Abstract

Massive plastics production has raised concerns about low recycling rates and disposal of these materials in nature, causing environmental and economic impacts. Poly(ethylene terephthalate) (PET) is one of main polymers used for manufacture of plastic packaging (e.g. bottles, trays). Enzymatic recycling of PET has been a route of increasing study aiming at to recover its monomers (terephthalic acid and ethylene glycol), resulting in a circular production chain. In this study, investigation of pH control and fractionation of enzyme feeding were explored in post-consumed PET (PC-PET) hydrolysis reactions catalyzed by Humicola insolens cutinase (HiC) in stirred reactors. It was found that the unbuffered reaction provided of pH control by 0.5 M NaOH addition showed 2.39-fold improvement in the released monomers (to a total of 26.3 mM), comparatively to the Tris–HCl-buffered reaction. In addition, it was observed a possibility of reducing the enzyme loading used in the process by half, leading to an increase of 2.41-fold in the specific terephthalic acid concentration released per protein amount, whilst maintaining a high products concentration (97 mM). A simplified cost analysis of reaction consumables was performed, and the data reported here demonstrates that these alternative process strategies contribute to costs reduction on the enzymatic depolymerization reactions of PET.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Since the development and industrial production of polymeric materials in the 1950s, their demand has grown exponentially over the years [1]. Plastic production reached 396 million metric tons only in 2016 and it is estimated to increase 40% until 2030 [2]. Food and beverage plastic packages have been a major target of concern, since these materials are generally for single use and then readily discarded after consumption [2, 3]. Due to low recycling rates, the majority of these residues are disposed in landfills or directly leaked into terrestrial and marine ecosystems, causing environmental impacts and economic loss due to waste of monomers present in these packages [4].

Poly(ethylene terephthalate) (PET) is one of the most used polymers for plastic packaging, especially for beverage bottles. Recycling of this polyester can be performed via different routes. Mechanical recycling aims to reprocessing of packages and remodeling them into new materials. However, after each cycle of this process, PET ends up losing some properties (e.g. molar mass, mechanical strength), which limits the application range of the final recycled material [5]. Chemical recycling method aims to depolymerize the PET polymer chain to recapture its initial monomers, terephthalic acid (TPA) and ethylene glycol (EG), but this route operates in harsh conditions and consumes reagents harmful to the environment [6, 7]. Since the discovery of enzymes capable of catalyzing hydrolysis of ester bonds present in the PET chain, enzymatic recycling route has emerged as an environmentally friendly alternative to chemical recycling in order to recapture monomers under mild operating conditions [8].

The enzymes reported so far for this application can be obtained from different microbial sources [9]. Recently, the discovery of PETase—an enzyme produced by the bacterium Ideonella sakaienses that degrades PET to consume its monomers as carbon sources—led to creation of poly(ethylene terephthalate) hydrolases class (EC 3.1.1.101) [10]. However, most of the enzymes described in literature belongs to other groups, such as lipases (EC 3.1.1.3) [11,12,13,14,15], cutinases (EC 3.1.1.74) [16,17,18,19,20,21,22,23] and carboxylesterases (3.1.1.1) [18, 24, 25].

Cutinase from Humicola insolens (HiC) have been shown as a potential thermostable biocatalyst for enzymatic recycling of PET. Ronkvist et al. demonstrated almost complete depolymerization (97% yield) of a PET film sample which presented low crystallinity (7%) [16]. Our previous reports explored the use of this enzyme in depolymerization of assorted post-consumer PET packages processed by mechanical recycling (herein referred as PC-PET), which has higher crystallinity (41.1%) than PET films [15, 26]. In small lab scale, we previously optimized five process variables to improve TPA concentration: PET concentration (80.8 g/L), enzyme loading (0.065 gprotein/gPET), Tris–HCl buffer concentration (397 mM), initial pH (8.95) and temperature (62.6 °C) [26]. Under these conditions, a 19.1% of PET conversion to TPA was reached after 14 days. In addition, the optimized reaction was scaled-up to lab bioreactors and a positive effect of mechanical agitation in hydrolysis rates was observed, increasing 1.5-fold TPA concentration [26].

To advance in the PC-PET recycling technology using HiC, this study aimed to investigate pH control and fractionation of enzyme feeding during reactions in stirred reactors as strategies to further boost TPA concentration released from PET hydrolysis. Also, we investigated reduction of the base-case enzyme loading previously studied, with a look at process costs reduction. A preliminary cost analysis associated to consumables was assessed for these strategies, which is an approach lacking in the literature for PET enzymatic recycling route.

Materials and methods

Materials

TPA and bis(2-hydroxyethyl terephthalate) (BHET) were purchased from Sigma-Aldrich, while mono(2-hydroxyethyl terephthalate) (MHET) was synthetized (> 99% purity) based on controlled hydrolysis reaction of BHET catalyzed by lipase B from Candida antarctica (CALB), as described by Carniel et al. [12]. Recycled post-consumer PET (PC-PET) was used as substrate and has high crystallinity (41.1%) and molar mass (43.38 g/mol), as determined previously by Castro et al. [15]. PC-PET was originated from an industrial scale PET recycling plant. The sample was milled in a knife mill and kindly given by Professor Marcos Lopes Dias (Federal University of Rio de Janeiro, Brazil). The commercial product Novozym 51032 was used as source of Humicola insolens cutinase (HiC). The sample was generously donated by Novozymes (Araucária, Brazil).

Investigation of pH control strategies

The influence of pH maintenance during PC-PET hydrolysis by HiC at the optimal level previously determined was investigated through controlled addition of NaOH or KOH solutions (0.5 M and 5 M). These reactions were carried out in vessels of 1 L (nominal volume), in stirred bioreactors (Multifors 2, Infors HT, Switzerland) at 50 °C and 300 rpm. Two types of reaction solutions were tested: (1) buffered solution with Tris–HCl buffer (397 mM; pH 8.95) and (2) unbuffered alkali water (initial pH 8.95). In both cases, reactions were performed in a final volume of 500 mL containing 80.76 g/L of PC-PET and enzyme loading of 0.065 gprotein/gPET.

Investigation of enzyme feeding strategies

Enzyme feeding study was performed by comparison of two conditions: (1) addition of the whole enzyme loading (0.065 gprotein/gPET) at once in the beginning of the reaction and (2) addition of half of this enzyme loading in the beginning and the other half in the middle of reaction time course. Depolymerization reactions were carried out in 0.5 L vessels (nominal volume) in stirred bioreactors Multifors 2 (Infors HT, Switzerland) at 50 °C and 300 rpm. The reactions contained 300 mL of Tris–HCl buffer (397 mM; pH 8.95) with 80.76 g/L of PC-PET [26].

Investigation of enzyme loading reduction

In order to evaluate the decrease of enzyme amount applied on PC-PET hydrolysis, reactions were performed reducing the previous optimal enzyme loading (0.065 gprotein/gPET) in 50%, 90% and 95%. Assays in triplicate were carried out in 15 mL Falcon tubes with 5 mL reaction volume containing Tris–HCl buffer (397 mM; pH 8.95) and 80.76 g/L of PC-PET. The tubes were incubated in a hybridization incubator (Combi-D24, FINEPCR) at 63 °C and 25 rpm.

Analyses and calculations

Protein concentration was determined according to Bradford method [27].

Concentrations of TPA, MHET and BHET were quantified in a Thermo Scientific Dionex UltiMate 3000 HPLC using a methodology described in our previous reports [12, 15, 26]. Also, EG quantification was determined in an Agilent 1260 Infinity HPLC equipped with Bio-Rad Aminex HPX-87H column (at 65 °C) and detection was performed in a refractive index (RID) cell at 35 °C. 5 mM H2SO4 solution was used as mobile phase, under flowrate of 0.7 mL/min, and sample injection volume was 20 μL.

Sum of hydrolysis products was expressed as TPA, MHET and BHET mole concentrations together. PET conversion to TPA (%) was calculated according to Eq. 1, based on theoretical TPA yield from total depolymerization of PET (0.864 gTPA/gPET). Mole fractions (χi; where i = BHET, MHET or TPA) were expressed as the ratio between molar concentration of one of this products (ni) and the sum of mole concentrations of these three components (Eq. 2). Specific TPA formation from PC-PET hydrolysis by total HiC mass (STPA) was calculated by ratio of TPA mole concentration (nTPA) and total protein added to the reaction (mprot) (Eq. 3):

For consumables cost analysis, Tris base, NaOH and KOH market prices (US$/kg) were obtained in Chemical Book and ECHEMI websites [28,29,30]. Tris mass used in reactions was fixed at optimized molarity buffer, as previously determined [26]. The cost of base used to control pH during hydrolysis reactions (CostpH control) was calculated according to Eq. 4, which is a relation between (1) base mass (mbase) and its price (pricebase) and (2) mass of hydrolysis products (mhydrolysis products = kg of TPA, MHET and BHET released). Costs are presented in US dollars:

Results and discussion

Investigation of pH control strategies

To evaluate impact of pH maintenance on hydrolysis rate during PC-PET depolymerization by HiC, the reactions were firstly performed using optimized conditions determined by Castro et al. [26], except for temperature due to operational limitation of the stirred reactor. Figure 1 illustrates time course of hydrolysis products concentration (TPA, MHET and BHET) and pH variation during Tris-buffered reactions with and without pH control at 8.95 ± 0.20 using NaOH 5 M solution. Table 1 shows the sum of products concentrations and molar fractions at the end of these reactions. In hydrolysis depolymerization without pH control (Fig. 1a), HiC led to total sum of products of 11.0 mM in 96 h and the pH decreased from 8.95 to 8.09, which can be attributed to high TPA release in the medium (χTPA = 0.917). When pH control at optimal pH value was applied during the whole reaction time (Fig. 1b), 14.5 mM of TPA was achieved as sole product (χTPA = 1). Thus, it was found that even a minor pH variation (0.86) is critical for HiC action in PC-PET depolymerization, leading to a decrease of 32% in the sum of final products when optimal pH was not maintained constant.

Time course of pH monitoring (crosses) and hydrolysis products concentrations—BHET (squares), MHET (circles) and TPA (triangles)—released during PC-PET depolymerization catalyzed by HiC in stirred reactor at 50 °C, 300 rpm. Reactions were performed using 80.8 g/L of PC-PET and 0.065 gprotein/gPET in Tris buffer (397 mM; pH 8.95) with a no pH control and b pH control by addition of 5 M NaOH solution

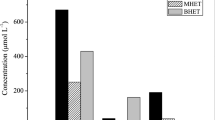

To reduce process costs, the possibility in eliminating buffer use from aqueous system and control the reaction pH by adding NaOH or KOH solutions (0.5 M) was evaluated. Additionally, a hydrolysis reaction without pH control was performed. As shown in Fig. 2a, pH decreased drastically from 8.95 to 5.59 when this parameter was not controlled, while the optimal pH was maintained by adding alkali solutions (Fig. 2b, c). In terms of sum of products released during the time course of the reactions and molar fractions profiles (Table 1), only 7.1 mM of TPA solely (χTPA = 1) were released from reaction without pH control, which resulted in a fast pH variation in the first 24 h of reaction. In contrast, 26.3 mM (χTPA = 0.557; χMHET = 0.423; χBHET = 0.021) was achieved by using pH adjustment with NaOH and 18.3 mM by using KOH (χTPA = 0.683; χMHET = 0.317). Surprisingly, these reactions performed in alkalinized water achieved higher concentrations of hydrolysis products than in the buffered system, even when optimal pH was maintained, with increase of approximately 81% and 26% for the use of NaOH and KOH solutions, respectively (Table 1). It is known that PET can be depolymerized by alkaline hydrolysis in the chemical recycling route using NaOH or KOH solutions (4–20% m/v) under high pressure (1.4–2.0 MPa) and temperatures (210–250 °C) [6]. However, these conditions are far beyond those performed in this study and, therefore, unlikely to have contributed to polymer hydrolysis.

Time course of pH monitoring (crosses) and hydrolysis products concentrations—BHET (squares), MHET (circles) and TPA (triangles)—released during PC-PET depolymerization catalyzed by HiC in stirred reactor at 50 °C, 300 rpm. Reactions were performed using 80.8 g/L of PC-PET and 0.065 gprotein/gPET in unbuffered condition with a no pH control and pH control by adding b 0.5 M NaOH or c 0.5 M KOH solutions

In terms of mole fraction profiles (Table 1), products released from hydrolysis reactions mediated by HiC were very distinct: TPA was almost the absolute product in the reactions without pH control, while there was intense accumulation of MHET and TPA in alkaline water conditions. Also, there was a significant difference in hydrolysis efficiency between conditions using different alkaline solution: reaction with pH adjustment by NaOH yielded 43% more products than the reaction using KOH.

These results suggest a possible modulation in molar fraction profiles and enzymatic hydrolysis rates by variation of ionic type and strength in the reaction medium. As MHET was not accumulated neither at acid pH nor in Tris–HCl buffering, the stability of this reaction products might have been disturbed under these conditions. However, studies on the physicochemical properties of MHET molecule still lacks in the literature to support this hypothesis and this investigation is encouraged.

Protein conformation, solubility, stability and activity are properties that are strictly dependent of several intra- and intermolecular forces such as hydrogen bonds, van der Waals interactions, solvation and polarization effects. Ions play an important role in water system containing proteins by their kosmotropic or chaotropic effects and ability to directly interact with macromolecule surface and water molecules present in first hydration shell of proteins [31]. Therefore, different salts and buffers influence protein behavior and can improve enzyme activity. Pinna et al. demonstrated that adding 2 M of sodium bromide (NaBr) to 5 mM sodium phosphate buffer led to a twofold increment on specific activity of lipase A from Aspergillus niger over p-nitrophenyl acetate, which was attributed to Br− anion adsorption at the enzyme surface [32]. Conversely, these solutes can also inhibit enzymatic activity. Schmidt et al. investigated effects of different buffer compositions and their concentrations on PET films hydrolysis rates catalyzed by two polyester hydrolases: LC cutinase and TfCut2 (from Thermobifida fusca). It was found that high concentrations of Tris and 3-(N-morpholino)propanesulfonic acid) (MOPS) buffers reduced hydrolysis rates for both enzymes, suggesting an inhibitory effect caused by the components of these buffers. This statement was confirmed by molecular docking studies that showed the binding of these molecules near to the catalytic site, interfering on the hydrolase binding to the polymeric substrate [17]. This fact could justify lower hydrolysis products concentration obtained in Tris-buffered reactions than in alkali water conditions (Table 1).

Thus, Tris–HCl buffer could be eliminated from PET enzymatic depolymerization using HiC by adopting pH control using NaOH solution, therefore reducing cost of this recycling process. Caustic soda is widely used for pH maintenance of several industrial processes, which, in our case, is at a moderately alkaline pH (8.95). Although it is known that NaOH can cause corrosive damages to metal industrial equipment (e.g. tanks and pipelines), it mostly occurs under harsh conditions, such as high alkali concentration and temperature [33]. Nonetheless, elimination of this alkali from wastewater is desirable for discharge in order to avoid environmental risks, which can be accomplished by implementing a neutralization step in the process, prior to final disposal. Also, MHET accumulated in this reaction condition must be hydrolyzed because: (1) TPA is the final monomer of depolymerization and main raw material used in industrial PET production and (2) its known inhibitory effect on enzymatic PET hydrolysis rates [19]. For this purpose, the use of ultrafiltration membrane reactor in order to continuously remove inhibitory products from amorphous PET films depolymerization by TfCu2 was investigated by Barth et al., contributing to an increase of 70% on hydrolysis rate over batch reaction mode [34]. Alternatively, our research group identified lipase B from Candida antarctica (product Lipozyme © CALB, Novozymes) as a highly selective biocatalyst for BHET and MHET conversion to TPA and explored its application at 37 °C as a following step to PET bottle hydrolysis catalyzed by HiC at 60 °C. A total depletion of accumulated MHET from reactions was observed after few hours [12, 15]. Barth et al. also proposed a dual enzyme system for amorphous PET films hydrolysis at 60 °C using LC-cutinase or Thermobifida fusca KW3 (TfCut2)—as free polyester hydrolases—, as well as an immobilized carboxylesterase from T. fusca KW3 (TfCa) to promote BHET and MHET hydrolysis from reactions [18]. However, to include one more biocatalyst to the PET depolymerization process could be costly.

Regarding the cost evaluation of pH control strategies during reactions (Table 1), the calculations here presented are based on the consumable mass used to neutralize all hydrolysis products released by HiC until the end of reaction (96 h). Average market price of Tris base, KOH and NaOH were estimated in 8.55 $/kg [28], 1.32 $/kg [30] and 0.46 $/kg [29], respectively. Tris–HCl-buffered conditions showed, by far, the highest costs to control pH, circa 220 $/kg of total products released, and this value is fixed since mass used in the system was independent of released product concentration and related to optimal molarity as described by Castro et al. [26]. However, when pH was controlled in alkali water reactions, the KOH mass addition resulted in a cost of 0.69 $/kg, while the use of NaOH solution showed the cheapest cost: 0.16 $/kg. Furthermore, reactions using NaOH solution achieved the highest released products concentration among all conditions investigated, which makes the use of this consumable the best cost–benefit for PC-PET depolymerization using HiC.

The two conditions with the highest product release and cost–benefit had their samples also analyzed according to EG content. As shown in Fig. 3, TPA and EG concentrations were well correlated (angular coefficient close to 1, with coefficient of determination—R2—also close to 1), despite being quantified under different conditions. This suggests that PET hydrolysis catalyzed by HiC is governed by sequential cleavage of ester bonds, as compared to a random attack of the polyester linkages. Also, the assessment of all main products concentration is of high importance for future process design, including downstream operations.

Correlation of TPA and EG concentrations, released during PC-PET depolymerization catalyzed by HiC in stirred reactor at 50 °C, 300 rpm. Reactions were performed using 80.8 g/L of PC-PET and 0.065 gprotein/gPET in unbuffered condition with pH control by addition of a 0.5 M NaOH or b 0.5 M KOH solutions

Investigation of enzyme feeding strategy

The fractionation of enzyme load feeding during reaction time instead of whole enzyme feeding in the beginning has been reported as a strategy to avoid enzyme deactivation in hydrolytic processes [35, 36]. Thus, it was investigated for PC-PET (initial concentration of 80.76 g/L) hydrolysis using Tris buffer, in stirred reactors at 50 °C. Total enzyme loading (0.065 gprotein/gPET) was fractionated by half: first feed was made in the beginning and the other one in the middle of the reaction time course (48 h). As shown in Fig. 4, similar products releases from PET hydrolysis were achieved in 96 h from both fractioned [10.90 mM of TPA with a release rate of 0.11 mM.h−1 (R2 = 0.997)] and regular [12.67 mM of TPA with a release rate of 0.13 mM.h−1 (R2 = 0.991)] enzyme feeding reactions, resulting in 14% reduction of final products concentration when fractionated enzyme feeding strategy was applied. Mole fractions profiles from both conditions were identical (χTPA = 0.083; χMHET = 0.978) and very similar with mole fractions obtained on previous Tris-buffered reaction without pH maintenance (Table 1).

Time course of hydrolysis products concentrations—BHET (squares), MHET (circles) and TPA (triangles)—released from PC-PET depolymerization catalyzed by HiC in stirred reactor at 50 °C, 300 rpm. Two enzyme feeding strategies were adopted: a 100% enzyme loading addition (0.065 gprotein/gPET) at the beginning of the reaction and b fractionated enzyme addition, being 50% at the beginning and 50% in 48 h. Reactions were performed using 80.8 g/L of PC-PET in Tris buffer (397 mM; pH 8.95)

To evaluate the impact of enzyme loading reduction on PC-PET depolymerization, a comparison of the TPA release rate in the first 48 h of reaction containing 100% of enzyme loading led to 5.54 mM at a rate of 0.12 mM.h−1 (R2 = 0.998), whereas with 50% of enzyme loading also reached a similar TPA concentration value: 5.24 mM at a rate of 0.11 mM.h−1 (R2 = 0.992). These results might suggest a possible limitation of enzyme activity on PC-PET depolymerization.

Enzymatic hydrolysis of PET is defined as a surface erosion process that is strongly influenced by mobility of polymeric chain and accessibility of the substrate to the catalytic site of the enzyme [37,38,39]. The semi crystalline nature of PET provides a heterogeneous distribution of amorphous and crystalline regions through the polymeric matrix [40]. Generally, PET hydrolases show preference to attack amorphous surface areas, due to the less chain mobility restriction, while crystalline areas remain in the final substrate, because they are more recalcitrant to enzyme access and action [9, 16, 39, 41]. To enhance hydrolysis rates, flexibility of surface polymer chains can be stimulated at temperatures close to the glass transition temperature (Tg) of PET in aqueous system (above 60 °C) to improve enzyme accessibility to target chain regions [39, 42]. These experiments were carried out at a temperature of 50 °C, which is below the Tg, and PC-PET is a highly crystalline substrate (41.1%) [15]. So, it is possible that all amorphous area available on polymer surface were already saturated with half of enzyme loading, limiting hydrolysis rate when the second half of enzyme loading was added. In summary, the fractionated enzyme feeding condition did not show a higher yield for PC-PET hydrolysis in this assay, although the results indicate that the enzyme loading variable could still be improved to reduce biocatalyst amount in the process and, therefore, reduce costs.

Investigation of enzyme loading reduction

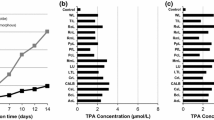

Motivated by the results discussed in previously section, assays with reduced enzyme loading were performed. The relative reduction factors investigated were 50%, 90% and 95% of HiC standard (base-case) loading in PC-PET depolymerization, using Tris buffer at 63 °C for 14 days in a hybridization reactor. Table 2 informs the sum of hydrolysis products, PET conversion to TPA and molar fractions profiles at the end of the reactions, being TPA the major product accumulated in all conditions (χ > 0.959). Figure 5 illustrates TPA concentration released during time course of PC-PET hydrolysis. A total release of 97.1 ± 1.6 mM of total products (χTPA = 0.994) was achieved in 14 days with 50% reduction of enzyme loading. In this condition, 23.0% of PET was converted to TPA, which represents an increase of 20% when compared with reference enzyme loading condition. This result suggests that high enzyme concentration in the reaction could decrease PET hydrolysis. Furukawa et al. already observed decrease of PET degradation rate with higher amounts of PETase adsorbed in low crystallinity films pre-incubated with anionic surfactants [43]. For other enzyme loading reductions, total products concentration and PET conversion to TPA were reduced 39% and 37%, respectively, by reducing enzyme loading ten times, while this decrease almost double when enzyme loading is reduced by 95%: 74% in total products concentration and 73% in PET conversion to TPA.

Time course of TPA concentration released from PC-PET depolymerization catalyzed by HiC with different reductions of standard enzyme loading (0.065 gprotein/gPET—squares) in 50% (diamonds), 90% (circles) and 95% (triangles). Reactions were performed in triplicate in hybridization incubator at 62 °C, 25 rpm, using 80.8 g/L of PC-PET in Tris buffer (397 mM; pH 8.95)

Alternatively, STPA (Eq. 3) was used to express specific TPA concentration released from PET hydrolysis by the amount of protein mass (g) added in each reaction condition (Table 2). Reducing 90% of standard enzyme loading led to 95.9 ± 3.9 mM per gram of protein, which represents an increase of 6.3 and 2.6–fold in comparison to the conditions using the reference enzyme loading and using its half one, respectively. Also, specific cost for TPA release per mass of enzyme was calculated for each condition, considering the standard enzyme loading (0.065 gprotein/gPET) as a normalizer, i.e., the specific cost for this loading was set as 1.00 (Table 2). The 10% of standard enzyme loading condition showed the lowest specific cost (0.16) to obtain TPA per enzyme mass, followed by 5% (0.19) and 50% (0.41). Therefore, reduction of enzyme loading strategy could led up to 84% savings in enzyme mass cost compared to standard enzyme loading condition.

In comparison to the results obtained in fractionated enzyme feeding strategy investigation (48 h—Fig. 4), similar TPA concentrations between standard HiC loading and half of the loading in hydrolysis reactions until 4 days were observed, while 10% and 5% of enzyme loading showed lower TPA concentrations (Fig. 5). Thus, these results support the saturation hypothesis previously discussed about amorphous surface area saturation by HiC. To overcome this limiting condition, increasing surface area of PC-PET particles could be an alternative to promote higher enzyme access to the internal regions of the polymer. Several reports have showed higher hydrolysis rates on enzymatic depolymerization when PET nanoparticles were used as substrate [19, 38, 44, 45]. Herzog et al. pointed a fourfold increment in hydrolysis rates of nanoscale polyester particles catalyzed by lipase from Candida cylindracea when compared to microscale sphere particles, even fixing total surface area available in the reactions. Then, it was suggested that this increase of enzymatic hydrolysis rate probably is also related to physical alteration of crystalline structures of the polymer when particle size was reduced beyond a critical value, as supported by Frank et al. [46], although this physical parameter was not possible to be determined by the authors [38]. The evaluation of of different PC-PET particle sizes (sieved fractions of PC-PET) effect in hydrolysis reactions catalyzed by HiC was also performed, and a tendency was observed: higher TPA concentrations were released as particle size decreased [26]. Even though reduction of particle size promotes higher conversions, the grinding process is an energy consuming step that must be considered in a detailed cost analysis of the enzymatic recycling route.

In addition, enzyme adsorption–desorption has also been recognized as a crucial step for enzymatic depolymerization of water insoluble substrates, such as polyesters, since it is a process limited to the substrate surface [8, 9, 47]. Several reports have shown by molecular docking and site-directed mutagenesis assays that enzyme adsorption probably occurs by affinity interactions between hydrophobic regions located in close vicinity to solvent-exposed catalytic site and the aromatic chain of PET [9, 48,49,50]. Some hydrolytic enzymes involved in depolymerization of natural polymers present specific binding modules on their structures that can act by two mechanisms: (1) increasing enzyme concentration attached on polymer surface and (2) partially disrupting polymer structure in order to produce accessible target sites to hydrolases activity. However, PET hydrolases lack a specific binding domain to PET substrate [9, 51]. Some studies have explored carbohydrate-binding modules (CBM) or polyhydroxyalkanoate-binding modules (PBM) fusions to different cutinases and results showed enhancement in enzyme adsorption and hydrolysis rates over PET substrates [22, 52]. Alternatively, fungal hydrophobins were fused to H. insolens and T. cellulosilytica cutinases and enzyme adsorption/activity were improved by reduction in PET surface hydrophobicity [53, 54]. Furukawa et al. explored the use of long alkyl chain anionic surfactants to polarize PET film surface in order to enhance adsorption of PETase from Ideonella sakaiensis, which displays a cationic polarity close to its active site, increasing PETase activity by 120-fold [43]. Thus, several strategies could still be adopted to improve enzymatic recycling of PC-PET.

Conclusions

In this study, it was demonstrated that unbuffered reaction system with pH control by addition of 0.5 M NaOH solution showed 81% increase in the hydrolysis products (TPA, MHET, BHET) concentrations (reaching a total of 26.3 mM, at 50 °C) as compared to Tris-buffered reaction. The use of the alkali also resulted in a more economical alternative. In addition, enzyme feeding fractionation was not effective to improve PET hydrolysis reaction in the condition studied, showing a reduction of 14% in the products released. However, based on this assay, it was observed that reduction of standard enzyme loading by half led to 1.16-fold increase of hydrolysis products, yielding a total of 83.5 mM (at 63 °C). Therefore, these findings herein reported represent important steps to reduce costs with consumables used in enzymatic PET recycling process.

References

Hamilton A, Scheer R, Stakes T, Allan S (2019) Solving plastic pollution through accountability. https://www.worldwildlife.org/publications/solving-plastic-pollution-through-accountability. Accessed 3 July 2020

Geyer R, Jambeck JR, Law KL (2017) Production, use, and fate of all plastics ever made. Sci Adv 3:e1700782. https://doi.org/10.1126/sciadv.1700782

Al-Salem SM, Lettieri P, Baeyens J (2009) Recycling and recovery routes of plastic solid waste (PSW): a review. Waste Manag 29:2625–2643. https://doi.org/10.1016/j.wasman.2009.06.004

New Plastics Economy (2016) Rethinking the future of plastics. https://www3.weforum.org/docs/WEF_The_New_Plastics_Economy.pdf. Accessed 3 July 2020

Awaja F, Pavel D (2005) Recycling of PET. Eur Polym J 41:1453–1477. https://doi.org/10.1016/j.eurpolymj.2005.02.005

Paszun D, Spychaj T (1997) Chemical recycling of poly(ethylene terephthalate). Ind Eng Chem Res 36:1373–1383. https://doi.org/10.1021/ie960563c

Bartolome L, Imran M, Gyoo B et al (2012) Recent developments in the chemical recycling of PET. In: Material recycling—trends and perspectives. InTech, pp 65–84

Wei R, Zimmermann W (2017a) Microbial enzymes for the recycling of recalcitrant petroleum-based plastics: how far are we? Microb Biotechnol 10:1308–1322. https://doi.org/10.1111/1751-7915.12710

Kawai F, Kawabata T, Oda M (2019) Current knowledge on enzymatic PET degradation and its possible application to waste stream management and other fields. Appl Microbiol Biotechnol 103:4253–4268. https://doi.org/10.1007/s00253-019-09717-y

Yoshida S, Hiraga K, Takehana T et al (2016) A bacterium that degrades and assimilates poly(ethylene terephthalate). Science 351:1196–1199. https://doi.org/10.1126/science.aad6359

Rim Kim H, Soon Song W (2010) Lipase treatment to improve hydrophilicity of polyester fabrics. Int J Cloth Sci Technol 22:25–34. https://doi.org/10.1108/09556221011008785

Carniel A, Valoni É, Nicomedes J et al (2017) Lipase from Candida antarctica (CALB) and cutinase from Humicola insolens act synergistically for PET hydrolysis to terephthalic acid. Process Biochem 59:84–90. https://doi.org/10.1016/j.procbio.2016.07.023

Wang X, Lu D, Jönsson LJ, Hong F (2008) Preparation of a PET-hydrolyzing lipase from Aspergillus oryzae by the addition of bis(2-hydroxyethyl) terephthalate to the culture medium and enzymatic modification of PET fabrics. Eng Life Sci 8:268–276. https://doi.org/10.1002/elsc.200700058

Eberl A, Heumann S, Brückner T et al (2009) Enzymatic surface hydrolysis of poly(ethylene terephthalate) and bis(benzoyloxyethyl) terephthalate by lipase and cutinase in the presence of surface active molecules. J Biotechnol 143:207–212. https://doi.org/10.1016/j.jbiotec.2009.07.008

de Castro AM, Carniel A, Nicomedes Junior J et al (2017) creening of commercial enzymes for poly(ethylene terephthalate) (PET) hydrolysis and synergy studies on different substrate sources. J Ind Microbiol Biotechnol 44:835–844. https://doi.org/10.1007/s10295-017-1942-z

Ronkvist ÅM, Xie W, Lu W, Gross RA (2009) Cutinase-catalyzed hydrolysis of poly(ethylene terephthalate). Macromolecules 42:5128–5138. https://doi.org/10.1021/ma9005318

Schmidt J, Wei R, Oeser T et al (2016) Effect of Tris, MOPS, and phosphate buffers on the hydrolysis of polyethylene terephthalate films by polyester hydrolases. FEBS Open Bio 6:919–927. https://doi.org/10.1002/2211-5463.12097

Barth M, Honak A, Oeser T et al (2016) A dual enzyme system composed of a polyester hydrolase and a carboxylesterase enhances the biocatalytic degradation of polyethylene terephthalate films. Biotechnol J 11:1082–1087. https://doi.org/10.1002/biot.201600008

Barth M, Oeser T, Wei R et al (2015) Effect of hydrolysis products on the enzymatic degradation of polyethylene terephthalate nanoparticles by a polyester hydrolase from Thermobifida fusca. Biochem Eng J 93:222–228. https://doi.org/10.1016/j.bej.2014.10.012

Wei R, Oeser T, Schmidt J et al (2016) Engineered bacterial polyester hydrolases efficiently degrade polyethylene terephthalate due to relieved product inhibition. Biotechnol Bioeng 113:1658–1665. https://doi.org/10.1002/bit.25941

Ferrario V, Pellis A, Cespugli M et al (2016) Nature inspired solutions for polymers: will cutinase enzymes make polyesters and polyamides greener? Catalysts. https://doi.org/10.3390/catal6120205

Ribitsch D, Yebra AO, Zitzenbacher S et al (2013) Fusion of binding domains to Thermobifida cellulosilytica cutinase to tune sorption characteristics and enhancing PET hydrolysis. Biomacromol 14:1769–1776. https://doi.org/10.1021/bm400140u

Ribitsch D, Acero EH, Greimel K et al (2012) Characterization of a new cutinase from Thermobifida alba for PET-surface hydrolysis. Biocatal Biotransform 30:2–9. https://doi.org/10.3109/10242422.2012.644435

Billig S, Oeser T, Birkemeyer C, Zimmermann W (2010) Hydrolysis of cyclic poly(ethylene terephthalate) trimers by a carboxylesterase from Thermobifida fusca KW3. Appl Microbiol Biotechnol 87:1753–1764. https://doi.org/10.1007/s00253-010-2635-y

Ribitsch D, Herrero Acero E, Greimel K et al (2012) A new esterase from Thermobifida halotolerans hydrolyses polyethylene terephthalate (PET) and polylactic acid (PLA). Polymers (Basel) 4:617–629. https://doi.org/10.3390/polym4010617

de Castro AM, Carniel A, Stahelin D et al (2019) High-fold improvement of assorted post-consumer poly(ethylene terephthalate) (PET) packages hydrolysis using Humicola insolens cutinase as a single biocatalyst. Process Biochem 81:85–91. https://doi.org/10.1016/j.procbio.2019.03.006

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254. https://doi.org/10.1016/0003-2697(76)90527-3

ChemicalBook (2020) https://www.chemicalbook.com/ProductChemicalPropertiesCB8336488_EN.htm. Accessed 1 July 2020

ECHEMI (2020) https://www.echemi.com/productsInformation/pd20150901041-caustic-soda-pearls.html. Accessed 1 July 2020

ECHEMI (2020) https://www.echemi.com/productsInformation/pd20150901020-potassium-hydroxide.html. Accessed 1 July 2020

Zhang Y, Cremer P (2006) Interactions between macromolecules and ions: the Hofmeister series. Curr Opin Chem Biol 10:658–663. https://doi.org/10.1016/j.cbpa.2006.09.020

Pinna MC, Salis A, Monduzzi M, Ninham BW (2005) Hofmeister series: the hydrolytic activity of Aspergillus niger lipase depends on specific anion effects. J Phys Chem B 109:5406–5408. https://doi.org/10.1021/jp050574w

American Petroleum Institute (2020) Damage mechanisms affecting fixed equipment in the refining industry API 571—3rd edn. https://mycommittees.api.org/standards/cre/sci/Documents/Forms/AllItems.aspx. Accessed 25 Sept 2020

Barth M, Wei R, Oeser T et al (2015) Enzymatic hydrolysis of polyethylene terephthalate films in an ultrafiltration membrane reactor. J Membr Sci 494:182–187. https://doi.org/10.1016/j.memsci.2015.07.030

Sugiharto YEC, Harimawan A, Kresnowati MTAP et al (2016) Enzyme feeding strategies for better fed-batch enzymatic hydrolysis of empty fruit bunch. Bioresour Technol 207:175–179. https://doi.org/10.1016/j.biortech.2016.01.113

Cui M, Zhang Y, Huang R et al (2014) Enhanced enzymatic hydrolysis of lignocellulose by integrated decrystallization and fed-batch operation. RSC Adv 4:44659–44665. https://doi.org/10.1039/C4RA08891C

Rolf-joachim M (2006) Biological degradation of synthetic polyesters—enzymes as potential catalysts for polyester recycling. Process Biochem 41:2124–2128. https://doi.org/10.1016/j.procbio.2006.05.018

Herzog K, Müller R-J, Deckwer W-D (2006) Mechanism and kinetics of the enzymatic hydrolysis of polyester nanoparticles by lipases. Polym Degrad Stab 91:2486–2498. https://doi.org/10.1016/j.polymdegradstab.2006.03.005

Fecker T, Galaz-Davison P, Engelberger F et al (2018) Active site flexibility as a hallmark for efficient PET degradation by I. sakaiensis PETase. Biophys J 114:1302–1312. https://doi.org/10.1016/j.bpj.2018.02.005

Demirel B, Yaraș A, Elçiçek H (2011) Crystallization behavior of PET materials. BAÜ Fen Bil Enst Derg Cilt 13:26–35

Guebitz GM (2010) Hydrolases in polymer chemistry: part III: synthesis and limited surface hydrolysis of polyesters and other polymers. In: Palmans A, Heise A (eds) Enzymatic polymerisation. Advances in polymer science, vol 237. Springer, Berlin

Kawai F, Oda M, Tamashiro T et al (2014) A novel Ca2+-activated, thermostabilized polyesterase capable of hydrolyzing polyethylene terephthalate from Saccharomonospora viridis AHK190. Appl Microbiol Biotechnol 98:10053–10064. https://doi.org/10.1007/s00253-014-5860-y

Furukawa M, Kawakami N, Oda K, Miyamoto K (2018) Acceleration of enzymatic degradation of poly(ethylene terephthalate) by surface coating with anionic surfactants. Chemsuschem 11:4018–4025. https://doi.org/10.1002/cssc.201802096

Wei R, Oeser T, Barth M et al (2014) Turbidimetric analysis of the enzymatic hydrolysis of polyethylene terephthalate nanoparticles. J Mol Catal B Enzym 103:72–78. https://doi.org/10.1016/j.molcatb.2013.08.010

Wei R, Oeser T, Billig S, Zimmermann W (2012) A high-throughput assay for enzymatic polyester hydrolysis activity by fluorimetric detection. Biotechnol J 7:1517–1521. https://doi.org/10.1002/biot.201200119

Frank CW, Rao V, Despotopoulou MM et al (1996) Structure in thin and ultrathin spin-cast polymer films. Science 273:912–915. https://doi.org/10.1126/science.273.5277.912

O’Neill A, Araújo R, Casal M et al (2007) Effect of the agitation on the adsorption and hydrolytic efficiency of cutinases on polyethylene terephthalate fibres. Enzyme Microb Technol 40:1801–1805. https://doi.org/10.1016/j.enzmictec.2007.02.012

Wei R, Oeser T, Zimmermann W (2014) Synthetic polyester-hydrolyzing enzymes from thermophilic actinomycetes. In: Advances in applied microbiology, 1st edn. Elsevier Inc., Amsterdam, pp 267–305

Herrero Acero E, Ribitsch D, Steinkellner G et al (2011) Enzymatic surface hydrolysis of PET: effect of structural diversity on kinetic properties of cutinases from Thermobifida. Macromolecules 44:4632–4640. https://doi.org/10.1021/ma200949p

Wei R, Zimmermann W (2017b) Biocatalysis as a green route for recycling the recalcitrant plastic polyethylene terephthalate. Microb Biotechnol 10:1302–1307. https://doi.org/10.1111/1751-7915.12714

Chen S, Su L, Chen J, Wu J (2013) Cutinase: characteristics, preparation, and application. Biotechnol Adv 31:1754–1767. https://doi.org/10.1016/j.biotechadv.2013.09.005

Zhang Y, Wang L, Chen J, Wu J (2013) Enhanced activity toward PET by site-directed mutagenesis of Thermobifida fusca cutinase—CBM fusion protein. Carbohydr Polym 97:124–129. https://doi.org/10.1016/j.carbpol.2013.04.042

Ribitsch D, Acero EH, Przylucka A et al (2015) Enhanced cutinase-catalyzed hydrolysis of polyethylene terephthalate by covalent fusion to hydrophobins. Appl Environ Microbiol 81:3586–3592. https://doi.org/10.1128/AEM.04111-14

Espino-Rammer L, Ribitsch D, Przylucka A et al (2013) Two novel class II hydrophobins from Trichoderma spp. stimulate enzymatic hydrolysis of poly(ethylene terephthalate) when expressed as fusion proteins. Appl Environ Microbiol 79:4230–4238. https://doi.org/10.1128/AEM.01132-13

Acknowledgements

To PETROBRAS for the financial support and infrastructure. M.A.Z. Coelho thanks CNPq and FAPERJ for financial support.

Author information

Authors and Affiliations

Contributions

AC performed the tests and calculations, and wrote the text; ACG supervised the tests and analyses; MAZC revised the text; AMC designed and supervised the tests, performed the calculations, and revised the text.

Corresponding author

Ethics declarations

Conflict of interest

PETROBRAS has patent applications in this topic.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Carniel, A., Gomes, A.d., Coelho, M.A.Z. et al. Process strategies to improve biocatalytic depolymerization of post-consumer PET packages in bioreactors, and investigation on consumables cost reduction. Bioprocess Biosyst Eng 44, 507–516 (2021). https://doi.org/10.1007/s00449-020-02461-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-020-02461-y