Abstract

Purpose The systematic review aims to evaluate the effect of light irradiance from light-curing units on microhardness of composite.

Materials and methods The protocol was registered in PROSPERO following which primary search was carried out via MedLine, Scopus and Cochrane Library. A customised tool was used to assess the risk of bias. Among the 303 records retrieved from the databases, only ten articles qualified for qualitative synthesis after meeting all the requirements of the eligibility criteria. Covidence software was used to record the decisions. The studies published until 31 March 2021 were taken up for the review. The articles showed a low-to-moderate risk of bias.

Results From a total of 303 articles, ten articles were reviewed for full text. Ten in vitro studies were included for qualitative analysis. There was heterogeneity in sample size, curing time and outcome measured. Therefore, meta-analysis was not performed. Out of ten studies, seven studies reported higher microhardness value for higher intensity than lower intensity of light.

Conclusion Despite the fact that the findings of the evaluated studies are quite variable, significant scientific evidence revealed that high light intensity can enhance the hardness of resin composites.

Similar content being viewed by others

Introduction

Resin-based composites (RBCs) have been widely utilised as a restorative material for both posterior and anterior teeth since their inception in the 1960s.1 RBCs were either chemically cured two-component compounds or photo-initiated materials. They initially began with ultraviolet (UV) initiators and then switched to visible light initiators, such as camphorquinone which was developed in 1978.2

Light-cured composites are cured by radical photopolymerisation. In the presence of activators, photoinitiators absorb light photons and produce free radicals. The polymerisation reaction would be triggered by the free radicals, resulting in polymerisation.3

Camphorquinone (CQ) is one of the most extensively used photoinitiators and has a peak wavelength near 470 nm in the visible light spectrum. Acyl phosphine oxide (APO), Ivocerin and phenyl propanedione (PPD) are the other photoinitiators. PPD absorbs light in a UV wavelength range to around 490 nm and has an absorbance peak at 398 nm and effectively tails off after 460 nm,4 while APO, such as Lucirin TPO (2,4,6-trimethylbenzoyldiphenyl phosphine oxide) absorbs light primarily in the UV range. APO has a peak of about 370 nm, which is significantly lower than CQ's. Ivocerin is a newly designed germanium photoinitiator with a sensitivity peak of around 420 nm and absorbs light across a wider wavelength spectrum than APO.5

As a result, monowave light-emitting diode (LED) light-curing units (LCUs) that produce light predominantly in the 445-480 nm spectral region would be inefficient in activating these photoinitiators.6,7,8,9,10,11 A third-generation curing light, polywave blue-violet LED-based LCUs,9,12has been introduced to address this restriction, claiming to polymerise all resin composite restorations. These blue-violet LCUs combine up to three different colours. LED chips of various 'colours', with spectral emissions peaking between 440-460 nm (blue) and 400-410 nm (violet). It can obtain irradiances of up to 3,200 mW/cm2and polymerisation in as little as six seconds, depending on the mode selected.12

Many variables affect the amount of light energy received on the top and bottom surfaces of a composite resin restoration, such as the design and size of the light guide, distance of the light guide tip from the composite resin, power density, exposure duration, shade and opacity of the composite resin, increment thickness, and material composition.13,14,15 The degree of monomer to polymer conversion is a defining factor for physical and mechanical characteristics of composite, and it is directly connected to irradiance.16,17 Spectral radiant power is the radiant power per wavelength.18 To adequately cure a photoactivated resin, the spectral output from the LCU must match the wavelength-dependent photosensitivity of the photoinitiator used in the resin.19 Insufficient radiant exposure (J/cm2), due to poor curing procedures, may trigger a snowball effect driving to shorten the long-term lifetime service of composites.20 Incomplete conversion of the polymer matrix, significant release of materials to the oral environment, high degradation upon oral fluids, increase of water sorption and increased roughness is the potential pathway of detrimental events leading to the increase of biofilm accumulation and, consequently, the risk of development of caries lesions around restorations (CARS) due to inappropriate curing procedures of the material.21

Researchers recommend for an effective polymerisation of maximum thickness of 2 mm increment of composite,8a minimum irradiance of 300 mW/cm2 should be ensured.16,17

Lights with outputs more than 800 mW/cm2 are available and require only shorter exposure time. Shorter irradiation periods, on the other hand, may result in inadequate composite resin conversion, particularly towards the bottom of the restoration.22,23,24 Furthermore, the use of high irradiance in the initial phase of curing should result in a greater number of growth centres and higher crosslink density.25

One of the most significant mechanical properties of dental composites is surface hardness. It is proportional to the rate of polymerisation conversion, which is affected by polymerisation time, distance of polymerisation light,26 irradiation27 and the type of material at the energy source's tip.28 Microhardness testing has long been recognised as a feasible approach for evaluating composite curing and the efficiency of the light source.29,30The degree of conversion, or the percentage change in monomer double bonds to a single polymeric bond, is determined by polymerisation. The degree of conversion is a crucial indicator of how well the monomers used to make resins are polymerised and crosslinked.

Dental practioners should be aware of the distinctions in LCUs such as irradiance and exposure time, and the effects these variances can have on the RBC as there are so many different types of LCUs available.

The key question addressed by this systemic review was: does variation in light irradiance from LED curing units influence the microhardness of the composite?

Materials and methods

This systematic review was piloted in accordance with the PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) reporting guidelines. The systematic review has been registered in the PROSPERO international database (CRD42021248471). The review aims to answer the guiding question: 'Does variation in irradiance from LED curing units influence microhardness of the composite?'

Inclusion criteria

-

Studies carried out until 31 March 2021

-

In vitro studies carried out on artificial molds

-

Comparative studies evaluating the microhardness of composite when cured with low irradiance (300-750 mW/cm2) and high irradiance (900-1300 mW/cm2) LED lights.

Exclusion criteria

-

Review articles in languages other than English

-

Ex vivo studies carried out on extracted teeth

-

Studies not following the inclusion criteria.

Literature search

Sources for the systematic review included Medline, Scopus, and the Cochrane Library. The articles were selected until 31 March 2021. Searches were re-run before extraction and analysis.

The search aimed to identify both published and unpublished studies. To acquire articles on the topic, a broad search of Medline, Scopus, the Cochrane library and EBSCO was undertaken to identify articles on the topic and hand searching was done on the first ten pages of Google Scholar. A comprehensive search method for Medline and Scopus was implemented using text words found in the titles and abstracts of relevant articles, as well as the index keywords used to describe the articles. Each database and/or information source was given its search strategy, which incorporated all of the specified keywords and index terms. Additional studies were evaluated from the reference list of all relevant sources of evidence (Table 1).

Study selection

After the literature search, the results were exported to Covidence software. Title and abstract screening of the articles was performed by two independent reviewers (NF and VK). This was followed by full-text screening which was also carried out by two independent reviewers. A third subject expert (RR) was invited to resolve conflicts of agreement. Covidence software was used for recording the decisions (Fig. 1).

Data collection process

After discussion with the team, a data extraction template was formulated and two independent reviewers (NF and VK) performed the extraction process. A third subject expert (RR) was invited to resolve conflicts of agreement. The data were extracted using a standardised form in Covidence software The data extracted included demographic data (year, author, country) and characteristics of the study (aim, study design, sample size). Details of the microhardness test performed included the type of composite used and sample characters, which were recorded. Intervention (higher irradiance of 900-1300 mW/cm2) and control (lower irradiance 300-750 Mw/cm2) were defined and curing time was noted. The definition and measurement of the main outcome (microhardness) were noted. Data was collected for assessing the primary outcome that is microhardness, which was evaluated using Vickers and Knoops hardness test and expressed in Vickers Hardness Number (VHN) and Knoop Hardness Number (KHN).

Quality assessment

The risk of bias was examined independently by two reviewers (NF and VK). There was no standardised tool available for assessing the risk of bias for in vitro studies. Previous studies have used customised tools. The present study also used a customised tool adapted from the study AlShwaimi et al.31 The following parameters were assessed and graded for calculating the risk of bias:

-

1.

Presence of control group

-

2.

Description of sample size calculation

-

3.

Light-curing procedure performed by a single operator

-

4.

Use of irradiance of light-curing units according to manufacturer's instructions

-

5.

Incubation performed before outcome assessment

-

6.

Using Vickers or Knoops test to determine hardness (assessment of top and bottom surfaces).

The risk of bias was recorded as low, unclear or high for each of these parameters. For the overall risk of bias, the articles that cited 1-2 items were categorised as having low risk of bias, 3-4 as moderate risk, and 5-6 as high risk.

Results

Descriptive analysis

All the ten studies selected were comparative in vitro studies carried out on various artificial models to support the restorations. The various molds used for the studies were spilt brass mold, aluminium rings, polyvinyl siloxane mold, Teflon mold, metallic matrices and cylindrical stainless steel mold. The specimen thickness ranged from 2-4 mm and the diameter ranged from 3-10 mm. For assessing the microhardness of composite, bulkfill composite,5,32,33,34microhybrid composite,35,36conventional and bulkfill composite,37 low shrink posterior composite and microhybrid,38 bulkfill and nanocomposite,39 microfilled and microhybrid40 were used.

Furthermore, most of the reviewed articles were published recently and the year of publication of studies ranged from 2005 to 2020. To evaluate microhardness, all of the reviewed studies (100%) employed either the Knoop or Vickers hardness tests as the primary testing method.5,32,33,34,35,36,37,38,39,40 In five of the studies, the outcome was measured using the Knoop hardness test5,36,37,38,40 and in the other five studies, it was the Vickers hardness test.32,33,34,35,39 The curing time in two of the studies was 20 seconds.32,37 In one of the studies, the curing time was 60 seconds35 and in another study it was 40 seconds.38 In some studies, they used multiple curing times: 5 seconds, 20 seconds and 80 seconds;36 10 seconds, 20 seconds and 40 seconds;33 and 20 seconds, 60 seconds, 80 seconds and 100 seconds.40 Three of the studies used different curing times for higher irradiance and lower irradiance5,34,39 (Table 2).

It can be concluded from Table 3 that in most of the studies,32,33,34,35,38,39,40higher irradiance of light showed significantly higher hardness value compared to the lower irradiance of light. However, the results of the studies by Haenel et al. in 2015, Gan et al. in 2018 and Soto Montero et al. in 2020 showed that lower irradiance of light has significantly higher hardness value5,36,37(Table 3).

Quality assessment

As per the parameters, four articles out of ten were graded as low risk5,35,37,40 and six articles were graded as moderate risk.32,33,34,36,38,39 None of the articles reported details on sample size estimation. Details of procedural and outcome measurement whether performed or recorded by a single operator were not reported in the ten articles (Table 4).

Discussion

Systematic reviews benefit clinical practitioners by generating precise evidence-based explanations to critical questions about the best available scientific knowledge. In addition, thorough reviews can lead to the development of new standardised research methods and procedures.

With the implementation of photopolymerisable composites, the intensity of the curing light is significant, and complete curing is difficult to achieve in practice. Bulk-fill composites have good mechanical qualities and little polymerisation shrinkage which can be cured in thick layers.41 LED curing light of the irradiance 400-500 mW/cm2 is required for adequate polymerisation. A light irradiance of 200-600 mW/cm2 with proper exposure duration is deemed sufficient to induce consistent polymerisation of RBCs.42 Improved LEDs with a higher irradiance range (500-1400 mW/cm2) offer a wider range of the visible blue light spectrum.43 Despite the fact that single-peak and multi-peak lights can create identical overall power output (watts) and supply the same power density (mW/cm2) to the restoration, spectral output discrepancies can have a substantial impact on the photoinitiating system.44 Microhardness is one of the most important physical features of dental materials,6 and investigating it can make you understand the setting characteristics and depth of cure resin-based restorative materials.45

Our systematic review indicated that the irradiance of light-curing units and the composition of the material has an influence on the microhardness of composite. There were a total of ten studies and the majority of them demonstrated that higher irradiance contributes to higher microhardness values. Only three included studies reported that lower irradiance of light produced higher microhardness value.5,36,37

Soto Montero et al.37 and Gan et al.5 in their studies compared the lower and higher irradiance of polywave light. The delivered irradiance for higher intensity was found between 935 and 1,200 mW/cm2 and lower irradiance was between 650 and 750 mW/cm2 in both studies. However, Haenel et al.36 compared the irradiance of polywave and monowave light; in this study, mean upper surface hardness of the polywave light of lower irradiance was greater than monowave light. The variations in polymerisation were reported by Miletic et al. to be attributable to variances in emitted wavelengths for distinct LCUs.46 The monowave light has a wavelength of 450 nm in distinction to the lower irradiance of polywave light with 463 nm, and this wavelength adapts better for CQ (470 nm).9 Park et al. reported that the additional wavelength range of polywave LCUs in the lesser range has an additional effect on the curing process.47 As a result, the improved condition of curing of the lower irradiance polywave light, which has a wavelength range of 390-435 nm, could be explained. To summarise, the variations in peak maxima and extra wavelength range explain why the higher irradiance of monowave light and the lower irradiance of polywave light have distinct curing effectiveness.

The higher microhardness values are attained when the emission spectra and the photoinitiator absorption spectra are related.

Composite resin restorations should preferably be cured evenly throughout. A 4 mm-thick bulkfill specimen's bottom-to-top hardness ratio should be close to or equal to 1 (100%). Due to light-curing and material constraints, several studies have chosen a hardness ratio of 0.8 or 80% as the criterion for a successful cure.48

The use of photoinitiators in resin composite formulations is an important factor affecting the material's depth of cure.49 New initiation systems based on benzoylgermanium derivatives have been synthesised and demonstrated to be efficient visible light photoinitiators.50,51,52,53 Similar to phosphine oxides, the benzoylgermanium initiators undergo photodecomposition to form radicals without the need for a co-initiator. The benzoylgermanium initiators exhibit strong absorption up to 450 nm, which is advantageous for improved initiation efficiency in dental materials. The novel initiators were demonstrated to exhibit improved UV stability, comparable shelf stability, improved bleaching, and increased cure depths and polymerisation rates relative to those of the CQ/amine systems.54 Also, Meenes et al. found no significant difference in cure depth of the bulk-fill resin-based composites Tetric Evoceram Bulk Fill (containing CQ and Ivocerin) and Filtek Bulk Fill Posterior (containing CQ) when cured with a monowave (Elipar S10) or a polywave (Bluephase G2). They conclude that there was some overlap between the absorbance of Ivocerin and the spectral output of the monowave S10 LCU, which may have allowed initiation of the Ivocerin in Tetric Evoceram Bulk Fill.55

Chemical variables have a significant impact on the polymerisation performance of composite resin. Filler size was raised in some commercially available bulk-fill resin-based composites, lowering overall particle volume percentage. As a result, the light scattering and filler matrix are reduced, allowing light to penetrate deeper zones.56 Furthermore, the viscosity of material appears to be a significant component in bulk-fill resin-based composite curing effectiveness, as several studies found that flowable materials had a greater depth of cure than materials with a higher viscosity.

The second generation single-peak LED LCUs emit a narrow spectrum of light that has a peak range of wavelength (450 nm to 470 nm), which matches CQ's absorbance wavelength.57 On the other hand, alternative photoinitiators (for example, 2,4,6-trimethylbenzoyldiphenylphosphine oxide [Lucirin TPO] and 1-phenyl-1,2-propanedione [PPD]), which are more sensitive to shorter wavelengths (<420 nm), have been introduced in some RBCs.58 The use to mix diverse photoinitiators leads to an improvement of DC and better aesthetic qualities59and reduces the rate of stress.60 The presence of these photoinitiators may reduce photoactivation effectiveness when a single-peak LED light (450-470 nm) is used.61 Third-generation multi-peak or polywave LED LCUs, provided with additional light output in the 400-415 nm range of wavelengths, are supposed to overcome that problem.62

Nevertheless, when the LED LCUs were used to cure the composite with two photoinitiators at an energy density of 16 J/cm2, the increasing power density was demonstrated to increase the microhardness.39

Microhardness assessment is an indirect means of determining the degree of conversion.63 For assessing the hardness of composite resins, three primary hardness tests have been recommended in the past (Barcol, Knoop and Vickers). The Vickers and Knoop hardness tests were used in the current systematic study.64

The higher microhardness value achieved at the upper surface of the specimens compared to their lower surface can be described by the light attenuation (due to absorption, reflection and dispersion) as it passes through the resin. Henceforth, at 2 mm depth, the attenuation of light may lessen the irradiance to nearly 75% of the irradiance that reaches the top surface.17

For all protocols, the microhardness values found after microhardness testing revealed that silorane-based resin showed statistically lower values than methacrylate-based resins. The chemical changes in the monomer, as well as changes in the distribution and type of inorganic particles, may explain why silorane-based resin has a lower polymerisation depth than methacrylate-based resin. The number of double bonds between carbon molecules that remain after polymerisation is used to determine the degree of conversion of methacrylate-based resins.65

According to Emami et al., the hardness and degree of cure values increase as irradiance and photoactivation duration increase. As a result, a material with improved mechanical properties is possible to obtain.66 However, Lovell et al. stated that a high irradiance paired with a short photoactivation period has been found to lower the degree of cure and the length of the kinetic chain.67

Long irradiation times are definitely of importance based on the microhardness data, as they resulted in improved microhardness on the bottom surface. However, Torno et al. believe that part of the favourable effect is due to the material being heated with light.68 According to Zach and Cohen, the temperature at which permanent pulpal lesions might occur is 5.5 °C, but this value is arguable.69 According to Baldissara et al., short exposure to temperature rises ranging from 8.9 °C to 14.7 °C did not appear to be a major negative factor for healthy dental pulps.70 In any event, it appears prudent to limit pulpal temperature variations to a minimum. Furthermore, due to many variables such as dentin thickness, preparation depth, output intensity and exposure period, predicting temperature rise in any given tooth is quite challenging.71 According to Peutzfeldt and Asmussen, temperature rise increases as power density increases.72

Extensive electronic searches in various databases, as well as other supplementary analyses, gave a wide overview of the obtained data, which might be regarded as the research's major strength. To adequately examine the selected works, stringent and methodical techniques were used during data extraction, in addition to a posterior risk of bias evaluation. Despite this, the main limitation identified was a high prevalence of low-to-medium risk of bias.To conclude, selected studies presented with significant methodological heterogeneity, specifically in terms of materials tested, assessment methods, exposure times and outcomes measured, which made it impossible to conduct a meta-analysis.

Conclusion

The irradiance of light is a relevant factor in the polymerisation of composite, influencing the hardness of the composite. To maintain the longevity and the quality of the restoration, it is essential to monitor the light irradiance of the light-curing units with a radiometer. Other factors could affect the power density and the resin-based material properties, including possible contamination and several sterilisations of the light guide, composition of composite and distance from the light guide to the restoration.

From the data obtained from the reported and selected studies, it is evident that most of the included studies showed favourable results for higher irradiance of light than lower irradiance of light on microhardness of composite - these results are based on articles. This systematic review highlighted the need for further studies with irradiance more than 1,300 mW/cm2 which consistently prove they provide a complete polymerisation of composite.

After considering other essential elements such as purchasing prices, chairside time considerations and longevity, the choice of curing light system should be made based on clinical preferences.

References

Leinfelder K F. A conservative approach to placing posterior composite resin restorations. J Am Dent Assoc 1996; 127: 743-748.

Bassiouny M A, Grant A A. A visible light-cured composite restorative. Clinical open assessment. Br Dent J 1978; 145: 327-330.

Stansbury J W. Curing dental resins and composites by photopolymerization. J Esthet Dent 2000; 12: 300-308.

Rueggeberg F A, Giannini M, Arrais C A G, Price R B T. Light curing in dentistry and clinical implications: a literature review. Braz Oral Res 2017; DOI: 10.1590/1807-3107BOR-2017.vol31.0061.

Gan J K, Yap A U, Cheong J W, Arista N, Tan C. Bulk-Fill Composites: Effectiveness of Cure With Poly-and Monowave Curing Lights and Modes. Oper Dent 2018; 43: 136-143.

Santini A, Miletic V, Swift M D, Bradley M. Degree of conversion and microhardness of TPO-containing resin-based composites cured by polywave and monowave LED units. J Dent 2012; 40: 577-584.

Leprince J, Devaux J, Mullier T, Vreven J, Leloup G. Pulpal-temperature rise and polymerization efficiency of LED curing lights. Oper Dent 2010; 35: 220-230.

Jandt K D, Mills R W. A brief history of LED photopolymerization. Dent Mater 2013; 29: 605-617.

Price R B T, Fahey J, Felix C M. Knoop microhardness mapping used to compare the efficacy of LED, QTH and PAC curing lights. Oper Dent 2010; 35: 58-68.

Schneider L F J, Cavalcante L M, Prahl S A, Pfeifer C S, Ferracane J L. Curing efficiency of dental resin composites formulated with camphorquinone or trimethylbenzoyl-diphenyl-phosphine oxide. Dent Mater 2012; 28: 392-397.

Price R B T, Felix C A. Effect of delivering light in specific narrow bandwidths from 394 to 515nm on the micro-hardness of resin composites. Dent Mater 2009; 25: 899-908.

Rueggeberg F A. State-of-the-art: dental photocuring-a review. Dent Mater 2011; 27: 39-52.

Yap A U. Effectiveness of polymerization in composite restoratives claiming bulk placement: impact of cavity depth and exposure time. Oper Dent 2000; 25: 113-120.

Price R B, Dérand T, Loney R W, Andreou P. Effect of light source and specimen thickness on the surface hardness of resin composite. Am J Dent 2002; 15: 47-53.

Sobrinho L C, Goes M F, Consani S, Sinhoreti M A, Knowles J C. Correlation between light intensity and exposure time on the hardness of composite resin. J Mater Sci Mater Med 2000; 11: 361-364.

Calheiros F C, Kawano Y, Stansbury J W, Braga R R. Influence of radiant exposure on contraction stress, degree of conversion and mechanical properties of resin composites. Dent Mater 2006; 22: 799-803.

Rueggeberg F A, Caughman W F, Curtis J W. Effect of light intensity and exposure duration on cure of resin composite. Oper Dent 1994; 19: 26-32.

Kirkpatrick S. A primer on radiometry. Dent Mater 2005; 21: 21-26.

Nomoto R. Effect of light wavelength on polymerization of light-cured resins. Dent Mater J 1997; 16: 60-73.

Khalichi P, Singh J, Cvitkovitch D G, Santerre J P. The influence of triethylene glycol derived from dental composite resins on the regulation of Streptococcus mutans gene expression. Biomaterials 2009; 30: 452-459.

Demarco F F, Collares K, Correa M B, Cenci M S, de Moraes R R, Opdam N J. Should my composite restorations last forever? Why are they failing? Braz Oral Res 2017; DOI: 10.1590/1807-3107BOR-2017.vol31.0056.

Caughman W F, Caughman G B, Shiflett R A, Rueggeberg F, Schuster G S. Correlation of cytotoxicity, filler loading and curing time of dental composites. Biomaterials 1991; 12: 737-740.

Oberholzer T G, Schünemann M, Kidd M. Effect of LED curing on microleakage and microhardness of Class V resin-based composite restorations. Int Dent J 2004; 54: 15-20.

Stansbury J W, Trujillo-Lemon M, Lu H, Ding X, Lin Y, Ge J. Conversion-dependent shrinkage stress and strain in dental resins and composites. Dent Mater 2005; 21: 56-67.

Filho J D N, Poskus L T, Guimarães J G A, Barcellos A A L, Silva E M. Degree of conversion and plasticization of dimethacrylate-based polymeric matrices: influence of light-curing mode. J Oral Sci 2008; 50: 315-321.

Pires J A, Cvitko E, Denehy G E, Swift E J. Effects of curing tip distance on light intensity and composite resin microhardness. Quintessence Int Berl Ger 1993; 24: 517-521.

Groninger A I S, Soares G P, Sasaki R T, Ambrosano G M B, Lovadino J R, Aguiar F H B. Microhardness of nanofilled composite resin light-cured by LED or QTH units with different times. Braz J Oral Sci 2011; 10: 189-192.

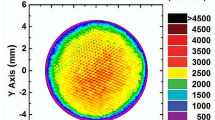

Vandewalle K S, Roberts H W, Rueggeberg F A. Power distribution across the face of different light guides and its effect on composite surface microhardness. J Esthet Restor Dent 2008; 20: 108-117; discussion 118.

Hansen E K, Asmussen E. Correlation between depth of cure and surface hardness of a light-activated resin. Scand J Dent Res 1993; 101: 62-64.

Baharav H, Abraham D, Cardash H S, Helft M. Effect of exposure time on the depth of polymerization of a visible light-cured composite resin. J Oral Rehabil 1988; 15: 167-172.

AlShwaimi E, Bogari D, Ajaj R, Al-Shahrani S, Almas K, Majeed A. In Vitro Antimicrobial Effectiveness of Root Canal Sealers against Enterococcus faecalis: A Systematic Review. J Endod 2016; 42: 1588-1597.

Alkhudhairy F I. The effect of curing intensity on mechanical properties of different bulk-fill composite resins. Clin Cosmet Investig Dent 2017; DOI: 10.2147/CCIDE.S130085.

Leprince J, Devaux J, Mullier T, Vreven J, Leloup G. Pulpal-temperature rise and polymerization efficiency of LED curing lights. Oper Dent 2010; 35: 220-230.

Conte G, Panetta M, Mancini M et al. Curing effectiveness of single-peak and multi-peak led light curing units on tpo-containing resin composites with different chromatic characteristics. Oral Implantol (Rome) 2017; DOI: 10.11138/orl/2017.10.2.140.

Park S-H, Kim S-S, Cho Y-S, Lee S-Y, Noh B-D. Comparison of linear polymerization shrinkage and microhardness between QTH-cured & LED-cured composites. Oper Dent 2005; 30: 461-467.

Haenel T, Hausnerová B, Steinhaus J, Price R B T, Sullivan B, Moeginger B. Effect of the irradiance distribution from light curing units on the local micro-hardness of the surface of dental resins. Dent Mater 2015; 31: 93-104.

Soto-Montero J, Nima G, Rueggeberg F A, Dias C, Giannini M. Influence of Multiple Peak Light-emitting-diode Curing Unit Beam Homogenization Tips on Microhardness of Resin Composites. Oper Dent 2020; 45: 327-338.

Cardia G S, Ishikiriama S K, Borges A F S, Bombonatti J F S, Furuse A Y, Francisconi P A S. Curing depth of a silorane-based resin composite. Revista Sul-Brasileira de Odontologia 2015; 12: 196-201.

Gritsch K, Souvannasot S, Schembri C, Farge P, Grosgogeat B. Influence of light energy and power density on the microhardness of two nanohybrid composites. Eur J Oral Sci 2008; 116: 77-82.

Cavalcante L M A, Valentino T A, Carlini B, Silikas N, Pimenta L A F. Influence of different exposure time required to stabilize hardness values of composite resin restorations. J Contemp Dent Pract 2009; 10: 42-50.

Bucuta S, Ilie N. Light transmittance and micro-mechanical properties of bulk fill vs. conventional resin based composites. Clin Oral Investig 2014; 18: 1991-2000.

Fan P L, Schumacher R M, Azzolin K, Geary R, Eichmiller F C. Curing-light intensity and depth of cure of resin-based composites tested according to international standards. J Am Dent Assoc 2002; 133: 429-434; quiz 491-493.

Al Shaafi M, Maawadh A, Al Qahtani M. Evaluation of light intensity output of QTH and LED curing devices in various governmental health institutions. Oper Dent 2011; 36: 356-361.

Rb P, Ca F. Effect of delivering light in specific narrow bandwidths from 394 to 515nm on the micro-hardness of resin composites. Dent Mater 2009; 25: 899-908.

Swift E J, Pawlus M A, Vargas M A, Fortin D. Depth of cure of resin-modified glass ionomers. Dent Mater 1995; 11: 196-200.

Miletic V, Santini A. Micro-Raman spectroscopic analysis of the degree of conversion of composite resins containing different initiators cured by polywave or monowave LED units. J Dent 2012; 40: 106-113.

Park H-J, Son S-A, Hur B, Kim H-C, Kwon Y-H, Park J-K. Effect of the difference in spectral outputs of the single and dual-peak LEDs on the microhardness and the colour stability of resin composites. J Korean Acad Conserv Dent 2011; 36: 108-113.

Watts D C, Amer O, Combe E C. Characteristics of visible-light-activated composite systems. Br Dent J 1984; 156: 209-215.

Cramer N B, Stansbury J W, Bowman C N. Recent advances and developments in composite dental restorative materials. J Dent Res 2011; 90: 402-416.

Ganster B, Fischer U K, Moszner N, Liska R. New Photocleavable Structures. Diacylgermane-Based Photoinitiators for Visible Light Curing. Macromolecules 2008; 41: 2394-2400.

Ganster B, Fischer U K, Moszner N, Liska R. New Photocleavable Structures, 4: Acylgermane-Based Photoinitiator for Visible Light Curing. Macromol Rapid Commun 2008; 29: 57-62.

Moszner N, Fischer U K, Ganster B, Liska R, Rheinberger V. Benzoyl germanium derivatives as novel visible light photoinitiators for dental materials. Dent Mater 2008; 24: 901-907.

Moszner N, Zeuner F, Lamparth I, Fischer U K. Benzoylgermanium Derivatives as Novel Visible-Light Photoinitiators for Dental Composites: Benzoylgermanium Derivatives as Novel Visible-Light Photoinitiators. Macromol Mater Eng 2009; 294: 877-886.

Cramer N B, Stansbury J W, Bowman C N. Recent Advances and Developments in Composite Dental Restorative Materials. J Dent Res 2011; 90: 402-416.

Menees T S, Lin C P, Kojic D D, Burgess J O, Lawson N C. Depth of cure of bulk fill composites with monowave and polywave curing lights. Am J Dent 2015; 28: 357-361.

Ilie N, Bucuta S, Draenert M. Bulk-fill resin-based composites: an in vitro assessment of their mechanical performance. Oper Dent 2013; 38: 618-625.

Price R B T, Felix C A, Andreou P. Third-generation vs a second-generation LED curing light: effect on Knoop microhardness. Compend Contin Educ Dent 2006; 27: 490-496; quiz 497, 518.

Ilie N, Hickel R. Can CQ be completely replaced by alternative initiators in dental adhesives? Dent Mater J 2008; 27: 221-228.

Schneider L F J, Pfeifer C S C, Consani S, Prahl S A, Ferracane J L. Influence of photoinitiator type on the rate of polymerization, degree of conversion, hardness and yellowing of dental resin composites. Dent Mater 2008; 24: 1169-1177.

Schneider L F J, Consani S, Sakaguchi R L, Ferracane J L. Alternative photoinitiator system reduces the rate of stress development without compromising the final properties of the dental composite. Dent Mater 2009; 25: 566-572.

Arikawa H, Takahashi H, Kanie T, Ban S. Effect of various visible light photoinitiators on the polymerization and colour of light-activated resins. Dent Mater J 2009; 28: 454-460.

Price R B T, Felix C A, Andreou P. Evaluation of a dual peak third generation LED curing light. Compend Contin Educ Dent 2005; 26: 331-332, 334, 336-338 passim; quiz 348.

Yearn J A. Factors affecting cure of visible light activated composites. Int Dent J 1985; 35: 218-225.

Della Bona A, Benetti P, Borba M, Cecchetti D. Flexural and diametral tensile strength of composite resins. Braz Oral Res 2008; 22: 84-89.

Watts D C. Reaction kinetics and mechanics in photo-polymerised networks. Dent Mater 2005; 21: 27-35.

Emami N, Soderholm K-J M. How light irradiance and curing time affect monomer conversion in light-cured resin composites. Eur J Oral Sci 2003; 111: 536-542.

Lovell L G, Lu H, Elliott J E, Stansbury J W, Bowman C N. The effect of cure rate on the mechanical properties of dental resins. Dent Mater 2001; 17: 504-511.

Torno V, Soares P, Martin J M H, Mazur R F, Souza E M, Vieira S. Effects of irradiance, wavelength, and thermal emission of different light curing units on the Knoop and Vickers hardness of a composite resin. J Biomed Mater Res B Appl Biomater 2008; DOI: 10.1002/jbm.b.30929.

Zach L, Cohen G. Pulp response to externally applied heat. Oral Surg Oral Med Oral Pathol 1965; 19: 515-530.

Baldissara P, Catapano S, Scotti R. Clinical and histological evaluation of thermal injury thresholds in human teeth: a preliminary study. J Oral Rehabil 1997; 24: 791-801.

Vandewalle K S, Roberts H W, Tiba A, Charlton D G. Thermal emission and curing efficiency of LED and halogen curing lights. Oper Dent 2005; 30: 257-264.

Asmussen E, Peutzfeldt A. Temperature rise induced by some light emitting diode and quartz-tungsten-halogen curing units. Eur J Oral Sci 2005; 113: 96-98.

Funding

None.

Author information

Authors and Affiliations

Contributions

Dr Neenu Francis, Dr Rakesh R. Rajan, Dr S.Vijay Kumar: conceptualisation and article screening. Dr Neenu Francis, Dr Vineetha Karuveetil: methodology and statistical analysis. Dr Neenu Francis, Dr Rakesh R. Rajan, Dr Anju Varughese, Dr C. M. Sapna: writing - original draft, writing - review and editing.

Corresponding author

Ethics declarations

The authors declare none.

Rights and permissions

About this article

Cite this article

Francis, N., Rajan, R., Kumar, V. et al. Effect of irradiance from curing units on the microhardness of composite - a systematic review. Evid Based Dent (2022). https://doi.org/10.1038/s41432-022-0824-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41432-022-0824-z

- Springer Nature Limited