Abstract

The drift capacity of reinforced concrete (RC) columns is a crucial factor in displacement and seismic based design procedure of RC structures, since they might be able to withstand the loads or dissipate the energy applied through deformation and ductility. Considering the high costs of testing methods for observing the drift capacity and ductility of RC structural members in addition to the impact of numerous parameters, numerical analyses and predictive modeling techniques have very much been appreciated by researchers and engineers in this field. This study is concerned with providing an alternative approach, termed as linear genetic programming (LGP), for predictive modeling of the lateral drift capacity (Δmax) of circular RC columns. A new model is developed by LGP incorporating various key variables existing in the experimental database employed and those well-known models presented by various researchers. The LGP model is examined from various perspectives. The comparison analysis of the results with those obtained by previously proposed models confirm the precision of the LGP model in estimation of the Δmax factor. The results reveal the fact that the LGP model impressively outperforms the existing models in terms of predictability and performance and can be definitely used for further engineering purposes. These approve the applicability of LGP technique for numerical analysis and modeling of complicated engineering problems.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The key consideration in the design and performance assessment of civil engineering structures and infrastructures is the fact that they must work efficiently during their service life. This is achieved through ensuring about the structural safety, i.e., strength and stability, and their serviceability. Particularly in seismic hazard zones, the performance and design of buildings and their structural members should also be examined according to seismic provisions recommended by codes and guidelines [1, 2]. In this regard, the shear strength and ductility of structural members under cyclic lateral loads, such as seismic loads, are two important factors should be scrutinized. Although the strength of structural elements is of paramount significance, the ductility and the deformability, in both elastic and plastic states, are also important, since the member might be still able to withstand larger loads through its deformation. In fact, the ductility also causes to dissipate the energy applied to the structure and its corresponding elements during the occurrence of an earthquake.

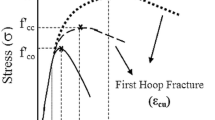

Amongst structural members, columns are usually considered as the major structural member, generally, as axial load-bearing components. In reinforced concrete (RC) members, the slight tensile strength and the brittle behavior of the concrete is commonly enhanced through augmenting it with materials such as steel bars owing to their higher deformability and tensile strength. Besides to the existing longitudinal reinforcement in RC columns, experimentations demonstrated that transverse reinforcement through steel stirrups or spirals arranged in different layers as confinement along the column length also increase their shear strength and ductility characteristics, particularly as they are subjected to earthquake and seismic loadings [3,4,5,6]. Therefore, it is obvious that the ductility of RC columns is provided by the longitudinal or transverse reinforcement commonly including steel bars. In many cases, lack of existing appropriate ductility in columns would lead to their brittle failure and this might also result in structural collapse, severe damage and fatalities. To rise above this, the lateral drift capacity or the maximum lateral displacement of RC columns is typically examined by the researchers and practicing engineers and this is a crucial factor in displacement-based design and seismic evaluation of structures, since the structure is expected to withstand a specific drift without structural damage [7,8,9].

Considering the expensive process of direct testing approaches to acquire and observe the drift capacity of RC columns under cyclic lateral and seismic loads, indirect estimation and numerical modeling techniques have been very much appreciated by engineers and researchers, mostly for pre-design purposes. The displacement-based design procedure for RC columns and pertinent approaches require estimation models of drift capacity [9]. In this regard, several models have been proposed by different researchers using analytical and empirical numerical analysis methods. Considering the plastic hinge concept, the lateral deformation and corresponding drift of RC columns can be represented as follows.

It can be realized from Fig. 1, the ultimate lateral drift capacity (Δmax) of the column can be considered as the summation of yield elastic displacement and plastic deformation, Δy and Δp, respectively, where L is the column length; P and V are axial and shear loads applied. The lateral drift capacity or ultimate deformation, i.e., Δmax is commonly defined as the lateral displacement of the column observed at 80% of peak shear strength (Vmax) in pertinent load–displacement curves acquired by experimental studies and testing methods, according to [10].

Pujol and his colleagues [11] have explored the displacement of RC columns in their nonlinear range of response to reduce earthquake impacts via energy dissipation. In addition, it is observed that the column drift capacity is a function of displacement history and, as well as the shear strength, it decreases as the number and amplitude of cycles increases [12]. The maximum drift capacity model for RC columns proposed is as follows [10, 11]:

where

Saatcioglu and Razavi [13] proposed a model based on column displacement analyses using different amounts of transverse reinforcement and levels of applying axial compressive loads, where the lateral displacement at 80% of lateral shear strength (Vmax) was considered as the Δmax. The model is given as follows:

In equation above

and there exist some conditions as follows:

Furthermore, Elwood and Moehle [10] formulated the drift of columns at 80% in peak shear strength based on experimental data gained by tests carried out on RC columns specimens [10]. The empirical drift capacity formula has been acquired by regression analysis and is as follows:

where

From a different perspective, drift capacity models are also valuable to recognize the critical columns in seismic assessment and rehabilitation of structures. It is clear that the lateral drift capacity of RC members is a complicated problem, since there are numerous parameters and their changes, in turn, influencing the system performance under loadings. This can also be realized as the expression of the aforementioned empirical and analytical based models have incorporated distinct parameters, e.g., P/Agf′c, ρt and a/Ls, as independent input variables to estimate the Δmax of RC columns. Nevertheless, there exist some defects associated with the models proposed. The most significant weakness of analytical methods is the fact that they cannot incorporate many parameters. This is due to that they are developed based on assumptions simplifying the problem. The empirical models based on regression analysis are usually calibrated and validated using few experimental data. In regression-based analysis few models are commonly checked to find the fittest model. The drift capacity equations provided by Pujol et al. [11] and Elwood and Mohele [10] incorporate the shear strength (Vmax) of the RC column as an input variable. The Vmax factor itself should be directly observed through experimental investigations and this is inefficient when indirect estimation is the purpose or it can be indirectly estimated through the numerical analysis which might produce negative effects on the accuracy of the drift capacity model in estimation. Furthermore, the design equation proposed by Saatcioglu and Razavi [13] is conditional, e.g., in Eq. 7, where P/P0 ≥ 2, and covers a small range. This would lead to its deficiency in predictability and approximation capability.

When it comes to approximation and modeling of complicated real-world problems, data-mining methods and soft computing (SC) techniques, can be selected as useful alternative approaches. In general, SC techniques are naturally motivated algorithms which are developed based on the analogy of biological activities, the behavior of natural systems or biological systems of living creatures. SC methods are data-mining computational tools that attempt to simulate and find the structure of the models existing between the independent input and corresponding output variables. These data-driven and self-adaptive approaches such as artificial neural networks (ANNs) and support vector machines (SVM) and genetic programming (GP) and their subdivisions have been very much employed for predictive modeling of engineering problems [8, 14,15,16,17,18]. However, these approaches have been trivially employed for indirect estimation and simulating of the drift capacity of RC columns. Inel [8] applied ANNs to model the ultimate deformation and estimates of RC columns using experimental data in which flexural failure was the criterion. The model proposed incorporates the aspect ratio, a/H, fc′ (MPa), fyl (MPa), fyt (MPa), s (mm), ρl (%), ρt (%), confinement effectiveness factor provided by [19] and the axial load ratio, P/fc′ Ag [8]. In addition, Gordon [20] also developed an ANN-based model for the prediction of the Δmax of RC columns using b or D for rectangular and circular RC column, respectively (m), d (m), P/√fc′ Ag, ρl (%), ρt (%) and a/L. Although the results of the ANN models produced were expressed to be promising in estimation, ANNs have been criticized to be black-box tools and this is a substantial deficit. This means that the ANN-based developed models can only be computed through computer. In other words, the mathematical structure of the obtained model cannot be presented as an explicit formula or an expression [6, 21, 22].

This paper is concerned with providing an alternative perspective on the numerical analysis and predictive modeling of the drift capacity of RC columns of circular cross section at their lateral strength with normal strength concrete. A robust SC technique, linear genetic programming (LGP) is employed to generate new predictive models. The superiority of LGP approach over other SC techniques is to create models that can be converted to explicit formulae and they can be employed for further design and calculation purposes. LGP has been successfully used to solve various engineering problems [16, 23,24,25,26,27,28]. A database consisting of 63 experimental results conducted on different types of circular RC columns is compiled for development of drift capacity models. Several runs have been done and many models have been developed using LGP approach for indirect estimation of the Δmax of RC columns. The optimal model has been selected based on the assessment of the generated models from various accuracy perspectives.

2 LGP approach

Genetic programming (GP) is a symbolic optimization technique that generates computer programs or models based on the principle of Darwinian natural selection [23, 24, 29]. GP programs are programmed using a functional language such as LISP [24, 25]. LGP is an improved subdivision of GP having a linear program assembly comparable to the structure of DNA existing in natural genomes. This algorithm develops variable-length sequences of a programming language, C or C++ [16, 29, 30]. The functions commonly used in LGP include arithmetic operations, e.g., +, −, / and × , unary functions such as Log, abs and Sqrt, conditionals such as if–then statements, and some of Trigonometric functions, Sin and Cosine. LGP algorithm can develop programs faster than other types of GP variants due to the simple formations of generated programs and the fact that these programs are not required to be interpreted [6, 22]. Figure 2 represents a linear shaped solutions generated by LGP.

In general, LGP starts with producing an initial number of individual programs or solutions. These are models, and therefore, their accuracy is assessed by means of a fitness function. After running a tournament, typically four programs are randomly chosen from the initial individuals [23, 26]. Those members with better fitness acquire a greater opportunity to grow into a parent in the next production of programs. Subsequently, those fittest individuals are reproduced or transformed randomly to new programs by means of genetic operators. To tackle bloating problem, i.e., the undue development of the program size without a noteworthy fitness improvement, LGP restricts the size of programs which can be predefined prior to the model development [16, 22, 31]. After the evaluation of the programs regarding their fitness, the procedure repeats till the stop conditions are reached and the best program is obtained [27, 32, 33].

2.1 Genetic operators

The main operation in evolutionary algorithms (EAs) is performed by genetic operators mainly including reproduction, mutation, crossover or recombination [23, 28, 31, 33]. GP optimizes the population of computer programs according to a fitness function. Hence, the fitness function is the objective function that GP optimizes [26]. In the procedure of training, some parts of programs are modified by genetic operators to enhance the program accuracy. Reproduction is basically carried out by duplicating a fitting program within the existing population to the next generation without any changes applied. In addition, crossover and mutation change, the programs and structures of individuals are illustrated in Fig. 3.

2.2 Fitness assessment

The fitness function is used to assess how close the estimated and observed or experimental values are. Therefore, it can also be used as a selection means of producing individuals with higher accuracy in the training process [15, 27]. Here, the a linear sum of errors function is employed as the fitness function to develop LGP programs and this can be calculated using a linear mean of errors function which is given as follows:

where Ei is the value of the outputs observed in experiments, and Pi is the equivalent predicted value using the LGP model for case i and N is the number of output data [16].

3 Experimental database and model variables

It is well-known that SC algorithms are data-driven. In present study, a valuable and reliable database already presented by the Pacific Earthquake Engineering Research Structural Performance Database (PEER-SPD) [34] is employed for the development of LGP models for indirect estimation of Δmax of RC columns. This comprehensive database is a collection of experimental studies previously conducted by several researchers in the literature to examine the precisions of seismic performance predictions for RC columns of different cross sections. The database contains the key RC columns material characteristics, mainly circular and rectangular cross section, geometry and reinforcement factors, the applied loads and observed damage, test results and so forth [20, 34]. The database used in this paper is presented in Appendix A.2. Test configurations considered are cantilever, double-curvature, double-ended, hammerhead, and cantilever-flexible-base testing methods [20, 34]. The samples have been tested under cyclic horizontal loading until failure. It is noteworthy that the shear failure was assumed and was defined by the maximum displacement, Δmax, where shear resistance fell below 80% of the maximum shear recorded [10, 20, 35]. Δy and Δmax acquired by load–displacement test results has been defined by Elwood and Mohele [10], as represented in Fig. 4.

∆s or ∆max is the displacement at 80% of Vmax, and ∆y is the displacement at the point of intersection of a horizontal line at the peak shear, and a line formed by the origin and the point on the force–displacement envelope, where the shear is at 70% of its peak value [20]. Nevertheless, the purpose of this study is to find a predictive model for the ∆max. The experimental data in which the shear failure of samples under cyclic lateral loading occurred were selected in presents study for the development of models. Two modes of shear failure reported in the database, i.e., flexural-shear and shear failure modes, are typically considered as the main reason to narrow down the PEER-SPD. Therefore, the LGP model is merely useful for these two type of failure modes. The descriptive statistical details of the database is summarized and given in Table 1. For further considerations, the whole experimental data used here is attached to this article as a supplementary file for online publication.

Considering the models proposed by different researchers and the incorporated variables previously mentioned, it is possible to find the significant variables to estimate the Δmax factor. The LGP-based Δmax model in this study is also assumed to be a function of the key independent input variables. Considering the available information in the experimental database, some significant variables such as L/D, which represents the slenderness of the column, can also be used to develop LGP models. It is worth mentioning that analytical models are commonly developed based on assumptions for simplifying the problem. These models might not be capable of capturing the impact of several important variables such as L/D. It is also noteworthy that the LGP model is free from the impact of Vmax, since new experiments are required to calculate this parameter and calculating this parameter from analysis may impact the accuracy of the model. This is the superiority of LGP over other approaches and also the fact that LGP models are based on experimental observations without any assumptions. The variables employed here are considered to be dimensionless and meaningful from engineering perspectives. The LGP Δmax (mm) function can be demonstrated as follows:

where L/D is the slenderness ratio which is defined as the column length to diameter or the circular column, ρt and ρl are the transverse and longitudinal reinforcement ratio (%), α is assumed to be the axial load ratio, P/Agfc′, and β is considered to be the transverse reinforcement index equal to ρtfyt/fc′, and γ is the longitudinal reinforcement index equal to ρlfyl/fc′, s/d is the transverse reinforcement spacing to depth ratio and a/Ls is the aspect ratio.

4 Data classification

To assess the potential of prediction models, i.e., to see whether they underfit or overfit and their generalization performance, many researchers recommended that the data sets be mainly classified into three groups, learning, validation and test data [6, 27, 36]. The learning group is applied to fit the models, i.e., LGP-generated programs, and the validation is utilized for the fitness assessment of learned programs. It is noteworthy that the learning and validation process is known as the training process. Another data set which is not employed in the training process and only to confirm the predictability of the obtained model and this set is so-called test data. Considering the recommended values by researchers, the training and testing data are usually taken 80% and 20% of all data, respectively, for model development through SC techniques [6, 21, 22, 33, 37]. Similarly, these values are considered in this study to explore the accuracy degree of the generated models. It is obvious that in case the performances of the model on different sets of data, e.g., learning, validation and test data, are good and close, overfitting and underfitting are avoided [6, 16].

5 LGP training parameters

To find the estimation models of Δmax for circular RC columns, Discipulus software provided by [38], was utilized in present study. In SC algorithms, There exist several parameters in the algorithms should be fixed or predefined to perform a run. Herein, the initial number of program population was considered to be first 500 and second 700. The number of generation of programs without improvement was fixed at 200 which mean that the generation of programs would be stopped when the fitness of 200 programs was not acceptable in that iteration. Various operators, +, −, × , /, mathematical operator, √, and random constants between − 10 and 10 have been selected to develop programs. These sorts of operators are considered here to find a simple LGP model which can be used via manual calculations. A significant problem in GP is the fact that the size of produced programs gradually increase without any improvement in their accuracy after a while and this is known as bloat. To rise above this, LGP restricts the size of programs generated to a number of orders [31,32,33]. In this study, the maximum program size was fixed at 120 bytes. In addition, demes, i.e., semi-isolated subgroups, classify program populations of equal size and this leads to a better evolution of generation in each run in LGP [6, 21]. The number of demes was considered to be equal to 20. There exist some other parameters such as the probability of crossover and mutation which were equal to 0.5 and 0.95, respectively. These parameters should be appropriately initialized to produce an accurate model. To adjust these parameters’ values, numerous runs might be required to be carried out through a process of trial and error. Albeit, those previously suggested values of the parameters by other researchers can also be used [6, 22, 31, 32].

6 Initial accuracy evaluation of LGP models

In general, there exist some statistical indices that are commonly utilized to examine the accuracy of predictive models. These indices mainly include coefficient of correlation (R), mean absolute error (MAE) and the root mean square error (RMSE). If the correlation coefficient (R) between the existing predicted values of the output by the model and those experimental or observed values becomes equal or more than 0.8, it can be proposed that the accuracy of the model generated in estimation is acceptable [32, 33, 39]. Besides to this, the MAE and RMSE are typically used to provide an overall insight to the error produced. It is clear that the less the MAE and RMSE values, the better the performance of the model will be. According to [25], R does not change significantly by shifting the output values of a model equally, and error functions (e.g., RMSE and MAE) only shows the error. Therefore, a better criteria can be used which can simultaneously incorporate the impact of R, RMSE and/or MAE such as performance index (PI) [25]. PI is proposed as a function of the relative root mean square error (RRMSE) and the R as the following equations.

In present study, these well-known indices are considered as the criteria for the assessment of the accuracy of LGP-based models for selecting the best model. It is noteworthy that supplementary analyses should be performed to discover the optimal model as are described in the following sections. These mathematical expressions of these indices are demonstrated as follows:

where n is the number of data samples, Pi is the model prediction hi and ti are the experimental value of the ith output, respectively, \(\overline{{P_{i} }}\) and \(\overline{{E_{i} }}\) are the mean value of the predicted and experimental values of outputs.

7 The proposed LGP-based model

A process of trial and error was carried out to select the best GP model for the prediction of the Δmax of circular RC columns in this study. Many runs were made and numerous LGP programs were produced through applying various combinations of the algorithm parameters and checking various input variables. Amongst all, the selection of a model initially depends on considering two criteria as a multi-objective strategy [22, 32]. First, the simplest model structure; albeit, this was not the main factor, and second, the optimal fitness value on the training data sets, i.e., learning and validation data. It is noteworthy that several other criteria are also conducted to evaluate the models and this procedure was performed for several times to propose the LGP model in present study. The processes are presented in the following sections. The fittest program generated LGP is in C or C ++ code and is provided in Appendix A for further considerations. Herein, the LGP program is converted into a mathematical expression through replacing the contributed variables. The optimal LGP-based formula of Δmax (mm) is represented in the following equation:

This LGP model is acquired after examining numerous models produced after a great process of training and validation. The proposed LGP model for Δmax is chosen among a total of 967, 302,012 programs produced after several runs and iteration. The accuracy of this model is also checked on a group of unseen data in the modeling process which presents the generalization performance and predictability. These major issues are the superiorities of LGP over regression-based techniques. It is worth remarking that the advantage of LGP approach over other SC techniques, e.g., ANNs and SVMs, is the fact that it can produce predictive models which can be converted to explicit formulae to be used for further design and calculation purposes [6, 16, 31].

8 Results and discussion

8.1 Evaluation of the performance of models

As was stated, during and after the process of modeling and performing training and validation procedures, several models are generated by LGP. With the intention to examine the fitness of models, some statistical indices, R, RMSE and MAE, are initially employed after the assessment of models used through a fitness function. The performance of the optimal model should be examined for different division of data, i.e., training data and test data. The last is known as the generalization performance or the predictability of the model [6]. Furthermore, PI can be used to evaluate the model incorporating the simultaneous impact of R, RMSE and/or MAE. These indices are calculated for different classes of data employed here In Table 2.

It is proposed that if PI value is close to zero (e.g., PI ≤ 0.2), the model predicts the actual values well and is the recommended acceptance threshold [25]. According to the PI values in Table 2, the performance of the LGP model proposed here is acceptable. Furthermore, a traditional way to assess the accuracy and fitness of a model in comparison to those existing in the literature for estimation of the drift capacity of RC columns is to indicate the model output results versus the experimental values [6, 17, 40]. Figure 5 shows a scatter plot of the obtained values of the Δmax of cyclically loaded circular RC columns obtained by the LGP and other models proposed by well-known researchers versus those experimentally observed.

The calculated values of R, RMSE, MAE and PI for all, training and test data presented in Table 2 imply that the LGP model does not underfit which means that it is capable of estimating Δmax factor with an acceptable degree of precision. In addition, the closeness of R, RMSE and MAE values calculated for training and test data indicates this fact that overfitting is eliminated. It can be figured out from Fig. 6 that the model provided in this study by LGP method considerably outperforms those well-known models suggested by researchers for indirect measurement of Δmax of RC columns.

Although the models provided by Elwood and Mohele [10] and Pujol [11] can to estimate the Δmax factor with an acceptable degree of accuracy, they present poor results for several cases. It can be seen in Fig. 5 that the PI calculated values are more than 0.2, while that of LGP is equal to 0.15 which demonstrates better performance of LGP model compared to these models. the calculated for This is mainly due to the fact that these models incorporate few input variables for the estimation of Δmax factor, e.g., Pujol [11] merely considered L, b, d, Vmax, ρt and fyt. Therefore, in case an ignored parameter changes cause variation of the model output, e.g., P, ρl and D which have not been considered in Pujol’s model, this impacts the model performance and cause poor estimations and inefficiency of that model for such data, similar to this study. In addition, the experimental data employed in other studies were mainly conducted on columns samples of rectangular cross section; albeit, the generated models are used for estimation of Δmax of RC columns of circular cross section. It can be also seen that the Elwood and Mohele’s model almost overestimated the Δmax factor in several cases. It is worth noting that the empirical model proposed by Saatcioglu and Razvi [13] was not able to estimate all Δmax values considered in the database employed here. The main reason is the fact that the model is conditional and developed based on limitations which cause deficiency and poor results and inapplicability for several data. Thus, the aforementioned model could not be presented here.

8.2 Additional indices for the evaluation of the model predictability

Some additional factors have been recommended by researchers in the existing literature which can be used to evaluate the generalization performance of mathematical models on unseen data [6, 17, 21, 33]. In present study, these criteria are considered for the assessment of the predictability of the LGP-based Δmax model and the obtained results are summarized in Table 3. Numbers in this table indicate the fact that the proposed model fulfills all of the conditions required and this approves the robustness of LGP model in prediction for unseen or test data.

According to [25], R does not change significantly by shifting the output values of a model equally, and error functions (e.g., RMSE and MAE) only shows the error. Therefore, a better criteria can be used which can simultaneously incorporate the impact of R, RMSE and/or MAE such as performance index (PI) [25]. PI is also calculated to evaluate the predictabilty of the proposed LGP model and is given in Table 2.

8.3 Parametric analysis of the LGP model

Considering the coefficients of different variables in Δmax models proposed by Elwood and Mohele [10], Pujol [11] and Saatcioglu and Razavi [13], the trend of Δmax can be realized when each variable varies. For instance, when P/Agfc′ increases, Δmax decreases which demonstrates that it has a negative coefficient in the model proposed by Elwood and Moehle [10]. Accordingly, it can be expected that Δmax must increase with increasing ρt, ρl, and a/Ls. The trend of the model to the changes of its independent variables must be proper and meaningful. Definitely, if the model behavior conforms to the outcomes in the literature, the model can be accepted from engineering viewpoints. In present study this behavior is explored for LGP models using a parametric analysis [6, 25, 33].

The methodology utilized here is dependent on merely varying one independent variable, while the other variables are considered to be equal to their mean values [6, 25, 33]. For this aim, a group of simulated data is generated for each input variable accounting for the variable’s range in the database. Then, the output value, which is the Δmax of circular RC columns here, is calculated by the predictive model using the virtual values of inputs. The aforementioned procedure is repeated similarly for another variable till the model response to all input variables has been obtained. Figure 6 shows the results of the parametric analysis carried out for the LGP model to assess its response to the changes of incorporated predictor variables, L/D, ρt, ρl α = P/Agfc′, β = ρtfyt/fc′, γ = ρlfyl/fc′, s/d and a/Ls. The results of the parametric analysis demonstrates that LGP model can perfectly capture the physical behavior of the system. This also represents the robustness of LGP as a soft computing algorithm for solving complicated engineering problems.

8.4 Sensitivity analysis

The crucial question when a model is used for estimation aims is the fact that how the output value varies as the values of each input variable changes. To explore this, a sensitivity analysis (SA) procedure is useful. This sort of analysis of the model can indicate how predictors which are independent input variables incorporated in a model impact the amount of changes of the dependent variable [6, 16, 25, 31, 32]. For this purpose, the sensitivity index (SI) can be utilized. In this study, the SI (%) can be obtained via the following equations:

where fmax (xi) is maximum value of the LGP model prediction for the ith input variable x, while fmax (xi) is calculated minimum value. These values are calculated by the model, where other inputs incorporated, except xi, are considered constant at their mean values and n is the number of independent input variables in the model.

It can be suggested that that input variables with higher value of the SI have greater impact compared to other input variables on the model performance and the output value and vice versa. This shows the significance of variables. In case the SI value become small or close to zero, the relevant variable poorly or does not influence on the model variations which means that it can be omitted. The SA process is carried out for the LGP model proposed in this study and the results are illustrated in Fig. 7.

Sezen [41] has stated that the shear deformation of RC columns greatly relevant to ρt, a/Ls, P and some other parameters [41]. In addition, the amount of transverse reinforcement radically impacts both the shear strength and ultimate drift capacity of RC columns [4, 6, 42]. A significant and new factor considered in this study was the slenderness ratio of the column, denoted by L/D. Although this factor can be regarded as a key parameter, it has not been incorporated in previous models proposed by researchers in the literature. As can be seen in Fig. 6, the SI (%) values obtained by the LGP model proposed in this study suggest that the L/D is the most influential input variable, followed by ρt and s/d, whereas the ρt and γ slightly impact the performance of the LGP-based Δmax model. The results precisely conform to those provided by researchers, e.g., [3, 10,11,12,13, 41]. It should be noted that the SI is a unique factor for every single of estimation models which should be given very much attention whenever an equation is used.

9 Summary and conclusion

This paper explored the applicability of a robust SC approach, called LGP, for predictive modeling of the Δmax of circular RC columns with normal strength concrete. A valuable experimental database, PEER-SPD, has been utilized to develop LGP-based estimation models. The new LGP design equation proposed in this study incorporates L/D, ρt, ρl α = P/Agfc′, β = ρtfyt/fc′, γ = ρlfyl/fc′, s/d and a/Ls as independent input variables which have also been presented as key parameters by other researchers for indirect estimation of the Δmax factor. The predictability and performance of the proposed LGP model was indicated through conducting some statistical analyses and was checked via comparing the results with some well-known models in the literature. It was stated that the model proposed by Saatcioglu and Razavi [13] was not able to estimate all data employed in this study and this is due to the fact that it is condictional and was developed based on simple regression-based analysis. The superiorities of the LGP model in comparison to other models are the consideration of more number of parameters to describe the Δmax of circular RC columns, accounting for the column slenderness ratio as an input, higher accuracy in estimation and the predictability and generalization performance, and being a computational intelligence based model. The last means that the optimal LGP model is selected amongst numerous models after performing a comprehensive process of trial and error and improvement and optimization of the models which does not occur in regression-based numerical modeling methods. To represent the influence of each variable on the model, a sensitivity analysis was carried out. In this study, the slenderness ratio of the RC columns is also incorporated for the prediction of the Δmax. The parametric analysis of the LGP model demonstrated that it can successfully capture the physical behavior off the system. The SA results presented that all variables contribute to the changes of Δmax factor, where L/D, ρt and s/d were the most significant influential variables. The accuracy of the LGP model proposed here taking into account several parameters compared to other conventional models confirm the capability of LGP approach for resolving complicated engineering problems. The authors are confident that the proposed LGP model is useful and valuable for the design of RC columns, particularly for pre-design aims.

Abbreviations

- a/L s :

-

Aspect ratio

- A c :

-

The area of RC column core within perimeter transverse reinforcement (center-to-center)

- A g :

-

Gross area of the column section

- A sl :

-

The total area of the longitudinal reinforcement

- A st :

-

The total area of transverse reinforcement

- b :

-

Column section width

- b c :

-

The column concrete core width

- d :

-

Effective depth

- D eq or D :

-

The diameter of the equivalent circular column cross section

- f′c :

-

Standard compressive strength of unconfined concrete samples

- f yl :

-

The yield strength of longitudinal steel reinforcement,

- f yt :

-

The yield strength of lateral or transverse steel reinforcement

- h c :

-

The column concrete core depth

- L :

-

Column length

- L/D :

-

The column slenderness ratio

- P :

-

The axial load applied to the column

- s :

-

The spacing between transverse reinforcement or spiral pitch

- V max :

-

The maximum shear strength

- α :

-

The axial load ratio calculated by P/Agf′c

- β :

-

The transverse reinforcement index equal to ρtfyt/f′c

- γ :

-

The longitudinal reinforcement index equal to ρlfyl/f′c

- Δmax :

-

The maximum lateral displacement or the drift capacity of circular RC columns

- ρ l :

-

The longitudinal steel ratio

- ρ t :

-

The ratio of the volume of lateral reinforcement to volume of confined concrete core

References

ACI Committee 318-14 Building code requirements for structural concrete (ACI 318 M-14) and commentary (ACI 318RM-14). In: 2015, American Concrete Institute

FEMA 356 (2000) Prestandard and commentary for the seismic rehabilitation of buildings. Federal Emergency Management Agency, Washington DC

Mander J, Priestley M, Park R (1988) Observed stress–strain behavior of confined concrete. J Struct Eng 114(8):1827–1849

Pujol S, Sözen M, Ramirez J (2000) Transverse reinforcement for columns of RC frames to resist earthquakes. J Struct Eng 126(4):461–466

Caglar N, Garip ZS (2013) Neural network based model for seismic assessment of existing RC buildings. Comput Concr 12(2):229–241

Sadrossadat E, Ghorbani B, Hamooni M, Moradpoor Sheikhkanloo MH (2018) Numerical formulation of confined compressive strength and strain of circular reinforced concrete columns using gene expression programming approach. Struct Concr 19(3):783–794

Priestley M, Park R (1987) Strength and ductility of concrete bridge columns under seismic loading. Struct J 84(1):61–76

Inel M (2007) Modeling ultimate deformation capacity of RC columns using artificial neural networks. Eng Struct 29(3):329–335

Zhu L (2005) Probabilistic drift capacity models for reinforced concrete columns. University of British Columbia, Columbia

Elwood KJ, Moehle JP (2005) Drift capacity of reinforced concrete columns with light transverse reinforcement. Earthq Spectr 21(1):71–89

Pujol S, Ramfrez J, Sozen MA (1999) Drift capacity of reinforced concrete columns subjected to cyclic shear reversals. Spec Publ 187:255–274

Pujol S (2002) Drift capacity of reinforced concrete columns subjected to displacement reversals. Purdue University, West Lafayette

Saatcioglu M, Razvi SR (2002) Displacement-based design of reinforced concrete columns for confinement. Struct J 99(1):3–11

Sadrossadat E, Heidaripanah A, Osouli S (2016) Prediction of the resilient modulus of flexible pavement subgrade soils using adaptive neuro-fuzzy inference systems. Constr Build Mater 123:235–247

Sadrossadat E, Heidaripanah A, Ghorbani B (2016) Towards application of linear genetic programming for indirect estimation of the resilient modulus of pavements subgrade soils. Road Mater Pavement Des 19(1):139–153

Rostami MF, Sadrossadat E, Ghorbani B, Kazemi SM (2018) New empirical formulations for indirect estimation of peak-confined compressive strength and strain of circular RC columns using LGP method. Eng Comput 34(4):865–880

Alavi AH, Gandomi AH, Sahab MG, Gandomi M (2010) Multi expression programming: a new approach to formulation of soil classification. Eng Comput 26(2):111–118

Khandelwal M, Faradonbeh RS, Monjezi M, Armaghani DJ, Abd Majid MZB, Yagiz S (2017) Function development for appraising brittleness of intact rocks using genetic programming and non-linear multiple regression models. Eng Comput 33(1):13–21

Sheikh SA, Uzumeri S (1982) Analytical model for concrete confinement in tied columns. J Struct Div 108(12):2703–2722

Gordon N (2015) Prediction of shear strength and ductility of cyclically loaded reinforced concrete columns using artificial intelligence. Dissertation, University of Nevada, Las Vegas

Tajeri S, Sadrossadat E, Bazaz JB (2015) Indirect estimation of the ultimate bearing capacity of shallow foundations resting on rock masses. Int J Rock Mech Min Sci 80:107–117

Alavi AH, Sadrossadat E (2016) New design equations for estimation of ultimate bearing capacity of shallow foundations resting on rock masses. Geosci Front 7(1):91–99

Gandomi AH, Yang XS, Talatahari S, Alavi AH (2013) Metaheuristic applications in structures and infrastructures. Elsevier, London

Gandomi AH, Yun GJ, Alavi AH (2013) An evolutionary approach for modeling of shear strength of RC deep beams. Mater Struct 46(12):2109–2119

Gandomi AH, Roke DA (2015) Assessment of artificial neural network and genetic programming as predictive tools. Adv Eng Softw 88:63–72

Gandomi AH, Alavi AH, Ryan C (2015) Handbook of genetic programming applications. Springer, Switzerland

Sadrossadat E, Basarir H (2019) An evolutionary-based prediction model of the 28-day compressive strength of high-performance concrete containing cementitious materials. Adv Civil Eng Mater 8(3):484–497

Sadrossadat E, Basarir H, Karrech A, Durham R, Fourie A, Bin H (2019) The optimization of cemented hydraulic backfill mixture design parameters for different strength conditions using artificial intelligence algorithms. In: Proceedings of the 28th international symposium on mine planning and equipment selection - MPES 2019, 2020, pp 219–227

Koza JR (1992) Genetic programming II, automatic discovery of reusable subprograms. MIT Press, Cambridge

Brameier MF, Banzhaf W (2007) Linear genetic programming. Springer, New York

Gandomi AH, Alavi AH, Sahab MG (2010) New formulation for compressive strength of CFRP confined concrete cylinders using linear genetic programming. Mater Struct 43(7):963–983

Alavi AH, Ameri M, Gandomi AH, Mirzahosseini MR (2011) Formulation of flow number of asphalt mixes using a hybrid computational method. Constr Build Mater 25(3):1338–1355

Sadrossadat E, Soltani F, Mousavi SM, Marandi SM, Alavi AH (2013) A new design equation for prediction of ultimate bearing capacity of shallow foundation on granular soils. J Civ Eng Manag 19(sup1):S78–S90

Berry M, Parrish M, Eberhard M (2004) PEER structural performance database, user’s manual (version 1.0). University of California, Berkeley

Baradaran Shoraka M, Elwood K (2013) Mechanical model for non ductile reinforced concrete columns. J Earthq Eng 17(7):937–957

Ziaee SA, Sadrossadat E, Alavi AH, Shadmehri DM (2015) Explicit formulation of bearing capacity of shallow foundations on rock masses using artificial neural networks: application and supplementary studies. Environ Earth Sci 73(7):3417–3431

Armaghani DJ, Faradonbeh RS, Momeni E, Fahimifar A, Tahir MM (2018) Performance prediction of tunnel boring machine through developing a gene expression programming equation. Eng Comput 34(1):129–141

Conrads M, Dolezal O, Francone F, Nordin P (2004) Discipulus–fast genetic programming based on AIM learning technology. Register Machine Learning Technologies Inc, Littleton CO

Smith GN (1986) Probability and statistics in civil engineering. Nichols Publishing Company, New York

Ghorbani B, Sadrossadat E, Bazaz JB, Oskooei PR (2018) Numerical ANFIS-based formulation for prediction of the ultimate axial load bearing capacity of piles through CPT data. Geotech Geol Eng 36(4):2057–2076

Sezen H (2008) Shear deformation model for reinforced concrete columns. Struct Eng Mech 28(1):39–52

Vu NS, Yu B, Li B (2016) Prediction of strength and drift capacity of corroded reinforced concrete columns. Constr Build Mater 115:304–318

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendix A

Appendix A

A.1. The optimum LGP program for the prediction of fc′c.

The following LGP program can be run in the Discipulus interactive evaluator mode or can be compiled in C++ environment. (Note: v[0], v, v [3],…, v [7], respectively, are L/D, ρt, β = ρtfyt/fc′, ρl, γ = ρlfyl/fc′, α = P/Agf′, s/d and a/Ls)

A.2. The database used in the present paper is attached as a supplementary file.

Rights and permissions

About this article

Cite this article

Rezvani Sharif, M., Sadri Tabaei Zavareh, S.M.R. Predictive modeling of the lateral drift capacity of circular reinforced concrete columns using an evolutionary algorithm. Engineering with Computers 37, 1579–1591 (2021). https://doi.org/10.1007/s00366-019-00904-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-019-00904-z