Abstract

In this study, N-vinylcaprolactam (VCL) and methacrylic acid (MAA) based copolymeric hydrogels with different VCL/MAA molar ratios were produced to develop a temperature-sensitive biomaterial for use in drug delivery systems. For this purpose, poly(N-vinylcaprolactam-co-methacrylic acid) hydrogels, symbolized p(VCL-co-MAA) were synthesized by free radical polymerization in an ethanol medium using different monomer ratios at 70 °C with 2,2′-azobis(2-methylpropionamidine) dihydrochloride (AMPA) as an initiator, and in the presence of crosslinking agent (N,N′-methylenebisacrylamide). The structures of hydrogels were confirmed by Fourier Transform Infrared Spectroscopy (FTIR). The addition of MAA, which has an ionizable group as a comonomer to the structure, it also provided pH sensitivity to VCL based hydrogels as well as its temperature sensitivity. In order to examine the drug release properties, first, the swelling-shrinking behaviors of these hydrogels were determined in the temperature range of 25–60 °C and different pH values (2.1, 5.5, and 7.2) in equilibrium time (24 h). Then, the drug release profiles of these hydrogels were assessed in “in vitro” conditions at 37 °C and different pH values using mimic biological fluids for Rhodamine B (Rh B), a cationic model drug. The maximum drug release values were founded in the range of 34–57%, 73–90%, 69–76% at pH 2.1, 5.5, and 7.2, respectively, for the hydrogels with different VCL/MAA molar ratios. At the end of the swelling and drug release experiments, it was seen that the swelling degree of synthesized hydrogel exhibited to both dependent temperature and pH. Furthermore, it was observed that the amount% of the drug and the rate of drug release also changed depending on the change in pH values. In addition, surface morphologies of hydrogels were examined by Scanning Electron Microscopy (SEM) before and after drug release. Then, the kinetic mechanism of the drug release behavior of hydrogels was investigated using zero-order, first-order, Higuchi, and Korsmeyer–Peppas models for all three pH values. The kinetic release profile of the p(VCL-co-MAA) hydrogel was determined to fit into the Higuchi model, generally. Although, the correlation coefficients showed that the hydrogel fitted to the Higuchi model at all pH conditions, analysis with the Korsmeyer-Peppas equation had been assisted more precisely in the understanding of one or more than one mechanisms controlling the release, at different pH values. According to the kinetic release modeling results, it may be concluded that swelling and diffusion processes were probably simultaneously effective on the drug release mechanism. All these results imply that prepared dual-responsive p(VCL-co-MAA) hydrogels may be used for potential applications such as long-term controlled drug release systems like 24 h in the gastrointestinal system with varying pH values.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Hydrogels are crosslinked polymer networks that can absorb water or biological fluids [1], and they are currently widely used in various fields such as separation technology, drug delivery, agriculture, horticulture, biomedical and pharmaceutical applications [2]. However, in recent years, temperature-sensitive hydrogels, that a special type of hydrogels, have become attractive in developing various new biomaterial applications [3]. These special type of smart hydrogels also so-called intelligent hydrogels exhibit significant changes in their physicochemical properties (in shape, surface characteristics, solubility e.g.,) when exposed to a minor temperature change in their environment [4, 5].

“Poly(N-isopropylacrylamide) (PNIPAm)” and “poly(N-vinylcaprolactam) (PVCL)” are the best-known temperature-sensitive polymeric networks. These water-soluble and non-ionic polymers exhibit a “lower critical solution temperature (LCST)”, at similar temperatures, at about 32–34 °C and 32–36 °C, respectively. [1, 6, 7]. Temperature-sensitive hydrogels, especially exhibit significant changes in their swelling properties in response to changes in temperature. This type of hydrogel has swollen form at room temperature, and when the temperature has been raised above the LCST, quickly undergoing a reversible phase transition and it turn a shrunk form [8, 9].

Especially, N-vinyl caprolactam (VCL) based materials have many applications in the biomaterial field, such as drug delivery systems and wound dressing materials due to their hydrophilic and hydrophobic character and also low toxic structure [10]. For example, for the treatment of some diseases (cancer, diabetes, etc.), PVCL, which is the second best known temperature-sensitive polymer after PNIPAm, has been used as a drug carrier for the manufacture of controlled drug delivery systems [11].

Another beneficial property of the temperature-sensitive VCL based polymers is that also highly biocompatible similar to natural polymers [12,13,14,15]. PVCL, which demonstrates higher biocompatibility compared with PNIPAm, can be degraded by a hydrolytic mechanism depending on the comonomer it contains [15, 16]. The PVCL has a repeating cyclic amide group with a direct bond via nitrogen to the hydrophobic polymer backbone and, unlike PNIPAm, small amide molecules do not occur during hydrolysis, which is leading to reduced cytotoxicity in comparison with PNIPAm [15, 17].

In addition, PVCL can also be synthesized copolymeric or terpolymeric structure thanks to amide group so that it has not only different functional groups but more strong mechanical properties [18, 19]. For example, Durkut has reported that dual (-thermo and -pH) responsive hydrogels based on VCL for the controlled release of the model protein bovine serum albumin. In the related study, carboxyl–terminated PVCL polymer chains have been enhanced via galactosylated chitosan, which has pH-responsive properties due to the effect of the remaining amino groups [20]. In another study, Kumar and co-workers have developed grafted copolymer of carboxymethylcellulose (CMC) and VCL, that the result materials have exhibited strong antibacterial activity against major bacterias [21].

With a similar approach to mentioned above studies related to VCL and natural polymers [20, 21], VCL monomer has also been used together with various synthetic monomers to form copolymeric and terpolymeric structures by several research groups, including ourselves [7, 22,23,24]. For example, in our previous work [7] on this topic, terpolymeric hydrogels based on N-vinylcaprolactam, 2-hydroxyethyl acrylate, and itaconic acid, symbolized as poly(VCL-HEA-IA), have been synthesized by free radical polymerization, and then drug release properties have been determined using the model drug. At the end of the study, it has been found that the model drug has released in proportion to 50% within the first 8 h at different pH values. In another study in the literature, Fallon and co-workers [22] have prepared temperature and pH-sensitive VCL and itaconic acid based copolymeric hydrogels. In mentioned study, the synthesis of hydrogels has been realized via a free-radical photopolymerization mechanism without any solvent. The authors, found that the drug release amounts of the hydrogels at pH 6.8 have higher than at pH 2.2, depending on the change in itaconic acid content. In other study conducted by Mundargi et al. [23], it has been investigated that the synthesis of dual-responsive VCL based copolymeric hydrogel microparticles via free radical polymerization for oral delivery of human insulin. In the related study, the experimental results showed that insulin had been released in %100 intestinal pH during 6 h while almost no release in gastrointestinal pH in the first 2 h. Different from these studies on hydrogels summarized above, copolymeric and terpolymeric “microgels” using together synthetic monomers (metacrylic acid and itaconic acid) and VCL monomer have also been synthesized via precipitation polymerization method in another else our research [1]. Then drug release properties of these microgels have been investigated using Rhodamine B (model drug) and Nadolol (beta-blocker drug).

As outlined above, in the existing literature, it has been reported that to improve and develop of the properties of VCL has been modified with different monomers, natural or synthetic. In addition, it has also been presented that used various techniques such as grafting or copolymerization for modifications, and it was obtained in different forms (hydrogel, microgel, nanogel, nanocomposite, bead, nanofiber, micro/nanoparticle etc.). In this study, it is focused on the design of stimuli-sensitive N-vinyl caprolactam (VCL) and methacrylic acid (MAA) based copolymeric hydrogel, and first time, investigated for drug release characteristics in different VCL/MMA ratios.

To the best of our knowledge, a detailed experimental study has not been reported yet on the drug release profiles of VCL and MAA based copolymeric hydrogels in different VCL/MMA molar ratios over a wide pH range in the literature. In this respect, our study differs from other similar studies. In this study, was investigated on the use of stimuli-sensitive poly(N-vinyl caprolactam-co-methacrylic acid) hydrogels symbolized as p(VCL-co-MAA) as a potential drug delivery system. Thus, how the drug release profile of copolymeric hydrogels changes with the effect of different pH values and changing VCL/MMA molar ratio was investigated for the first time in this study.

In the extent of this study, first of all, p(VCL-co-MAA) hydrogels were synthesized in different VCL/MAA molar ratios. Then, FTIR analyses were performed to characterize the obtained hydrogels, and the swelling and shrinkage properties of the hydrogels were investigated at different pH and temperatures. Afterward, the synthesized p(VCL-co-MAA) hydrogels were loaded with Rhodamine B (Rh B) as a model drug, and drug release capacities and behaviors were investigated at different pH values. The Rh B release profiles of these temperature-sensitive hydrogels were determined at 37 °C at pH 2.1, 5.5, and 7.2. Then, the drug release kinetics and release mechanism of hydrogels were evaluated using four different release kinetic models.

Materials and methods

Materials

The monomer (N-vinylcaprolactam, VCL) (Sigma-Aldrich, USA) was purified before use by repeated recrystallization in hexane and dried in the vacuum oven at 40 °C. The other monomer (methacrylic acid, MAA) (Merck, Germany), the initiator (2,2′-azobis(2-methylpropionamidine) dihydrochloride, AMPA) (Merck, Germany), the crosslinker (N,N′-methylenebisacrylamide, NMBA) (Sigma-Aldrich, USA), the model drug (Rhodamine B, Rh B) (Merck, Germany) and the solvent (ethanol, 98%) (Merck, Germany) were used as supplied. Deionized water was used throughout all solutions and standards.

Instruments

The structure of p(VCL-co-MAA) copolymeric hydrogels synthesized in this study was investigated by Fourier Transform Infrared Spectroscopy (FTIR, Thermo Scientific, Nicolet 380, USA). In drug release studies, the amount of model drug remaining in solution after adsorption was measured by UV–Visible Spectrophotometer (UV–Vis, PG Instruments, T80 + , UK). After drug loading and release, the surface morphologies of the hydrogels were determined by Scanning Electron Microscopy (SEM, Quanta FEG 450, USA).

Synthesis of the hydrogels

The p(VCL-co-MAA) copolymeric hydrogels were synthesized by free-radical adding polymerization in the solvent (ethanol) medium using the initiator (AMPA) and the crosslinker (NMBA). Before the synthesis of hydrogels, 1 mol MAA was reacted with 2 mol 1 N NaOH in order to obtain sodium salt of methacrylic acid (MAA-Na).

In the synthesis of hydrogels, it was studied at five different VCL/MAA-Na molar ratios with a total concentration of the reaction medium to be 2 M. Calculated amounts of the monomers were weighed into the glass tubes (16 × 130 mm, diameter × length), and the crosslinker (2% mole ratio of the total monomer amount) and ethanol were added. This mixture was stirred continuously at a constant speed for 15 min using a magnetic stirrer to allow them to dissolve all starting materials to be completely dissolved in ethanol. After the mouths of the glass tubes were closed with a rubber stopper, nitrogen gas was passed through the solutions with the help of an injector needle for 30 min, and the tubes were placed in a water bath at 70 °C. After 15 min, the calculated amount of initiator dissolved in distilled water (1% mole ratio of the total monomer amount) was added to the tubes with the help of an injector. To complete of the reaction, the tubes were kept in a water bath at 70 °C for 24 h. After 24 h, the tubes were taken out of the water bath, cooled to room temperature, and the hydrogels inside were taken into 1 L beakers containing ethanol. They were purified for 4 days by changing the solvent twice a day. Subsequently, the hydrogels were dried in an oven at 50 °C for 24 h. The symbols of the hydrogels, their feed compositions, and reaction conditions are presented in Table 1.

FTIR analyses

In order to the structural characterization of the synthesized copolymeric hydrogels, the FTIR spectra of the hydrogels were obtained with a “Thermo Scientific, Nicolet 380” Fourier Transform Infrared Spectrophotometer in the range 400–4000 cm−1. In this stage, first, dried and ground hydrogel samples were diluted with IR grade Merck potassium bromide powder (KBr) (sample/KBr: 1/200 (w/w)) and compressed into a disk form under pressure, and then these disks were used for FTIR analyses.

Swelling–Shrinkage studies

Before investigating the drug release properties of the hydrogels, first of all, their swelling and shrinkage (deswelling) behaviors in buffer solutions were investigated. For this purpose, besides the equilibrium swelling values of the hydrogels at different temperatures and pH values, the time-dependent changing of the shrinkage values of the hydrogels at different pH values were also determined as detailed below.

The swelling behaviors of temperature-sensitive p(VCL-co-MAA) hydrogels were examined at nine different temperatures varying from 25 to 60 °C (25, 30, 37, 40, 44, 46, 48, 50, 60 °C) and three different pH values (2.1, 5.5, and 7.2), gravimetrically. To determine the equilibrium swelling ratio, the dried hydrogel samples (0.5 g) were placed in the glass tubes containing 50 mL solution and kept for 24 h until the swelling equilibrium was reached. At the equilibrium time (24 h), the swollen hydrogel samples were taken out of the solution and weighed after the excess water was removed on the surfaces. The swelling degrees of the hydrogels at the equilibrium were calculated using the following equation.

where Qe is the equilibrium swelling ratio (or swelling degree at equilibrium) (g/g); Wwet and Wdry are the weights (g) of the swollen hydrogel and the dry hydrogel, respectively.

In order to determine the variation of the shrinkage values of the hydrogels with time, hydrogel samples, which were weighed in certain amounts and had swelling equilibrium value, were immersed in buffer solutions at 37 °C, at three different pH values (2.1, 5.5, 7.2) and kept in these solutions for a certain time. The hydrogels, which were removed from the buffer solutions at certain time intervals, were weighed again after their surfaces were dried with filter paper, and the weight loss of the hydrogel was observed depending on time. Equation 1 was also used in the calculations of the water retention values, here.

Drug release studies

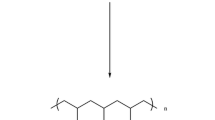

In drug release studies, Rhodamine B (Rh B) was used as a model drug, and it was studied in vitro conditions. Rh B is a water-soluble cationic dye, and its chemical structure is shown in Fig. 1.

At this stage, first, the Rh B model drug solution was prepared at a concentration of 500 mg/L using pH 7.2 phosphate buffer solution and second, the optimum hydrogel form for drug release was investigated. After optimum hydrogel form has been determined, the model drug was loaded onto the hydrogels, and then drug release studies were carried out under appropriate conditions.

Determination of optimum hydrogel form for drug release

First of all, two different forms of hydrogels were tested in drug release studies in order to determine which form of hydrogels is more effective in drug release. For this purpose, the powder form of hydrogel was prepared by grinding 0.1 g of dried hydrogel after loading the model drug. Then, 0.1 g of dried hydrogel after loading the model drug was pressed by applying 10 bar pressure, and thus, the disk-shaped tablet form (cylindrical) of hydrogel was prepared. Afterward, as described below, the hydrogels in powder and tablet forms loaded with Rh B were kept in phosphate buffer solution (pH 7.2) at 37 °C, and samples were taken from the buffer solutions at the end of 8, 24, and 48 h. Then the model drug release amounts from hydrogels were determined using UV–Vis. spectrophotometer.

Model drug loading

Dry hydrogel samples (0.05 g) were immersed into model drug Rh B solutions (500 mg/L, 50 mL), and they were kept in this solution for 1 week. At the end of 1 week, the remaining amount of model drug in the model drug solution was determined by UV–Vis spectrophotometer at 554 nm. Thus, the model drug loading capacities of each hydrogel sample were calculated using the following equation.

where, LC (loading capacity) is the loaded amount of model drug per gram hydrogel (mg/g); Ci is the initial concentration of model drug solution (mg/L); Ct is the concentration of model drug solution after loading process at time t (mg/L); V is the volume of the model drug solution used (L), and W is the amount of dry hydrogel sample used (g).

Then, in order to be used in the drug release experiments, these drug-loaded hydrogels were washed with phosphate buffer solution to remove the probable remaining Rh B on their surface and dried in an oven at 40 °C for 2 days.

Model drug release

Drug release studies of model drug-loaded and dry hydrogel samples were carried out at 37 °C and in buffer solutions prepared at different pH values (2.1; 5.5; 7.2). Rh B-loaded hydrogel samples were immersed in these buffer solutions, and they were kept in them for a certain time. Then, the measurements of the buffer solutions at selected time intervals were made at 554 nm using a UV–Vis spectrophotometer. Thus, the model drug release capacities of each hydrogel sample were calculated using the following equation

where, RC (release capacity) is the released amount of model drug per gram hydrogel (mg/g); CR is the concentration of model drug in the buffer solution after release process (mg/L); V is the volume of the buffer solution used (L), and W is the amount of model drug-loaded dry hydrogel used (g).

In addition, cumulative release percents of the hydrogel samples were also calculated using the following equation.

where, CR% (cumulative release percent); LC and RC are the loading capacity and the release capacity of the hydrogel samples, respectively, as stated above.

SEM analyses

In order to examine the surface morphologies of the hydrogels, SEM photographs were taken at 20,000 magnifications after model drug loading and release, besides the untreated hydrogel, using “Quanta FEG 450” Scanning Electron Microscopy. In these analyses, the samples were coated with a very thin (200 A°) gold layer necessary to obtain a clear image.

Drug release kinetics studies

To evaluate the drug release kinetics and to investigate the mechanisms of drug release profile from the polymer matrix in in vitro conditions, four different kinetic models were used, including Zero-order, First-order, Higuchi, and Korsmeyer-Peppas equations. Then, the data that best fits any of these models were determined by calculating the correlation coefficient.

The data obtained from drug release assays were evaluated using the following equations [24,25,26,27,28,29,30,31,32,33,34].

The zero-order model

The first-order model

The Higuchi model:

The Korsmeyer-Peppas model:

In these equations, qo is the initial amount of the drug in the solution (it is usually zero), qt is the amount of the released drug over time t, q∞ is the amount of drug at the equilibrium state. q∞ can also be expressed as the amount of drug released over a very long time that corresponds to the initial loading, therefore sometimes very close to the amount of drug contained in the dosage form at the beginning of the release process [33, 34]. qt/q∞ is the fraction of drug release, n is the diffusional exponent (related to the drug release mechanism and in function of time) and t is the release time. ko, k1, kH and kKP are the zero-order release constant, the first-order release constant, Higuchi release constant, and Korsmeyer-Peppas constant (or release velocity constant), respectively. Korsmeyer-Peppas release velocity constant also contains the structural modifications and geometrical characteristics of the system [24,25,26,27,28,29,30,31,32,33,34].

In the zero-order kinetic model, the release of drug is very slow, and a steady-state is observed that the rate of the release process is independent of the released concentration. Thus, changing the concentration does not affect the rate of diffusion [35,36,37]. It is observed a “constant release” that can be expressed as the same amount of drug released per unit time, during the process that fitted this kinetic model [32]. This model can be used in several types of modified release systems, such as matrix tablets with low soluble drugs in coated forms. [35,36,37]. Drug applications operating in accordance with this kinetic model can be oral, transdermal, implantable, matrix, coated, osmotic systems or suspension types [33, 38].

In the case of the first-order kinetic model that is applied based on Fick’s law of diffusion, the rate of release is dependent on the released concentration. In this type of release kinetics, the concentration of the released drug is proportional to the concentration of remaining material in the matrix and decomposes as a function of time [35, 39]. This model can be preferred for different forms that containing water-soluble drugs in porous matrices [36, 40]. Drug applications following this kinetic model can be different forms such as dissolution or diffusion controlled release matrix and sustained release systems [33, 38].

The Higuchi kinetic model is based on Fick’s first law of diffusion, and it was developed for different porous and geometric systems that water-soluble and materials having low solubility that are encapsulated into solid or semi-solid matrices [33, 41]. In studies conducted by Higuchi to investigate drug release behavior in matrix systems, it was determined the drug release rate from drugs in suspension in 1961 [42], from ointments in 1962 [43], and a “continuous-acting drug mechanism” was proposed in 1963 [44]. Later, the Higuchi model has been the most used mathematical equation and has also allowed the development of many theoretical models [33]. This model is based on various hypotheses listed below. (1) At the beginning of the process, the concentration of the drug is higher than its solubility. (2) It is assumed that one-dimensional diffusion of the drug takes place. (3) The thickness of the system is more than drug particles. (4) The dissolution and swelling of the matrix can be neglected. (5) The coefficient of diffusion (drug diffusivity) is constant. (6) The excellent sinking conditions exist in the release medium [33, 35, 36, 44, 45]. This model can be applied in varied types of modified release systems, matrix tablets with water-soluble drugs, the drug systems encapsulated as solid or semi-solid with low solubility, and microspheres and microcapsules [33, 36, 38, 41, 44, 46].

The Korsmeyer-Peppas kinetic model is proposed as a simple equation for describing the controlled release of polymeric systems [33, 47, 48], especially hydrophilic matrix systems [49]. This model was developed to investigate both release fickian drug release obeying Fickian-law and non-fickian drug release not obeying Fickian-law in swelling polymeric and non-swelling polymeric delivery systems [38]. Therefore, this model is known as a more general semi-empirical relationship used to model the swelling-controlled drug release processes [33]. This kinetic model finds application area especially in swellable and erodible hydrophilic systems that exhibit erosion and diffusion-controlled anomalous diffusion behavior [32,33,34, 50]. In general, the model is used when the amount of released material is less than 60%, and there is an exponential proportionality between the amount of released material and time [35, 36, 51]. This model can be utilized in formulations of drug release from polymeric systems, and the magnitude of “n” in the Korsmeyer-Peppas equation is an indication of diffusion-controlled drug release [36, 47, 52]. In other words, the diffusional exponent (n) in the Korsmeyer-Peppas equation describes the mechanism of drug release.

According to the n value that best fits the release profile of an active substance from a matrix system and the type of behavior observed in the system, a general classification can be made as follows [33].

(I) Fickian model (Case I);

(II) Non-Fickian models (Case II, Anomalous Case, and Super Case II)

In addition, the Interpretation of the release models of the active agent from polymeric matrices were made according to their geometry, and the limits of the release exponent (n) values were given differently in the planar (thin films), cylindric and spherical systems [33, 47]. The values defined for cylindrical systems are also as follows.

For the case of n ≤ 0.45, the overall mechanism is defined as “Fickian release (Case I)”; when 0.45 < n < 0.89, “non-Fickian release (Case II)” is observed; “Anomalous Case” transport is observed in n = 0.89, and n > 0.89 expressed as the “Super Case II” transport [24,25,26,27,28,29,30,31, 33, 47].

In general, in this model, takes place the superposition of two seemingly independent of each other mechanisms (e.g., relaxation, diffusion) of drug transport. In “Case I”, the drug release is managed by the diffusion process. Since the transport rate or diffusion is much greater than that of the polymeric chain relaxation process, this case is characterized by the diffusivity phenomenon. When “Case II” is valid, the drug release rate fits zero-order release kinetics, and the mechanism leading to drug release is the swelling or relaxation of polymeric chains. In the “Anomalous Case” transport, the drug release mechanism is managed by diffusion and swelling (or relaxation) simultaneously. The rearrangement of polymeric chains and the diffusion process occurred at the same time, and this situation causes anomalous effects [33]. In addition, in this case, the drug release mechanism may be a combination of both drug diffusion and polymer erosion [50]. However, “Super Case II” model is known as an extreme form of transport. It is observed that tension and breaking of the polymer occur during this process [33, 34, 50].

Results and discussion

In this section, first of all, the results of the FTIR analysis performed to determine the structural characterization of p(VCL-co-MAA) hydrogels are presented. Then, to determine the swelling and shrinking properties of these hydrogels, the equilibrium swelling values at different temperatures, the equilibrium swelling values at different pH values, and the time-dependent shrinkage values were investigated, and our results were presented as detailed. Also, drug loading and release properties were examined by presenting the results of optimum hydrogel form and drug loading and release capacities of hydrogels. And then, morphological properties were researched with taken SEM photographs of hydrogels before drug loading, in the drug-loaded state, and after drug release, and the results were presented comparatively. In addition, with in vitro drug release kinetics studies under each pH condition, the kinetic mechanism of model drug release was explored using different kinetics models such as Zero-order, First-order, Higuchi, and Korsmeyer-Peppas, and obtained parameters were presented and discussed in detail. In the end, drug release results compared with the studies in the literature. Besides these, swelling/shrinking behavior due to phase transition was schematized together with molecular structure and drug release behavior of p(VCL-co-MAA) temperature-sensitive hydrogels.

FTIR analysis results

The prepared temperature-sensitive p(VCL-co-MAA) hydrogels’ structures were confirmed by FTIR. The IR frequencies of the characteristic groups of VCL and MAA monomers are presented in Table 2 according to the literature [53,54,55,56]. The FTIR spectra of the copolymeric p(VCL-co-MAA) hydrogels are also presented in Fig. 2.

As summarized in Table 2, there are also peaks in the spectrum of both monomers (VCL and MMA) arising from the C–H in-plane bending of the –CH2 group at 1430–1-1480 cm−1. In addition, there are two peaks attributed to C = O stretching vibration in the amide structure observed at 1658 cm−1 and 1625 cm−1 in the spectrum of the VCL monomer. Furthermore, there is a peak at 1698 cm−1 attributed to the carboxylic acid C = O stretch in the spectrum of the MMA monomer.

In the spectra of all hydrogels presented in Fig. 2, there is a strong and very broad peak at approximately 1630 cm−1. This peak is probably due to the interference of the peaks due to the C = O stretching vibration in the amide structure in the VCL spectrum with the peak attributed to the carboxylic acid C = O stretching in the MAA spectrum.

As a result, the peak belonging of the –CH = CH2 group located at 1635 cm−1 in the spectrum of the MAA monomer has not been observed in the spectra of the hydrogels due to the polymerization reaction between VCL and MAA. Furthermore, as mentioned above, a broad interference peak is appeared at 1630 cm−1 due to C = O stretching vibrations in the amide and carboxylic acid structure in the spectrum of the copolymer, which clearly shows that the copolymeric structure has formed. In addition, the IR spectra of the hydrogels compared to each other, it has been seen that this new peak also increased in intensity in that area as the ratio of MAA increased in hydrogel structure [21, 22].

As known, MAA has an ionizable group, indicating a pronounced pH sensitivity in the system, and the presence of ionic components may provide pH sensitivity to non-ionic gels. In this way, the pH sensitivity of hydrogels can be achieved by incorporating the ionizable groups of various acids [57,58,59]. The addition of hydrophilic ionic comonomers, such as itaconic acid, maleic acid or methacrylic acid, provides that the thermosensitivity property of the polymer can be controlled by pH value of the external media [60,61,62,63,64]. It has also been known that by adding a hydrophilic monomer to the thermosensitive polymer network, the hydrogel swelling and polymer phase transition allow changing the properties of the hydrogel [22, 60].

According to this, in this study, MAA with hydrophilic properties was used as a comonomer in the copolymer structure to achieve pH sensitivity. Thus, it has been provided pH-sensitivity property to the hydrogels besides having temperature sensitivity that makes them extremely attractive for pharmaceutical and medical applications. To give an example, the change of pH value throughout the gastrointestinal system taken into account, it is seen that it varies from the acidic pH of the stomach increasing gradually in the small intestine to neutral or slightly basic pH in large intestine. These dual-sensitivities of p(VCL-co-MAA) hydrogels will be beneficial and convenient in delivering drugs to a body location with a specific pH value at human body temperature [57, 65]. As a result, the p(VCL-co-MAA) hydrogels synthesized in this study and whose structures were confirmed by FTIR show pH-sensitivity as well as temperature-sensitivity as there are examples in the literature [66,67,68,69].

Swelling and shrinking properties

Equilibrium swelling values at different temperatures

The swelling behavior of the hydrogel is a significant parameter in the design, development, and use of temperature-sensitive hydrogels networks. For this purpose, first, we investigated the swelling capacities of the p(VCL-co-MAA) hydrogels in different temperature values ranging from 25 to 60 °C to find their LCST. Equilibrium swelling values of the hydrogels obtained at the end of the swelling experiments realized at different temperatures (at pH 5.5 and 24 h) are presented in Fig. 3.

As mentioned above, VCL, one of the monomers in the composition of p(VCL-co-MAA) hydrogels, is a monomer used in the synthesis of temperature-sensitive polymers, and its LCST is given in the literature as 32–34 °C [70] In this study, when the equilibrium swelling values of p(VCL-co-MAA) hydrogels at different temperatures were examined, it was observed that a gradual decrease in the swelling equilibrium values as the temperature increased up to 37 °C. However, a sharp decrease was also observed in the equilibrium swelling values obtained after 40 °C. These findings indicate that the LCST’s of the hydrogels are around in the range of 37–40 °C. As known, both the swelling degree and the LCST value of a gel are affected by the hydrophobic/hydrophilic structure and amounts of the monomers that constituted the polymer [71]. The presence of long and short chains in the polymer segments in the hydrogel structure causes them to release water at different temperatures and rates [72, 73]. As a result of this situation, the LCST of hydrogels was observed on a certain temperature range, not on the single temperature value. In addition, as it is seen in Fig. 3, as the ratio of MMA causing the more hydrophilic group content in the composition of the copolymeric hydrogel increased, the equilibrium swelling values of the hydrogels also increased [22]. This differentiation observed in the change in equilibrium swelling values of copolymeric hydrogels has arisen depending on the presence and amount of hydrophilic monomer in the hydrogel structure, as expected.

Equilibrium swelling values at different pH values

In order to investigate the effect of pH on the swelling behavior of hydrogels, the equilibrium swelling values of hydrogels were determined at different pH values (7.2, 5.5, and 2.1). Equilibrium swelling values of the hydrogels obtained at the end of the swelling experiments realized at different pH values (at 25 °C and 24 h) are presented in Fig. 4.

As shown in Fig. 4, as the total hydrophilic monomer ratio in the composition of the copolymeric hydrogel increased, the equilibrium swelling values of the hydrogels also increased at all pH values. Moreover, the equilibrium swelling values observed at all hydrogels at pH 7.2 were found as significantly higher than those observed at pH 5.5 and pH 2.1. As can be seen from the obtained experimental results, the equilibrium swelling values of these hydrogels containing acidic groups noticeably increased with the increased in pH value. For example, when the pH value was increased from 2.1 to 5.5, the equilibrium swelling values of hydrogels increased approximately 2 times, and when increased from 2.1 to 7.2, approximately 3.5 times.

The fact that the hydrogels exhibited maximum swelling capacity at equilibrium time at pH 7.2 is caused by the carboxylic acid group of MAA in dissociated form (COO-) at this pH. Therefore, as a result, as the amount of MAA in the copolymer structure is increased, the swelling degree of all hydrogels has increased since the ionizable groups it contained will also increase [45, 74]. Since the change in the pH value of the environment will cause the change of ionization degree of the hydrogel, it also caused a change in the equilibrium swelling values of hydrogels, as a natural consequence of this situation [75].

The time-dependent shrinkage values

As known, in various systems where stimuli sensitive hydrogels are used as carriers for controlled drug release, the swelling-shrinkage response of the hydrogel, which is proportional to the stimulus magnitude, is an important parameter in adjusting the rate of drug release. For this purpose, time-dependent shrinkage behaviors of hydrogels at different pHs were also investigated in this study. Since synthesized temperature-sensitive p(VCL-co-MAA) hydrogels will be used in the drug release systems, their shrinkage behaviors were investigated at 37 °C, which is close to the LCST of VCL and is compatible with human body temperature.

The time-dependent shrinkage values of the hydrogels obtained at the end of the experiments realized at different pH values (7.2, 5.5, and 2.1), at 37 °C and 1 week are presented in Fig. 5.

When the graphs of the shrinkage values of the hydrogels are examined, it is seen that all the hydrogels shrank rapidly until the 10th h, after the 10th h the shrinkage rate gradually decreased and reached equilibrium at the end of 24 h. The shrinkage values of hydrogels increased as the ionic monomer content increased for all pH values. In addition, it was observed that at all pH values and at 37 °C, all hydrogels show a gradual shrinkage behavior and shrunk at a certain ratio, and their shrinkage percentages were almost close to each other at the first 100 min. After 1 h, all hydrogels showed shrinkage of approximately 50% at all pH values. However, at the end of 24 h, they showed shrinkage of around 70–80% at pH 2.1, 80–95 at pH 5.5, and 60–75% at pH 7.2. As a result, it is seen that the shrinkage behavior of the hydrogels is dependent on pH as well as temperature. Thus, it can be said that the shrinkage behaviors of the prepared p(VCL-co-MAA) hydrogels are also to be suitable for usage in drug release applications.

Drug loading and release properties

Optimum hydrogel form

In preliminary trials to determine which form of hydrogel is more effective in drug release, The time-dependent Rh B release values (%) of the disc-shaped tablet (cylindric form) hydrogel and the powder hydrogel have been determined. At the end of these trials, it was observed that there was no significant difference between the drug release amounts of these two hydrogel forms.

Drug loading and release capacities

At the end of the model drug loading experiments, which were carried out by keeping the hydrogels in model drug solution at pH 7.2, and at room temperature for 1 week, the model drug (Rh B) loading capacities of hydrogels were determined. The final model drug loading values were found as 55, 188, 347, 349, and 370 mg drug/g polymer for hydrogels named VM-100, VM-95, VM-90, VM-85, and VM-80, respectively. As can be seen from these values, as the ratio of monomer (MAA), which containing hydrophilic group in the hydrogel composition, was also increased, the amount of drug loading (loading capacity) of the hydrogel increased in parallel to this, as expected.

Drug release studies of model drug-loaded dried hydrogel samples were carried out at 37 °C and in buffer solutions prepared at different pH values (2.1, 5.5, 7.2) for 1 week. The release profiles of the model drug (Rh B) loaded hydrogels obtained from drug release studies in in vitro conditions are presented in Fig. 6.

In addition, also experimental results obtained from drug release studies of the hydrogels at different pH values (model drug release values determined at the end of 8. 24., 48., and 168. h as mg/g and %) are presented all together in Table 3.

As shown in Fig. 6 and Table 3, after the first 8 h, model drug (Rh B) release values of p(VCL-co-MAA) hydrogels were observed in the range of 47–56%, 50–79%, and 30–45%, at pH 7.2, 5.5, and 2.1, respectively. In addition, it was observed that the model drug was rapidly released from the hydrogels in the first 8 h; after 24 h almost reached the equilibrium, then the rate of release decreased, but the release of the drug continued to increase slightly up to 48 h, and the completely has become stable at the end of 1 week. While after 24 h, drug release values were obtained in the range of %56–68 at pH 7.2, %56–84 at pH 5.5, and %34–52 at pH 2.1, at the end of 1 week, these values were 69 – 76% at pH 7.2, 73–90% at pH 5.5, and 34–57% at pH 2.1.

The obtained results show that the amount of Rh B release from p(VCL-co-MAA) hydrogels increases when the pH scale is slides from acidic to basic values. This behavior can probably be explained by the ionization of the carboxylic groups of MAA located in the hydrogel structure in the release medium. In addition, there is an anion-anion repulsion between carboxylic ions at around pH 7, and there is deprotonation of carboxylic groups between polymer chains at around pH 1. Depending on these circumstances, at more basic pH values, the expansion of polymer chains results in more swelling, and, thus, more drug release takes place from the system. However, at more acidic pH values, due to less water diffusion through the network, the hydrogels remain as a shrunk form in the medium, and drug release is relatively prevented [76]. In this also our study, when acidic neutral and basic pH environments were compared with each other, different ionic interactions occurred at different pH values due to all these ionic interactions mentioned above, and accordingly, changes in drug release were observed. Consequently, when all the results are evaluated together, it can be said that the drug release behavior of p(VCL-co-MAA) hydrogel formulation was practically pH-dependent and, they may be suitable for long-term controlled drug release systems that can release the drug gradually for up to 1 week. Optionally, it can be used in drug systems that release for 8, 24, 48 h or 1 week. These hydrogels can preserve the drug in the hydrogel network at acidic pHs (pH 2.1), such as in stomach conditions, while they can release it from the hydrogel network at pH 5.5 and 7.2, like intestinal conditions, at human body temperature (37 °C).

SEM analysis results

The physically cross-linked hydrogels generally have a morphological structure with interconnected pores, and this characteristic presents significant potential, especially for drug delivery applications enabling the diffusion of drug molecules. In addition, the macroporosity enables the swelling of the hydrogels facilitating by decreasing the diffusion resistances [45, 77, 78]. As mentioned above, the surfaces of the VM-80 hydrogel, which has the highest drug loading capacity, before drug loading, in the drug-loaded state, and after drug release were examined by SEM analysis, and the obtained SEM photographs are presented in Fig. 7.

As seen from the SEM photographs, the VM-80 hydrogel initially has a relatively porous surface. After the drug loading process, the surface became differentiated, and the initial partially porous surface was no longer observed. In addition, after the drug loading process, any drug crystals were also not observed on the hydrogel surface. These images showed that Rh B was loaded into the hydrogel, successfully. After drug release, completely different from the first two images, the hydrogel surface acquired relatively smooth morphology. According to these results, it may be said that the drug, the release conditions of hydrogel, and the release environment demonstrated compatibility with each other [45, 77,78,79].

Drug release kinetics

Today, controlled drug release systems based on polymeric matrix have been widely preferred due to their low cost, developable and reasonable performance. In such systems, usually, a release behavior is observed, which is defined by the Higuchi model and where the drug release is proportional to the square root of time. This release behavior is also characterized by non-uniform release rates, which initially decrease continuously and then decrease more rapidly. However, for controlled drug release systems, constant or near-constant release rates are desirable, and the benefit of hydrogels appears at this stage [80, 81]. For example, in systems is used hydrogels, relatively predictable drug release behavior occurs as a result of expansion due to swelling and squeezing due to shrinkage during syneresis of the hydrogel [80, 82].

However, it should be noted that the drug release behavior of hydrogels, which is the sum of the release capacity, release time, release rate and release mechanism, depends on many also factors. These factors can be counted as release conditions of the environment, such as temperature and pH, as well as the physical form, surface area, and pore size of the polymeric network [76]. Depending on the type of drug release system (swelling or dissolution or erosion controlled systems etc.), the swelling-shrinkage behavior of the polymeric network, the chemical structure/solubility of the drug, and the degradability of the polymeric structure also appear as other important factors affecting the drug release behavior [83].

To describe the transport phenomenon from drug-loaded polymeric matrices, Fick's diffusion law has been taken as the basis, in line with the acceptance that the main driving forces are solute drug diffusion, matrix swelling, and polymer degradation [84, 85]. Here, the transport process, in which the polymer relaxation time is much greater than the solvent diffusion time, is expressed by Fickian diffusion. When the polymer relaxation time and the solvent diffusion time are approximately equal, the release becomes abnormal or non-Fickian [84, 86]. Therefore, in this transfer mechanism, also called anomalous diffusion, there is a time-dependent relationship between drug release and diffusion [87, 88].

However, drug release from swellable polymeric matrices is a complex process. Especially, in swellable polymer systems, erosion is another important factor to consider, which leads to a different release mechanism [47, 52]. Although some release processes can be identified as diffusion-controlled or erosion-controlled, in these systems, drug release is mainly governed by also both mechanisms [52]. Although, alternative equations trying to express a dual release mechanism in the form of drug diffusion through the gel matrix and erosion of the gel layer have been suggested before, the most common among them is known as the Peppas equation [48, 52]. Lately, in general in such cases, that is, when multiple mechanisms are involved in drug release or the mechanism is unknown, the Korsmeyer-Peppas kinetic model is preferred [87, 89, 90].

Consequently, since the purpose of analyzing the drug release process with mathematical modeling is to describe this complex process more simply and easily, usually, it is focused on one or two dominant driving forces based on a specific mathematical model. It should not beeing forgotten, however, that since multiple driving forces are involved in a single transport process, possible discrepancies between theories and experimental data are an expected and natural consequence [84].

Evaluation of drug release kinetics parameters

For the purpose of the investigation of the kinetic mechanism of model drug release, firstly, under each pH condition, three kinetic models such as Zero-order, First-order, and Higuchi were applied to in vitro experimental data of the hydrogels. Then, the linearity of the plots drawn for each kinetic model was evaluated according to the closeness of the regression coefficient to unity. The obtained correlation coefficient values showed that hydrogels were found to follow the Higuchi model more than the others. Then, the Korsmeyer–Peppas model was also used to further examine the drug release mechanism, and it was seen that the hydrogels have a high correlation coefficient in this model, too [87] Analysis of the experimental data through Korsmeyer–Peppas equation, then evaluation and interpretation of the diffusional exponents (n values), have been assisted more precise understanding of one or more than one mechanisms controlling the release.

Kinetic parameters of the hydrogel named VM-80 that calculated from data in drug release experiments realized at 37 °C and different pH values (7.2, 5.5, and 2.1) were presented in Table 4. In addition, swelling/shrinking behavior due to phase transition was schematized together with molecular structure and drug release behavior of p(VCL-co-MAA) hydrogels (Scheme 1).

The results obtained from the release kinetic studies for each pH value, which are shown in Table 4, are evaluated in detail below.

In the case of pH 2.1, the mathematical equation that best describes the drug release of the hydrogel is Korsmeyer–Peppas model with the highest correlation value (R2 = 0.975). At this pH value, the Higuchi model also showed a good result (R2 = 0.963). In addition, the diffusional exponent (n) found as approximately 0.562 using Korsmeyer–Peppas model equation predicted that the mechanism of diffusion is non-Fickian release.

In the case of pH 5.5, the mathematical expression that best fitted the drug release of the hydrogel is Korsmeyer–Peppas model with a correlation value (R2) found as 0.985. At this pH value, the Higuchi model also showed an acceptable result (R2 = 0.932). In addition, the diffusional exponent (n) found as 0.402 expressed that the mechanism of diffusion is Fickian release.

In the case of pH 7.2, the kinetic model that best defines the drug release behavior of the hydrogel is the Higuchi model with R2 = 0.975. In addition, the release exponent (n) obtained from the Korsmeyer–Peppas model (n = 0.536) showed that the drug release mechanism was the non-Fickian character.

In general, according to these kinetic release data, it can be said that the Higuchi model, which is defined as the diffusion process of drug release based on Fick's law, is a suitable kinetic model for these hydrogels. However, when all above results obtained in this study more detailed considered collectively can be evaluated as follows.

At pH 5.5, the exponential parameter of the Korsmeyer-Peppas equation (n value) was found as below 0.45 for p(VCL-co-MAA) hydrogel named as VM80. The found this diffusional exponent (n) value below from 0.45 have been confirmed the results obtained with Higuchi model, which shows the Fickian character drug diffusion through the polymeric matrix. Thus we can say that the hydrogel follows the Fickian diffusion mechanism, which indicates the drug release by diffusion, at around neutral pH. In other words, Fickian diffusion is the main factor in drug release at this pH.

However, at pH 2.1 ve pH 7.2, the diffusional exponent values from the Korsmeyer-Peppas equation, which have been obtained between 0.45 and 0.89, correspond to anomalous (non-Fickian) transport. These n values between 0.45 and 0.89, which have been attributed to the non-Fickian transport mechanism in which the release of drug by diffusion occurs simultaneously with the relaxation of the polymer chains [90]. Therefore, these values show that the drug release is simultaneously linked to both diffusion and matrix erosion and/or swelling behavior. In other words, the transport behavior of drug from polymer network probably corresponds to matrix erosion controlled and/or swelling controlled drug release combined with the diffusion of drug through the polymer, simultaneously at these pH values [76]. Since these two drug release mechanisms taking place together at these pH values, more slow drug release behavior can be observed probably in relation to this coexistence [52].

Herein, since the swellable polymers are involved, probably, a slow-release was observed when the rate of drug release by diffusion is added to the rate of drug release by shrinkage because the overall rate of the process depends on these simultaneous processes [87, 88]. Furthermore, with another approach, this slow release behavior may also probably be due to the aggregation of polymer chains by the highly hydrophobic interaction above the LCST, and the result of this aggregation, the hydrogel network begins to shrink, and drug release from the network slows down [76, 91,92,93]. In also such cases, where the drug release is slow, the effectiveness of the drug is likely to continue for a long time [87].

As mentioned above, while Fickian transport was observed in drug release in an environment close to a neutral area, a non-Fickian character was observed in environments with more acidic and basic pH values. In this case, another consequence to consider is that this observed status is probably the result of variability in the expansion and contraction phenomenons, which results from varying speeds of swelling and shrinkage of the hydrogel network due to different ionic interactions occurring at different pH values [94]. This means that the swelling behavior rather than the erosion process, as well as the diffusion process, is highly effective in the drug release mechanism of the temperature and pH sensitive P(VCL-co-MAA) hydrogel.

In previous studies, the temperature-sensitive and pH-sensitive types of hydrogels have been used before for oral, gastric, intestinal, gastrointestinal, and intra-vascular drug, etc., release systems [80, 95,96,97]. When all the results obtained in this study are evaluated together, these temperature-sensitive hydrogels, which show different release mechanisms and rates in different pH environments, are also predicted to be used in similar body regions that require long-term slow and controlled drug release at human body temperature.

Comparison with the literature

For the purpose of comparison, the results of our study and reported data about drug release capacities of VCL based materials in several previous studies [1, 7, 20, 98,99,100,101,102,103] were presented in Table 5.

As seen in Table 5, our findings in our study about drug release capacities of temperature- and pH-sensitive p(VCL-co-MAA) hydrogels for model drug are acceptable and compatible compared with the data presented in the literature.

Conclusions

In this study, we studied the potential use of p(VCL-co-MAA) stimuli-sensitive hydrogels for use in drug delivery systems. The following conclusions can be drawn from this study are summarized as follows:

-

(1)

It has been achieved pH sensitivity property to the VCL based copolymer, which is temperature-sensitive, with the incorporation of MAA as a hydrophilic ionic comonomer having ionizable groups to the structure, and thus a dual-sensitive copolymeric network synthesized.

-

(2)

The LCST’s of hydrogels have been observed in a certain temperature range, not at a single temperature value. These values were found around in the range of 37–40 °C.

-

(3)

As the total hydrophilic monomer (MAA) ratio in the hydrogel composition increased, the equilibrium swelling values also increased at all pH values due to the ionizable groups it contained increase. However, significantly higher values have been found at pH 7.2 than at pH 5.5 and pH 2.1 due to the carboxylic acid group of MAA was dissociated form.

-

(4)

All hydrogels showed shrinkage of approximately 50% at all pH values at the end of 1 h, while at the end of 24 h, they showed shrinkage of around 70–80% at pH 2.1, 80–95 at pH 5.5, and 60–75% at 9H 7.2. It has been seen that the shrinkage behavior of the synthesized hydrogel is dependent on pH as well as temperature.

-

(5)

In the in vitro drug release studies, it has been observed that the model drug was rapidly released from the hydrogels in the first 8 h; after 24 h, the release almost reached the equilibrium, and the completely has become stable at the end of 1 week. While after 24 h, drug release values were obtained in the range of %56–68 at pH 7.2, %56–84 at pH 5.5, and %34–52 at pH 2.1, at the end of 1 week, these values were 69–76% at pH 7.2, 73–90% at pH 5.5, and 34–57% at pH 2.1.

-

(6)

The amount of Rh B release from hydrogels increased when the pH scale is slides from the acidic to the basic values due to probably the ionization of the carboxylic groups of MAA located in the hydrogel structure in the release medium.

-

(7)

At the end of the SEM analyses, after drug loading, any pores and any drug crystals have not been observed on the surface of the hydrogel, which had a relatively porous surface. After drug release, a relatively smooth surface has been observed at first. All of these have indicated that the drug, the release conditions of hydrogel, and the release media are compatible with each other.

-

(8)

For the purpose of the investigation of the model drug release profile under each pH condition, three kinetic models such as Zero-order, First-order, and Higuchi were applied to in vitro experimental data of the hydrogels. The obtained correlation coefficient values showed that hydrogels were found to follow the Higuchi model more than the others.

-

(9)

The Korsmeyer-Peppas equation has been used for the understanding of the mechanisms controlling the release. According to diffusional exponent values, the hydrogel has followed the Fickian diffusion mechanism, which indicates the drug release by diffusion at pH 5.5. However, at pH 2.1 and pH 7.2, the anomalous transport mechanism, in which the release of drug by diffusion occurs simultaneously with the relaxation of the polymer chains, have been observed.

-

(10)

The changes observed in drug release rate and mechanism of the p(VCL-co-MAA) hydrogels are probably the result of variability in the expansion and contracted phenomenons, which results from varying speeds of swelling and shrinkage of the hydrogel network due to the different ionic interactions occurring at different pH values. This means that the swelling behavior as well as the diffusion process, is also highly effective in the drug release mechanism of the temperature- and pH-sensitive P(VCL-co-MAA) hydrogel.

-

(11)

Since the drug release behavior of this hydrogel was pH-dependent, gradually, and relatively slow, they may be suitable for long-term pH-controlled drug release systems that can release the drug gradually for up to 1 week. Optionally, they can be used in systems that release drugs for 8, 24, 48 h or 1 week. These hydrogels can preserve the drug in their network at acidic pHs (pH 2.1), such as in stomach conditions, while they can release the drug out from their network at pH 5.5 and 7.2, like intestinal conditions, at human body temperature (37 °C).

As a results, these temperature-sensitive hydrogels, which show different release mechanisms and rates in different pH environments, are predicted to be used in different body regions that require long-term slow and controlled drug release at human body temperature. These temperature-sensitive and pH-sensitive hydrogels may be recommended as a potential drug carrier for oral, gastric, intestinal, gastrointestinal, and intra-vascular drug, etc., controlled release systems.

Finally, p(VCL-co-MAA) dual-responsive hydrogels having relatively high drug release percent, gradually release behavior, a release amount and rate that changes with pH change, an average equilibrium time and probably simultaneous diffusion and swelling controlled release mechanism, seem to be promising candidates for new potential biomedical applications such as drug delivery.

References

Özkahraman B, Acar I, Gök MK, Güçlü G (2016) N-vinylcaprolactam-based microgels: synthesis, characterization and drug release applications. Res Chem Intermed 42:6013–6024. https://doi.org/10.1007/s11164-016-2422-1

Thakur S, Thakur VK, Arotiba OA (2018) History, Classification, Properties and Application of Hydrogels. An Overview. In: Thakur V, Thakur M (eds) Hydrogels. Gels Horizons: From Science to Smart Materials. Springer, Singapore. https://doi.org/10.1007/978-981-10-6077-9-2

Cortez-Lemus NA, Licea-Claveria A (2016) Poly(N-vinylcaprolactam), A comprehensive review on a thermoresponsive polymer becoming popular. Prog Polym Sci 53:1–51. https://doi.org/10.1016/j.progpolymsci.2015.08.001

Wells CM, Harris M, Choi L, Murali VP, Guerra FD, Jennings JA (2019) Stimuli-responsive drug release from smart polymers. J Funct Biomater 10(3):34. https://doi.org/10.3390/jfb10030034

Pişkin E (2004) Molecularly designed water soluble, intelligent, nanosize polymeric carriers. Int J Pharm 277(1–2):105–118. https://doi.org/10.1016/j.ijpharm.2003.06.003

Özkahraman B, Acar I, Emik S (2011) Removal of cationic dyes from aqueous solutions with poly(N-isopropylacrylamide-co-itaconic acid) hydrogels. Polym Bull 66:551–570. https://doi.org/10.1007/s00289-010-0371-1

Özkahraman B, Acar I, Güçlü G (2016) Synthesis and characterization of poly(VCL-HEA-IA) terpolymer for drug release applications. J. Polym. Mater. 33:351–363 https://www.printspublications.com/journal/journalofpolymermaterialsaninternationaljournal13712463644

Özkahraman B, Yıldırım E, Emik S, Acar I (2021) The removal of Cu(II) and Pb(II) ions from aqueous solutions by temperature-sensitive hydrogels based on N-isopropylacrylamide and itaconic acid. Main Group Chem 20(3):389–407. https://doi.org/10.3233/MGC-210056

Kozlovskaya V, Kharlampieva E (2019) Self-assemblies of thermoresponsive poly(N-vinylcaprolactam) polymers for applications in biomedical field. ACS Appl Polym Mater 2(1):26–39. https://doi.org/10.1021/acsapm.9b00863

Durkut S, Elçin YM (2020) Synthesis and characterization of thermosensitive poly(N-vinyl caprolactam)-grafted-aminated alginate hydrogels. Macromol Chem Phys 221(2):1900412. https://doi.org/10.1002/macp.201900412

Anirudhan TS, Christa J (2020) Temperature and pH sensitive multi-functional magnetic nanocomposite for the controlled delivery of 5-fluorouracil, an anticancer drug. J Drug Deliv Sci Technol 55:101476. https://doi.org/10.1016/j.jddst.2019.101476

Banihashem S, Nezhati MN, Panahia HA (2020) Synthesis of chitosan-grafted-poly(N-vinylcaprolactam) coated on the thiolated gold nanoparticles surface for controlled release of cisplatin. Carbohydr Polym 227:115333. https://doi.org/10.1016/j.carbpol.2019.115333

Özkahraman B, Emeriewen K, Saleh GM, Thanh NTK (2020) Engineering hydrogel nanoparticles to enhance transdermal local anaesthetic delivery in human eyelid skin. RSC Adv 10(7):3926–3930. https://doi.org/10.1039/C9RA06712D

Wu JZ, Yang Y, Li S, Shi A, Song B, Niu S, Chen W, Yao Z (2019) Glucose-sensitive nanoparticles based on poly(3-acrylamidophenylboronic acid-block-N-vinylcaprolactam) for insulin delivery. Int J Nanomedicine 14:8059–8072. https://doi.org/10.2147/IJN.S220936

Hogan KJ, Mikos AG (2020) Biodegradable thermoresponsive polymers: Applications in drug delivery and tissue engineering. Polymer 211:123063. https://doi.org/10.1016/j.polymer.2020.123063

Imaz A., Forcada J. (2010). N‐vinylcaprolactam‐based microgels for biomedical applications. J. Polym. Sci. Part A: Polym. Chem. 48(5), 1173–1181. https://doi.org/10.1002/pola.23876

Vihola H, Laukkanen A, Valtola L, Tenhu H, Hirvonen J (2005) Cytotoxicity of thermosensitive polymers poly(N-isopropylacrylamide), poly(N-vinylcaprolactam) and amphiphilically modified poly(N-vinylcaprolactam). Biomater 26(16):3055–3064. https://doi.org/10.1016/j.biomaterials.2004.09.008

Fernandez-Quiroz D, Loya-Duarte J, Silva-Campa E, Argüelles-Monal W, Sarabia-Sainz A, Lucero-Acuna A, Castillo-Castro T, Roman JS, Lizardi-Mendoza J, Burgara-Estralla AJ, Casteneda B, Soto-Puebla D, Pedroza-Montero M (2019) Temperature stimuli-responsive nanoparticle from chitosan-grafted-poly(N-vinylcaprolactam) as a drug delivery system. J Appl Polym Sci 136(32):47831. https://doi.org/10.1002/app.47831

Cerda-Sumbarda YD, Dominguez-Gonzalez C, Zizumbo-Lopez A, Licea-Claverie A (2020) Thermoresponsive nanocomposite hydrogels with improved properties based on poly(N-vinylcaprolactam). Mater Today Commun 24:101041. https://doi.org/10.1016/j.mtcomm.2020.101041

Durkut S (2019) Thermoresponvive poly(N-vinylcaprolactam)-g-galactosylated chitosan hydrogels: synthesis, characterization, and controlled release properties. Int J Polym Mater Polym Biomater 68:1034–1047. https://doi.org/10.1080/00914037.2018.1525546

Kumar A, Deepak SS, Afgan S, Kumar R, Keshari AK, Srivasta R (2018) Development of graft copolymer of carboxymethylcellulose and N-vinylcaprolactam towards strong antioxidant and antibacterial polymeric materials. Int J Biol Macromol 112:780–787. https://doi.org/10.1016/j.ijbiomac.2018.02.030

Fallon M, Halliga S, Pezzoli R, Geever L, Higginbotham C (2019) Synthesis and characterisation of novel temperature and pH sensitive physically cross-linked poly(N-vinylcaprolactam-co-itaconic acid) hydrogels for drug delivery. Gels 5(3):41–54. https://doi.org/10.3390/gels5030041

Mundargi RC, Rangaswamy V, Aminabhavi TM (2011) Poly(N-vinylcaprolactam-co-methacrylic acid) hydrogels microparticles for oral insulin delivery. J Microencapsul 28:384–394. https://doi.org/10.3109/02652048.2011.576782

Xu J, Xu B, Shou D, Xia X, Hu Y (2015) Preparation and evaluation of vancomycin-loaded N-trimethyl chitosan nanoparticles. Polymers 7(9):1850–1870. https://doi.org/10.3390/polym7091488

Özbaş Z, Özkahraman B, Öztürk BA (2018) A controlled release profile of 5-fluorouracil loaded P(AAM-co-NVP-co-DEAEMA) microgel prepared via free precipitation polymerization. Polym Bull 75(7):3053–3067. https://doi.org/10.1007/s00289-017-2202-0

Karimini S, Shamsipur A, Shamsipur M (2016) Analytical characteristics and application of novel chitosan coated magnetic nanoparticles as an efficient drug delivery system for ciprofloxacin. Enhanced drug release kinetics by low-frequency ultrasounds. J Pharm Biomed Anal 129:450–457. https://doi.org/10.1016/j.jpba.2016.07.016

Huanbutta K, Sangnim T (2019) Design and development of zero-order drug release gastroretentive floating tablets fabricated by 3D printing technology. J Drug Deliver Sci Tech 52:831–837. https://doi.org/10.1016/j.jddst.2019.06.004

Pooresmaeil M, Namazi H (2020) Facile preparation of pH-sensitive chitosan microspheres for delivery of curcumin; characterization, drug release kinetics and evaluation of anticancer activity. Int J Biol Macromol 162:501–511. https://doi.org/10.1016/j.ijbiomac.2020.06.183

Costa P, Sousa Lobo JM (2003) Evaluation of mathematical models describing drug release from estradiol transdermal systems. Drug Dev Ind Pharm 29(1):89–97. https://doi.org/10.1081/DDC-120016687

Reddy NS, Sowmya S, Bumgardner JD, Chennazhi KP, Biswas R, Jayakumar R (2014) Tetracycline nanoparticles loaded calcium sulfate composite beads for periodontal management. Biochim Biophys Acta Gen Subj 1840(6):2080–2090. https://doi.org/10.1016/j.bbagen.2014.02.007

Hayashi T, Kanbe H, Okada M, Suzuki M, Ikeda Y, Onuki Y, Kaneko T, Sonobe T (2005) Formulation study and drug release mechanism of a new theophylline sustained-release preparation. Int J Pharm 304(1–2):91–101. https://doi.org/10.1016/j.ijpharm.2005.07.022

Vigata M, Meinert C, Hutmacher DW, Bock N (2020) Hydrogels as drug delivery systems: A review of current characterization and evaluation techniques. Pharmaceutics 12(12):1188. https://doi.org/10.3390/pharmaceutics12121188

Bruschi M.L. (Ed.) (2015). Mathematical models of drug release (Chapter 5), in Strategies to Modify the Drug Release from Pharmaceutical Systems, Woodhead Publishing, Pages 63–86, ISBN 9780081000922, https://doi.org/10.1016/B978-0-08-100092-2.00005-9

Efentakis M, Naseef H, Vlachou M (2010) Two-and three-layer tablet drug delivery systems for oral sustained release of soluble and poorly soluble drugs. Drug Dev Ind Pharm 36(8):903–916. https://doi.org/10.3109/03639040903585119

Malekjani N, Jafari SM (2021) Modeling the release of food bioactive ingredients from carriers/nanocarriers by the empirical, semiempirical, and mechanistic models. Compr Rev Food Sci Food Saf 20(1):3–47. https://doi.org/10.1111/1541-4337.12660

Dash S., Murthy P.N., Nath L., Chowdhury P. (2010). Kinetic modeling on drug release from controlled drug delivery systems. Acta Pol. Pharm. 67(3), 217–223. https://www.ptfarm.pl/pub/File/Acta_Poloniae/2010/3/217.pdf

Freitas MN, Marchetti JM (2005) Nimesulide PLA microspheres as a potential sustained release system for the treatment of inflammatory diseases. Int J Pharm 295(1–2):201–211. https://doi.org/10.1016/j.ijpharm.2005.03.003

Rizwan IM, Damodharan N (2020) Mathematical modelling of dissolution kinetics in dosage forms. Research J Pharm and Tech 13(3):1339–1345. https://doi.org/10.5958/0974-360X.2020.00247.4

Bruschi ML (2015) Mathematical models of drug release. Strategies to modify the drug release from pharmaceutical systems. Woodhead Publishing, Cambridge, UK, pp 63–86

Bravo S.A., Lamas M.C., Salomón C.J. (2002). In-vitro studies of diclofenac sodium controlled-release from biopolymeric hydrophilic matrices. J. Pharm. Pharm. Sci. 5(3), 213–219. https://sites.ualberta.ca/~csps/JPPS5(3)/S.Bravo/diclofenac.pdf

Costa P, Lobo JMS (2001) Modeling and comparison of dissolution profiles. Eur J Pharm Sci 13(2):123–133. https://doi.org/10.1016/S0928-0987(01)00095-1

Higuchi T (1961) Rate of release of medicaments from ointments bases containing drugs in suspension. J Pharm Sci 50(10):874–875. https://doi.org/10.1002/jps.2600501018

Higuchi WI (1962) Analysis of data on the medicament release from ointments. J Pharm Sci 51(8):802–804. https://doi.org/10.1002/jps.2600510825

Higuchi T. (1963). Mechanism of sustained‐action medication. Theoretical analysis of rate of release of solid drugs dispersed in solid matrices. J. Pharm. Sci. 52(12), 1145–1149. https://doi.org/10.1002/jps.2600521210

Bal A., Özkahraman B., Özbaş Z. (2016). Preparation and characterization of pH responsive poly(methacrylic acid‐acrylamide‐N‐hydroxyethyl acrylamide) hydrogels for drug delivery systems. J. App. Polym. Sci.133(13). https://doi.org/10.1002/app.43226

Shoaib M.H., Tazeen J., Merchant H.A., Yousuf R. I. (2006). Evaluation of drug release kinetics from ibuprofen matrix tablets using HPMC. Pak. J. Pharm. Sci. 19(2), 119–124. http://eprints.hud.ac.uk/id/eprint/19640/1/MerchantEvalShoaib_et_al_Pak_J_Pharm_Sci_2006.pdf

Korsmeyer RW, Gurny R, Doelker E, Buri P, Peppas NA (1983) Mechanisms of solute release from porous hydrophilic polymers. Int J Pharm 15(1):25–35. https://doi.org/10.1016/0378-5173(83)90064-9

Ritger P.L., Peppas N.A. (1987). A simple equation for description of solute release II. Fickian and anomalous release from swellable devices. J. Control. Release. 5(1), 37–42. https://doi.org/10.1016/0168-3659(87)90035-6

Samie M, Bashir S, Abbas J, Khan S, Aman N, Jan H, Muhammad N (2018) Design, formulation and in vitro evaluation of sustained-release tablet formulations of levosulpiride. Turkish J Pharm Sci 15(3):309. https://doi.org/10.4274/tjps.29200

Mikac U, Sepe A, Gradišek A, Kristl J, Apih T (2019) Dynamics of water and xanthan chains in hydrogels studied by NMR relaxometry and their influence on drug release. Int J Pharm 563:373–383. https://doi.org/10.1016/j.ijpharm.2019.04.014

Lao LL, Peppas NA, Boey FYC, Venkatraman SS (2011) Modeling of drug release from bulk-degrading polymers. Int J Pharm 418(1):28–41. https://doi.org/10.1016/j.ijpharm.2010.12.020

Boateng JS, Matthews KH, Auffret AD, Humphrey MJ, Stevens HN, Eccleston GM (2009) In vitro drug release studies of polymeric freeze-dried wafers and solvent-cast films using paracetamol as a model soluble drug. Int J Pharm 378(1–2):66–72. https://doi.org/10.1016/j.ijpharm.2009.05.038

Silverstein RM, Bassler GC (1966) Spectrometric Identification of Organic Compounds, 4th edn. Publisher John Wiley, New York, USA

Boyko V, Pich A, Lu Y, Richter S, Arndt KF, Adler HJP (2003) Thermo-sensitive poly(N-vinylcaprolactam-co-acetoacetoxyethyl methacrylate) microgels: 1-synthesis and characterization. Polymer 44(26):7821–7827. https://doi.org/10.1016/j.polymer.2003.09.037

Erdik E., (1993). Organik Kimyada Spektroskopik Yöntemler (Turkish), Publisher: Gazi Yayınevi, Ankara, Turkey, ISBN:9757373041

Simons WW (1978) The Sadtler Handbook of Infrared Spectra, Publisher Sadtler Research Laboratories. ISBN- 10:0845600346

Kalagasidis KM, Ilić M, Filipović J (2009) Swelling behaviour and paracetamol release from poly(N-isopropylacrylamide-itaconic acid) hydrogels. Polym Bull 63(2):197–211. https://doi.org/10.1007/s00289-009-0086-3

Huglin MB, Liu Y, Velada J (1997) Thermoreversible swelling behaviour of hydrogels based on N-isopropylacrylamide with acidic comonomers. Polymer 38(23):5785–5791. https://doi.org/10.1016/S0032-3861(97)00135-3

Kalagasidis KM, Filipović J (2006) Copolymer hydrogels based on N-isopropylacrylamide and itaconic acid. Polymer 47(1):148–155. https://doi.org/10.1016/j.polymer.2005.11.002

Spasojević J, Radosavljević A, Krstić J, Jovanović D, Spasojević V, Kalagasidis-Krušić M, Kačarević-Popović Z (2015) Dual responsive antibacterial Ag-poly(N-isopropylacrylamide/itaconic acid) hydrogel nanocomposites synthesized by gamma irradiation. Eur Polym J 69:168–185. https://doi.org/10.1016/j.eurpolymj.2015.06.008

Taşdelen B, Kayaman-Apohan N, Güven O, Baysal BM (2004) Investigation of drug release from thermo-and pH-sensitive poly(N-isopropylacrylamide/itaconic acid) copolymeric hydrogels. Polym Adv Tech 15(9):528–532. https://doi.org/10.1002/pat.505

Ramírez-Fuentes YS, Bucio E, Burillo G (2008) Thermo and pH sensitive copolymer based on acrylic acid and N-isopropylacrylamide grafted onto polypropylene. Polym Bull 60(1):79–87. https://doi.org/10.1007/s00289-007-0827-0

Cortés JA, Mendizábal E, Katime I (2008) Effect of comonomer type and concentration on the equilibrium swelling and volume phase transition temperature of N-isopropylacrylamide-based hydrogels. J Appl Polym Sci 108(3):1792–1796. https://doi.org/10.1002/app.27632

Constantin M., Cristea M., Ascenzi P., Fundueanu G (2011) Lower critical solution temperature versus volume phase transition temperature in thermoresponsive drug delivery systems. Express Polym Lett 5(10):839–848. https://doi.org/10.3144/expresspolymlett.2011.83

Hörter D, Dressman JB (2001) Influence of physicochemical properties on dissolution of drugs in the gastrointestinal tract. Adv Drug Deliv Rev 46(1–3):75–87. https://doi.org/10.1016/S0169-409X(00)00130-7

Çavuş S., Çakal E. (2012) Synthesis and characterization of novel poly(N-vinylcaprolactam-co-itaconic acid) gels and analysis of pH and temperature sensitivity. Ind Eng Chem Res 51(3):1218–1226. https://doi.org/10.1021/ie2008746

Shtanko NI, Lequieu W, Goethals EJ, Du Prez FE (2003) pH-and thermo-responsive properties of poly (N-vinylcaprolactam-co-acrylic acid) copolymers. Polym Int 52(10):1605–1610. https://doi.org/10.1002/pi.1347

Lou S., Gao S., Wang W., Zhang M., Zhang Q., Wang C., Li C., Kong, D. (2014) Temperature/pH dual responsive microgels of crosslinked poly (N‐vinylcaprolactam‐co‐undecenoic acid) as biocompatible materials for controlled release of doxorubicin. J. Appl. Polym. Sci. 131(23). https://doi.org/10.1002/app.41146

Popescu I., Prisacaru A.I., Suflet D.M., Fundueanu, G (2014) Thermo-and pH-sensitivity of poly (N-vinylcaprolactam-co-maleic acid) in aqueous solution. Polym Bull 71(11):2863–2880. https://doi.org/10.1007/s00289-014-1227-x

Crespy D, Rossi RM (2007) Temperature-responsive polymers with LCST in the physiological range and their applications in textiles. Polym Int 56(12):1461–1468. https://doi.org/10.1002/pi.2277

Özturk V, Okay O (2002) Temperature sensitive poly(N-t-butylacrylamide-co-acrylamide) hydrogels: synthesis and swelling behavior. Polymer 43(18):5017–5026. https://doi.org/10.1016/S0032-3861(02)00357-9

Shibayama M., Tanaka T. (1993) Volume phase transition and related phenomena of polymer gels. In: Dušek K. (eds) Responsive Gels: Volume Transitions I. Advances in Polymer Science, vol 109. Springer, Berlin, Heidelberg. https://doi.org/10.1007/3-540-56791-7_1

Gehrke SH, Andrews GP, Cussler EL (1986) Chemical aspects of gel extraction. Chem Eng Sci 41(8):2153–2160. https://doi.org/10.1016/0009-2509(86)87131-7

Medeiros SF, Lopes MV, Rossi-Bergmann B, Ré MI, Santos AM (2017) Synthesis and characterization of poly(N-vinylcaprolactam)-based spray-dried microparticles exhibiting temperature and pH-sensitive properties for controlled release of ketoprofen. Drug Dev Ind Pharm 43(9):1519–1529. https://doi.org/10.1080/03639045.2017.1321660

Brønsted H., Kopecek J. (1992) Polyelectrolyte Gels: Properties, Preparation and Applications, R.S. Harland R.S., Prud'homme R.K. (Eds.), American Chemical Society, Washington, DC, USA pp. 285–304

Ilgin P, Ozay H, Ozay O (2019) A new dual stimuli responsive hydrogel: Modeling approaches for the prediction of drug loading and release profile. Eur Polym J 113:244–253. https://doi.org/10.1016/j.eurpolymj.2019.02.003

Özkahraman B., Tamahkar E. (2017) Synthesis of chitosan-based hydrogels as a novel drug release device for wound healing. Hittite Journal of Science and Engineering, 4(2), 137–144. https://doi.org/10.17350/HJSE19030000060.

Tamahkar E., Özkahraman B. (2015) Potential evaluation of PVA-based hydrogels for biomedical applications. Hittite Journal of Science and Engineering, 2(2), 165–171. https://doi.org/10.17350/HJSE19030000021.

Jannesari M, Varshosaz J, Morshed M, Zamani M (2011) Composite poly(vinyl alcohol) / poly(vinyl acetate) electrospun nanofibrous mats as a novel wound dressing matrix for controlled release of drugs. Int J Nanomedicine 6:993–1003. https://doi.org/10.2147/IJN.S17595

Gupta P, Vermani K, Garg S (2002) Hydrogels: from controlled release to pH-responsive drug delivery. Drug Discov Today 7(10):569–579. https://doi.org/10.1016/S1359-6446(02)02255-9

Korsmeyer R.W., Peppas, N.A. (1983) Macromolecular and modeling aspects of swelling-controlled systems. In: Controlled Release Delivery Systems (Roseman T.J., Mansdorf S.Z., eds), pp. 77–90, Marcel Dekker.

Gutowska A, Bark JS, Kwon IC, Bae YH, Cha Y, Kim SW (1997) Squeezing hydrogels for controlled oral drug delivery. J Control Release 48(2–3):141–148. https://doi.org/10.1016/S0168-3659(97)00041-2

Zarzycki R, Modrzejewska Z, Nawrotek K (2010) Drug release from hydrogel matrices. Ecol Chem Eng S 17(2):117–136. https://www.researchgate.net/publication/228503143_Drug_release_from_hydrogel_matrices

Fu Y, Kao WJ (2010) Drug release kinetics and transport mechanisms of non-degradable and degradable polymeric delivery systems. Expert Opin Drug Deliv 7(4):429–444. https://doi.org/10.1517/17425241003602259