Abstract

This paper presents a case study on foundation seepage problems encountered at an earth dam over the last 55 years with various remediation efforts. The Pipasi Dam, 26.0 m in height, was built on a pervious foundation without any seepage control measures during its first phase construction. The geological conditions along with the leakages, remedial measures and the evaluation of the groundwater level measurements are presented. It is concluded that the past seepage problems within the dam foundation were caused by the geological condition. Neogene conglomerate outcrops in both abutments, and is overlaid by the relatively thin Quaternary deposit in the riverbed. Early treatments, such as the cutoff wall placed beneath the upstream toe and the upstream clay blanket, were only carried out in individual locations, and thus cannot form a continuous and complete spatial waterproofing system. The installed grouting curtain was regarded as a complete control measure. However, the initial design arrangement was changed during its actual installation, and also cannot form a closed-type one. In addition, the grouting effectiveness of the conglomerate is doubtful according to the check hole results, which reveal the loosened structures. As a result, hydraulic gradients and seepage amounts are still found to be higher than the expected level. Therefore, a secondary closed-type grouting curtain, which upwardly reaches into the dam body, should be installed into bedrock to eliminate future seepage problems. Meanwhile, regarding the spatial variation, the groutability of the conglomerate needs precise understanding as well.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Reservoir water leakage is a common problem in most dam sites where the impounded water seeks paths of least resistance through the dam, its foundation and abutments. The ground conditions and the geological features of the dam site greatly influence the amount of seepage and its relevant effects (ODNR 1994, 2003; Wiesner and Ewert 2013). Many seepage problems and dam failures have occurred because of inadequate seepage control measures or incomplete cleanup and preparation of the core, foundation and abutments of the dam, which can result in dam failure. Specifically, seepage failure within the dam body or the foundation accounts for 30 % of total failures. This problem was the main concern for many research fellows in recent years. In total, 593 failure cases on earth dams were utilized by Zhang et al. (2007) to study earth dam failures with statistical analyses. An earth dam with either a small reservoir capacity or a relatively low height appears to have a relatively high possibility to have failed in the past. Most of the cases are caused by overtopping or quality problems. The most adverse factors are cracks caused by differential settlement within the dam body, foundation defects, and imperfect interface.

Therefore, seepage must be controlled to prevent erosion of the dam or foundation, and thus to maintain its global integrity and stability. However, seepage controls that occur after construction are difficult and quite expensive (Dunbar and Sheahan 1999). It is not usually attempted unless the seepage has lowered the pool level or is endangering the dam or appurtenant structures. The need for seepage control will depend on the quantity, content, and location of the seepage. Typical remedial measures are used to control seepage, like the use of an upstream blanket, the installation of a cutoff wall, or a grout curtain.

Seepage problems were reported due to the presence of pervious sand-gravel strata in the foundation of Bakoyianni dam, Greece (Kalkani 1997), Hodges Village earthen dam, Oxford Masschusetts (Dunbar and Sheahan 1999), Waddell earthen dam, Phoenix, Arizona (Welch et al. 1999), and Maskinala earthen dam, Kamataka (Gupta et al. 2004), etc. For example, the Hodges Village Dam in Oxford, Mass. consists of relatively pervious materials and sits on pervious foundation soils. Despite this, no dam or foundation seepage control measures were constructed for the original dam. Serious seepage events occurred after the impounding; thus, a series of remediation efforts have been taken to resolve the problem over dozens of years (Dunbar and Sheahan 1999). Maskinala earthen dam in the Raichur District of Kamataka was constructed on the pervious foundation by providing a partial cutoff and an upstream blanket. Based on the finite element steady seepage analysis, an additional defensive measure in the form of a cut off wall beneath the upstream toe was recommended, which should be embedded at least 1.0 m in impermeable bedrock (Gupta et al. 2004). A similar pervious conglomerate stratum was uncovered during the construction, and was only also found in the Pipasi Dam 27 years after the first impounding.

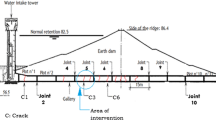

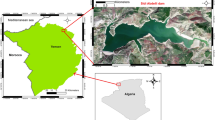

The Pipasi Reservoir is located 5 km west of the town of Yigou, Anyang city in the province of Henan in central China, on the upper reach of the Yongtong River, a major tributary of Wei River (Fig. 1). It is a multi-purpose project, embracing multiple functions, mainly including flood control, irrigation, and water supply, as well as aquaculture. The project mainly consists of a homogeneous earth dam with a maximum dam height of 26.0 m, a crest length of 1176 m, a spillway tunnel and an emergency spillway on the left side. A plan of the general arrangement is shown in Fig. 2. Maximum reservoir storage is 20.54 million m3, and the corresponding PMF reservoir level is 124.82 m.

Due to historical factors, this dam was constructed by staged construction spanning 24 years. The project was primarily constructed during 1957 and 1959, a famine period, with the crest elevation 119.5 m. There were no foundation seepage control measures constructed as part of the original dam according to the project records. In 1968, the dam was raised an additional 2.2 m to a crest elevation of 121.6 m using the downstream construction method. Meanwhile, the horizontal drainage body was prolonged downstream correspondingly. The existing project was completed in 1974 and 1975, including an additional 3.6 m raise and corresponding drainage body extension, to meet the demand for flood control and water supply.

Mainly because this dam sits on pervious strata, seepage problems have been severe at various times over the last years. The object of this study was to evaluate hydrologic conditions implying possible water leakage through the dam foundation, to identify water leakages or possible leakage pathways. Thus the comprehensive geological conditions, all the implemented remedial measures, the dam foundation grouting, the effect on leakages, and the evaluation of piezometer measurements are presented.

Geology and hydrogeology

Geological characteristics

Many factors, and in particular, the geological characteristics of the site, can affect the water leakage from a dam (Uromeihy and Farrokhi 2012; Karimi et al. 2007). The geological background of the area in which the Pipasi Reservoir is located is defined by neo-cathaysoid tectonic system in China. Fluvial terraces at the Pipasi Dam site are formed by the downcutting of the Yongtong River and neotectonic movement. Four terraces were identified from the lowest terrace to the highest. The terraces are characterized by lower fluvial conglomerates underlined with marl–shale, and an upper layer of clay and mild clay deposits.

At the site, the Yongtong River flows from northwestward to southeastward through a narrow gorge with the right abutment relatively higher, with hill slopes 25 m above the riverbed, thus makes an asymmetric V-shaped valley. The valley is 400 m in width, and the elevation is 102 m at the dry river level. In contrast with the right abutment, the left abutment is relatively flat and slightly lower in elevation, the top elevation of which is 125 m. The geological mapping revealed that the materials exposed at the dam site belong to Quaternary deposits. The river washed against the right abutment of the dam site, with the result that the Neogene conglomerate stratum outcrops.

The dam axis runs almost perpendicularly to the river flow at the site. The thickness of the conglomerate stratum increases towards both abutments, and becomes thick from west to east along the riverbed. The strata at the dam site run almost parallel to the river flow, generally striking 93°–95° and dip moderately north-east with a dipping angle of 3°–4°. Therefore, these strata are present in the form of a monoclinal structure, with the undulation feature.

Strata beneath this dam are not complex, and consist of Hebi formation (N 2 h) of Neogene Pliocene, underlain successively by Middle Pleistocene series (Q el-al2 ) as well as recently deposited clay. A brief description of these lithological characteristics is presented below.

Neogene Pliocene (N 2 h)

The Neogene Pliocene includes two different lithologic levels, which are characterized by conglomerate and marl–shale, as shown in Fig. 3. (1) Conglomerate stratum. Conglomerates are light grey in colour, and the thickness of this stratum changes from 2.0 to 8.0 m. These thick-bedded conglomerates are composed mainly of limestone cobbles in a calcareous or mud matrix, which accounts for more than 90 %, and small amounts of sandstone. In general, the gravels have diameters of from 20 to 40 mm, with the biggest one up to 60–70 mm. Meanwhile, the cementation degrees vary with locations, and are loose except in individuals according to core drilling data. The drilled boreholes showed that this stratum varies in thickness, and at times, is thinning out. The conglomerate stratum spreads over the surface or between the surface and the marl–shale stratum. More specifically, conglomerate is exposed at upper levels in the reservoir area above elevation 120.0 m on the right abutment, and outcrops at elevation 120.0 m in the reservoir area at station 0+300 and 115.0 m in the downstream on the right abutment. However, conglomerate is covered by Quaternary deposit in the riverbed. The conglomerate is the main pervious stratum in the study site. (2) Marl–shale stratum. This stratum is, in general, interwoven with marl and shale layers. Shale is greyish white to brownish yellow in colour, is characterized by graniphyric with calcareous, argillaceous and arenaceous portions. It softens quickly when in contact with water. Marl is greyish white to brown yellow in colour. In addition, calcareous and argillaceous sandstones were also identified within this stratum (Fig. 3). Marl–shale is, in general, buried deep below the conglomerate stratum, whereas on the left abutment, outcrops are at stations from 0+000 to 0+350 and are in direct contact with the dam body. The marl–shale stratum at the dam’s foundation is about 15 m thick, and is generally impermeable.

Middle Pleistocene (Q el-al2 )

This Quaternary deposit at the site covers riverbed and terraces, and its thickness is up to 7.0 m. This deposit is brown red to light yellow clay and silty clay, which is loose and extremely porous with gravels, calcareous concretions, and shell inclusions. It becomes cohesive when in contact with water. Recently deposited clay, with a thickness of 0.5–2.0 m, is prevalent in the upper levels of the stratum. At the base of the stratum, fragments of the underlying bedrock are observed.

Local hydrogeology characteristics

Hydrogeology cross sections along the dam axis and typical transverse section are respectively shown in Fig. 4a–e. It is observed that the hydrogeological condition at the site seems not to be complex. Below the dam foundation, groundwater is revealed in the conglomerate of Neogene Pliocene. The Neogene Pliocene conglomerate is the main water-bearing formation at the dam site. The Neogene marl–shale and the Quaternary clay is the upper aquifuge and the Neogene marl–shale is the lower aquifuge, respectively.

The water tests indicated that the conglomerate aquifer, with strong hydraulic permeability, is characterized by its wide spatial variability. Generally, the thickness of the conglomerate in the area is about 7.0 m; however, it increased notably, reaching 15 m in some parts. The greater unit absorption w ranges from 4.040 to 1.250 L/(min m m), and that of smaller is between 0.091 and 0.008 L/(min m m). A statistical mean of 0.134–0.834 L/(min m m) was estimated. The conglomerate located in the riverbed is covered by Middle Pleistocene stratum in various extents, which makes the aquifer confined. Seepage flow passes through the conglomerate stratum and discharges towards the downstream riverbed. The ground water head was consistent with the reservoir water level, and the confined water heads were in the range of 100.0 to 108.0 m in the riverbed.

The Quaternary deposits under the dam body were not cleaned up during the initial construction and are in direct contact with the dam body at present. The permeability coefficient is in the range of 1.2 × 10−8 to 3.5 × 10−7 cm/s; this indicates that this unit is relatively impermeable, and can be considered as the upper aquifuge. The thickness of the marl–shale stratum is about 15.0 m, and the unit absorption w range is from 0.000 to 0.008 L/(min m m). Thus this stratum can be regarded as the lower aquifuge.

Foundation seepages, field investigations and remedial measures

Despite the presence of pervious conglomerate stratum, there were no foundation seepage control features constructed as part of the original dam. Just after the filling of the reservoir, it was found that the foundation leaked considerably. Since then, the dam has experienced seepage problems for more than 50 years.

Foundation seepages

Before 1986

Right after the first impounding of the reservoir, water seepage emerged through the foundation in the riverbed, as well as through the abutments of the two sides. Wet areas were observed downstream in both abutments, and spread to wide areas when the reservoir water level rose. Particularly the right abutment is relatively severe, and the maximal area reached approximately 40,000 m2 prior to treatments.

An initial treatment program was started in 1981. A clay cutoff wall, approximately 130 m long with a depth of 2.5–3.5 m, was installed along the upstream toe between stations 0+210 and 0+340. Another program of remedial measures was carried out in 1986; the upstream clay blankets of 1.0–4.0 m thickness, extending for 100–200 m from upstream toe, were placed between stations 0+200 to 0+450, 0+900 to 1+005, and 1+020 to 1+090, to reduce outflow by increasing the length of the flow path. These remedial measures are roughly shown in Fig. 2. However, there was no obvious decrease in the seepage discharge. In fact, seepage conditions became worsethan ever. The total quantity of seepage increased with time, from a value of 30 L/s in the initial impoundment period, and rose further to 500 L/s in 2000 when the reservoir level reached an elevation of 120 m.

Between 1987 and 2001

A seepage diversion ditch was excavated beneath the downstream toe, and along stations 0+080 to 0+500, of the dam. For the left abutment, seepage varied in appearance from a wet area to a flowing “spring”. In August 2000, a seepage spring, which was 50 mm in diameter and 2.9 m depth, was noticed 83 m downstream of the toe at station 0+080, and coincided with muddy water. The seepage forces were large enough; thus, little gravel particles were eroded from the foundation, which is called sand boil. The seepage flow from this spring was approximately 69 m3/h. This seepage flow, which is muddy and carrying gravel particles, is evidence of “piping”. Then, in April 2001, when the reservoir water level was raised to the elevation 120.0 m, clear seepage flowed from the stilling basin of the spillway tunnel at station 0+080, and four springs developed. The total combined seepage flow from these springs was 40 m3/h, and muddy water flowed out from the large one. Meanwhile, several seepage springs were also observed on the west side of the gully between stations 0+100 and 0+400, approximately 100 m downstream of the toe. According to these visual inspections, it can be judged that the excess pressure caused heaving of the upper soil layers and ruptured at these weak spots with a resulting concentration of seepage flow. Then flow from these weakened locations increased to form sand boils. In addition, the concentrated seepage flow eroded fine soil particles. As the erosion process continued, pipes formed through the top stratum. If these pipes increase in size and/or length, there may be a progressively greater concentration of flow into it, with a still greater tendency for erosion to progress beneath the dam, which would damage the foundation and result in settlement, and have the potential to cause catastrophic failures of dams. Following these events, emergency procedures, including the grouting curtain beneath the left abutment between stations 0+000 to 0+350 and the right abutment between stations 1+000 and 1+176, were carried out to guard against leakage. After grouting, the seepage flow was initially was decreased significantly. However, it was not effective in reducing seepage quantity for the seepage location 83 m downstream of the toe of the dam.

A number of these above efforts fell short of fully remediating the seepage problems. This dam still suffered from several problems in 2001, among them were the following. (1) When the reservoir water level was raised to 120.0 m, water leakage and discharging points were observed at the riverbed downstream beyond the toe between stations 0+400 and 0+600; this must, therefore, be controlled to prevent foundation erosion. (2) Wet areas presented downstream on right abutments between stations 0+700 and 1+000. As the Pipasi Dam is located in drought area, the heavy loss of water due to seepage was intolerable.

Clearly, extensive remedial work on the dam that would address the more systemic seepage problems for long-term operation needs was required. The basic goal of the remediation was to minimize the exit gradients that can lead to failure of the dam, and to attenuate seepage discharge.

Field investigations

The abnormal seepage emerged points and wet areas are highlighted in Fig. 5, which was depicted on the base of the satellite image (Google Maps 2015). In order to elucidate the mechanism of the seepage problem and identify the seepage path under the Pipasi Dam, the following field investigations were carried out, based on the available geological and hydrogeological information.

The Dam is directly located on Quaternary clay due to natural deposits, which were not cleaned up during the initial construction. Though this deposit is mainly composed of clay, it is characterized by a porous and loosened structure with sand grains, gravels, and calcareous concretions, and interbedded with thin-layers of medium-fine sand. This leads to the fact that the deposit has relative strong water permeability, and therefore is responsible for foundation seepage in the riverbed.

The Neogene shale-male layer extends along the left abutment, this layer is thick, and forms the aquifuge; thus, it had very little effect on the left abutment leakage.

For the terrace between the stations 0+000 and 0+250, the Neogene marl–shale with a thickness of 7 m is exposed and overlies the conglomerate stratum. The unit absorption w is about 1.25 L/(min m m).

For stations 0+250 to 0+350 on the terrace in the left bank, the Neogene conglomerate is exposed at the elevation of 120.0 m in the reservoir area, and 115.0 m in the downstream respectively. The core borings revealed the conglomerate layer is serious broken and porous, and directly contacted the dam body. It is in the conglomerate layer, which presents no resistance for seepage flow, that the serious seepage problems occurred. In addition, the shale and the red clay, which overlie the conglomerate layer, thus behave as the aquifuge of relatively low permeability. Seepage flows from the upstream, then directly percolates into the conglomerate layer, and exists beyond the toe. Seepage emerged to the downstream ground surface along the interface between the shale and the red clay.

For stations 0+350 to 0+500, and 0+700 to 0+950, the foundation deposit beneath the dam varies between 4.0 and 8.0 m thick and primarily is red clay. Although this deposit has not a close hydraulic connection with the underlying conglomerate layer, and did not exhibit leakage phenomenon, the seepage problem within the underlying layer in is undeniable. According to the monitoring data, the ground water levels were increasing in accordance with the rise in the reservoir level.

For stations 0+500 to 0+700 in the river bed, the average thickness of the deposit clay is 6 m. As the reservoir water level rose, which induced high hydrostatic pressure, the leakage points emerged in right side of the riverbed beyond the downstream toe, and the total leakage discharge reached at 0.01 m3/min. When the reservoir water level continued rising, the leaking water discharge was expected to increase; however, this was not observed.

The dam is lower than 3.8 m at station 0+950 to 1+200 on the terrace in the right bank, but unfortunately the conglomerate layer is directly exposed below the low dam section. This conglomerate layer varies in thickness from 8.0 to 15.0 m, and the maximal unit absorption reached 4.04 L/(min m m); thus, this is the primary seepage zone. The reservoir water flowed into the conglomerate layer, and out to the downstream ground surface along the boundary of the downstream conglomerate and red clay layers. Then this leakage water spread towards the downstream land between stations 0+700 and 1+000, and a wet area was seen at this location.

The Neogene conglomerate layer extends along the right abutment. This layer is weathered, loose and porous, and mainly presents as sands and gravels with developed cracks. Although this layer is thick, it still formed a concentrated leakage pathway as the reservoir level rose.

The above analyses revealed that the groundwater divides at the dam site are near stations 0+250 to 0+350, stations 1+050 to 1+100, and at the elevations of 118.0 and 124.0 m, for the left and right banks respectively. Correspondingly, leakage points were observed downstream at elevations between 107.0–114.0 m, and between 110.0–115.4 m, respectively. When the reservoir level rose to an elevation of 120.0 m, the seepage water in the left bank discharged directly out from the downstream toe; by contrast, that in the right bank bypassed the downstream toe, and entered into the downstream land at stations 0+700 to 1+000, and led to a large wet area.

Based on the previous analytical analysis, available geological and hydrogeological data, and from site inspections, the following can be concluded for the Pipasi Dam seepage problem: (1) the highly pervious conglomerate layer is directly exposed or underlain the relatively thin clay, which led to the fact that the natural hydrogeology condition cannot satisfy the request of water resisting. What’s worse, the natural foundation was not excavated at all during dam construction. (2) Most of the seepage water flowing out the downstream came mainly from water flowing through the conglomerate layer beneath the dam. (3) Some remedial measures, such as the cut-off wall beneath the upstream toe, the upstream clay blanket, and the seepage diversion ditch on the downstream face, were already carried out during the dam operation. However, these measures were either not systematic and not discontinuous in the space, or not applicable. Thus, these methods were not effective.

Dam foundation grouting

In the upper overlying layer and the stratified conglomerate layer, the most serious seepage problems occurred. For dams on pervious conglomerate strata, upstream clay blanket is least effective and was not applicable for this dam as mentioned above; thus, the impervious blanket was ruled out. A long-term alternative, namely dam foundation grouting, which is the injection of a fluidized material into a soil or rock formation to reduce its permeability, was considered for this dam.

Grouting design

According to the experiences obtained from dams suffered similar seepage problems, the grouting depth should be not less than 5 m into the aquifuge underlining the pervious layer when this aquifuge is not deeply buried (Weaver and Bruce 2007). According to the geological characteristics of this dam, the maximal buried depth of the aquifuge, namely the Neogene marl–shale, is only 32.0 m. Thus, the grouting curtain was designed as an enclosed type. With regards to the fact that significant leakage bypassed both banks and flowed out to the downstream, it was decided to extend the grouting curtain 100 m into both abutments, because the normal water level and the aquifuge intersect at these points.

An initial arrangement was proposed and is described as follows. The grouting curtain was placed in a row along the axis 1.8 m downstream from the parapet wall. It was designed to extend from station 0−100 on the left abutment, to up to station 1+276 m towards the right abutment, and to continue 5 m in the Neogene marl–shale, to reach 2.0 m above the dam foundation. The layout of this arrangement is presented in Fig. 6a and c. The target of this operation was to achieve a coefficient of permeability of less than 10−4 cm/s, and the allowable hydraulic gradient was 18.

Grouting

The geological and structural characteristics have a direct relationship with its groutability (Weaver and Bruce 2007; Uromeihy and Farrokhi 2012). Trial grouting procedures were performed to evaluate the groutability of the material properties beneath the dam foundation. Three trial sections, as listed in Table 1, were carried out according to the geological condition. Specifically, these sections include two strong permeable sections, namely station 0+200 to 0+230 and station 1+100 to 1+130, and one weakly permeable section of station 0+680 to 0+700. These trial grouting holes were performed at 2.0 m spacings, and three sequences of grouting operations. Considering the dam safety, trial grouting operations were performed in two steps. The first step was for foundation consolidation, and the second step formed the grout curtain. In all grouting holes, packer grouting was used, while grouting intervals varied according to the permeability rates of the packers. The grouting operations were respectively performed in holes spaced at 5.0 m and 3.0 m intervals for strong and medium permeable layers. Initially, a light mixture of 1:5 (i.e., 1 cement:5 water) was used; then, heavier mixtures were gradually used. During the trial grouting process of the trial section at stations 0+680 to 0+700, the dam body was split, a longitudinal crack along the dam axis extended for some 68 m, and the crack opening width was about 10 mm.

The grouting takes were recorded during the trial process, and then water pressure tests were carried out, and the corresponding results are listed respectively in Tables 1 and 2. The results obtained from the trial grouting procedures show that the permeability and the grouting take depended on grouting sequences. In addition, the effectiveness of the grouting was obvious when using three sequences.

Unfortunately, the above design arrangement was changed. All the grouting intervals in the dam body and the natural clay deposit were canceled due to the remedial cost budget. The upper boundary of the grout curtain was designed to continue 2 m in the Neogene marl–shale for stations 0−100 to 0+245, and was to reach the top of the conglomerate layer for stations 0+245 to 1+276. In other word, the grouting in the natural clay deposit was not complemented. Their total length of grout curtain holes prior and after design changing were 13357.5 and 8000 m, respectively.

The cross section along the axis and the typical transverse section of the final grouting curtain were shown respectively in Fig. 6b and c. For station 0−000 to 0+600, a total of 345 holes were sunk, and a total weight of 533 ton of cement was used. The average grout consumptions were, respectively, 145, 179, and 109 kg/m for grouting sequences 1–3 in the conglomerate layer. For stations 0+600–1+276, a total of 339 holes were sunk, and a total weight of 682 ton of cement was used. The average grouting consumptions were, respectively, 204 and 105 kg/m for grouting in the conglomerate layer and in the marl–shale layer. The grouting program started in October 2002, and then ended in May 2003.

Effect on leakages

After the completion of grouting, the reservoir was impounded gradually. Surprisingly, leakages emerged in the riverbed again, when the reservoir level was above an elevation of 111.70 m in August 2003. The rise in the reservoir level was still directly affecting the total leakage amount. There was no decrease in the number of the leakage points and locations prior to and after the grouting operations. The total amount was measured as 0.12 m3/s when the reservoir level reached an elevation of 121.0 m, and in contrast, the recorded value was 0.42 m3/s under the same operation condition before the grouting. In addition, the large wet area was not observed in the downstream left bank between stations 0+300 and 0+400. The construction of grouting resulted in a decrease of leakage amount, but not to the expected effectiveness.

Check holes

Six check holes, as shown in Fig. 7, were drilled along the dam axis to examine the grouting curtain and to identify the cause of the leakage. Water pressure tests were performed along the holes to check the grouting. Detail information on these holes, cut through locations where grout consumption values or seepage were abnormal, is listed in Table 3. Specifically, hole J6 was located at the station 0+753 where a seepage point emerged in the downstream, hole J5 was located at the station 0+609 where the downstream seepage point was close to the elevation of the boundary of the conglomerate and red clay layers, hole J1 was located at the station 0+261 near where five leakage points were observed downstream, and hole J3 at the station 0+033 where the grouting consumption reached 1080 kg/m. The check program started in November 2003, and ended in December 2003. Total check hole length was 159.8 m, and 18 intervals were used for water pressure tests. The results of stratum lithology, water pressure test, and grouting take of these check holes are listed in Table 3. The results show that there was a significant reduction in the permeability rate. However, among these check holes, Lugeon values of the conglomerate intervals of four holes, namely J1, J4, J5, and J6, were larger than 5.0, which was the designed value.

Based on the geology information and data acquired from check holes, it can be found that the grouting effectiveness was significant in the locations where the conglomerates are cemented with calcareous or arenaceous matrix and cracks were connected, and in contrast, that was ineffective where the conglomerates are cemented with mud matrix and cracks were not connected.

Processing discovery of check hole operations

The reservoir elevation during the check hole operations was retained near an elevation of 121.0 m.

Check hole J1 (station 0+261). When this hole was drilled at a depth of 9.2 m (i.e., 116.4 m elevation), the groundwater appeared and remained unchanged in the conglomerate layer. This ground water level was approximately 5.0 m below the reservoir level, which was at the elevation 121.3 m.

Check hole J2 (station 0+065). Groundwater was not observed in this hole. When this hole was drilled to 106.0 m elevation (i.e., depth of 19.6 m), where is just the boundary of the conglomerate and marl–shale layers, hole collapse occurred in the conglomerate interval.

Check hole J3 (station 0+033). Neither groundwater nor hole collapse were observed in this hole.

Check hole J4 (station 0+565). The groundwater emerged when this hole was at a depth of 23.2 m (i.e., 102.3 m elevation), where the boundary of the conglomerate and the natural clay deposit layers is. The groundwater level was initially at the elevation of 116.08 m, and finally remained stable at the elevation of 115.97 m. Hole collapse was not observed in this hole.

Check hole J5 (station 0+609). The groundwater emerged when this hole was at a depth of 22.4 m (i.e., 103.2 m elevation), where the boundary of the conglomerate and the natural clay deposit layers is. The groundwater level was initially at the elevation of 113.2 m, and finally remained stable at the elevation of 114.1 m. Hole collapse was not observed in this hole.

Check hole J6 (station 0+753). The groundwater emerged when this hole was at a depth of 16.2 m (i.e., 109.4 m elevation), where it is in the natural deposit layers. The groundwater level was initially at the elevation of 114.2 m, and finally remained stable at an elevation of 115.1 m. In addition, water released from the dam crest, when water pressure tests were carried out in the conglomerate interval at the depth between 16.6 and 20.0 m. Hole collapse was not observed in this hole.

Seepage monitoring and tracking analysis

Instrument arrangement and data acquisition

The monitoring system of the Pipasi Dam, established in the months from July to September 2005, consists of several devices that make it possible to measure quantities such as phreatic surface within the dam body, groundwater level in its foundation, seepage flow discharge weir, and local precipitation. Among these devices, seepage monitoring measurements, including a total of 26 standpipe piezometers and seven seepage monitoring weirs, were installed to monitor the effectiveness of the grouting curtain. A plan location of the standpipe piezometers and seepage flow discharge weirs is shown in Fig. 8a.

Both the phreatic surface in the dam body and the groundwater levels are monitored by standpipe piezometers. In what follows, only instruments and measurements functional to the scope of the work will be considered. The 18 standpipe piezometers, installed in three typical cross sections at stations 0+400, 0+565, and 0+400, which will be considered in characterizing the hydraulic behavior of the dam foundation, are placed within the conglomerate or natural deposit layers. For these three monitoring sections, the 12 piezometers (i.e., P9–P20) on the upstream crest, on the upper downstream slope, on the first berm, and on the horizontal drain were extended 2 m into the conglomerate layer. The other four piezometers (i.e., P21–P26) are respectively located on the upstream crest and the downstream beyond the horizontal drain, and designed to continue 4 m in the natural deposit layer. Typical cross section of the dam (i.e., station 0+565) and its observation instrumentations are shown in Fig. 8b.

The weirs were installed to collect seepage flows from the shallow foundation, and respectively located in the downstream river bed (i.e., W1), and drainage ditches from which the seepage from abutments flow into the riverbed (i.e., W2–W7). The relative locations of these weirs are shown in Fig. 8b. According to their locations, the recorded amounts are mainly attributed to the leakage through the foundation.

Figure 9 presents two graphs, one presenting the historical variations of the daily mean reservoir levels, and the other presenting the historical variations of the daily accumulated precipitation. The historical time series of the piezometers installed in the dam foundation from January 2006 to December 2014 are respectively presented in Figs. 10 and 11, for three typical cross sections. To compare the reservoir water level and seepage discharge, graphs shown in Fig. 12, which cover from the impounding period after grouting until now, were prepared too. The measurements in the period from July 2005 to June 2007 are unavailable due to weir maintenance.

Qualitative analysis

Figure 13 shows the relationship between the reservoir water level and the total leakage amount, based on measurements taken between September 2003 and December 2014; namely, after grouting. It can be seen from Fig. 13 that obvious leakages emerged in the riverbed when the reservoir level was above an elevation of 114.00 m, and the rise in the reservoir level was still directly affecting the total leakage amount. Specifically, the relationship between the total discharge and the reservoir water level can be explained by the power function, which agrees more or less with the general law for earth dams on pervious conglomerate strata (Lee et al. 2005). In addition, a discharge of 0.12 m3/s was measured when the reservoir level reached an elevation of 121.0 m, and in contrast, the recorded value was 0.42 m3/s under the same operation condition before the grouting.

The relationship between the groundwater levels in the conglomerate and natural deposit layers and the reservoir water level of the three typical cross sections are respectively shown in Figs. 14 and 15.

It is observed that results obtained from both sections of stations 0+595 to 0+800 are similar. The results indicate that groundwater levels within the conglomerate layer vary consistently with the reservoir level. More specifically, both the groundwater levels in the single row of standpipes along the cross section from upstream to downstream, and their correlations with the reservoir level decrease successively, but all the correlation coefficients are larger than 0.91. In addition, the recorded groundwater levels in pairs of monitoring standpipes of the grouting curtain decrease remarkably across the curtain, and a drastic depression of the water head occurs across the curtain. Data from the measurements indicate that the grouting curtain was effective in controlling the seepage flow within the foundation. Meanwhile, the groundwater level within the natural deposit has characteristics similar to those of the conglomerate layer. Moreover, the values are larger than those within the conglomerate layer for the same locations. It is understood that the grout curtain has effectiveness. The reason for the unexpected large amount of water leaks into the dam foundation is that the deposit layer, which was planned, was grouted to cut off the flow through the unconsolidated deposits. Consequently, the potential flow bypasses the grouting curtain through the unconsolidated deposits.

The upstream groundwater levels of station 0+400 vary in a pattern similar to those of stations 0+565 and 0+800. Groundwater levels within the conglomerate and the natural posit layers vary consistently with the reservoir level, show strong correlation and all their coefficients are larger than 0.94. The groundwater levels in standpipes P12 and P22, which locate downstream of the horizontal drain, keep stable, and the elevations are close to that of the standpipe bottoms. According to the installation records, it was estimated that the values were measured from the accumulated water in the sedimentary intervals. The relationship between the groundwater level in standpipe P11, which is located at the first berm of the downstream face, and the reservoir water level, is not as direct as that of upstream ones. It is noteworthy that a drastic depression of water head does not occur across the grouting curtain, indicating that the barrier was not effective in controlling the seepage flow.

Seepage flow behavior analysis

The seepage flow behaviors through the dam foundation were analyzed by using a steady-state flow theory, with the reservoir level higher than the elevation of 118.0 m. Based on the in situ data, Figs. 16 and 17 show the water head in percent difference from upstream to downstream in the dam foundation at the typical cross sections, respectively.

It is observed from Fig. 16 that the grouting curtain is effective in lowering the groundwater level in the conglomerate layer at sections of stations 0+565 to 0+800. As shown in Fig. 16, the grouting curtain bears about 50 % of the groundwater head difference from upstream to downstream in the dam foundation, which is consistent with the expected value of design. However, for the section at station 0+400, the groundwater head difference is linear along the river flow direction. This result indicates that the performance of the grouting curtain is not guaranteed at this section, or there is a pervious zone along the boundary of the conglomerate and natural deposit layers.

Tables 4 and 5, respectively, present the computed hydraulic gradients along the conglomerate and natural deposit layers for the 121 m elevation of the reservoir. The mean gradient within the natural deposit layer is about 0.22. As listed in Table 4, the hydraulic gradients within the grouting curtain are obviously larger, especially for sections at stations 0+565 and 0+800. In addition, the mean gradient downstream the grouting curtain reaches a maximal value of 0.75 for section at station 0+400 compared with other measured locations or sections. The hydraulic gradient required to cause heaving, namely, the critical hydraulic gradient, is usually about 0.7–0.85. In this dam downstream, concentrations of seepage were found in the left abutment, at thin or weak spots in the top stratum.

Current condition investigation

As a result of the overall grouting measure, the foundation seepage amount observed downstream decreased, and the large wet area was not observed in the downstream left bank between stations 0+300 to 0+400. However, the seepage paths pass through the foundation and change with time, so that the seepage problems still exist. Specifically, according to the visual inspection before the flooding season in 2014, it was observed that the large wet area distributed in the downstream left bank between stations 0+250 and 0+300, and clear flow emerged in the drainage ditch at the downstream toe of dam in the south of station 0+800, when the reservoir level reached an elevation of 121.0 m. Meanwhile, seepage water gushed from the bottom of the outlet of the south irrigation tunnel, piping and springs appeared in the ditch downstream of the spillway tunnel. The seepage amount increased in accordance with the rise in the reservoir level.

Recommendation

Field investigation and seepage behavior analyses have provided better insight into the dam’s seepage problems. The seepage behavior in the dam foundation is still not satisfactory, especially for local sections. It may be concluded that the efficiency of the grouting is affected by the change of the initial design arrangement, since there is a significant spatial variability in the permeability property. Probably because the grouting curtain does not upwardly extend sufficiently into the relatively impermeable layer namely dam body, leakage through the foundation might bypass the current grouting curtain and flow along the boundary of conglomerate/clay towards the downstream.

The groutability varies in locations due to the loosened structures. Based on information from available data, the reason for the leakage occurring in the dam foundation can be attributed to: (1) the lower groutability of locations of the conglomerate layer; (2) the relatively higher permeability property of locations of the natural deposit layer.

As such, other additional grouting treatments preventing seepage below the foundation are required. It is therefore suggested that a secondary grouting curtain downstream from the existing one, extending at least 2 m into the dam body, should be installed covering the conglomerate and natural deposit layers to eliminate future seepage problems. In addition, considering the likelihood of the failure of the grouting curtains, it is also suggested that relief wells should be installed along the downstream toe to prevent excessive uplift pressures and piping through the foundation.

Conclusions

The geological conditions of the Pipasi Dam in China, along with the leakages, the seepage grouting and the evaluation of the groundwater level measurements, are presented. Based on these results, the following can be concluded.

-

1.

The foundation of this dam consists of Neogene Pliocene conglomerate, Neogene Pliocene Marl–shale, and Middle Pleistocene clay deposit. Neogene conglomerate outcrops in both abutments, and are overlaid by Quaternary deposit with the thickness only about 6.0 m in the riverbed. In fact, the dam foundation of plain reservoirs generally consists of a top stratum of silts or clays underlain by a pervious substratum comprised of fine to coarse gravels. The alluvial fill generally overlies limestone rock. In some locations, the top stratum has been either completely or largely removed by river downcutting, thereby creating a ready source for exit of seepage through the underlying pervious substratum. Therefore, where such foundation characteristics are present, the seepage control method should be chosen carefully.

-

2.

Most of the seepage water collected at the downstream comes mainly from water flowing through the conglomerate layer and partially from the natural deposit layer. The seepage problems, which can be attributed to the geological condition, have become serious at various times over the last 55 years.

-

3.

Early treatments, such as the cutoff wall at the upstream and the upstream clay blanket, were intended to prolong the seepage path. However, these efforts were only carried out in individual locations, and thus cannot form a continuous spatial waterproofing system. In addition, the upstream clay blanket is probably not effective or applicable to leakage in the previous layers beneath an earth dam. The installed grouting curtain produced a significant decrease in groundwater head and the discharge of seepage water within the dam foundation. However, hydraulic gradients and seepage amounts are still found to be higher than expected level. Due to the hanging curtain type, leakage bypasses the curtain, and flows through the overlaid natural deposit layer. Moreover, the groutabilty of the conglomerate varies widely, depending on its location, considering the loosened structure. Therefore, the grouting effectiveness is doubtful. Current foundation seepage behavior calls for a complete control measure, namely a secondary closed type grouting curtain that should be upwardly embedded into the dam body, to be installed to bedrock to eliminate future seepage problems.

-

4.

The choice of seepage control measures depends on a number of factors, including: (a) plane and spatial configurations of the pervious conglomerate stratum and their relation to the dam, the physical and mechanical properties (i.e., grain gradation, permeability coefficient, and critical hydraulic gradient); (b) characteristics and thickness of the top stratum; (c) and cost and permanency. Extensive and detailed geological investigations should be implemented to understand the character of the foundation. Generally, three methods may be used for these dam foundations, such as upstream impervious blankets, complete vertical cutoffs (i.e., compacted backfill trenches, slurry walls, grouting curtains, and concrete walls), and downstream seepage drains. Among these, a complete cutoff is the most positive one to cut off all pervious strata beneath a dam by means of an impervious barrier that will eliminate both excess substratum pressures and the problem of seepage water landward. Where practicable, compacted backfill trench may be used for new projects. When the earth dam has already been constructed and needs remedial measures, the grouting curtain may be used to minimize foundation seepage. Considering the likelihood of the failure of the complete vertical cutoff, relief wells installed along the downstream toe of the dam may be used in combination with the grouting curtain to prevent excessive uplift pressures and piping through the foundation.

-

5.

Seepage control measures that occur after construction are difficult and quite expensive. Data from monitoring piezometers can be collected to identify probable seepage zones or seepage pathways, which provide better insight on the dam’s problems and determine the optimal seepage control method.

This case study provided some good lessons for future dam projects, both new and remedial. Presence of pervious strata in the foundation of an earthen dam would bring in a serious problem of seepage. As this case study showed, these types of problems may not only take years to develop, but also may take years to resolve.

References

Dunbar S, Sheahan T (1999) Seepage control remediation at Hodges Village Dam, Oxford, Massachusetts. J Geotech Geoenviron Eng 125(3):198–206

Google Maps (2015) [Pipasi Reservoir, Tangyin County] [Satellite image]. Retrieved from http://www.google.cn/maps/place/%E5%AE%89%E9%98%B3%E5%B8%82%E6%B1%A4%E9%98%B4%E5%8E%BF%E7%90%B5%E7%90%B6%E5%AF%BA%E6%B0%B4%E5%BA%93/@35.8241575,114.256801,2952m/data=!3m2!1e3!4b1!4m2!3m1!1s0x35dbe6c49d942c5b:0x9617328f26253d56. Accessed 26 July 2015

Gupta RP, Muralidhar B, Vaidya MM (2004) Post construction remedial measures against suspected high seepage in earth dam. ISH J Hydraulic Eng 10(2):58–70

Kalkani EC (1997) Geological conditions, seepage grouting, and evaluation of piezometer measurements in the abutments of an earth dam. Eng Geol 46:93–104

Karimi H, Keshavarz T, Mohammadi Z, Raeisi E (2007) Potential leakage at the Khersan 3 Dam Site, Iran: a hydrogeological approach. Bull Eng Geol Environ 66(3):269–278

Lee JY, Choi Y, Kim HS, Yun ST (2005) Hydrologic characteristics of a large rockfill dam: implications for water leakage. Eng Geol 80(1–2):43–59

ODNR (Ohio Department of Natural Resources) (1994) Dam safety: seepage through earthen dams. In: Division of Water, Dam Safety Engineering Program, Fact Sheet 94-31

ODNR (Ohio Department of Natural Resources) (2003) Dam safety: seepage through earthen dams. In: Division of Water, Dam Safety Engineering Program, Fact Sheet 03-08

Uromeihy A, Farrokhi R (2012) Evaluating groutability at the Kamal-Saleh Dam based on Lugeon tests. Bull Eng Geol Environ 71(2):215–219

Weaver K, Bruce D (2007) Dam foundation grouting (revised edn). American Society Of Civil Engineers, Reston

Welch LR, Paul AP, Leung CF (1999) Performance of the New Waddell dam seepage control feature field measurement in geomechanics. In: International symposium on field measurement in geomechanics, FMGM 99, Singapore vol 5, pp 345–353

Wiesner E, Ewert FK (2013) Resolving serious seepage through karstified limestone at the Mujib Dam, Jordan. Bull Eng Geol Environ 72(2):149–162

Zhang LM, Xu Y, Jia JS (2007) Analysis of earth dam failures—a database approach. In: ISGSR2007 first international symposium on geotechnical safety and risk, Shanghai, pp 293–302

Acknowledgments

This research was funded by the National Natural Science Foundation of China (NSFC) (Grant Nos. 51409167 and 51139001), the CRSRI Open Research Program (Program SN. CKWV2014216KY), and the Fundamental Research Funds for the Central Public Welfare Research Institute (No. Y715018). The observation data provided by the Tangyin Water Conservancy Burea is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, J., Ma, F. Evaluation of remedial measures against foundation leakage problems of earth dams on pervious conglomerate strata: a case study. Bull Eng Geol Environ 75, 1519–1540 (2016). https://doi.org/10.1007/s10064-015-0795-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-015-0795-9