Abstract

A 2 M sodium acetate buffer at pH 4.2 was tried to simplify the step of pH adjustment in a laboratory dry-grind procedure. Ethanol yields or conversion efficiencies of 18 sorghum hybrids improved significantly with 2.0–5.9% (3.9% on average) of relative increases when the method of pH adjustment changed from traditional HCl to the acetate buffer. Ethanol yields obtained using the two methods were highly correlated (R 2 = 0.96, P < 0.0001), indicating that the acetate buffer did not influence resolution of the procedure to differentiate sorghum hybrids varying in fermentation quality. Acetate retarded the growth of Saccharomyces cerevisiae, but did not affect the overall fermentation rate. With 41–47 mM of undissociated acetic acid in mash of a sorghum hybrid at pH 4.7, rates of glucose consumption and ethanol production were inhibited during exponential phase but promoted during stationary phase. The maximum growth rate constants (μ max) were 0.42 and 0.32 h−1 for cells grown in mashes with pH adjusted by HCl and the acetate buffer, respectively. Viable cell counts of yeast in mashes with pH adjusted by the acetate buffer were 36% lower than those in mashes adjusted by HCl during stationary phase. Coupled to a 5.3% relative increase in ethanol, a 43.6% relative decrease in glycerol was observed, when the acetate buffer was substituted for HCl. Acetate helped to transfer glucose to ethanol more efficiently. The strain tested did not use acetic acid as carbon source. It was suggested that decreased levels of ATP under acetate stress stimulate glycolysis to ethanol formation, increasing its yield at the expense of biomass and glycerol production.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Interest in ethanol as a clean-burning fuel is stronger than ever. Use of ethanol as a fuel additive has grown over the past few years, and this growth is expected to continue. Corn constitutes about 97.5% of the feedstock for ethanol production in the United States. In 2007, conversion to ethanol accounted for 2.3 billion bushels of corn [26], nearly 18% of the total US corn crop production of 13.1 billion bushels [35]. Likely, many sources of biomass and species will be selected for their ecological fit as well as their production and processing capability. In addition to corn, breeders are working with several other crops including sorghum, wheat, millet, rice, and barley to study the performance of these crops in ethanol fermentation. There is a large variation in fermentation quality among the hundreds of cereal hybrids used in the commercial channel; thus, it is important for the ethanol industry and crop producers to have proper methods to predict ethanol yields as well as conversion efficiencies of these hybrids.

Laboratory fermentation is the most direct and reliable method of evaluating fermentation qualities of cereal grains. Many laboratories have reported their dry-grind procedures [5, 10–12, 16, 17, 28, 29, 32, 34, 37–42], which are similar to each other to some extent. The traditional procedure described by Wu et al. [41] was tedious and laborious, especially in the steps of mash preparation, pH adjustment, and yeast preculture preparation. To save time, increase experiment repeatability, and mimic fuel ethanol production in the dry-grind industry, we modified that procedure as follows: liquefaction was simplified from two steps (95°C for 45 min and 80°C for 30 min) to one step (86°C for 90 min), yeast preculture preparation was substituted with commercially available active dry yeast, and simultaneous saccharification and fermentation (SSF) were applied. In a recent study [43], we reported that there was a strong linear relationship in ethanol yields of 18 sorghum hybrids between the traditional and SSF procedure. Ethanol yield improved significantly using SSF. On average, changing from the traditional fermentation procedure to SSF resulted in a relative increase in ethanol yield of 3.0%. In both procedures, pH of mashes was adjusted one by one after saccharification via 2 M HCl using a pH meter. No fixed quantity of acid solution was titrated, and the adjustment process was time-consuming because the buffering capacity of whole grain mashes differed among samples [2], even within the same crop variety (e.g., sorghum). Moreover, the risk of microbial contamination would have been increased. A much simpler method for pH adjustment was anticipated.

Acetic acid is well known for its toxicity and is used as an antimicrobial food additive. Maiorella et al. [15] noted that 7.5 g/L of this acid was enough to induce 80% inhibition on the performance of S. cerevisiae. Pampulha and Loureiro [20] reported a 90% inhibition of the growth of S. cerevisiae when total acetic acid concentration was 80 mM at pH 3.5–4.5. Phowchinda et al. [24] observed a 75% reduction in the maximum specific growth rate of S. cerevisiae when 6 g/L acetic acid was added to the medium. A complete inhibition of S. cerevisiae could be obtained if a high amount of acetic acid (10 g/L) is added [15, 20, 24]. Early experiments concluded that toxicity of acetic acid for various microorganisms including S. cerevisiae is not confined to the hydrogen-ion concentration alone but seems to be a function of the concentration of their undissociated forms [13]. It was also reported that acetic acid inhibits hexokinase, phosphofructokinase, and enolase in yeast cell and then inhibits fermentation [22].

The equilibrium between dissociated and undissociated states is pH-dependent in both extra- and intra-cellular environment, as described by the Henderson–Hasselbach equation

where pKa = 4.74 for acetic acid; [Ac−] and [HAc] are the molarities of dissociated and undissociated species, respectively. There is a general agreement in the literature [2, 7, 18, 19, 21, 23, 30, 33] that the undissociated form of the molecule diffuses passively into the microbial cell because of its high solubility in the phospholipid portion of the plasma membrane and reaches the more alkaline environment of cellular cytoplasm where dissociation occurs. This leads to a massive accumulation of dissociated anions and protons within the cell, thereby acidifying the cytoplasm, disrupting homeostasis of intracellular pH, and increasing the inhibitory activity. Thus, the magnitude of growth inhibition is enhanced as extracelluar pH decreases, because this shifts the equilibrium in favor of the undissociated acid. Working at extracellular pH of 3.5–5.5, Pampulha and Loureiro-Dias [21] reported that the internal pH (pHi) of S. cerevisiae is a function of the concentration of undissociated form of acetic acid only, independent of extracellular pH. However, Thomas et al. [33] argued that it was the total concentration of acetic acid, not the concentration of undissociated acid alone, that determines the extent of growth inhibition, although only undissociated acid diffuses into the cells.

Yeast cells are known to maintain their pHi within the narrow physiological range of 5.0–7.1 despite wider variations in external pH of 2.0–10.0 [6, 8, 9, 25, 31, 36]. As reviewed in detail by Madshus [14], prominent regulation mechanisms of pHi in eukaryotic cells include Na+/H− antiport, anion antiport, Na+/HCO3 −symport, and H+-translocating adenosinetriphosphatase (H+-ATPase). In the case of yeast, the latter mechanism is widely recognized in the presence of acetic acid [2, 18, 19, 23, 30, 33]. Undissociated acid that diffuses through the plasma membrane may dissociate to an extent determined by pHi. This results in the formation of charged anions and protons and may cause reduction in pHi once buffering capacity is exceeded. The cell, however, tries to maintain its pHi homeostasis by extruding the excess protons via the plasma H+-ATPase, which uses energy from ATP hydrolysis for its activity. Narendranath et al. [18] demonstrated that pHi of yeast cells was not significantly affected by acetic acid up to a concentration of 42 mM in the medium, whereas activity of the plasma membrane H+-ATPase increases linearly with increasing concentrations of acetic acid. It takes time for yeast to pump out excess protons to achieve the required pHi for growth, as indicated by the increase in the duration of the lag phase at increasing acetic acid concentrations [19]. However, maintenance of pHi homeostasis results in significant depletion of cellular ATP [15, 30]; 1 mol of ATP was consumed for every mole of acetic acid entering the yeast cells [23]. Increased diversion of energy (ATP) for cell maintenance can impair growth, because, under anaerobic conditions, biomass is directly related to ATP production. Biomass yield on ATP and growth rate are affected. Subsequent reductions in biomass yield, maximum specific growth rate, or rate of glucose depletion have been demonstrated [15, 19, 20, 24, 30].

During the development of a small-scale mashing (SSM) procedure [43], the pH of liquefied mashes was found to be very important for saccharification, and a 2 M acetate buffer at pH 4.2 was optimized to conveniently adjust pH of mashes. One particular aim in this study was to apply the acetate buffer for pH adjustment of liquefied mashes in the SSF procedure. We expected that acetic acid would behave as a friend [30] in laboratory fermentation, affecting neither the anaerobic conversion of glucose to ethanol by S. cerevisiae nor the resolution of the SSF procedure in differentiating grain samples varying in fermentation quality. Thus, our laboratory fermentation procedure would be further simplified and more maneuverable.

Materials and methods

Preparation of samples

The 18 sorghum hybrids (I–XVIII) described by Zhao et al. [43] were used in this study. Two additional sorghum hybrids, XIX and XX, were also selected and tested. Samples for ethanol fermentation were ground into fine meals in a Magic Mill III Plus grain mill (Magic Mill Products and Appliances, Monsey, NY, USA) set at Level III. For starch analysis, sorghum kernels were ground using an Udy mill (Udy Corp., Fort Collins, CO, USA) through a 1.0-mm screen.

Preparation of mashes

For mashing, 30 g of ground sorghum (dry matter) was dispersed in a 250-mL Erlenmeyer flask with an aliquot of 100 mL of fermentation solution, which was prepared by mixing 1 L of distilled water (60–65°C) with 1.0 g of KH2PO4, 3.0 g of yeast extract, and 200 μL of Liquozyme SC DS (240 KNU/g, 1.25 g/mL; Novozymes, Franklinton, NC, USA), an enzyme preparation containing thermostable alpha-amylase. Flasks were then inserted into a water bath shaker (Amerex Instruments, Inc., Lafayette, CA, USA) oscillating at 100 rpm. The water bath had been preheated to 95°C. Initially, flasks were shaken manually to prevent gel formation. This shaking process required several minutes depending on the number of flasks inserted. The water bath temperature was decreased to 82–87°C at the end of shaking with slurries in the flasks well-dispersed. The temperature was brought to 86°C and held for 90 min with continuous shaking. Flasks were then removed from the water bath, and the material on the inner surface of the flasks were scraped back into the bottom with a spatula and rinsed with 3–5 mL of deionized distilled water (DD-water) using a sterilized fine-tipped polyethylene transfer pipette.

pH adjustment

After cooling to ambient temperature, the pH of liquefied mashes was adjusted in two ways. Some mashes were aseptically adjusted to pH 4.2–4.3 by 2 M HCl with a pH meter being used. For pH adjustment by acetate, 5.0 mL of 2 M sodium acetate buffer at pH 4.2 was added to the mash in a flask in most experiments, and 2.5, 7.5, or 10.0 mL of the buffer was also used in some cases. For comparison, no pH adjustment was performed to some mashes or 5 mL of DD-water was used as a control.

Preparation of inoculum

One gram of active dry yeast (Red Star Ethanol Red, Lesaffre, Milwaukee, WI, USA) was dispersed in 19 mL of a preculture broth containing glucose (20 g/L), peptone (5 g/L), yeast extract (3 g/L), KH2PO4 (1 g/L), and MgSO4·7H2O (0.5 g/L), and incubated at 38°C for 30 min in an incubator operating at 200 rpm.

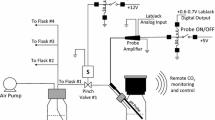

Simultaneous saccharification and fermentation

One milliliter of the above activated yeast culture and 100 μL of Spirizyme Fuel (750 AGU/g, 1.15 g/mL, Novozymes, Franklinton, NC, USA), an enzyme preparation containing glucoamylase, were added to each flask, which was subsequently sealed with an S-shaped airlock filled with ≈2 mL of mineral oil. The ethanol fermentation was performed in an incubator shaker (Model I2400, New Brunswick Scientific Inc., Edison, NJ, USA) at 30°C, with continuous shaking at 200 rpm. The fermentation process was monitored by measuring the mass losses of mash because of the emission of CO2 during fermentation. The fermentation time was normally 72 h, but some flasks were removed for beer sampling and analyses at fermentation times of 0, 4, 10, 16, 22, 28, 34, 40, 48, and 72 h.

Beer diluting and sampling

For flasks removed at the previously described fermentation times, pH of the beer was determined using a pH meter. Then, all of the beer in each flask was diluted to 1 L with DD-water. After mixing thoroughly, diluted beers were sampled immediately for HPLC and microbiological analyses through a set of pipettes and presterilized tips. Prior to HPLC analyses, all diluted beer samples were filtered through a 0.20-μm Millipore membrane.

Viable cell counts

After serial decimal dilutions (up to 10−6) of the diluted beer samples using a 0.1% sterile peptone solution, 0.1 mL of the 10−3, 10−4, and 10−5 dilutions were spread-plated onto triplicate Potato Dextrose Agar of pH 3.5 adjusted with 10% (w/v) tartaric acid for yeast-mold counts. One milliliter of the 10−5 and 10−6 dilutions was also plated on 3M Petrifilms for total cell counts (3M Microbiology Products, St Paul, MN, USA). All plates and Petrifilms were incubated at 32°C for 48–72 h, and then cell counts were calculated.

Distillation

In some experiments, all of the beer in a flask was transferred to a 500-mL distillation flask with a total 100 mL of DD-water at the final fermentation time (72 h). The transferred beer was distilled on a distillation heating unit, and the distillate was collected into a 100-mL volumetric flask that was dipped into ice water. Distillation was stopped when distillate approached the 100-mL mark (≈99 mL). The collected distillate was then equilibrized to 25°C and brought to 100 mL. The residue (distiller’s grains with solubles, DGS) remaining in each distillation flask was diluted to 1 L with DD-water. Prior to HPLC analyses, all diluted DGS samples were filtered through a 0.20-μm Millipore membrane.

Experimental design

A split-plot design was conducted to investigate the effect of acetic acid on yeast growth and its metabolites during fermentation (Table 1). Experiments were carried out in two separate weeks, which were treated as blocks to remove source variability caused by any possible changes in the laboratory, such as room temperature and humidity, during testing periods. The two methods of pH adjustment, by 2 M HCl and by 5 mL of 2 M sodium acetate buffer at pH 4.2, were selected as the whole-plot factors in a randomized complete block structure with fermentation times as the subplot factors. For one pH treatment during one single testing period (a block), a total 12 flasks of mashes were prepared at the beginning of fermentation and one flask was randomly removed for beer diluting and sampling at fermentation times of 0, 4, 10, 16, 22, 28, 34, 40, 48, and 72 h. There were two flasks left at the 72 h fermentation time for each pH treatment in each block; masses of ethanol in these flasks were obtained via distillation, and masses of glycerol in diluted DGS were also measured.

Analytical methods

Moisture content was measured using AACC-Approved Method 44-15A [1]. Total starch content was determined using a Megazyme total starch kit (Megazyme International Ireland Ltd, Wicklow, Ireland) according to AACC-Approved Method 76-13 [1]. Method B was used, which involves pretreatment with dimethyl sulfoxide at 100°C. Glucose, glycerol, and ethanol in diluted beer samples; glycerol in diluted DGS samples; and ethanol in distillate samples were determined using a Shimadzu (Shimadzu Scientific Instruments, Inc., Columbia, MD, USA) HPLC system equipped with a Rezex RCM 300 × 7.8 mm column (Phenomenex, Torrance, CA, USA) with a security guard column. The mobile phase used was DD-water at a flow rate of 0.6 mL/min. Injection volume was 20 μL. Concentrations of all mentioned metabolites were detected with a refractive index detector (Model RID-10A, Shimadzu). Temperatures of the column and detection cell were maintained at 80 and 40°C, respectively. HPLC data were processed using EZStart 7.4 software (Shimadzu), and the amounts of each metabolite at different fermentation times were compared according to their total masses in each flask. Ethanol yields (%, v/v) of sorghum hybrids were quoted as concentrations of ethanol in their distillates.

Calculation of the masses of ethanol or glycerol in a fermentation flask

The beer and the DGS samples in Fig. 1 originated from two different flasks with pH adjusted by 2 M HCl at fermentation time of 72 h, and they were diluted to 1 L before sampling for HPLC analyses. The peak of glycerol from the diluted DGS sample identically matched its counterpart from the diluted beer sample. The profile of ethanol in the diluted beer sample was obtained by subtracting the profile of glycerol in the diluted DGS sample from that of glycerol and ethanol in the diluted beer sample. Thus, the peak areas of glycerol (Ag) and ethanol (Ae) were integrated separately. Atol was equal to the sum of Ag and Ae (Fig. 1). At a fermentation time of 72 h, Ag and Ae accounted for 15.9 and 84.1% of Atol, respectively, for the diluted beer sample in the fermentation flask with pH adjusted by 2 M HCl; the ratio of Ag to Atol decreased to 9.5% and the ratio of Ae to Atol increased to 90.5% when pH was adjusted by the acetate buffer. Using the same ground meal (from sorghum hybrid XIX) with the same fermentation conditions, all diluted beer samples at different fermentation times had profiles very similar to that at 72 h, except that their glycerol and ethanol peaks differed mainly in the magnitude of height. We assumed that the productions of glycerol and ethanol by yeast were concomitant (i.e., the ratios of Ag or Ae to Atol would be constant throughout fermentation, irrespective of the fermentation times). Thus, we used the ratios of Ag or Ae to Atol at 72 h to calculate the peak areas of glycerol and those of ethanol at the other fermentation times after the total areas of glycerol and ethanol were obtained by HPLC analyses, and then the masses of glycerol or ethanol in each fermentation flask were calculated conveniently.

Chromatograms of glycerol and ethanol in a beer sample (upper solid line) and glycerol in a DGS sample (lower solid line) at a fermentation time of 72 h. The beer and the DGS originated from two different fermentation flasks with pH adjusted by 2 M HCl, and they were diluted to the same volume (1 L) before sampling for HPLC analyses. The chromatogram of ethanol was obtained by subtracting the chromatogram of glycerol in the diluted DGS sample from that of glycerol and ethanol in the diluted beer sample (lower dotted line). Atol, Ag, and Ae represent the peak areas under the corresponding chromatograms

Statistical analyses

All experiments were performed at least in duplicate. Results presented are the mean values of the repeated experiments. Analysis of variance, split-plot design, and linear regression were performed using SAS software version 9.1 (SAS Institute, Cary, NC, USA).

Results

Application of acetate buffer in pH adjustment of mash

In a small-scale mashing (SSM) procedure [43], the pH of a liquefied mash containing 300 mg of ground grain and a total 1.1 mL of enzyme dilutions in a microtube was adjusted easily by mixing with 50 μL of 2 M sodium acetate buffer at pH 4.2. Then, we attempted to use this acetate buffer to adjust the pH of liquefied mashes prepared for laboratory SSF, in which 2 M HCl was usually used for pH adjustment. Ethanol fermentation processes (Fig. 2) were monitored by measuring the masses of the flasks with S-shaped airlocks, because the mass losses by CO2 evolution are proportional to the amounts of ethanol produced during ethanol fermentation [39]. Fermentation sped up in the mashes with pH adjusted either by 2 M HCl or by the acetate buffer, indicating that pH adjustment was necessary in SSF. The ground meal (from sorghum hybrid XIX) had a total starch content of 73.0% (dry matter). After 72 h of fermentation, the ethanol yield and conversion efficiency of the control (no pH adjustment) were 14.04% (v/v) and 88.6%, respectively. When pH was adjusted by 2 M HCl, the ethanol yield and conversion efficiency increased slightly but significantly (P < 0.01) to 14.18% (v/v) and 89.5%, respectively. An unexpected 5.1% relative increase in ethanol yield or conversion efficiency was achieved when acetate buffer was used as a substitute for 2 M HCl.

Comparison among curves of mass losses from CO2 evolution in a laboratory SSF procedure using different methods for pH adjustment on the mashes from the same ground meal (from sorghum hybrid XIX). For pH adjustment by acetate, 5 mL of 2 M buffer at pH 4.2 was added to the mash in a fermentation flask before inoculation. Duplication (two flasks) for each pH treatment with repeated measurements taken over time. Standard error for mean values of mass losses was 0.03

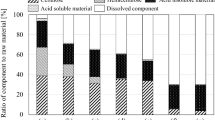

After the promising results, we extended the application of the acetate buffer in SSF to 18 other sorghum hybrids. As reported by Zhao et al. [43], these hybrids had ethanol yields of 12.38–14.77% (v/v) (13.78% on average) and conversion efficiencies of 87.3–92.3% (89.9% on average) using the SSF procedure with pH adjusted by 2 M HCl. Using the same SSF procedure but with pH adjusted by the acetate buffer (Fig. 3), their ethanol yields or conversion efficiencies improved significantly (P < 0.0001), with ranges of 12.87–15.21% (v/v) (14.29% on average) and 91.4–95.7% (93.4% on average) for ethanol yields and conversion efficiencies, respectively. Relative increases in their ethanol yields or conversion efficiencies were 2.0–5.9% (3.9% on average). Ethanol yields with pH adjusted by the acetate buffer were highly related to those adjusted by 2 M HCl (R 2 = 0.96, P < 0.0001).

Relationship between ethanol yields of 18 sorghum hybrids (I–XVIII) using a laboratory SSF procedure with the pH of their mashes adjusted by 2 M HCl or acetate buffer before inoculation. For pH adjustment by acetate, 50 μL of 2 M buffer at pH 4.2 was added to the mash in a fermentation flask before inoculation

Effects of acetate buffer on ethanol fermentation in SSF

Compared with the measurement of mass losses in Fig. 2, it was not as convenient to analyze how yeast cells grew and their metabolites developed in flasks during fermentation, because the beers had to be sampled at different fermentation times. If repeated measurements were taken over time using the same beer in a flask, oxygen would enter into the flask at each sampling time. Results would be incomparable to those obtained with flasks sealed by S-shaped airlocks throughout fermentation. To avoid disturbing the anaerobic conditions, one flask was randomly removed from a total 12 flasks of mashes at the required fermentation times for one pH treatment during one testing period. The growth kinetics of S. cerevisiae in sorghum mashes are shown in Figs. 4 and 5. In Fig. 4, viable cell counts (VCCs) are plotted over time on a semilogarithmic scale, whereas pH values and mass losses on the same graph using a linear scale. For simplicity, mashes in the flasks with pH adjusted by HCl and by the acetate buffer are referred to as Mash I and Mash II, respectively.

Changes in VCC, pH, and ML of mashes from the same sorghum meal (from sorghum hybrid XIX) during SSF fermentation. Each filled square, circle, or triangle represents a different fermentation flask. VCC viable cell counts, ML mass losses, [HCl] pH adjusted by 2 M HCl, [Acetate] pH adjusted by 5 mL of 2 M acetate buffer at pH 4.2. Standard errors of mean values were 1.4 × 109 cells/flask, 0.02, and 0.07 g/flask for VCC, pH, and ML, respectively

Glucose depletion and production of ethanol and glycerol by S. cerevisiae in mashes from the same sorghum meal (from sorghum hybrid XIX) during SSF fermentation. Each filled square, circle, or triangle represents a different fermentation flask. [HCl] pH adjusted by 2 M HCl, [Acetate] pH adjusted by 5 mL of 2 M acetate buffer at pH 4.2. Standard errors (g/flask) of mean values were 0.08, 0.08, and 0.02 for glucose, ethanol, and glycerol, respectively

Effect on pH

The main purpose of pH adjustment was to optimize the activity of the enzyme, amyloglucosidase, which had an optimum pH range of 3.5–4.5. As shown in Fig. 4, the pH of Mash I decreased gradually (from initial 4.2 to the lowest 3.4) during fermentation, but there was a sharp reduction in the period from 4 to 10 h of fermentation, during which the yeast cells grew most rapidly. The pH values remained unchanged (P > 0.05) during 28–48 h, and then increased slightly but significantly (P < 0.0001) to 3.5 at the end of fermentation, which might be related to release of amino acids from autolysing yeast cells [27]. The acetate buffer did not adjust the pH values of Mash II to 4.2 as expected, but it kept them very stable (from 4.7 to 4.5) throughout the fermentation process.

Effect on yeast growth

The growth curves of S. cerevisiae (Fig. 4) show that the yeast cells grew exponentially within the first 10 h. The maximum growth rate constants (μ max) were 0.42 and 0.32 h−1 for cells grown in Mash I and Mash II, respectively. The deceleration phase for Mash I was shorter than that for Mash II. The stationary phase for Mash I started from the fermentation time at 16 to 40 h, and then a death phase. After the fermentation time at 28 h, the VCC for Mash II decreased continuously but not significantly (P > 0.07). Acetate retarded the growth of yeast cells in sorghum mash. The VCC in Mash II was 36% lower than that in Mash I during the stationary phase. It was difficult to detect any red colonies on the 3M Petrifilms even after 3 days of incubation, and we concluded that the 3M Petrifilm for total cell counts was not a good medium for yeast and mold. However, the results showed that no bacteria contamination was found in the mashes. Mashing (86°C, 90 min) acted as a pasteurization process, and all bacteria in sorghum meal could be killed successfully.

Effect on consumption of glucose

In SSF, amyloglucosidase and yeast were added simultaneously, and sugars (mainly glucose, maltose, and maltotriose) were released by amyloglucosidase and consumed by yeast continuously throughout the process. Each flask contained 30 g of dry sorghum meal with starch content of 73.0% (dry matter), and the theoretical glucose content was 24.3 g if starch could be hydrolyzed to glucose completely. The amounts of glucose in mashes were supposed to be near zero at the beginning of fermentation, but 13–15 g of glucose, as shown in Fig. 5, was detected in each flask as there was a period of time from the addition of amyloglucosidase to sample preparation until final HPLC analysis. Again, glucose content in Mash II (15.0 g/flask) was higher than that in Mash I (13.3 g/flask) immediately after inoculation, which might be related to the fact that the diluted samples from Mash II were always analyzed by HPLC after their counterparts from Mash I. The speed of glucose release by amyloglucosidase was far beyond that of glucose consumption by yeast in SSF. The dynamic glucose levels (Fig. 5) in Mash II were always higher than their counterparts in Mash I within the first 22 h (P < 0.001). This was related to the fact that yeast cells in Mash I came to the stationary phase 6 h earlier than their counterparts in Mash II. However, yeast cells in Mash II consumed glucose more rapidly as there was no significant difference (P = 0.60) in glucose between the two kinds of mashes at 22 h, and after that time the glucose contents in Mash II were lower than those in Mash I till the glucose had almost been nearly depleted at 40 h.

Effect on production of glycerol and ethanol

Production of glycerol and ethanol from glucose happened simultaneously with anaerobic fermentation by yeast cells (Fig. 5). In Mash II, maximum ethanol production occurred at a fermentation time of 48 h [i.e., there was no significant difference in ethanol (P = 0.42) between fermentation time at 48 and 72 h], whereas in Mash I, production of ethanol ended later. This was in compliance with the consumption of glucose and the evolution of CO2 monitored by mass losses (Fig. 4). Although ethanol contents in Mash II were lower than their counterparts in Mash I within the first 16 h, they increased more rapidly after fermentation time at 10 h and led to higher values at completion. On the contrary, glycerol was produced at much lower levels in Mash II throughout the SSF process. In each flask at fermentation time of 72 h, Mash II contained 11.71 g of ethanol and 0.62 g of glycerol, and Mash I contained 11.12 g of ethanol and 1.09 g of glycerol. Compared with pH adjustment by HCl, a 5.3% relative increase in ethanol and a 43.6% relative decrease in glycerol were obtained when the acetate buffer was used.

Effect of the volume of acetate buffer on ethanol fermentation

As shown in Fig. 6, the volume of the buffer influenced ethanol fermentation significantly. Similar to the observation in Fig. 2, the control mash (pH adjustment by DD-water) had an overall lower fermentation speed and mass loss than its counterparts with pH adjusted by 2.5 or 5 mL of the buffer. The time at which the mass loss of the mash in a flask could be observed was delayed after the buffer volume was increased from 5 to 10 mL. Yeast growth was almost completely inhibited when 10 mL buffer was added. After the 24 h fermentation time, the mash with 5 mL buffer had a higher degree of mass losses than the mash with 2.5 mL buffer (P < 0.01). Although fermentation in the mash with 7.5 mL buffer started almost 18 h later than its counterpart with 5 mL buffer, there was no difference (P > 0.42) in mass losses between the two mashes at the final period of time (64–72 h). The ground meal (from sorghum hybrid XX) had a total starch content of 72.0% (dry matter). After 72 h of fermentation, ethanol yields were 13.73, 14.43, 14.72, 14.76, and 0.59% (v/v) for the mashes with 0, 2.5, 5, 7.5, and 10 mL of the buffer, respectively. The ethanol yield from the mash with 7.5 mL buffer was not significantly higher (P = 0.31) than that from the mash with 5 mL buffer.

Comparison among curves of mass losses from CO2 evolution in a laboratory SSF procedure using different volumes of acetate buffer for pH adjustment on the mashes from the same ground meal (from sorghum hybrid XX). Before inoculation, 2.5, 5.0, 7.5, or 10.0 mL of 2 M buffer at pH 4.2 was added to the mash in a fermentation flask. DD-water was also used as a control. Duplication (two flasks) for each volume treatment with repeated measurements taken over time. Standard error for mean values of mass losses was 0.03

Discussion

Currently, one of the research activities of our group is to select a relatively large and diverse set of samples from the huge pool of sorghum breeding lines, evaluate their performance in a bench-scale “dry-grind” conversion of sorghum to ethanol, and identify key factors affecting ethanol yield and conversion efficiency. To save time and reduce the risk of contamination, an acetate buffer was quantitatively pipetted to liquefied mashes before inoculation in our SSF procedure. Ethanol yields or conversion efficiencies of 18 sorghum hybrids improved significantly with 2.0–5.9% (3.9% on average) of relative increases when the method of pH adjustment changed from traditional HCl to the acetate buffer. Ethanol yields obtained using the two methods were highly correlated (Fig. 3), indicating that the acetate buffer did not influence resolution of the SSF procedure to differentiate grain samples varying in fermentation quality. Thus, several experiments were conducted to elucidate the reason why ethanol yields or conversion efficiencies improved.

In previous researches [2, 19, 20, 24, 33], acetic acid was observed to decrease rates of glucose consumption and ethanol production. Contrastively, results in this research showed that they are unnecessarily always reduced during fermentation. With 5 mL of the acetate buffer added into mash, they were inhibited during exponential phase but promoted during stationary phase (Figs. 4, 5). Thus, the overall fermentation rate in the mash with pH adjusted by the acetate buffer was comparable to its counterpart HCl (Figs. 2, 4, 5), and even faster than control without pH adjustment (Figs. 2, 6). No inhibition in rate of mass loss (i.e., ethanol production) was observed when 2.5 mL of the acetate buffer was added to a flask (Fig. 6). Acetate retarded yeast growth, but did not affect overall fermentation rate.

One purpose of pH adjustment was to optimize the activity of the enzyme, amyloglucosidase, which had an optimum pH range of 3.5–4.5 [43]. Our results also showed the necessity of pH adjustment in SSF for obtaining higher conversion efficiency and faster fermentation rate (Fig. 2). Because of the buffering capacity of whole grain mashes [2, 33], 5 mL of the acetate buffer did not bring the pH of mash to 4.2 as expected after inoculation, but it kept the system stable (pH from 4.7 to 4.5) throughout the fermentation process (Fig. 4), indicating that a buffer pair had been developed. With 5 mL of the acetate buffer added into a flask, the estimated volume of the liquid mash after inoculation was about 110–125 mL, and the total concentration of acetic acid including its undissociated and dissociated forms was 80–90 mM. Thus, at the beginning of fermentation (pH 4.7), the concentration of the undissociated acetic acid in sorghum mashes was about 41–47 mM, calculated according to the Henderson–Hasselbach equation. The undissociated form of the molecule diffused passively into the yeast cells and led to an accumulation of dissociated anions and protons within the cells. The cells, however, tried to maintain pHi homeostasis by extruding the excess protons via the plasma H+-ATPase, which used energy from ATP hydrolysis. Depletion of energy (ATP) for maintenance of pHi homeostasis impaired yeast growth as evidenced by the decrease in VCC and μ max (Fig. 4). As elucidated by Thomas et al. [33], the buffer pairs, formed extracellularly by addition of the acetate buffer and intracellularly from the acid accumulated inside the cells, probably helped stabilize pH of the medium by sequestering protons and making pHi of yeast cells not being significantly affected, lessening the negative impact of the pH drop on yeast growth. Consequently, as suggested in previous studies [2, 19, 23], decreased levels of ATP under moderate stress of acetic acid might stimulate the energy-producing glycolytic pathway, increasing ethanol yield at the expense of biomass production. The magnitude of growth inhibition was enhanced, as the volume of the acetate buffer increases. It took more time for yeast to adapt to the culture conditions (i.e., longer duration of the lag phase) with higher concentrations of acetic acid in the mash (Fig. 6). Likely, more acetate added into mash, more undissociated form of the molecule accumulated inside the cells and more extreme stress yeast confronted. Five milliliters of the acetate buffer happened to be the optimum addition in terms of fermentation rate and ethanol yield. A proper addition (e.g., 5 mL) of the acetate buffer increased the production of ethanol yield as well as conversion efficiency and decreased the production of glycerol significantly. Taherzadeh et al. [30] also obtained a 21% increase in ethanol yield and 50% decrease in glycerol yield adding 21 mM acetic acid at pH 3.5. In this research, the estimated total concentration of acetic acid was 154–174 mM when 10 mL of the acetate buffer was added into mash; at pH 4.2, concentration of the undissociated acetic acid was about 120–135 mM, which almost completely inhibits the growth of S. cerevisiae (Fig. 6) and the yeast cell might be stressed out. In contrast, Thomas et al. [33] produced as much as 20% more ethanol when 167 mM of acetic acid was present in the medium at pH 4.5 than when it was absent.

Theoretically, acetate ions may be used in formation of acetyl-CoA via the action of acetyl-coenzyme A synthetase and consumed in the citric acid cycle, sparing some pyruvic acid associated with anaerobic cell growth and increasing fermentative production of ethanol. Taherzadeh et al. [30] observed net acetate assimilation in some cases, but the rate of acetate consumption is small compared with the diffusion rate of undissociated acetic acid. However, analysis results confirmed that yeast does not metabolize acetic acid as long as glucose remains in the medium [23, 33]. No glucose was left in Mash II and the production of ethanol stopped after a fermentation time of 48 h (Fig. 5), suggesting that no acetic acid was consumed by yeast to produce ethanol. HPLC analysis further showed that there was no change (P > 0.05) in total acetic acid before and after fermentation with the pH of mashes adjusted by 5 mL of the acetate buffer, indicating that the yeast did not use acetic acid as a carbon source (results not shown).

Data (Fig. 5) showed that the decrease in production of the by-product glycerol was the most apparent reason for the increase in ethanol yield. To reoxidize surplus NADH, formed in the synthesis of biomass and secondary fermentation products during anaerobic conditions, to NAD+, cells of S. cerevisiae reduce dihydroxyacetone phosphate by NAD+-dependent glycerol 3-phosphate dehydrogenase to glycerol 3-phosphate, which is then dephosphorylated to glycerol by glycerol 3-phosphatase [4, 27]. Glycerol helps S. cerevisiae to maintain cells’ redox balance. Taherzadeh et al. [30] elucidated several reasons for decreased glycerol yield with the addition of acetate; particularly, they pointed out that decreases in biomass yield and formation of acetate will reduce surplus formation of NADH. The fuel ethanol industry, however, is increasingly interested in developing a competitive bioprocess that can reduce yields of fermentation by-products (e.g., glycerol) and increase conversion efficiency [3], as the soaring price of raw materials determines the overall economy of the process. Results in this study afforded an approach to reduce glycerol production during ethanol fermentation.

There was a strong, linear relationship (R 2 = 0.997, P < 0.0001) between mass losses and ethanol contents for all mashes (Figs. 4, 5), suggesting that the evolution of CO2 was directly related to the production of ethanol, and the pathway to produce glycerol during anaerobic fermentation by S. cerevisiae had no effects on CO2. Monitoring mass losses of mashes in fermentation flasks would be a very simple, reliable, and also reproducible method of estimating ethanol yields in the laboratory SSF procedure.

References

AACC International (2000) Approved methods of the American association of cereal chemists, 10th edn. Methods 44-15A and 76-13. AACC International, St Paul

Abbott DA, Ingledew WM (2004) Buffering capacity of whole corn mash alters concentrations of organic acids required to inhibit growth of Saccharomyces cerevisiae and ethanol production. Biotechnol Lett 26:1313–1316. doi:10.1023/B:BILE.0000044924.76429.71

Bideaux C, Alfenore S, Cameleyre X, Molina-Jouve C, Uribelarrea JL, Guillouet SE (2006) Minimization of glycerol production during the high-performance fed-batch ethanolic fermentation process in Saccharomyces cerevisiae, using a metabolic model as a prediction tool. Appl Environ Microbiol 72:2134–2140. doi:10.1128/AEM.72.3.2134-2140.2006

Cronwright GR, Rohwer JM, Prior BA (2002) Metabolic control analysis of glycerol synthesis in Saccharomyces cerevisiae. Appl Environ Microbiol 68:4448–4456. doi:10.1128/AEM.68.9.4448-4456.2002

Devantier R, Pedersen S, Olsson L (2005) Characterization of very high gravity ethanol fermentation of corn mash. Effect of glucoamylase dosage, pre-saccharification and yeast strain. Appl Microbiol Biotechnol 68:622–629. doi:10.1007/s00253-005-1902-9

Domberk KM, Ingram LO (1987) Ethanol production during batch fermentation with Saccharomyces cerevisiae: changes in glycolytic enzymes and internal pH. Appl Environ Microbiol 53:1286–1291

Freese E, Sheu CW, Galliers E (1973) Function of lipophilic acids as antimicrobial food additives. Nature 24:321–325. doi:10.1038/241321a0

Imai T, Ohno T (1995) Measurement of yeast intracellular pH by image processing and the change it undergoes during growth phase. J Biotechnol 38:165–172. doi:10.1016/0168-1656(94)00130-5

Imai T, Ohno T (1995) The relationship between viability and intracellular pH in the yeast Saccharomyces cerevisiae. Appl Environ Microbiol 61:3604–3608

Ingledew WM, Thomas KC, Hynes SH, McLeod JG (1999) Viscosity concerns with rye mashes used for ethanol production. Cereal Chem 76:459–464. doi:10.1094/CCHEM.1999.76.3.459

Ingledew WM, Jones AM, Bhatty RS, Rossnagel BG (1995) Fuel alcohol production from hull-less barley. Cereal Chem 72:147–150

Lee WJ, Yoon JR, Park KJ, Chung KM (2000) Fermentation of corn and wheat with supplementation of inactive dry brewer’s yeast. J Am Soc Brew Chem 58:155–159

Levine AS, Fellers CR (1940) Action of acetic acid on food spoilage microorganisms. J Bacteriol 39:499–515

Madshus IH (1988) Regulation of intracellular pH in eukaryotic cells. Biochem J 250:1–8

Maiorella B, Blanch HW, Wilke CR (1983) By-product inhibition effects on ethanolic fermentation by Saccharomyces cerevisiae. Biotechnol Bioeng 25:103–121. doi:10.1002/bit.260250109

Mojovic L, Nikolic S, Rakin M, Vukasinovic M (2006) Production of bioethanol from corn meal hydrolyates. Fuel 85:1750–1755. doi:10.1016/j.fuel.2006.01.018

Naidu K, Singh V, Johnston DB, Rausch KD, Tumbleson ME (2007) Effects of ground corn particle size on ethanol yield and thin stillage soluble solids. Cereal Chem 84:6–9. doi:10.1094/CCHEM-84-1-0006

Narendranath NV, Thomas KC, Ingledew WM (2001) Acetic acid and lactic acid inhibition of growth of Saccharomyces cerevisiae by different mechanisms. J Am Soc Brew Chem 59:187–194

Narendranath NV, Thomas KC, Ingledew WM (2001) Effects of acetic acid and lactic acid on growth of Saccharomyces cerevisiae in a minimal medium. J Ind Microbiol Biotechnol 26:171–177. doi:10.1038/sj.jim.7000090

Pampulha ME, Loureiro V (1989) Interaction of the effects of acetic acid and ethanol on inhibition of fermentation in Saccharomyces cerevisiae. Biotechnol Lett 11:269–274. doi:10.1007/BF01031576

Pampulha ME, Loureiro-Dias MC (1989) Combined effect of acetic acid, pH and ethanol on intracellular pH of fermenting yeast. Appl Microbiol Biotechnol 31:547–550. doi:10.1007/BF00270792

Pampulha ME, Loureiro-Dias MC (1990) Activity of glycolytic enzymes of Saccharomyces cerevisiae in the presence of acetic acid. Appl Microbiol Biotechnol 34:375–380. doi:10.1007/BF00170063

Pampulha ME, Loureiro-Dias MC (2000) Energetics of the effect of acetic acid on growth of Saccharomyces cerevisiae. FEMS Microbiol Lett 184:69–72. doi:10.1111/j.1574-6968.2000.tb08992.x

Phowchinda O, Delia-Dupuy ML, Strehaiano P (1995) Effects of acetic acid on growth and fermentative activity of Saccharomyces cerevisiae. Biotechnol Lett 17:237–242. doi:10.1007/BF00127996

Ramos S, Balbib M, Raposo M, Valle E, Pardo LA (1989) The mechanism of intracellular acidification induced by glucose in Saccharomyces cerevisiae. J Gen Microbiol 64:91–99

Renewable Fuels Association (RFA) (2008) Changing the climate: ethanol industry outlook 2008. http://www.ethanolrfa.org/media/pdf/outlook_2008.pdf. Accessed on 6 March 2008

Russell I (2003) Understanding yeast fundamentals. In: Jacques KA, Lyons TP, Kelsall DR (eds) The alcohol textbook, 4th edn. Nottingham University Press, Nottingham, pp 85–119

Singh V, Batie CJ, Aux GW, Rausch KD, Miller C (2006) Dry-grind processing of corn with endogenous liquefaction enzymes. Cereal Chem 83:317–320. doi:10.1094/CC-83-0317

Singh V, Graeber JV (2005) Effect of corn hybrid variability and planting location on ethanol production. Trans ASAE 48:709–714

Taherzadeh MJ, Niklasson C, Liden G (1997) Acetic acid—friend or foe in anaerobic batch conversion of glucose to ethanol by Saccharomyces cerevisiae? Chem Eng Sci 15:2653–2659. doi:10.1016/S0009-2509(97)00080-8

Taipa MA, Cabral JMS, Santos H (1993) Comparison of glucose fermentation by suspended and gel-entrapped yeast cells: an in vivo nuclear magnetic resonance study. Biotechnol Bioeng 41:647–653. doi:10.1002/bit.260410607

Thomas KC, Dhas A, Rossnagel BG, Ingledew WM (1995) Production of fuel alcohol from hull-less barley by very high gravity technology. Cereal Chem 72:360–364

Thomas KC, Hynes SH, Ingledew WM (2002) Influence of medium buffering capacity on inhibition of Saccharomyces cerevisiae growth by acetic and lactic acids. Appl Environ Microbiol 68:1616–1623. doi:10.1128/AEM.68.4.1616-1623.2002

Thomas KC, Ingledew WM (1990) Fuel alcohol production: effects of free amino nitrogen on fermentation of very-high-gravity wheat mashes. Appl Environ Microbiol 56:2046–2050

United States Department of Agriculture (USDA) (2008) Crop production 2007 summary. http://usda.mannlib.cornell.edu/usda/current/CropProdSu/CropProdSu-01-11-2008.pdf. Accessed on 6 March 2008

Valli M, Sauer M, Branduardi P, Borth N, Porro D, Mattanovich D (2005) Intracellular pH distribution in Saccharomyces cerevisiae cell populations, analyzed by flow cytometry. Appl Environ Microbiol 71:1515–1521. doi:10.1128/AEM.71.3.1515-1521.2005

Wang S, Ingledew WM, Thomas KC, Sousulski K, Sosulski FW (1999) Optimization of fermentation temperature and mash specific gravity for fuel alcohol production. Cereal Chem 76:82–86. doi:10.1094/CCHEM.1999.76.1.82

Wang S, Thomas KC, Ingledew WM, Sosulski K, Sosulski FW (1997) Rye and triticale as feedstock for fuel ethanol production. Cereal Chem 74:621–625. doi:10.1094/CCHEM.1997.74.5.621

Wu X, Wang D, Bean SR, Wilson JP (2006) Ethanol production from pearl millet using Saccharomyces cerevisiae. Cereal Chem 83:127–131. doi:10.1094/CC-83-0127

Wu X, Zhao R, Bean SR, Seib PA, McLaren JS, Madl RL et al (2007) Factors impacting ethanol production from grain sorghum in the dry-grind process. Cereal Chem 84:130–136. doi:10.1094/CCHEM-84-2-0130

Wu X, Zhao R, Wang D, Bean SR, Seib PA, Tuinstra MR et al (2006) Effects of amylose, corn protein and corn fiber contents on production of ethanol from starch rich media. Cereal Chem 83:569–575. doi:10.1094/CC-83-0569

Zhan X, Wang D, Bean SR, Mo X, Sun XS, Boyle D (2006) Ethanol production from supercritical-fluid-extrusion cooked sorghum. Ind Crops Prod 23:304–310. doi:10.1016/j.indcrop.2005.09.001

Zhao R, Bean S, Wang D, Park SH, Schober TJ, Wilson J (2008) Small-scale mashing procedure for predicting ethanol yield of sorghum grain. J Cereal Sci 48 (in press)

Acknowledgments

This project was supported by the National Research Initiative of the USDA Cooperative State Research, Education and Extension Service, grant number 2004-35504-14808. Authors would like to thank Novozymes Inc. for providing Liquozyme SC DS and Spirizyme Fuel, and Fermentis of S.I. Lesaffre for the active dry yeast used in this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Names are necessary to report factually on available data; however, the U.S. Department of Agriculture neither guarantees nor warrants the standard of the product, and use of the name by the U.S. Department of Agriculture implies no approval of the product to the exclusion of others that may also be suitable.

Rights and permissions

About this article

Cite this article

Zhao, R., Bean, S.R., Crozier-Dodson, B.A. et al. Application of acetate buffer in pH adjustment of sorghum mash and its influence on fuel ethanol fermentation. J Ind Microbiol Biotechnol 36, 75–85 (2009). https://doi.org/10.1007/s10295-008-0474-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-008-0474-y