Abstract

Companies collect their used products and use them again to enhance their environmental and social profiles besides obtaining profit from using them again in the forward flow. By adding collecting and handling products at the end of their lifecycle in the context of reverse logistics, companies create closed-loop supply chains. The processes of a network can be sustainably optimized by adjusting the performance of its different facilities regarding sustainability dimensions. In circumstances that there is more than one facility on a specific level, they can be prioritized by different means such as multi-criteria decision-making or risk assessment techniques. In evaluating facilities with each method, some criteria might not be addressed appropriately, so combining these methods can produce a satisfactory answer. In this study, the performance level of each collection center regarding the sustainability of their performance and the risk associated with their operations in a reverse steel supply chain is evaluated. For this aim, the Failure Mode and Effects Analysis, Fuzzy Analytic Network Process, and Fuzzy Technique for Order of Preference by Similarity to Ideal Solution have been integrated. The main contribution of this study is addressing the performance level of collection centers, as a vital facility in reverse logistics, from both operational and risk aspects considering sustainability dimensions. The applicability of the suggested methodology is demonstrated through its application in a steel manufacturer in the north of Iran, and the required sensitivity analyses are presented. Finally, managerial insights are discussed to enhance the performance of collection centers.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

One of the most critical materials used in engineering and construction is steel (Nezamoleslami and Hosseinian 2020). Regarding the characteristics of this product, it can be used again after the end of its lifecycle, adding reverse logistics to a supply chain and creating a closed-loop supply chain (Conejo et al. 2020). Because of reasons such as the pollution caused to the water, soil, and air during the operation of facilities in a reverse supply chain, and the social benefits incorporated with it, researchers intend to optimize a supply chain sustainably (Pourmehdi et al. 2020). The process of sustainably optimizing the performance of a supply chain can be amended by adjusting the performance level of different facilities of the network. In this regard, researchers evaluated the performance level of suppliers to have a sustainable supply chain (Li et al. 2020). In reverse logistics, one of the most important facilities is the collection center, which should be sustainably selected to have a sustainable reverse logistics system.

In the process of evaluating and prioritizing facilities, some criteria might not be addressed appropriately. Many criteria could be considered to appraise the performance level of different alternatives with multi-criteria decision-making (MCDM) approaches. However, some criteria might be more appropriately addressed as a risk parameter (Lo et al. 2020). Hence, combining these methods could produce a thorough answer. Many studies evaluate the risk associated with different activities of a cooperation or supply chain to have a low-risk performance (Liu et al. 2017). Also, risk parameters can have an influence on the performance of a supply chain, aiming to reach its sustainability goals (Harclerode et al. 2016). Since in real problems, some criteria might have connections with each other and could have an influence on other criteria, their weight should be calculated appropriately (Keramati and Salehi 2013). In this regard, the method used for calculating the given weight to the criteria in this study is the Fuzzy Analytic Network Process (FANP). This study also uses the Fuzzy Technique for Order of Preference by Similarity to Ideal Solution (FTOPSIS) as a part of its solution approach. FTOPSIS is one of the most practical techniques used for appraising the performance of different alternatives that address the uncertainty in the opinion of decision-makers (Alguliyev et al. 2020; Feng et al. 2020b). Finally, this study integrated the mentioned method with Failure Mode and Effects Analysis (FMEA) to have a thorough evaluation of the performance level of collection centers.

The motivation behind considering experts' opinions as fuzzy numbers is the existing uncertainty in their opinions and the extensive use of fuzzy numbers in the literature (Liu et al. 2018; Ali et al. 2019; Feng et al. 2020a), indicating their validation. Also, to better address the interrelation of criteria, the FANP is used for calculating their weights as a reliable method. Moreover, the repetition in the use of FTOPSIS and FMEA in the literature indicates their validation. Since both the performance level and the risk associated with the operation of collection centers should be addressed for an overall evaluation, the integration of these methods is considered for addressing this issue. Moreover, some of the criteria could be considered from different perspectives, which are addressed using different approaches. Also, since the final result of each of these methods is a number showing the scores that each collection centers got based on the considered criteria in each method, they could be incorporated with each other to find the final ranking of each center.

The remainder of this study is organized as follows. The literature review is presented in Sect. 2. Section 3 thoroughly introduces the research methodology. The case study and the solution process are explored in Sect. 4. Section 5 represents the sensitivity analysis and managerial insights. Finally, the conclusion and potential future research areas are presented in Sect. 6.

2 Literature review

Evaluating collection centers has not been investigated in many studies. In some studies that considered the performance level of collection centers, the evaluation process was not considered thoroughly for presenting sustainable and low-risk solutions. The studies that somehow analyzed the performance of collection centers are stated in the following.

Pochampally and Gupta (2004) investigated the selection of collection centers in one of the two parts of their study. They evaluated the success of the operations of collection centers from three points of view, including consumers with the main concern of convenience, government officials with the primary concern of environmental effects, and supply chain managers with the prime concern of profit. Paydar et al. (2017) used the FMEA method to calculate the risk associated with the collection process in a reverse engine oil supply chain. They considered the associated risk of the collection as an objective function in their study. Cheraghalipour et al. (2017) considered collection center selection as part of their research in a reverse supply chain that collects effete tire and ball bearings of cars. They used a hybrid Fuzzy Decision-Making Trial and Evaluation Laboratory (FDEMATEL) and evaluation of qualitative and quantitative data to evaluate collection centers, considering security, transportation conditions, costs, and environmental conditions as criteria. In the latest study associated with collection center selection, Tosarkani and Amin (2018) examined the performance level of recovery centers in a reverse battery supply chain. They used the FANP to measure the environmental effects of recovery centers.

Since there is a resemblance between collection centers and circular suppliers, the studies that evaluated the performance level of circular suppliers are also mentioned in the following. Combining the circular economy and supply chain management obliges suppliers to deliver raw materials that are retrievable and would not have adverse impacts on the environment (Zhu et al. 2010). Prosman and Sacchi (2018) analyzed the performance of suppliers in the cement industry through usability, transport, and affected handling activity as the criteria in their evaluation process. A hybrid approach of FANP, FDEMATEL, and multi-objective linear programming model was presented by Govindan et al. (2020) for circular supplier selection considering on-time delivery, quality, and circular criteria. Finally, in one of the latest studies on circular supplier selection, Kannan et al. (2020) used the interval VIKOR approach and fuzzy best–worst method to rank sustainable suppliers in the circular network of the wire-and-cable industry, considering circular, social, and economic criteria.

Some of the most recent studies that utilized each one of the selected approaches in the solution process of this research or their combinations are reviewed here to indicate their validation. The combination of different MCDM approaches is widely applied in different kinds of studies. Analytic Hierarchy Process (AHP) and Analytic Network Process (ANP) are combined with multiple MCDM methods like Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) in various studies, some of which are reviewed in the following. Roy and Dutta (2019) and Dogan et al. (2020) proposed integrating FAHP and FTOPSIS for electro discharge machining process multi-objective optimization and corridor selection for locating autonomous vehicles, respectively. Also, the combination of ANP and TOPSIS has been employed in different problems, such as Abdel-Basset et al. (2018) for sustainable supplier selection problem, Kar and Jha (2020) for evaluating the construction materials’ criticality in the procurement problem, and Agrawal et al. (2020) for software security estimation as a design tactics perspective problem.

Moreover, incorporating the fuzzy sets logic into the MCDM approaches and their combinations is vastly utilized for finding more realistic solutions (Chen et al. 2016; Feng et al. 2019; Deveci et al. 2020). As for showing the flexibility and effectiveness of the selected approach for the risk analysis section, some of the most recent studies that utilized the FMEA approach are reviewed in the following. Nie et al. (2018) proposed the use of the FMEA to guarantee the safety and reliability of supercritical water gasification systems. Shafiee et al. (2019) suggested the use of the FMEA approach for the analysis of subsea blowout preventer systems. Also, the application of FMEA for improving medication safety companied by a systematic review presented by Anjalee et al. (2020) indicated the applicability of this approach in multidisciplinary areas of research. In one of the latest studies using the FMEA, Anjalee et al. (2021) applied this approach to analyze the risk associated with the safety of the production process of Chinese coal-to-methanol enterprises.

The mentioned studies considered the performance of collection centers and the risk associated with their operations independently. Hence, the main contribution of this study is to evaluate the performance of collection centers regarding the dimensions of sustainability and the associated risk in their operations to present a solution for having sustainable and low-risk collection centers and subsequently a reverse logistics system. This is done with the integration of the FANP computing the required weights of criteria, the FTOPSIS calculating the performance level of the collection centers, and the FMEA computing the risk associated with the operation of the centers in a comprehensive manner and finally rank the potential collection centers through their integration.

3 Research methodology

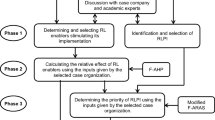

The procedure for evaluating the performance level of each collection center in this study is consists of two main steps. In the first step, the weight of each criterion for both methods of FTOPSIS and FMEA is computed through the FANP approach. In this method, the relations between the criteria are considered to present more realistic weights. After assessing the required weights of criteria, FTOPSIS and FMEA approaches are used to evaluate the performance of the collection centers regarding the economic, environmental, and social aspects and the risk associated with their performance. All of the mentioned approaches require the opinion of experts from the steel industry for their process. The experts are selected based on predetermined requirements: the selected experts should have at least five years of experience in steel supply chain management and be familiar with the concepts of risk management and sustainability. The proposed framework of the research is illustrated in Fig. 1.

3.1 Fuzzy analytic network process (FANP)

Saaty presented the ANP as an extension of the AHP to cope with the interaction and dependence of criteria and sub-criteria, which can influence their weights (Saaty and Vargas 2006). FANP was introduced to address the uncertainty associated with the preference of experts in the pairwise comparison. The steps of the applied FANP for calculating weights of criteria are mentioned in the following (Saaty and Vargas 2006):

Step 1: Creating the network of the problem by specifying the relations between different elements of the network.

Step 2: Forming the comparison matrices through pairwise comparison of different related elements of the network using triangular fuzzy numbers based on the scale presented by Saaty. The linguistic term for comparison and the triangular fuzzy number assigned to them are presented in Table 7.

Step 3: Forming the supermatrix.

The weight of each criterion and sub-criterion should be calculated to form the supermatrix. Since the elements of each comparison matrix are in the triangular fuzzy form, the weights are calculated based on the extent analysis method developed by Chang (1996), which consists of the following steps (Meshram et al. 2019).

Step 3.1: Computing the value of the fuzzy synthetic extent for each criterion.

Assume that P is a pairwise comparison matrix:

where

and

Step 3.2: Computing the degree of the possibility for each Si over others.

Step 3.3: Computing the weight of each criterion with the degree of possibility for a convex fuzzy number to be greater than k convex fuzzy numbers.

Step 3.4: Computing the normalized weight vector.

After calculating the weights of each pairwise comparison matrix, the supermatrix can be formed as follows:

Step 4: Computing the final weight vector of each sub-criteria.

3.2 Fuzzy Technique for Order of Preference by Similarity to Ideal Solution (FTOPSIS)

The FTOPSIS method was first introduced by Chen (2000), and after that, it has been widely applied for evaluating alternatives in different situations. This method can rank alternatives based on their proximity or similarity to an ideal solution (Roy and Dutta 2019). The steps of the applied FTOPSIS are mentioned in the following (Alguliyev et al. 2020):

Step 1: Computing the normalized decision matrix (DM).

Assume that D is the normalized fuzzy DM:

Each element of the DM is normalized according to the category of each criterion. Whether the criterion is a benefit or cost one, meaning that an increase in their magnitude is favorable in the first category, and for the second category, the decrease in the magnitude is favorable. Each element of the normalized DM is calculated through the following equations based on their category:

\(d_{ij} = \left( {\frac{{l_{ij} }}{{u_{j}^{ + } }},\frac{{m_{ij} }}{{u_{j}^{ + } }},\frac{{u_{ij} }}{{u_{j}^{ + } }}} \right)\) where \(u_{j}^{ + }\) is the maximum \(u_{ij}\) for benefit criteria

\(d_{ij} = \left( {\frac{{l_{j}^{ - } }}{{u_{ij} }},\frac{{l_{j}^{ - } }}{{m_{ij} }},\frac{{l_{j}^{ - } }}{{l_{ij} }}} \right)\) where \(l_{j}^{ - }\) is the minimum \(l_{ij}\) for cost criteria

Step 2: Computing the weighted normalized DM.

The weight of criterion i is presented as wi, and the weighted normalized DM is calculated as follows:

Step 3: Specifying the fuzzy positive ideal (PI) and negative ideal (NI) solutions.

\(PI = \left( {v_{1j}^{ + } , \ldots ,v_{ij}^{ + } } \right)\) for benefit criteria, \(PI = \left( {v_{1j}^{ - } , \ldots ,v_{ij}^{ - } } \right)\) for cost criteria

\(NI = \left( {v_{1j}^{ - } , \ldots ,v_{ij}^{ - } } \right)\) for benefit criteria, \(NI = \left( {v_{1j}^{ + } , \ldots ,v_{ij}^{ + } } \right)\) for cost criteria

where \(v_{j}^{ + }\) is the maximum \(v_{ij}\), \(v_{j}^{ - }\) is the minimum \(v_{ij}\), and \(i = 1, \ldots ,m\quad j = 1, \ldots ,n\).

Step 4: Computing the distance of each alternative from PI and NI.

The distance between two triangular fuzzy numbers can be computed as follows:

Step 5: Computing the closeness coefficient factor (CC).

Step 6: Prioritizing the alternatives.

Each alternative gets ranked according to the value of its CCj, and due to the nature of the formula for calculating the closeness coefficient, the alternative that has the highest CCj value gets ranked higher in the ranking list.

3.3 Failure mode and effect analysis (FMEA)

FMEA is a well-organized technique, discovering the probable failure modes in a system, facility, or process. It analyzes the potential causes and effects of the failure modes and adopts some measures, diminishing or dismissing the risk of failures (Fang et al. 2020). The first official employment of the FMEA was done due to safety and reliability analysis of the product design phase in the aerospace industry in the 1960s (Huang et al. 2021). Due to the practicability and effectiveness of the FMEA, it has grown to be one of the most frequently used techniques with the goal to identify decisive failure modes, and it has been widely applied in multiple areas of research, such as healthcare systems (Dağsuyu et al. 2016; Anjalee et al. 2021), manufacturing systems (Bhuvanesh Kumar and Parameshwaran 2018; Lo et al. 2020), and supply chain management (Mangla et al. 2018; Wan et al. 2019; Alizadeh et al. 2020).

The process of risk measurement according to FMEA is mentioned in the following (Li and Zeng 2016). The first step in evaluating the risk associated with the operations of a facility or a procedure based on FMEA is to determine the risk criteria through the information about the specified operation or facility. The next step is determining three aspects of risk, including severity, occurrence, and detection, based on the scheme proposed by Li and Zeng (2016), which has a 1–10 point scale. The general evaluation scheme is presented in Table 8.

The final step in the FMEA approach is computing the risk priority number (RPN) to rank the alternatives. Assume that S, O, and D represent the ranking numbers for severity, occurrence, and detection, respectively. The 10-point scale measures each risk factor, where 10 represents the most severe or frequent case or the least detectable case. The larger RPN score indicates greater risks threatening the processes of the system. The formula for calculating the RPN is mentioned in the following (Li and Zeng 2016; Paydar et al. 2017).

4 Case study

The applicability of the presented methodology is evaluated through a real case study in a reverse steel supply chain that intends to choose the collection centers with the best performance level and lowest risk among the existing ones regarding the dimension of sustainability. The manufacturer of the considered case produces steel billets, and the production of steel billets requires scrap, which is the final product of the steel supply chain itself. Since the scrap is the final product of the steel supply chain, using it requires adding reverse logistics to the classic supply chain, forming a closed-loop supply chain. In a classic supply chain, supplier selection is an integral part of reaching sustainability. Like suppliers, in reverse logistics, collection center selection can significantly affect the sustainability of a reverse supply chain. Currently, decision-makers select collection centers based on the final price of scrap, comprised of transportation cost and the price of scrap, and purchase history, which is not a sustainable and scientific approach. Because of the privacy measure of the investigated manufacturer, the names of the collection centers are not expressed clearly. Instead of their names, they are presented by a number.

Moreover, the mentioned requirements for selecting the experts led to choosing four experts from the considered manufacturer and three academic researchers that had experience with the mentioned topics. Two of the experts were production managers of the considered company with six and nine years of experience. The other two were the production planner and a member of the research and development department of the company, with eight and five years of experience, respectively. The selected academic researchers were actually three professors from the most prestigious universities in Iran, each of whom with more than ten years of experience in research on sustainability dimensions of supply chains.

4.1 Sustainability criteria

Determining the critical sustainable criteria regarding the characteristics of the case study is one of the initial steps in the process of collection center prioritization and selection. Therefore, the attendance of the experts held a meeting and introduced the selected criteria regarding three aspects of sustainability. The criteria, a short description, and the method within which they are used are mentioned in Table 1. Since there is a small similarity between the operation of suppliers and collection centers, some of the more frequent criteria used in supplier selection that can be considered in collection center selection are adopted from research regarding steel supplier selection (Azimifard et al. 2018). Some other unique criteria cited in the following such as soil pollution (Barbosa et al. 2020) were chosen regarding the characteristics of the problem and the experts' opinion. The method column of the following table represents the method within which the mentioned criterion is used. The applicability of a criterion in a method is determined regarding the nature of that criterion, meaning that the experts were asked to determine which criterion would be better presented as a risk criterion or performance evaluation criterion. They were supposed to answer this question regarding the description of each criterion and their own experience. The specification of the method means that the determined criterion can be better addressed in the specified method. When a criterion is considered in both methods, it means that the criterion is addressed regarding its performance and the risk associated with its operations.

4.2 Determining the weights of the criteria

The weight of each criterion for both the FTOPSIS and FMEA is calculated through the FANP method explained in Sect. 3.1. The networks designed for each approach and the relation between criteria and sub-criteria are illustrated in Fig. 2. The pairwise comparison matrices are formed considering the relation of criteria and sub-criteria specified in the presented network for each method.

Table 9 illustrates a single comparison matrix filled with the experts' opinions for the calculation of weights of criteria in the FMEA approach. The calculating of the weight of each sub-criteria with regard to their criterion is done based on the four steps of the extent analysis method, which is explained in detail in Sect. 3.1. After computing weights from comparison matrices according to the structure of networks and applying the final step of FANP, the final weight of each sub-criterion for each method would be determined. The final weights of sub-criteria for FTOPSIS and FMEA are presented in Tables 2 and 3, respectively.

4.3 Evaluation of the performance level of collection centers

In order to evaluate the performance level of each collection center regarding the dimensions of sustainability, the FTOPSIS method has been used. In this part, it is assumed that all of the sub-criteria are benefit criteria, and the experts have been asked to score the performance of each collection center in each sub-criteria based on the linguistic terms mentioned in Table 7. After collecting the experts' opinions, converting them to fuzzy numbers, and computing their average, the initial DM is formed. The initial DM should be normalized based on the method explained in Sect. 3.2. The normalized DM is represented in Table 10.

After multiplying the determined weights to the normalized DM and applying steps 2–5 of FTOPSIS, the distance of each alternative from the PI and NI solutions and the closeness coefficient would be available, which can be used for ranking the collection centers. The closeness coefficient factor and the ranking of collection centers based on the FTOPSIS method are shown in Table 4.

4.4 Evaluating the associated risk with the performance of collection centers

Since some of the criteria are not appropriately addressed in MCDM methods, and it could be better to consider them as risk criteria, the FMEA method has been chosen to calculate the risk associated with the operation of collection centers. FMEA scheme for the cost, and the determined rank of severity, occurrence, and detection of each criterion according to experts' judgment are illustrated in Tables 11 and 12, respectively.

After calculating the risk of each criterion by the mentioned formula in Sect. 3.3 and multiplying the weight of each criterion to the RPN of that criteria, the final risk of purchasing scrap from each collection center would be calculated. The RPN of each criterion and collection center, the total risk, and the rank of each collection center based on the FMEA method are shown in Table 5.

4.5 The final ranking of collection centers

Each of the MCDM and risk assessment methods consider a single aspect of the problem, so they should be considered simultaneously to properly evaluate the performance level of each collection center and present a thorough ranking. It means that the final results of both methods for ranking the facilities should be used to rank them. Before using the final results of the FTOPSIS and FMEA, they should be converted to the same kind of criteria. The closeness coefficient factor is a benefit criterion. The total risk is a cost criterion that should be converted to benefit criteria, so their multiplication produces the final score of collection centers. The total risk calculated for the operation of each collection center is a number between zero and one. Hence, to convert the risk criterion, the number one should be subtracted by the total risk, so it represents a benefit criterion. The benefit criteria for risk can be called reliability. The lower the risk, the higher the reliability, meaning that a collection center performs more efficiently. The final ranking of collection centers is presented in Table 6, and the ranking of collection centers based on each method is illustrated in Fig. 3, where TRi is the total risk, and Ri is reliability.

As illustrated in Fig. 3, evaluating collection centers separately with FTOPSIS or FMEA method presents a different ranking. These different priorities show that each method has a disadvantage in some areas, meaning that the selected collection center based on a single method would not operate in the best way possible. However, when the two approaches are integrated for selecting collection centers, all of the necessary criteria would be considered in the evaluation process, presenting an answer that thoroughly shows the performance level of collection centers. The ranking presented by the integration of MCDM and risk assessment approaches specifies the collection center with the best condition.

5 Sensitivity analyses and managerial insights

The sensitivity analyses on the effects of the method used for computing the weights of the criteria and the performance level of collection centers with and without consideration of sustainability aspects are presented in this section. Three approaches are proposed for evaluating the effectiveness of the methods used for computing the weights of criteria and their influence on the final ranking of collection centers. In the first case, it has been assumed that all of the criteria have equal weights, and in the second case, the weights are calculated through the FAHP method. Finally, the primary approach used in this study, which calculates the weight of criteria by the FANP method, is assumed to be the third case. The final ranking of collection centers in the three mentioned situations is presented in Fig. 4.

As shown in Fig. 4, the weight of each criterion can have a significant effect on the final ranking of collection centers. Because of that, the method used for this goal should be appropriately selected. Assuming that the weight of each criterion is equal to other criteria is unrealistic, and since experts should ascertain the importance of criteria, the FAHP is one of the methods that come into mind. Even though FAHP can produce more realistic weights for criteria, some relations and dependencies to other criteria are neglected in evaluating weights with this method. Finally, FANP was chosen for computing the required weights so they would represent more sensible weights.

Three different cases are investigated to evaluate the effects of sustainability dimensions on the final ranking of collection centers. In the first case, solely the economic criterion is addressed, and in the second one, the green criterion is added to the problem meaning that the environmental and economic criteria are considered concurrently. Finally, the third case, which is the main problem solved in this study, ranks collection centers based on all three sustainability dimensions. In all three mentioned cases, both the FTOPSIS and FMEA are used simultaneously, and the method used for computing weights of criteria is FANP. The final ranking of collection centers in the three mentioned circumstances is presented in Fig. 5.

According to Fig. 5, the final ranking of collection centers differs in situations where one, two, or all sustainability dimensions are taken into account in evaluating the performance of collection centers. In each of the cases mentioned above, the weights of criteria are recalculated regarding the considered criteria used for ranking, affecting the weights by eliminating some criteria and the relation of those criteria to the existing ones.

5.1 Managerial insights

Solving the proposed model and analyzing the effects of different circumstances on the final weight of criteria and the final ranking of collection centers could be used in presenting insights for the managers that intend to enhance the operation of their organization. The result of this study singled out the criteria that have the most significant effects on the final result and implied that by implicating some precaution measures, the performance level of collection centers could be improved.

-

The final result of computing the weights of criteria for the TOPSIS method shows the significance of rights of employee, quality, and carbon footprint in the social, economic, and environmental aspects of the performance of collection centers, respectively. The score of collection centers can be significantly improved by enhancing their performance in the mentioned criteria. Managers can control the quality of scrap by filtering their suppliers, asking for a lower price for purchasing scrap with lower quality, or improving the holding condition of collected scrap before transferring them. The carbon footprint has a direct correlation with the condition of vehicles used in transportation, and it can be handled by the use of better equipment in the transportation section. Finally, managers can improve the condition of the workplace and offer a small rise to the employees who work better and offer them paid leaves to improve their performance regarding the rights of employees.

-

The weights of criteria show that the most important criteria in economic, environmental, and social aspects of the operation of a collection center based on the FMEA method are cost, water pollution, and safety, respectively. When the managers of a collection center intend to reduce the risk associated with the operation of their organization, they should focus on these criteria. They can do this by filtering their suppliers or reducing the cost associated with the operations of their organization, which can lead to a reduction in the cost of scrap. To reduce the effect of water pollution, they can make a barrier between precipitation and scrap or scrap and the groundwater and rivers. Finally, they can educate their employees and improve safety measures to improve their safety.

-

Managers can have a more comprehensive result by collecting data from the collection centers themselves and asking their opinion about the importance or relation of different criteria. By doing so, they can present more realistic weights for the selected criteria or even add new criteria to the set, which would not have been necessary according to the opinion of current experts. The sensitivity analyses showed that considering the relation between criteria can significantly affect the final ranking of collection centers. Because of that, they should make the process of evaluating the weights of criteria more precise.

-

In situations that collection centers intend to improve their conditions regarding their environmental and social performance, manufacturers can help them by offering the same money that other collection centers ask for scrap. However, they do not intend to improve their condition or even have a good condition regarding environmental and social issues. It is applicable for situations that collection centers with good intentions have limited resources and sell scrap at a reasonable price. This might seem like manufacturers are helping collection centers to operate better, but by looking at the big picture, it is apparent that the final performance of the whole chain would be enhanced.

6 Conclusion

Collection centers are an essential part of reverse supply chains, and managers try to optimize their operations to have more reliable supply chains. Numerous studies have been done concentrating on the supplier selection problem, but few of them did the same thing for collection centers. Since the nature of the operation of these facilities is different, the evaluation of their performance level and risk, mainly the criteria considered in their evaluation, would be different. This research fits among the few studies evaluating the performance level of collection centers, evaluating the performance of collection centers with both the MCDM and FMEA methods to present a practical decision for having a sustainable and low-risk reverse logistics system. This methodology is applied because some criteria are not appropriately addressed in MCDM methods, and risk assessment measures like FMEA can address those criteria more adequately.

To the best of authors’ knowledge, the collection center selection with both the MCDM and risk assessment measures has not been investigated in previous research. Therefore, this study is the first one to investigate the performance of these facilities regarding sustainability aspects through the integration of FANP, FTOPSIS, and FMEA. In order to address the uncertainty in the opinion of experts, the fuzzy sets theory is used in the FANP and TOPSIS approaches. Evaluating the performance level of collection centers only with an MCDM or risk assessment approach might present different final rankings. As presented in this study, the FTOPSIS method determined that the fifth collection centers have the best performance level. However, FMEA estimated that the risk associated with the operation of the eighth collection center would be the lowest, and the integration of these methods specified the eight collection centers as the most reliable collection center. The proposed methodology presents the final ranking of the collection centers giving equal importance to the MCDM and FMEA approaches. Hence, the limitation of this approach could be that the decision-makers cannot assign different weights to each method to analyze the different circumstances. Finally, sensitivity analysis showed both the methods used for computing the weights of criteria, and the sustainability aspects could change the final ranking of collection centers in different ways.

In future research, the performance level of all the facilities and the risk associated with their operations in reverse logistics or closed-loop supply chains can be considered, balancing the different aspects of sustainability. The research can be extended, and a mathematical model can be added to the model, so other parts of a sustainable supply chain can be addressed. Moreover, other criteria besides sustainable criteria in the MCDM and FMEA methods can be added to the evaluation process to have a more comprehensive collection center evaluation. Addressing the opinion of experts using novel fuzzy methods might represent more realistic results. Adding more generic criteria considering a wide range of industries and possibly using questionnaires through the Internet for seeking more experts might also create more generic information and managerial insights for evaluating the performance level of collection centers considering risk.

References

Abdel-Basset M, Mohamed M, Smarandache F (2018) A hybrid neutrosophic group ANP-TOPSIS framework for supplier selection problems. Symmetry 10:226. https://doi.org/10.3390/sym10060226

Agrawal A, Seh AH, Baz A, Alhakami H, Alhakami W, Baz M, Kumar R, Khan RA (2020) Software security estimation using the hybrid fuzzy ANP-TOPSIS approach: design tactics perspective. Symmetry 12:1–21. https://doi.org/10.3390/SYM12040598

Alguliyev R, Aliguliyev R, Yusifov F (2020) Modified fuzzy TOPSIS + TFNs ranking model for candidate selection using the qualifying criteria. Soft Comput 24:681–695. https://doi.org/10.1007/s00500-019-04521-2

Ali MI, Feng F, Mahmood T, Mahmood I, Faizan H (2019) A graphical method for ranking Atanassov’s intuitionistic fuzzy values using the uncertainty index and entropy. Int J Intell Syst 34:2692–2712. https://doi.org/10.1002/int.22174

Alizadeh M, Makui A, Paydar MM (2020) Forward and reverse supply chain network design for consumer medical supplies considering biological risk. Comput Ind Eng 140:106229. https://doi.org/10.1016/j.cie.2019.106229

Anjalee JAL, Rutter V, Samaranayake NR (2021) Application of Failure Mode and Effect Analysis (FMEA) to improve medication safety: a systematic review. Postgraduate Med J. https://doi.org/10.1136/postgradmedj-2019-137484

Azimifard A, Moosavirad SH, Ariafar S (2018) Selecting sustainable supplier countries for Iran’s steel industry at three levels by using AHP and TOPSIS methods. Resour Policy 57:30–44. https://doi.org/10.1016/j.resourpol.2018.01.002

Barbosa JZ, Poggere GC, Teixeira WWR, Motta ACV, Prior SA, Curi N (2020) Assessing soil contamination in automobile scrap yards by portable X-ray fluorescence spectrometry and magnetic susceptibility. Environ Monit Assess 192:46. https://doi.org/10.1007/s10661-019-8025-8

Bhuvanesh Kumar M, Parameshwaran R (2018) Fuzzy integrated QFD, FMEA framework for the selection of lean tools in a manufacturing organisation. Prod Plan Control 29:403–417. https://doi.org/10.1080/09537287.2018.1434253

Chang D-Y (1996) Applications of the extent analysis method on fuzzy AHP. Eur J Oper Res 95:649–655. https://doi.org/10.1016/0377-2217(95)00300-2

Chen C-T (2000) Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Sets Syst 114:1–9. https://doi.org/10.1016/S0165-0114(97)00377-1

Chen SM, Cheng SH, Lan TC (2016) Multicriteria decision making based on the TOPSIS method and similarity measures between intuitionistic fuzzy values. Inf Sci 367–368:279–295. https://doi.org/10.1016/j.ins.2016.05.044

Cheraghalipour A, Paydar MM, Hajiaghaei-Keshtelia M (2017) An integrated approach for collection center selection in reverse logistic. Int J Eng 30:1005–1016. https://doi.org/10.5829/ije.2017.30.07a.10

Conejo AN, Birat JP, Dutta A (2020) A review of the current environmental challenges of the steel industry and its value chain. J Environ Manag 259:109782. https://doi.org/10.1016/j.jenvman.2019.109782

Dağsuyu C, Göçmen E, Narlı M, Kokangül A (2016) Classical and fuzzy FMEA risk analysis in a sterilization unit. Comput Ind Eng 101:286–294. https://doi.org/10.1016/j.cie.2016.09.015

Deveci M, Cali U, Kucuksari S, Erdogan N (2020) Interval type-2 fuzzy sets based multi-criteria decision-making model for offshore wind farm development in Ireland. Energy 198:117317. https://doi.org/10.1016/j.energy.2020.117317

Dogan O, Deveci M, Canıtez F, Kahraman C (2020) A corridor selection for locating autonomous vehicles using an interval-valued intuitionistic fuzzy AHP and TOPSIS method. Soft Comput 24:8937–8953. https://doi.org/10.1007/s00500-019-04421-5

Fang H, Li J, Song W (2020) Failure mode and effects analysis: an integrated approach based on rough set theory and prospect theory. Soft Comput 24:6673–6685. https://doi.org/10.1007/s00500-019-04305-8

Feng F, Fujita H, Ali MI, Yager RR, Liu X (2019) Another view on generalized intuitionistic fuzzy soft sets and related multiattribute decision making methods. IEEE Trans Fuzzy Syst 27:474–488. https://doi.org/10.1109/TFUZZ.2018.2860967

Feng F, Xu Z, Fujita H, Liang M (2020a) Enhancing PROMETHEE method with intuitionistic fuzzy soft sets. Int J Intell Syst 35:1071–1104. https://doi.org/10.1002/int.22235

Feng F, Zheng Y, Alcantud JCR, Wang Q (2020b) Minkowski weighted score functions of intuitionistic fuzzy values. Mathematics 8:1143. https://doi.org/10.3390/math8071143

Govindan K, Mina H, Esmaeili A, Gholami-Zanjani SM (2020) An integrated hybrid approach for circular supplier selection and closed loop supply chain network design under uncertainty. J Clean Prod 242:118317. https://doi.org/10.1016/j.jclepro.2019.118317

Harclerode MA, Macbeth TW, Miller ME, Gurr CJ, Myers TS (2016) Early decision framework for integrating sustainable risk management for complex remediation sites: drivers, barriers, and performance metrics. J Environ Manag 184:57–66. https://doi.org/10.1016/j.jenvman.2016.07.087

Huang G, Xiao L, Zhang G (2021) Risk evaluation model for failure mode and effect analysis using intuitionistic fuzzy rough number approach. Soft Comput. https://doi.org/10.1007/s00500-020-05497-0

Kannan D, Mina H, Nosrati-Abarghooee S, Khosrojerdi G (2020) Sustainable circular supplier selection: a novel hybrid approach. Sci Total Environ 722:137936. https://doi.org/10.1016/j.scitotenv.2020.137936

Kar S, Jha KN (2020) Assessing criticality of construction materials for prioritizing their procurement using ANP-TOPSIS. Int J Constr Manag. https://doi.org/10.1080/15623599.2020.1742637

Keramati A, Salehi M (2013) Website success comparison in the context of e-recruitment: an analytic network process (ANP) approach. Appl Soft Comput J 13:173–180. https://doi.org/10.1016/j.asoc.2012.08.021

Li S, Zeng W (2016) Risk analysis for the supplier selection problem using failure modes and effects analysis (FMEA). J Intell Manuf 27:1309–1321. https://doi.org/10.1007/s10845-014-0953-0

Li F, Wu CH, Zhou L, Xu G, Liu Y, Tsai SB (2020) A model integrating environmental concerns and supply risks for dynamic sustainable supplier selection and order allocation. Soft Comput. https://doi.org/10.1007/s00500-020-05165-3

Liu J, An R, Xiao R, Yang Y, Wang G, Wang Q (2017) Implications from substance flow analysis, supply chain and supplier’ risk evaluation in iron and steel industry in Mainland China. Resour Policy 51:272–282. https://doi.org/10.1016/j.resourpol.2017.01.002

Liu X, Kim HS, Feng F, Alcantud JCR (2018) Centroid transformations of intuitionistic fuzzy values based on aggregation operators. Mathematics 6:1–17. https://doi.org/10.3390/math6110215

Lo HW, Shiue W, Liou JJH, Tzeng GH (2020) A hybrid MCDM-based FMEA model for identification of critical failure modes in manufacturing. Soft Comput. https://doi.org/10.1007/s00500-020-04903-x

Mangla SK, Luthra S, Jakhar S (2018) Benchmarking the risk assessment in green supply chain using fuzzy approach to FMEA: Insights from an Indian case study. Benchmarking 25:2660–2687. https://doi.org/10.1108/BIJ-04-2017-0074

Meshram SG, Alvandi E, Singh VP, Meshram C (2019) Comparison of AHP and fuzzy AHP models for prioritization of watersheds. Soft Comput 23:13615–13625. https://doi.org/10.1007/s00500-019-03900-z

Nezamoleslami R, Hosseinian SM (2020) An improved water footprint model of steel production concerning virtual water of personnel: the case of Iran. J Environ Manag 260:110065. https://doi.org/10.1016/j.jenvman.2020.110065

Nie R, Tian Z, Wang X, Wang J, Wang T (2018) Risk evaluation by FMEA of supercritical water gasification system using multi-granular linguistic distribution assessment. Knowl-Based Syst 162:185–201. https://doi.org/10.1016/j.knosys.2018.05.030

Paydar MM, Babaveisi V, Safaei AS (2017) An engine oil closed-loop supply chain design considering collection risk. Comput Chem Eng 104:38–55. https://doi.org/10.1016/j.compchemeng.2017.04.005

Pochampally KK, Gupta SM (2004) A business-mapping approach to multi-criteria group selection of collection centers and recovery facilities. In: IEEE international symposium on electronics and the environment, 2004. Conference record. 2004. IEEE, pp 249–254. https://doi.org/10.1109/ISEE.2004.1299724

Pourmehdi M, Paydar MM, Asadi-Gangraj E (2020) Scenario-based design of a steel sustainable closed-loop supply chain network considering production technology. J Clean Prod 277:123298. https://doi.org/10.1016/j.jclepro.2020.123298

Prosman EJ, Sacchi R (2018) New environmental supplier selection criteria for circular supply chains: lessons from a consequential LCA study on waste recovery. J Clean Prod 172:2782–2792. https://doi.org/10.1016/j.jclepro.2017.11.134

Roy T, Dutta RK (2019) Integrated fuzzy AHP and fuzzy TOPSIS methods for multi-objective optimization of electro discharge machining process. Soft Comput 23:5053–5063. https://doi.org/10.1007/s00500-018-3173-2

Saaty TL, Vargas LG (2006) Decision making with the analytic network process. Springer, Berlin

Sehra SK, Brar YS, Kaur N, Sehra SS (2019) Software effort estimation using FAHP and weighted kernel LSSVM machine. Soft Comput 23:10881–10900. https://doi.org/10.1007/s00500-018-3639-2

Shafiee M, Enjema E, Kolios A (2019) An integrated FTA-FMEA model for risk analysis of engineering systems: a case study of subsea blowout preventers. Appl Sci (Switzerland). https://doi.org/10.3390/app9061192

Tosarkani BM, Amin SH (2018) A possibilistic solution to configure a battery closed-loop supply chain: multi-objective approach. Expert Syst Appl 92:12–26. https://doi.org/10.1016/j.eswa.2017.09.039

Wan C, Yan X, Zhang D, Qu Z, Yang Z (2019) An advanced fuzzy Bayesian-based FMEA approach for assessing maritime supply chain risks. Transp Res Part E: Logist Transp Rev 125:222–240

Zhu Q, Geng Y, Lai K (2010) Circular economy practices among Chinese manufacturers varying in environmental-oriented supply chain cooperation and the performance implications. J Environ Manag 91:1324–1331. https://doi.org/10.1016/j.jenvman.2010.02.013

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Extra tables

Appendix: Extra tables

See Tables 7, 8, 9, 10, 11 and 12.

Rights and permissions

About this article

Cite this article

Pourmehdi, M., Paydar, M.M. & Asadi-Gangraj, E. Reaching sustainability through collection center selection considering risk: using the integration of Fuzzy ANP-TOPSIS and FMEA. Soft Comput 25, 10885–10899 (2021). https://doi.org/10.1007/s00500-021-05786-2

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00500-021-05786-2