Abstract

In this study, an integrated citric acid-methane fermentation process was established to solve the problem of wastewater treatment in citric acid production. Citric acid wastewater was treated through anaerobic digestion and then the anaerobic digestion effluent (ADE) was further treated and recycled for the next batch citric acid fermentation. This process could eliminate wastewater discharge and reduce water resource consumption. Propionic acid was found in the ADE and its concentration continually increased in recycling. Effect of propionic acid on citric acid fermentation was investigated, and results indicated that influence of propionic acid on citric acid fermentation was contributed to the undissociated form. Citric acid fermentation was inhibited when the concentration of propionic acid was above 2, 4, and 6 mM in initial pH 4.0, 4.5 and, 5.0, respectively. However, low concentration of propionic acid could promote isomaltase activity which converted more isomaltose to available sugar, thereby increasing citric acid production. High concentration of propionic acid could influence the vitality of cell and prolong the lag phase, causing large amount of glucose still remaining in medium at the end of fermentation and decreasing citric acid production.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Citric acid (2-hydroxy-1, 2, 3-propanetricarboxylic acid), first isolated from lemon juice in 1784, is one of the most important organic acids today and has been widely used in food, beverage, chemical, and metallurgical industries [1–3]. Currently, the majority of citric acid is manufactured through submerged fermentation of starch-based or sucrose-based feedstock by the filamentous fungus A. niger due to its high citric acid productivity [4]. In 2010, approximately one million tons of citric acid was produced in China and 50–60 million tons of citric acid wastewater were generated as each ton product of citric acid can produce 50–60 tons of wastewater [5]. This wastewater contains high concentration of chemical oxygen demand (COD) (15,000–20,000 mg/L) and low pH (4.5–4.8) and its treatment has seriously restricted the development of citric acid production plant [6, 7].

In the conventional process, citric acid wastewater is usually treated with anaerobic–aerobic digestion and then the effluent is transported to municipal sewage plant and further treated with physical and chemical methods to meet the national discharge standard (Fig. 1a) [8, 9]. However, capital investment and operation costs of the aerobic digestion are high. Fenton’s reagent, emulsion liquid membrane, microwave radiation and other physical–chemical methods are also investigated to treat citric acid wastewater [10–12]. Efficiencies of these methods are high and their COD removal rates are 69.0–98.0 %. However, these methods have the disadvantages of large amount of inorganic reagents consumption and complex operation in practice. Recently, Photosynthetic bacteria and Chlorella vulgaris which can grow in polluted wastewater and produce valuable sources of proteins, vitamins, and other compounds for animal feed constitution, have been widely used for citric acid wastewater treatment [5, 13]. Using this method, the removal rates of COD, biochemical oxygen demand, and nitrogen in wastewater are all above 90 % and the remains can be used as animal feedstuff. However, the effluent after such treatment cannot meet national discharge standard and further treatment is still necessary. Therefore, the treatment of wastewater is still a tough work for the citric acid manufacturers.

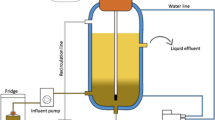

To completely solve the disposal problem of citric acid wastewater mentioned above, an integrated citric acid–methane fermentation process was developed by our laboratory [14]. In this process, cassava and corn starch are used as raw materials to produce citric acid, while unused materials (fiber and pectin) and metabolites of A. niger in citric acid fermentation are converted to biogas through mesophilic anaerobic digestion (Fig. 1b). The biogas can be used to produce electricity and heat, while the ADE was further treated by air stripping and solid–liquid separation to remove ammonia and part of precipitable metal ions which were confirmed to be the inhibitors for citric acid fermentation in pervious experiment [15]. Then the supernatant was recycled for the next batch citric acid fermentation, thereby avoiding the wastewater discharge and decreasing the water resource consumption.

Tap water was used to make mash for the first batch of citric acid fermentation and performed as the control. The proposed process had performed for 10 batches and citric acid production in recycling (2nd–10th) decreased by 2.5 % compared with the control [16], indicating inhibitors were contained in the treated ADE and could inhibit citric acid fermentation. In this paper, essential chemical characteristics of ADE were detected and the accumulation of propionic acid was found in recycling process. Therefore, effects of propionic acid on the citric acid fermentation were investigated. Based on the results, corresponding approaches were provided to avoid further deterioration of the proposed process when acidification conditions occurred in anaerobic digestion system.

Materials and methods

Strain and seed culture conditions for citric acid fermentation

A. niger strain used for citric acid fermentation throughout this study was obtained from Anhui Fengyuan Co., Ltd., China, which was an industrial strain, and potato dextrose agar (PDA) slants stored at 4 °C was used for its preservation. Subculture was performed every 2 months to maintain the strain vitality.

100 g cassava powder (starch content 65–70 % (w/w), size is approximately 0.45 mm, provide by the Henan Tianguan Co. Ltd., China) was mixed with 400 mL tap water to prepare seed culture medium in this study and the slurry pH was adjusted to 6.0 using 30 % (w/w) sulfuric acid or 10 % (w/v) sodium hydroxide. Then, 10 U/g high-temperature amylase (20,000 U/mL, provide by Genencor China Co. Ltd.) was added and the slurry was maintained at 100 °C for 2 h. When the slurry is cooled to room temperature, water loss during liquefaction was made up with tap water and 0.1 % (w/v) ammonium sulfate was supplemented as nitrogen source for spore germination. The slurry pH was adjusted to 5.5 before autoclaving at 115 °C for 20 min and conidia from a 7-day-old PDA slant were used for inoculation. 10 mL of a spore suspension in sterile water, containing approximately 6 × 106/mL of conidia, was inoculated to the 70 mL sterile medium in a 1000 mL shake flask. The shake flask was conducted at 200 rpm, 36 ± 1 °C for 20 h before the seed culture was used for citric acid fermentation.

Citric acid fermentation

80 g cassava powder and 20 g corn powder (starch content 75–80 % (w/w), size is approximately 0.45 mm, provide by the Henan Tianguan Co. Ltd., China) were added to 450 mL process water to prepare the fermentation media. The liquefaction and autoclave operation were same to that of seed medium, and the initial total sugar of fermentation media was regulated to approximately 155 g/L. 6 mL, seed broth was inoculated to 34 mL sterile fermentation media in a 500 mL shake flask and then conducted at 260 rpm, 37.5 ± 1 °C for 92 h. All shake flask experiments were conducted in triplicates. For the citric acid fermentation in agitator bioreactor (LiFlus GX, provide by Korea bioreactor Co. Ltd., with 5-L total capacity), 450 mL seed broth was inoculated to 2550 mL sterile fermentation media to initiate the fermentation. Temperature during the fermentation was maintained at 37.5 ± 1 °C using a heating jacket, while dissolved oxygen was monitored online by the dissolved oxygen electrode (InPro6800, provide by Mettler Toledo, Greifensee, Switzerland) and was conducted by the three-bladed impellers operating at 600 rpm with an aeration rate of 2 vvm. The pH in the fermentation was monitored by the pH electrode (K8S-325, provide by Mettler Toledo, Greifensee, Switzerland). Fermentation time was conducted at 72 h and samples were analyzed in an interval of 12 h.

Effect of propionic acid on citric acid fermentation in different initial pH

Propionic acid was added to the mash to the final concentrations of 1.0, 2.0, 4.0, 6.0, 8.0, and 10.0 mM, respectively. The resulting slurry pH was adjusted to approximately 4.1, 5.5 or 6.8 using 30 % (w/w) sulfuric acid or 10 % (w/v) sodium hydroxide, thereby the fermentation pH after inoculation dropped to approximately 4.0, 4.5, and 5.0, respectively. Undissociated propionic acid was calculated using the Henderson-Hasselbalch equation, pH = pKa + log ([A−]/[HA]), and propionic acid pKa of 4.87.

Methane fermentation condition

Methane fermentation in this paper was performed in upflow anaerobic sludge blanket reactor (provide by Shanghai Daming, China, with a working volume of 5 L). Circulator bath was used to maintain temperature at 35 ± 1 °C and approximately 30 % of the mesophilic anaerobic granular sludge (provide by Yixing Xielian Biological Chemical Co. Ltd., China) was inoculated in reactor. Citric acid wastewater from a citric acid production plant (Yixing Xielian Biological Chemical Co. Ltd., China) was used to start the methane fermentation and in recycling batches, citric acid wastewater was obtained from the extraction operation of the medium at the end of citric acid fermentation by our laboratory. Every day citric acid wastewater was entered into reactor for methane fermentation by an adjustable-speed peristaltic pump. The hydraulic retention time was approximately 8.7 ± 0.8 days and the mean organic loading rate was approximately 2.2 ± 0.2 kg/m3/day. After the methane fermentation, the ADE was centrifuged at 4000×g for 20 min and the supernatant was analyzed prior to store at 4 °C and recycled for citric acid fermentation.

Analytical methods

Citric acid, residual glucose, isomaltose, acetic, and propionic acid were detected using a Dionex U3000 high-performance liquid chromatography (HPLC), which was equipped with an ultraviolet and refraction index detector (UV/RID) and C18 3.9 × 300 mm column. The column was operated at 65 °C and eluted with 0.005 mol/L sulfuric acid at a flow rate of 0.6 mL/min. The collected samples were centrifuged at 10,000×g for 20 min, followed by filtering through a 0.45 μm membrane prior to analysis. Total sugars were measured using the biosensor (SBA-40B, provide by Shandong Academy of Sciences, China) after the samples were subject to acid hydrolysis (20 g/L hydrochloric acid, 100 °C for 2 h). Isomaltase activity in citric acid fermentation was analyzed by measuring the decrease of isomaltose concentration in the reaction mixture which contained 1 mL acetate buffer (pH 4.5, 0.1 M), 1 mL isomaltose (10 g/L) and 1 mL supernatant of fermentation broth. One unit of isomaltase activity was defined as the amount of enzyme which consumed 1 mg isomaltose per minute at pH 4.5, 50 °C. Biomass in fermentation medium was evaluated by microscope count method after suitably diluted and 20 times analyzed for each sample to obtain sufficiently precise measurements. COD, NH3-N, volatile fatty acids (VFAs) and, alkalinity were determined according to standard methods [17]. Methane production in anaerobic digestion was measured using water replacement method with the removal of carbon dioxide and hydrogen sulfide by 2 N sodium hydroxide solutions [18].

Results and discussion

Chemical characteristics of the ADE in recycling

Chemical characteristics of the ADE in recycling were detected and the results are shown in Fig. 2. The COD concentration in ADE was stable in the first three batches and then 93.6 % of increase from 1100 to 2130 mg/L was detected from the fourth batch (Fig. 2a). Correspondingly, the COD removal rate slightly increased in the first three batches and then significantly decreased in the following batches. However, the COD removal rates were still above 90 % throughout the recycling process which indicated that the anaerobic digestion operation was relatively stable. Moreover, the average methane yield and pH was approximately 292.3 ± 15.2 mL/g TCODremoved and 7.06 ± 0.05 (Fig. 2a, b), respectively. This also proved the anaerobic digestion was efficient and stable in operation as Speece [19] had reported that the theory methane yield in anaerobic digestion was 350 mL/g TCODremoved and the optimum pH range was 6.5–8.2. Meanwhile, 32.4 % decrease of the ammonia concentration in ADE, from 506.8 to 342.8 mg/L in recycling, was found (Fig. 2b). This result was consistent with our previous study which suggested that wastewater from the citric acid factory was used to start the methane production and this feed contained relatively more organic nitrogen because of the extensive extraction process, thus causing high initial ammonia concentration in the effluent [14]. In recycling, citric acid wastewater produced by our laboratory was used as influent which contained relatively less organic nitrogen and caused the decreased concentration of ammonia in reactor.

Alkalinity in ADE slightly increased from 3225 to 3500 mg CaCO3/L, increasing by 7.8 % in recycling while the VFAs concentrations significantly increased from 55.8 to 505.5 mg/L. Sung and Santha [20] reported that the ratio of VFAs to alkalinity is a key indicator to evaluate the stability of anaerobic digestion and this ratio should be below 0.10 in mesophilic reactor. In the first six batches, the ratios of VFAs to alkalinity were below 0.10, however, they are above 0.10 from the seventh batch, indicating the slight acidification occurred in methane production.

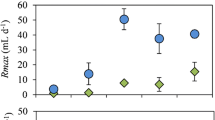

VFAs were the main precursors of methane production in anaerobic conditions and accumulated as the fluctuation of organic loading rate, causing the acidification of anaerobic digestion [21, 22]. Except for anaerobic digestion, there was no way to further remove VFAs from ADE in proposed process, and therefore VFAs could enter and influence citric acid fermentation system. The composition of VFAs was detected by HPLC and the results indicated that acetic acid and propionic acid were the two most abundant acids in recycling, with concentration up to 268 mg/L (4.7 mM) and 218 mg/L (2.9 mM), respectively (Fig. 3). The previous experiment indicated that citric acid fermentation was not inhibited by acetic acid when acetic acid concentration was below 8 mM in initial pH 4.5 [23], therefore, acetic acid in recycling could not influence citric acid fermentation. As for propionic acid, the concentration contained in ADE was lower than acetic acid and its influence on the citric acid fermentation was unknown. However, we considered it exhibited a stronger inhibition to A. niger than acetic acid as Freese et al. [24] reported that low propionate concentrations inhibited amino acid transport across bacterial membrane vesicles and were thus more toxic than other acids. Meanwhile, acetic acid could be used by A. niger when glucose was at a low concentration [25], while propionic acid had not been reported to be utilized by A. niger in citric acid fermentation. Moreover, the rate of propionic acid conversion to methane was much lower compared with acetic acid under the same conditions [26, 27]. Therefore, propionic acid more easily and gradually accumulated and influenced the integrated process. It is necessary to investigate the effect of propionic acid on citric acid fermentation and the established recycling process.

Effect of propionic acid on citric acid fermentation in a 5-L fermenter

Effect of propionic acid on citric acid fermentation was investigated in a 5-L fermenter and citric acid fermentation with tap water was performed as control in this study. Propionic acid was added to fermentation medium to the final concentration of 2.0, 4.0, 6.0 or 8.0 mM after inoculation and the pH at the start of the fermentation was adjusted to approximately 4.5 (Fig. 4). With 2 mM propionic acid addition, the citric acid fermentation was hardly influenced and the citric acid production was 146.1 g/L which was even slightly higher than the control (144.3 g/L) (Fig. 4a). When propionic acid contained in medium increased to 4 mM, the citric acid fermentation was slightly inhibited and the lag phase increased to 6 h, while only lag phase of 4 h was found when fermented with tap water. However, the final citric acid production approached to 146.8 g/L which was still higher than the control. This result was similar to our previous experiments with acetic acid addition, which proved that citric acid production increased as acetic acid concentration was below 8 mM in initial pH 4.5 [23]. Moreover, ethanol fermentation by S. cerevisiae with acetic acid and propionic acid addition also achieved the similar result. Thomas et al. [28] confirmed that ethanol production increased by 20 % with 167 mM acetic acid addition in pH 4.5 medium. Taherzadeh et al. [29] proved that a 21 % increase in ethanol yield was found when 3.5 g/L of acetic acid was added at pH 3.5. Zhang et al. [30] reported that ethanol production increased by 11.1 % when 30 mM propionic acid contained in fermentation medium with the initial pH of 4.0. Therefore, it should be noted that low concentration of propionic acid (below 4 mM) could slightly improve citric acid production and appropriate concentration of propionic acid contained in the ADE could be useful to promote citric acid fermentation in the integrated citric acid-methane fermentation process.

As propionic acid concentration continuously increased to 6 mM, the citric acid fermentation was significantly inhibited and the lag phase extended to 10 h was found. The citric acid production at the end of fermentation was 133.4 g/L, decreasing by 7.6 % compared with the control. When 8 mM propionic acid was added to medium, the lag phase of citric acid fermentation significantly increased to 28 h and the citric acid production was only 60.6 g/L, declined by 58.0 %. This phenomenon indicated that high concentration of propionic acid could prolong the lag phase of citric acid fermentation and decrease the citric acid production. These results were also supported by the change of pH and citric acid production rate during fermentation (Fig. 4d, f). Papagianni [31] reported that medium pH could sharply decline to below 3.0 at the initial growth stage in normal citric acid fermentation by A. niger. When propionic acid in medium was below 4 mM, the changes of pH in citric acid fermentation were almost same to the control which sharply declined to below 3.0 in the first 12 h. As the propionic acid concentration increased to 6 mM and 8 mM, the difference occurred and the pH decreased to below 3.0 at 24 and 48 h, respectively, indicating the extension of the lag phase. Similarly, the citric acid production rate was hardly influenced when propionic acid concentration was below 4 mM and the highest citric acid production rate was found at 24 h. As increasing the propionic acid concentration, the highest citric acid production rate was extended at 36 and 72 h. Meanwhile, the citric acid production rate also decreased as the propionic acid concentration increased. These results were similar to the reports by Zhang et al. [32] who confirmed that in ethanol fermentation by S. cerevisiae, fermentation time and ethanol productivity were rarely influenced by low propionic acid concentrations, however, fermentation time prolonged and ethanol productivity decreased with high propionic acid concentrations addition. Therefore, it should be noted that high concentration of propionic acid (above 6 mM) could inhibit citric acid fermentation by prolonging the lag phase and decreasing the citric acid production rate.

Changes of residual total sugar and glucose in citric acid fermentation were also detected (Fig. 4b, c). When propionic acid concentration in fermentation medium was below 4 mM, the consumption rates of total sugar were same to the control. The residual total sugars at the end of fermentation were 17 g/L which were even lower than those of the control (18 g/L) (Fig. 4b). Moreover, the changes of the residual glucose were almost same to the control which were approximately 35 g/L in initial culture medium and then completely consumed at the end of fermentation (Fig. 4c). This result indicated that part of sugars which could not be used in the fermentation with tap water, had been consumed to produce citric acid when low concentration of propionic acid (below 4 mM) was added to fermentation medium. Ion chromatography (provide by Dionex ICS-5000, USA) was used to separate the components of residual sugar at the end of fermentation and the result indicated that the concentration of residual isomaltose decreased with propionic acid addition (data not shown). Xu et al. [16] reported that residual isomaltose concentration could be an important parameter to evaluate the normal of citric acid fermentation, and inhibition of citric acid fermentation could result in increasing of residual isomaltose. When 2 and 4 mM propionic acid was added, the residual isomaltose (the initial isomaltose concentration in culture medium is approximately 28.6 g/L) were 0.82 and 1.07 g/L, respectively, which were lower than the control (1.82 g/L). Isomaltase activity in citric acid fermentation with propionic acid addition was detected and the result is shown in Fig. 4e. Fermentation with tap water, the isomaltase activity in medium increased in first 24 h and then sharp decrease occurred, followed by inactivation in 60 h. When low concentration of propionic acid was contained in medium, the change trends of isomaltase activity were the same to the control which also increased in first 24 h and the highest isomaltase activity approached to the control. Then the declines of isomaltase activities were found and the decreasing rates were lower than the control where the enzyme activities could not be detected until 72 h. These results indicated that low concentration of propionic acid (below 4 mM) could promote isomaltase activity in citric acid fermentation which converted more isomaltose to available sugar, causing residual isomaltose concentration decrease and citric acid production increase. When 6 and 8 mM propionic acid was added to medium, the residual total sugars were 24 and 85 g/L, respectively, which were significantly higher than the control (Fig. 4b). Moreover, part of glucose were also not completely consumed and still contained in medium at the end of citric acid fermentation (Fig. 4c), while the residual isomaltose concentrations were 3.91 and 19.25 g/L, respectively. The isomaltase activities during citric acid fermentation were detected and the result showed that the activities of isomaltase were greatly inhibited and the highest isomaltase activities were lower than the control (Fig. 4e). These results indicated that high concentration of propionic acid (above 6 mM) could greatly inhibit the vitality of A. niger and decrease the ability of consuming glucose to produce citric acid.

Although a maximum of 2.9 mM propionic acid in recycling could not inhibit citric acid fermentation (Fig. 4), ADE sample from citric acid industrial was detected and 1.50 g/L (approximately 20.3 mM) propionic acid was found under acidification conditions [23]. Therefore, it was necessary to systematically evaluate the effect of propionic acid on citric acid fermentation under different conditions to support and understand the application of this coupled process on the industrial scale.

Effect of propionic acid on citric acid fermentation in different initial pH

Many researchers have reported that the inhibitory effect of weak organic acids on microorganisms could be related to the medium pH [28, 32, 33]. Therefore, effect of propionic acid on citric acid fermentation in different initial pH was investigated in this study and the result is shown in Fig. 5. The inhibition of citric acid fermentation by propionic acid became stronger as the initial pH of medium decreased (Fig. 5a). Citric acid production declined when the concentration of propionic acid was above 2, 4, and 6 mM in initial pH 4.0, 4.5, and 5.0, respectively. Below inhibition concentration, citric acid production was hardly influenced by propionic acid and even slightly higher than the control. However, citric acid production significantly decreased as the concentration of propionic acid increased to the above inhibition value.

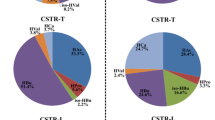

The mechanisms of the propionic acid influencing citric acid fermentation by A. niger have been hardly investigated up to now. As to S. cerevisiae, propionic acid is considered to diffuse freely into the cell in the undissociated form [30]. Previous study has also proved that undissociated acetic acid was the effective inhibitory form to influence the citric acid fermentation by A. niger [23]. Therefore, the effect of undissociated propionic acid on citric acid fermentation was investigated. As shown in Fig. 5b, the effect of propionic acid on citric acid production was most likely associated with undissociated propionic acid, regardless of its total concentration at different pH. Consequently, it should be noted that similar to acetic acid, the influence of propionic acid on citric acid fermentation could also be through its undissociated form. Effect of propionic acid on biomass in medium in different initial pH was also studied to confirm above conclusion (Fig. 6). Biomass in medium decreased sharply when the concentration of propionic acid was above 2, 4, and 6 mM in initial pH 4.0, 4.5, and 5.0, respectively (Fig. 6a). Similarly, the effect of propionic acid on biomass was most likely related to undissociated acid (Fig. 6b), which also proved that the effect of propionic acid on citric acid fermentation was due to its undissociated form.

When the concentration of undissociated propionic acid was below 2.82 mM, citric acid production slightly improved, while biomass in medium was hardly influenced (Figs. 5b, 6b). This phenomenon was similar to widely reported results of ethanol fermentation by S. cerevisiae when propionic acid is added to the medium. Zhang et al. [30] explained that propionic acid can diffuse through the plasma membrane, dissociate intracellularly, and thus acidify the cytoplasm. Concurrently, to maintain a constant intracellular pH, protons must be transported across the membrane by plasma membrane ATPase, resulting in increased ATP consumption and improved ethanol production. Similarly, the intracellular pH of A. niger cell in normal citric acid fermentation was 6.5–7.0 [34]. With propionic acid addition, the greater demand for ATP to maintain a constant intracellular pH led to more glucose entering into tricarboxylate cycle and participating in the synthesis of ATP which could also be the reason to increase citric acid production in our experiment and relative research is underway. When the undissociated propionic acid concentration was above 2.82 mM, citric acid fermentation was inhibited and the citric acid production and biomass in medium decreased sharply. This phenomenon could be explained that undissociated propionic acid entering into the cell had exceeded the ability of cell to pump out the protons to remain the intracellular pH stable. Therefore, cytoplasmic acidification and intracellular accumulation of acid anion occurred, which could influence the vitality of cell and even result in complete autolysis [35], causing the citric acid production and biomass in medium decreased.

Concentrations of residual total sugar, glucose, and isomaltose at the end of fermentation are shown in Table 1. Fermentation with tap water in initial pH 4.0, residual total sugar, and isomaltose significantly increased compared with fermentation with higher initial pH, while glucose in medium was almost completely consumed at the end of fermentation. Moreover, citric acid production in initial pH 4.0 was also lower than the others (Fig. 5a). Therefore, it should be noted that the breakdown of isomaltose was influenced by the low initial pH which decreased the available sugar concentration for citric acid fermentation, causing residual total sugar increase and decreased citric acid production. When propionic acid concentration was below inhibition value, glucose in medium was almost completely consumed, while residual total sugar and isomaltose were lower than the control, indicating the promotion of the isomaltase activity. Increasing propionic acid concentration to above inhibition value, citric acid fermentation was inhibited and residual total sugar concentration and isomaltose were increased, while residual glucose was not completely consumed and still remained in medium. When acetic acid was added to the medium in ethanol fermentation by S. cerevisiae, increased yeast growth and ethanol production were also considered to the function of the buffer pairs formed from acetic acid which could protect against a rapid decrease in medium pH [28]. Propionic acid was a weak organic acid which could also form buffer pairs and maintain the stablility of the medium pH. With propionic acid addition, the pH decline was slower than the control (Fig. 4d) and the isomaltase was functioned until 72 h (Fig. 4e). Therefore, propionic acid addition that promoted the citric acid fermentation could also be the reason of forming buffer pairs and maintaining the stable pH of the medium, which promoted the activity of isomaltase and decreased residual isomaltose concentration to achieve more available sugar and improve the citric acid production.

In normal citric acid fermentation by A. niger, pH of medium could sharply decline to below 3 at the initial growth stage [31]. In our experiment in the 5-L fermenter, the pH of medium in normal citric acid fermentation was also decreased to below 3.0 in first 12 h (Fig. 4d) and under this condition propionic acid completely existed in the undissociated form (propionic acid pKa of 4.88). If citric acid fermentation was inhibited by propionic acid at fermentation stage, the magnitude of inhibition should depend on total concentration and regardless of initial medium pH, which was opposite with the result. Therefore, similar to acetic acid [23], propionic acid might influence citric acid fermentation at growth stage.

In the normal anaerobic digestion, propionic acid could be completely consumed to produce methane [30]. However, acidification of methane fermentation could result in propionic acid accumulation in ADE and significant inhibit citric acid fermentation in recycling. Therefore, methane fermentation must be strictly controlled to ensure the propionic acid concentration below inhibition value. Meanwhile, initial fermentation pH could be adjusted to avoid or alleviate the potential inhibitory effect when propionic acid concentration in ADE was excessive.

Conclusions

In this study, an integrated citric acid-methane fermentation process was proposed to solve the problem of wastewater treatment in citric acid production. Citric acid wastewater was used to produce biogas through anaerobic digestion and then the ADE was further treated and recycled to make mash for next batch citric acid fermentation, thus eliminating wastewater discharge and reducing water resource consumption. Propionic acid was found in ADE which could significantly inhibit citric acid fermentation in high concentration. However, low concentration of propionic acid could promote isomaltase activity and slightly increase citric acid production. Therefore, propionic acid in the ADE was not always harmful to citric acid fermentation, and regulating propionic acid concentration within a reasonable range could be useful to promote the integrated citric acid-methane fermentation process.

References

Ates S, Dingil N, Bayraktar E, Mehmetoglu U (2002) Enhancement of citric acid production by immobilized and freely suspended Aspergillus niger using silicone oil. Process Biochem 38:433–436

Chang VS, Holtzapple MT (2000) Fundamental factors affecting biomass enzymatic reactivity. Appl Biochem Biotechnol 84–86:5–37

Mattey M (1992) The production of organic acids. Crit Rev Biotechnol 12:87–132

Dhillon GS, Brar SK, Verma M, Tyagi RD (2011) Recent advances in citric acid bio-production and recovery. Food Bioprocess Technol 4:505–529

Li C, Yang HL, Xia X, Li Y, Chen L, Zhang M, Zhang L, Wang W (2013) High efficient treatment of citric acid effluent by Chlorella vulgaris and potential biomass utilization. Bioresour Technol 12:248–255

Zhi X, Yang H, Berthold S, Doetsch C, Shen J (2010) Potential improvement to a citric wastewater treatment plant using bio-hydrogen and a hybrid energy system. J Power Sources 195:6945–6953

Zhu YR, Zhou C, Wang JH, Xie HS, Gao MX (2004) Treatment of high concentration wastewater from citric acid production. Tech Equip Environ Pollut Control 5:64–66 (in Chinese)

Colleran E, Pender S, Philpott U, Flaherty V, Leahy B (1998) Full-scale and laboratory-scale anaerobic treatment of citric acid production wastewater. Biodegradation 9:233–245

Zhu LH, Xu X, Wang R (2007) Study on the treatment of wastewater from citric acid production by UASB-BIOFOR process. Ind Water Treat 27:39–41 (in Chinese)

Shi ZL, Li W, Yao SH (2009) Wastewater treatment of citric acid by emulsion liquid membrane method. J Shenyang Univ Chem Technol 23:289–293 (in Chinese)

Fu GL, Xu XY, Fan LH, Zhang M (2007) Experimental study of fentons reagent treated lemon acid wastewater. J Huaihai Inst Technol 16:44–46 (in Chinese)

Cheng T, Lin T (2008) Experimental study of lemon acid wastewater with microwave radiation by MnO2. GuiZhou Chem Ind 33:41–42 (in Chinese)

Kayombo S, Mbwette TSA, Katima JHY, Jorgensen SE (2003) Effects of substrate concentrations on the growth of heterotrophic bacteria and algae in secondary facultative ponds. Water Res 37:2937–2943

Xu J, Chen YQ, Zhang HJ, Tang L, Wang K, Zhang JH, Chen XS, Mao ZG (2014) Production of citric acid using its extraction wastewater treated by anaerobic digestion and ion exchange in an integrated citric acid–methane fermentation process. Bioprocess Biosyst Eng 37:1659–1668

Xu J, Chen YQ, Zhang HJ, Tang L, Wang K, Zhang JH, Chen XS, Mao ZG (2015) Optimization of the integrated citric acid–methane fermentation process by air stripping and glucoamylase addition. Bioprocess Biosyst Eng 38:411–420

Xu J, Chen YQ, Zhang HJ, Bao JW, Tang L, Wang K, Zhang JH, Chen XS, Mao ZG (2015) Establishment and assessment of an integrated citric acid–methane production process. Bioresour Technol 176:121–128

APHA (1995) Standard methods for the examination of water and wastewater, 17th edn. American Public Health Association (APHA), New York

Wang J, Yue ZB, Chen TH, Peng SC, Yu HQ, Chen HZ (2010) Anaerobic digestibility and fiber composition of bulrush in response to steam explosion. Bioresour Technol 101:6610–6614

Speece RE (1996) Anaerobic biotechnology for industrial wastewaters. Vanderbilt University, Archae Press, Tennessee

Sung S, Santha H (2003) Performance of temperature-phased anaerobic digestion (TPAD) system treating dairy cattle wastes. Water Res 37:1628–1636

Alkaya E, Kaptan S, Ozkan L, Uludag-Demirer S, Demirer GN (2009) Recovery of acids from anaerobic acidification broth by liquid–liquid extraction. Chemosphere 77:1137–1142

Pavlostathis S, Giraldo-Gomez E (1991) Kinetics of anaerobic treatment: a critical review. Crit Rev Environ Sci Technol 21:411–490

Xu J, Chen YQ, Zhang HJ, Tang L, Wang K, Zhang JH, Chen XS, Mao ZG (2014) Effect of acetic acid on citric acid fermentation in an integrated citric acid–methane fermentation process. Appl Biochem Biotechnol 174:376–387

Freese E, Sheu CW, Galliers E (1973) Function of lipophilic acids as antimicrobial food additives. Nature 241:321–325

Kornberg H, Gotto A (1961) The metabolism of C2 compounds in micro-organisms. Biochem J 78:69

Wang Y, Zhang Y, Wang J, Meng L (2009) Effects of volatile fatty acid concentrations on methane yield and methanogenic bacteria. Biomass Bioenergy 33:848–853

Ren NQ, Liu M, Wang A, Ding J, Li H (2003) Organic acids conversion in methanogenic-phase reactor of the two-phase anaerobic process. Chin J Environ Sci 24:89–93

Thomas K, Hynes S, Ingledew W (2002) Influence of medium buffering capacity on inhibition of Saccharomyces cerevisiae growth by acetic and lactic acids. Appl Environ Microbiol 68:1616–1623

Taherzadeh MJ, Niklasson C, Lidén G (1997) Acetic acid—friend or foe in anaerobic batch conversion of glucose to ethanol by Saccharomyces cerevisiae. Chem Eng Sci 52:2653–2659

Zhang CM, Jiang L, Mao ZG, Zhang JH, Tang L (2011) Effects of propionic acid and pH on ethanol fermentation by Saccharomyces cerevisiae in cassava mash. Appl Biochem Biotechnol 165:883–891

Papagianni M (2007) Advances in citric acid fermentation by Aspergillus niger: biochemical aspects, membrane transport and modeling. Biotechnol Adv 25:244–263

Zhang CM, Du FG, Wang X, Mao ZG, Sun PY, Tang L, Zhang JH (2012) Effect of propanoic acid on ethanol fermentation by Saccharomyces cerevisiae in an ethanol–methane coupled fermentation process. Chin J Chem Eng 20:942–949

Zhao R, Bean SR, Crozier-Dodson BA, Fung DYC, Wang DH (2009) Application of acetate buffer in pH adjustment of sorghum mash and its influence on fuel ethanol fermentation. J Ind Microbiol Biotechnol 36:75–85

Jernejc K, Legiša M (2004) A drop of intracellular pH stimulates citric acid accumulation by some strains of Aspergillus niger. J Biotechnol 112:289–297

Verduyn C, Postma E, Scheffers W, Van Dijken J (1990) Energetics of Saccharomyces cerevisiae in anaerobic glucose-limited chemostat cultures. J Gen Microbiol 136:405–412

Acknowledgments

This work was supported by Research and Innovation Program for Graduate Students of Jiangsu Province (KYLX15-1144). We thank the Yixing Xielian Biological Chemical Co. Ltd., China for their support and anonymous reviewers for critically evaluating this manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, J., Bao, JW., Su, XF. et al. Effect of propionic acid on citric acid fermentation in an integrated citric acid–methane fermentation process. Bioprocess Biosyst Eng 39, 391–400 (2016). https://doi.org/10.1007/s00449-015-1522-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-015-1522-4