A, Álvarez Vigil AE (2006) Modification of rock failure criteria considering the RMR caused by joints. Comput Geotechn 33(8):419–431

Hudson JA, Harrison JP (1997) Engineering rock mechanics, an introduction to the principles. Pergamon Press, Oxford, p 458

IWPCO (Iran water and power resources dev. Co.) (2005) Rock mechanics studies. Final report. Upper Gotvand dam and HPP

Kayabasi A, Gokceoglu C, Ercanoglu M (2003) Estimating the deformation modulus of rock masses: a comparative study. Int J Rock Mech Min Sci 40:55–63

Khademi Hamidi J, Shahriar K, Rezai B, Rostami J (2010) Performance prediction of hard rock TBM using rock mass rating (RMR) system. Tunn Undergr Space Technol 25(4):333–345

Kim CY, Bae GJ, Hong SW, Park CH (2001) Neural network based prediction of ground surface settlements due to tunneling. Comput Geotechn 28:517–547

Liu J, Elsworth D, Brady BH (1999) Linking stress-dependent effective porosity and hydraulic conductivity fields to RMR. Int J Rock Mech Min Sci 36(5):581–596

Malkawi AIH, Hassan FW, Abdulla FA (2000) Uncertainty and reliability analysis applied to slope stability. Struct Saf 22:161–187

Meulenkamp F, Alvarez Grima M (1999) Application of neural networks for the prediction of the unconfined compressive strength (UCS) from Equotip hardness. Int J Rock Mech Min Sci 36:29–39

Mitri HS, Edrissi R, Henning J (1994) Finite element modelling of cablebolted stopes in hard rock ground mines. In: Presented at the SME annual meeting. Albuquerque, pp 94–116

Monjezi M, Amiri H, Farrokhi A, Goshtasbi K (2010) Prediction of rock fragmentation due to blasting in Sarcheshmeh copper mine using artificial neural networks. Geotech Geol Eng 28:423–430

Nejati HR, Ahmadi M, Hasheomolhosseini H, Hayati M (2012) Probabilistic analysis of ground surface vibration due to train movement, a case study on Tehran metro line 4. Geotech Geol Eng 30:1137–1146

Nicholson GA, Bieniawski ZT (1990) A nonlinear deformation modulus based on rock mass classification. Int J Min Geol Eng 8:181–202

Palmstrom A, Singh R (2001) The deformation modulus of rock masses – comparisons between in situ tests and indirect estimates. Tunn Undergr Space Tech 16:115–131

Polson D, Curtis A (2010) Dynamics of uncertainty in geological interpretation. J Geol Soc Lond 167:5–10

Read SAL, Richards LR, Perrin ND (1999) Applicability of the Hoek-Brown failure criterion to New Zealand greywacke rocks. In: Proc 9th Int Cong on Rock Mechanics, Paris, pp 655–660

Rubinstein RY, Kroese DP (2007) Simulation and the Monte Carlo method. Wiley, New York

Rumelhart DE (1986) Learning representations by back-propagating errors. Nature 323:533–536

Serafim JL, Pereira JP (1983) Considerations on the geomechanical classification of Bieniawski. In: Proceedings of the symposium on engineering geology and underground openings. Lisboa, pp 1133–44

Singh VK, Singh D, Singh TN (2001) Prediction of strength properties of some schistose rocks from petrographic properties using artificial neural networks. Int J Rock Mech Min Sci 38:269–284

Singh TN, Sinha S, Singh VK (2007) Prediction of thermal conductivity of rock through physico-mechanical properties. Build Environ 42:146–155

Sonmez H, Gokceoglu C, Ulusay R (2004) Indirect determination of the modulus of deformation of rock masses based on the GSI system. Int J Rock Mech Min Sci 41(5):849–857

Sonmez H, Gokceoglu C, Nefeslioglu HA, Kayabasi A (2006) Estimation of rock modulus: for intact rocks with an artificial neural network and for rock masses with a new empirical equation. Int J Rock Mech Min Sci 43:224–235

Zhang L, Einstein H (2004) Using RQD to estimate the deformation modulus of rock masses. Int J Rock Mech Min Sci 41:337–341

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nejati, H.R., Ghazvinian, A., Moosavi, S.A. et al. On the use of the RMR system for estimation of rock mass deformation modulus. Bull Eng Geol Environ 73, 531–540 (2014). https://doi.org/10.1007/s10064-013-0522-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-013-0522-3