Abstract

We studied the dynamics of ethanol production on lactose-hydrolyzed whey (LHW) and lactose-hydrolyzed whey permeate (LHWP) in batch fluidized-bed bioreactors using single and co-cultures of immobilized cells of industrial strains of Saccharomyces cerevisiae and non-industrial strains of Kluyveromyces marxianus. Although the co-culture of S. cerevisiae CAT-1 and K. marxianus CCT 4086 produced two- to fourfold the ethanol productivity of single cultures of S. cerevisiae, the single cultures of the K. marxianus CCT 4086 produced the best results in both media (Y EtOH/S = 0.47–0.49 g g−1 and Q P = 1.39–1.68 g L−1 h−1, in LHW and LHWP, respectively). Ethanol production on concentrated LHWP (180 g L−1) reached 79.1 g L−1, with yields of 0.46 g g−1 for K. marxianus CCT 4086 cultures. Repeated batches of fluidized-bed bioreactor on concentrated LHWP led to increased ethanol productivity, reaching 2.8 g L−1 h−1.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Environmental concerns about the use of fossil fuels and the amounting agro-industrial residues have put growing pressure on research for innovative technologies for energy production and waste reuse. Cheese whey (or whey) and whey permeate are by-products of dairy industries, presenting potential sources of environmental pollution when improperly discarded. These products have the potential to be used in bioprocess because of their unique composition characteristics. Whey is a rich substrate for ethanol fermentation because of its high lactose content (45–50 g L−1), protein (6–8 g L−1), lipids (4–5 g L−1), and mineral salts (5–7 g L−1). Whey permeate, the product of protein removal from whey, has a lactose content (around of 45 g L−1) and minerals salts (3–5 g L−1), and could also be considered for bioprocesses as a source of cheap substrate [1–3]. Direct fermentation of the liquid slurry of whey and whey permeate is not economically feasible because of their low sugar concentrations, implying high distillation costs [2, 4]. However, dried or evaporated whey and whey permeate might be attractive raw materials for ethanol fermentation because these materials have a characteristically low water content and high lactose concentrations, being cheap and extremely convenient for storage, transportation, and use [4]. In this context, the production of ethanol from whey is expected to become increasingly important.

Several yeasts have shown the ability to metabolize the lactose present in whey and whey permeate, but traditional yeasts used for industrial fermentation processes showing high ethanol and sugar tolerance, such as Saccharomyces cerevisiae, cannot use lactose as carbon source, because they lack lactose permease and β-galactosidase enzymes [5, 6]. Therefore, a preliminary reaction of enzymatic or chemical hydrolysis of lactose is required to use whey or whey permeate as substrate for ethanol production using S. cerevisiae [7, 8]. One possibility is the pre-treatment of whey and whey permeate with β-galactosidase, which catalyzes the hydrolysis of lactose liberating an equimolecular mixture of glucose and galactose [9]. Biological alternative technologies for this enzymatic reaction rely on the use of yeast strains capable of metabolizing lactose, such as the genus Kluyveromyces, and the use of co-cultures of different strains, including S. cerevisiae [5–8]. The genus Kluyveromyces has been well characterized concerning its ability to use lactose, and several strains of Kluyveromyces marxianus have successfully been used to convert whey and/or whey permeate into ethanol. Alternatively, the engineering of S. cerevisiae by different strategies has been investigated, but most strains obtained in this way showed undesirable characteristics such as low growth, genetic instability, and low ethanol production [5, 6]. Another alternative strategy consists in the co-culture of K. marxianus and S. cerevisiae, which brings together the advantages of these two strains: the adapted growth of Klyuveromyces in lactose and galactose, and the high ethanol tolerance and faster glucose consumption of Saccharomyces strains [1, 10].

Cell immobilization, a strategy of cell confinement in appropriate inert supports, can contribute to bioprocess optimization because of their characteristics such as high productivity, lower fermentation time, small operational volume, cell protection against inhibitory products, reduced contamination risks, and ease downstream processing [11, 12]. The ethanol production using cell immobilized bioreactors has been developed in recent years using different immobilization strategies and supports such as agar [13], alginate [14–16], sorghum bagasse [17], and sugarcane bagasse [18]. Among these, the use of alginate is the most widespread technique because this material is non-toxic, inexpensive, allows for high cell density entrapment, and it is simple to prepare [11, 12, 19].

In this context, the aims of this research were to analyze the dynamics of several possibilities of using lactose-hydrolyzed whey (LHW) and lactose-hydrolyzed whey permeate (LHWP) as substrates for ethanol production using different yeasts, as single cultures of industrially important strains of S. cerevisiae or non-industrial strains of K. marxianus, and also as co-cultures of both yeasts. The cultures were run using Ca-alginate immobilized-cell systems in batch and repeated batches in fluidized-bed bioreactors. Fermentative parameters of ethanol production, yields, and productivities were evaluated.

Materials and methods

Yeasts, cell maintenance, and materials

The yeast strains Saccharomyces cerevisiae CAT-1 and PE-2, and Kluyveromyces marxianus CCT 4086 were used in this research. The S. cerevisiae strains were chosen because of their good ethanol and sugar tolerance [1, 20]. Although they are commercially available, the stocks used by us were kindly supplied by the Department of Genetics from the Biological Sciences Center, Federal University of Pernambuco (Recife, Brazil). The K. marxianus CCT 4086 was provided by the Tropical Culture Collection of André Tosello Foundation (Campinas, Brazil). This strain of K. marxianus was chosen because it demonstrated a high capacity of lactose bioconversion into ethanol [15]. Cells were kept frozen at −20 °C, in a 60 % cell suspension in glycerol, whereas for immediate use, cells were kept on YEPD or YEP–lactose agar slants (yeast extract, 10 g L−1; bactopeptone, 20 g L−1; glucose or lactose, 20 g L−1, agar, 20 g L−1), at 4 °C [21].

All chemicals used in this research were purchased from Sigma-Aldrich (São Paulo, Brazil, or St. Louis, USA), unless otherwise indicated.

Lactose hydrolysis in whey and in whey permeate

Dried whey (powder) and dried whey permeate were used in this research (Elegê Laticínios S.A., and Sooro, Brazil, respectively). Reconstituted whey composition was: 56 g L−1 of lactose, 9 g L−1 of protein, and 5 g L−1 of minerals; reconstituted whey permeate composition was: 56 g L−1 of lactose, 1 g L−1 of protein, and 3 g L−1 of minerals. Lactose hydrolysis was performed using a commercial β-galactosidase (Maxilact LX 5000, enzymatic activity of ≥5000 NLU g−1, DSM Food Specialties, Heerlen, The Netherlands). A volume of 0.5 mL L−1 of enzyme was added to reconstituted whey (70 g L−1 whey powder) or to whey permeate (60 g L−1 whey permeate powder) and the mixture was kept at 25 °C, under slow agitation, reaching a maximum hydrolysis efficiency of >90 % around 8 h of reaction. For the hydrolysis of concentrated whey permeate (180 g L−1 whey permeate powder), a volume of 1.5 mL L−1 of enzyme was used, and the reaction was performed under the same conditions described above. Samples were periodically withdrawn, filtered through a 0.22 µm acetate cellulose membrane to remove proteins that may cause interference with the analysis, and the glucose liberation was determined using an enzymatic kit (Labtest Diagnóstica S. A., Brazil).

Yeast cell immobilization

The yeast strains were immobilized by entrapment in Ca-alginate beads. S. cerevisiae and K. marxianus strains were grown in 2 L flasks filled with 800 mL of YEPD or YEP–lactose media, respectively, pH 7.0, and at 30 °C, in an orbital shaker at 180 rpm for 15 h to obtain exponential-phase cells. At this point, cells were harvested by centrifugation (3000×g, 15 min), washed twice, and resuspended in 10 mL of sterile distilled water at 4 °C. The cell suspension was added to a sterile solution of sodium alginate (40 g L−1) to a final biomass concentration of 20 g L−1. The mixture was immediately dropped through a 14 G needle (2.1 mm of diameter) using a peristaltic pump into a 0.1 M CaCl2 sterile solution at 35 °C, and gently agitated for 30 min to stabilize the system. The beads were washed thrice with distilled water at 4 °C and kept in peptone water (1 g L−1) with 0.1 M CaCl2 overnight. Then, the beads were washed thrice with sterile distilled water at 4 °C and transferred into the bioreactors. Approximately, 150 beads of every batch of immobilization were measured for their diameters using a pachymeter, with measuring results showing an average diameter of 3.8 ± 0.05 mm.

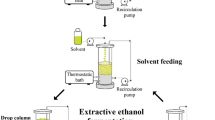

Bioreactor cultivations

Batch fluidized-bed cultivations were performed in glass column bioreactors [15] filled with 85 mL of alginate beads and 250 mL of medium. In the co-culture experiment, the glass column was filled with 42.5 mL of beads each of yeasts. Lactose-hydrolyzed whey or whey permeate was used as culture media without any addition of other nutrients. Prior to the sterilization process (121 °C, 15 min), whey proteins were hydrolyzed with a commercial protease (Alcalase 2.4 L, 2.4 UA-A/g, Novozymes, Araucária, Brazil), using 1 mL L−1 of the enzyme preparation at pH 8.5, 55 °C for 3 h, to avoid protein precipitation. The cultures were carried out at 30 °C and fluidization was performed by recirculating the culture medium upward through the column by a peristaltic pump at a flow rate of 250 mL min−1.

Repeated batches of fluidized-bed cultivations were carried out in a similar mode to the batch fluidized-bed cultivations. Concentrated lactose-hydrolyzed whey permeate was used as culture medium. After 24 h, all cultivation broth was drained and the immobilized cells were retained in the bioreactor. The same amount of concentrated lactose-hydrolyzed whey permeate was immediately replaced to start the next cycle. This procedure was repeated for ten cycles, completing a total of 240 h of cultivation.

All experiments were carried out in duplicate. The ethanol productivities (Q P) and yields (Y EtOH/S) in batch fluidized-bed cultivations were calculated considering the maximum ethanol concentration in the process.

Obtained data throughout the work were statistically evaluated by analysis of variance (ANOVA) using Statistica 10.0 software (StatSoft, USA).

Analytical determinations

Samples were collected from the top of bioreactors using a sterile needle, centrifuged (3000×g, 15 min) and the supernatants were analyzed for sugar and ethanol concentrations. Lactose, galactose, glucose, and ethanol concentrations were determined by HPLC (Shimadzu, Japan) with refractive index detector and Bio-Rad HPX-87H column (300 mm × 7.8 mm) using 5 mM sulfuric acid as eluent at 45 °C, flow rate of 0.6 mL min−1, and sample volumes of 20 μL.

Results and discussion

Dynamics of cultures in LHW and LHWP in the batch fluidized-bed bioreactors with single and co-cultures of S. cerevisiae and K. marxianus

This experimental step was carried out to compare the dynamics of fermentation kinetics of Saccharomyces and Kluyveromyces in LHW and LHWP because of the unique characteristics of these yeasts. S. cerevisiae CAT-1 and PE-2 strains are widely used in Brazil for ethanol production from sugarcane because they show high ethanol tolerance and excellent yields of fermentation [20], but they were never tested on hydrolysed lactose. On the other hand, strains of K. marxianus are highly adapted to grow in lactose and galactose media [1, 14], and we decided to test K. marxianus CCT 4086 (to our knowledge never applied in industrial fermentations) because of its high bioconversion of whey and permeate into ethanol, as previously described by our research group [15, 22], and compare it with the Saccharomyces strains.

The batch kinetics of Ca-alginate immobilized cells of CAT-1 and PE-2 in the fluidized-bed bioreactors using LHW and LHWP are presented in Figs. 1 and 2. The two strains showed similar diauxic growth kinetics in the liberated mixture of glucose and galactose in media. The conversion of galactose into glycolytic intermediate needs energy and additional catabolic steps, since the glycolytic enzymes are not galactose specific, thus the Leloir pathway is switched on to convert galactose into glucose 6-phosphate, which is in turn metabolized in the glycolysis pathway and finally reduced to ethanol [10, 23]. Maximal ethanol concentrations of 18.6 g L−1 and 18.8 g L−1 were observed for S. cerevisiae CAT-1 and PE-2, respectively, in LHW medium. When LHWP was used, the consumption of galactose was slower compared to LHW, and ethanol concentrations were lower, reaching maximal concentrations of 15.4 and 15.1 g L−1 for S. cerevisiae CAT-1 and PE-2, respectively. One possible explanation for these differences is the fact that whey is a richer medium in minerals and protein than whey permeate, containing all necessary nutrients for cell growth and product formation [24]. For both S. cerevisiae strains, the highest ethanol yields (Y EtOH/S) and ethanol productivities (Q P) were observed in LHW medium (Table 1), reaching 0.44 g g−1 and 0.78 g L−1 h−1, compared to only 0.36 g g−1 and 0.31 g L−1 h−1 in LHWP. It is clear that these yeast strains require richer nutrient media, especially in nitrogen, in order to efficiently convert galactose into ethanol. This behaviour was also observed for recombinant S. cerevisiae T1-E, which showed higher ethanol production when deproteinized whey was supplemented with corn liquor [25]. Comparatively with the results obtained in our work, Ramakrishnan and Hartley [26], reported ethanol yields of 0.48 g g−1 in cultures of recombinant S. cerevisiae GRF167 strain in synthetic medium containing glucose and galactose (20 g L−1). Also working with recombinant strains of S. cerevisiae (strain T1), obtained 0.40 g L−1 h−1 of ethanol productivity and 60 % of yield efficiency in lactose (50 g L−1) [27]. It is important to stress that these recent reports used recombinant strains and did not use cell immobilization, factors that can result in physiological and mass transfer differences.

Kinetics of glucose and galactose consumption, and ethanol production in lactose-hydrolyzed whey (a) and lactose-hydrolyzed whey permeate (b) by Saccharomyces cerevisiae CAT-1 on batch fluidized-bed bioreactor at 30 °C. Glucose (filled square), galactose (filled circle), and ethanol (filled triangle)

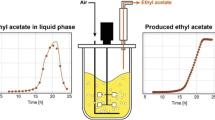

The yeasts of genus Kluyveromyces have been extensively used for the fermentation of non-hydrolysed whey, but in this research, we carried out the hydrolysis of the lactose to allow the direct comparison with kinetics of glucose and galactose use by S. cerevisiae. Results are shown in Fig. 3. The profile of the glucose and galactose consumption were quite similar in LHW and LHWP media, indicating that the K. marxianus CCT 4086, strongly contrasting with S. cerevisiae, is adapted to grow in media containing lower amounts of nitrogen and minerals, such as LHWP. Another important difference was that the sugars were metabolized simultaneously, with maximal ethanol productions of 22.9 and 20.9 g L−1 in LHW and LHWP, respectively. K. marxianus CCT 4086 single culture produced high ethanol yields (Y EtOH/S) and productivity (Q P) in both media, reaching 0.49 g g−1 and 1.68 g L−1 h−1 in LHW and 0.47 g g−1 and 1.39 g L−1 h−1 in LHWP, respectively (Table 1). Klyuveromyces strains are adapted to galactose metabolism and the expressions of GAL genes are not repressed by glucose, allowing the simultaneous glucose and galactose consumption, hence reducing fermentation time [1]. The characteristics of GAL genes expression in these yeasts, especially the promoter regions, are important factors influencing galactose repression metabolism. There are several binding sites of glucose-triggered transcriptional repression in S. cerevisiae, whereas in Klyuveromyces there is only one [1, 10]. The slower galactose metabolism in S. cerevisiae can be explained by the low galactose affinity for the galactose-permease and the low expression of GAL2 gene, thus the reduced enzyme activities involved in Leloir pathway [10, 23]. Results obtained in this work were higher than other reports using K. marxianus in whey or permeate, although most of the reports were conducted in shaker instead of bioreactors. For instance, Marwaha and Kennedy [28] obtained yields of 0.40 g g−1 with Ca-alginate immobilized K. marxianus NCYC 179 cultures in 50 g L−1 whey permeate. Lins and Leão [19] reported low efficiencies of conversion (70 %) by immobilized K. marxianus CBS 6164 growing in skimmed milk medium. Guo et al. [29] observed low ethanol yields (0.34 g g−1) and productivities (0.30 g L−1 h−1) using whey as substrate (100 g L−1) with K. marxianus TY-3 immobilized in Ca-alginate. Different results reflect physiological characteristics of varying strains of K. marxianus, which show substantial degree of intraspecific polymorphism [30] and because of physiological behaviour caused by bioreactor cultivations greatly differing from shaker flask. Results obtained in this work are comparable with those in a previous work, in which we used non-hydrolyzed whey permeate [22]. Similar yield efficiency (η) and ethanol productivity were observed, indicating the possible use of this strain to ethanol production directly from whey permeate, without substrate hydrolysis, contrasting with that requirement when S. cerevisiae is used.

Kinetics of glucose and galactose consumption, and ethanol production in lactose-hydrolyzed whey (a) and lactose-hydrolyzed whey permeate (b) by Kluyveromyves marxianus CCT 4086 on batch fluidized-bed bioreactor at 30 °C. Glucose (filled square), galactose (filled circle), and ethanol (filled triangle)

The kinetics of the co-cultures of S. cerevisiae CAT-1 and K. marxianus CCT 4086 in LHW and LHWP are shown in Fig. 4. These experiments were carried out to investigate the possible synergistic effects of combining these two different yeasts on the sugar consumption profile and ethanol. As expected, glucose and galactose were metabolized simultaneously, contrasting with the single culture of S. cerevisiae strains, because Klyuveromyces is not repressed, as stated above. Consumption of glucose and galactose was fast in LHW medium, with ethanol concentration peaking at 21.4 g L−1. Again, the yeast metabolism was slower in LHWP, but still all sugars were consumed, and maximal ethanol concentration of 20.8 g L−1 was achieved. In LHW medium, ethanol yield of 0.44 g g−1 was obtained, corresponding to 86 % of the theoretical, and an ethanol productivity of 1.32 g L−1 h−1 represented an increase of 69 % compared to Sacchamomyces single cultures. However, the effect of the co-culture on the fermentative parameters was more pronounced in LHWP, with an increase of 14 % in ethanol yields (from 0.35 to 0.40 g g−1) and approximately four times higher productivity (0.31–1.30 g L−1 h−1). The results reflect the absence of the diauxic metabolism in the co-culture, which reduced the fermentation time. Comparatively, Guo et al. [29] reported ethanol yields and productivity of 0.43 g g−1 and 0.88 g L−1 h−1 by immobilized co-culture of K. marxianus TY-3 and S. cerevisiae AY-5 in 100 g L−1 of whey. Although improvements were obtained using the co-culture, the single culture of K. marxianus showed better results concerning ethanol production in both LHW and LHWP media, suggesting that this is the best yeast for cultivations.

Kinetics of glucose and galactose consumption, and ethanol production in lactose-hydrolyzed whey (a) and lactose-hydrolyzed whey permeate (b) by co-culture of Kluyveromyves marxianus CCT 4086 and Saccharomyces cerevisiae CAT-1 on batch fluidized-bed bioreactor at 30 °C. Glucose (filled square), galactose (filled circle), and ethanol (filled triangle)

Differences in the fermentation kinetics and ethanol yield of single cultures and co-culture are strongly related to differences of GAL genes and carbon metabolism of genera Saccharomyces and Kluyveromyces. One of the most important of these is glucose repression of galactose utilization in Saccharomyces strains, as mentioned before and discussed.

Dynamics of cultures in concentrated LHWP in batch fluidized-bed bioreactors with mono and co-cultures of S. cerevisiae and K. marxianus

Concentrated lactose-hydrolyzed whey permeate (180 g L−1) was tested as substrate to increase the ethanol productivity and determine the behavior of the strains under high sugar and ethanol concentrations. This sugar concentration is close to that used in sugarcane fermentation (around 200 g L−1 of sucrose) and to the solubility of lactose (approximately 220 g L−1 at 25 °C) [31]. Whey permeate was chosen because it showed to be an appropriate substrate when used in the co-culture fermentation; its lower cost compared to whey; and because it does not require the hydrolysis of proteins, making the whole process less expensive. The kinetics of sugars consumption and ethanol production in the single culture of S. cerevisiae CAT-1 or K marxianus CCT 4086 and the co-culture of these two strains are shown in Fig. 5. In this set of experiments, lactose was not completely hydrolyzed, with a residual concentration of 20 g L−1. The β-galactosidase was probably inhibited by the high concentration of liberated products. For the commercial source of β-galactosidase from Kluyveromyces lactis used in this work, glucose is a non-competitive inhibitor, whereas galactose acts as a competitive inhibitor [32]. Results show that, although as a single culture, S. cerevisiae CAT-1 (Fig. 5a) consumed glucose faster than K. marxianus CCT 4086 (Fig. 5b) and than in the co-culture (Fig. 5c), galactose consumption was slow, as expected. The highest ethanol concentration in S. cerevisiae CAT-1 single culture was 48.0 g L−1 in 96 h, and only 30.4 g L−1 was produced in the first 12 h of cultivation, which was mainly from glucose. K. marxianus CCT 4086 metabolized the total sugars, lactose, glucose, and galactose simultaneously (Fig. 5b), reaching ethanol concentrations of 79.1 g L−1. In the co-culture, lactose, glucose, and galactose were also metabolized simultaneously, reaching the maximal ethanol concentration of 69.4 g L−1. The ethanol yields (Y EtOH/S) and productivities (Q P) of S. cerevisiae CAT-1 single cultures were lower (0.36 g g−1 and 0.50 g L−1 h−1) than for K. marxianus CCT 4086 single culture (0.46 g g−1 and 1.65 g L−1 h−1) and than for the co-culture (0.42 g g−1 and 1.44 g L−1 h−1) (Table 2). Comparatively, the results obtained in this research fare well against other reports on the literature. Using recombinant S. cerevisiae T1-E to ferment concentrated whey permeate (150 g L−1 of lactose) in shaker flask (30 °C, 150 rpm), Silva et al. [25] reported an ethanol productivity of 1.2 g L−1 h−1. Guimarães et al. [6] reported ethanol productivities of 1.5 g L−1 h−1 using recombinant S. cerevisiae T1-E in synthetic lactose medium (150 g L−1) in shaker cultivation (30 °C, 150 rpm). K. fragilis (Kf1) showed the ability to convert concentrated whey permeate (150 g L−1 of lactose) into 55.9 g L−1 of ethanol in shaker cultivation at 30 °C, reaching yields of 0.37 g g−1 and productivity of 1.27 g L−1 h−1 [4]. The same authors obtained theoretical yield of 77.4 % when the lactose concentration was increased to 200 g L−1, reaching an ethanol concentration of 80.9 g L−1. Kargi and Ozmihci [33] reported yields of 0.54 g g−1 and final ethanol concentrations of approximately 81 g L−1 when using K. marxianus NRRL-1195 strain in batch cultivations on concentrated whey (150 g L−1 of lactose). Finally, ethanol yields (0.53 and 0.51 g g−1) and ethanol productivities (1.5 and 1.0 g L−1 h−1) were reported for batch fermentations of 170 g L−1 of lactose (whey permeate) using K. marxianus UFV-3, reaching final ethanol concentrations of 76 and 80 g L−1 [34]. Furthermore and positively, the ethanol produced in this work is practically free of fusel oil, which is characterized as a by-product of ethanol fermentation, mostly composed of higher alcohols, such as isoamyl and isobutyl [35–37]. According to Patil et al. [35], the formation of higher alcohols can be influenced by fermentation conditions, raw materials, microorganism, and fermentation time. Moreover, in our work, the glycerol produced from concentrated LHWP was also low (around of 3 g L−1), corresponding to 2–3 % of the total sugar consumed. Generally, in the fermentation process, the yeasts use up to 9 % of the total sugar to glycerol bioconversion [20].

Kinetics of lactose, glucose, and galactose consumption, and ethanol production in concentrated lactose-hydrolyzed whey permeate by S. cerevisiae CAT-1 single culture (a), K. marxianus CCT 4086 (b), and co-culture of K. marxianus CCT 4086 and S. cerevisiae CAT-1 (c) on immobilized batch bioreactor at 30 °C. Lactose (star), glucose (filled square), galactose (filled circle), and ethanol (filled triangle)

Reusability of immobilized cells: repeated batches of fluidized-bed bioreactors using concentrated LHWP as substrate

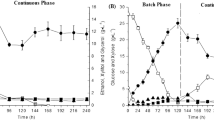

Cost reductions in bioprocesses are extremely important to turn biofuels competitive against fossil sources. The use of the same biocatalysts was tested in this work by repeated batches of experiments using immobilized K. marxianus CCT 4086 to investigate the reusability and stability of beads. The kinetics of sugars consumption and ethanol production for the ten cycles are shown in Fig. 6. Lactose and glucose were rapidly and totally consumed, in all cycles tested (Fig. 6a), whereas galactose was slowly metabolized. In the first cycle, lactose and glucose were exhausted in 24 h. From the second cycle on, sugars were depleted more rapidly, showing cell adaptation to medium and conditions. This behavior can also be associated with high cell density into the bead spheres, as it has previously been observed [15]. This behavior can be evidenced by faster galactose utilization from the seventh cycle on. Likewise, the ethanol production increased along cycles (Fig. 6b), being 44 % higher at the end of the tenth cycle in relation to the start of cultivation. The gradual increase of ethanol concentration along the ten cycles led to improvements in ethanol productivities, varying from 1.9 g L−1 h−1 in the first cycle to 2.8 g L−1 h−1 in the tenth cycle (Fig. 6c).

Repeated batches of fluidized-bed cultivations of immobilized cells of K. marxianus CCT 4086 in concentrated lactose-hydrolyzed whey permeate at 30 °C: (a) kinetics of lactose, glucose, and galactose consumption; (b) kinetics of total sugar consumption and ethanol production; (c) profile of ethanol productivity (Q P) in the ten cycle batches. Lactose (star), glucose (filled square), galactose (filled circle), total sugar (times symbol), ethanol (filled triangle), and ethanol productivity (filled diamond)

Although not directly comparable with results in this research, other yeasts, substrates, and material supports were also investigated by several authors in repeated batches of cultures and results showed the same profile of increment in sugar consumption, ethanol concentration, productivities, and yields along subsequent batches [17, 38–43]. Higher values of ethanol concentration, productivities, and yields were obtained in this work when compared with other researches using repeated batches using immobilized cell cultures on whey as substrate. Ethanol concentrations varying from 41.0 to 51.0 g L−1 and an overall productivity of 0.65 g L−1 h−1 were observed in repeated batches of immobilized recombinant S. cerevisiae T1-E in deproteinized whey supplemented with corn liquor [25]. Guo et al. [29] reported ethanol productivities of 0.80 g L−1 h−1–0.88 g L−1 h−1 for immobilized co-cultures of K. marxianus TY-3 and S. cerevisiae AY-5 growing in whey. Our results are also higher than those demonstrated for the traditional industrial whey-to-ethanol Carbery process, in plants of New Zealand and The United States of America, where K. marxianus is used in repeated batch processes, showing ethanol production of 2.5–3.5 % (volume fraction) and average productivity of 1.5 g L−1 h−1 [25, 44]. Therefore, our results strongly suggest that the ethanol production from concentrated whey permeate using immobilized K. marxianus CCT 4086 can be economically competitive for fuel ethanol production.

Conclusions

Although S. cerevisiae, especially the industrially adapted strains such as those used in this research, are the choice yeasts for the production of ethanol, for the bioconversion of whey or whey permeate, it is required that the hydrolysis of these substrates to allow their utilization. Alternatively, K. marxianus can readily be used without substrate treatments being required and the ethanol production by this yeast is even higher, under conditions as such used in this work. The use of immobilized-cell bioreactors allowed the reuse of the biocatalyst, further increasing ethanol production, yields, and productivities, for both concentrated and non-concentrated media from these residue sources. Reuse showed the adaptability of cells to environmental process, fact that can be further exploited in scaling-up this process. Considering the positive results obtained using K. marxianus CCT 4086 in this work when compared against industrial whey-to-ethanol production already in place, this strain could be potentially explored for the scaling-up of this process.

References

Guimaraes P, Teixeira J, Domingues L (2010) Fermentation of lactose to bio-ethanol by yeasts as part of integrated solutions for the valorisation of cheese whey. Biotechnol Adv 28(3):375–384

Ozmihci S, Kargi F (2009) Fermentation of cheese whey powder solution to ethanol in a packed-column bioreactor: effects of feed sugar concentration. J Chem Technol Biotechnol 84(1):106–111

Siso MIG (1996) The biotechnological utilization of cheese whey: a review. Bioresour Technol 57(1):1–11

Dragone G, Mussatto SI, Silva J, Teixeira JA (2011) Optimal fermentation conditions for maximizing the ethanol production by Kluyveromyces fragilis from cheese whey powder. Biomass Bioenergy 35(5):1977–1982

Rubio-Texeira M (2006) Endless versatility in the biotechnological applications of Kluyveromyces LAC genes. Biotechnol Adv 24(2):212–225

Guimarães PMR, Teixeira JA, Domingues L (2008) Fermentation of high concentrations of lactose to ethanol by engineered flocculent Saccharomyces cerevisiae. Biotechnol Lett 30(11):1953–1958

Lewandowska M, Kujawski W (2007) Ethanol production from lactose in a fermentation/pervaporation system. J Food Eng 79(2):430–437

Tahoun MK, El-Nemr TM, Shata OH (1999) Ethanol from lactose in salted cheese whey by recombinant Saccharomyces cerevisiae. Zeitschrift Fur Lebensmittel-Untersuchung Und-Forschung a- Food Res Technol 208(1):60–64

Grosova Z, Rosenberg M, Rebros M (2008) Perspectives and applications of immobilised beta-galactosidase in food industry—a review. Czech J Food Sci 26(1):1–14

Rubio-Texeira M (2005) A comparative analysis of the genetic switch between not-so-distant cousins: Saccharomyces cerevisiae versus Kluyveromyces marxianus. FEMS Yeast Res 5(12):1115–1128

Kourkoutas Y, Bekatorou A, Banat I, Marchant R, Koutinas A (2004) Immobilization technologies and support materials suitable in alcohol beverages production: a review. Food Microbiol 21(4):377–397

Verbelen P, De Schutter D, Delvaux F, Verstrepen K, Delvaux F (2006) Immobilized yeast cell systems for continuous fermentation applications. Biotechnol Lett 28(19):1515–1525

Nigam J, Gogoi B, Bezbaruah R (1998) Alcoholic fermentation by agar-immobilized yeast cells. World J Microbiol Biotechnol 14(3):457–459

Christensen AD, Kadar Z, Oleskowicz-Popiel P, Thomsen MH (2011) Production of bioethanol from organic whey using Kluyveromyces marxianus. J Ind Microbiol Biotechnol 38(2):283–289

Gabardo S, Rech R, Ayub MAZ (2012) Performance of different immobilized-cell systems to efficiently produce ethanol from whey: fluidized batch, packed-bed and fluidized continuous bioreactors. J Chem Technol Biotechnol 87(8):1194–1201

Najafpour G, Younesi H, Ismail K (2004) Ethanol fermentation in an immobilized cell reactor using Saccharomyces cerevisiae. Bioresour Technol 92(3):251–260

Yu JL, Zhang X, Tan TW (2007) An novel immobilization method of Saccharomyces cerevisiae to sorghum bagasse for ethanol production. J Biotechnol 129(3):415–420

Kumar S, Singh SP, Mishra IM, Adhikari DK (2011) Continuous ethanol production by Kluyveromyces sp. IIPE453 immobilized on bagasse chips in packed bed reactor. Petroleum Technol Alternative Fuels 2(1):1–6

Lins A, Leao M (2002) Removal of skim milk lactose by fermentation using free and immobilized Kluyveromyces marxianus cells. World J Microbiol Biotechnol 18(3):187–192

Basso LC, de Amorim HV, de Oliveira AJ, Lopes ML (2008) Yeast selection for fuel ethanol production in Brazil. FEMS Yeast Res 8(7):1155–1163

Furlan SA, Carvalho-Jonas MF, Merkle R, Bértoli GB, Jonas R (1995) Aplicação do sistema Microtiter Reader na seleção de microrganismos produtores de ß galactosidase. Brazilian Arch Biol Technol 38(4):1261–1268

Gabardo S, Rech R, Rosa CA, Ayub MAZ (2014) Dynamics of ethanol production from whey and whey permeate by immobilized strains of Kluyveromyces marxianus in batch and continuous bioreactors. Renew Energy 69:89–96

Timson DJ (2007) Galactose metabolism in Saccharomyces cerevisiae. Dynamic Biochemistry, Process Biotechnology and and Molecular Biology In: Global Sci Book (1):63–73

Parrondo J, Garcia LA, Diaz M (2009) Nutrient balance and metabolic analysis in a Kluyveromyces marxianus fermentation with lactose-added whey. Brazilian J Chem Eng 26(3):445–456

Silva A, Guimares PMR, Teixeira JA, Domingues L (2010) Fermentation of deproteinized cheese whey powder solutions to ethanol by engineered Saccharomyces cerevisiae: effect of supplementation with corn steep liquor and repeated-batch operation with biomass recycling by flocculation. J Ind Microbiol Biotechnol 37(9):973–982

Ramakrishnan S, Hartley BS (1993) Fermentation of lactose by yeast-cells secreting recombinant fungal lactase. Appl Env Microbiol 59(12):4230–4235

Domingues L, Dantas MM, Lima N, Teixeira JA (1999) Continuous ethanol fermentation of lactose by a recombinant flocculating Saccharomyces cerevisiae strain. Biotechnol Bioeng 64(6):692–697

Marwaha SS, Kennedy JF (1984) Ethanol-production from whey permeate by immobilized yeast-cells. Enz Microb Technol 6(1):18–22

Guo XW, Zhou J, Xiao DG (2010) Improved Ethanol production by mixed immobilized Cells of Kluyveromyces marxianus and Saccharomyces cerevisiae from cheese whey powder solution fermentation. Appl Biochem Biotechnol 160(2):532–538

Fonseca GG, Heinzle E, Wittmann C, Gombert AK (2008) The yeast Kluyveromyces marxianus and its biotechnological potential. Appl Microbiol Biotechnol 79(3):339–354

Gosling A, Stevens GW, Barber AR, Kentish SE, Gras SL (2010) Recent advances refining galactooligosaccharide production from lactose. Food Chem 121(2):307–318

Bellaver LH, de Carvalho NMB, Abrahao-Neto J, Gombert AK (2004) Ethanol formation and enzyme activities around glucose-6-phosphate in Kluyveromyces marxianus CBS 6556 exposed to glucose or lactose excess. FEMS Yeast Res 4(7):691–698

Kargi F, Ozmihci S (2006) Utilization of cheese whey powder (CWP) for ethanol fermentations: effects of operating parameters. Enz Microb Technol 38(5):711–718

Silveira WB, Passos F, Mantovani HC, Passos FML (2005) Ethanol production from cheese whey permeate by Kluyveromyces marxianus UFV-3: a flux analysis of oxido-reductive metabolism as a function of lactose concentration and oxygen levels. Enz Microb Technol 36(7):930–936

Patil A, Koolwal S, Butala H (2002) Fusel oil: composition, removal and potencial utilization. Int Sugar J 104:51–58

Solmaz H (2015) Combustion, performance and emission characteristics of fusel oil in a spark ignition engine. Fuel Proces Technol 133:20–28

Mayer FD, Feris LA, Marcilio NR, Hoffmann R (2015) Why small-scale fuel ethanol production in Brazil does not take off? Renew Sustain Energy Rev 43:687–701

Sakurai A, Nishida Y, Saito H, Sakakibara M (2000) Ethanol production by repeated batch culture using yeast cells immobilized within porous cellulose carriers. J J Biosci Bioeng 90(5):526–529

Athanasiadis I, Boskou D, Kanellaki M, Koutinas AA (2001) Effect of carbohydrate substrate on fermentation by kefir yeast supported on delignified cellulosic materials. J J Agric Food Chem 49(2):658–663

Abe A, Furukawa S, Watanabe S, Morinaga Y (2013) Yeasts and lactic acid bacteria mixed-specie biofilm formation is a promising cell immobilization technology for ethanol fermentation. Appl Biochem Biotechnol 171(1):72–79

Fan C, Qi K, Xia XX, Zhong JJ (2013) Efficient ethanol production from corncob residues by repeated fermentation of an adapted yeast. Bioresour Technol 136:309–315

Watanabe I, Miyata N, Ando A, Shiroma R, Tokuyasu K, Nakamura T (2012) Ethanol production by repeated-batch simultaneous saccharification and fermentation (SSF) of alkali-treated rice straw using immobilized Saccharomyces cerevisiae cells. Bioresour Technol 123:695–698

Rattanapan A, Limtong S, Phisalaphong M (2011) Ethanol production by repeated batch and continuous fermentations of blackstrap molasses using immobilized yeast cells on thin-shell silk cocoons. Appl Energy 88(12):4400–4404

Ling K (2008) Whey to ethanol: a biofuel role for dairy cooperatives? USDA Rural Development (Report 214):Washington

Acknowledgments

The authors wish to thank CNPq and CAPES (Brazil) for the financial support of this research and scholarships (first and second authors).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gabardo, S., Pereira, G.F., Klein, M.P. et al. Dynamics of yeast immobilized-cell fluidized-bed bioreactors systems in ethanol fermentation from lactose-hydrolyzed whey and whey permeate. Bioprocess Biosyst Eng 39, 141–150 (2016). https://doi.org/10.1007/s00449-015-1498-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-015-1498-0