Abstract

A wide variety of well drilling techniques and well completion methods is used in the installation of dewatering and artificial recharge wells for the purpose of construction dewatering. The selection of the optimal well type is always a trade-off between the overall costs of well completion and development, the optimal well hydraulics of the well itself, the hydraulic impact of the well on its surroundings, and the required operational life span of the well. The present study provides an analytical framework that can be used by dewatering and drilling companies to quantify the contribution to head loss of typical dewatering and artificial-recharge well configurations. The analysis shows that the placement of partially penetrating wells in high-permeability layers could promote the use of quick and cheap installation of naturally developed wells using jetting or straight-flush rotary drilling. In high-permeability layers, such wells can be favorable over wells completed with filter pack, which require extensive well development to remove the fines from the filter cake layer. The amount of total head loss during discharge/recharge at a volumetric rate of 20 m3/h per meter of filter length, into or from a gravely aquifer layer, is reduced by factors of 3–4 while using naturally developed well types instead of well types completed with a filter pack that contains a filter cake layer due to borehole smearing.

Résumé

Une grande variété de techniques de forage de puits et de méthodes de complétion d’ouvrages est utilisée dans l’installation de puits de dénoyage et de recharge artificielle à des fins de mise hors d’eau de construction. La sélection du type de puits optimal est toujours un compromis entre les coûts globaux de réalisation et de développement du puits, les caractéristiques hydrauliques optimales du puits lui-même, l’impact hydraulique du puits sur son environnement, et la durée de vie opérationnelle requise du puits. La présente étude fournit un cadre analytique qui peut être utilisé par les entreprises de dénoyage et de forage pour quantifier la contribution à la perte de charge des configurations typiques de puits de dénoyage et de recharge artificielle. L’analyse montre que la mise en place de puits partiellement pénétrants dans des couches à haute perméabilité pourrait favoriser l’utilisation d’une installation rapide et bon marché de puits développés naturellement à l’aide de forage au rotary à jets ou chasse directe. Dans les couches à haute perméabilité, de tels puits peuvent être favorables par rapport aux puits complétés par un ensemble de filtres, qui nécessitent un développement de puits approfondi pour éliminer les fines de la couche de la galette filtration colmatée sur les parois de l’ouvrage. La quantité de perte de charge totale pendant la décharge/recharge à un taux volumétrique de 20 m3/h par mètre de longueur de filtre, dans ou à partir d’une couche aquifère graveleuse, est réduite par des facteurs de 3–4 tout en utilisant des types de puits développés naturellement au lieu de puits types complets avec un massif filtrant qui contient une couche de galette filtrante en raison des projections de boue lors de la foration.

Resumen

En la instalación de pozos de drenaje y de recarga artificial para la construcción de sistemas de drenaje se utiliza una amplia variedad de técnicas de perforación y de métodos de terminación de pozos. La selección del tipo de pozo óptimo es siempre un compromiso entre los costos generales de terminación y desarrollo del pozo, la hidráulica óptima del pozo en sí, el impacto hidráulico del pozo en su entorno y la vida útil requerida del pozo. El presente estudio ofrece un marco analítico que pueden utilizar las empresas dedicadas a la perforación y el drenaje para cuantificar la contribución a la pérdida de carga de las configuraciones típicas de los pozos de drenaje y de recarga artificial. El análisis muestra que la colocación de pozos parcialmente penetrantes en capas de alta permeabilidad podría promover el uso de la instalación rápida y económica de pozos desarrollados naturalmente mediante la perforación por chorro o rotación directa. En las capas de alta permeabilidad, tales pozos pueden ser favorables sobre los pozos completados con prefiltros, que requieren un extenso desarrollo del pozo para eliminar los finos. La cantidad de pérdida total de carga durante la descarga/recarga a una tasa volumétrica de 20 m3/h por metro de longitud de filtro, en o desde una capa de acuífero gravitacional, se reduce en factores de 3–4 al utilizar tipos de pozos desarrollados naturalmente en lugar de los pozos terminados con un pack de filtros que contiene una capa en el filtro debido al arrastre de la perforación.

摘要

为了进行工程疏干, 在疏干和人工补给井的安装中使用了各种钻井技术和完井方法。最佳井型的选择始终需要权衡完井和开采的总成本、井本身的最佳井水力学、井对周围环境的水力影响以及井所需的使用寿命之间的关系。本研究提供了一个可供疏干和钻井公司用来量化典型疏干和人工补给井设计对水头损失贡献的分析框架。分析表明, 将非完整井放置在高渗透率层中, 有便于使用快速和廉价的自然开发井(采用旋喷或垂直冲洗旋钻)进行安装。在高渗透率层中, 采用充填过滤器的完井方式较好, 这需要钻探大量的井才能从滤饼层中除去细颗粒物。使用自然开发的油井类型而不是由于钻孔拖尾而包含滤饼层的充填过滤器的完井类型时, 当每米过滤器的长度的排泄或补给率在20 m3/h时, 总水头损失减少了3到4倍。

Resumo

Uma ampla variedade de técnicas de perfuração e métodos de preenchimento anelar é utilizada na instalação de poços de bombeamento e de recarga artificial para fins de rebaixamento de nível freático para obras de construção civil. A seleção do tipo de poço ideal frequentemente pondera custos de instalação e desenvolvimento do poço, as condições hidráulicas ideais intrínsecas ao poço, o impacto hidráulico do poço no seu entorno, e a vida útil poço. O presente estudo provê um arcabouço analítico que pode ser utilizado por empresas de rebaixamento de nível freático e de perfuração de poços para quantificar a contribuição da perda de carga hidráulica em configurações típicas de poços de rebaixamento de nível freático e recarga artificial. A análise mostra que a alocação de poços parcialmente penetrantes em camadas altamente permeáveis pode promover a utilização de instalação rápida e barata de poços de desenvolvimento natural utilizando jateamento ou sondagem rotativa com circulação direta. Em zonas de alta permeabilidade, tais poços podem ser mais favoráveis do que poços preenchidos com pré-filtro, o qual exige desenvolvimento extensivo para remover materiais finos do envoltório do poço e retido no pré-filtro. A quantidade total de perda de carga hidráulica durante a descarga/recarga volumétrica de 20 m3/h por metro de comprimento do filtro, adentro ou a partir de uma cama aquífera de cascalho, é reduzida entre 3–4 vezes quando utilizado poços de desenvolvimento natural ao invés de poços preenchidos com pré-filtro.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In order to obtain an optimal, energy-efficient well design, thorough understanding of the well hydraulics is required to minimize head losses during abstraction or recharge of water from or into the subsurface (Driscoll 1986; Barker and Herbert 1992; Houben 2015a, b). For a properly designed and developed water well, the largest head loss occurs in the aquifer material (Powers et al. 2007; Houben 2015b).

To date, most studies have investigated the efficiency of abstraction wells for freshwater supply (e.g. Driscoll 1986; De Zwart 2007; Van Beek et al. 2009a, b; Houben 2015a, b; Houben et al. 2018). These studies focus on typical well designs for drinking water wells (Barker and Herbert 1992; Houben 2015b), as well as the well efficiency reduction over time by mechanical or chemical clogging (e.g. De Zwart 2007; Van Beek et al. 2009a, b; Houben et al. 2018). Drinking water wells are designed to operate for decades, and hence high costs of proper extensive well development and completion usually overcome the additional pumping costs of cheaper but poorly developed and completed abstraction wells. Typically, such wells are screened over a large portion over the aquifer in order to reduce additional head loss by partial penetration.

However, for many water well applications, partially penetrating wells (PPWs) are unavoidable to optimize the entire well-system. Water well systems such as combined dewatering and artificial recharge systems at construction sites (Powers et al. 2007; Van Lopik 2020; Van Lopik et al. 2020a), aquifer storage and recovery (ASR) systems (Zuurbier et al. 2014), and high temperature aquifer thermal energy storage (HT-ATES) systems (Buscheck et al. 1983; Van Lopik 2020), can be improved with PPWs that target specific portions of the aquifer. During construction dewatering, PPWs (deep-wells or vacuum point-wells) are screened at the required drawdown depth to obtain the desired groundwater levels at the construction site. The installation of such dewatering PPWs require less drilling and completion costs compared to wells that screen a large portion of the aquifer. For combined well systems of dewatering wells and artificial recharge wells to reinfiltrate the pumped groundwater in the target aquifer, dewatering companies in the Netherlands and Germany have started to use recharge PPWs to minimize the hydraulic impact at shallow subsurface levels during construction dewatering (see Van Lopik et al. 2020a). Often, such PPWs are naturally developed (installed without filter pack) and placed with quick, relatively cheap drilling methods such as jetting or straight-flush rotary to save the costs of the entire dewatering scheme for an excavation. Consequently, the well hydraulics of such artificial recharge wells differ significantly from conventional artificial recharge wells.

Particularly for dewatering at construction sites, a wide range of well completion methods are used to install dewatering wells (e.g. deep wells or vacuum points wells) to lower the water table and, optionally, artificial recharge wells to reinject water into the aquifer. The selected type of well completion of such water wells largely determines the entire efficiency of the dewatering system (Powers et al. 2007; Cashman and Preene 2013). Therefore, the efficiencies of the various abstraction and artificial recharge well-types in construction dewatering are critical to reduce the pumping costs and overall carbon footprint during the dewatering operation. Dewatering companies have the opportunity to select from a wide range of drilling techniques to install the most suitable, least-expensive well-type based on the extent and operational time of the dewatering system. In general, the operational life-span of a dewatering abstraction or artificial recharge well is significantly lower than in other well applications. Hence, the costs and time of proper well completion and development need to be balanced with the overall pumping costs for a specific dewatering application.

During artificial recharge and abstraction, the effect of additional head losses by non-linear flow behaviour in the filter pack, as well as in the aquifer material, can be significant due to increased flow velocities by diverging/converging flow lines in the vicinity of wells (e.g. Basak 1978, Barker and Herbert 1992; Houben 2015a, b). In the initial stage of well operation of properly designed and developed drinking water wells in sandy aquifers, hardly any effect of nonlinear flow behaviour is observed (<4% of additional head loss; Barker and Herbert 1992; Houben 2015b). However, during well operation, clogging of abstraction and injection wells can cause additional head losses (Olsthoorn 1982; De Zwart 2007; Van Beek et al. 2009a, b; Powers et al. 2007; Martin 2013; Houben et al. 2018). Severe clogging of wells could result in reduced porosity in the filter pack and drastic increase of nonlinear flow behaviour (Houben et al. 2018).

In the present study, the important aspects of well hydraulics of typical well-types used for construction dewatering are investigated using analytical equations. To date, the well specification of such wells are generally based on the equipment and expertise of the drilling or dewatering company (Powers et al. 2007; Cashman and Preene 2013). Existing literature focusses on the well hydraulics of typical drinking water well types that are completed with a proper filter pack (e.g. Barker and Herbert 1992; Houben 2015a, b). However, the well hydraulics of naturally developed wells used in construction dewatering, which are installed with cheap, quick well completion methods such as jetting and straight-flush rotary drilling, differs from typical drinking water wells (e.g. Powers et al. 2007; Van Lopik 2020). In order to compare the well efficiency of naturally developed wells and proper completed wells with a filter pack screened in different kinds of aquifer types (ranging from sand to gravel), the contributors of the individual head components to the total head loss outside the well screen are evaluated in the present study. This is done by using actual hydraulic properties for a broad range of filter sands and natural sand and gravel deposits from aquifers that include the nonlinear flow behaviour characteristics obtained from experimental datasets (Van Lopik et al. 2017, 2020b). Besides the wide variety in well completion methods used in construction dewatering, the effect of partial penetration on well efficiency is investigated. Generally, additional head loss of PPWs that only screen a small portion of the aquifer results in large additional head losses (e.g. Barker and Herbert 1992; Houben 2015a; Tügel et al. 2016). However, accounting for the aquifer heterogeneity during PPW placement in high-permeability strata of the aquifer, instead of considering homogeneous anisotropic conditions for the aquifer, might significantly reduce additional head losses due to partial penetration. The current analytical analysis will provide insight to what extent cheap installation of naturally developed wells, as well as PPWs that only screen a small portion of the aquifer, can be used at reasonable well efficiency during operation compared to more costly well completion with a filter pack and wells that screen a large portion of the aquifer for dewatering purposes.

Theory

Well completion with various drilling techniques

In practice, a broad variety of well-types is available for dewatering with deep wells or injection with artificial recharge wells (Powers et al. 2007). The selection of the well-type (e.g. borehole diameter, well diameter, filter screen, filter pack, screen slot dimensions) depends on the pumped or injected volumes, aquifer characteristics and operational life span of the well. For example, relatively cheap PVC wells that need to be operative for a couple of weeks usually suffice for most dewatering projects. Moreover, in practice, the expertise of each specific dewatering company, as well as the availability of specific drilling equipment, also largely determines well design (especially for smaller dewatering projects).

In the present study, typical drilling and well completion methods for dewatering and artificial recharge wells in unconsolidated soils used by the dewatering companies are considered. Two different well completion methods are investigated:

-

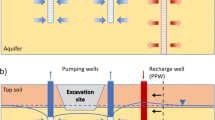

Naturally developed wells assuming completion without a filter pack with a larger borehole diameter than the well diameter and a zone of aquifer collapse (well-types WAC1–2, see Fig. 1a and Table 1).

-

Well completion with a filter pack and filter cake (well-types WFP1–2, see Fig. 1b and Table 1).

Head losses (blue line) during artificial recharge in an aquifer for a a naturally developed well drilled with the jetting or straight-flush rotary drilling method considering aquifer collapse (well-type with aquifer collapse, WAC) and b a well drilled with the reverse-circulation rotary drilling method considering filter pack and filter cake with positive skin layer (well-type with filter pack WFP). In this figure, rs is the radius of the screen, rb is the radius of the borehole, rsk-in is the radius from well centre to the inner boundary of the skin layer, rsk-out is the radius from well centre to the outer boundary of the skin layer, ro is the radius of influence where head increase is zero (h0). Also, the components of head loss in the aquifer material (∆haq), collapsed aquifer zone (∆hAC), filter pack (∆hfp) and skin layer (∆hsk) are shown

Aquifer collapse with no filter pack (naturally developed wells)

In practice, manual jetting and straight-flush rotary drilling are suitable methods for relatively cheap and quick installation of dewatering and artificial recharge naturally developed wells without artificial filter pack (Powers et al. 2007). Similar to manual jetting, during mechanical drilling by straight-flush rotary, a drilling-fluid is pumped down the drill-rod of the drilling rig to flush out the debris mixture of water and soil. A rotating drill-bit cuts and penetrates the soil. The velocity of the drilling fluid in the borehole annulus must be sufficient to lift the debris up to the surface level. Large quantities of the flushed water volume pumped down the drill-pipe are infiltrated into the surrounding soil during this drilling method (Powers et al. 2007). Drilling through high-permeability layers in the aquifer causes a significant loss of flushed water volume into the surrounding soil and a sudden reduction in debris flush velocity in the borehole annulus. This allows for quick and cheap placement of partially-penetrating wells in high-permeability strata in the aquifer without a filter pack using straight-flush rotary or jetting (e.g. Van Lopik 2020).

Typical drilling fluids for jetting or straight-flush rotary drilling techniques are water, bentonite-mud and polymeric drilling fluids (Powers et al. 2007). If clean water is used as a drilling fluid during uncased drilling methods such as jetting or straight-flush rotary, the lack of filter cake formation results in an unstable borehole wall and hence, proper well completion with a filter pack in sandy aquifers is difficult. Placement with jetting of naturally developed dewatering well points without a filter pack are common practice in sandy aquifers. In the last decade, dewatering companies in the Netherlands and Germany started to install naturally developed partial-penetrating artificial recharge wells using jetting or straight-flush rotary drilling with clean water as drilling fluid (Van Lopik 2020). After proper well development, such naturally developed wells could have a negative well skin, due to improved hydraulic conductivities in the vicinity of the well by easy mobilization of finer particles during well development after jetting or straight-flush rotary drilling with a clean drilling fluid, limited formation of filter-cake, and aquifer collapse within the area between the well and the outer borehole diameter after placement (rs < r < rb; Driscoll 1986; Roscoe Moss Company 1990). Moreover, the filter-cake that is formed due to precipitation of fines by the up-flowing debris along the borehole collapses and mixes with the aquifer material (Fig. 1a). Generally, the borehole radius of jetting and straight-flush rotary drilled wells in stratified soils is highly irregular. In the present study, the radius rb was used as the outer radius of the negative skin zone with collapsed aquifer material.

Stable borehole with filter pack

For prolonged recharge or dewatering purposes, reverse-circulation rotary drilling is a widely used method for well placement of deep wells or artificial recharge wells (Powers et al. 2007). This method enables drilling of large diameter boreholes, and hence large diameter wells can be placed while allowing for proper completion with a filter pack. The drilling method also uses a rotating drilling bit to penetrate and cut the soil. However, the drilling fluid flows down the borehole outside the drill-rod and lifts the drilling fluid and soil to surface level through the drill-rod by suction.

Usually, filter cake at the borehole surface is formed due to precipitation of fines and drilling mud during well placement, causing a small positive skin zone of low permeability. If the well is properly designed and developed, the second-most significant portion of the total additional well loss occurs in this well skin (e.g. Houben 2015b; Houben et al. 2016). Prolonged, costly well development procedures are required to minimize the additional head loss due to well skin. Hence, in practice, significant head loss often occurs due to the positive well skin in dewatering deep wells and artificial recharge wells.

Nonlinear flow behaviour in porous media

Commonly, the Reynolds number (Re) is used to indicate whether flow is in the laminar Darcian flow regime or in the nonlinear flow regime (Bear 1988):

where v [m2/s] is the is the kinematic viscosity of the fluid and d50 [m] is the characteristic pore length by means of the median particle diameter. Most studies consider Reynolds numbers ranging from 1 to 10 for transition between laminar Darcian flow and nonlinear flow (e.g. Bear 1988; Houben 2015a; Van Lopik et al. 2017, 2020b). Nonlinear post-Darcian flow behavior can be described by the alternative flow law of Forchheimer (1901):

where a [s/m] is a parameter equal to the reciprocal of the hydraulic conductivity (i.e., a = 1/K) and b [s2/m2] is the empirical Forchheimer coefficient. Similar to the Kozeny-Carman relationship, Ergun (1952) related the Forchheimer coefficients to the grain size and porosity by:

where g [m/s2] is the acceleration due to gravity, d [m] is the characteristic pore length by means of the particle diameter, n [−] is the porosity, A and B [−] are the Ergun constants.

Natural sand and gravel deposits

A broad dataset of Forchheimer coefficients a and b for granular material is found in the literature (e.g. Moutsopoulos et al. 2009; Van Lopik et al. 2017, 2020b). Most studies provide data related to uniformly graded material with coefficients of uniformity (Cu = d60/d10) smaller than 3. The study of Van Lopik et al. (2020b) shows that for a wide range of grain size distributions with Cu > 3 and low porosity values, the amount of fines (characteristic pore length of d10) can be used to predict the Forchheimer coefficients a and b. For the present study, experimentally derived Forchheimer coefficients from packed bed experiments on natural sands and gravel are used (Table 2).

Filter packs

Usually, basic criteria for the selection of suitable filter packs are provided in the literature for artificial recharge and dewatering deep wells (Pyne 2005; Powers et al. 2007). Ideally, the used filter pack is based on the aquifer material, and grain size analysis of the aquifer is required (Driscoll 1986; Roscoe Moss Company 1990; Powers et al. 2007):

-

The filter pack is as coarse as possible. However, selection of filter packs with grain sizes that are too coarse allows passing and migration of fines, from the aquifer towards the well screen during abstraction. In highly stratified soils, filter packs should be based on the finest strata. During well development of artificial recharge wells, the risk of mobilization of fines into the filter pack should be taken into account and hence, selection of filter pack is approximately similar to that of dewatering deep wells (e.g. Powers et al. 2007).

-

The filter material is uniformly graded (Cu < 3). More specifically, the filter pack should have a lower Cu than the aquifer material.

-

The median grain size (d50) of the filter pack should be 4–6 times higher than the aquifer material.

Due to high flow velocities (Re > 10) by converging or diverging flow lines in the filter pack of respectively abstraction and recharge wells, head loss due to nonlinear flow behaviour occurs (e.g. Houben 2015a, b). Van Lopik et al. (2017) investigated the nonlinear flow behaviour through packed-bed experiments of typical filter pack sands and gravels (with Cu < 3). Five types of different filter pack material were selected for this study, ranging from medium to very coarse sand, in order to investigate the nonlinear flow head losses in wells (Table 2). Filter pack porosities of 0.34–0.36 are realistic values for the packing density of filter packs of dewatering wells (Houben et al. 2016).

Well hydraulics of artificial recharge and deep wells

The present study focusses on the different individual components of head loss in the filter pack and aquifer for typical artificial recharge wells and deep wells used by dewatering companies in various parts of the world. In order to investigate the head losses during artificial recharge or groundwater abstraction in a confined aquifer by a vertical, fully penetrating well, analytical equations are used to obtain a general overview for different well-types (see Houben 2015b). Typical geometry and parameters for deep wells and artificial recharge wells are used, see Table 1 for specifications. In general, additional head loss due to free flow in the well interior (well casing and screen) and through the screen slots is very small (Barker and Herbert 1992; Houben 2015b). Hence, this study solely focuses on the head losses outside the well screen.

Darcian and non-Darcian flow towards a well

For classical abstraction or recharge wells that screen large parts of the aquifer, flow is solely in the lateral direction and radial-symmetric flow conditions can be assumed. Hence, steady-state groundwater flow to and from such abstraction or recharge wells in a fully confined homogeneous aquifer can be described by Thiem’s equation (1870):

where Δh [m] is the head loss, Q [m3/s] is the volumetric well discharge/recharge, H [m] is the aquifer thickness and r1 and r2 [m] are the radial distances.

At high abstraction or injection flow velocities in the vicinity of the well, Reynolds numbers are high (Re > 10) and nonlinear flow behaviour could occur (e.g. Engelund 1953; Basak 1978; Houben 2015a, b). The extended form of Thiem’s equation can be used to account for nonlinear Forchheimer flow head losses in the gravel pack or aquifer:

Flow convergence/divergence near screen slots

Close to the screen slots, the convergence or divergence of flow lines to or from the screen slots causes an additional head loss. The equation for flow line convergence/divergence by Boulton 1947 (as cited by Houben 2015b) during abstraction or injection is verified and extended for both Darcian and Forchheimer flow (see Appendix):

where K [m/day] is the hydraulic conductivity, Ls [m] is the length of the screen (equals aquifer thickness in this study), ns [−] is the number of slots inside the circumference of the well, rs [m] is the radius of the well screen and δs [−] is the ratio of slot aperture and circumference of the well.

This extended equation is applied for the component of head loss due to flow convergence/divergence in the collapsed aquifer zone for well-types WAC1–2 (Eq. 7, in Table 3), as well as in the filter pack for well-types WFP1–2 (Eq. 10, in Table 3).

Equations for individual components of head loss

Equation (5) is used to account for the individual components of head loss in both the collapsed aquifer zone (Eq. 8) as well as the aquifer itself (Eq. 9) for the well-types WAC1–2 (Table 3). Similarly, Eq. (5) is used to account for the individual components of head loss in both the filter pack (Eq. 11) and the aquifer itself (Eq. 13) for the well-types WFP1–2. To obtain a rough estimate of the additional head loss due to the formation of a filter cake (positive skin), the Thiem equation is considered (Eq. 12). In general, the hydraulic conductivity and thickness of the well skin is difficult to predict, since in-situ samples are required to make proper estimates (Powers et al. 2007; Houben 2015b; Houben et al. 2016). The present study assumed a filter cake layer of 1 mm at rb (rsk-in < r < rsk-out) with a hydraulic conductivity (Ksk) of 1e-6 m/s, which are reasonable values for water wells (Houben et al. 2016).

Methods

The different components of head losses for typical artificial recharge and dewatering deep wells are estimated analytically for four different kind of well-types (Table 1). In the present study, the effects of nonlinear flow behaviour in well hydraulics were investigated using the provided experimental datasets on packed-bed flow experiments of filter sands (Van Lopik et al. 2017) and natural sands (Van Lopik et al. 2020b; Table 2). The impact on well hydraulics is investigated for:

-

The individual components of total head loss of the different well types in the different aquifer materials ranging from coarse sand to coarse gravel (Table 2). The contributions to the total head loss in the collapsed aquifer zone (∆hAC) and aquifer (∆haq) are investigated for well types WAC1–2, as well as in the filter pack (∆hfp), skin (∆hsk) and aquifer (∆haq) for WFP1–2 (Table 3).

-

The efficiency of the filter packs ranging from medium to very coarse sand. These are investigated and compared to a hypothetical case with no filter pack (assuming the characteristics of aquifer material within the borehole radius).

-

The effect of well-clogging in the filter pack.

-

The effect of additional head loss by partial penetration of the well.

Individual components of total head losses in different aquifer types

To calculate the individual components of head loss, the analytical equations listed in Table 3 are used. For the well types with filter pack (WFP1–2), completion with very coarse sand (FP-VCS1 with Kfp = 823 m/day) is considered. The associated hydraulic properties of the filter pack FP-VCS1 and the aquifer materials are listed in Table 2.

For the collapsed aquifer zone around the well drilled by jetting/straight-flush rotary methods (well types WAC1–2), an improved hydraulic conductivity which is two times lower than the actual aquifer material is assumed. For estimation of the reduced nonlinear flow resistance, coefficient b is estimated by: b = 172.77a0.548 (see Van Lopik et al. 2017).

Additional head loss in the filter pack

Selection of a suitable filter pack is essential for a proper well completion. Ideally, the filter pack is selected such that the flow resistance is lower than the aquifer material (see section ‘Filter packs’). Hence, in order to compare the efficiency of different filter pack types with equivalent scenarios considering only aquifer material within the well bore zone, the additional head losses by laminar Darcy flow, nonlinear flow and flow convergence/divergence to screen slots within the zone of rs < r < rb are calculated for the sand types listed in Table 2.

Clogging of the filter pack

Clogging of water wells could occur inside the well interior, screen slots and the filter pack (Olsthoorn 1982; De Zwart 2007; Van Beek et al. 2009a, b; Houben et al. 2018). Usually, severe clogging of well screens and well interior by biofouling of incrustation of dewatering deep wells or artificial recharge wells (Powers et al. 2007) can be reversed after proper well development. However, well development does not remove all clogging particles in the filter pack, at the borehole wall, and in the aquifer itself (Houben et al. 2016, 2018). The most important factor in well clogging is the clogging of the filter pack (Houben et al. 2018).

Therefore, similar to the Houben et al. (2018) study on filter pack ageing of drinking water wells, the increase in head losses due to porosity reduction in the filter pack is investigated for well-type WFP1 and the hydraulic properties of filter and natural sand based on Van Lopik 2017 and 2020b. The Ergun relation (Eq. 3) is used with the Ergun constants A and B of respectively 233.5 and 2.88 and d50 for filter pack clogging. These values have shown representative prediction of nonlinear flow behaviour through packed beds of various filter sands and gravels (Van Lopik et al. 2017). The effect of reduced porosity values by clogging on the hydraulic conductivity and Forchheimer coefficient b is shown in Fig. 2 for the filter packs of medium sand (FP-MS1), coarse sand (FP-CS2) and very coarse sand (FP-VCS2). Moreover, the effect of porosity reduction by clogging of well-type WAC2 is shown, considering the aquifer materials of A-VCS1 and A-CG1 in the collapsed aquifer zone for a naturally developed well. For these cases, the modified form of the Ergun relationship (Eq. 3) for natural sands is considered (Van Lopik et al. 2020b). Hence, Ergun constants A and B of respectively 69.0 and 1.85, and the grain size of d10 as a characteristic length scale, are assumed to estimate the effects of porosity reduction by the formation of a positive skin layer due to aquifer clogging (see Fig. 2). In this study, the filter sands with hydraulic conductivities of 60.6 m/day (FP-MS1), 351 m/day (FP-CS1) and 1,339 m/day (FP-VCS2) are used as reference and tested for additional head loss by well clogging.

Effect of partial penetration on additional head loss

In the aforementioned scenarios, axi-symmetric flow in solely the lateral direction is considered using the Thiem equation, which is valid when the Dupuit-Forchheimer approximation holds, see Eqs. (4) and (5). However, well-types for dewatering and artificial recharge at construction sites such as given in Table 1 are generally not fully screened over the entire depth of the aquifer. Dewatering deep wells are placed at depth for the required drawdown for construction. Artificial recharge wells could be screened in deeper parts of the aquifer to minimize hydraulic impact on the excavation site and allowing for closer placement to the dewatered area (Van Lopik et al. 2020a).

In order to estimate additional head loss by partial penetration compared to an equivalent scenario of full penetration over the entire aquifer thickness, many equations have been postulated (e.g. Barker and Herbert 1992; Kasenow 2010; Houben 2015a). In the present study, the equation of Barker and Herbert (1992) is used to account for anisotropic aquifer conditions and determine analytically the impact of different aquifer characteristics on head loss for PPWs. Additional head losses by partial penetration of the well in a homogeneous, anisotropic aquifer can be calculated by:

where Kh [m/day] is the horizontal hydraulic conductivity, Kv [m/day] is the vertical hydraulic conductivity, pp [−] is the partial penetration ratio between screen length and the aquifer thickness (H) and ε [−] is the eccentricity of the well, described by:

where zc [m] is the vertical distance between the middle of the aquifer and the centre of the well screen. Note that Eq. (14) is only applicable for Darcian flow conditions and pp ratios between 0.1 and 0.9. Considering nonlinear flow behaviour only occurs in the near vicinity of the well (e.g. filter pack or collapsed aquifer zone), this equation is valid to estimate additional head loss by partial penetration.

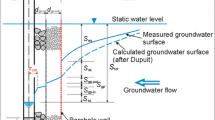

Generally, high-permeability layers in a given target aquifer are selected in order to optimize the well design (Fig. 3a). Often, poor aquifer characterization by a rough estimate of the horizontal hydraulic conductivity and vertical hydraulic conductivity based on an assumed anisotropy factor with typical educated guesses for a (= Kh/Kv) values that range from 2 to 10 for natural aquifers (e.g. Kasenow 2010) results in poor well design. The predicted additional head loss by partial penetration is highly overestimated due to underestimating the in-situ aquifer permeability at injection depth (Fig. 3b). In order to estimate the overestimation in head loss, this study considered a high-permeability layer (hydraulic conductivity of K1 and thickness of H1) under- and overlain by low-permeability layers (K2) of equal thickness (H2; Fig. 3a). The average horizontal hydraulic conductivity Kh,av over the entire aquifer thickness (Fig. 3b) is calculated by (Kasenow 2010):

The average vertical hydraulic conductivity Kz,av for both the heterogeneous aquifer and the equivalent anisotropic homogeneous aquifer (see Fig. 3) is calculated by Kasenow (2010):

Results

Components of head loss in artificial recharge or dewatering deep wells

The maximum recharge/discharge rate that is investigated for the sandy aquifers (ACS-1 and AVCS-1) is 20 m3/h. This results in very high total head losses in the range of 10.7–15.7 m (Fig. 4a–b). At a rate of 10 m3/h, the total head losses are in the range of 5.3–7.8 m, which are still high for well operation in such sandy aquifers. No large differences in well-efficiency between the naturally developed well-types (WAC1–2) and well-types with filter pack (WFP1–2) are observed (Fig. 4a–b). Comparing the analysis on the components of head loss between the well-types WAC1–2 and WFP1–2, the difference in total head loss between the two well completion methods is large for the wells screened in coarse gravely aquifers (A-CG1–2; Fig. 4c–d). At recharge/discharge rates of 20 m3/h in aquifer A-CG1, the total head losses are only 2.45 and 2.16 m for WAC1 and WAC2 respectively, while the total head losses for WFP1–2 are much higher, with values of 6.35 and 5.39 m respectively (Fig. 4c).

Head losses in the aquifer during artificial recharge/dewatering with the four different well-types (Table 1) at volumetric discharge/recharge rates (Q) over a 1-m filter length (L) of 5, 10, 20 and 30 m3/h. The aquifer types in Table 2 are used with a A-CS1 (d50 = 0.77 mm), b A-VCS (d50 = 1.5 mm), c A-CG1 (d50 = 9.5 mm), d A-CG2 (d50 = 6.3 mm). Note that for well types WAC the collapsed aquifer hydraulic conductivity is two times higher than the aquifer material and for well types WFP the filter pack F-VCS1 is considered

For well completion with filter pack of well-types WFP1–2 with very coarse filter sand (FP-VCS1) in gravely aquifers A-CG1–2, the head loss in the skin layer is the most important contributor to the total head loss due to the assumption of a low-permeability skin layer (Ksk = 1E-6 m/s). At volumetric recharge/discharge rates of 20 m3/h, the percentage of relative head loss due to skin ranges between 65 and 80% of the total head loss for well-types WFP1–2 that are screened in A-CG1–2 (Fig. 4c–d). Hence, extensive well development after reverse-circulation rotary drilling is required to remove filter cake and increase the Ksk to values of approximately 1E-3 m/s in order to achieve similar head loss of 1.3 m, as for the equivalent case with WAC2.

For the estimated additional head loss components in the aquifer and collapsed aquifer zone for the naturally developed well-types WAC1–2, a higher hydraulic conductivity (negative skin) for the collapsed aquifer is assumed (Fig. 1a). This results in slightly reduced head losses in the collapsed aquifer zone. For example, a volumetric recharge/discharge rate of 20 m3/h for WAC2 screened in the gravely aquifer ACG-1 results in an estimated head loss of only 0.06 m in the collapsed aquifer zone, which is only 4.3% of the total head loss (see Fig. 4c). Compared to a scenario with no formation of negative skin layer and permeability enhancement after completion and development of well-type WAC2 in the borehole area (rs < r < rb), the estimated head loss is 0.21 m (Fig. 5c), which is only 9.3% of the total head loss. Only for severe reduction of permeability (positive skin) in the borehole area (rs < r < rb), the contribution to the total head loss can be significant. For example, in order to obtain a similar total head loss as for WFP1 at a discharge/recharge rate of 20 m3/h in A-CG1 (total head loss of 6.35 m; Fig. 4c), the hydraulic conductivity in the borehole area (rs < r < rb) needs to be reduced from 328 to 19 m/day (with b coefficient of 23,700 s2/m2) for WAC2. This can be the case for scenarios with poor or no well development in the borehole area in WAC1–2.

Head losses in the borehole area of the aquifer during artificial recharge/dewatering with the four different well-types (Table 1) at volumetric discharge/recharge rates (Q) over a 1-m filter length (L) of 10, 20 and 30 m3/h. The head loss is calculated within the radius of the borehole (rs < r < rb), to compare and investigate the efficiency increase with well completion using a filter pack. The aquifer types in Table 2 are used with a A-CS1 (d50 = 0.77 mm), b A-VCS (d50 = 1.5 mm), c A-CG1 (d50 = 9.5 mm), d A-CG2 (d50 = 6.3 mm)

Head losses in the filter pack and collapsed aquifer zone

The selection of a proper very coarse filter sand (FP-VCS1 with Kfp = 823 m/day) for well-types WFP1–2 results in limited additional head loss in the filter pack compared to head losses in the skin layer and aquifer. The hydraulic conductivity of the filter pack is a factor of 15.4 and 12.6 higher than the aquifer hydraulic conductivities of A-CS1 and A-VCS1 respectively. In contrast, the advantage of well completion with filter pack FP-VCS1 (d50 = 1.5 mm) in coarse gravel deposits (A-CSG1–2) is limited, resulting in higher aquifer hydraulic conductivities by a factor of only 2.5 and 1.6 respectively. Therefore, the advantage of using filter pack FP-VCS1 instead of the actual aquifer material in the borehole area (rs < r < rb) is small in the gravely aquifers (A-CG1–2). For example, the difference in head loss at 20 m3/h with WFP1 between the filter pack (∆hfp = 0.075 m; Fig. 6d) and a hypothetical scenario of aquifer material A-CG2 in the borehole area (∆haq = 0.126 m; Fig. 5d) is negligible. For the sandy aquifers the difference in head loss is much higher, where ∆haq equals 0.97 m (A-CS1) and 1.06 m (A-VCS1; Fig. 5a–b). The selection of coarser, more permeable filter packs in homogeneous gravel aquifers could potentially increase the well efficiency. The use of filter pack FP-VCS2 in a high-permeability layer of A-CG2 could reduce the head loss significantly by a factor of 2.7. However, the selection of coarser gravel packs (d50 > 2 mm) could result in mobilization of fine material from the well-graded gravel with fine sand/silt and the risk of sand pumping (Powers et al. 2007). In practice, the selected grain size of the uniformly graded filter packs by dewatering companies for well completion in sandy natural aquifers are commonly 1.0–2.0 mm (e.g. FP-CS2 and FP-VCS1–2).

Head losses in the filter pack during artificial recharge/dewatering with the four different well-types (Table 1) at volumetric discharge/recharge rates (Q) over a 1-m filter length (L) of 10, 20 and 30 m3/h. The considered types of filter packs (Table 2) are used with a FP-MS1 of medium sand (d50 = 0.39 mm), b FP-CS1 of coarse sand (d50 = 0.71 mm), c FP-CS2 of coarse sand (d50 = 1.0 mm), d FP-VCS1 of very coarse sand (d50 = 1.5 mm) and e FP-VCS2 of very coarse sand (d50 = 2.1 mm). Note that well-types WAC1–2 are usually completed without filter pack

For wells screened in stratified aquifers, filter packs should be based on the finest strata. As a consequence, the selection of filter packs for well-types WFP1–2 based on the finer low-permeability layers in highly heterogeneous sandy or gravely aquifers does not necessarily mean significant reduction in well losses compared to naturally developed well-types without filter pack (WAC1–2). Most flow will occur in the high-permeability layers in the aquifer such as A-CG1 (K = 328 m/day) and A-CG2 (K = 527 m/day). In such case, the use of WFP1–2 for dewatering and artificial recharge does not necessarily result in a better well performance than well-types WAC1–2.

The nonlinear flow head losses in the filter packs are small compared to the total head loss (Figs. 4 and 6). Due to relatively high Forchheimer coefficients b with respect to the hydraulic conductivity of natural sands and gravels with high Cu values and low porosity values compared to filter sands (Table 2), the component of head loss due to nonlinear flow behaviour is slightly higher for ACG1–2 (Fig. 5c–d). Considering the use of well-types WAC1–2 with no collapsed aquifer zone (negative skin) in these aquifer types, the percentage of nonlinear flow head loss is approximately still only 4% of the total head loss. Note that in typical collapsed aquifer zones (after well completion by jetting of straight-flush rotary), the porosity is increased and the relative fraction of nonlinear flow behaviour head loss is lower. Therefore, one can state that the effect of nonlinear flow behaviour on head loss is limited for both naturally developed (WAC1–2) and filter pack well-types (WFP1–2) in sandy to fine-gravelly aquifers after proper well completion and development. This is in line with the non-Darcian head losses in common water wells (Barker and Herbert 1992; Houben 2015a, b).

However, in uniformly graded gravely to boulder-type aquifers, the effect of nonlinear flow behaviour will become more significant. For example, considering a high-permeability aquifer with the aquifer characteristics of FP-VCS2 (K = 1339 m/day) and no well skin or filter pack on well-type WAC2, the total head loss will be 0.84 m with a non-Darcian head loss component of 7% at Q = 30 m3/day. Therefore, screening well-types WAC1–2 in high-permeability gravel layers (K > 1,000 m/day), which will allow for considerably higher volumetric discharge/recharge rates, the additional head loss by nonlinear flow behaviour should be taken into account.

Similar to Houben (2015b), the additional head loss due to flow convergence/divergence in the filter pack is negligible (e.g. only <0.03% of the total head loss for WAC1–2 and WFP1–2 with FP-VCS1; Figs. 4 and 6d). The additional head losses due to convergence/divergence are calculated based on the assumption that the flow lines solely converge/diverge at the interface between the filter pack and well screen, see Appendix. To determine if this is a proper assumption, numerical modelling and experimental work is required. Presumably, convergence or divergence of flow lines during respectively abstraction or injection will not solely occur at this interface, but over a wider region in the filter pack and is much more complex than the assumption made in Appendix for Boulton’s equation (1947; Eq. 6). Therefore, the components of head loss due to divergence or convergence in the present study should be taken as a proxy. Nonetheless, it makes sense that the major contribution of head loss occurs by the axi-symmetric Darcian and nonlinear flow as shown in Figs. 5 and 6, and the zone of diverging/converging flow lines occurs in the nearest vicinity of the screen, and will be very small.

Clogging of the filter pack

Severe clogging of the filter pack of artificial recharge and dewatering deep wells (well-type WFP1), could result in high additional head losses (Fig. 7). For example, considering filter pack FP-CS2, a porosity reduction to a value of 0.18 by clogging could result in increased total head loss by a factor 2 during abstraction or recharge in aquifer A-VCS1. The reduction in well efficiency due to clogging by lower porosity values is greatest for the filter pack with the lowest average grain size (FP-MS1; d50 = 0.39 mm). Assuming a reduction of the porosity from a value of 0.34 to a value of 0.25, the additional head loss is increased by a factor of 7.5. This is only a factor of 2.4 for the filter pack FP-VCS2 (d50 = 2.0 mm). Note that for naturally developed well types (with natural sands and gravels with Cu > 3 within the area rs < r < rb) the initial porosities of the aquifer material can be significantly lower than the porosities of uniformly graded filter sands. Hence, well-types WAC1–2 with lower initial porosities of the aquifer material in the vicinity of the well screen compared to equivalent cases with filter pack might be more susceptible for additional head loss due to well clogging over time.

Effect of partial penetration of wells

In general, optimal efficiency for water wells is obtained when the filter screen is placed over a large portion of the aquifer in order to reduce head losses by converging or diverging flow lines in the vertical direction due to partial penetration (e.g. Houben 2015a). However, in construction dewatering, PPWs are used to target the desired hydraulic impact at a given depth in the aquifer. Hence, the reduction in well efficiency on the one hand, and the desired hydraulic impact at a given aquifer depth on the other hand, need to be taken into account in order to define the optimal well design. The optimal ratio of partial penetration is a trade-off between these two issues.

The latter scenarios in the present study, assuming the Dupuit-Forchheimer approximation with lateral flow behaviour in the entire aquifer system, can be considered as an upper estimate of the maximum head loss of a PPW screened in a given portion of the aquifer. In such scenario, all flow in the screened portion of the aquifer (Q/L) is assumed to be in the lateral direction, and no flow in the vertical direction towards over- and underlying aquifer layers occurs.

In Fig. 8, the additional head loss due to partial penetration in aquifer type A-VCS1 is shown using Eq. (14). Especially for partial penetration ratios smaller than 0.2 the additional head loss is significant, while considering an anisotropic, homogeneous aquifer. Screening PPWs in the top or bottom of the aquifer (ε = 1 in Eq. 15), the additional head loss due to partial penetration is the highest. PPWs screened in the middle of the aquifer (ε = 0 in Eq. 15) result in the smallest additional head loss for a given partial penetration ratio (Fig. 8). These results are in line with the numerical modelling results of Tügel et al. (2016), while considering uniform screen inflow at the abstraction PPW. However, note that in practice, inflow and outflow over a PPW screen is not constant over the entire filter length (e.g. Ruud and Kabala 1997; Houben 2015a; Tügel et al. 2016; Zhu and Wen 2019). The volumetric flow rate at the top and bottom end of a PPW is generally higher than in the middle portion of the well screen. Moreover, factors such as aquifer heterogeneity (Ruud and Kabala 1997; Houben and Hauschild 2011), the pump position (Tügel et al. 2016) or nonlinear flow behaviour in the well vicinity (Zhu and Wen 2019) could have an impact on additional head loss calculations and require a numerical approach and flow meter logs for more detailed investigation (e.g. Houben 2015b).

Additional head due to partial penetration compared to an equivalent scenario of a fully penetrating well for well-type WFP1 and a volumetric discharge/recharge rate (Q) of 10 m3/h in an aquifer of very coarse sand (A-VCS1: d50 = 1.5 mm). The solid lines represent PPWs screened in the centre of the aquifer. The dashed lines represent PPWs screened at the top/bottom of the aquifer (well screen placed below/above confining unit)

For heterogeneous aquifers, the assumption of equivalent anisotropic homogenous aquifer conditions does not hold for wells screened in a high-permeability layer while using low partial penetration ratios (0.1 < pp < 0.5). The actual horizontal hydraulic conductivity can be drastically underestimated by using a simplified characterization of the aquifer with anisotropic homogeneous conditions. Table 4 shows that poor aquifer characterization by using one bulk Kh,av and Kv,av for the anisotropic homogeneous aquifer results in drastic overestimation of the additional head loss by partial penetration. Using a PPW of well-type WFP-1 that screens a 2-m-thick high-permeability layer of 328 m/day, under- and overlain by lower-permeability layers of 32.8 m/day of 9-m thickness each, the additional head loss by partial penetration is only 0.52 m (Table 4). If the high-permeability layer is not taken into account and the simplified equivalent anisotropic homogenous aquifer is considered, the additional head loss is overestimated by a factor of 4 (2.0 m). Hence, the selection of the screen interval depth of a dewatering deep well or artificial recharge PPW should be based on good soil characterization in order to minimize additional head loss by partial penetration. Especially, the placement of an artificial recharge PPW to discharge dewatered groundwater in a high-permeability layer overlain by low-permeability strata could reduce the hydraulic impact on the overlaying dewatered strata at a minimized additional head loss due to partial penetration.

Discussion

Differences in head loss due to well completion method

The results in the present study suggest that use of relatively cheap and quick drilling methods (jetting and straight flush rotary) for well completion of well-types WAC1–2 without placement of a filter pack does not necessarily mean increased head losses and higher pumping costs. Especially, well screen placement in high-permeability aquifers (A-CG1–2) with WAC1–2 results in better well performance compared to placement of WFP1–2 with reverse-circulation rotary drilling (Fig. 4c–d). Comparing the well-types WAC1–2 with no clear formation of a thin skin layer by filter cake and a zone of collapsed aquifer (Fig. 1a) with wells drilled by reverse-circulation rotary drilling with a positive skin layer (well-types WFP1–2; Fig. 1b), the amount of total head loss by discharging/recharging water at Q of 20 m3/h into or from the gravely aquifers (A-CG1–2) is reduced by factors of 3–4.

Uncertainties in the hydraulic characteristics of the well skin and collapsed aquifer zone

This study assumed a filter cake layer of 1 mm at rb (rsk-in < r < rsk-out) with a hydraulic conductivity (Ksk) of 1e-6 m/s. Ideally, well development in formations of high hydraulic conductivity should be applied for hours, and development in formations of low hydraulic conductivity may take days to remove the filter cake (Powers et al. 2007). However, in practice, dewatering companies often choose to apply well development over a limited time span for the smaller dewatering projects that are operational over only a small period of time. Especially compared to drinking-water, ASR or ATES wells that are operational over a much longer time span, the impact of skin layers on total head loss in dewatering deep wells and artificial recharge wells can be large. As a consequence, well completion with reverse-circulation rotary drilling (e.g. WFP1–2) could result in a distinct skin layer. Drilling with drilling mud, which is usually done with reverse-circulation rotary drilling, will always result in a filter cake and poorer well performance over time compared to drilling techniques without drilling additives (Timmer et al. 2003). Hence, the assumption of a skin layer with Ksk of 1e-6 m/s for well-types WFP1–2 is a good indication for the potential contribution of head losses due to skin in dewatering and artificial recharge wells. In practice, the actual thickness and hydraulic conductivity of the skin layer of such wells are unknown, since no samples of the skin layer are available, and these properties should be determined indirectly from pumping tests (Barrash et al. 2006; Houben 2015a). So far, only a few in-situ skin layer samples have been analyzed by permeameter tests (e.g. Houben et al. 2016). Similar to the latter study, in-situ sampling of the borehole area at well-types such as WFP1–2 and WAC1–2 could provide useful insight into the hydraulic characteristics of the skin layer and filter pack on the one hand and the collapsed aquifer zone on the other hand.

For well types WAC1–2, the assumption of an improved collapsed aquifer zone (negative skin) with a hydraulic conductivity reduction by a factor 2 is an optimistic estimate. In reality, similar to the hydraulic conductivity of the skin permeability in the filter cake for WFP1–2, the permeability in this collapsed aquifer zone could vary for each well depending on aquifer type, well completion, and well development method. Using clean water as drilling fluid, the amount of fines in this zone will be low and the assumption of enhanced permeability is reasonable. However, poor well development or the use of a bentonite mud or circulation water as drilling fluid could cause permeability reduction in the collapsed aquifer zone. Generally, dewatering companies in the Netherlands are using clean surface water or groundwater to drill down to depths of 20 m below ground level. Therefore, considering no permeability reduction/enhancement in the collapsed zone should provide a good estimate for the upper limit of head losses in the initial stage of well operation for well-types WAC1–2 after well completion and proper well development.

Only severe reduction of permeability in the collapsed aquifer zone due to poor well development after well completion with jetting and straight-flush rotary drilling for WAC1–2 will result in high contributions to the total head loss in the borehole area (rs < r < rb). Note that the absence of a filter cake layer after aquifer collapse for WAC1 (Fig. 1a) allows for easier, less extensive well development, which makes the assumption of enhanced permeability or in-situ aquifer permeability within the borehole area (rs < r < rb) reasonable. Hence, the reduced total head loss in gravely aquifers by using WAC1–2 is a good indication of the potential advantage of using WAC1–2 instead of WFP1–2.

Predicting additional head loss by well clogging

Well ageing of abstraction and recharge wells can occur due to mechanical and geochemical clogging (De Zwart 2007; Van Beek et al. 2009a, b; Houben et al. 2018). This proccess could occur due to clogging of the filter pack, screen slots and well casing interior (Houben et al. 2018). The most important contributor to head loss by well ageing is clogging of the filter pack, while increased head loss only occurs when there is severe clogging of the screen slots and well casing interior. In practice, clogging of the filter pack and screen slots can be observed by the increasing difference in head over time between the abstraction water well itself and the observation well in its gravel pack (Van Beek et al. 2009b). Moreover, clogging could occur at the borehole interface between the filter pack and aquifer material by the formation of a thin skin layer (Timmer et al. 2003; De Zwart 2007; Van Beek et al. 2009b). Ongoing accumulation of fine materials at the borehole wall causes this zone to slowly expand outwards and increase in thickness, and hence increases flow resistance over time during abstraction (higher ∆hsk for Eq. 12).

During artificial recharge in a water well, the recharged water always contains impurities that cause well clogging (plugging) over time (Olsthoorn 1982; Bouwer 2002; Bear 2007; Powers et al. 2007; Martin 2013). These impurities can range from organic matter, air entrainment, to fine aquifer material (such as clay, loam or silt) or precipitates of minerals (such as manganese- or iron-oxides and calcite). For recharge wells, suspended solids or chemicals are transported into the filter pack and aquifer. Moreover, rapid clogging of artificial recharge wells immediately after the start of the recharge procedure could occur due to degassing of depressurized water and formation of air bubbles in the filter pack or aquifer (Olsthoorn 1982; Martin 2013). Generally, clogging during recharge occurs in the gravel pack (if present), the borehole interface and in the target formation immediately surrounding the borehole (Martin 2013).

The clogging of the filter pack or aquifer material, by particle migration, biofouling and mineral precipitation or free gas, could result in significant porosity reduction. In the present study, the clogging mechanism is determined by only reducing porosity in the Ergun relationships (Eq. 3) based on packed bed experiments of filter sands at porosity values of 0.25–0.35. Exact determination of nonlinear flow behaviour through severely clogged packed beds are required to investigate to what extent nonlinear flow behaviour causes additional head losses. This should be done for the various mechanisms of clogging to obtain a more detailed overview of the extent to which well clogging could cause additional head losses during well operation. During well operation, there are methods to analyze the clogging potential of an artificial well such as membrane filtration index (MFI; for the suspended solid content of the recharged water) and assimilable organic carbon content (AOC; for the growth potential of microorganisms in water; Bouwer 2002).

Increasing injection pressure to maintain the desired recharge rate of the well is not a successful solution to overcome the problems of clogging. Such a solution could even lead to enhanced clogging potential, due to enhanced inflow of clogging mass and compression of the clogging layer (Bouwer 2002). Noncontinuous recharge schemes with periods of rest could significantly enhance the well efficiency and reduce the effects of clogging (Olsthoorn 1982; Bouwer 2002; De la Loma González 2013) by remobilization of finer particles by switching from a rest period to recharge. A similar procedure is suggested for groundwater abstraction (Van Beek et al. 2009a, b). Such recharge schemes might be preferable for artificial recharge wells near dewatering sites using a buffer container or two sets of artificial recharge wells. Well development of artificial recharge and deep wells can be realized by a wide range of methods such as brushing or scratching the inner screen surface, surge (flushing) pumping, air lifting, or the use of chemicals (Olsthoorn 1982; Powers et al. 2007). In most cases, well development could remove clogging particles from the well screen. However, the development of the filter pack and aquifer is more difficult, due to fractions of clogging particles that remain in the filter pack, borehole wall or aquifer.

Conclusions

The present study provides a detailed overview of the contributions to the head loss for typical well configurations of dewatering deep wells and artificial recharge wells. Typical well completion methods in unconsolidated aquifers used by dewatering companies are considered. To investigate the hydraulics of such water wells, the method described by Houben (2015b) while using the hydraulic characteristics of the filter pack and aquifer material obtained from packed-bed flow experiments conducted by Van Lopik et al. (2017 and 2020b) are used.

The well efficiency of wells drilled by relatively cheap and quick drilling methods, such as jetting and straight-flush rotary, without a proper well completion with a filter pack, does not necessarily mean increased head losses and higher pumping costs compared to wells completed with a filter pack (with reverse-circulation rotary drilling). The main component of head loss occurs in the aquifer for well completion without filter pack by jetting or straight-flush rotary drilling. In such case, the formation of negative skin in the borehole area and no filter cake layer continuously spread over the entire borehole wall can be considered due to aquifer collapse after removing the drilling rod or jetting tube from the unconsolidated soil. Only severe permeability reduction by residual mud additives or fines in the collapsed aquifer zone after poor well development could result in positive skin for such wells. In well-types with a filter pack (WFP), besides the component of head loss in the aquifer itself, the contribution to the total head loss by a positive skin layer of filter cake after well completion can be significant. Especially for high-permeability aquifers, the absence of a positive skin layer on the borehole wall in wells completed without a filter pack results in equal or better well performance compared to the more expensive drilling method of reverse-circulation rotary drilling. Intensive and costly well development would be required to lower the amount of positive well skin on such wells to operate at similar efficiency.

Selection of a proper filter pack (with average grain size of 1.0–2.0 mm) for wells screened in sandy to gravely aquifers (50 < K < 500 m/day) results in only a minor contribution to the total head loss. The component of head loss due to nonlinear flow behavior in the filter pack or aquifer is small, if sandy to gravely aquifers (K < 500 m/day) and maximum discharge or recharge rates of 30 m3/h over 1 m filter length are assumed.

Clogging of the filter pack is considered by assuming uniform reduction of the porosity values. Due to the reduction of the pore space, the main contributor to additional head loss by filter pack clogging is the effect of nonlinear flow behavior. Filter packs or aquifer material with smaller grain sizes and low initial porosity values are more susceptible to increase in head losses due to porosity reduction by clogging.

It is recommended that dewatering companies investigate the characteristics of the aquifer prior to well installation of dewatering wells and artificial recharge wells. Especially for PPWs, good aquifer characterization is required to screen artificial recharge wells in high-permeability strata. Not accounting for heterogeneity in aquifers with gravely strata could easily overestimate the required well head by factors higher than 2 for PPWs with small partial penetration ratios. Good exploration of the dewatering site could promote the use of dewatering deep wells and artificial recharge PPWs to minimize the hydraulic impact of short-term dewatering operations. Moreover, the selection of high-permeability layers could promote the use of quick and cheap well completion without a filter pack using jetting or straight-flush rotary drilling instead of using full-penetration wells completed with filter pack and extensive well development to remove the fines from the filter cake layer.

References

Barker JA, Herbert R (1992) A simple theory for estimating well losses: with application to test wells in Bangladesh. Appl Hydrogeol 0:20–31

Barrash W, Clemo T, Fox JJ, Johnson TC (2006) Field, laboratory, and modeling investigations of the skin effect at wells with slotted casing, Boise Hydrogeophysical Research Site. J Hydrol 326(1–2):181–198

Basak P (1978) Analytical solutions for two-regime well flow problems. J Hydrol 38(1–2):147–159

Bear J (ed) (1988) Dynamics of fluids in porous media. Dover, New York

Bear J (ed) (2007) Hydraulics of groundwater. Dover, New York

Boulton NS (1947) Discussion of drawdown test to determine effective radius of artesian well by C. E. Jacob. Trans Am Soc Civil Eng 112(1):1065–1068

Bouwer H (2002) Artificial recharge of groundwater: hydrogeology and engineering. Hydrogeol J 10(1):121–142

Buscheck TA, Doughty C, Tsang CF (1983) Prediction and analysis of a field experiment on a multilayered aquifer thermal energy storage system with strong buoyancy flow. Water Resour Res 19(5):307–1315

Cashman PM, Preene M (2013) Groundwater lowering in construction: a practical guide to dewatering, 2nd edn. Taylor and Francis, Boca Raton, FL

De Zwart AH (2007) Investigation of clogging processes in unconsolidated aquifers near water supply wells. PhD Thesis, Technische Universiteit, Delft, The Netherlands

Driscoll FG (ed) (1986) Ground water and wells, 2nd edn. Johnson Filtration Systems, St. Paul, MN

Engelund F (1953) On the laminar and turbulent flow of groundwater through homogeneous sands. Transactions of the Danish Academy of Technical Sciences, Copenhagen, A.T.S. 3, Bulletin 4, Hydraulic Laboratories, Technical University of Denmark, Kongens Lyngby, Denmark

Ergun S (1952) Fluid flow through packed columns. Chem Eng Prog 48(2):89–94

Forchheimer PH (1901) Wasserbewegung durch Boden [Movement of water through soil]. Zeitschr Vereines Deutscher Ing 50(1736–1741):1781–1788

Houben GJ (2015a) Review: Hydraulics of water wells—flow laws and influence of geometry. Hydrogeol J 23(8):1633–1657

Houben GJ (2015b) Review: Hydraulics of water wells—head losses of individual components. Hydrogeol J 23(8):1659–1675

Houben GJ, Hauschild S (2011) Numerical modeling of the near-field hydraulics of water wells. Ground Water 49(4):570–575

Houben GJ, Halisch M, Kaufhold S, Weidner C, Sander J, Reich M (2016) Analysis of wellbore skin samples: typology, composition, and hydraulic properties. Ground Water 54(5):634–645

Houben GJ, Wachenhausen J, Guevara Morel CR (2018) Effects of ageing on the hydraulics of water wells and the influence of non-Darcy flow. Hydrogeol J 26(4):1285–1294

Kasenow M (2010) Applied ground-water hydrology and well hydraulics, 3rd edn. Water Resources Publ., Highlands Ranch, CO

de la Loma González B (2013) Clogging of deep well infiltration recharge systems in the Netherlands. In: Martin R (ed) Clogging issues associated with managed aquifer recharge methods. IAH Commission on Managing Aquifer Recharge, Richmond North, VIC, Australia, pp 163–173

Martin R (ed) (2013) Clogging issues associated with managed aquifer recharge methods. IAH Commission on Managing Aquifer Recharge, Richmond North, VIC, Australia

Moutsopoulos KN, Papaspyros INE, Tsihrintzis VA (2009) Experimental investigation of inertial flow processes in porous media. J Hydrol 374(3–4):242–254

Olsthoorn TN (1982) Verstopping van persputten [The clogging of recharge wells]. Keuringsdienst voor Waterleidingartikelen KIWA N.V, Rijswijk, The Netherlands

Powers P, Corwin A, Schmall P, Kaeck W (2007) Construction dewatering and groundwater control, 3rd edn. Wiley, Hoboken, NJ

Pyne RDG (2005) Aquifer storage recovery: a guide to groundwater recharge through wells, 2nd edn. ASR Systems, Gainesville, FL

Roscoe Moss Company (1990) Handbook of ground water development. Wiley, New York

Ruud NC, Kabala ZJ (1997) Response of a partially penetrating well in a heterogeneous aquifer: integrated well-face flux vs. uniform well face flux boundary conditions. J Hydrol 194:76–94

Timmer H, Verdel J-D, Jongmans AG (2003) Well clogging by particles in Dutch well fields. J Am Water Works Ass 95(8):112–118

Tügel F, Houben GJ, Graf T (2016) How appropriate is the Thiem equation for describing groundwater flow to actual wells? Hydrogeol J 24(8):2093–2101. https://doi.org/10.1007/s10040-016-1457-0

Van Beek CGEM, Breedveld RJM, Juhász-Holterman M, Oosterhof A, Stuyfzand PJ (2009a) Cause and prevention of well bore clogging by particles. Hydrogeol J 17(8):1877–1886

Van Beek CGEM, Breedveld RJM, Stuyfzand PJ (2009b) Preventing two types of well clogging. J Am Water Works Assoc 101(4):125–134

Van Lopik JH (2020) Design of recharge and abstraction well systems in heterogeneous aquifers: modeling and experimental studies. In: PhD Thesis, Utrecht University, Utrecht, The Netherlands

Van Lopik JH, Snoeijers R, van Dooren TCGW, Raoof A, Schotting RJ (2017) The effect of grain size distribution on nonlinear flow behavior in sandy porous media. Transp Porous Med 120(1):37–66

Van Lopik JH, Hartog N, Schotting RJ (2020a) Taking advantage of aquifer heterogeneity in designing construction dewatering systems with partially penetrating recharge wells. Hydrogeol J. https://doi.org/10.1007/s10040-020-02226-7

Van Lopik JH, Zazai L, Hartog N, Schotting RJ (2020b) Nonlinear flow behavior in packed beds of natural and variably graded granular material. Transp Porous Med 131:957–983

Zhu Q, Wen Z (2019) Combined role of leaky and non-Darcian effects on the flow to a pumping well with a non-uniform flux well-face boundary. J Hydrol 580:123532. https://doi.org/10.1016/j.jhydrol.2019.02.058

Zuurbier KG, Zaadnoordijk WJ, Stuyfzand PJ (2014) How multiple partially penetrating wells improve the freshwater recovery of coastal aquifer storage and recovery (ASR) systems: a field and modeling study. J Hydrol 509:430–441

Acknowledgements

The authors wish to thank Georg J. Houben from the Bundesanstalt für Geowissenschaften und Rohstoffe for his critical comments on prior drafts of this paper and Dr. A. Mouraz Miranda and an anonymous reviewer for their constructive feedback. Moreover, the authors wish to thank dewatering companies Theo van Velzen, Henk van Tongeren and P.J. de Vet & Zonen for providing well specifications of typical dewatering deep wells and artificial recharge wells.

Funding

This work was supported by the foundations STW (Foundation for Technical Sciences) and O2DIT (Foundation for Research and Development of Sustainable Infiltration Techniques).

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Solution for the Darcy-Forchheimer equation for converging flow in filter packs towards screen slots

Inside a filter pack, groundwater flow is affected by the presence of well screens. During abstraction, groundwater has to converge to the screen slots, which causes an additional head called ∆hcv. Boulton (1947) derived an equation for ∆hcv based on the ratio (δs) of slot aperture (l) and circumference of the well:

where ns is the number of slots inside the circumference of a well and R is the radius of the well. The equation by Boulton (1947) is given by (Houben 2015b):

where Kfp is the hydraulic conductivity of the gravel pack and Ls is the length of the screen. Unfortunately, the derivation of Boulton’s equation is not given in that article and therefore the assumptions behind the equation are unknown; thus, a derivation of the equation for ∆hcv is given in the following.

The starting point of the derivation is the Darcy-Forchheimer equation, which is given by:

where r is a radial coordinate. By separating variables, one can obtain:

The Darcy-Forchheimer equation is independent of slot aperture, therefore a geometric consideration is conducted before solving the Darcy-Forchheimer equation.

In order to obtain Boulton’s equation, the distance between the well circumference and the opening (distance D) has to be considered constant (see Fig. 9). This assumption implies that flow remains radial inside the gravel pack until the groundwater is very close to the well. As a consequence, stagnant zones of groundwater arise between the screen slots (see Fig. 9) which forces the remaining groundwater towards the screen openings. Distance D is defined for any circle having a radius r as such that D is constant (based on trigonometry; see Fig. 9):

Differentiating Eq. (22), yields:

Using Eqs. (22 and 23), the Darcy-Forchheimer equation becomes:

In Eq. (24), the radial coordinates are projected on δ coordinates, which represents flow perpendicular to the radius. The boundary conditions for Eq. (24) are:

Defining integration of Eq. (24) yields:

Finally, one can obtain:

where the Forchheimer coefficient \( b=\frac{\beta }{K_{\mathrm{fp}}^2} \)

Schematic overview of flow convergence in the filter pack (assumption by Boulton 1947)

Rights and permissions

About this article

Cite this article

van Lopik, J.H., Sweijen, T., Hartog, N. et al. Contribution to head loss by partial penetration and well completion: implications for dewatering and artificial recharge wells. Hydrogeol J 29, 875–893 (2021). https://doi.org/10.1007/s10040-020-02228-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10040-020-02228-5