Abstract

ε-Poly-l-lysine (ε-PL) is produced by Streptomyces as a secondary metabolite with wide industrial applications, but its production still needs to be further enhanced. Environmental stress is an important approach for the promotion of secondary metabolites production by Streptomyces. In this study, the effect of acidic pH shock on enhancing ε-PL production by Streptomyces sp. M-Z18 was investigated in a 5-L fermenter. Based on the evaluation of acidic pH shock on mycelia metabolic activity and shock parameters optimization, an integrated pH-shock strategy was developed as follows: pre-acid-shock adaption at pH 5.0 to alleviate the damage caused by the followed pH shock, and then acidic pH shock at 3.0 for 12 h (including pH decline from 4.0 to 3.0) to positively regulate mycelia metabolic activity, finally restoring pH to 4.0 to provide optimal condition for ε-PL production. After 192 h of fed-batch fermentation, the maximum ε-PL production and productivity reached 54.70 g/L and 6.84 g/L/day, respectively, which were 52.50 % higher than those of control without pH shock. These results demonstrated that acidic pH shock is an efficient approach for improving ε-PL production. The information obtained should be useful for ε-PL production by other Streptomyces.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

ε-Poly-l-lysine (ε-PL) is an unusual cationic, naturally occurring homopolymer of 25–35 l-lysine residues, characterized by an isopeptide bond between α-carboxyl and ε-amino groups [1]. It is water soluble, heat stable, biodegradable, edible and nontoxic toward humans and the environment. Therefore, ε-PL and its derivates have obtained wide spread interest in recent years for a broad range of industrial applications such as food, medicine, environment and electronics [2]. Moreover, the wide antimicrobial spectrum, including yeast, fungi, Gram-positive and Gram-negative bacteria, as well as antiphage activity of ε-PL, has led to it being introduced as a natural food preservative in Japan, South Korea, United States and other countries [3]. Encouragingly, ε-PL has also been approved as a safe food additive by China in April 2014. As a result, the global demand for ε-PL is increasing tremendously.

Currently, commercial ε-PL production is only based on microbial fermentation by Streptomyces, and the price of ε-PL is about 2.0 × 105 USD/metric ton [4]. The high price of ε-PL impairs its economy and utilization field expansion. Therefore, the economy of ε-PL has to be enhanced to meet the increasing global demand. Producing ε-PL from agro-industrial by-products with an efficient fermentation strategy may make it economically competitive for industrial production. In our previous studies, agro-industrial by-products, industrial glycerol and fish meal coupled with corn steep liquor, have been successively employed as carbon and organic nitrogen sources for ε-PL production [4, 5]. Industrial glycerol is a main by-product of the biodiesel industry [6]. Fish meal and corn steep liquor are the by-products of fish processing and preservation and of corn wet-milling industries [7, 8], respectively. Since the cost of raw materials has already been reduced, exploitation of an efficient fermentation strategy, which is one of the most important factors for the economical production of ε-PL on industrial scale, has becoming highly desired.

It is well known that fermentation process regulation has played an important role in the enhancement of ε-PL production. For example, Kahar et al. [9] developed a two-stage pH control strategy to supply sufficient biomass for ε-PL production, in which pH was first maintained above 5.0 for about 48 h and then naturally declined to about 4.0 and maintained stability afterwards. Based on the kinetic analysis of specific ε-PL formation rate, a novel two-stage pH control strategy of pH changes from 3.5 to 3.8 was established by Chen et al. [10]. Strategies of cells immobilization on loofah sponge and resin-based in situ product removal have also been employed for ε-PL production [11, 12]. Although many attempts have been made in the previous studies, the exploitation of an environmental stress for the promotion of ε-PL production has been scarcely reported. Environmental stress is an important approach for the promotion of secondary metabolites production by Streptomyces. It has been reported that regulators involved in signal transduction networks of Streptomyces are sensitive to external stimuli [13, 14]. Therefore, environmental signals can enhance secondary metabolites production in Streptomyces by initiating complex signal transduction system [15]. In fact, there have been many successful studies adopting an environmental stimulus for the enhancement of secondary metabolites production, e.g. an abrupt change in the environmental conditions, such as pH shock [16, 17], heat shock [18] and salt stress [19, 20]. Consequently, we speculated that the introduction of an environmental stress could also be an effective approach for the enhancement of ε-PL production.

This work aimed to establish an efficient fermentation strategy employing environmental stress to improve ε-PL production from agro-industrial by-products. First, pH was selected as environmental stress to improve ε-PL production in terms of bioprocess and metabolic activity analyses. Furthermore, the effects of pre-acid-shock adaption and pH-shock interval on cell growth and ε-PL production were successively studied, and an efficient fermentation strategy with integrated pre-acid-shock adaption and pH shock was constructed. Finally, ε-PL production was markedly enhanced after fed-batch fermentation. To the best of our knowledge, this is the first attempt on ε-PL fermentation adopting an environmental stress.

Materials and methods

Chemicals

Industrial glycerol was purchased from Kerry Oleochemical Industrial Co., Ltd. (Shanghai, China). Fish meal (nitrogen content 97.00 mg/g) was obtained from Xinggang Co., Ltd. (Binzhou, China). Corn steep liquor (nitrogen content 35.43 mg/g) was a kind gift from Linghua Group Co., Ltd. (Ji’ning, China). All other chemicals were analytical grade and purchased from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China).

Microorganism, culture media and inoculum preparation

The strain Streptomyces sp. M-Z18 was used throughout this study. This strain was isolated from soil as described by Nishikawa and Ogawa [21] and subjected to ultraviolet and nitrosoguanidine mutagenesis as described by Hiraki et al. [22]. Agar slant medium, used to maintain the strain, was composed of (g/L): glucose 10, yeast extract 5, beef extract 5, MgSO4·7H2O 0.5, K2HPO4·3H2O 1, and agar 20, along with pH 7.0 before sterilization [10]. Seed culture medium (M3G), contained (g/L): glucose 50, yeast extract 5, (NH4)2SO4 10, KH2PO4 1.36, K2HPO4·3H2O 0.8, MgSO4·7H2O 0.5, ZnSO4·7H2O 0.04, FeSO4·7H2O 0.03 [9]. The fermentation medium employing agro-industrial by-products, consisted of (g/L): industrial glycerol 83, (NH4)2SO4 8, fish meal 15, corn steep liquor 5, KH2PO4 5, MgSO4·7H2O 2, FeSO4·7H2O 0.1 [4]. Initial pH values of the above two media were adjusted to 6.8 with 2 M NaOH and/or 1 M H2SO4. All the media were sterilized in an autoclave for 20 min at 121 °C. In each case, glucose was autoclaved separately. The slants were inoculated and incubated at 30 °C for 7 days to obtain a heavy sporulated growth. After that time, spores were used for seed-culture inoculation (in a concentration of about 2 × 105 spores/L). The seed culture was grown in a 500 mL shake-flask containing 80 mL of liquid medium and incubated at 30 °C on a rotary shaker (200 rpm) for 24 h.

Bioreactor cultures

A 5-L fermenter (BIOTECH-5BG, BaoXing Bio-Engineering Equipment Co., Ltd., Shanghai, China) with a 3.5-L working volume and two Rushton turbines was employed for batch and fed-batch fermentations in this study. Before the inoculation, temperature, aeration rate and agitation speed were maintained at 30 °C, 0.5 vvm and 200 rpm, respectively, and initial pH was controlled at 6.8 via manual addition of ammonia water (12.5 %, w/v). Approximately, 300 mL of seed culture was used as the inoculum. Dissolved oxygen (DO) was set above 30 % of air saturation before pH declined to 4.0 and above 20 % of air saturation afterwards, which was controlled by manually adjusting agitation speed by the step of 50 rpm from 200 to 800 rpm during fermentation. When agitation speed reached to 800 rpm, aeration rate was then manually increased by the step of 0.5 vvm with a range of 0.5–2.5 vvm. During the fermentation process, pH and DO were, respectively, monitored online by pH and DO electrodes (K8S-225 and InPro6800, Mettler Toledo, Greifensee, Switzerland), while dry cell weights (DCW), ε-PL production, glycerol, and NH4 +-N were analyzed offline as described in the section of “Analytical methods”. In fed-batch fermentation, sterilized pure glycerol was automatically added by peristaltic pump to maintain the concentration of glycerol in the fermentation broth at about 10 g/L. Residual ammonia nitrogen (NH4 +-N) was maintained at about 0.5 g/L by feeding 600 g/L sterilized (NH4)2SO4 solution just as the feeding of glycerol.

CTC staining

5-Cyano-2,3-ditolyl-tetrazolium chloride (CTC) is a soluble and non-fluorescing stain. It could be adsorbed and reduced into an insoluble red-fluorescent substance (CTC formazan) by respiring cells via the electron transport chain and accumulated in the cell. Therefore, this redox dye has been widely used to determine the respiratory activity of bacteria [23]. The higher fluorescence intensity represents higher respiratory activity. Biomass samples drawn at different time points from the bioreactor were centrifuged, washed twice and re-suspended with saline (0.9 %) NaCl for about 105–106 pellets/mL. CTC staining was conducted in a 1.5 mL Eppendorf tube by use of a Bacstain-CTC rapid staining kit (Dojindo Laboratories, Kumamoto, Japan) for 30 min at 30 °C according to the manufacturer’s instructions. Twenty microliter of stained samples were deposited on a clean slider and observed under a Leica confocal laser-scanning microscope (TCS-SP8, Leica Microsystems, Wetzlar, Germany) at the excitation wavelength of 488 nm and emission wavelength from 620 to 640 nm. Fluorescence intensity was quantified with the software provided by the manufacturer. A significant number of images were analyzed in a minimum of three independent culture analyses.

Viability staining

To evaluate the viability of the cultured mycelia, the LIVE/DEAD Bac-Light Bacterial Viability Kit L-13152 (Invitrogen detection technologies, California, USA) containing two nucleic acid staining dyes, propidium iodide (PI) and SYTO 9 was used. The STYO9 is a green fluorescent stain which enters all the cells, those with intact membranes as well as those with damaged ones. In contrast, PI only penetrates dead cells with damaged membranes. However, PI has a higher affinity for the nucleic acids and displaces SYTO 9 in dead cells. Therefore, in the presence of both stains, bacteria with intact cell membranes appear fluorescent green, whereas bacteria with damaged membranes appear red [24]. Culture samples were obtained and processed for microscopy at different time points, as previously described in the section “CTC staining”. The two stains were prepared and mixed together (1:1, v/v) as recommended by the manufacturer. Equal volume (20 μL) of the stain mixture and culture samples were mixed on a clean slide and left in the dark for at least 10 min [25]. Then, the sample covered with a cover slip, analyzed under a Leica TCS-SP8 confocal laser-scanning microscope, was sequentially excited at wavelengths of 488 and 568 nm and observed at emission wavelengths of 530 nm (green) and 630 nm (red), respectively. A significant number of images were analyzed in a minimum of three independent culture analyses.

Average specific cell growth rate (\(\overline{{\mu_{x} }}\)) and average specific ε-PL formation rate (\(\overline{{\mu_{p} }}\))

The values of \(\overline{{\mu_{x} }}\) and \(\overline{{\mu_{p} }}\) were calculated according to the following equations, respectively:

where, x is DCW, p is ε-PL concentration and t is fermentation time.

Analytical methods

DCW determination: 10-mL aliquots of culture broth was subjected to centrifugation at 4,500×g for 10 min, and then the precipitate was collected and washed twice with distilled water. The washed mycelia were filtered through a pre-weighed filter paper and dried at 105 °C to a constant weight prior to measuring the biomass of the culture. The centrifugal supernatant was used to determine the ε-PL concentration according to the procedure described by Itzhaki [26]. The concentration of glycerol was determined using an HPLC system (U-3000, Dionex, Sunnyvale, USA) with a refractive index detector (Shodex RI-101, Tokyo, Japan) and an ion exchange column (Aminex HPX-87H, 300 × 7.8 mm, Hercules, CA). The column was eluted with 5 mM H2SO4 at a temperature of 60 °C and a flow rate of 0.6 mL/min. NH4 +-N was analyzed by means of a colorimetric method using Nessler reagent [27]. The intracellular ATP concentration was determined as described by Zeng et al. [28]. The above experiments were carried out at least duplicate.

Results and discussion

Batch fermentation of Streptomyces sp. M-Z18 for ε-PL production without pH control

A proper environmental factor, which could regulate the metabolic activity of cells, is prerequisite for the construction of an environmental stress. It has been reported that pH was the most important environmental factor for ε-PL production [9, 10]. To evaluate the effect of pH on metabolic activity of Streptomyces sp. M-Z18, batch fermentation without pH control was conducted in a 5-L fermenter (Fig. 1). During the fermentation process, pH spontaneously declined from initial 6.8 to the final 3.0 within 24 h and then stayed constant afterwards. Cell growth and ε-PL production were both affected by the pH decline. When pH was above 4.0, cell growth was rapid and DCW increased to 7.34 g/L at 18 h. Subsequently, the growth of biomass slowed down prominently and then quick cell-lysis happened for the continued decline of pH. ε-PL was detected in the period of rapid pH-drop and accumulated to the maximum of 2.81 g/L at 48 h. However, ε-PL production rate began to decrease when pH was below 4.0. Moreover, the decrease of production rate was accelerated as the continuous decline of pH, which eventually ceased ε-PL production. Glycerol consumption occurred along with cell growth and ε-PL production, from its initial concentration of 88.41 to the final of 67.17 g/L within 42 h and then stopped afterward (Fig. 1a). The changes of average specific cell growth rate (\(\overline{{\mu_{x} }}\)) and average specific ε-PL formation rate (\(\overline{{\mu_{p} }}\)) also demonstrated the regulation effect on cell growth and ε-PL production by the pH decline (Fig. 1b, d). The influence of pH decline on accumulation of intracellular ATP was also investigated (Fig. 1c). During the first 24 h, ATP accumulated accompanied by the decline of pH with the maximum of 102.48 mg/g protein at 24 h, and that the accumulation rate elevated since 18 h when pH was below 4.0. After 24 h, ATP accumulation rapidly diminished to the final value of 17.87 mg/g protein at 48 h. When pH was above 4.0 (0–18 h), intracellular ATP was mainly used for cell growth and ε-PL production [29], which resulted in the slow ATP accumulation. When pH was below 4.0 (18–24 h), cell growth and ε-PL production was suppressed, and therefore ATP accumulation rate increased. After 24 h, when pH was stable at 3.0, the intracellular ATP was rapidly consumed to stabilize the intracellular pH [30].

Time profiles of batch fermentation for ε-PL production without pH control by Streptomyces sp. M-Z18. a pH, ε-PL production, DCW and glycerol; b average specific cell growth rate (\(\overline{{\mu_{x} }}\)); c agitation speed, DO, respiratory activity and ATP; and d average specific ε-PL formation rate (\(\overline{{\mu_{p} }}\)). Respiratory activity is presented as the percentage of fluorescence intensity determined in the 0-h mycelia. pH (short dot line); ε-PL (square); DCW (circle); glycerol (up triangle); agitation speed (solid line); DO (dash line); respiratory activity (down triangle); ATP (diamond); \(\overline{{\mu_{x} }}\) (left triangle) and \(\overline{{\mu_{p} }}\) (right triangle)

Influence of pH on mycelia viability in batch fermentation without pH control

Mycelia viability was analyzed under confocal microscopy by means of viability staining with SYTO9 and propidium iodide (Fig. 2). At 0 h (viz. seed culture), dead cells appeared in the pellets of Streptomyces sp. M-Z18, moreover, an inner core of dead mycelia turned up in the bigger pellets. However, most of the dead mycelia disappeared at 12 h (Fig. 2a, b). This phenomenon may attribute to the difference of pH between shake flask and fermenter. In the late phase of seed culture with shake flask, massive mycelia growth caused rapid pH decline to below 4.0 and eventually lead to death mycelia in the pellets. After being transferred to fermenter, mycelia grew well under higher pH of above 6.0 and cell death barely happened at 12 h. When pH declined to 3.0 at 24 h, dead cells appeared again in the central core of pellets and accounted for a large proportion (Fig. 2c). Due to the continuous low pH value of 3.0 from 24 to 48 h, the central core of dead cells grew at a relatively fast rate and a major fraction of the pellets consisted of dead cell mass by 48 h (Fig. 2d, e). Respiratory activity of mycelia was determined by 5-cyano-2,3-ditolyl-tetrazolium chloride (CTC) staining throughout the fermentation process. CTC formazan, which has a red fluorescence when excited by blue light, has accumulated inside all the samples but with different fluorescence intensity (Fig. 3). As shown in Fig. 1c, respiratory activity of mycelia increased to 117.08 % of the control level at 12 h and then gradually decreased to 33.75 % of the control level at 48 h, which was consistent with the result of viability staining. Besides, the change of DO concentration also proved the authenticity of viability and CTC staining (Fig. 1c).

In conclusion, pH could affect mycelia viability and further regulate the metabolic activity of Streptomyces sp. M-Z18. The effect of pH on mycelia growth and secondary metabolite (ganoderic acid) production was also reported in submerged fermentation of Ganoderma lucidum [31]. Therefore, pH was well suited to construct an environmental stress for ε-PL production.

Regulation on mycelia metabolic activity by acidic pH shock in batch fermentation for ε-PL production

As it is known, acidic pH (pH < 4.5) was essential for ε-PL production, which derived from the accumulation of intracellular ATP for ε-PL synthetase and suppression of ɛ-PL degrading enzyme [29]. Thus, an acidic pH stress was preferable to conduct the environmental stress. Besides, pH decline from 4.0 to 3.0 and maintenance showed strong inhibition effect on mycelia metabolic activity, which was also benefit for the accumulation of intracellular ATP (Figs. 1, 2, 3). Therefore, we selected it to serve as the acidic pH stress. Moreover, pH 4.0 was chosen as the recovery condition because the average specific ε-PL formation rate (\(\overline{{\mu_{p} }}\)) was found to be highest at pH 4.0 (Fig. 1d). Based on the above consideration, an acidic pH-shock strategy was established, in which pH declined from 4.0 to 3.0 and maintained (viz. pH shock), after that pH was restored to 4.0 for the subsequent fermentation. In this experiment, the pH-shock time was set as 12 h (Fig. 4a). The metabolic activity of mycelia was severely suppressed under pH shock, while, mycelia could recover metabolic activity after pH shock just as expected. Moreover, cell growth and ε-PL production rates increased over time after pH shock with the final DCW and ε-PL production of 30.61 and 10.39 g/L, respectively (Fig. 4a). Conversely, mycelia metabolic activity was not suppressed throughout the fermentation process in the control strategy with controlled pH of 4.0. Finally, DCW and ε-PL production reached 28.14 and 9.07 g/L, which were 8.0 and 12.7 % lower, respectively, compared to those of the acidic pH-shock strategy (Fig. 4b). Therefore, the acidic pH-shock strategy constructed in this study was feasible and benefit for the enhancement of cell growth and ε-PL production in batch fermentation by Streptomyces sp. M-Z18.

Kinetic parameters of batch fermentation for ε-PL production by Streptomyces sp. M-Z18 with different strategies. a pH-shock strategy with shock time of 12 h; b control strategy with controlled pH of 4.0. pH (short dot line); agitation speed (solid line); DO (dash line); ε-PL (square); DCW (circle); and glycerol (up triangle)

CTC staining of mycelia at different time in batch fermentations with both strategies was shown in Fig. 5. The respiratory activity was determined according to the fluorescence intensity of CTC staining (Fig. 6a). In the control strategy, respiratory activities of mycelia at 12, 28 and 36 h decreased continuously from 100 % over 73.7 to 50.1 % of the control level. However, respiratory activities of mycelia in the pH-shock strategy fluctuated from 105.2 to 40.2 % and then to 72.3 % of the control level, which indicated that the pH-shock phase affected mycelia respiration indeed. Moreover, respiratory activity of mycelia in the pH-shock strategy was 44.3 % higher than that in the control strategy at 36 h, which meant that more ATP would be supplied for the function of ε-PL synthetase by respiration after pH shock [29]. The average specific cell growth rate (\(\overline{{\mu_{x} }}\)) and average specific ε-PL formation rate (\(\overline{{\mu_{p} }}\)) were also distinguished between both strategies (Fig. 6b, c). Compared to the control strategy, both \(\overline{{\mu_{x} }}\) and \(\overline{{\mu_{p} }}\) of the pH-shock strategy were lower under pH shock while they became higher after that, which were consistent with the result of respiratory activity. In conclusion, the pH-shock strategy could first suppress and then elevate mycelia metabolic activity. Due to the regulation effect of the acidic pH-shock strategy on mycelia metabolic activity, the capacity of the unit biomass for cell growth and ε-PL production could be improved after pH shock.

Confocal laser scanning microscopy of CTC staining cells of Streptomyces sp. M-Z18 in batch fermentation with different pH-control strategies. a pH-shock strategy with shock time of 12 h; b control strategy with controlled pH of 4.0. 12 h represents the time when cells grow before pH shock with the external pH of about 6.0; 28 h represents the time when cells grow under pH shock with the external pH of about 3.0; 36 h represents the time when cells grow after pH shock with the external pH of 4.0

Time profiles of a respiratory activity, b average specific cell growth rate (\(\overline{{\mu_{x} }}\)), and c average specific ε-PL formation rate (\(\overline{{\mu_{p} }}\)) in batch fermentations of Streptomyces sp. M-Z18 with different strategies. 12 h represents the time when cells grow before pH shock with the external pH of about 6.0; 28 h represents the time when cells grow under pH shock with the external pH of about 3.0; 36 h represents the time when cells grow after pH shock with the external pH of 4.0. Respiratory activity is presented as the percentage of fluorescence intensity determined in the 12-h mycelia with control strategy. Statistical significance is denoted by asterisks for the same time and different letters for the same strategy, respectively. Control strategy (blank square) and pH-shock strategy (filled square)

Kim et al. [32] considered that an acidic pH shock has positively contributed to the stimulation of actinorhodin biosynthesis by S. coelicolor A3 (2) in a concerted manner, by means of regulators activation and upregulation of genes associated with actinorhodin production, secretion and the major central metabolic pathways. Besides, a wide range of sigma factors and shock-related proteins, which related to actinorhodin biosynthesis by mediating the pH shock signal to regulators or biosynthesis genes for actinorhodin production, were also found to be upregulated by pH shock [33]. Therefore, we speculated that the enhanced effect of the pH-shock strategy on cell growth and ε-PL production in this study similarly attributed to the positive regulation of the mycelia metabolism.

Pre-acid-shock adaption for the induction of acid tolerance response

In the pH-shock strategy, cells were exposed to acid stress for12 h (viz. pH-shock phase) and the metabolic activity of mycelia was suppressed (Figs. 4, 5, 6). The consequences of acid stress include an acidified intracellular pH (pHi) followed by damage to various macromolecules [34]. Therefore, some protections would be needed before pH shock to alleviate the caused damage. The acid tolerance response (ATR) is one of the most important candidates. ATR is a complex stress response involving the induction of 50 acid-shock proteins (ASPs), some of which are regulated by the iron-regulatory protein Fur, while others require the alternate sigma factor RpoS (σ S) [34]. It could be induced by cell-growth increase for one doubling at a less acidic pH, called pre-acid-shock adaption.

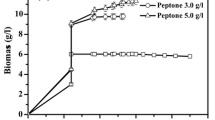

Based on the above theory, pre-acid-shock adaption was applied to induce the ATR of the cultured Streptomyces sp. M-Z18 before pH shock (Fig. 7). The adaption pH values were set at 5.0 and 4.0, respectively, until DCW was doubled and then pH shock was conducted for 12 h (Fig. 7a). As shown in Fig. 7c, cells that pre-adaption at pH 4.0 lysed under pH shock, and cell growth delayed about 12 h after pH shock in contrast to those pre-adaption at pH 5.0. Although the final ε-PL production of the pH 4.0 pre-adaption cells was slightly higher (Fig. 7b), the whole process (4.24 g/L/day) and recovery (5.74 g/L/day) productivities of ε-PL were reduced by 7.08 and 50.35 %, respectively, compared to those of the cells pre-adaption at pH 5.0 (Table 1). Thus, we concluded that pH 5.0 was more suitable for the pre-acid-shock adaption in this study. Table 1 has listed comparison among the three modes of pH-shock batch fermentations. It was observed that pre-adaption at pH 5.0 could not only shorten fermentation time but also increase ε-PL productivity. The fermentation time was shortened from 58 to 54 h, while the productivities of ε-PL in the whole process (from 4.30 to 4.54 g/L/day) and recovery phase (from 7.12 to 8.63 g/L/day) were increased by 5.58 and 21.12 %, respectively, as compared with those of the un-adaption cells. In conclusion, pre-acid-shock adaption at pH 5.0 was essential for ε-PL production in the pH-shock strategy, which could induce the ATR of Streptomyces sp. M-Z18.

The pre-acid-shock adaption is thought to induce an undefined emergency pH homeostasis system that prevents pHi from falling much when cells are exposed to extremely acidic external pH values [35]. The less acidic is pHi then it is thought to allow ASPs synthesize. Consequently, the damage to bacteria would be mitigated under pH shock, and then more bacteria could survive and preserve higher metabolic activity to assure quicker recovery when external pH was shifted back to normal level.

Effect of different pH-shock interval on ε-PL production in batch fermentation

Although pre-acid-shock adaption could decrease the damage that caused by the acid stress of the pH-shock phase, however, the extremely low pH value was still harmful to the cultured bacteria. Therefore, cells could not retain activity all the time under long-time acidic pH stress. Accordingly, the pH shock interval should be optimized to avoid unnecessary stress and damage. In this study, four different time intervals of 12, 18, 24 and 48 h were maintained in a series of cultures to explore the optimal time length of pH shock (Fig. 8).

As shown in Fig. 8, DO concentrations quickly increased in all of the four pH-shock phases, which indicated that the suppression of mycelia metabolic activity by pH shock still existed even after pre-acid-shock adaption at pH 5.0. Interestingly, when pH was shifted back to 4.0, mycelia in all of the four cultivations could restore metabolic activities after long-time acidic pH stress (from 12 to 48 h). Table 2 summarized the effect of pH-shock interval on cell growth and ε-PL production. It was observed that the lag time prolonged from 0 to 18 h after pH shock with the increase of pH-shock interval. Thus, the fermentation time was extended from 54 to 117 h. Besides, the prolonged pH-shock time showed no positive effect and even led to decline on ε-PL production (from the maximum of 10.21 to the minimum of 9.29 g/L), and the same trend was also found for cell growth (from the maximum of 28.36 to the minimum of 23.90 g/L). Moreover, ε-PL productivities both in the whole process and the recovery phase reduced with the increase of pH-shock interval (Table 2). In summary, it is obvious that pH-shock interval of 12 h was enough for the triggering of enhanced ε-PL production and cell growth.

Fed-batch fermentation for ε-PL production with integrated acidic pH-shock strategy

The period of batch fermentation was too short to reflect the full potential of the acidic pH-shock strategy. As reported in the mycelia fermentation of Ganoderma lucidum for hyperproduction of polysaccharide and ganoderic acid, feeding strategy was applied to enhance the metabolites production [36]. Therefore, fed-batch fermentation was carried out in this study to explore the sufficient production of ε-PL (Fig. 9). As shown in Fig. 9a, the whole process of the integrated acidic pH-shock strategy was divided into three phases. Phase 1, pre-acid-shock adaption, pH was maintained at 5.0 until DCW was doubled for the induction of ATR, which would alleviate the damage that caused by the extremely low pH value of the followed pH-shock phase. Phase 2, acidic pH shock, pH declined from 4.0 to 3.0 and maintained amounting to 12 h, which would positively regulate the metabolic activity of mycelia. Phase 3, recovery, pH was restored to 4.0 for the subsequent fermentation, which would provide optimal condition for ε-PL production. In the control strategy, ε-PL production and DCW increased rapidly between 0 and 126 h, which reached 29.67 and 56.53 g/L at 126 h, respectively. But after that, ε-PL production and cell growth slowed down prominently, only with the final value of 35.87 and 64.02 g/L at 192 h, respectively (Fig. 9b). On the contrary, ε-PL production and cell growth kept rapid increase throughout the fed-batch fermentation process of the pH-shock strategy. The final ε-PL production and DCW of 54.70 and 76.35 g/L were obtained at 192 h, which were 52.50 and 19.26 % higher than those of the control strategy, respectively (Fig. 9a). It is obvious that the only difference between the two strategies is the pH-shock phase. In the pH-shock phase, mycelia metabolic activity was severely inhibited (Figs. 4, 5, 6), which would lead to the induced overproduction of regulatory, biosynthetic and stress-response genes [32, 33]. Therefore, ε-PL production and cell growth could be markedly enhanced when external pH was adjusted back to normal value. Moreover, the production of ε-PL obtained in this study was also higher than those of S. albulus S410 [9] and the same Streptomyces sp. M-Z18 [4, 10]. Notably, the whole work that had been done in the previously developed pH-control strategies was to pursue the optimal pH values for ε-PL production and cell growth, while the suppression on mycelia metabolic activity did not happen [9, 10]. In conclusion, the integrated pH-shock strategy proposed in this study was quite different and also much efficient for ε-PL production. The same enhanced effect of pH shock was also found in the production of kasugamycin by Streptomyces kasugaensis, and the final kasugamycin productivity was approximately seven-fold higher than that of the control [17]. These results demonstrated that acidic pH shock could also be a powerful and efficient strategy for the production of ε-PL.

Time courses of fed-batch fermentations by Streptomyces sp. M-Z18 with different strategies. a Integrated pH-shock strategy with pre-acid-shock adaption at pH 5.0 and then acidic pH shock for 12 h before pH was restored to 4.0; b control strategy with pre-acid-shock adaption at pH 5.0 and then controlled pH of 4.0. pH (solid line); ε-PL (square); DCW (circle); glycerol (up triangle) and NH4 +-N (diamond)

Conclusion

The present study indicated that the introduction of an environmental stress of acidic pH shock could efficiently enhance the production of ε-PL. After 192 h fed-batch fermentation with the developed pH-shock strategy, the final ε-PL production and productivity reached 54.70 g/L and 6.84 g/L/day, respectively, and 52.50 % higher than those of the control strategy without pH shock. However, the physiological changes and related regulation genes behind the acidic pH shock still needs to be further studied. The obtained results would be useful to large-scale ε-PL production and provide new information on ε-PL biosynthesis mechanism.

References

Shima S, Sakai H (1977) Polylysine produced by Streptomyces. Agric Biol Chem 41:1807–1809

Shih IL, Shen MH, Van YT (2006) Microbial synthesis of poly (ε-lysine) and its various applications. Bioresour Technol 97:1148–1159

Shima S, Matsuoka H, Iwamoto T, Sakai H (1984) Antimicrobial action of ε-poly-l-lysine. J Antibiot 37:1449–1455

Ren XD, Chen XS, Tang L, Sun QX, Zeng X, Mao ZG (2014) Efficient production of ε-poly-l-lysine from agro-industrial by-products by Streptomyces sp. M-Z18. Ann Microbiol. doi:10.1007/s13213-014-0913-0

Chen XS, Tang L, Li S, Liao LJ, Zhang JH, Mao ZG (2011) Optimization of medium for enhancement of ε-poly-l-lysine production by Streptomyces sp. M-Z18 with glycerol as carbon source. Bioresour Technol 102:1727–1732

da Silva GP, Mack M, Contiero J (2009) Glycerol: a promising and abundant carbon source for industrial microbiology. Biotechnol Adv 27:30–39

Zouari N, Achour O, Jaoua S (2002) Production of delta-endotoxin by Bacillus thuringiensis subsp kurstaki and overcoming of catabolite repression by using highly concentrated gruel and fish meal media in 2-and 20-dm3 fermenters. J Chem Technol Biotechnol 77:877–882

Parekh M, Formanek J, Blaschek H (1999) Pilot-scale production of butanol by Clostridium beijerinckii BA101 using a low-cost fermentation medium based on corn steep water. Appl Microbiol Biotechnol 51:152–157

Kahar P, Iwata T, Hiraki J, Park EY, Okabe M (2001) Enhancement of ε-polylysine production by Streptomyces albulus strain 410 using pH control. J Biosci Bioeng 91:190–194

Chen XS, Li S, Liao LJ, Ren XD, Li F, Tang L, Zhang JH, Mao ZG (2011) Production of ε-poly-l-lysine using a novel two-stage pH control strategy by Streptomyces sp. M-Z18 from glycerol. Bioprocess Biosyst Eng 34:561–567

Liu S, Wu Q, Zhang J, Mo S (2011) Production of ε-poly-l-lysine by Streptomyces sp. using resin-based, in situ product removal. Biotechnol Lett 33:1581–1585

Zhang Y, Feng X, Xu H, Yao Z, Ouyang P (2010) ε-Poly-l-lysine production by immobilized cells of Kitasatospora sp. MY 5-36 in repeated fed-batch cultures. Bioresour Technol 101:5523–5527

Beppu T (1995) Signal transduction and secondary metabolism: prospects for controlling productivity. Trends Biotechnol 13:264–269

Horinouchi S (2003) AfsR as an integrator of signals that are sensed by multiple serine/threonine kinases in Streptomyces coelicolor A3 (2). J Ind Microbiol Biotechnol 30:462–467

Rehm HJ, Reed G (1997) Biotechnology: products of secondary metabolism, 2nd edn. VCH A wiley company, Weinheim

Hayes A, Hobbs G, Smith CP, Oliver SG, Butler PR (1997) Environmental signals triggering methylenomycin production by Streptomyces coelicolor A3 (2). J Bacteriol 179:5511–5515

Kim CJ, Chang YK, Chun GT (2000) Enhancement of Kasugamycin production by pH shock in batch cultures of Streptomyces kasugaensis. Biotechnol Prog 16:548–552

Doull JL, Ayer SW, Singh AK, Thibault P (1993) Production of a novel polyketide antibiotic, jadomycin B, by Streptomyces venezuelae following heat shock. J Antibiot 46:869–871

Xu YN, Zhong JJ (2012) Impacts of calcium signal transduction on the fermentation production of antitumor ganoderic acids by medicinal mushroom Ganoderma lucidum. Biotechnol Adv 30:1301–1308

Himabindu M, Potumarthi R, Jetty A (2007) Enhancement of gentamicin production by mutagenesis and non-nutritional stress conditions in Micromonospora echinospora. Process Biochem 42:1352–1356

Nishikawa M, Ki Ogawa (2002) Distribution of microbes producing antimicrobial ε-poly-l-lysine polymers in soil microflora determined by a novel method. Appl Environ Microbiol 68:3575–3581

Hiraki J, Hatakeyama M, Morita H, Izumi Y (1998) Improved ε-poly-l-lysine production of an S-(2-aminoethyl)-l-cysteine resistant mutant of Streptomyces albulus. Seibutsukogaku 76:487–493

Winding A, Binnerup SJ, Sørensen J (1994) Viability of indigenous soil bacteria assayed by respiratory activity and growth. Appl Environ Microbiol 60:2869–2875

Rioseras B, López-García MT, Yagüe P, Sánchez J, Manteca Á (2014) Mycelium differentiation and development of Streptomyces coelicolor in lab-scale bioreactors: programmed cell death, differentiation, and lysis are closely linked to undecylprodigiosin and actinorhodin production. Bioresour Technol 151:191–198

Singh KP, Mahendra AL, Jayaraj V, Wangikar PP, Jadhav S (2013) Distribution of live and dead cells in pellets of an actinomycete Amycolatopsis balhimycina and its correlation with balhimycin productivity. J Ind Microbiol Biotechnol 40:235–244

Itzhaki R (1972) Colorimetric method for estimating polylysine and poly-arginine. Anal Biochem 50:569–574

AOAC International (formerly the Association of Official Analytical Chemists) (1995) Official Methods of Analysis Arlington. AOAC International, VA

Zeng X, Chen XS, Ren XD, Liu QR, Wang L, Sun QX, Tang L, Mao ZG (2014) Insights into the role of glucose and glycerol as a mixed carbon source in the improvement of ε-poly-l-lysine productivity. Appl Biochem Biotechnol 173:2211–2224

Yamanaka K, Kito N, Imokawa Y, Maruyama C, Utagawa T, Hamano Y (2010) Mechanism of ε-poly-l-lysine production and accumulation revealed by identification and analysis of an ε-poly-l-lysine-degrading enzyme. Appl Environ Microbiol 76:5669–5675

Even S, Lindley ND, Loubière P, Cocaign-Bousquet M (2002) Dynamic response of catabolic pathways to autoacidification in Lactococcus lactis: transcript profiling and stability in relation to metabolic and energetic constraints. Mol Microbiol 45:1143–1152

Fang QH, Zhong JJ (2002) Effect of initial pH on production of ganoderic acid and polysaccharide by submerged fermentation of Ganoderma lucidum. Process Biochem 37:769–774

Kim YJ, Song JY, Moon MH, Smith CP, Hong SK, Chang YK (2007) pH shock induces overexpression of regulatory and biosynthetic genes for actinorhodin productionin Streptomyces coelicolor A3(2). Appl Microbiol Biotechnol 76:1119–1130

Kim YJ, Moon MH, Song JY, Smith CP, Hong S-K, Chang YK (2008) Acidic pH shock induces the expressions of a wide range of stress-response genes. BMC Genom 9:604

Park YK, Bearson B, Bang SH, Bang IS, Foster JW (1996) Internal pH crisis, lysine decarboxylase and the acid tolerance response of Salmonella typhimurium. Mol Microbiol 20:605–611

Foster JW, Hall HK (1991) Inducible pH homeostasis and the acid tolerance response of Salmonella typhimurium. J Bacteriol 173:5129–5135

Tang YJ, Zhong JJ (2002) Fed-batch fermentation of Ganoderma lucidum for hyperproduction of polysaccharide and ganoderic acid. Enzyme Microb Technol 31:20–28

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (31301556), the Jiangsu Key Project of Scientific and Technical Supporting Program (BE2012616), the Cooperation Project of Jiangsu Province among Industries, Universities and Institutes (BY2013015-11), the Jiangsu Province “Collaborative Innovation Center for Advanced Industrial Fermentation” Industry Development Program, the Priority Academic Program Development of Jiangsu Higher Education Institutions, the 111 Project (111-2-06) and the National Natural Science Foundation of China (21376106).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ren, XD., Chen, XS., Zeng, X. et al. Acidic pH shock induced overproduction of ε-poly-l-lysine in fed-batch fermentation by Streptomyces sp. M-Z18 from agro-industrial by-products. Bioprocess Biosyst Eng 38, 1113–1125 (2015). https://doi.org/10.1007/s00449-015-1354-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-015-1354-2