Abstract

Purpose

The objective of this study was to perform an integrative review on the effect the inorganic fillers on the light transmission through the resin-matrix composites during the light-curing procedure.

Method

A bibliographic review was performed on PubMed using the following search terms: “fillers” OR “particle” AND “light curing” OR “polymerization” AND “light transmission” OR “light absorption” OR “light irradiance” OR “light attenuation” OR “light diffusion” AND “resin composite.” The search involved articles published in English language in the last 10 years.

Results

Selected studies reported a decrease in biaxial strength and hardness in traditional resin-matrix composites in function of the depth of polymerization. However, there were no significant differences in biaxial strength and hardness recorded along the polymerization depth of Bulk-Fill™ composites. Strength and hardness were enhanced by increasing the size and content of inorganic fillers although some studies revealed a progressive decrease in the degree of conversion on increasing silica particle size. The translucency of glass–ceramic spherical fillers promoted light diffusion mainly in critical situations such as in the case of deep proximal regions of resin-matrix composites.

Conclusions

The amount of light transmitted through the resin-matrix composites is influenced by the size, content, microstructure, and shape of the inorganic filler particles. The decrease of the degree of conversion affects negatively the physical and mechanical properties of the resin-matrix composites.

Clinical relevance

The type and content of inorganic fillers in the chemical composition of resin-matrix composites do affect their polymerization. As a consequence, the clinical performance of resin-matrix composites can be compromised leading to variable physical properties and degradation. The polymerization mode of resin-matrix composites can be improved according to the type of inorganic fillers in their chemical composition.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Dental resin-matrix composites have become the most requested materials for direct and indirect restorations as a result of the technological enhancement of their mechanical and optical properties [1, 2]. However, concerns have been reported regarding light transmission during polymerization. Light scattering caused by inorganic fillers is a phenomenon that can cause changes in light transmission through the resin-matrix composites during the light-curing procedure [3–8]. Different monomers and filler fraction combination influences the light transmission, translucency, and color appearance of resin-matrix composites [9]. Therefore, the chemical composition, size, and morphological aspects of inorganic fillers should be clarified. The release of the monomers as a consequence of improper polymerization can cause cytotoxicity of the surrounding tissues and an inflammatory reaction over time [10–14]. The continuous presence of monomers may cause disruption of pulp and gingival cells and are probably also involved in the toxic potential of the material [10, 13].

The resin-matrix composites are composed of inorganic fillers dispersed in an organic matrix. The organic matrix involves a cross-linking of dimethacrylate monomers such as bisphenol A-glycidyl dimethacrylate (Bis-GMA), triethylene glycol dimethacrylate (TEGDMA), urethane dimethacrylate (UDMA), and ethoxylated bisphenol A dimethacrylate (Bis-EMA) [1, 12, 15, 16]. That results in a polymeric matrix which depends on the structure of the monomer as well as the polymerization conditions [16, 17]. The accomplishment of the polymerization of the organic matrix leads to densely cross-linked, glassy polymer networks that provide high values of physical properties such as elastic modulus, strength, fracture toughness, hardness, and wear resistance [1, 17]. The degree of conversion (DC) represents the percentage of polymerized monomers after light-curing [18–20]. Thus, DC consists in the percentage of double carbon bonds (C = C) in the chemical reaction to become converted into single bonds within the polymer chain. For instance, the degree of conversion of the organic matrix has been assessed by chemical analyses by FTIR to determine the aliphatic C = C peak absorption at 1637 cm−1 and the aromatic C = C peak absorption at either 1608 cm−1, utilizing a base line technique following the Beer–Lambert law [16, 21, 22]. DC has been assessed on the top and bottom specimen surfaces or by sectioning the specimens longitudinally. Then, results are correlated with the physical properties (e.g., hardness, elastic modulus), biocompatibility, and optical outcomes of experimental and commercial resin-matrix composites [12, 23–25]. However, DC does not consider the heterogeneity of the material, and therefore, the evaluation of the cross-linking density (CLD) has also been studied by microhardness testing [16].

The polymerization of resin-matrix composites for direct restorations can be achieved by demand using light-curing units (LCU) as a source of light ranging from 360 up to 500 nm. In the organic matrix, the photoinitiator system, such as camphorquinone (CQ)/tertiary amine, is stimulated by visible light irradiation in the range between 420 and 490 nm [1, 26, 27]. Also, acyl and bisacyl phosphine oxide initiators can be utilized as single-component light alpha-cleavage initiators at wavelengths usually below 450 nm [1, 17]. Nowadays, the most used light sources are light-emitting diodes (LED) within wavelength ranging from 360 up to 500 nm, light irradiance between 300 and 1765 mW/cm2, and light exposure from 20 to 60 s. The time of light exposure depends on the light irradiance as well as type and thickness of the resin composite to reach the energy required for the polymerization of the resin-matrix composite [27–30].

The inorganic filler content of resin-matrix composites consists in silanized inorganic particles at different size and morphological aspects (i.e., spherical and irregular fillers). The most used inorganic fillers are composed of silica [15, 31] (16). Commercially available resin-matrix composites reveal a weight percentage of filler content ranging from 40 up to 90 wt% [24, 32, 33]. A combination of different inorganic fillers (i.e., silica and glass ceramics) at different sizes can be found in the chemical composition of recent materials [1, 5, 22, 23, 23, 34, 35]. For instance, spherical silica particles at 20–60 nm in combination with micro-scale glass–ceramics (i.e., zirconium or barium silicates at 1–2 µm) are common fillers added into the chemical composition of resin-matrix composites [1, 2, 34, 36, 37]. Nano- and micro-scale particles are combined in the resin-matrix composite microstructure to provide a mechanical reinforcement under further mastication loading [5, 36, 38]. Thus, a high content of nano- and micro-scale particles results in a low organic matrix volume under polymerization [23, 39–41]. However, the effects of the morphological aspects of fillers such as size and shape on the polymerization are not entirely clarified in literature. Also, the chemical composition, content, and microstructure of the fillers affect the light transmission that should be understood regarding the development of novel resin-matrix composites.

The objective of this study was to perform an integrative review on the effect the inorganic fillers on the light transmission through the resin-matrix composites during the light-curing procedure. It was hypothesized that size, content and chemical composition of inorganic fillers can affect light transmission through resin-matrix composites over the light-curing procedure.

Method

Search strategy

A bibliographic review was performed on PubMed (via National Library of Medicine) considering that includes the major journals in the field of dentistry and biomaterials. The present search of studies was carried out in accordance with previous integrative review articles [12, 42–46]. The following search terms were applied: “fillers” OR “particle” AND “light curing” OR “polymerization” AND “light transmission” OR “light absorption” OR “light irradiance” OR “light attenuation” OR “light diffusion” AND “resin composite.” Also, a hand-search was performed on the reference lists of all primary sources and eligible studies of this integrative review for additional relevant publications. The inclusion criteria encompassed articles published in the English language from January 2011 up to February 2022, focusing on the effects of the size and chemical composition of fillers on the light transmission through resin-matrix composites during the light-curing procedure. The eligibility inclusion criteria used for article searches also involved in vitro studies; randomized controlled trials; animal assays; and prospective cohort studies. The exclusion criteria were the following: papers without abstract; case report with short follow-up period; reviews; pilot studies; studies on the effect of fillers through other composite materials applied in different biomedical or engineering fields. Studies based on publication date were not restricted during the search process.

Study selection and data collection process

The selection of studies was carried in three steps. At first, studies were scanned for relevance by title, and the abstracts were assessed for those that were not excluded at this step. Three of the authors (JCMS, DC, RF-P) independently analyzed the titles and abstracts of the retrieved, potentially relevant articles meeting the inclusion criteria. A fourth author intervened in case of disagreements during the scanning of the articles. The total of articles was compiled for each combination of key terms, and therefore, the duplicates were removed using Mendeley Reference Manager (ed. Elsevier). The second step comprised the evaluation of the abstracts and non-excluded articles, according to the eligibility criteria on the abstract review. Selected articles were individually read and analyzed concerning the purpose of this study. At last, the eligible articles received a study nomenclature label, combining first author names and year of publication. The following variables were collected for this review: authors’ names, journal, publication year, aims, organic matrix type, fillers (size, chemical composition, types), light-curing (methods and equipment), light transmission analyses, polymerization evaluation (degree of conversion), and related mechanical characterization. PICO question was adjusted to the issue where “P” was related to the materials or specimens and “I” referred to the methods of analyses while “C” was related to comparison of findings and “O” to the main outcomes. Data of the reports were harvested directly into a specific data collection form to avoid multiple data recording regarding multiple reports within the same study (e.g., reports with different set-ups). A critical evaluation of the selected studies was performed individually by two researchers, followed by a joint discussion to examine the scientific significance of the studies.

Results

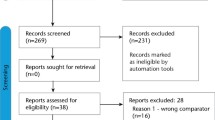

The initial search in the available database yielded a total of 136 articles of which 56 duplicate articles were eliminated. Of the remaining 80 articles, the titles and abstracts were read seeking concordance with the inclusion criteria of the present study and then 53 studies were discarded because they did not meet the inclusion criteria. The evaluation of titles and abstracts resulted in the selection of 27 potential articles although 9 articles were excluded because they did not provide comprehensive data. The results of the selection of articles are shown in Fig. 1.

Of the 18 articles included in this review, five studies (27.78%) evaluated the chemical composition, properties, and light-curing transmission of bulk-fill resin-matrix composites [15, 47–50]. One study focused on the effect of filler amount on the effectiveness of light transmission of resin-matrix composites [41]. Two studies (11.1%) assessed different light-curing units considering the light transmission through resin-matrix composites such as quartz-tungsten-halogen lamp and a diode-pumped solid state (DPSS) laser [18, 26]. Three studies (16.6%) assessed the effect of spherical glass fillers (SGMFs) to decrease the shrinkage of resin-matrix composites in direct dental restorations [7, 8, 19], while one study also performed the evaluation of optical properties [51]. Four studies assessed the light transmission through resin-matrix composites reinforced with different contents of bioactive glass fillers [7, 19, 52, 53]. Only two articles (11.1%) assessed zirconia as a filler for enhancement of the mechanical properties and the degree of conversion depending on the light transmission through the material [34, 54]. One in vitro study evaluated the presence of different co-initiators, namely, diphenyliodonium hexafluorophosphate (DPI) and bis(4-methyl phenyl)iodonium hexafluorophosphate (BPI), on the chemical and mechanical properties of resin-matrix composites [55]. Two studies analyzed the resin-matrix composite under different thermal specific conditions, by increasing and decreasing the temperature [50, 56]. Different amount and size of silica fillers was carefully evaluated by four studies (22.2%) regarding light transmission and polymerization of the organic matrix [5, 8, 22, 35].

The major findings are shown in Table 1 and described as follows:

-

Traditional nanohybrid resin-matrix composites which contained Bis-GMA, UDMA, and TEGDMA revealed the highest flexural modulus (5.11 GPa), while Bulk-Fill™ composites revealed the lowest flexural modulus (2.5 GPa). Also, the highest values of biaxial flexural strength (154 MPa) were recorded for materials with Bis-GMA, UDMA, and TEGDMA, while the lowest values (77 MPa) were recorded for Bulk-Fill™ (9,28,30,34,39).

-

The mechanical properties of traditional resin-matrix composites showed significant variation regarding the depth of polymerization since the biaxial strength and hardness decreased with the depth of polymerization [57]. The Bulk-Fill™ composites did not reveal significant differences in biaxial strength and hardness along the depth of polymerization [15, 47–49]. However, Bulk-Fill™ composites with lower content of inorganic fillers showed the lowest values of elastic modulus, biaxial strength, and hardness [49]. The size and the content of inorganic fillers highly enhanced the strength and elastic modulus properties of the resin-matrix composites [8, 15, 31].

-

The polymerization efficiency of resin-matrix composites under the ramp-polymerization mode was higher when compared to the low-irradiance polymerization mode. The use of the quartz-tungsten-halogen lamp in the studies promoted a higher degree of conversion than those achieved by LED lamp [26].

-

The translucency of the glass–ceramic spherical fillers promoted light diffusion within light-curing resin-matrix composites, mainly in critical situations such as in the case of deep proximal cavities [7, 19]. Bulk-Fill™ composites allowed higher light transmission when compared to traditional resin-matrix composites [15, 47]. Light transmission changes over polymerization did not alter polymerization kinetics in modern Bulk-Fill™ composites [47].

-

The light transmission decreased as the thickness of the resin-matrix composite (regular or Bulk-Fill™) increased [57]. In addition, a progressive decrease in the degree of conversion of the resin-matrix composites occurred with increasing silica particle size [20]. Composites containing novel photoinitiators such as diphenyliodonium hexafluorophosphate (DPI) and bis(4-methyl phenyl)iodonium hexafluorophosphate (BPI) showed significantly higher rate of polymerization, shrinkage strain, and the maximum strain when compared to composites containing camphorquinone (CQ) [55].

Discussion

The present integrative review reported the major results of relevant previous studies taking into account the effect of the inorganic fillers of resin-matrix composites on the degree of conversion of monomers during light-curing procedure. The type, size, shape, and content of fillers do affect the degree of conversion and shrinkage of the organic matrix. Also, the light source, irradiance level (light-curing mode), the photoinitiator efficacy, and the material thickness do affect the mechanical properties of the resin-matrix composite. Therefore, the findings validate the hypothesis of this study. A detailed discussion of the main factors that affect the properties of the resin-matrix composites on light-curing is given as follows.

Resin-matrix composites

The traditional formulation of resin-matrix composites involves silanized inorganic filler particles embedded in an organic matrix [1, 36, 58]. Organic matrix is often composed of dimethacrylate monomers bisphenol A-glycidyl dimethacrylate (Bis-GMA), triethylene glycol dimethacrylate (TEGDMA), urethane dimethacrylate (UDMA), and ethoxylated bisphenol A dimethacrylate (Bis-EMA). The most common photoinitiator system consists in camphorquinone (CQ) associated with a tertiary amine as a reducing agent, namely, dimethylaminoethyl methacrylate (DMAEMA). To decrease the yellow color and maintain the polymerization efficiency of resin-matrix composites, CQ has been combined with alternative photoinitiators, such as 2,4,6-trimethylbenzoyl- diphenylphosphine oxide (Lucerin-TPO™) or 1-phenyl-1,2- propanedione (PPD) [1, 12, 17, 20]. Recent formulations of resin-matrix composites are mentioned in the selected studies, as shown in Table 1 and Fig. 2.

Commercially available resin-matrix composites can have spherical or irregular filler inorganic particles [33] with average size between 40 nm and 40 µm [1, 32, 36], as seen in Fig. 2. A combination of micro-scale (1–10 µm) and nano-scale (40–60 nm) fillers is often found in the resin-matrix composite microstructure [1, 32]. The weight percentage of inorganic fillers in commercially available resin-matrix composites varies from 40 up to 90 wt%. Glass–ceramic fillers based on aluminum, barium silicate, borosilicate, colloidal silica, ytterbium fluoride, and zirconium silicate can be found in the resin-matrix composites inorganic content, as shown in Table 1. Inorganic fillers are industrially functionalized with silane coupling agents to establish a chemical bonding to the organic matrix. Silane-based coatings of inorganic fillers can increase the surface wettability and establish an intrinsic chemical bonding to the carbon-based matrix via SiO2 and hydroxyl groups. Thus, a chemical bonding takes place through the condensation of silanol groups on the particle surface, followed by a chemical reaction of free radicals in the monomers’ matrix to achieve a stable chemical bond [1, 17, 20, 59]. Prepolymerized inorganic fillers are also currently used to decrease the viscosity and polymerization shrinkage while maintaining the overall physical properties of the resin-matrix composites.

Recently, resin-matrix composites with bioactive glass fillers have been studied aiming to achieve optimal bioactivity without compromising other relevant properties, such as degree of conversion of the monomers, translucency, and color of the resin-matrix composite [7, 19, 52, 53]. However, the effect of bioactive glass fillers on the degree of conversion and other mechanical properties needs to be further investigated. The balance of opacity and transparency of inorganic fillers and organic matrix is a challenge to achieve required optical properties of resin-matrix composites that mimic the optical properties of enamel and dentin [42, 60]. However, the selection of resin-matrix composites regarding optical properties such as translucency and color of inorganic fillers and organic matrix is not a well-accurate procedure in clinical practice.

Physicochemical properties of resin-matrix composites are dependent on the proportion and chemical composition of organic matrix and inorganic fillers [1, 61]. A continuous occlusal loading results in a progressive degradation and generation of micro-cracks, which causes failures of the resin-matrix composites [36, 37]. Previous studies have performed static and dynamic mechanical tests to estimate the polymerization status of the resin-matrix composites, as seen in Fig. 3. Static mechanical assays involve compressive, flexural, and tensile tests although flexural strength is quite assessed by biaxial, three-, or four-point bending strength tests [8, 34, 62]. Flexural strength and elastic modulus increased with the amount of inorganic fraction. The fracture toughness has been also assessed to evaluate the resistance to the propagation of cracks through the resin-matrix composites [63]. As expected, resin-matrix composites with high content of inorganic fillers showed enhanced mechanical properties [8, 36, 63]. Also, the volume of the organic matrix decreased that affects its shrinkage, light transmission, and degree of conversion on polymerization.

Polymerization of resin-matrix composites

The polymerization of resin-matrix composites involves a cross-linking among different monomers that is dependent on intrinsic and extrinsic factors, such as wavelength of emitted light, type of photoinitiator, light irradiance, exposure time, distance, and type of the resin-matrix composite [65]. In the majority of previous studies, resin-matrix composites were light-cured using light-emitting diodes (LEDs) and quartz-tungsten-halogen (QTH). The irradiance of light-curing units (LCU) was reported at approximately 900–1765 mW/cm2 for LED and 100–700 mW/cm2 for QTH [15, 26]. The light time exposure over light-curing was performed for 20, 40, or 60 s between each resin-matrix composite increment. Distance between LCU and surface of resin-matrix composite was around 1–3 mm, and the LCU angulation tip has been perpendicularly positioned to the restoration surface plane [15, 26, 33, 65].

The previous selected studies reported results on different physicochemical methods of characterization regarding the influence of inorganic fillers on the material polymerization, as shown in Fig. 3. On mechanical assessment, flexural strength and microhardness values have been recorded and correlated with the degree of conversion (DC) of the monomers [20, 32, 57]. The following tests have been used for morphological inspection of inorganic fillers: scanning electron microscopy (SEM), transmission electron microscopy (TEM), optical microscopy, focused ion beam (FIB), atomic force microscopy (AFM), and micro-CT [32, 34, 36]. The degree of conversion (DC) represents the percentage of polymerized monomers after setting that is measured by FTIR considering the residual double bonds (C = C) [18–20, 54, 57, 66]. The DC values of the resin-matrix composites range between 52 and 75% [19, 50, 67], although DC might reach a higher value for 24 h from the polymerization procedure [24, 32]. The DC magnitude is proportional to the resin-matrix composite polymerization shrinkage since a high amount of monomers are binding in the carbon-based chain [19]. However, DC is altered by the chemical composition of the resin-matrix composite and the light-curing source. Additionally, the particle size of inorganic fillers can impact the light-curing transmission and evidently influence the DC [19]. On the decrease of DC, a slightly cross-linking density (CLD) of the polymer take place. It means a decrease in their strength, hardness, wear resistance, and color stability leading to failures and change of optical properties [19]. Thus, a high DC of monomers and efficient polymerization of the resin-matrix composites depends on the following parameters: (i) light irradiation and exposure time; (ii) visible light irradiance and wavelength; (iii) type, size, and content of inorganic fillers; (iv) distance between LCU tip and resin composite; (v) organic matrix; and (vi) refraction index of the organic and inorganic components [21, 22, 68].

In general, the polymerization modes involve low and high light irradiance or pulse mode. The dental pulp may be affected due to a high heating generated over a long period of light exposure. For this reason, the use of low light irradiance is required to preserve pulp vitality and to avoid postoperative sensitivity [69, 70]. Even though recent resin-matrix composites show a minimum shrinkage level as a result of molecular cross-linking and densification, shrinkage stresses still take place during polymerization [61, 71, 72]. Polymerization shrinkage occurs due to the cross-linking of monomers, and then, residual stresses are generated at the restorative interfaces [15]. Other factors determine the magnitude of the shrinkage stresses such as pre-gel flowing, cavity design, molecular weight, and chemical composition [39, 50, 71, 73]. Differences in shrinkage stresses regarding filler particle size, content, and shape were statistically significant. Lower shrinkage stresses were noticed in materials containing spherical fillers when compared to irregular filler particles [8, 51, 71, 72]. Several studies recommend incremental filling techniques to decrease the shrinkage stresses and to achieve an optimum degree of conversion of the organic matrix [61, 71, 74]. The average maximum thickness of around 2 mm is recommended for each resin-matrix composite increment to achieve optimal light-curing parameters leading to the polymerization of the resin-matrix composites [15, 48, 75]. On traditional resin-matrix composites, the light could not reach the depth of the restoration at the initial irradiance when the material thickness is over 4–5 mm, and therefore, the polymerization is not entirely accomplished [15, 69]. Such variation in polymerization with the function of depth takes place due to light irradiance attenuation, which leads to a slower polymerization reaction in the deepest resin-matrix composite regions.

In fact, light transmission through a resin-matrix composite depends on reflection, scattering, and absorption of the light, which vary accordingly to the chemical composition and microstructure of the material. Material light scattering is directly related to the differences in organic matrix polymer refractive indexes and inorganic fillers [19, 52, 68]. Also, porosity, oxide additives, fillers’ size, and restoration thickness can control the dispersion and absorption of light during the polymerization [42, 60]. Low absorption, scattering, and transmittance of visible light result in limitations of monomeric mobility at reactive species over gel and vitrification processes, leading to a low DC of monomers, poor cross-linking density, and high release of monomers to the surrounding environment [5]. An optimal correlation among the absorption of visible light, photoinitiator system, and the visible light wavelength spectrum is also a key factor for the polymerization process [17, 61]. The photoinitiator consumption also reduces the material light absorption during polymerization, which results in a transmittance increase.

Thus, the light transmission reaches its maximum value of around 68% immediately after the light-curing irradiation. However, the inorganic particles can interfere in the light transmission depending on their translucency, size, and microstructure. The visible light transmission gradually decreases as the material polymerization occurs [33]. Increasing the size of silica particles reduces the polymerization rate at the deeper region of the resin-matrix composites. Inorganic filler particles with diameter approaching half of the wavelength of light transmittance tends to increase light scattering and transmittance. Another study revealed that the translucency and depth polymerization of resin-matrix composites were inversely affected by the particle size. Such findings were validated by the light scattering and reflection from the presence of smaller particles [5–7, 74]. On the other hand, a high filler content reduces light transmission due to the increase of light refraction at interfaces between the inorganic filler particles and the resin matrix with different refractive index [5, 15]. A previous study reported that the inorganic filler and organic matrix must have similar refractive index match to achieve a high translucency in bulk-fillTM composites. Bulk-fillTM resin-matrix composites have reduced inorganic filler content aiming to achieve a high light transmission when compared to traditional resin-matrix composites [49].

On the other hand, most of clinicians are not aware of the LCU maintenance. For instance, the measurement of the light irradiance should be periodically carried out by using standard hand-held radiometers to make sure the LCU is working properly. Such periodical inspection of the LCU can guarantee the adequate energy required for polymerization of the organic matrix that also depends on the use and the type of LED. Also, the light-curing unit can de damaged over the clinical practice by accident (e.g., tumbling) and then the light irradiance should be immediately measured again. Inadequate operation of LCU can cause iatrogenesis and can negatively affect the long performance of the restoration [27].

The release of monomers from resin-matrix composites to the surrounding tissues can occur due to several factors, such as insufficient polymerization, thermal oscillations, fatigue, wear, and corrosion [11, 12, 14, 36, 64]. Monomers can be released to saliva and oral tissues, causing a risk of inflammatory reactions, as illustrated in Fig. 2. Cytotoxicity is related to initial short-term release of free monomers during monomer-polymer conversion, immediately after polymerization, and over performance in oral cavity [11, 13]. Studies have shown that most monomers react with the polymeric network during initial polymerization step. Thus, the percentage of free monomers is approximately 1.5–5% although a low amount of monomer molecules could be enough to provide a cytotoxic effect [10, 13, 64, 76]. In vitro studies revealed alterations in gingival and pulp cells caused by free monomers [10, 13, 64, 76]. Further research is required to precisely evaluate the degree of conversion, cross-linking density, and release of monomers and their chemical effects on the surrounding tissues [12].

The present review is classified as an integrative review that consists in a scoping review of the existing literature as a “systematic” process since the method is well-described. The present review involved quantitative and qualitative studies, therefore “integrative” inclusive, as well as critical evaluation, and synthesis of the available evidence on the research topic. However, a statistical analysis of results was not performed in this integrative review. Also, the present integrative review reveals some limitations since the selected articles showed limited data considering the effects of inorganic fillers on the light-transmission through resin-matrix composites during the light-curing procedure. Thus, the translucency of the glass–ceramic spherical fillers promoted light diffusion through the resin-matrix composite during the light-curing procedure. The light-transmission and diffusion into the resin-matrix composite is strongly beneficial in critical situations such as in the case of deep and proximal regions. Nevertheless, the effects of the chemical composition, microstructure, and morphological aspects of the inorganic fillers on light-transmission are not entirely clarified in the previous studies. Most of the selected studies estimate the degree of conversion of commercially available resin-matrix composites by measurement of overall mechanical properties such as hardness, strength, and elastic modulus. The assessment of commercially available materials become a challenge since those materials can have two or three different types of inorganic fillers at different micro- and nano-scale dimensions. Further studies should also be performed on experimental resin-matrix composites to validate the effects of the chemical composition and microstructure (type and content of glass–ceramics) followed by the effects of morphological aspects of the fillers such as spherical or irregular particles and micro- or nano-scale dimensions. The preparation of experimental resin-matrix composites may focus on chemical formulations involving different content, size, and type of fillers. Then, the evaluation of commercially available resin-matrix composites could be correlated with the results recorded for experimental materials.

Conclusions

Within the limitations of the in vitro selected studies, the following concluding remarks can be drawn.

The amount of light transmitted through the resin-matrix is strongly influenced by the size, content, microstructure, and shape of the inorganic filler particles. As a consequence, the light source could not be enough for a proper degree of conversion of monomers into a highly cross-linked polymer along thick resin-matrix composite increments. Thus, the decrease in the degree of conversion negatively affects the physical properties of the resin-matrix composite with a significant impact on their strength and optical properties. As a consequence, residual monomers are progressively released to the surrounding medium triggering a toxic cell response in the oral tissues. Previous studies highly recommend the control of the following light-curing factors: light irradiance, irradiation time, distance between material surface, light-curing unit conditions, and the compatibility between light wavelength and photoinitiator compounds [15, 16, 18, 26]. Also, the selection of the resin-matrix composite become a key role considering the effects of the size, shape, and chemical composition of the inorganic fillers. Further studies should carefully evaluate the correlation of the polymerization depth and the physical properties of recent resin-matrix composites taking into account the development of glass-ceramic fillers.

References

Ferracane JL (2011) Resin composite - State of the art. Dent Mater 27:29–38

Yang J, Shen J, Wu X et al (2020) Effects of nano-zirconia fillers conditioned with phosphate ester monomers on the conversion and mechanical properties of Bis-GMA- and UDMA-based resin composites. J Dent 94:103306. https://doi.org/10.1016/j.jdent.2020.103306

Almasabi W, Tichy A, Abdou A et al (2021) Effect of water storage and thermocycling on light transmission properties, translucency and refractive index of nanofilled flowable composites. Dent Mater J 40:599–605. https://doi.org/10.4012/dmj.2020-154

Graf N, Ilie N (2022) Long-term mechanical stability and light transmission characteristics of one shade resin-based composites. J Dent 116:103915. https://doi.org/10.1016/j.jdent.2021.103915

Sirovica S, Solheim JH, Skoda MWA et al (2020) Origin of micro-scale heterogeneity in polymerisation of photo-activated resin composites. Nat Commun 11:1849. https://doi.org/10.1038/s41467-020-15669-z

Horie K, Nakajima M, Hosaka K et al (2012) Influences of composite-composite join on light transmission characteristics of layered resin composites. Dent Mater 28:204–211. https://doi.org/10.1016/j.dental.2011.10.006

AndreasiBassi M, AndreasiBassi S, Andrisani C et al (2016) Light diffusion through composite restorations added with spherical glass mega fillers. Oral Implantol (Rome) 9:80–89. https://doi.org/10.11138/orl/2016.9.1S.080

Habib E, Wang R, Zhu XX (2017) Monodisperse silica-filled composite restoratives mechanical and light transmission properties. Dent Mater 33:280–287. https://doi.org/10.1016/j.dental.2016.12.008

Leyva Del Rio D, Johnston WM (2022) Optical characteristics of experimental dental composite resin materials. J Dent 118:103949. https://doi.org/10.1016/j.jdent.2022.103949

Goldberg M (2008) In vitro and in vivo studies on the toxicity of dental resin components: a review. Clin Oral Investig 12:1–8. https://doi.org/10.1007/s00784-007-0162-8

Koulaouzidou EA, Roussou K, Sidiropoulos K et al (2018) Investigation of the chemical profile and cytotoxicity evaluation of organic components eluted from pit and fissure sealants. Food Chem Toxicol 120:536–543. https://doi.org/10.1016/j.fct.2018.07.042

Lopes-Rocha L, Ribeiro-Gonçalves L, Henriques B et al (2021) An integrative review on the toxicity of Bisphenol A (BPA) released from resin composites used in dentistry. J Biomed Mater Res B Appl Biomater. https://doi.org/10.1002/jbm.b.34843

Kim K, Son KM, Kwon JH et al (2013) The effects of restorative composite resins on the cytotoxicity of dentine bonding agents. Dent Mater J 32:709–717. https://doi.org/10.4012/dmj.2012-335

Al-Hiyasat AS, Darmani H, Milhem MM (2005) Cytotoxicity evaluation of dental resin composites and their flowable derivatives. Clin Oral Investig 9:21–25. https://doi.org/10.1007/s00784-004-0293-0

Fronza BM, Ayres A, Pacheco RR et al (2017) Characterization of Inorganic Filler Content, Mechanical Properties, and Light Transmission of Bulk-fill Resin Composites. Oper Dent 42:445–455. https://doi.org/10.2341/16-024-L

Al-Zain AO, Eckert GJ, Lukic H et al (2019) Polymerization pattern characterization within a resin-based composite cured using different curing units at two distances. Clin Oral Investig 23:3995–4010. https://doi.org/10.1007/s00784-019-02831-1

Stansbury JW (2012) Dimethacrylate network formation and polymer property evolution as determined by the selection of monomers and curing conditions. Dent Mater 28:13–22. https://doi.org/10.1016/j.dental.2011.09.005

Lise DP, Van Ende A, De Munck J et al (2018) Light irradiance through novel CAD-CAM block materials and degree of conversion of composite cements. Dent Mater 34:296–305. https://doi.org/10.1016/j.dental.2017.11.008

Par M, Tarle Z, Hickel R, Ilie N (2018) Polymerization kinetics of experimental bioactive composites containing bioactive glass. J Dent 76:83–88. https://doi.org/10.1016/j.jdent.2018.06.012

Karabela MM, Sideridou ID (2011) Synthesis and study of physical properties of dental light-cured nanocomposites using different amounts of a urethane dimethacrylate trialkoxysilane coupling agent. Dent Mater 27:1144–1152. https://doi.org/10.1016/j.dental.2011.08.008

Rueggeberg FA, Hashinger DT, Fairhurst CW (1990) Calibration of FTIR conversion analysis of contemporary dental resin composites. Dent Mater 6:241–249. https://doi.org/10.1016/S0109-5641(05)80005-3

Karabela MM, Sideridou ID (2011) Synthesis and study of properties of dental resin composites with different nanosilica particles size. Dent Mater 27:825–835. https://doi.org/10.1016/j.dental.2011.04.008

Sideridou ID, Karabela MM, Vouvoudi EC (2011) Physical properties of current dental nanohybrid and nanofill light-cured resin composites. Dent Mater 27:598–607. https://doi.org/10.1016/j.dental.2011.02.015

Sideridou ID, Karabela MM, Micheliou CN et al (2009) Physical properties of a hybrid and a nanohybrid dental light-cured resin composite. J Biomater Sci Polym Ed 20:1831–1844. https://doi.org/10.1163/156856208X386435

Kwaśny M, Bombalska A, Obroniecka K (2022) A reliable method of measuring the conversion degrees of methacrylate dental resins. Sensors (Basel) 22:. https://doi.org/10.3390/s22062170

Baek D-M, Park J-K, Son S-A et al (2013) Mechanical properties of composite resins light-cured using a blue DPSS laser. Lasers Med Sci 28:597–604. https://doi.org/10.1007/s10103-012-1117-0

Par M, Marovic D, Attin T et al (2020) Effect of rapid high-intensity light-curing on polymerization shrinkage properties of conventional and bulk-fill composites. J Dent 101:103448. https://doi.org/10.1016/j.jdent.2020.103448

Daugherty MM, Lien W, Mansell MR et al (2018) Effect of high-intensity curing lights on the polymerization of bulk-fill composites. Dent Mater 34:1531–1541. https://doi.org/10.1016/j.dental.2018.06.005

Aravamudhan K, Floyd CJE, Rakowski D et al (2006) Light-emitting diode curing light irradiance and polymerization of resin-based composite. J Am Dent Assoc 137:213–223. https://doi.org/10.14219/jada.archive.2006.0147

Franco EB, dos Santos PA, Mondelli RFL (2007) The effect of different light-curing units on tensile strength and microhardness of a composite resin. J Appl Oral Sci 15:470–474. https://doi.org/10.1590/s1678-77572007000600003

Sabbagh J, Ryelandt L, Bachérius L et al (2004) Characterization of the inorganic fraction of resin composites. J Oral Rehabil 31:1090–1101. https://doi.org/10.1111/j.1365-2842.2004.01352.x

Beun S, Glorieux T, Devaux J et al (2007) Characterization of nanofilled compared to universal and microfilled composites. Dent Mater 23:51–59. https://doi.org/10.1016/j.dental.2005.12.003

Fujita K, Ikemi T, Nishiyama N (2011) Effects of particle size of silica filler on polymerization conversion in a light-curing resin composite. Dent Mater 27:1079–1085. https://doi.org/10.1016/j.dental.2011.07.010

Hong G, Yang J, Jin X et al (2020) Mechanical properties of nanohybrid resin composites containing various mass fractions of modified zirconia particles. Int J Nanomedicine 15:9891–9907. https://doi.org/10.2147/IJN.S283742

Chen W-C, Wu H-Y, Chen H-S (2013) Evaluation of reinforced strength and remineralized potential of resins with nanocrystallites and silica modified filler surfaces. Mater Sci Eng C Mater Biol Appl 33:1143–1151. https://doi.org/10.1016/j.msec.2012.12.022

Souza JCM, Bentes AC, Reis K et al (2016) Abrasive and sliding wear of resin composites for dental restorations. Tribol Int 102:154–160. https://doi.org/10.1016/j.triboint.2016.05.035

Rodrigues DS, Buciumeanu M, Martinelli AE et al (2015) Mechanical strength and wear of dental glass-ionomer and resin composites affected by porosity and chemical composition. J Bio- Tribo-Corrosion 1:24. https://doi.org/10.1007/s40735-015-0025-9

Drummond JL (2008) Degradation, fatigue, and failure of resin dental composite materials. J Dent Res 87:710–719. https://doi.org/10.1177/154405910808700802

Xu T, Li X, Wang H et al (2020) Polymerization shrinkage kinetics and degree of conversion of resin composites. J Oral Sci 62:275–280. https://doi.org/10.2334/josnusd.19-0157

Gonçalves F, Azevedo CLN, Ferracane JL, Braga RR (2011) BisGMA/TEGDMA ratio and filler content effects on shrinkage stress. Dent Mater 27:520–526. https://doi.org/10.1016/j.dental.2011.01.007

Sudheer V, Manjunath M (2011) Contemporary curing profiles: Study of effectiveness of cure and polymerization shrinkage of composite resins: an in vitro study. J Conserv Dent 14:383–386. https://doi.org/10.4103/0972-0707.87205

Tafur-Zelada CM, Carvalho O, Silva FS et al (2021) The influence of zirconia veneer thickness on the degree of conversion of resin-matrix cements: an integrative review. Clin Oral Investig. https://doi.org/10.1007/s00784-021-03904-w

Souza JCM, Fernandes V, Correia A et al (2022) Surface modification of glass fiber-reinforced composite posts to enhance their bond strength to resin-matrix cements: an integrative review. Clin Oral Investig 26:95–107. https://doi.org/10.1007/s00784-021-04221-y

Messous R, Henriques B, Bousbaa H et al (2021) Cytotoxic effects of submicron- and nano-scale titanium debris released from dental implants: an integrative review. Clin Oral Investig. https://doi.org/10.1007/s00784-021-03785-z

Souza JCM, Pinho SS, Braz MP et al (2021) Carbon fiber-reinforced PEEK in implant dentistry: a scoping review on the finite element method. Comput Methods Biomech Biomed Engin 24:1355–1367. https://doi.org/10.1080/10255842.2021.1888939

Cunha W, Carvalho O, Henriques B et al (2022) Surface modification of zirconia dental implants by laser texturing. Lasers Med Sci 37:77–93. https://doi.org/10.1007/s10103-021-03475-y

Ilie N (2017) Impact of light transmittance mode on polymerisation kinetics in bulk-fill resin-based composites. J Dent 63:51–59. https://doi.org/10.1016/j.jdent.2017.05.017

Omran TA, Garoushi S, Abdulmajeed AA et al (2017) Influence of increment thickness on dentin bond strength and light transmission of composite base materials. Clin Oral Investig 21:1717–1724. https://doi.org/10.1007/s00784-016-1953-6

Son S-A, Park J-K, Seo D-G et al (2017) How light attenuation and filler content affect the microhardness and polymerization shrinkage and translucency of bulk-fill composites? Clin Oral Investig 21:559–565. https://doi.org/10.1007/s00784-016-1920-2

Germscheid W, de Gorre LG, Sullivan B et al (2018) Post-curing in dental resin-based composites. Dent Mater 34(9):1367–1377. https://doi.org/10.1016/j.dental.2018.06.021

Perez MM, Hita-Iglesias C, Ghinea R et al (2016) Optical properties of supra-nano spherical filled resin composites compared to nanofilled, nano-hybrid and micro-hybrid composites. Dent Mater J 35:353–359. https://doi.org/10.4012/dmj.2015-126

Par M, Prskalo K, Tauböck TT et al (2021) Polymerization kinetics of experimental resin composites functionalized with conventional (45S5) and a customized low-sodium fluoride-containing bioactive glass. Sci Rep 11:21225. https://doi.org/10.1038/s41598-021-00774-w

Par M, Spanovic N, Mohn D et al (2020) Curing potential of experimental resin composites filled with bioactive glass: a comparison between Bis-EMA and UDMA based resin systems. Dent Mater 36:711–723. https://doi.org/10.1016/j.dental.2020.03.015

Garoushi S, Vallittu P, Lassila L (2019) Mechanical properties and radiopacity of flowable fiber-reinforced composite. Dent Mater J 38:196–202. https://doi.org/10.4012/dmj.2018-102

Verzola KC, Dressano D, Saraceni CHC et al (2020) Bis(4-methyl phenyl)iodonium as an alternative component to diphenyliodonium in camphorquinone-based ternary initiating systems. Dent Mater 36:1282–1288. https://doi.org/10.1016/j.dental.2020.06.002

Canché-Escamilla G, Duarte-Aranda S, Toledano M (2014) Synthesis and characterization of hybrid silica/PMMA nanoparticles and their use as filler in dental composites. Mater Sci Eng C Mater Biol Appl 42:161–167. https://doi.org/10.1016/j.msec.2014.05.016

Faria-E-Silva AL, Pfeifer CS (2017) Impact of thio-urethane additive and filler type on light-transmission and depth of polymerization of dental composites. Dent Mater 33:1274–1285. https://doi.org/10.1016/j.dental.2017.07.020

Scougall-Vilchis RJ, Hotta Y, Hotta M et al (2009) Examination of composite resins with electron microscopy, microhardness tester and energy dispersive X-ray microanalyzer. Dent Mater J 28:102–112. https://doi.org/10.4012/dmj.28.102

Ferracane JL, Stansbury JW, Burke FJT (2011) Self-adhesive resin cements - chemistry, properties and clinical considerations. J Oral Rehabil 38:295–314. https://doi.org/10.1111/j.1365-2842.2010.02148.x

Caprak YO, Turkoglu P, Akgungor G (2019) Does the Translucency of novel monolithic CAD/CAM materials affect resin cement polymerization with different curing modes? J Prosthodont Off J Am Coll Prosthodont 28:e572–e579. https://doi.org/10.1111/jopr.12956

Ferracane JL, Hilton TJ, Stansbury JW et al (2017) Academy of dental materials guidance—resin composites: Part II—technique sensitivity (handling, polymerization, dimensional changes). Dent Mater 33:1171–1191. https://doi.org/10.1016/j.dental.2017.08.188

Pontes LF, Alves EB, Alves BP et al (2013) Mechanical properties of nanofilled and microhybrid composites cured by different light polymerization modes. Gen Dent 61:30–33

Elbishari H, Silikas N, Satterthwaite J (2012) Filler size of resin-composites, percentage of voids and fracture toughness: is there a correlation? Dent Mater J 31:523–527. https://doi.org/10.4012/dmj.2011-256

Gupta SK, Saxena P, Pant VA, Pant AB (2012) Release and toxicity of dental resin composite. Toxicol Int 19:225–234. https://doi.org/10.4103/0971-6580.103652

Malhotra N, Mala K (2010) Light-curing considerations for resin-based composite materials: a review. Part I. Compend Contin Educ Dent 31:498–505 (quiz 506, 508)

Son S-A, Roh H-M, Hur B et al (2014) The effect of resin thickness on polymerization characteristics of silorane-based composite resin. Restor Dent Endod 39:310–318. https://doi.org/10.5395/rde.2014.39.4.310

Moldovan M, Balazsi R, Soanca A, et al (2019) Evaluation of the degree of conversion, residual monomers and mechanical properties of some light-cured dental resin composites. Mater (Basel, Switzerland) 12:. https://doi.org/10.3390/ma12132109

Fidalgo-Pereira R (2022) Relationship between the inorganic content and the polymerization of the organic matrix of resin composites for dentistry: a narrative review. RevSALUS - Revista Científica Internacional Da Rede Académica Das Ciências Da Saúde Da Lusofonia 4(1). https://doi.org/10.51126/revsalus.v4i1.136

Knezević A, Tarle Z, Meniga A et al (2005) Influence of light intensity from different curing units upon composite temperature rise. J Oral Rehabil 32:362–367. https://doi.org/10.1111/j.1365-2842.2004.01418.x

Wahbi MA, Aalam FA, Fatiny FI et al (2012) Characterization of heat emission of light-curing units. Saudi Dent J 24:91–98. https://doi.org/10.1016/j.sdentj.2012.01.003

Satterthwaite JD, Maisuria A, Vogel K, Watts DC (2012) Effect of resin-composite filler particle size and shape on shrinkage-stress. Dent Mater 28:609–614. https://doi.org/10.1016/j.dental.2012.01.007

Spinell T, Schedle A, Watts DC (2009) Polymerization shrinkage kinetics of dimethacrylate resin-cements. Dent Mater 25:1058–1066. https://doi.org/10.1016/j.dental.2009.04.008

Delgado AHS, Owji N, Ashley P, Young AM (2021) Varying 10-methacryloyloxydecyl dihydrogen phosphate (10-MDP) level improves polymerisation kinetics and flexural strength in self-adhesive, remineralising composites. Dent Mater 37:1366–1376. https://doi.org/10.1016/j.dental.2021.06.006

Habib E, Wang R, Wang Y et al (2016) Inorganic fillers for dental resin composites: present and future. ACS Biomater Sci Eng 2:1–11

Palin WM, Leprince JG, Hadis MA (2018) Shining a light on high volume photocurable materials. Dent Mater 34:695–710. https://doi.org/10.1016/j.dental.2018.02.009

Wegehaupt FJ, Lunghi N, Belibasakis GN, Attin T (2016) Influence of light-curing distance on degree of conversion and cytotoxicity of etch-and-rinse and self-etch adhesives. BMC Oral Health 17:12. https://doi.org/10.1186/s12903-016-0239-3

Funding

This work was supported by FCT-Portugal [UID/EEA/04436/2013, SFRH/BPD/123769/ 2016, and Project LaserMULTICER [POCI-01–0145-FEDER-031035].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fidalgo-Pereira, R., Carpio, D., Torres, O. et al. The influence of inorganic fillers on the light transmission through resin-matrix composites during the light-curing procedure: an integrative review. Clin Oral Invest 26, 5575–5594 (2022). https://doi.org/10.1007/s00784-022-04589-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00784-022-04589-5