Abstract

This paper reports the site investigations (geological, geophysical and geotechnical) for the construction of a block of five buildings, with nine storeys each, in the Muratpasa District, Antalya. The base rocks consist of travertines that have been affected by domestic and industrial liquid wastes that were injected directly into the travertine plateau through septic holes prior to 2000. Therefore, the travertine rocks have poor engineering properties, such as high deformability and insufficient strength. This causes problems in the construction of engineered structures, and detailed investigations were required to determine the potential risk to the foundations of the buildings, and what measures would be required to mitigate those risks. In this study, the effects of injected wastewaters on the mass and material properties of travertine rocks, as well as overall reinforcement of the foundation, were investigated. Further investigations for foundations were recommended and implemented.

Résumé

Cet article présente les enquêtes sur le terrain (géologiques, géophysiques et géotechniques) pour la construction d’un bloc de cinq bâtiments, avec neuf étages chacun, dans le district de Muratpasa, Antalya. Les roches de base se composent de travertins qui ont été touchées par les déchets liquides domestiques et industriels qui ont été injectés directement dans le plateau de travertin à travers les trous septiques avant 2000, donc, les rochers de travertin ont des propriétés d’ingénierie pauvres, comme la haute déformabilité et résistance insuffisante. Cela provoque des problèmes dans la construction des ouvrages d’art et des analyses détaillées ont été nécessaires pour déterminer le risque potentiel pour les fondations des bâtiments, et les mesures qui seraient nécessaires pour atténuer ces risques. Dans cette étude, les effets d’eaux usées injectées sur les propriétés de masse et matériels de roches de travertin, ainsi que le renforcement global de la fondation, ont été étudiés. D’autres investigations pour les fondations ont été recommandées et mises en œuvre.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The design and construction of foundations in travertine areas have posed various problems to geotechnical engineers, due to the karst structures of travertine. They need to have a good knowledge of subsurface conditions beneath the building foundations (Deceuster et al. 2006). Karst structures can take the form of significant cavities several metres wide, or networks of more limited open fractures (White 1988). They can also include areas of surficial dissolution on the uppermost zone of exposed karstified rocks (Klimchouck 1997). Chalikakis et al. (2011) have published a review of the different geophysical techniques applicable to karst systems.

At present, Antalya has a population of more than one million. This population increases significantly in the summer due to tourist influx to the city. The importance of the area, with respect to the natural beauty of the region, and the geological and hydrogeological complexity of the karst system, has attracted researchers. Special studies have been undertaken on the geology and geomorphology of the Antalya travertine complex (Burger 1990; Glover and Robertson 2003; Karabıyıkoglu et al. 2005). The hydrogeology of the springs and their karst system was studied by General Directorate State Hydrolic Works (1985), Nativ et al. (1999) and Basal and Ekmekci (2000). Geotechnical properties of Antalya travertine were explained by Kilic and Yavuz (1994). Foundation systems in karst areas are a peculiar challenge to individual projects, as has been reported by many researchers (Brinker et al. 2004; Siegel et al. 2005; Quinta Ferreira and Velho 2006). The use of high capacity micropiles to solve foundation problems in karst structures was successfully adopted and published by Traylor et al. (2002), Dotson and Tarquinio (2003) and Uranowski et al. (2004). This micropiling reinforcement of the foundations was applied to the karstic rocks in Malaysia that cross an area underlain by limestone formations and were affected by catastrophic subsidence (Tan and Chow 2006). Ballouz (2005) suggested the application of micropiling in karstic rock in Zouk-Mosbeh city, Lebanon. The behaviors of micropiles under vertical loads in rock were evaluated by Cushing et al. (2004). He compared the results of more than 54 tests done on micropiles in rock and proposed the installation of micropiles under spread footings resting in karstic rocks.

Around Antalya, the wastewater of residential areas and existing industries has been connected to septic holes for discharge for several years. Septic holes allow surface and wastewater to percolate downwards through cracks in the underlying karst travertine. This action in effect causes weathering of the travertines, implying geotechnical problems for the construction of buildings. The construction of a block of five buildings, with nine storeys each, covering an area of 9,774 m2 located in Muratpasa District, Antalya, led to the investigation conducted in this study. The foundation depth designed for the buildings is 3 m. During the early stage of the excavation, dissolution structures were found. Since the area had never been subjected to geotechnical investigation, it was decided that the extent of the karst, its characteristics, and the problems that the karst travertine can cause to the buildings under construction should be evaluated.

This paper reports the geological, geophysical and geotechnical wastewater effects on mass and material properties of karst travertine and on the reinforcement of the foundation.

Regional and site geology

Regional geology

Geological units exposed in the Antalya area are differentiated according to their lithological characteristics (Fig. 1).

Location and simplified geologic map of the study area (modified from General Directorate State Hydrolic Works 1985)

The limestone exposed on the western side of Antalya travertines are dark-grey in colour, massive and microcrystalline in structure. The units’ fracture systems are perpendicular to each other, with the dissolution cavities parallel to dip and karstic in appearance. The karstification is associated with the increase in carbonate content and secondary porosity of the unit. Units formed by the Triassic–Cretaceous Period sandstone, shale, mudstone and limestone horizon are exposed on the NE and SW areas of Antalya. Molasse series of the Miocene limestone, sandstone, marl are cemented conglomerate. The thickness of the series is ~120 m (General Directorate State Hydrolic Works 1985).

Site engineering geology

Travertines are exposed in an area of 630 km2. The different textures in travertines show frequent lateral and vertical transitions (General Directorate State Hydrolic Works 1985). In this study, travertines are classified as massive, weak and spongy. Massive and weak travertines are gradational both laterally and vertically and their thickness is variable.

Site investigations

Site observations after initial excavation of soils

Preliminary investigations of the site revealed several dissolution structures in the travertine already exposed by excavation. After verifying the importance and extent of the problem, it was decided that the construction can only continue after a detailed study of the foundation. Because of the high dimension of the buildings, the cost of the site investigation and the solutions for the treatment of the foundation became a great concern. All the works on the site were completed after having tried to obtain maximum information regarding the karst process and, eventually, the structure of the residential building. For the investigation of the ground conditions, where the foundations were to be constructed, it was considered necessary to follow some guidelines (Quinta Ferreira and Velho 2006):

-

1.

To dig some reconnaissance pits at selected locations according to land use purposes;

-

2.

To remove all the soils above the travertine in order to locate the upper karst structures;

-

3.

To clean all the soils and rock fragments filling the dissolution cavities;

-

4.

To map and describe all the karst structures;

-

5.

To evaluate the need for additional geotechnical investigation, mainly in areas where the foundations will induce higher stress;

-

6.

To execute additional site investigation;

-

7.

To choose the best solutions for the treatment of the karst structures.

To achieve the desired results for the site investigation, the geotechnical study was sub-divided into drilling, geophysical measurements, laboratory testing and ground treatment.

The work started with the excavation of the entire area above the level of the foundation of the building. The cleaning of the excavation surfaces and ground treatment of the area were made without mechanical investigation because it was decided that construction should continue in the area immediately after the results of the surface reconnaissance. During the study, geological reconnaissance of the site with execution of pits in the foundation, cleaning of karstic spots, ground treatment of the same area, cleaning of the karst structures and filling of the dissolution pores (7 m3 concrete), foundation reinforcement and construction of the buildings, was undertaken. In selecting the site investigation techniques, three main aspects should be taken into account: the information that each technique would allow one to collect, reasonable costs and execution time. Field studies show that the choice of reinforcement of foundation works has a major effect on the cost and execution time. The decisive factor in this respect is ground improvement. It has been found that the reinforcement of foundation for grouting depends not only on its technical parameters, but also on the conditions in which site works are conducted. In engineering practice, the ability to quickly assess the ground improvement work conditions is very helpful in solving decision problems.

Geophysical investigations

For several decades, numerous geophysical studies have been carried out in order to investigate karst structures (Guérin et al. 2009). Ground-based geophysical methods can play an important role in the study of the karst structure. But suitable characterisation of heterogeneities in the karst environment is very challenging, and the choice of adequate methods remains mainly site-related (Chalikakis et al. 2011). Most of the techniques used were developed to detect water-filled, air-filled or sediment-filled cavities, as some of their physical properties may be significantly different from those of the host bedrock. The methods tested include magnetometry (Gibson et al. 2004; Rybakov et al. 2005; Mochales et al. 2008; Pueyo-Anchuela et al. 2010), ground penetrating radar (Beres et al. 2001; Al-fares et al. 2002; El-Qady et al. 2005; Mochales et al. 2008; Pueyo-Anchuela et al. 2010), seismic reflection (Cook 1965; Karaman and Karadaylar 2004), surface wave analysis (Thierry et al. 2005), micro-gravimetry (Bishop et al. 1997; Beres et al. 2001; Thierry et al. 2005; Mochales et al. 2008) and DC resistivity tomography (Kaufmann and Quinif 2001, 2002; Sumanovac and Weisser 2001; Roth et al. 2002; Van Schoor 2002; Zhou et al. 2002; Gibson et al. 2004; Kaufmann and Deceuster 2005; Deceuster et al. 2006; Abu-Shariah 2009; Kaufmann et al. 2012; Carrière et al. 2013). Most of these methods were aimed at detecting voids or cavities filled with allochthonous sediments, sometimes in a covered karst context.

Seismic studies

A seismic refraction method was performed to investigate karst structures, because seismic velocity may indicate the relative strength and weakness of the travertine, since seismic velocity is usually related to the relative density of the rock mass, and density is often related to strength of the rock. The seismic investigation was performed using a SmartSeis S 3000 seismometer (GEOMETRICS Co.), with a sledgehammer seismic source with an array of geophones placed sequentially at 2 m spacing across the entire footprint of the buildings designated as A, B, C, D, and E. About 2,600 m2 of the total footprint were surveyed. Apart from the seismic velocities (Vp, Vs), the thicknesses of the rock units that are located at different depths were determined. The most relevant investigations are detailed in the subsections underneath. In order to study the seismic velocity, 26 P-wave and S-wave surveys were conducted. A vertical section to a depth of 20 m was thus investigated. Velocity changes on travel-time curves were clear and revealed two zone structures. Weak travertine zone thicknesses varied between approximately 0.50 and 3.00 m. It was found that the velocity was particularly low in the weak travertine unit. Vp ranged from 420 to 439 m/s and Vs ranged from 206 to 218 m/s. The velocity of the massive travertine was higher than that of the weak travertine. Weak travertine zones were locally contained in the spongy travertine. Vp of the spongy travertine ranged between 1,845 and 1,925 m/s, and Vs between 688 and 663 m/s. P-wave velocity values of different studies are given in Table 1.

The first travertine zone has a 0.34 Poisson ratio, while the second zone has a 0.43 Poisson ratio. This result shows that when the Poisson ratio increases, porosity also increases. This is due to the fact that samples with higher porosity absorb more water. The data were processed by engineers who produced a record for interpretation. The seismic refraction survey discriminates between areas of higher and lower seismic velocity, which were interpreted as indications of rock density variations. This result indicates that potential shallow subsurface voids and weak rock zones occur throughout the footprint of the buildings. However, the level of details provided was not sufficient to accurately delineate specific zones of voids and weak rocks. The seismic survey did provide sufficient evidence to infer that the karst features observed on the excavated rock surfaces extend into the shallow subsurface of the rock. The seismic data was used to a limited degree for planning the drilling program. However, based on the results of the seismic survey, the data was insufficient to focus mitigation works on only specific foundation locations.

Drilling and sampling investigation

A total of 56 points were drilled in the investigation area. The drilling locations were selected according to foundation location and seismic survey results. The total length of the drill is 1,080 m, with an average depth of 17.85 m per borehole. The borings expended to depths ranging from 10 to 28 m below the surface. The locations of the borings were selected so as to define the subsurface profile. Intact samples were taken from the boreholes for laboratory analysis. The soils were identified to be clay at the site. Blocks A and B have a foundation with an area of 880 m2. The foundations of blocks, C, D and E have 840 m2. The car park area was examined with 26 boreholes having a depth of 10 m, and borehole location was selected by using a grid method at this site. Weak travertine was cut by all the drillings at the site. The massive travertine was only encountered at depths between 1 and 3 m, in the drillings done in transition between block C, block D and block E (boreholes numbered between 19 and 30). The massive travertine fragments were found in several boreholes (21, 22, 23, 24, 27, 28 and 56). Boreholes 8, 10, 11, 15, 40, 51 and 52 contained clay fillings. Boreholes 33, 38, 43, 47, 54 and 55 intersected karst structures. The karst structures found in boreholes 3, 4 and 24 do not seem to be continuous. In boreholes 12, 50 and 56, it was observed that the compressed air used to operate the hammer flowed out from the contiguous boreholes and dissolution chimneys. The observations in boreholes 3 and 4 together with the surface observations revealed dissolution structures greatly affecting the foundations of the buildings. Where the excavations for the foundations were executed before drilling, it was necessary to refill these spaces. A filling thickness of between 0.45 and 0.60 m provided a regular surface for the operation of the drilling equipment (boreholes 3, 4 and 8). During the execution of the drillings, the fills that were dumped and were very loose showed some heave around the boreholes, due to the up-lift pressure of the compressed air used in the drilling operations.

Test pit investigation

The peculiar way the travertine formed, resulting from the precipitation of calcite around the wastewater, created a high porosity and a very permeable rock mass, where the percolation of water is intense, promoting the development of dissolution structures (dissolution pores, cavities, chimneys, joints). Prior to human interference, a stream flowed in the area where the building was to be constructed. At present, the stream artificially flows at an upper level, in the south limit of the construction site. The infiltration of water from the stream and rain paved way for the development of the dissolution structures.

The observed dissolution chimneys have a circular shape, mostly with a diameter around 0.1–0.15 m. It was possible to ascertain that they usually link to deeper dissolution chambers located below. To confirm this, I referred to the dissolution cavity detected after the execution of pit (P1), following a dissolution chimney of about 0.12 m diameter. Similarly, the opening of a pit in the place of chimneys revealed more cavities partly filled with clay. A few more chimneys were identified during the site investigation. The dissolution structures have an important development, and are sub-vertical and slightly inclined to the east (Fig. 2). The walls of these planar structures are covered by karst structures resulting from the precipitation of calcite. The planar structures are the result of fractures that were enlarged by dissolution and that had posterior precipitation of calcite in the walls. Dissolution joint (DJ1) is the longest karst structure found on site, having a visible extension around 30 m. Its width at the level of the foundation is between 0.15 and 0.5 m. Its geometry indicates that it is the result of the conjunction of two structures with different directions. This dissolution structure is clearly linked with other adjacent structures. Its reconnaissance was difficult because it was filled with red clay. Dissolution joint (DJ2) is about 20 m in length, 0.5–0.6 m in width and has a height of up to 1.0 m. This structure developed essentially in the unit of the cover soils, mixed with travertine. It was partly filled with clay, and a large part of this structure was removed during the excavation operations.

The dissolution cavities in the travertine showed variable dimensions and geometry, and are frequently linked to other dissolution structures (Fig. 3).

Some examples are cavity (C1) located on the east side, underneath the point where dissolution chimney (DC1) was first identified. The excavation of pit (P1) revealed a cavity, below the foundation level, with over 2 m difference between the highest and the lowest points. The width of the cavity varies from a few decimetres to more than 1.0 m. The extent of the cavity could not be ascertained because it was partly filled with clay, reducing the accessibility. This cavity was linked to other adjacent karst structures according to borehole records. On the south face of the excavation, several dissolution cavities were identified above the foundation level of the building. The most important dissolution cavities are 0.5 m high by 1.2 m wide, have a very irregular shape and are in continuity with dissolution structures. The excavation executed on pit (P2) identified another dissolution cavity at a depth of more than 0.6 and height of 0.3 m , which could not be completely evaluated because it was also filled with clay. This structure developed essentially in the unit of the cover soils, mixed with travertine. It was partly filled with clay, and a large part of this structure was removed during the excavation operations. The dissolution cavities in the travertine showed variable dimensions and geometry, and were frequently linked to other adjacent structures. Their reconnaissance was difficult because they were filled with red clay.

Laboratory analysis for rock strength

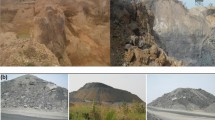

The effect of wastewater on travertine materials was investigated in the laboratory because of the karst structures found on site. The wastewater came from the residential units and industries that are connected to the septic holes for discharge. These septic holes allow the wastewater to percolate downwards through cracks in the underlying travertine over several years. Physical and mechanical properties of three types of travertines were determined. Chemical weathering due to changing pH values in sewage water had a negative impact on the strength of the rock (Singh et al. 1999; Asta et al. 2010). For this purpose, laboratory study was conducted on the massive, weak and spongy travertine samples (Fig. 4).

All rocks were tested using unweathered or slightly weathered samples. The specimens were tested for their engineering properties in the laboratory at different pH values. After analysis, wastewater taken from the septic hole was injected into the rock samples as a reacting fluid. The chemical composition of the wastewater is given in Table 2. Three sequences were taken into consideration during the test. First, the core samples were saturated with wastewater for 90 days before the experiment. Then, the experiments were carried out at ambient conditions, at a controlled temperature of 23 °C. Finally, samples were dried over a period of 48 h at a temperature of 105 °C to obtain dry travertines with very low water content. The specimens were prepared and tested in accordance with the procedures given in ISRM (1981) and TSE (1987).

Physical properties, such as specific gravity, dry weight and saturated unit weight (with wastewater) were analysed. The unit weight was determined using the saturation method. The specific gravities, dry weights and saturated unit weights of the travertines are given in Table 3.

After the physical tests, the mechanical properties of the travertines were determined by a variety of laboratory tests in accordance with the procedures given in ISRM (1981) and TSE (1987). The mechanical properties determined for the selected core samples include the uniaxial compressive strength (UCS) and wet-to-dry strength ratio. The point load index was used to test core specimens in accordance with ISRM (1981) specifications. The results are given in Table 4. UCS of the travertine samples (dry and saturated at different pH value), was determined for the prepared core samples using a uniaxial compression testing machine according to the ISRM (1981) specification. The calculated wet-to-dry strength ratio of the travertine is given in Table 5. Point load and Schmidt rebound hammer tests are most commonly used for strength of rock materials, principally because they may be used on a greater variety of rock types with better predictability of strength (Johnson and De Graff 1988). Additionally, the variations of point load and Schmidt rebound hammer values are given in Table 4.

Foundation mitigation measures

Dissolution structures (dissolution pores, cavities, chimneys, joints) cause severe damage to buildings worldwide and the main aim of site investigations in geotechnical programs is to evaluate, assist and determine the vertical and lateral distributions of these foundation problems, in order to adopt the most economic solution for treatment. Several engineering methods have been used worldwide in several projects, including engineering fill, engineering fill and geosynthetic materials, concrete filling and Portland cement grout low pressure injection (Abdeltawab 2013). This is a viable option when the rock mass is riddled with small cavities and when the rock cavities are relatively free of soil filling. By filling a large proportion of the cavities with Portland cement grout, it is possible to improve the strength and reduce compressibility (Arosemena 2007; Epting et al. 2009). Other benefits of grouting include reducing the possibility of the collapse of small caves, and also limiting the erosion of overburden soil into cavities and the development of further erosion of the overburden soil. However, it is very common that not all the primary porosities will be filled. In terms of cost, rock improvement by grouting is a very expensive technique, mainly because of the cost of introducing the material into the cavities through several drill holes (Arosemena 2007). Also, it is a very expensive technique because a significant amount of the Portland cement grout is wasted by its flow through the larger cavities into areas of no concern at the site and sometimes off the site into properties owned by others. Groundwater flow is also affected as the normal water flow through the soil and cavities is forced to seek new paths (Waltham et al. 2005). Karst structures found in the area between block A and block B are well defined in the foundation platform, due to the low content of clay in the travertine.

The procedure adopted in executing the remedial treatment of the foundation is described below.

Before the placement of the regularization concrete, all the soils were removed by cleaning the pores with a jet of water, to allow identification of the karst structures. In the karst structures filled with soils, cleaning was performed, at least 1 m below the lowest foundation level, and the volume was filled with concrete (Fig. 5).

The open karst structures in the foundation area were filled with gravel, up to a depth of 1 m below the base of the foundation. The upper part was filled with Portland cement grout. To reduce the loss of concrete into the granular material, a transition zone of fine sand was used. The open karst structures outside the foundation area were filled with gravel. At the surface, the granular materials were covered by a layer of fine sand.

The data obtained from the borehole numbers 13, 16 and 17 together with surface observations revealed the larger open cavity close to the surface (DJ3), which greatly affected the foundations of the buildings. To fill this cavity, it was necessary to use 5 m3 of concrete. Dissolution joints (DJ4) were taken from boreholes 44, 48 and 49. This cavity is located under an important building foundation, and if it had not been detected and treated, serious problems would have arisen from the failure of the ground, due to the weight of the building. In borehole 7, at the depths of between 8.5 and 8.8 m, a pore having high continuity with the karst system was detected. More than 1 m3 of Portland cement grout was completely lost when trying to fill this pore. The drill hole was later filled with 0.2 m3 of gravel. Most of the boreholes were filled with Portland cement grout.

Foundation design recommendations

As the travertine formation gently slopes to the NS (under 5°), all of the foundations balanced entirely on the travertine. This situation tends to deepen the base of the footings in the NS part of block A in order to pour the cover soils mixed with travertine, and to achieve similar foundation conditions in all the blocks. The travertine showed the required bearing capacity for the foundation construction.

Based on the extent of the karst structures found in the travertine, and the experience reported by other authors (Fischer and Fischer 1997; Mishu et al. 1997; Quinta Ferreira and Velho 2006; Stille et al. 2012; Abdeltawab 2013), it was considered necessary to reinforce the foundation. The treatments include:

-

1.

Cleaning excavation surfaces and filling every dissolution pore at the level of the foundation with Portland cement grout and granular material;

-

2.

Reinforcement of the foundations and structure of the building with more steel;

-

3.

Adding a continuous foundation beam that holds the foundations together.

It was considered that the foundation after reinforcement should reserve an empty span of 3 m, which could result from the collapse of an undisclosed karst structure. The span of 3 m was considered suitable, with the dimensions of the identified karst structures being similar to the one suggested by Fischer and Fischer (1997). According to Dotson and Tarquinio (2003), the ability to install micropiles in karst topography is a major advantage in their use as a foundation system. This micropiling reinforcement of the foundations has been applied to the karstic rocks in Malaysia that cross an area underlain by limestone formations and were affected by catastrophic subsidence (Tan and Chow 2006).

Since the performance of the pile is dependent on the bond between the grout and the competent rock (Fig. 6), the integrity of the grouted bond zone in karst is of primary importance. Site-specific installation techniques must be selected with this in mind. This is achieved principally by the optimal selection of drilling and grouting techniques.

To reduce the risk of further instability in the foundation, it was considered adequate to drain all the water from seepage, rain, gardening or even accidental sewage rupture. To achieve this objective, a drain at the bottom of the perimeter retaining wall of the excavation and also a drainage blanket below the foundation were used.

The cost of the geotechnical study and site investigations, including the mechanical drillings, is only 1 % of the total construction cost (Table 6).

The ground treatment and the reinforcement of the foundation and buildings contributed to the increased total construction cost. Considering the cost of the foundations in relation to the total cost of the building, it increased that predicted in the original design by 2 %. This increased cost arose from the encountering of travertines in the area.

Conclusions and recommendations

Travertines are formed by the precipitation of calcite around materials like clay, gravel, sand or even plants. This complex origin creates the condition for a heterogeneous and unpredictable material, presenting important geotechnical problems for the construction of buildings. The present geotechnical study permitted the identification of a few karst structures and clarified the main problems that could arise from their presence, and also assisted in the selection of the most suitable procedures to overcome the construction challenges they may present. The overall analysis of all the geological, geophysical, geotechnical and engineering data led to the selection of solutions for the foundations and the buildings that were considered suitable to overcome the karstification problems in the area. The results revealed several important karst structures causing serious problems for the building foundation and structure, and many smaller dissolution cavities, sometimes filled with clayey soils.

For this purpose, the engineering properties of three kinds of travertines (massive travertine, weak travertine and spongy travertine) were determined. The travertine texture depends on the conditions of the rock formation (sedimentation, climatic and morphological condition). Chemical weathering due to changing pH values in wastewater impacted the strength of these travertines. After 90 days of saturation, dry UCS tests were conducted on the three kinds of sampled travertine. The results indicate that lower values of UCS strength vary between 6.8 and 22.2 MN/m2. The massive travertine presents the highest UCS strength (22.2 MN/m2 at pH > 8), the weak travertine appears to be weaker (with a maximum strength of 18.4 MN/m2 at pH > 8), and spongy travertine is the weakest (6.8 MN/m2 at pH > 8). Travertine’s strength variations are closely linked to the travertine textures. The greatest and smallest decrease of UCS strength are observed in the spongy travertine and massive travertine, respectively. All travertine samples affected by wastewater show a reduction in strength.

Therefore, the design and construction of foundations in karst travertine areas requires careful planning from the design stage to the construction stage, where continuous input from the construction team and design team is very important to ensure successful construction and satisfactory performance. The buildings, constructed in the investigation area, have not shown any signs of damage until date. Based on the findings of the geological, geophysical, and geotechnical investigations (drilling, laboratory testing and ground treatment) and observations, it is recommended that for the buildings located on the karstic area, piles or micropiles are should be taken into consideration for construction.

References

Abdeltawab S (2013) Karst limestone foundation geotechnical problems, detection and treatment: case studies from Egypt and Saudi Arabia. Int J Sci Eng Res 4(5):376–387

Abu-Shariah MII (2009) Determination of cave geometry by using a geoelectrical resistivity inverse model. Eng Geol 105:239–244

Al-fares W, Bakalowicz M, Guérin R, Duckam M (2002) Analysis of the karst aquifer by means of a ground penetrating radar (GPR): example of the Lamalou area (Hérault, France). J Appl Geophys 51:97–106

Arosemena RL (2007) Effect of horizontal piles on the soil bearing capacity for circular footing above cavity. B.S. Peruvian University of Applied Sciences, Department of Civil and Environmental Engineering, MSc thesis, Orlando

Asta MP, Gimeno MJ, Auqué LF, Gómez J, Acero P, Lapuente P (2010) Secondary processes determining the pH of alkaline waters in crystalline rock systems. Chem Geol 276:41–52

Ballouz M (2005) Micropiling in karstic rock: new CMFF foundation solution applied at the Sanita Factory, technical paper, ASCE Special Publication. In: Tenth multidisciplinary conference on sinkholes and the engineering and environmental impact of karst TM, San Antonio

Basal A, Ekmekci M (2000) Natural attenuation characteristics of the Antalya Travertine Plateau soil zone as protective cover for the aquifer. Earthsciences 22:79–95

Beres M, Luetscher M, Olivier R (2001) Integration of ground penetrating radar and microgravimetric methods to map shallow caves. J Appl Geophys 46:249–262

Bishop I, Styles P, Emsley SJ, Ferguson NS (1997) The detection of cavities using the microgravity technique: case histories from mining and karstic environments. Geol Soc Lond Eng Geol Spec Publ 12:153–166

Brinker FA, Kazaniwsky PW, Logan M (2004) Case history illustrating the challenges of foundation design and construction in karst terrain. In: Proceedings of the fifth international conference on case histories in geotechnical engineering, New York, 13–17 April 2004

Burger A (1990) The travertine complex of Antalya, Southwest Turkey. Z Geomorphol Suppl Bd 77:25–46

Carrière SD, Chalikakis K, Sénéchal G, Danquigny C, Emblanch C (2013) Combining electrical resistivity tomography and ground penetrating radar to study geological structuring of karst unsaturated zone. J Appl Geophys 94:31–41

Chalikakis K, Plagnes V, Guerin R, Vallois R, Bosch FP (2011) Contribution of geophysical method for karst-system exploration: an overview. Hydrogeol J 19:1169–1180

Cook JC (1965) Seismic mapping of underground cavities using reflection amplitudes. Geophysics 30(4):527–538

Cushing AG, Stonecheck SA, Campbell BD, Dodds SD (2004) An evaluation of the load-displacement behavior and load test interpretation of micropiles in rock. In: Proceedings of fifth international conference on case histories in geotechnical engineering, New York, 13–17 April 2004

Deceuster J, Delgranche J, Kaufmann O (2006) 2D cross-borehole resistivity tomographies below foundations as a tool to design proper remedial actions in covered karst. J App Geophys 60:68–86

Dotson D, Tarquinio F (2003) A creative solution to problems with foundation construction in karst. In: Ninth multidisciplinary conference on sinkholes and the engineering and environmental impacts of karst, Huntsville

General Directorate of State Hydraulic Works (1985) Antalya-Kirkgoz kaynakları ve traverten platosu karst hidrojeolojik etud raporu. Jeoteknik Hizmetler ve Yeraltısuyu Dairesi Baskanlıgı, Ankara, 131 pp. (in Turkish)

El-Qady G, Hafez M, Abdalla MA, Ushijima K (2005) Imaging subsurface cavities using geoelectric tomography and ground-penetrating radar. J Cave Karst Stud 67:174–181

Epting J, Huggenberger P, Glur L (2009) Integrated investigations of karst phenomena in urban environments. Eng Geol 109:273–289

Fischer JA, Fischer JJ (1997) Wyndham farms—a karst case study. In: Beck BF and Stephensen JB (eds) The engineering geology and hydrogeology of karst terranes. Proceedings of the 6th multidisciplinary conference on sinkholes and the engineering and environmental impacts of karst, Springfield, Missouri, 6-9 April, Brookfield (VT): A.A. Balkema, Rotterdam, pp 287-292

Gibson PJ, Lyle P, George DM (2004) Application of resistivity and magnetometry geophysical techniques for near-surface investigations in karstic terranes in Ireland. J Cave Karst Stud 66(2):35–38

Glover C, Robertson AF (2003) Origin of tufa (cool-water carbonate) and related terraces in the Antalya area, SW Turkey. Geol J 38:329–358

Guérin R, Baltassat JM, Boucher M, Chalikakis K, Galibert PY, Girard JF, Plagnes V, Valois R (2009) Geophysical characterisation of karstic networks—application to the Ouysse system (Poumeyssen, France). C R Geosci 341:810–817

ISRM (International Society for Rock Mechanics) (1981) Rock characterization, testing and monitoring. In: Brown ET (ed) ISRM suggested methods. Pergamon, Oxford

Johnson RB, De Graff VJ (1988) Principles of engineering geology. Willey, New York

Karabıyıkoglu M, Tuzcu S, Ciner A, Deynoux M, Orcen S, Hakyemez A (2005) Facies and environmental setting of the Miocene coral reefs in the late-orogenic fill of the Antalya Basin, western Taurides, Turkey: implications for tectonic control and sea-level changes. Sediment Geol 173:345–371

Karaman A, Karadaylar T (2004) Identication of karst features using seismic p-wave tomography and resistivity anisotropy measurements. Environ Geol 45:957–962

Kaufmann O, Deceuster J (2005) Ground investigation in covered karst near Tournai, Belgium. Case study. In: Waltham T, Bell F, Culshaw M (eds) Sinkholes and subsidence-karst and cavernous rocks in engineering and construction. Praxis, Chichester, pp 347–350

Kaufmann O, Quinif Y (2001) An application of cone penetration tests and combined array 2D electrical resistivity tomography to delineate cover-collapse sinkholes prone areas. In: Beck BF, Herring JG (eds) Geotechnical and environmental applications of karst geology and hydrology. Balkema, pp 359–364

Kaufmann O, Quinif Y (2002) Geohazard map of cover-collapse sinkholes in the Tournaisis area, southern Belgium. Eng Geol 65:117–124

Kaufmann O, Deceuster J, Quinif Y (2012) An electrical resistivity imaging-based strategy to enable site-scale planning over covered palaeokarst features in the Tournaisis area (Belgium). Eng Geol 133–134:49–65

Kilic R, Yavuz S (1994) Relationship between geotechnical properties of the Antalya travertine (Turkey). Bull Int Assoc Eng Geol 50:43–50

Klimchouck A (1997) The nature and principal characteristics of epikarst. In: Proceedings of the 12th international congress speleology, La Chauds-de-Fonds, Aug 1997

Mishu LP, Godfrey JD, Mishu JR (1997) Foundation remedies for residential construction over karst limestone in Nashville, Tennessee. In: Beck BF, Stephensen JB (eds) Karst Geohazards: Engineering and Environmental Problems in Karst Terrane. Proceedings of the sixth multidisciplinary conference on sinkholes and the engineering and environmental impacts of karst, Springfield, Missouri, 6-9 April, Brookfield (VT): A.A. Balkema, Rotterdam, pp 319–323

Mochales T, Casas AM, Pueyo EL, Pueyo Ó, Román MT, Pocoví A, Soriano MA, Ansón D (2008) Detection of underground cavities by combining gravity, magnetic and ground penetrating radar: a case study from the Zaragoza area, NE Spain. Environ Geol 53(5):1067–1077

Nativ R, Gunay G, Hotzl H, Reichert B, Solomon DK, Tezcan T (1999) Separation of groundwater-flow components in a karstified aquifer using environmental tracers. Appl Geochem 14:1001–1014

Pueyo-Anchuela O, Casas-Sainz AM, Soriano MA, Pocoví-Juan A (2010) A geophysical survey routine for the detection of doline areas in the surroundings of Zaragoza (NE Spain). Eng Geol 114:382–396

Quinta Ferreira M, Velho JL (2006) Construction problems on the karstified limestone tuffs of Condeixa, central Portugal: a case study. Geotech Geol Eng 24:101–116

Roth MJS, Mackey JR, Mackey C, Nyquist JE (2002) A case study of the reliability of multielectrode earth resistivity testing for geotechnical investigations in karst terrains. Eng Geol 65:225–232

Rybakov M, Rotstein Y, Shirman B, Al-Zoubi A (2005) Cave detection near the Dead Sea—a micromagnetic feasibility study. Lead Edge (Soc Explor Geophys) 24(6):585–590

Siegel TC, Caskey JM, Huckaba DA (2005) Combination of ground improvement techniques for support of shallow foundations in karst. Geotechnical Special Publications 130–142 and GRI-18. In: Proceedings of the geo-frontiers 2005 congress, Austin, 24–26 Jan 2005

Singh TN, Singh SK, Mishra A, Singh PK, Singh VK (1999) Effect of a acidic water on physico-mechanical behaviour of rock. Indian J Eng Mater Sci 6:66–72

Stille H, Gustafson G, Hassler L (2012) Application of new theories and technology for grouting of dams and foundations on rock. Geotech Geol Eng 30:603–624

Sumanovac F, Weisser M (2001) Evaluation of resistivity and seismic methods for hydrogeological mapping in karst terrains. J Appl Geophys 47:13–28

Tan YC, Chow CM (2006) Foundation design and construction practice in limestone area in Malaysia. HKIE-IEM Seminar on Geotechnical Works in Marble, Hong Kong

Thierry P, Debeblia N, Bitri A (2005) Geophysical and geological characterisation of karst hazards in urban environments: application to Orleans (France). Bull Eng Geol Environ 64:139–150

Traylor RP, Cadden AW, Bruce DA (2002) High capacity micropiles in karst: challenges and opportunities. In: Proceedings of the international deep foundations congress, Orlando, pp 743–759, 14–16 Feb 2002

TSE (1987) Methods of testing rocks. Turkish Standards Institute-699, Ankara, Turkey

Turker AE, Keceli DA, Kamacı Z, Kaya MA (1991) The ground problems of urban area in Antalya and their resolutions by means of geophysical methods. Jeofizik 5:27–42 (in Turkish with English abstract)

Uranowski DD, Dodds SD, Stonecheck SA (2004) Micropiles in karstic dolomite: similarities and differences of two case histories. In: Proceedings of sessions of the geosupport conference: innovation and cooperation in the geo-industry, Orlando, 29–31 Jan 2004

Van Schoor M (2002) Detection of sinkholes using 2D electrical resistivity imaging. J Appl Geophys 50:393–399

Waltham T, Bell F, Culshaw M (2005) Sinkholes and subsidence-karst and cavernous rocks in engineering and construction. Praxis, Chichester 382 pp

White WB (1988) Geomorphology and hydrology of karst terrains. Oxford University Press, Oxford 464 pp

Zhou W, Beck BF, Adams AL (2002) Effective electrode array in mapping karst hazards in electrical resistivity tomography. Environ Geol 42:922–928

Acknowledgments

The author would like to thank the building owner and design consultants who provided the necessary data for this study. Special thanks are due to Dr. Konstantinos Chalikakis and Dr. John Deceuster for their comments, which helped improve the content and quality of this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ozcelik, M. Effect of wastewater on building foundation in karst travertine areas in Antalya, Turkey. Bull Eng Geol Environ 74, 1213–1224 (2015). https://doi.org/10.1007/s10064-014-0695-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-014-0695-4