Abstract

An improvement for rock engineering system (RES) coding method is done in this paper by using fuzzy systems. A fuzzy expert semi-quantitative coding methodology is designed to assess the cavability of rock mass within the RES framework. The proposed fuzzy method has the advantage of allowing consideration of uncertainties in the RES analysis by using membership functions in comparison with classic expert semi-quantitative coding method that only unique codes are used to quantify the interaction matrix. Since the cavability of the rock mass is one of the fundamental issues for the caving mining method, the presented improved coding method is creatively used to assess the influencing parameters on cavability of rock mass in block caving mines. Fifteen parameters are considered as the main factors modeling the cavability of the rock mass, and the interactions between these parameters are calculated by proposed fuzzy system. Finally in this paper, the parameters, which are dominant or subordinant, and also the parameters, which are interactive, are introduced. The proposed approach could be a simple but efficient tool in evaluation of the parameters affecting the cavability of rock mass in block caving mines and hence be useful in decision making under uncertainties.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The block caving method is a large-scale and high-intensity mining method, in which the orebody caves by field stress and ore moves by gravity. As the special mechanism in mechanics and technology, an important subject is to determine the orebody cavability in block caving before determining whether to use this mining method. Cavability of a deposit is a function of natural factors such as the geomechanical properties of the rock mass and mining-induced factors. Although the importance of these factors had been recognized for some time and several attempts had been made to codify or quantify their influences [1–3], it was not until the development of Laubscher’s caving chart approach in the 1981s [4] that a method of achieving this became widely available [5]. Although not used in some caving mines, Laubscher’s caving chart [6–9] is the general industry standard method of assessing cavability. Numerical modeling holds the possibility of providing a more fundamental and rigorous assessment of cavability than empirical methods. This approach may have advantages in cases for which current experience is lacking or not well developed [10].

If the cavability of the orebody is not assessed with a reasonable accuracy, expensive and time-consuming measures may be required subsequently to initiate or sustain caving [11, 12]. Therefore, it is of great importance to identify the most significant parameters (and interactions among parameters) that have an influence on the cavability of rock mass and also to identify which parameters (or-interactions) are beneficial for the engineering performance and, conversely, which ones are detrimental for engineering performance.

Rock engineering system, which was first introduced by Hudson in 1992 to deal with complex engineering problems, is one of the most powerful approaches in rock engineering, as it combines adaptability, comprehensiveness, repeatability, efficiency and effectiveness [13]. The main element in the RES method is the interaction. The interaction matrix is the presentational technique for characterizing the important parameters and the interaction mechanisms in a rock engineering system [13]. In this matrix, the main factors are arranged along the main diagonal elements of a matrix and the interrelations between pairs of factors are identified in off-diagonal elements.

Many researches have attempted to develop the RES method in various fields in rock mechanic such as [14–17]. They work on the instability potential of natural slopes and mine slops. Budetta et al. [18] used RES method for landslide hazard mapping. Zhang et al. [19] used rock engineering systems methodology in rockfall hazard assessment. Younessi and Rasouli [20] introduced fracture sliding potential index for wellbore stability analysis using RES method. Faramarzi et al. [21] proposed a new model for prediction of rock fragmentation by blasting based upon the basic concepts of rock engineering systems. Huang et al. [22] presented a new method for automated zonation and classification of rock mass based on rock engineering system and computer programming. Frough and Torabi [23] used the rock engineering systems for estimating TBM downtimes. The main objective of this study is application of RES for calculating geology and rock mass-related downtimes index (GRDi) based on predominant rock mass properties and rock mass-related downtimes.

The RES approach has also been widely applied to various engineering problems, including environmental studies regarding the disposal of spent fuel [24], river catchment pollution [25], forest ecosystems [26], traffic-induced air pollution [27] and risk of reservoir pollution [28].

Quantification of the interaction matrix is one of the most important parts of the RES method. There are several methods to quantify the interaction matrix. One of the mostly used techniques is the “expert semi-quantitative” (ESQ) coding method. In the ESQ coding method, one value is deterministically assigned to each interaction. Therefore, it is implicitly considered that there are no uncertainties when the influence of one parameter on the others is expressed in the matrix. According to this coding technique, the interaction intensity is denoted by integral values from 0 to 4, from “no interaction” to “critical interaction” [29].

The main weakness of this coding method is its great variability of value which is assigned to the classes. As a result, it is unable to explain all mechanisms of the parameters and their relations. Also in this coding method, the values are not always constant, and in the most cases, it is not possible to consider an exact digit-code for the correct particular interaction [30]. This could be due to uncertainties in the assignments of values or even due to uncertainties on the physics of the problem. Therefore, in this study, a novel “Fuzzy ESQ” (FESQ) coding approach is proposed for use within the RES systems framework. In this novel method by using the fuzzy system and parameters membership functions, uncertainties in the assignment of codes are dealt. Finally, the dominant and subordinant parameters and also the interactive parameters in the potential of rock mass cavability are introduced using the proposed fuzzy interaction matrix.

The rest of the paper is organized as follows. The cavability of rock mass is introduced in Sect. 2. In this section, the parameters influencing the cavability of rock mass will be assessed. In the Sect. 3, the fuzzy systems is explained. The Sect. 4 reviews the rock engineering system. After that in Sect. 5 the proposed methodology is investigated where a fuzzy system is designed to quantify the interaction matrix of parameters influencing cavability of rock mass. Section 6 concludes the paper.

2 Cavability of rock mass

Cavability refers to the capability of an in situ rock mass to unravel when undercut and considers all three stages of caving: initiation, propagation and continuous caving [31]. The cavability of an orebody is strongly influenced by the natural properties of the rock mass and is also enhanced by induced features that are directly attributable to the mining process. Predicting the cavability of a rock mass is an area of primary importance in block cave design [32]. The reliable prediction of cavability is critical in determining the undercut dimensions required to initiate and continuously cave an orebody. The cavability of the rock mass will control mine design and economic issues for a given geological environment and is a fundamental issue in establishing successful block caving mines [31].

2.1 Factors influencing rock mass cavability

Cavability of a deposit is a function of natural factors such as the geomechanical properties of the rock mass and mining-induced factors. Pre-mining stresses and rock mass properties fall into the category of natural factors, while induced stresses and mining-related effects are induced factors that influence cavability [31]. In Fig. 1, the main factors affecting the cavability of the rock mass in block caving mines are shown. These factors are selected based on the study of various sources [5, 11, 31, 33].

2.1.1 In situ stress regime and direction

The magnitude and orientation of the regional stress play a significant role in caving [31]. Developing away from the principal stress is advisable in the case of weak ground. The orientation of the principal stress on the sides or the back of the cave opening can be significant [34]. Large horizontal stress acting on the long face would lead to failure, whereas the same stress acting on a circular cave could be stable [10].

Undercutting toward the principal stress will improve the cavability and fragmentation, but could squeeze damage or rockbursts. Developing away from the principal stress is advisable in the case of weak ground. Large horizontal stress acting on a long face leads to failure, whereas the same stress acting on a circular cave could have stabilizing effect [31].

2.1.2 Uniaxial compressive strength (UCS)

Uniaxial compressive strength is one of the most crucial engineering properties of rocks. Rock material strength is used as an important parameter in many rock classification systems. UCS is influenced by many characteristics of rocks such as weathering or alteration rate, micro-cracks and internal fractures, density and porosity [35]. It is clear that cavability of rock mass decreases when the strength of rock mass increases.

2.1.3 Water

Surface and groundwater management is of little concern in some caving operations but is vitally important in others. It is therefore necessary that issues such as the location of surface water paths and storages, rainwater drainage and groundwater hydrology are evaluated in the feasibility study stage. Water in the potential cave zone can assist the cave by reducing friction on joints or with the effect of increased pore water pressure. The source of the water can be the groundwater or the water introduced during the rainy seasons [36].

2.1.4 Discontinuity properties

The properties of the discontinuities include the number of discontinuity sets and their spacing, the orientation of discontinuities with respect to the cave face, the aperture of discontinuities and the persistence of discontinuities.

Determination of discontinuities orientation is one of the most important issues in cavability assessment. Orientation of the in situ stresses with respect to the orientation of the main discontinuity sets is an important consideration in determining the effectiveness of arching and locking-in of rock blocks [11]. Low-angle structures lead to suitable vertical displacement in the rock mass during the mining operation. They can accommodate both shear and gravity failure [5]. Based on the simplistic cave demonstration model which is presented by Sainsbury [37], the following conclusions can be made:

-

Joints that are orientated perpendicular to the direction of draw (i.e., in most cases, horizontal joints) are favorable for cave propagation. The mobilized zone advances vertically at the most rapid rate. In this case, the rate at which the mobilized zone progresses far exceeds the production draw rate.

-

Joints that are orientated parallel to the direction of draw (i.e., in most cases, vertical joints) are not favorable for cave propagation. Minimal displacement of the rock mass is achieved above the mining footprint

-

Joints that are orientated at an angle to the direction of draw result in a preferred cave propagation direction

Filling and persistence of discontinuities have a bearing on the cavability of the rock mass because these properties have an important role in the strength of rock mass [31].

2.1.5 Caving rate

The rate of upward advance of the yield zone is known as the “caving rate.” Block caving is a low-selectivity mining method, and caving rate is the only means of delaying dilution ingress into the broken ore in the cave. The rate of caving can be slowed by controlling the draw as the cave can only propagate if there is space into which the rock can move. Controlling the caving rate significantly affects the caving and fragmentation behavior [34]. Caving rate influences the rock mass quality, induced stresses and the rate of development joints [36].

While the propagation of the cave can be monitored, it is necessary to predict the rate of caving and any anticipated problem [5].

2.1.6 Fragmentation

The overall success and profitability in block caving mines are significantly dependent on the fragmentation of the orebody during caving process. The design and operating parameters influenced by fragmentation include [8]:

-

Drawpoint size and spacing

-

Equipment selection

-

Draw control procedures

-

Production rates and productivity

-

Dilution entry into the draw column

-

Hangups and the need for secondary breakage or blasting with associated costs and damage

-

Subsequent commination processes and costs.

The prediction of rock fragmentation during caving process needs to understand the natural fragmentation of the rock mass and the fragmentation processes that take place in the draw column [34]. The factors that influence fragmentation are as follows [36]:

-

The in situ network of discontinuities as defined by their orientation, size, spacing, condition and termination,

-

The in situ stresses and the stresses induced in the cave face or back (varying with cave height),

-

Rock strengths,

-

Draw column height and residence times.

2.1.7 Block height

Block height depends on the geometry of ore, fragmentation and properties of cap rock. The vertical distance between mining levels will affect the rock mass cavability [11]. Secondary fragmentation of caving material occurs through attrition as the ore is drawn down through the column. Thus, the cavability of ore, cap rock and result of fragmentation influence the determination of optimal block height.

2.1.8 Undercut

Mining the undercut to initiate failure in the cave is extremely important in terms of cavability and ultimate behavior of the rock mass over the early life of the cave. A poor undercut excavation can lead to the formation of pillars, piping or large blocks and could eventually lead to the cave failing to initiate [11]. The direction of advance of undercut into the principal stress direction will influence the magnitude of abutment stresses. Thus, to reduce clamping stresses in the cave back, the undercuts usually are extracted in the direction of the maximum principal stress [5]. In summarizing the nature and importance of undercutting, Butcher has suggested that it has three aims [38].

-

To extract a void of sufficient dimensions to allow caving to occur;

-

To achieve the required undercut dimension to initiate caving with minimum damage to the surrounding rock mass; and

-

To advance (in time as rapidly as possible) to caving hydraulic radius, initiate caving, propagate the cave and consequently reduce undercut abutment stress.

A concave undercut face provides better control of major structures and a more secure undercut level. The cavability of the immediate back will be controlled. If possible, the cave front should not be the advanced structure that could initiate massive wedge failures (Fig. 2) [10].

Favorable and unfavorable undercut directions [10]

2.1.9 Hydraulic radius (HR)

The hydraulic radius is a term used in hydraulics and is a number derived by dividing the area by the perimeter. The hydraulic radius required to ensure propagation of the cave refers to the unsupported area of the cave back, that is, space into which caved material can move. No pillars can be left and caved material must be removed [36].

The maximum area for the minimum perimeter will be achieved with a circle and then a square. The minimum span is a critical dimension in promoting caving and the hydraulic radius caters for it even though the area is the same. In cases where the hydraulic radius of the orebody is borderline and the ratio of maximum span to minimum span to minimum span is high, then a small increase in the minimum span will have a significant influence on the hydraulic radius [33].

3 Fuzzy system

To deal with vagueness of human thought, Zadeh introduced the fuzzy set theory [39], which was oriented to the rationality of uncertainty due to imprecision or vagueness. A major contribution of fuzzy set theory is its capability of representing vague data [40].

Fuzzy systems are knowledge-based or rule-based systems. The heart of a fuzzy system is knowledge based consisting of the so-called fuzzy IF–THEN rules. The basic configuration of a fuzzy system consists of four principal elements: fuzzifier, fuzzy rule base, fuzzy inference engine and defuzzifier. A fuzzy logic system (FLS) can be seen as a function \(f:U \subset R^{n} \to V \subset R\), where U is the input space and V is the output space. The fuzzifier is a mapping from the observed crisp input space \(U \subset R^{n}\) to the fuzzy sets defined in U, where a fuzzy set defined in U is characterized by a membership function \(\mu_{\text{f}} :U \to \left[ {0 ,1} \right]\) and is labeled by a linguistic term. The structure of fuzzy system is shown in Fig. 3.

Schematic diagram of the fuzzy system [41]

The fuzzy rule base is a set of linguistic rules in the form of “if a set of conditions is satisfied, then a set of consequences is inferred.” For an n-input single-output fuzzy system, the fuzzy rule base may consist of the following M rules:

where \(j = 1,2, \ldots ,M\), \(x_{i} \left( {i = 1,2, \ldots ,n} \right)\) are the input variables of the fuzzy system, y is the output variable of the fuzzy system and \(B^{j}\) and \(A_{i}^{j}\) are fuzzy sets. The defuzzifier performs a mapping from the fuzzy sets in the output space V to the crisp points in V [41].

The output of a FLS with singleton fuzzifier, product inference and center average defuzzifier can be written as:

where \(\mu_{{A_{i}^{j} }}\) is the membership function for the fuzzy set \(A_{i}^{j}\) and \(\bar{y}^{j}\) is center of fuzzy set \(B^{j}\).

4 Rock engineering system

The rock engineering systems (RES) approach can be used for the analysis of coupled mechanisms in rock engineering problems [29]. RES method aims to prepare a useful checklist for a rock engineering project. More importantly, it also aims to prepare a framework from which the complete design procedure can be evaluated, leading a rock engineering project to an optimal result [42].

The interactions between parameters in the RES approach are represented using an “interaction matrix” in Fig. 4. In the interaction matrix, all factors influencing the system are arranged along the leading diagonal of the interaction matrix. The influence of each individual factor on any other factor is included at the corresponding off-diagonal position of the matrix, so that the (A, B)-th element represents the influence of parameter A on parameter B.

Principle of the interaction matrix [29]

In principle, there is no limitation to the number of factors that may be included in an interaction matrix.

A more common illustration of a higher-dimensional interaction matrix is shown in Fig. 5. To quantify the importance of the interactions, a coding method is required. The most common approach is the expert semi-quantitative (ESQ) method proposed by Hudson [29]. Typically, coding values between 0 and 4 are employed with ESQ coding schemes as shown in Table 1.

Summation of coding values in the row and column through each parameter to establish the cause and effect coordinates [13]

After coding the matrix, from the matrix construction, the rows and columns of the interaction matrix are added so that each classification category represents the cause and effect of the influence on the entire system. The degree of influence of each classification category (i) on the entire system, as a “cause,” is denoted with \(C_{pi}\), and as an “effect” with \(E_{pi}\). \(C_{pi}\) is specified on the right of each row and \(E_{pi}\) is specified below each column, as illustrated in Fig. 5. The two categories can be expressed in following Eqs. (1 and 2):

where \(a_{ij}\) is the interaction of parameter i on the parameter j which is located on the row ith and column jth in the interaction matrix, and “n” is number of effective parameters.

The effective role of each factor is shown in the cause versus effect diagram (Fig. 6). In this figure, the diagonal of the diagram is the locus of points that have the same value. Along this diagonal and far away from the center of the coordinate system, the summation of cause and effect (C + E) increases. The factors located in the bottom right portion of the diagram are “dominant” in the system. In a similar manner, the “subordinate” factors are defined as those which are highly dominated by the system and are located in the top left corner of the diagram. The cause–effect plot is a helpful tool in understanding the behavior of each factor individually as well as studying the whole system. For example, the points tend to distribute perpendicularly to the C = E diagonal show a low level of interactivity between factors, whereas a high interactivity will result in the points being distributed along the main diagonal line [29].

(C, E) plot comprising N influencing factors for the supposed case [29]

5 Fuzzy ESQ coding method for rock mass cavability assessment

As was mentioned, in the ESQ coding method, one value is deterministically assigned to each interaction. Therefore, it is implicitly considered that there are no uncertainties when the influence of one parameter on the others is expressed in the matrix. Therefore, in this study, a novel “Fuzzy ESQ” (FESQ) coding approach is proposed to overcome this problem.

The first step is to form the interaction matrix between effective parameters on cavability that is shown in Fig. 7. Then, the questionnaires are prepared and experts are asked to specify the value of interaction between each pair of parameters based on Table 1.

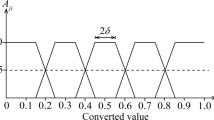

To fuzzify the interaction matrix, for each element of the matrix, the number of each state of interactions based on the expert’s judgment is considered, which are named as n A (number of no interaction), n B (number of weak interactions), n C (number of medium interactions), n E (number of strong interactions) and n F (number of critical interactions). These values are firstly normalized and used as the inputs of the fuzzy system. For each fuzzy system input, two fuzzy sets “Low” and “High” are considered which are shown in Fig. 8. For example, if n A is “High,” it means that most of the experts mentioned there is no interaction, and the probability of mode A (no interaction) is higher.

If the normalized value considered for each element in the interaction matrix is less than 0.4, the membership function value of “Low” set is greater than the membership function of “High” set and vice versa. Selection of “Low” and “High” membership function for each input of fuzzy system depends on the expert’s judgment.

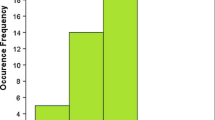

Nine fuzzy sets (m 1 to m 9) are defined for output of the fuzzy system. To better illustrate the intermediate state of the output and to increase the accuracy of it, nine fuzzy sets are considered between 0 and 4. The form of output sets is shown in Fig. 9.

There are five inputs and each input has two modes; 25 rules could thus be defined. A fuzzy system with five inputs, one output and 32 rules is shown in Fig. 10. For example, for the interaction of parameter P 1 (UCS) on P 12 (fragmentation), six persons out of 10 experts filled the questionnaires mentioned “strong interaction,” three persons said “critical interaction” and one person mentioned “medium interaction.” So the normalized value of fuzzy system input would be \(n_{\text{A}} = 0\), \(n_{\text{B}} = 0\), \(n_{\text{C}} = 0.1\), \(n_{\text{D}} = 0.6\) and \(n_{\text{F}} = 0.3\). The rule base is fired as it is displayed in Fig. 11, and the output is equal to 3.16.

Finally, by applying the judgments of experts to the fuzzy system and using fuzzy rules on their views, the fuzzy interaction matrix is formed that is given in Table 2. The cause–effect diagram can be used to identify the dominance and interactive parameters. The parameter interaction intensity (PII) of each parameter can be calculated with the equation \(\left( {C + E} \right)/\sqrt 2\) and the parameter dominance (PD) with \(\left( {C - E} \right)/\sqrt 2\) [29]. Geometrically, PII is the distance of the projection point, of each parameter on the C = E line, to the origin (0, 0), and PD is the distance of the parameter itself to the C = E line (Fig. 12) [22]. The diameter of this graph represents the locus of C = E line. Along this line, the value of (C + E) increases. If the parameter has a large value of (C − E), it is located in the bottom right portion of the diagram and it is “dominant” on the system. Parameters that are affected by the system are located in the top left corner of the diagram and have the smaller value of (C − E). The cause–effect plot is a helpful tool in understanding the behavior of each factor individually as well as studying the whole system. Figure 13 shows the cause–effect diagram of 15 parameters which influence the cavability of rock mass.

View of (C, E) plot to show lines of equal parameter interaction intensity and dominance [22]

It is clear from Fig. 13 that for some parameters position in the (C, E) plot tends to assume positions further away from the diagonal line with equation C = E, therefore, indicating that they have high dominance on the system (when the location of the parameter is on the lower right region; see, e.g., P1, P2 and P4 in Fig. 13); that the system has a dominance on them (when the location of the parameter is on the upper left region; see, e.g., P11, P12 and P15 in Fig. 13); or that they are “neutral” with respect to the system (when the location of the parameter is mainly on the C = E line; see, e.g., P14 and P6 in Fig. 13).

Due to the importance of system interaction, the sum of cause and effect value is selected as the distinguishing factor between parameters. Generally, when the value of interaction of a system is large, the system is potentially unstable. In other words, there is a greater chance that a small change in a parameter greatly affects the system’s behavior [29].

By obtaining the sum and the difference of the causes and effects (C + E, C − E) for each parameter, the interaction intensity histogram for each parameter can be plotted (Figs. 14, 15).

It is clear from the histogram of the interactive intensity versus the parameters (Fig. 14) that the intensity for the majority of the parameters is slightly above the mean value. From all the above, it is concluded that the 15 parameters selected to be the principal ones and acting as a combined set of assessment criteria are all passing the “importance threshold”. Also the interaction intensity histogram shows that in situ stress (P 2) and caving rate (P 11) have the largest interaction in the system, and this means that a little change in these parameters has a significant effect on the system’s behavior.

It is also concluded from C–E histogram (Fig. 15) that the parameter P4 (joint orientation) which has maximum value of C–E dominates the system. This result is also confirmed by Sainsbury research. Sainsbury [37] models the effect of the joint orientation on the cave propagation. The result of the model is shown in the Fig. 16. As shown in Fig. 16, the joint orientation completely affects the cavability system which confirms the results obtained from the FRES model in our paper.

Cave scale model results for varying joint orientations [37]

In addition, based on the cause–effect diagrams of the 15 parameters considered in the presented rock cavability analysis (Figs. 13, 14, 15), the following remarks can be made:

-

The most interactive parameters are the in situ stress (P 2) and caving rate (P 11) which have the maximum value of C + E.

-

The less interactive is the UCS (P 1) which has the minimum value of C + E.

-

The joint orientation (P 4) is the one that dominates the system since it has the maximum value of C − E.

-

The fragmentation (\(P_{12}\)) and the potential cavability (\(P_{15}\)) parameters which have the minimum value of C − E are most dominated by the system.

The results show that all the 14 “input” parameters are rather interactive and have a significant influence on the “outcome” parameter (i.e., cavability potential) so that, therefore, they should be taken into account in the engineering decisions.

6 Conclusion

A fuzzy rock engineering system has been designed to assess parameters influencing cavability of rock mass in block caving mines. The proposed fuzzy coding method has the ability to incorporate uncertainties and variabilities into the analysis of the main factors influencing the cavability and to reduce problems associated with the subjectivity in the coding of interaction matrices for RES analysis.

To assess the cavability 14 parameters were considered as effective factors on the cavability of rock mass, and as a new idea, the rock engineering system was formulated using fuzzy system. So in the first step the fuzzy interaction matrix is created, and then, the values of cause and effect for parameters are calculated. According to the cause–effect diagram and histogram of interactive intensity, the parameters with the highest dominant or subordinant and also the parameters with the highest interactive are identified. Such information has important practical use and, for instance, has implications on site characterization since it allows the designer to identify parameters that should be characterized in more detail in any particular case. For example, results show that the parameter related to in situ stress (P 2) has the highest expected interaction with the system (in other words, the most important parameter), therefore, suggesting the importance of performing a site survey for cavability assessment. This agrees well that experimental data have been used to illustrate how the existence of a high confining stress can inhibit failure and caving of the rock mass. Similarly, “hydraulic radius” and “caving rate” have also been found to be quite significant parameters. Also joint orientation has more effects on systems (dominate parameter), while the fragmentation and the potential cavability parameters are most dominated by the system (subordinant parameter). From all the results, it can be concluded that the presented fuzzy ESQ coding method has good performance in assessment of effective parameters in cavability and well covered the uncertainties and experts disagree in the interactions between parameters.

References

Coates D (1970) Rock mechanics principles: mines branch monographs, American Society Photogrammetry

McMahon B, Kendrick R (1969) Predicting the block caving behavior of ore bodies. SME-AIME preprint, No. 69-AU-51, Society of Mining Engineers of the American Institute of Mining, Metallurgical, and Petroleum Engineers, Inc., New York, pp 1–15.

Mahtab MA, Bolstad DD, Kendorski FS (1972) Analysis of the geometry of fractures in San Manuel Copper Mine, Arizona, vol 7715. US Dept. of Interior Bureau of Mines, Washington, DC

Laubscher D (1981) Selection of mass underground mining methods. In: Stewart D (ed) Design and Operation of Caving and Sublevel Stoping Mines, Chap 3, SME-AIME, New York, pp 23–38

Laubscher DH (2000) A practical manual on block caving. Julius Kmttschnitt Mineral Research Centre, Brisbane

Diering J (1987) Practical approach to the numerical stress analysis of mass mining operations. In: Mining Latin America/Minería Latinoamericana, Springer, Netherlands, pp 87–99

Laubscher DH (1990) A geomechanics classification system for the rating of rock mass in mine design. JS Afr Inst Metall 90(10):267–273

Laubscher DH (1994) Cave mining—the state of the art. J South Afr Inst Min Metal 94(10):2279

Laubscher D (2001) Cave mining—the state of the art. Underground mining methods: engineering fundamentals and international case studies society of mining, metallurgy and exploration, 8307 Shaffer Parkway, Littleton, CO 80127, USA, pp 455–463

Brown E (2003) Block caving geomechanics (international caving study I, 1997–2000). University of Queensland, JKMRC monograph series in mining and mineral processing, Brisbane

Kendorski FS (1978) Cavability of ore deposits. Min Eng 30:628–631

Van As A, Jeffrey R (2000) Hydraulic fracturing as a cave inducement technique at Northparkes Mines. In: Proceedings MassMin, pp 165–172

Hudson J, Harrison J (1992) A new approach to studying complete rock engineering problems. Q J Eng Geol Hydrogeol 25(2):93–105

Jiao Y, Hudson JA (1995) The fully-coupled model for rock engineering systems. Int J Rock Mech Min Sci Geomech Abstr 32(5):491–512

Jiao Y, Hudson J (1998) Identifying the critical mechanisms for rock engineering design. Geotechnique 48(3):319–335

Shang Y, Wang S, Li G, Yang Z (2000) Retrospective case example using a comprehensive suitability index (CSI) for siting the Shisan-Ling power station, China. Int J Rock Mech Min Sci 37(5):839–853

Rozos D, Pyrgiotis L, Skias S, Tsagaratos P (2008) An implementation of rock engineering system for ranking the instability potential of natural slopes in Greek territory. An application in Karditsa County. Landslides 5(3):261–270

Budetta P, Santo A, Vivenzio F (2008) Landslide hazard mapping along the coastline of the Cilento region (Italy) by means of a GIS-based parameter rating approach. Geomorphology 94(3):340–352

Zhang L, Yang Z, Liao Q, Chen J (2004) An application of the rock engineering systems (RES) methodology in rockfall hazard assessment on the Chengdu-Lhasa Highway, China. Int J Rock Mech Min Sci 41:833–838

Younessi A, Rasouli V (2010) A fracture sliding potential index for wellbore stability analysis. Int J Rock Mech Min Sci 47(6):927–939

Faramarzi F, Mansouri H, Farsangi ME (2013) A rock engineering systems based model to predict rock fragmentation by blasting. Int J Rock Mech Min Sci 60:82–94

Huang R, Huang J, Ju N, Li Y (2013) Automated tunnel rock classification using rock engineering systems. Eng Geol 156:20–27

Frough O, Torabi SR (2013) An application of rock engineering systems for estimating TBM downtimes. Eng Geol 157:112–123

Skagius K, Wiborgh M, Ström A, Morén L (1997) Performance assessment of the geosphere barrier of a deep geological repository for spent fuel: the use of interaction matrices for identification, structuring and ranking of features, events and processes. Nucl Eng Des 176(1):155–162

Matthews M, Lloyd B (1998) The river test catchment surveillance project. South Water Utilities Final Research Report, Department of Civil Engineering, University of Surrey, UK

Velasco H, Ayub J, Belli M, Sansone U (2006) Interaction matrices as a first step toward a general model of radionuclide cycling: application to the 137 Cs behavior in a grassland ecosystem. J Radioanal Nucl Chem 268(3):503–509

Mavroulidou M, Hughes SJ, Hellawell EE (2007) Developing the interaction matrix technique as a tool assessing the impact of traffic on air quality. J Environ Manag 84(4):513–522

Condor J, Asghari K (2009) An alternative theoretical methodology for monitoring the risks of CO2 leakage from wellbores. Energy Procedia 1(1):2599–2605

Hudson JA (1992) Rock engineering systems, theory and practice. Ellis Horwood, Chichester, UK

Yang Y-J, Zhang Q (1998) The application of neural networks to rock engineering systems (RES). Int J Rock Mech Mining Sci 35:727–745

Mawdesley C (2002) Prediction rock mass cavability in block caving mines. PhD Thesis. University cf Queensland

Lorig LJ, Board MP, Potyondy DO, Coetzee MJ (1995) Numerical modelling of caving using continuum and micro-mechanical models. In: CAMr95:3rd Canadian conference on computer applications in the minerals industry, Montreal, Canada

Brown ET (2007) Block caving geomechanics: international caving study 1997–2004. Julius Kruttschnitt Mineral Research Centre, The University of Queensland, Brisbane

Brady BHG, Brown ET (2004) Rock mechanics for underground mining. Springer, Berlin

Bieniawski ZT (1989) Engineering rock mass classifications. Wiley, NewYork, NY

Laubscher DH (2003) Cave mining handbook. De Beers, Johannesburg

Sainsbury B-A (2012) A model for cave propagation and subsidence assessment in jointed rock masses. The University of New South Wales, Sydney

Butcher R (2000) Block cave undercutting–aims, strategies, methods and management. Proc Massmin 2000:405–411

Zadeh LA (1965) Fuzzy sets. Inf Control 8(3):338–353

Zimmermann H-J (2001) Fuzzy set theory—and its applications. Springer, Berlin

Klir GJ, Yuan B (1995) Fuzzy sets and fuzzy logic, vol 4. Prentice Hall, New Jersey

Latham J-P, Lu P (1999) Development of an assessment system for the blastability of rock masses. Int J Rock Mech Min Sci 36(1):41–55

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rafiee, R., Ataei, M., KhaloKakaie, R. et al. A fuzzy rock engineering system to assess rock mass cavability in block caving mines. Neural Comput & Applic 27, 2083–2094 (2016). https://doi.org/10.1007/s00521-015-2007-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-015-2007-8